Visit to download the full and correct content document: https://ebookmass.com/product/3d-printing-for-energy-applications-vincenzo-esposito /

More products digital (pdf, epub, mobi) instant download maybe you interests ...

3D Printing: A Revolutionary Process for Industry Applications Richard Sheng

https://ebookmass.com/product/3d-printing-a-revolutionaryprocess-for-industry-applications-richard-sheng/

3D Printing Technology for Water Treatment Applications

Jitendra Kumar Pandey

https://ebookmass.com/product/3d-printing-technology-for-watertreatment-applications-jitendra-kumar-pandey/

3D Printing Richard Sheng

https://ebookmass.com/product/3d-printing-richard-sheng/

Fundamentals of 3D food printing and applications Godoi

https://ebookmass.com/product/fundamentals-of-3d-food-printingand-applications-godoi/

3D Printing for the Radiologist 1st Edition Nicole Wake

https://ebookmass.com/product/3d-printing-for-theradiologist-1st-edition-nicole-wake/

Multimaterial 3D Printing Technology Jiquan Yang

https://ebookmass.com/product/multimaterial-3d-printingtechnology-jiquan-yang/

3D and 4D Printing of Polymer Nanocomposite Materials: Processes, Applications, and Challenges 1st Edition Kishor

Kumar Sadasivuni

https://ebookmass.com/product/3d-and-4d-printing-of-polymernanocomposite-materials-processes-applications-andchallenges-1st-edition-kishor-kumar-sadasivuni/

Customized Production Through 3D Printing in Cloud Manufacturing Lin

Zhang

https://ebookmass.com/product/customized-productionthrough-3d-printing-in-cloud-manufacturing-lin-zhang/

4D Printing: Fundamentals and Applications Rupinder

Singh

https://ebookmass.com/product/4d-printing-fundamentals-andapplications-rupinder-singh/

3D Printing for Energy Applications

3D Printing for Energy Applications

Edited by Albert Tarancón

Catalonia Institute for Energy Research and ICREA

Barcelona, Spain and Vincenzo Esposito

Department of Energy Conversion and Storage

Technical University of Denmark

Fysikvej

Lyngby, Denmark

Copyright © 2021 by The American Ceramic Society. All rights reserved.

Published by John Wiley & Sons, Inc., Hoboken, New Jersey.

Published simultaneously in Canada.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording, scanning, or otherwise, except as permitted under Section 107 or 108 of the 1976 United States Copyright Act, without either the prior written permission of the Publisher, or authorization through payment of the appropriate per-copy fee to the Copyright Clearance Center, Inc., 222 Rosewood Drive, Danvers, MA 01923, (978) 750-8400, fax (978) 750-4470, or on the web at www.copyright. com. Requests to the Publisher for permission should be addressed to the Permissions Department, John Wiley & Sons, Inc., 111 River Street, Hoboken, NJ 07030, (201) 748-6011, fax (201) 748-6008, or online at http://www.wiley.com/go/permissions.

Limit of Liability/Disclaimer of Warranty: While the publisher and author have used their best efforts in preparing this book, they make no representations or warranties with respect to the accuracy or completeness of the contents of this book and specifically disclaim any implied warranties of merchantability or fitness for a particular purpose. No warranty may be created or extended by sales representatives or written sales materials. The advice and strategies contained herein may not be suitable for your situation. You should consult with a professional where appropriate. Neither the publisher nor author shall be liable for any loss of profit or any other commercial damages, including but not limited to special, incidental, consequential, or other damages.

For general information on our other products and services or for technical support, please contact our Customer Care Department within the United States at (800) 762-2974, outside the United States at (317) 572-3993 or fax (317) 572-4002.

Wiley also publishes its books in a variety of electronic formats. Some content that appears in print may not be available in electronic formats. For more information about Wiley products, visit our web site at www.wiley.com.

Library of Congress Cataloging-in-Publication Data:

Names: Taranco´n, Albert, editor. | Esposito, Vincenzo, editor.

Title: 3D printing for energy applications / edited by Albert Tarancón and Vincenzo Esposito.

Description: First edition. | Hoboken, New Jersey : Wiley-American Ceramic Society, [2021] | Includes bibliographical references and index.

Identifiers: LCCN 2020031685 (print) | LCCN 2020031686 (ebook) | ISBN 9781119560753 (cloth) | ISBN 9781119560760 (adobe pdf) | ISBN 9781119560784 (epub)

Subjects: LCSH: Three-dimensional printing. | Energy industries–Technological innovations.

