SteelSurfaces

inArchitectureandArt

L.WilliamZahner

Thisbookisprintedonacid-freepaper.

Copyright©2021byJohnWiley&Sons,Inc.Allrightsreserved

PublishedbyJohnWiley&Sons,Inc.,Hoboken,NewJersey

PublishedsimultaneouslyinCanada

Nopartofthispublicationmaybereproduced,storedinaretrievalsystem,ortransmittedinanyformorbyany means,electronic,mechanical,photocopying,recording,scanning,orotherwise,exceptaspermittedunderSection 107or108ofthe1976UnitedStatesCopyrightAct,withouteitherthepriorwrittenpermissionofthePublisher,or authorizationthroughpaymentoftheappropriateper-copyfeetotheCopyrightClearanceCenter,222Rosewood Drive,Danvers,MA01923,(978)750-8400,fax(978)646-8600,oronthewebatwww.copyright.com.Requeststo thePublisherforpermissionshouldbeaddressedtothePermissionsDepartment,JohnWiley&Sons,Inc.,111 RiverStreet,Hoboken,NJ07030,(201)748-6011,fax(201)748-6008,oronlineatwww.wiley.com/go/permissions.

LimitofLiability/DisclaimerofWarranty:Whilethepublisherandauthorhaveusedtheirbesteffortsinpreparing thisbook,theymakenorepresentationsorwarrantieswiththerespecttotheaccuracyorcompletenessofthe contentsofthisbookandspecificallydisclaimanyimpliedwarrantiesofmerchantabilityorfitnessforaparticular purpose.Nowarrantymaybecreatedorextendedbysalesrepresentativesorwrittensalesmaterials.Theadvice andstrategiescontainedhereinmaynotbesuitableforyoursituation.Youshouldconsultwithaprofessional whereappropriate.Neitherthepublishernortheauthorshallbeliablefordamagesarisingherefrom.

Forgeneralinformationaboutourotherproductsandservices,pleasecontactourCustomerCareDepartment withintheUnitedStatesat(800)762-2974,outsidetheUnitedStatesat(317)572-3993orfax(317)572-4002.

Wileypublishesinavarietyofprintandelectronicformatsandbyprint-on-demand.Somematerialincludedwith standardprintversionsofthisbookmaynotbeincludedine-booksorinprint-on-demand.Ifthisbookrefersto mediasuchasaCDorDVDthatisnotincludedintheversionyoupurchased,youmaydownloadthismaterialat http://booksupport.wiley.com.FormoreinformationaboutWileyproducts,visitwww.wiley.com.

LibraryofCongressCataloging-in-PublicationData

Names:L.WilliamZahner,author.

Title:Steelsurfaces:aguidetoalloys,finishes,fabricationand maintenanceinarchitectureandart/L.WilliamZahner.

Description:Hoboken,NewJersey:Wiley,2021.|Series:Zahner’s architecturalmetalsseries|Includesindex.

Identifiers:LCCN2020021102(print)|LCCN2020021103(ebook)|ISBN 9781119541622(paperback;acid-freepaper)|ISBN9781119541554(adobe pdf)|ISBN9781119541646(epub)

Subjects:LCSH:Steel–Surfaces.|Steel–Finishing.|Architectural metal-work.|Artmetal-work.

Classification:LCCTS320.Z2852021(print)|LCCTS320(ebook)|DDC 672—dc23

LCrecordavailableathttps://lccn.loc.gov/2020021102

LCebookrecordavailableathttps://lccn.loc.gov/2020021103

CoverDesign:Wiley

CoverImage:©lior2/GettyImages

PrintedintheUnitedStatesofAmerica

10987654321

ThisbookisinhonorofDavidNorris.Afriendandmentor.

CHAPTER4Expectations117

CHAPTER5DesigningwiththeAvailableForms163

CHAPTER6WorkingwithSteels205

GalvanicCorrosionandGalvanicProtectionofSteels294

GalvanicCorrosionandtheRatioofAreas297 KeyConditionsNeededforGalvanicCorrosiontoOccur298 TransferCorrosion299 PittingCorrosion300 IntergranularCorrosion300 CreviceCorrosion300 LineCorrosion302

CHAPTER8MaintainingtheSteelSurface305 Introduction305 PaintedSteelSurfaces305 DevelopaMaintenanceStrategy308 MaintainingSteelsinDifferentEnvironments311 Vandalism334

APPENDIXATerms345

APPENDIXBComparativeAttributesofMetals349

APPENDIXCAlloyCrossReferences351

APPENDIXDAbrasivePreparationofSteels353

APPENDIXESpecificationInformation355

APPENDIXFAFewRelevantspecificationsfromtheASTMInternational–(NotaCompleteList)365

APPENDIXGHot-DippedGalvanizingSpecification367

Index369

Preface

“Knowyourownvalue.”

