METALADDITIVE MANUFACTURING

EhsanToyserkani,DyutiSarker,OsezuaObehiIbhadode, FarzadLiravi,PaolaRusso,KatayoonTaherkhani

UniversityofWaterloo Waterloo,Ontario Canada

Thiseditionfirstpublished2022 ©2022JohnWiley&SonsLtd

Allrightsreserved.Nopartofthispublicationmaybereproduced,storedinaretrievalsystem,ortransmitted,inany formorbyanymeans,electronic,mechanical,photocopying,recordingorotherwise,exceptaspermittedbylaw. Adviceonhowtoobtainpermissiontoreusematerialfromthistitleisavailableathttp://www.wiley.com/go/ permissions.

TherightofEhsanToyserkani,DyutiSarker,OsezuaObehiIbhadode,FarzadLiravi,PaolaRusso,andKatayoon Taherkhanitobeidentifiedastheauthorsofthisworkhasbeenassertedinaccordancewithlaw.

RegisteredOffice

JohnWiley&Sons,Inc.,111RiverStreet,Hoboken,NJ07030,USA

EditorialOffice 111RiverStreet,Hoboken,NJ07030,USA

Fordetailsofourglobaleditorialoffices,customerservices,andmoreinformationaboutWileyproducts,visitusat www.wiley.com.

Wileyalsopublishesitsbooksinavarietyofelectronicformatsandbyprint-on-demand.Somecontentthatappearsin standardprintversionsofthisbookmaynotbeavailableinotherformats.

LimitofLiability/DisclaimerofWarranty

Whilethepublisherandauthorshaveusedtheirbesteffortsinpreparingthiswork,theymakenorepresentationsor warrantieswithrespecttotheaccuracyorcompletenessofthecontentsofthisworkandspecificallydisclaimall warranties,includingwithoutlimitationanyimpliedwarrantiesofmerchantabilityorfitnessforaparticularpurpose.No warrantymaybecreatedorextendedbysalesrepresentatives,writtensalesmaterials,orpromotionalstatementsforthis work.Thefactthatanorganization,website,orproductisreferredtointhisworkasacitationand/orpotentialsourceof furtherinformationdoesnotmeanthatthepublisherandauthorsendorsetheinformationorservicestheorganization, website,orproductmayprovideorrecommendationsitmaymake.Thisworkissoldwiththeunderstandingthatthe publisherisnotengagedinrenderingprofessionalservices.Theadviceandstrategiescontainedhereinmaynotbe suitableforyoursituation.Youshouldconsultwithaspecialistwhereappropriate.Further,readersshouldbeawarethat websiteslistedinthisworkmayhavechangedordisappearedbetweenwhenthisworkwaswrittenandwhenitisread. Neitherthepublishernorauthorsshallbeliableforanylossofprofitoranyothercommercialdamages,includingbut notlimitedtospecial,incidental,consequential,orotherdamages.

LibraryofCongressCataloging-in-PublicationData

Names:Toyserkani,Ehsan,author.|Sarker,Dyuti,1983-author.| Ibhadode,OsezuaObehi,1989-author.|Liravi,Farzad,1990-author.| Russo,Paola,1986-author.|Taherkhani,Katayoon,1989-author.|John Wiley&Sons,publisher.

Title:Metaladditivemanufacturing/EhsanToyserkani,DyutiSarker, OsezuaObehiIbhadode,FarzadLiravi,PaolaRusso,KatayoonTaherkhani.

Description:Hoboken,NJ:Wiley,2021.

Identifiers:LCCN2021028894(print)|LCCN2021028895(ebook)|ISBN 9781119210788(cloth)|ISBN9781119210849(adobepdf)|ISBN 9781119210832(epub)

Subjects:LCSH:Additivemanufacturing.|Metalpowderproducts–Designand construction.|Powdermetallurgy.