Classification: LCC TS171.95 .A165 2021 (print) | LCC TS171.95 (ebook) | DDC 621.9/88–dc23

LC record available at https://lccn.loc.gov/2020031685

LC ebook record available at https://lccn.loc.gov/2020031686

Cover Design: Wiley

Cover Image: © Used with permission with IREC

Set in 9.5/12.5pt STIXTwoText by SPi Global, Pondicherry, India

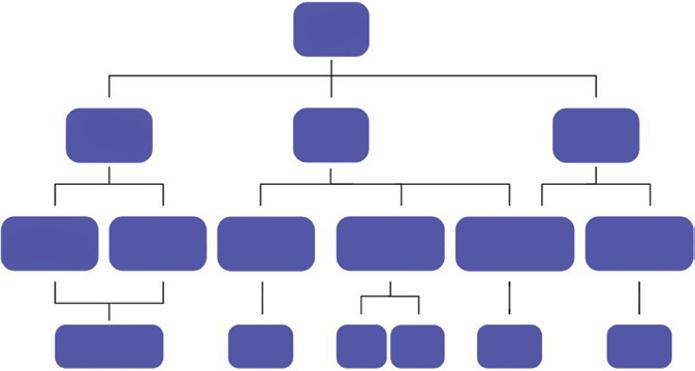

Contents

Contributor xiii

Introduction to 3D Printing Technologies xvii

Part I 3D printing of functional materials 1

1 Additive Manufacturing of Functional Metals 3 Venkata Karthik Nadimpalli and David Bue Pedersen

1.1 Introduction 3

1.1.1 Industrial Application of Metal AM in the Energy Sector 5

1.1.2 Geometrical Gradients in AM 6

1.1.3 Material Gradients in AM 6

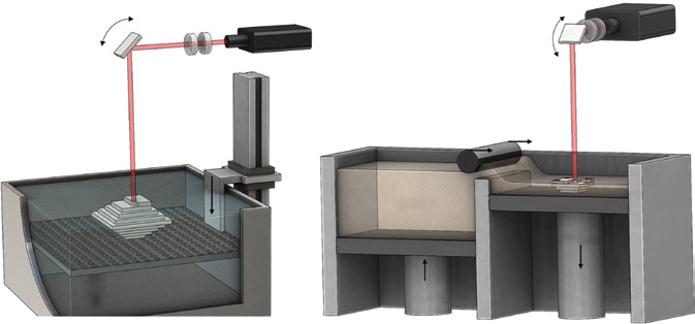

1.2 Powder Bed Fusion AM 7

1.2.1 Geometric Gradients in PBF 8

1.2.2 Material Gradients in PBF 9

1.3 Direct Material Deposition 12

1.3.1 Powder and Wire Feedstock for Near-Net-Shape AM 12

1.3.2 Functional Material Gradients in DED 13

1.4 Solid-State Additive Manufacturing 16

1.5 Hybrid AM Through Green Body Sintering 19

1.5.1 Common AM Technologies for Green Body Manufacturing 19

1.5.2 CAD Design and Shrinkage Compensation 20

1.5.3 Additive Manufacture 20

1.5.4 Debinding and Sintering 21

1.5.5 Functionally Graded Components in Sintered Components 22

1.6 Conclusions 22

Acknowledgment 24

References 24

2 Additive Manufacturing of Functional Ceramics 33

José Fernando Valera-Jiménez, Juan Ramón Marín-Rueda, Juan Carlos Pérez-Flores, Miguel Castro-García, and Jesús Canales-Vázquez