HankRearden ofReardenSteel

AtlasShrugged byAynRand

SteelwasoneofthefirstmetalsIbecameacquaintedwithearlyinmycareer.Itwasdifferentthan theshinycoppertheshophadstackedinaneatpileorthelightweightaluminumstoredinracks upofftheground.Steelwasheavy,thickerthanmostothersheetmetals,andoftenpossessedthe intricatespangleofzinccrystalsonthesurfacefromthehot-dipgalvanizingprocess.

Steelwastreatedrougher.Storedinopenstacks.Oftencoatedinalayerofslickoil.Ithada smelltoit—thesmellofmachinery,thesmellofindustry.Steellackedthecareandconcernthe othermetalsseemedtoberegarded.Itwasthemetalusedformakingpatterns,1 beforetheshapes wouldbecutincopper,aluminum,orsteel’sroyalcousin,stainlesssteel.Afterwhich,theywouldbe relegatedtothescrapbintoberecycled.Weusedtorecycleallthemetals,andonoccasionIwould takeamassiveloadofsteelscraptotherecyclingyard,onlytoreceivelessthan20dollars.Ithardly seemedworthit,butwewereacompanythathadworkedwithmetalsthroughthehardtimesof theDepression,andyouwastednothing.Everysteelpackagingbandwascollectedandrecycled.

ThefirstmajorprojectsIwasinvolvedwithoutofcollegehadsteelsidingpanelsforcladding thewallsoflargecoal-poweredelectricalgeneratingplantsthatdottedtheMissouriRiver.These heavypanelswereroll-formedfrom18-gaugecold-rolledsteelsheetmadebyINRYCO,shortforthe InlandRyersonCompany,aoncemassivelylargesteelproducerintheUnitedStates.InlandSteel Company,foundedin1893,wasoneofthelastintegratedsteelcompaniesthatturnedoreintosteel andintosemifabricatedwroughtmaterials.Itssubsidiary,InlandBuildingSystems,mergedwith RyersonandlaterbecameINRYCO,buteventuallyfelttheimpactofforeignsourcesofsteeland modernizationandefficienciesofthemini-mills.

Thesesteel-cladpowerplantshavestoodforover40years.Thepaintcoatingsusedonthesteel structureandonthesteelpanelsIworkedwithwasofveryhighqualityandtodayshowlittlesigns ofdeterioration—somefadingwithtimeandultravioletexposure,butgenerallythesurfacesarein excellentcondition.

1 Upuntiltheearly1980s,patternsweremadefrompaperblueprints.TherewerenoCAD–CAMfiles.Steelpatterns wouldbecuttoforlaterusetomakeelbowsorroofjacks.Thepatternswerehungfromhooksonthewall,andwhen similaritemsweremade,thepatternswouldbeusedonthelayoutbenches.Abitarchaicinlightofthetechnology oftoday.

Overtime,myexperiencemovedawayfromthemildcarbonsteelsofsidingandmetaldecking. Aluminumbecamethebasemetalforhigh-qualitypaintsystems.Stainlesssteel,copperalloys,and laterzincwerethemetalsfordesignofexposed,uncoatedsurfaces.

Buttherewasthisotherinterestingsteel,aparadoxofmetal.ItwascalledCorten.

Herewasthisstrangesteelthatyouwantedthesurfacetocorrode.Itwouldstaineverything belowitwhileitformedtheinitialrust,yetitwassupposedtolastaslongasthestainlesssteels.

Thecompanybuiltitsfirstmajorbuildingin1982,andthedesignerwantedanaturalappearance.HechoseCortensidingfortheplantportionandalcladaluminumfortheoffice.Thesiding wasroll-formedbyINRYCOasoneofthelastgaspsofsteelproduction,asINRYCOwastocloseits doorsin1986.Thearchitectdescribedhisdesignasthenewgrowingfromtheold–theoldbeing therustymetalsurfaceofCorten.Itisinterestingthatoverthelast40years,itistheCorten,the weatheringsteel,thathasembracedthefutureandstillappearssturdyandstrongwhilealuminum islookingfragileandantiquated.