Classification:LCCTS183.25.T692021(print)|LCCTS183.25(ebook)| DDC621.9/88–dc23

LCrecordavailableathttps://lccn.loc.gov/2021028894

LCebookrecordavailableathttps://lccn.loc.gov/2021028895

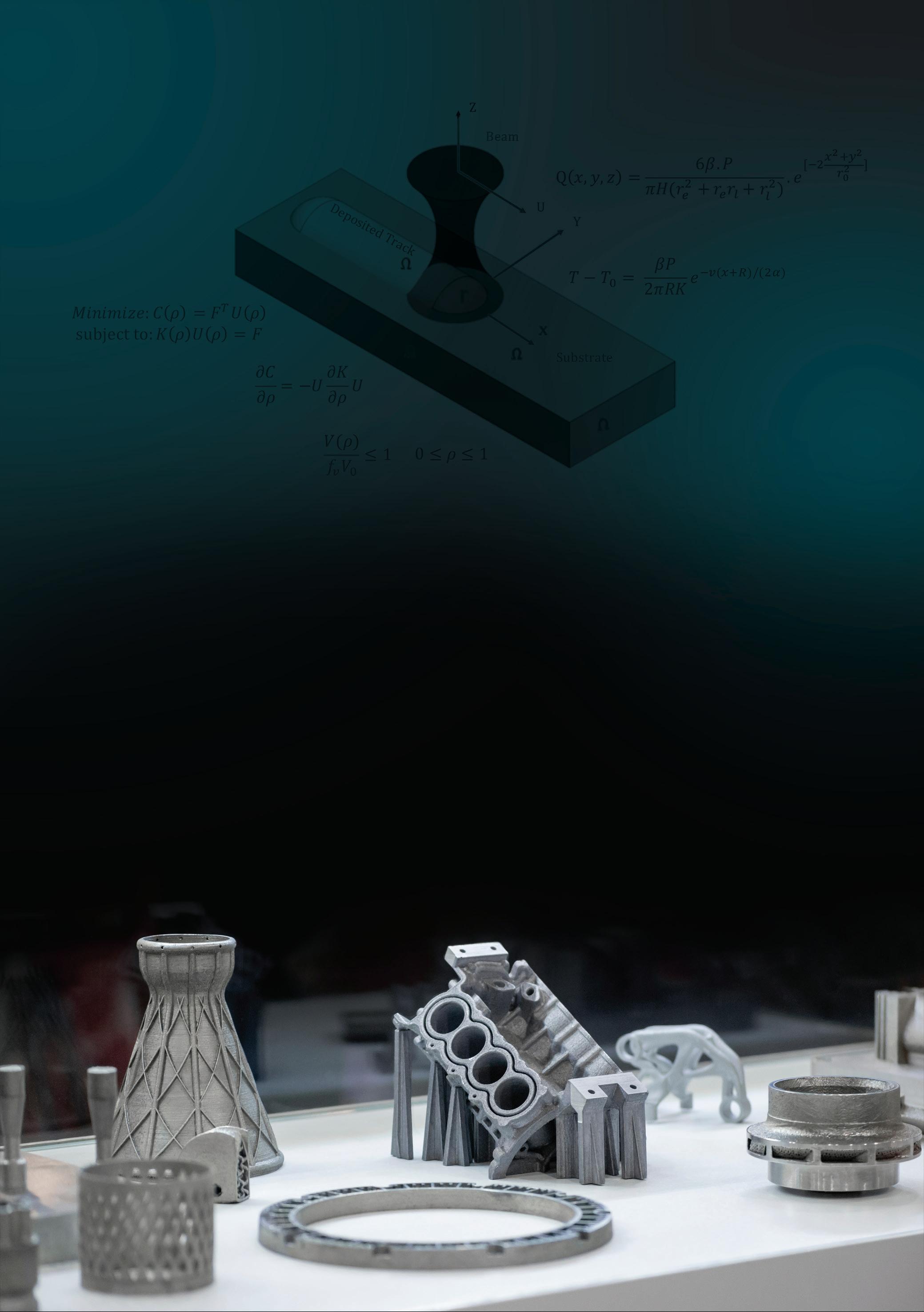

CoverDesign:Wiley

CoverImage:CourtesyofEhsanToyserkani(top);©MarinaGrigorivna/Shutterstock

Setin10/12ptTimesLTStdbyStraive,Pondicherry,India

Inmemoryof ProfessorPearlSullivan(1961–2020)

FormerDeanofFacultyofEngineering,UniversityofWaterloo,Canada

Atrueleader,anexemplaryadvocateforengineeringeducation,andagreatfriend

1AdditiveManufacturingProcessClassification,Applications,Trends, Opportunities,andChallenges1

1.1AdditiveManufacturing:ALong-TermGameChanger1

2.3.1MainOutputParameters

2.3.2CombinedThermalEnergySourceParametersPBFandDED

2.3.3BeamScanningStrategiesandParametersforPBFandDED

2.3.4PowderPropertiesforPBF,DED,andBJ

2.3.5WirePropertiesforDED

2.3.6LayerThicknessforPBF,DED,andBJ

2.3.7AmbientParametersforPBF,DED,andBJ

2.3.8Geometry-SpecificParameters(PBF)

2.3.9SupportStructuresforPBF

2.3.10BinderPropertiesforBJ

2.4.1FerrousAlloys

2.4.2TitaniumAlloys

2.4.3NickelAlloys

2.4.4AluminumAlloys

3.2.1LaserPowderBedFusion(LPBF)

3.2.2LaserDirectedEnergyDeposition(LDED)withBlownPowder KnownasLaserPowder-Fed(LPF)

3.2.3BinderJetting(BJ)

3.3LaserBasics:ImportantParametersNeededtobeKnownforAM93

3.3.1LaserTheory

3.3.2LaserComponents

3.3.3ContinuousVs.PulsedLaser

3.3.4LaserTypes

3.3.5LaserBeamProperties

3.4ElectronBeamBasics114

3.4.1ComparisonsandContrastsbetweenLaserandElectronBeams

3.4.2ElectronBeamPowderBedFusionSetup

3.4.3ElectronBeamMechanism

3.4.4VacuumChambers

3.5PowderFeedersandDeliveryNozzlesTechnology121

3.5.1ClassificationofPowderFeeders

3.5.2PowderDeliveryNozzlesforDED

3.5.3PowderBedDeliveryandSpreadingMechanisms

3.5.4WireFeedSystem

3.5.5PositioningDevicesandScannersinLaser-BasedAM

3.5.6Print-HeadinBinderJetting

3.6CADFileFormats133

3.6.1CAD/CAMSoftware

4DirectedEnergyDeposition(DED):PhysicsandModelingofLaser/Electron BeamMaterialProcessingandDED137 4.1Introduction137

4.2LaserMaterialInteractionandtheAssociatedSignificantParametersto LaserAM140

4.2.1ContinuousVersusPulsed/ModulatedLasers

4.2.2Absorption,Reflection,andTransmissionFactors

4.2.3DependenciesofAbsorptionFactortoWavelengthandTemperature

4.2.4AngleofIncidence

4.2.5SurfaceRoughnessEffects

4.2.6ScatteringEffects

4.3E-beamMaterialInteraction148

4.4PowerDensityandInteractionTimeforVariousHeatSource-based MaterialProcessing149