2.1 Introduction 33

2.1.1 Why 3D Printing of Technical Ceramics? 35

2.1.2 Materials and Applications 35

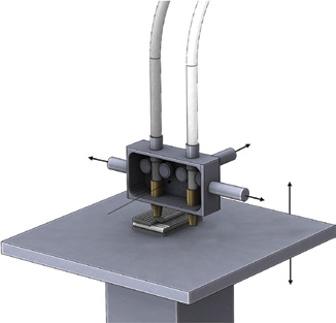

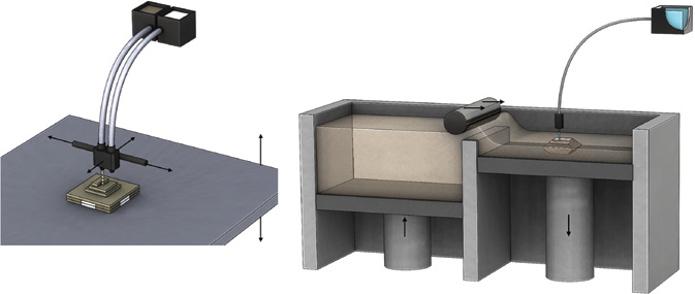

2.2 Ceramics 3D Printing Technologies 36

2.2.1 Lamination Object Modeling (LOM) 37

2.2.2 Ceramics Extrusion 38

2.2.2.1 Robocasting/Direct Ink Writing 39

2.2.2.2 Fused Deposition of Ceramics 42

2.2.3 Photopolymerization 44

2.2.4 Laser-Based Technologies 47

2.2.5 Jetting 49

References 52

3 3D Printing of Functional Composites with Strain Sensing and Self-Heating Capabilities 69 Xin Wang and Jihua Gou

3.1 Introduction 69

3.2 Carbon Nanotube Reinforced Functional Polymer Nanocomposites 70

3.2.1 Strain Sensing of CNT Reinforced Polymer Nanocomposites 70

3.2.2 Resistive Heating of CNT Reinforced Polymer Nanocomposites 71

3.3 Printing Strategies 72

3.3.1 Spray Deposition Modeling and Fused Deposition Modeling 72

3.3.2 Printing of Highly Flexible Carbon Nanotube/Polydimethylsilicone Strain Sensor 73

3.3.3 Printing of Carbon Nanotube/Shape Memory Polymer Nanocomposites 73

3.4 Strain Sensing of Printed Nanocomposites 73

3.5 Electric Heating Performance Analysis 79

3.6 Electrical Actuation of the CNT/SMP Nanocomposites 82

3.7 Conclusions 85

References 87

Part II 3D printing challenges for production of complex objects 91

4 Computational Design of Complex 3D Printed Objects 93

Emiel van de Ven, Can Ayas, and Matthijs Langelaar

4.1 Introduction 93

4.2 Dedicated Computational Design for 3D Printing 95

4.2.1 Overhang Angle Control Approaches 96

4.2.1.1 Local Angle Control 96

4.2.1.2 Physics-Based Constraints 97

4.2.1.3 Simplified Printing Process 97

4.2.2 Design Scenarios 98

4.3 Case Study: Computational Design of a 3D-Printed Flow Manifold 99

4.3.1 Fluid Flow TO 100

4.3.2 Front Propagation-Based 3D Printing Constraint 102

4.3.3 Fluid TO with 3D Printing Constraint 103

4.4 Current State and Future Challenges 104

References 105

5 Multicomponent and Multimaterials Printing: A Case Study of Embedded Ceramic Sensors in Metallic Pipes 109 Cesar A. Terrazas, Mohammad S. Hossain, Yirong Lin, and Ryan B. Wicker

5.1 Multicomponent Printing: A Short Review 109

5.2 Multicomponent Printing: A Case Study on Piezoceramic Sensors in Smart Pipes 111

5.2.1 Brief Introduction to AM of Embedded Sensors for Smart Metering 111

5.2.2 Fabrication of the Embedded Piezoceramic Sensor in Metallic Pipes 114

5.2.2.1 Smart Coupling Fabrication Process Using EPBF Technology 114

5.2.2.2 Materials 116

5.2.2.3 Sensor Housing 117

5.2.2.4 Re-poling of PZT 118

5.2.2.5 Impact in Sensing Properties Due to Heat-Treatment Induced By AM Process 119

5.2.2.6 Smart Coupling Component 119

5.2.2.7 Compressive Force Sensing 119

5.2.2.8 Temperature Sensing 120

5.2.3 Impact of the AM and Performance of the Multicomponent Printed Device 122

5.2.3.1 Compressive Force Sensing 122

5.2.3.2 Temperature Sensing 124

5.2.3.3 Crystalline Structure Analysis 126

5.3 Summary and Outlook 128 Acknowledgments 129

References 130

6 Tailoring of AM Component Properties via Laser Powder Bed Fusion 135

Simon Ewald, Maximilian Voshage, Steffen Hermsen, Max Schaukellis, Patrick Köhnen, Christian Haase, and Johannes Henrich Schleifenbaum

6.1 Introduction 135

6.2 Machines, Materials, and Sample Preparation 138

6.3 Sample Preparation and Characterization Techniques 139

6.4 Material Qualification and Process Development 140

6.5 Tailoring Grain Size via Adaptive Processing Strategies 143

6.6 Tailoring Material Properties By Using Powder Blends 146

6.7 Tailoring Properties By Using Special Geometries Such As Lattice

Structures 148

Funding 150

Conflicts of Interest 150

References 150

7 3D Printing Challenges and New Concepts for Production of Complex Objects 153 Hayden Taylor, Hossein Heidari, Chi Chung Li, Joseph Toombs, and Sui Man Luk