Ihaveworkedwithweatheringsteel,thenameusedasoftenastheolderCorten—or COR-TEN®,astheinventorandtrademarkholder,USSteelcallsit.CORstandsforcorrosion resistanceandTENstandsfortensilestrength.Bothofthesecharacteristicsandmorearepossessed bythisamazingsteel.

Nearly25yearsagowerealizedthemajordrawback,fromanaestheticstandpoint,wasthetime ittookfortherealdeepcolortoappear.Peopledidnotwanttowaitandwatchastheirbuildingrusted andpaintedthesidewalksandstoneworkwitharedstain.Theideaofpreweatheringthistypeof steelseemedtobetheanswer.Manyanartistpushedthemetaltoachievethispreweatheringon theirsculptureusingacidsandwettingthesurface.Inadditiontobeinghazardoustoone’shealth andsafety,thisprocessisimpracticalforlargeprojects.

Afterabitoftestingandtrials,wecameupwithaprocesswenowcall Solanum, theLatin wordforeggplant.Thecolorofeggplantisadeeppurplebrown,similartowhatisachievedwhen weatheringsteelreachesitspointofsurfaceequilibrium. Solanum soundedfittingforametal,in tunewiththegreatSirHumphreyDavy,whonamedsuchmetalsaspotassium,sodium,and,of course,aluminum.

Theideawithpreweatheringistocontroltheoxidedevelopmentinanenvironmentspecifically controlledforthisspecialsteeltocorrodeslowlyandformthreerichformsofoxideonthesurface, similarto,butmuchquickerthan,thecolorthatformedafteryearsofexposure.Thestainingwould becontainedforthemostpartandcollectedinourplant.

Theweatheringsteelshavearichcolortonethatcomesacrossasamaterialoftheearth.Like brick,wood,orpatinacopper,weatheringsteelhasaverynatural,pleasingappearanceoncethe oxidationtakesroot.Manyoftheprojectsshowninthisbookdemonstratethenaturalcharacterof thisamazingsteel.

Thesteelswesometimesrefertoasmildsteelorcarbonsteelareubiquitousinoureveryday environment.Unliketheweatheringsteels,wedonotnoticethemuntiltheydobegintocorrode. Otherwise,theygoabouttheirbusinessofprotectingusaswedrivedowntheroad,orholdour buildingsupagainsttheforcesofgravityandwind.Oncetheystarttocorrode,theygetnoticedlike moldonbread.Thecarbonsteelswiththeirbeautifullyrugged,darkgray-bluecolorrequiresome

formofprotectiontoholdbackrustfromdeveloping.Itisthematerialofbattleshipsandtanks, armortobeabusedandtowithstandabuse,butalittlemoistureandtroublesetsin.

Moreandmoredesignersareseeingtheintrinsicbeautyofthecarbonsteels.Conquering,orat leastforestalling,theonsetofthefeelingofneglecttheconditionofrustcanportrayisparamount. Iron,themainelementinsteel,wantstojoinupwithoxygen–andironhasmorewaystojoinwith oxygenthanwecancountonbothhands.Thereare16oxideformsofiron.Youwanttokeepthe steelsurfacedry;wateristhecatalystforthiscouplingwithoxygen.

Conversioncoatingsslowdownthemarriagewithoxygenbyintroducingotherelementssuch asphosphates,sulfates,andcopperselenidecoatingsthatclingtotheironsurfaceandformabarrier ofdarkenedcolor.Atthesametime,thesecoatingscanofferauniqueappearancewhilemaintaining theintrinsicbeautyofsteel.

OfallthemetalsIhavewrittenabout,steelhasbeenoneofthemorechallenging.Fromanart andarchitectureperspective,steelhasplayedavaluablerole,butasabitplayer,itisaninexpensive alternative.Withnewtechniquesofpreweatheringthehigh-strength,low-alloy(HSLA)steels,this surfaceisbeingrecognizedasabeautiful,naturalmaterialbydesignersandartistsaroundtheworld. Thedarkening,bluing,andvariegatefinishonecanobtainfromthemildcarbonsteelsaddsan entirenewarrayofpossibilitiestothedesigncommunity.Easytoworkwith,weldable,andnow withappealingsurfacefinishing,steelisgivingnewvaluetothedesignerandartist.

L.WilliamZahner

CHAPTER 1 Introduction

Theonlywaytoknowhowstrongyouareistokeeptestingyourlimits.

Jor–LtoSuperman,themanofSteel.