4.5PhysicalPhenomenaandGoverningEquationsDuringDED150

4.5.1Absorption

4.5.2HeatConduction

4.5.3SurfaceConvectionandRadiation

4.5.4FluidDynamics

4.5.5PhaseTransformation

4.5.6RapidSolidification

4.5.8FlowFieldinDEDwithInjectedPowder

4.6ModelingofDED161

4.6.1AnalyticalModeling:Basics,SimplifiedEquations,andAssumptions 161

4.6.2NumericalModelsforDED

4.6.3Experimental-basedModels:BasicsandApproaches 166

4.7CaseStudiesonCommonModelingPlatformsforDED168

4.7.1LumpedAnalyticalModelforPowder-FedLDED 168

4.7.2ComprehensiveAnalyticalModelforPowder-FedLDED(PF-LDED) 172

4.7.3NumericalModelingofLDED:HeatTransferModel 184

4.7.4ModelingofWire-FedE-beamDED(WF-EDED) 193

4.7.5AStochasticModelforPowder-FedLDED 195 4.8Summary200 References200

5PowderBedFusionProcesses:PhysicsandModeling203

5.1IntroductionandNotestoReaders203

5.2PhysicsofLaserPowderbedFusion(LPBF)204

5.2.1HeatTransferinLPBF:GoverningEquationsandAssumptions 205

5.2.2FluidFlowintheMeltPoolofLPBF:GoverningEquations andAssumptions 215

5.2.3VaporizationandMaterialExpulsion:GoverningEquations andAssumptions 218

5.2.4ThermalResidualStresses:GoverningEquationsandAssumptions 219

5.2.5NumericalModelingofLPBF 220

5.2.6CaseStudiesonCommonLPBFModelingPlatforms 222

5.3PhysicsandModelingofElectronBeamAdditiveManufacturing228

5.3.1ElectronBeamAdditiveManufacturingParameters

5.3.2EmissionsinElectronBeamSources

5.3.3MathematicalDescriptionofFreeElectronCurrent

5.3.4ModelingofElectronBeamPowderBedFusion(EB-PBF)

5.3.5CaseStudies

5.3.6Summary

References251

6BinderJettingandMaterialJetting:PhysicsandModeling255 6.1Introduction255

6.2PhysicsandGoverningEquations257

6.2.1DropletFormation

6.2.2Droplet–SubstrateInteraction

6.2.3BinderImbibition

6.3NumericalModeling270

6.3.1Level-SetModel

6.3.2LatticeBoltzmannMethod

7MaterialExtrusion:PhysicsandModeling279 7.1Introduction279

7.2AnalyticalModelingofME281

7.2.1HeatTransferandOutletTemperature

7.2.2FlowDynamicsandDropPressure

7.2.3DieSwell

7.2.4DepositionandHealing

7.3NumericalModelingofME291 7.4Summary296 References296

8MaterialDesignandConsiderationsforMetalAdditiveManufacturing297

8.1HistoricalBackgroundonMaterials297

8.2MaterialsScience:Structure–PropertyRelationship298

8.3ManufacturingofMetallicMaterials299

8.4SolidificationofMetals:Equilibrium301

8.5SolidificationinAdditiveManufacturing:Non-Equilibrium302

8.6EquilibriumSolidification:TheoryandMechanism304

8.6.1CoolingCurveandPhaseDiagram 304

8.7Non-EquilibriumSolidification:TheoryandMechanism307

8.8SoluteRedistributionandMicrosegregation308

8.9ConstitutionalSupercooling312

8.10NucleationandGrowthKinetics314

8.10.1Nucleation

8.10.2GrowthBehavior

8.11SolidificationMicrostructureinPureMetalsandAlloys321

8.12DirectionalSolidificationinAM324

8.13FactorsAffectingSolidificationinAM325

8.13.1CoolingRate

8.13.2TemperatureGradientandSolidificationRate

8.13.3ProcessParameters

8.13.4SolidificationTemperatureSpan

8.13.5GasInteractions

8.14SolidificationDefects330

8.14.1Porosity

8.15PostSolidificationPhaseTransformation337

8.15.1FerrousAlloys/Steels

8.15.2AlAlloys

8.15.3NickelAlloys/Superalloys

8.15.4TitaniumAlloys

8.16PhasesafterPost-ProcessHeatTreatment357

8.16.1FerrousAlloys

8.16.2AlAlloys

8.16.3NiAlloys

8.17.3FatigueBehaviorofAM-ManufacturedAlloys

8.18Summary371 References375

9AdditiveManufacturingofMetalMatrixComposites383 9.1Introduction383

9.2ConventionalManufacturingTechniquesforMetalMatrix Composites(MMCs)384

9.3AdditiveManufacturingofMetalMatrixComposites(MMCs)385 9.4AMChallengesandOpportunities386

9.5PreparationofCompositeMaterials:MechanicalMixing387

9.6DifferentCategoriesofMMCs389

9.7AdditiveManufacturingofFerrousMatrixComposites390

9.7.1316SS-TiCComposite 390

9.7.2316SS–TiB2 Composite

9.7.3H13–TiB2 Composite

9.7.4H13–TiCComposite

9.7.6Ferrous–

9.8AdditiveManufacturingofTitanium-MatrixComposites(TMCs)395

9.8.1Ti–TiCComposite

9.8.2Ti–TiBComposites

9.8.3Ti–Hydroxyapatite(Ti–HA)Composites

9.8.4Ti-6Al-4V-MetallicGlass(MG)Composites

9.8.5Ti-6Al-4V+B4CPre-alloyedComposites

9.8.6Ti-6Al-4V+MoComposite

9.8.7StructureandPropertiesofDifferentTMCs

9.9AdditiveManufacturingofAluminumMatrixComposites403

9.9.1Al–Fe2O3 Composite

9.9.2AlSi10Mg–SiCComposite

9.9.3AlSi10Mg–TiCComposite

9.9.42024Al–TiB2 Composite

9.9.5AlSi10Mg–TiB2 Composite

9.9.6AA7075–TiB2 Composite

9.10AdditiveManufacturingofNickelMatrixComposites407

9.10.1Inconel625–TiCComposites

9.10.2Inconel625–TiB2 Composite

9.11.1MixingofMatrixandReinforcingElements

9.11.2SizeofReinforcingElements

9.11.3DecompositionTemperature

9.11.4ViscosityandPoreFormation

9.11.5VolumeofReinforcingElementsandPoreFormation

9.11.6BuoyancyEffectsandSurfaceTensionForces

TopologyOptimization

10.1.4MultifunctionalOptimizationMethodologyforDfAM

10.2.1LaserPowderBedFusion(LPBF)