7.1 Introduction 153

7.2 Geometrical Complexity 154

7.3 Material Complexity 155

7.4 Energy Requirements 156

7.5 Promising Metal Deposition Approaches 157

7.6 Multimaterial and Multi-property SLA 159

7.7 Temporal Multiplexing 159

7.8 Resin Formulations with Multiple End-States 160

7.9 Associated Processing Considerations 160

7.10 Bioprinting of Realistic and Vascularized Tissue 162

7.11 Emerging Volumetric Additive Processes 163

7.12 Computation for CAL 166

7.13 Material–Process Interactions in CAL 167

7.14 Current Challenges in CAL 169

7.15 Expanding the Capabilities of CAL 170

7.16 Concluding Remarks and Outlook 171

Acknowledgments 172

References 172 Part III 3D printing of energy devices 181

8 Current State of 3D Printing Technologies and Materials 183 Poul Norby

8.1 3D Printing of Energy Devices 183

8.1.1 Batteries 183

8.1.1.1 3D Printing Structured Electrodes 186

8.1.1.2 3D Printing Solid Electrolytes 195

8.1.1.3 3D Printed Full Batteries 197

8.1.1.4 Conclusion and Outlook 200

References 200

9 Capacitors 205

Lukas Fieber and Patrick S. Grant

9.1 Introduction 205

9.2 Capacitors and Their Current Manufacture 206

9.2.1 Capacitor Classifications, Operating Principles, Applications, and Current Manufacture 206

9.2.1.1 Electrostatic Capacitors 206

9.2.1.2 Electrolytic Capacitors 209

9.2.1.3 Electrochemical Capacitors 210

9.2.2 Capacitor Components: Function and Requirements 211

9.2.3 Performance 213

9.2.4 The Challenge of Manufacturing Capacitors 214

9.3 The Promise of Additive Manufacturing 215

9.4 Additive Manufacturing Technologies: Considerations for Capacitor Fabrication 217

9.4.1 AM Process Categories 217

9.4.1.1 Material Extrusion – Fused Filament Fabrication 217

9.4.1.2 Material Extrusion – Direct Ink Writing 221

9.4.1.3 Vat Polymerization 223

9.4.1.4 Powder Bed Fusion 225

9.4.1.5 Material Jetting 227

9.4.1.6 Binder Jetting 228

9.4.2 Multi-technology or Hybrid Printing 229

9.4.3 Complete Capacitor Devices Fabricated by Additive Manufacturing 230

9.5 Summary and Outlook 232

Acronyms 233 References 235

10 3D-Printing for Solar Cells 249

Marcel Di Vece, Lourens van Dijk, and Ruud E.I. Schropp

10.1 Introduction 249

10.2 Examples of 3D-Printing for PV 250

10.3 Geometric Light Management 255

10.3.1 Background 255

10.3.2 Optical Model for External Light Trapping 257

10.3.3 Design and 3D-Printing of the External Light Trap 260

10.3.4 Characterization 261

10.4 Conclusions 266

References 267

11 3D Printing of Fuel Cells and Electrolyzers 273 A. Hornés, A. Pesce, L. Hernández‐Afonso, A. Morata, M. Torrell, and Albert Tarancón

11.1 Introduction 273

11.2 3D Printing of Solid Oxide Cells Technology 274

11.2.1 Solid Oxide Fuel Cells 275

11.2.1.1 SOFC Electrolyte 276

11.2.1.2 SOFC Electrodes 278

11.2.2 Solid Oxide Electrolysis Cells 283

11.2.3 SOC Stacks and Components 284

11.3 3D Printing of Polymer Exchange Membranes Cells Technology 286

11.3.1 Polymeric Exchange Membrane Fuel Cells 287

11.3.1.1 PEMFC Electrolyte 288

11.3.1.2 PEMFC Catalysts Layer 288

11.3.1.3 PEMFC Gas Diffusion Layer 289

11.3.1.4 PEMFC Bipolar Plates and Flow Fields 290

11.3.2 Polymer Exchange Membrane Electrolysis Cells 293

11.3.2.1 PEMEC Liquid Gas Diffusion Layer 293

11.3.2.2 PEMEC Bipolar Plates and Flow Fields 293

11.3.2.3 Fully Printed PEMEC 294

11.4 3D Printing of Bio-Fuel Cells Technology 294

11.5 Conclusions and Outlook 297 References 297

12 DED for Repair and Manufacture of Turbomachinery Components 307 S. Linnenbrink, M. Alkhayat, N. Pirch, A. Gasser, and H. Schleifenbaum