IRONANDSTEEL

Ironandsteelhavealonghistorywithmankind.

Thehistoryofcontemporarycivilizationisintermingledwiththeprowessofironandsteel.Steel isanalloyofironwithasmallamountofcarbon,usuallylessthan2%.Ironhasbeenusedthroughout civilizationtomakeusefultoolsandarmaments.Implementsmadefromironwereharderandcould holdanedgebetterthananyothersubstanceknownatthattime.Eventoday,hardnessandstrength arecomparedtoiron.

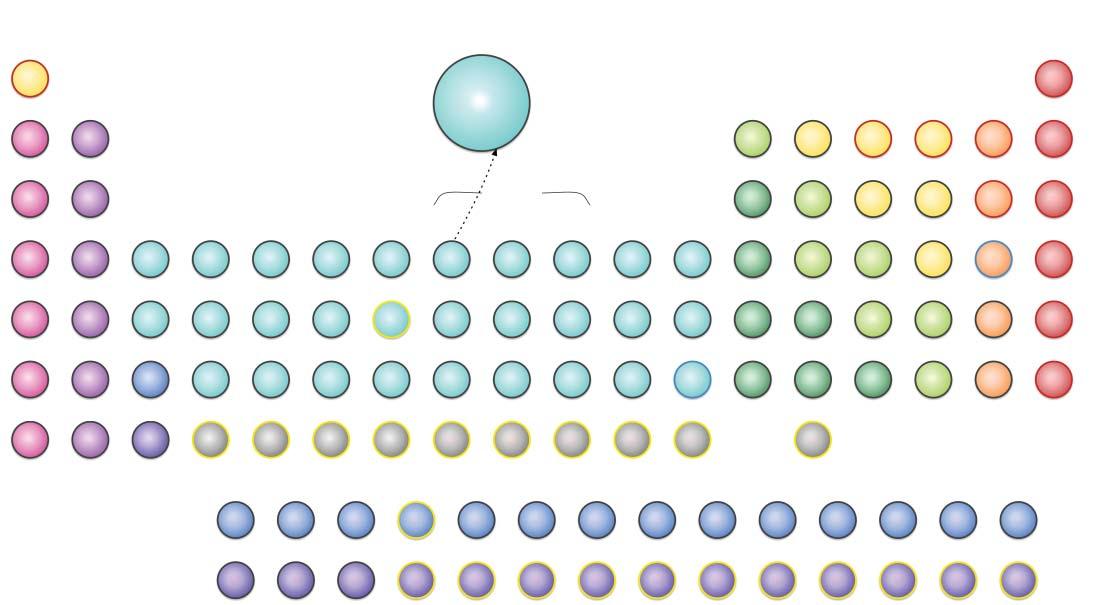

TheatomicsymbolforironisFe,whichisshortenedfromtheLatinwordforthemetal, ferrum, whichmeans“firmness.”Ironiselement26ontheperiodicchart.SeeFigure1.1.

Ironsitsbetweenmanganeseandcobaltandinthesamelinewithrutheniumandosmium,two verydenseelements.

IronisthefourthmostabundantelementfoundontheEarth’soutercrustbehindoxygen,silicon,andaluminum,whilethecoreoftheEarthissaidtobecomposedmostlyofiron.

Ironisoneofthefewsubstancesthatdemonstratemagnetism. Ferromagnetism isatermgiven todescribeaphenomenonofafewmaterialstoshowmagneticattraction.Ironischiefamongthese; nickelandcobaltaretwootherelementsthatexhibitthistrait.Ferromagnetismoccursintherare earthelementgadoliniumandafewothercompounds.Neodymium,rareearthmagnets,arealloys ofneodymium,iron,andboron.Theseexhibitastrongmagneticfield.

FIGURE1.1 Periodictableoftheelements.

VIIIA

Oneofironschiefores,magnetite,sometimescalledthe lodestone, wasknowntoearlymanas aspecialmaterialthat,whenattachedtoathread,alwaysalignedinagivendirection.Thiswasthe firstcompass,andtheterm lodestone means“leadingstone,”foritwouldpointtheway.

Thereisamysterysurroundingtheabilityofmagnetitetobecomemagnetic.Notallmagnetiteis magnetic,andtomakeitintoalodestonesomestrongmagneticfieldhastobeapplied.Itissuggested thatlightningstrikesnearoredepositscausedsomeofthemagnetitetobecomestronglymagnetized becausetheelectricalcurrentassociatedwithlightningpossessesastrongmagneticfieldandthis magnetizedthemagnetitenearby.