10.6.2DesignandDevelopmentofaStructuralMemberinaSuspension AssemblyUsingEBPowderBedFusion

10.6.3BinderJettingoftheFrameworkofaPartialMetalDenture

10.6.4RedesignofaCrankandConnectingRod

10.6.5RedesignofaMechanicalAssembly

References501

11MonitoringandQualityAssuranceforMetalAdditiveManufacturing507

11.1WhyareClosed-LoopandQualityAssurancePlatformsEssential?507

11.2In-SituSensingDevicesandSetups509

11.2.1TypesofSensorsUsedinMetalAM 509

11.2.2MountingStrategiesforIn-lineMonitoringSensorsinMetal AMSetups 521

11.3CommerciallyAvailableSensors522

11.3.1LPBFCommercialSensors 522

11.3.2LDEDCommercialSensors 525

11.4Signal/DataConditioning,Methodologies,andClassicControllersfor Monitoring,Control,andQualityAssuranceinMetalAMProcesses526

11.4.1Signal/DataConditioningandControllersforMeltPool GeometricalAnalysis 526

11.4.2Signal/DataConditioningandMethodologiesforTemperature MonitoringandAnalysis 531

11.4.3Signal/DataConditioningandMethodologiesfortheDetection ofPorosity 532

11.4.4Signal/DataConditioningandMethodologiesforDetectionof CrackandDelamination 537

11.4.5Signal/DataConditioningandMethodologiesforDetectionof PlasmaPlumeandSpatters 538

11.5MachineLearningforDataAnalyticsandQualityAssuranceinMetalAM539

11.5.1SupervisedLearning 539

11.5.2UnsupervisedLearning 549

Preface

Additivemanufacturing(AM)promisestochangetheentiremanufacturingenterpriseoverthe nexttwodecades.Nolongerlimitedtoprototypingandlow-volumemanufacturing,AMis beingadoptedfor economiesofscale withoutcompromising economiesofscope.Theneed forthedigitizationofmanufacturing,on-demandpersonalizedmanufacturing,distributedproduction,andrapidproductionintheeventofcriseshaveallelevatedthepositionofAMinthe medicalandengineeringsectors.AMisnowamajorresearchtargetforindustrializedcountries astheyseektoregainleadershipinadvancedmanufacturingthroughinnovation.Theglobal economyisonthevergeofthenextindustrialrevolutionandsectoraftersectorispullingaway fromtraditional,conventionalproductionmethodstoengageinandutilizeAM.However,this promisedoescomewithmanychallenges,particularlyformetalAM.Researchanddevelopmentactivitiesareprogressingatfullsteamtoaddressmultipletechnicalchallenges,suchas speedandproductivity,qualityassurance,standards,andend-to-endworkflow.

Amajorskillsetsgapcurrentlyhinderseffortstotacklethesechallenges.Forcompanies seekingtoembraceAM,thisgaptranslatesintoalimitedavailabilityofexpertisetodraw anentrystrategytotheAMindustry.ThewideradoptionofAMwillrequireovercoming thelimitedfoundationalunderstandingofAMthatcurrentlyexistswithintheworkforce. AthoroughunderstandingofAMcapabilitiesisnecessaryfortechnicalexpertstoaccurately communicatetheprosandconsofAMtodecision-makers,whilepreventingmisconceptions andmisinformationaboutAMcapabilities.Currently,theknowledgegapissignificantly impactingprogressinthesector,ascompanieshavedifficultiesinrecruitingAMexpertsto helpthemdevelopeffectivedesignsforAMaswellasmeaningfulbusinesscasesfor metalAM.

Thisbookisdesignedtohelpacademiaandindustrymovetowardfillingthisgap.Enhancing AMskillswillrequirethedevelopmentoffoundationalknowledgeofAMstartingattheundergraduatelevel.Toourknowledge,thereiscurrentlynotextbookavailablethatlinksthebasics offundamentalundergraduateEngineeringcourseswithmetalAMprocesses.Thereisaclear needtocustomizeundergraduateconceptsintechnicalcoursesrelatedtodesign,heattransfer, fluidmechanics,solidmechanics,andcontrol,withrespecttoAMapplications.Additionally, business-andmanagement-orientedcoursesshouldincludeAMtofacilitatetheconsideration

ofAMinconjunctionwithlifecycleassessmentandbusinessmodeldevelopmentsamong students.

Thedevelopmentofthisbookwasmotivatedbyourdesiretoprovidefoundationalmaterial foracoreundergraduatecourseinMechanicalandManufacturingEngineering,andweenvisionitsuseingraduatecoursesaswell.Universitiesgloballyarerevisingtheircurriculumto incorporateAM-relatedcourses.Thistextbookmayprovideanintroductoryplatformtobe adoptedinsuchcoursestopromoteanappreciationforandgraspofAMamongbothundergraduateandgraduatestudents.Thisbookmayalsofillagapforengineersworkingoutside academiawhowanttoappreciateAMprocessesbyidentifyinglinksbetweentraditionalcore physicsandengineeringconceptscoursesandAM.Thebookprovidesastep-by-stepunderstandingofmetalAMandasolidfoundationofthetopicforreaders,whowillsubsequentlybe wellequippedtoexploreAMresearchingreaterdepth.