12.1 Introduction 307

12.2 DED Based Repair of Turbomachinery Components 309

12.2.1 DED Process 310

12.2.2 Work Environment 310

12.2.3 Process Chain for the Repair of Turbine Blades 310

12.2.3.1 Step 1: “Machining & Preparation” 310

12.2.3.2 Step 2: “Reverse Engineering” 311

12.2.3.3 Step 3: “Generation of Tool Paths” 313

12.2.3.4 Step 4: “DED Process” 313

12.2.3.5 Step 5: “Adaptive Machining” 314

12.3 DED Based Hybrid Manufacturing of New Components 314

12.3.1 Hybrid Additive Manufacturing 315

12.3.2 Turbocharger Nozzle Ring 317

12.3.3 Hybrid Production Cell 319

12.3.4 Process Chain for Hybrid Additive Manufacturing of Nozzle Rings 320

12.3.4.1 Step 1: “Choice of DED Strategy” 320

12.3.4.2 Step 2: “DED Process” 321

12.3.4.3 Step 3: “Optical Metrology” 322

12.3.4.4 Step 4: “Adaptive Milling” 322

12.3.4.5 Step 5: “Joining of Top Ring” 322

12.4 Summary 323 Acknowledgments 324

References 324

13 Thermoelectrics 327 Fredrick Kim, Seungjun Choo, and Jae Sung Son

13.1 Introduction 327

13.2 Additive Manufacturing Techniques of Thermoelectric Materials 328

13.2.1 Extrusion-Based Additive Manufacturing Process 328

13.2.2 Fused Deposition Modeling (FDM) Technique 336

13.2.3 Stereolithography Apparatus (SLA) Process 337

13.2.4 Selective Laser Sintering (SLS) Process 339

13.2.5 Summary and Outlook 345 Acknowledgements 345

References 345

14 Carbon Capture, Usage, and Storage 351

Jason E. Bara

14.1 Introduction 351

14.2 Can 3D Printing Be Used to Fabricate a CO2 Capture Process at Scale? 354

14.3 A Brief Note on 3D Printing and CO2 at Smaller Scales & Research Efforts 356

14.4 Conclusions 358 References 358

Index 361

Contributors

Venkata Karthik Nadimpalli

Department of Mechanical Engineering,

Technical University of Denmark, Kgs. Lyngby, Denmark

David Bue Pedersen

Department of Mechanical Engineering,

Technical University of Denmark, Kgs. Lyngby, Denmark

José Fernando Valera-Jiménez

3D‐ENERMAT, Materials for Energy & 3D Printing Lab, Renewable Energy Research Institute, Universidad de Castilla‐La Mancha, Albacete, Spain

Juan Ramón Marín-Rueda

3D‐ENERMAT, Materials for Energy & 3D Printing Lab, Renewable Energy Research Institute, Universidad de Castilla‐La Mancha, Albacete, Spain

And

Print3D Solutions, Albacete, Spain

Juan Carlos Pérez-Flores

3D‐ENERMAT, Materials for Energy & 3D Printing Lab, Renewable Energy Research Institute, Universidad de Castilla‐La Mancha, Albacete, Spain

Miguel Castro‐García

3D‐ENERMAT, Materials for Energy & 3D Printing Lab, Renewable Energy Research Institute, Universidad de Castilla‐La Mancha, Albacete, Spain

Jesús Canales-Vázquez

3D‐ENERMAT, Materials for Energy & 3D Printing Lab, Renewable Energy Research Institute, Universidad de Castilla‐La Mancha, Albacete, Spain

Xin Wang

Composite Materials and Structures Laboratory, Department of Mechanical and Aerospace Engineering, University of Central Florida, Orlando, FL, USA

Contributors xiv

Jihua Gou

Composite Materials and Structures Laboratory, Department of Mechanical and Aerospace Engineering, University of Central Florida, Orlando, FL, USA

Emiel van de Ven

II Optomechatronics Group, Netherlands Organisation for Applied Scientific Research TNO, Delft, The Netherlands

Can Ayas

I Structural Optimization and Mechanics Group, Delft University of Technology, Delft, The Netherlands