Forabroadrangeofreaders,thisbookshedslightonvariouskeymetalAMtechnologies, focusingonbasicphysicsandmodeling.Thistextbookisnotaliteraturesurvey,norisit intendedforreaderswithnoengineeringbackground.Incontrast,itisanintroductiontobasic physicalconceptsandphenomenaofmetalAMprocessesandtheirapplications.Relevant foundationalconcepts,suchasenergydeposition,powderbedfusion,andbinderjettingprocesses,areexplainedin-depthandillustratedbycasestudiesthroughoutthebook.Additionally, twoemergingprocessesformetalAM:materialextrusionandmaterialjetting,aredescribed. BasicdesignforAM(DfAM)andqualityassuranceprinciplesarealsocovered.

Wewouldliketoexpressoursinceregratitudetoseveralpeoplewhohelpedinthepreparationofthisbook.SpecialthankstoFrancisDibia,AliKeshavarzkermani,ZhidongZhang, YuzeHuang,MazyarAnsari,AndrewBarlow,MishaKarpinska,DonovanKwong,andEniife Elebute,whohelpeduswithsomematerialsandproducedsomeofthefigures,asattributedin thebook.Inaddition,weacknowledgeallorganizations,publishers,authors,andcompanies thatpermitteduseoftheirfigures,plots,andtexts;theyhavebeencitedaccordinglythroughout thebook.Lastbutnotleast,thankstoourfamilies,whomakeitallworthwhile.

Likeanyfirstedition,thistextbookmaycontainerrorsandtypos.Weopenlywelcomethe reader’ssuggestionstobeconsideredinthesecondeditionofthistextbookinwhichmultiple problemsetsforeachchapterwillbeintroduced.

January2021EhsanToyserkani,DyutiSarker,OsezuaObehiIbhadode,FarzadLiravi, PaolaRusso,KatayoonTaherkhani Waterloo,Ontario,Canada

Abbreviations

2D Two-Dimensional

3D Three-Dimensional

3DQCN Three-DimensionalQuasi-ContinuousNetwork

AI ArtificialIntelligence

AE Auto-Encoder

Al Aluminum

AL AbsoluteLimits

ALE ArbitraryLagrangian–Eulerian

AM AdditiveManufacturing

AMCs AluminumMatrixComposites

AMF AdditiveManufacturingFileFormat

AMGTA AdditiveManufacturerGreenTradeAssociation

ANFIS AdaptiveNeuro-FuzzyInferenceSystem

ANN ArtificialNeuralNetwork

ANOVA AnalysisofVariance

ANSI AmericanNationalStandardsInstitute

APG AbsorptivityProfileGroup

ASCII AmericanStandardCodeForInformationInterchange

ASTM AmericanSocietyforTestingandMaterials

BD BigData

BESO BidirectionalEvolutionaryStructuralOptimization

BJ BinderJetting

BJP BinderJetPrinting

BP Backpropagation

BSE BackscatteredElectrons

CAD Computer-AidedDesign

CAE Computer-AidedEngineering

CAGR CompoundAnnualGrowthRate

CAM Computer-AidedManufacturing

CCD Charged-coupleddevice

CCT ContinuousCoolingTransformation

CDA ConstantDrawingArea

CET Columnar-to-EquiaxedTransition

CFD ComputationalFluidDynamics

CL Cathodoluminescence

CMOS ComplementaryMetal-OxideSemiconductor

CNC ComputerNumericalControl

CNN ConvolutionalNeuralNetwork

COLIN ConvexLinearization

CS CrackSusceptibility

CT ComputedTomography

μCT microComputedTomography

CVD ChemicalVaporDeposition

CW ContinuousWave

DAE Differential-AlgebraicEquation

DBN DeepBeliefNetwork

DC DirectCurrent

DDA DecreasingDrawingArea

DED DirectedEnergyDeposition

DEM Discrete/DynamicElementModel

DfAM DesignforAM

DfM DesignforManufacturing

DHA DustHazardAnalysis

DL DeepLearning

DMLS DirectMetalLaserSintering

DoD Drop-on-Demand

DoG DifferenceofGaussian

DXF DrawingExchangeFormat

EA ElectricalArc

EAM Embedded-AtomMethod

EB ElectronBeam

EBAM ElectronBeamAdditiveManufacturing

EB-DED ElectronBeamDirectedEnergyDeposition

EBF3 ElectronBeamFreeformFabrication

EBF3 ElectronBeamFusion

EBM ElectronBeamMelting

EB-PBF ElectronBeamPowderBedFusion

EDM ElectricalDischargeMachining

EIGA ElectrodeInductionMeltingInertGasAtomization

EKF ExtendedKafmanFilter

ELT EffectiveLayerThickness

EMFs ElectricandMagneticFields

ESO EvolutionaryStructuralOptimization

FBG FiberBraggGratings

FCC FaceCenteredCubic

FCM FiniteCellMethod

FDM FusedDepositionModeling

FE FiniteElement

FEA FiniteElementAnalysis

FEG Field-EmissionGun

FEM FiniteElementMethod

FFT FastFourierTransformation

FGM FunctionallyGradedMaterial

FGSs FunctionallyGradedStructures

FIS FuzzyInferenceSystem

FMC FordMotorCompany

FN FalseNegative

FP FalsePositive

FS FreeSurface

GD GradientDescent

GM GeneralMotors

GMG GeometricallyModifiedGroup

GP GaussianProcess

HA Hydroxyapatite

HAZ Heat-AffectedZone

HDR HeatingDepthRatio

HF HighlyFilled

HIP HotIsostaticPressing

HPM HeavisideProjectionMethod

ICI InlineCoherentImaging

IDAM IndustrializationandDigitizationofAdditiveManufacturing

IDT InterdigitatedTransducers

IN Inconel

IoT InternetofThings

ISO InternationalStandardsOrganization

ISO InternationalStandardsOrganization

KF KafmanFilter

KNN K-nearestneighbors

LaB6 LanthanumHexaboride

LBM Lattice–BoltzmannMethod

LCA LifeCycleAssessment

LCF LowCycleFatigue

LDED LaserDirectedEnergyDeposition

LENS LaserEngineeredNetShaping

LGA LatticeGasAutomata

LM Levenberg–Marquardt

LN LargeNegative

LoF LackofFusion

LP LargePositive

LPBF LaserPowderBedFusion

LPM LaserPowerMonitoring

LSF LevelSetFunctions

LSM LevelSetMethod

LWIR LongWaveInfrared

MAPE MeanAbsolutePredictionError

MC MetalCarbide

MD MolecularDynamics

ME MaterialExtrusion

MG MetallicGlass

MJ MaterialJetting

MMA MethodofMovingAsymptotes

MMCs MetalMatrixComposites

MME MetalMaterialExtrusion

MMP Micro-MachiningProcess

MMV MovingMorphableVoids

MOV MainOxidizerValve

MPC Metal–PolymerComposite

MPE MaximumPermissibleExposure

MPM MeltPoolMonitoring

MS Multi-Speed

MSDS MaterialSafetyDataSheet

MSE MeanSquaredError

MTPS MultifunctionalThermalProtectionSystem

Nd Neodymium

NDT Non-DestructiveTesting

NFPA NationalFireProtectionAssociation

nHA Nano-Hydroxyapatite

NHZ NominalHazardZone

Ni Nickle

NIR Near-Infrared

NIST NationalInstituteofStandardsandTechnology

NN NeuralNetwork

NS Navier–Stokes

OCM OptimalityCriterialMethod

OCT OpticalCoherenceTomography

OEM OriginalEquipmentManufacturers

OPD OpticalPenetrationDepth

OTLs OrthogonalTranslationalLattices

PBF PowderBedFusion

PCA PrincipalComponentAnalysis

PDF PointDistributionFunction

PF Powder-Fed

PI Proportional–Integral

PID Proportional–Integral–Derivative

PMC PolymerMatrixComposite

PMZ PartiallyMeltedZone

PPE PersonalProtectiveEquipment

PPHT Post-ProcessingHeatTreatment

PREP PlasmaRotateElectrodeProcess

PSD ParticleSizeDistribution

PTA-DED PlasmaTransferredArcDirectedEnergyDeposition

PVD PhysicalVaporDeposition

PW PulsedWave

PZT Piezoelectric

R&D Researchanddevelopment

RAMP RationalApproximationofMaterialProperties

RDM RelativeDensityMapping

REP RotatingElectrodeProcess

RF RadioFrequency

RGB Red-Green-Blue

RLS RecursiveLeastSquare

RMSE RootMeanSquareError

RNN RecurrentNeuralNetworks

ROS ReactiveOxygenSpecies

RTE RadiationTransferEquation

SAW SurfaceAcousticWave

SD SignalDynamics

SDAS SecondaryDendriticArmSpacing

SE SecondaryElectrons

SIMP SolidIsotropicMaterialwithPenalization

SINH SineHyperbolicFunction

SL SheetLamination

SLD Super-LuminescentDiode

SLD-OCT Super-LuminescentDiode OpticalCoherenceTomography

SLM SelectiveLaserMelting

SLP SequentialLinearProgramming

SLR Single-LensReflex

SLS SelectiveLaserSintering

SN SmallNegative

SOM Self-OrganizingMap

SP SmallPositive

SQP SequentialQuadraticProgramming

SRAS SpatiallyResolvedAcousticSpectroscopy

STF Short-TermFluctuations

STL StandardTessellationLanguageorStereoLithography

STP StandardfortheProductData

ST-PCA SpatiallyWeightedPrincipalComponentAnalysis

SVD SingularValueDecomposition

SVM SupportVectorMachine

TCP TopologicalClose-Packed

TEM TransverseElectromagneticModes

TGM TemperatureGradientMechanism

Ti Titanium

TiC TitaniumCarbide

Ti-HA Titanium-Hydroxyapatite

TMCs Titanium-MatrixComposites

TN TrueNegative

TP TruePositive

TPMS TriplyPeriodicMinimalSurface

TRL TechnologyReadinessLevel

TTT TransformationTimeTemperature

VC VanadiumCarbides

VED VolumetricEnergyDensity

VoF Volume-of-Fluid

VTM VirtualTemperatureMethod

WF Wire-Fed

WF-EDED Wire-FedElectronBeamDirectedEnergyDeposition

XRD X-RayDiffraction

XRF X-RayFluorescence

YAG YttriumAluminumGarnet

YLF YttriumLithiumFluoride

YVO4 YttriumOrthovanadate

Nomenclature

Unlessotherwisestatedinthetext,thesesymbolshavethefollowingmeanings

a Characteristiclength

a Energybilinearfunctionforinternalenergy(Chapter10)

A Spotarea – heatsourceinteractionarea

A Filamentornozzlecross-sectionarea(Chapter7)