Matthijs Langelaar

I Structural Optimization and Mechanics Group, Delft University of Technology, Delft, The Netherlands

Cesar A. Terrazas

W.M. Keck Center for 3D Innovation, The University of Texas at El Paso, El Paso, TX, USA

Yirong Lin

W.M. Keck Center for 3D Innovation, The University of Texas at El Paso, El Paso, TX, USA

Ryan B. Wicker

W.M. Keck Center for 3D Innovation, The University of Texas at El Paso, El Paso, TX, USA

Mohammad S. Hossain

W.M. Keck Center for 3D Innovation, The University of Texas at El Paso, El Paso, TX, USA

Simon Ewald

Digital Additive Production, RWTH Aachen University, Aachen, Germany

Maximilian Voshage

Digital Additive Production, RWTH Aachen University, Aachen, Germany

Steffen Hermsen

Digital Additive Production, RWTH Aachen University, Aachen, Germany

Max Schaukellis

Digital Additive Production, RWTH Aachen University, Aachen, Germany

Patrick Köhnen

Steel Institute, RWTH Aachen University, Aachen, Germany

Christian Haase

Steel Institute, RWTH Aachen University, Aachen, Germany

Johannes Henrich Schleifenbaum

Digital Additive Production, RWTH Aachen University, Aachen, Germany And Fraunhofer Institute for Laser Technology ILT, Aachen, Germany

Hayden Taylor

Department of Mechanical

Engineering, University of California, Berkeley, CA, USA

Hossein Heidari

Department of Mechanical Engineering, University of California, Berkeley, CA, USA

Chi Chung Li

Department of Mechanical Engineering, University of California, Berkeley, CA, USA

Joseph Toombs

Department of Mechanical Engineering, University of California, Berkeley, CA, USA

Sui Man Luk

Department of Mechanical Engineering, University of California, Berkeley, CA, USA

Poul Norby

Department of Energy Conversion and Storage, Technical University of Denmark, Lyngby, Denmark

Lukas Fieber

Department of Materials, University of Oxford, Oxford, UK

Patrick S. Grant

Department of Materials, University of Oxford, Oxford, UK

Marcel Di Vece

Interdisciplinary Centre for Nanostructured Materials and Interfaces (CIMaINa) and Physics

Department “Aldo Pontremoli”, University of Milan, Milan, Italy

Lourens van Dijk

Soluxa B.V., Nijmegen, The Netherlands

Ruud E.I. Schropp

Department of Physics and Astronomy, University of the Western Cape, Belville, South Africa

A. Hornés

Department of Advanced Materials for Energy, Catalonia Institute for Energy Research (IREC), Barcelona, Spain

A. Pesce

Department of Advanced Materials for Energy, Catalonia Institute for Energy Research (IREC), Barcelona, Spain

L. Hernández-Afonso

Department of Chemistry, University of La Laguna, Tenerife, Spain

A. Morata, Department of Advanced Materials for Energy, Catalonia Institute for Energy Research (IREC), Barcelona, Spain

M. Torrell

Department of Advanced Materials for Energy, Catalonia Institute for Energy Research (IREC), Barcelona, Spain

Albert Tarancón

Department of Advanced Materials for Energy, Catalonia Institute for Energy Research (IREC), Barcelona, Spain and

Catalan Institution for Research and Advanced Studies (ICREA), Barcelona, Spain

S. Linnenbrink

Fraunhofer Institute for Laser Technology (ILT), Aachen, Germany

M. Alkhayat

Fraunhofer Institute for Laser Technology (ILT), Aachen, Germany

Contributors xvi

N. Pirch

Fraunhofer Institute for Laser Technology (ILT), Aachen, Germany

A. Gasser

Fraunhofer Institute for Laser Technology (ILT), Aachen, Germany and Chair for Laser Technology (LLT), Aachen, Germany

H. Schleifenbaum

Fraunhofer Institute for Laser Technology (ILT), Aachen, Germany and Digital Additive Production (DAP), Aachen, Germany

Fredrick Kim

School of Materials Science and Engineering, Ulsan National

Institute of Science and Technology (UNIST), Ulsan, Republic of Korea

Seungjun Choo

School of Materials Science and Engineering, Ulsan National Institute of Science and Technology (UNIST), Ulsan, Republic of Korea

Jae Sung Son

School of Materials Science and Engineering, Ulsan National Institute of Science and Technology (UNIST), Ulsan, Republic of Korea

Jason E. Bara

University of Alabama, Tuscaloosa, AL, USA