Aat Attenuatedarea

Ac Cross-sectionarea

Aliq jet Intersectionofmeltpoolareaonsubstrateandpowderstream

Ajet Cross-sectionofpowderstreamonsubstrate

AG Propertyoffilamentmaterial

Aij,Bij Einsteincoefficients

AS Surfacearea

b Meltpooldepth

b Bias(Chapter11)

B Sizeofgap(Chapter7)

B Magneticfield

B Differentialshapefunctionmatrix(Chapter10)

c Speedoflight

cp Heatcapacity

cyl FunctionbasedonBesselfunctions

cs Speedofsoundinthefluid

C Dutycycle

C Compliance(Chapter10)

Ca Capillarynumber

Cs Solidcomposition

CL Liquidcomposition

C0 Nominalalloycompositionorsoluteconcentration

d Spotsize

d Euclideandistance(Chapter11)

d0 Dropletdiameter

d3,2 Surfacemeanparticlediameter

dcon Semisphericaldroplet

D Laserbeamdiameter

D Materialmatrix

Df Diffusionconstant

Dijmn Tensorofelasticcoefficients

DL Solutediffusioncoefficient

DØ Diffusioncoefficient

e Whensubscriptorsuperscript,signifiesavariableinitselementalform

ei Vectorpointing

E Laserbeamenergy

E Electricfield(Chapter5)

E Young’smodulusmatrix(Chapter10)

Ea Energyofactivation

Eb E-beamenergy

Ei Inputlaserenergy

Ekin Kineticenergy

Er Reflectedenergy

Et Transmittedenergy

Ei Energylevels(Chapter3)

Especific TheenergyentersthesubstratefromthesurfaceinDED

f Frequency

f Volumefraction(Chapter10)

fs Fractionofsolid

fL Fractionofliquid

f(R)Functionofsurfaceroughness

fi(x, t)Densityofparticlesmovinginthe ei direction

f eq i x, t Equilibriumdistribution

F Force

F0 Fouriernumber

0 Zero-orderBesselfunctionofitsfirstkind

1 Thefirst-orderBesselfunctionofthefirstkind

FCap Capillaryforce

Fst Surfacetensionforce

Fth Thermalstressload

FWet Wettingforce

g Gravity

gi Effectofexternalforces

G Temperaturegradient

GS Gibbsfreeenergyforsolid

GL Gibbsfreeenergyforliquid

Gz Graetznumber

ΔG TotalGibbsfreeenergychange

ΔG∗ Criticalfreeenergychange

ΔGV Freeenergychangeperunitvolume

h Plank’sconstant(Chapter3)

h Heightofahexahedralelement(Chapter10)

hc Heatconvectioncoefficient

hi Convectiveheatloss(cooling)coefficients

ha Averageheattransfercoefficientofconvection

hw Distancebetweenthenozzleandsurface

hr Radiativeheattransfercoefficient

hmin Minimumradiusoftheliquidcolumn

H Barrellengthorheightoftrack

H∗ Heightofthemeltpolymer

ΔH Enthalpydifference

HDR Heatingdepthratio

I Intensity:energyperarea

I Currentinelectronbeam(Chapter5)

I(x)Indicatorfunction(Chapter11)

I0 Intensityscalefactororinitialintensity

Ib Beamcurrentintheelectron-beamprocess

J Freeelectroncurrent

k Propagationfactor

k Equilibriumdistributioncoefficient(Chapter8)

k Solutepartitioncoefficient(Chapter9)

K Thermalconductivity

K Globalstiffnessmatrix(Chapter10)

Kc Conductivitymatrix(Chapter10)

Kh Connectivematrix(Chapter10)

K∗ Modifiedthermalconductivity

K0 Besselfunctionofthesecondkindandzeroorder

l Layerthickness

l Loadlinearfunctionforexternalwork(Chapter10)

L Transformationmatrix

L Linkintensity

Lc Characteristiclengthbasedondomainsize

Lf Latentheatoffusion

Lp

l Laguerrepolynomialoforderpandindexl

m Atomicmass

mb Massoftheball(Chapter9)

mb Depositedbinder(Chapter6)

mp Particlemass

mp Massoftheboundpowder(Chapter6)

mf Fluidmass

m Massflowrate

M2 Beamqualityfactor

Ma Marangoninumber

n Reflection’sindex

N Matrixofshapefunctionformeshelement

Ni Numberofatomsorelectronsperunitvolumeintheenergylevels

NL Amountofatomsperunitvolumeofliquid

Nlx Neumannfunction

NS Amountofatomsperunitvolumeofsolid

Nu Nusseltnumber

Nth Shapevectorforthermalexpansion

Oh Ohnesorgenumber

p Constantcharacteristicofthematerial(Chapter4)

p Pressure

p Penaltyvalue(Chapter10)

pc Capillaryforce

Pf Packingfraction

P Power

Pat Attenuatedlaserpowerbyparticles

Pel PowerofelectricalmotorinFDMsystem

Pl Net/averagelaserpower

Ppeak Peakpowerperpulse

Pon Onthestateofthelaserpower

Poff Offstateofthelaserpower

Ptot Totaldeliveredbeampower

Pe Pecletnumber

Pr Prandtlnumber

PR Packingdensityofthepowder

PW Pulsedwavelaser

P(∞)Valueoftheextrudatepropertyafteraninfinitehealingtime

q Heatflux

Q Powergeneratedperunitvolume(inallchaptersexceptChapter3)

Q Beampropagationfactor(Chapter3)

Qc Totalenergyabsorbedbythesubstrate

Qext Extinctcoefficient

Ql Laserenergy

Qrs Reflectedenergyfromthesubstrate

QL Latentenergyoffusion

Qv Volumetricflowrate

r Radiusofnucleus(Chapter8)

r ∗ Criticalnucleusradius

rb Ballmillradius

rf Filamentradius

r0l Beamradiusofthewaist

rjet Radiusofpowdersprayjet

rl Beamspotradiusonthesubstrate

rs Powderstreamdiameter

rp Powderparticleradius

R Reflectivity

R Solidificationratewhereitisreferredto

Rc Cladsurfacecurvature

Rcur Radiusofcurvature

Re Reynoldsnumber

Re∗ Property-basedReynoldsnumber

Rh Heatloadbyconvection

Rh(t)Intrinsichealingfunction

RL Localgrowthrate

RN Nominalgrowthrate

Rr Radiusoftheactuatingmotor

Rpore Effectiveporediameterinthebed

Rq Heatloadbysurfaceconduction

RQ Heatloadbyvolumeconduction

s Hatchspacing

s0 Specificsurfacearea

S Bindersaturation

Sij Lateraldistancebetweenneuron i and j (Chapter11)

Smax Spreadingratio

Smeas Amountofsignal(Chapter11)

SØ SourcetermcorrespondingtoØ

S (ϕ)Shapefactor

SS Scanspeed

S Strainratedeformationtensor

ΔS Expansionofsurfacearea

t Timeand/orlaserinteractiontime

t∗ Dimensionlesstime

tc = tμ Viscoustime

tCDA Correspondingpenetrationtime

tf Solidificationtime

tI Inertial-capillarytime

tV Viscous-capillarytime

T Temperature

Tα Referencetemperature

Tave Averagetemperature

Tin Filamenttemperature

Tg Glasstransitiontemperature

Tout Outlettemperature

T m Temperatureoftheliquefierwall

Td Dryingtime

Te Equilibriumtemperature

Tl Liquidustemperature

T0 Ambienttemperature

Tm Materialsmeltingpoint

Tp Maximumtemperature

ΔT Undercoolingtemperature

ΔTtot Totalundercoolingtemperature

ΔTC Undercoolingtemperature:solutediffusion

ΔTT Undercoolingtemperature:thermaldiffusion

ΔTK Undercoolingtemperature:attachmentkinetics

ΔTR Undercoolingtemperature:solid–liquidboundarycurvature

TEMpl Gaussian–Laguerretransverseelectromagneticmodes

U Beamvelocity

U Travelvelocityvector

U Globaldisplacementvector(Chapter10)

Up Particlevelocityvector

Us Rateofsolidification

v Scanningspeed

vc Collisionvelocity

υj Jetvelocity

vp Velocityoftheparticle

vprint Velocityoftheprinthead

V Volumeofmeltpool

V Designvolume(Chapter10)

Va Accelerationvoltage

VS Volumeofnucleus

VED TheenergyentersthesubstratefromthesurfaceinLPBF

w Trackormeltpoolwidth

w Neuronweight(Chapter11)

wi Weightfactor

W Laserpulsewidth

We Webernumber

Xs + c Weightpercentofelement X inthetotalsurfaceofthecladregion

Xc Weightpercentofelement X inthepowderalloy

Xs Weightpercentofelement X inthesubstrate

y Dendritearmspacing(Chapter8)

z Distancefromthesurface

z0 Waistlocationwithrespecttoanarbitrarycoordinatealongthepropagationaxis

Z Printabilityofaliquid

Zh Heatpenetrationdepth

GreekSymbols

α Thermaldiffusivity

αt Coefficientofthermalexpansion

β Absorptionfactor

β Absorptionfactor

β p Powderparticles’ absorbedcoefficient

β w Substratelaserpowerabsorptivity

γ Surfacetension

γ Netelectronbeamenergy(Chapter5)

γ E Specificsurfaceenergy

γ SL Solid–liquidinterfacialfreeenergy

γ SV Solid–vaporinterfacialenergy

γ LV Liquid–vaporinterfacialenergy

γ Shearrate

Γ TorqueofelectricalmotorsinFDM

Γ Surfacefunction(Chapter10)

δ Solid/liquidinterfacethickness

δ Diracdeltafunction(Chapter6)

ε Totalstrain

εc Coolingrate

εt Emissivity

ε M Mechanicalstrains

ε T Thermalstrains

εp Equivalentplasticstress

ε0 Vacuumpermittivity

εm Mechanicalstrain

εth Thermalstrain

Σ Covariancematrix

η Dynamicviscosity

η Powdercatchmentefficiency(whereveritreferstothroughoutchapters)

η NumericaldampingcoefficientforOCM(Chapter10)

η Learningrate(Chapter11)

ηe Absorptionefficiencyforelectronbeam

ηd Dynamicviscosity

ηp Powdercatchmentefficiency

θ Representingdifferentanglesbasedonfigures

θ Wettingangle(Chapter2)

θ Far-fielddivergenceangle(Chapter3)

θ Dimensionlesstemperatureinnumericalmodels(Chapter7)

θ jet Anglebetweenpowderjetandsubstrate

θ d Dynamicwettingangle

θ eq Steady-stateangle

Θ Dimensionlesstempinanalyticalmodels

λ Wavelength

λ Lagrangemultiplier(Chapter10)

λn Rootsofzero-orderBesselfunctionofitsfirstkind

μ Viscosity

μ Membershipfunction(Chapter11)

υ Frequency(Chapter3)

υ Kinematicviscosity

ρ Density

ρb Densityofbinder

ρpb Powderbeddensity

ρc Densityofmeltedpowderalloy

ρs Densityofsubstratematerial

ρs Packingdensityofthepores(Chapter6)

σ Stefan–Boltzmannconstant

σ Covariance(Chapter11)

σ c Chargedensity

σ ij Elasticstress

τ Thermaltimeconstant

τ c Dimensionlesscapillarytime

ϕ Differentlabelforanglesasindicatedintheassociatedfigures