Artisticadaptionstoironimplementsinvolvedetchingthesurfaceofforgedironusing organicacidstoselectivelyremoveareasofmetal.Inlaysofsoftermetalssuchasbronze,copper, andevensilvercouldfurtherenhancetheironsurface.Thesesoftermetalscouldbehammered intogroovesinthemuchharderiron,keyingthemintothesurfacetocreatecontrastingartistic effects.Earlymanufacturingtechniquesanduseofironallowedthedevelopmentofartisticsurface treatmentsthatexpandedtheintricatedetailingalreadyunderwayonthesoftermetalsofbronze andcopper.

Ironisenigmatic.Withalliron’sstrengthandhardness,itisquicktogiveitup.Airandmoistureareallthatareneededtostripthisstrengthfromiron.Thosetwoelectronsintheoutershell anxiouslycombinewithoxygen,sulfur,oranynumberofotherelements(Figure1.3).Ironisnever foundpureinnature.Ironfindsthermodynamicequilibriumwhenitcombineswithoxygenand othersubstances.Withiron,unlikeothermetalssuchasaluminumandtitanium,whenitcombineswithoxygenandwaterispresent,itexpandsasitformsoxyhydroxide.So,asthesurfaceof ironoxidizes,ittakesupmorevolume,creatingcracksandallowingmoreironunderthesurfaceto beexposed.

FIGURE1.2 Bodycenteredcubicstructureofironcrystal.

FIGURE1.3 Theironatom.

IronElement26

IronisthefourthmostabundantelementonEarth’ssurface;6.3%ofEarth’scrustiscomposed ofiron.

Steelisanalloyofiron.Carbonisthemainalloyingelementintroducedintoirontocreate steel.Otherelementsareaddedinsmallamountstocreatespecificproperties.

Excellentductility,deepformingability,superiorhardness,machinable.Canbebothcold andhotworked.

Highfracturetoughness

Highelasticity–resiliencyundershockloading.Highvibrationresistance.

Hardedge.Canbesharpenedandholdanedge.

Nontoxic.

Poorcorrosionresistanceunlessalloyedwithspecificelementsorcoatedwithsacrificial metals.

Finishes:

Millfinishinmostapplications. Rarelypolishedormechanicallyfinished. Usuallycoated.

Organiccoatingsintheformofpolymersandresinsarecommoncoatings. Inorganiccoatingsintheformofglass,likeporcelains,arecommoncoatings.

Metalcoatingsbyhotdippingorbyelectroplatingarecommoncoatings.

Metaloxidesaltsarecommonblackeningtechniquesthatprovidebothappearanceandcorrosionresistance.

Oxyhydroxidelayersthatdeveloponparticularsteelalloyscalled weatheringsteels are commonsurfacesusedinartandarchitecture.

Artificialpatina

Darkappearance

Blacksandmottledgrays.Darkgreensanddarkredscanbeproduced onsteels.

Ironabsorbsandreflectsevenlyacrossthespectrumwithslightly moreontheshorterwavelengthsportionofthespectrum.Alloysalter thisreflection.Weatheringsteelshavegreateremissionaroundthe yellowwavelengthsandtheredendofthevisiblespectrum.

(continued)

(continued)

Reflectance

ofUltraviolet Verygood ofInfrared Poor.Copperabsorbsinfraredwavelengths.

Relativecost Low

Strengthening Coldworking,alloying,andtemperingaremethodsusedtoadjustthe strengthofsteels.

Recyclability Easilyrecycled.Highermeltingpointandcoatingsonthesteelmake thescrapvalueverylow.

Weldingandjoining Canbewelded,brazed,andsoldered.

Casting Steelisfrequentlycastusingallcastmethodologies.

Plating Commonlyelectroplatedwithzinc,nickel,andchrome.

Etchingandmilling Canbeetchedandchemicallymilled.

HISTORY

Ironartifacts,asoldas3500 BCE,havesurvivedtothisday.Nickelwasfoundmixedwithmanyof theseartifacts,indicatingthesourceofthemetalwasmeteoritescollectedfromthegroundrather thanmined. 1

Theearliestusesofironoccurredinvariousregionsaroundtheworld.Anatonia,India,Egypt, Greece,Babylon,Japan,China,andmuchofnorthernAfrica,whererichironoreconcentrations arestillminedtoday,weresomeofthefirstregionstocreateironimplementsforuseineveryday life,warfare,andart.

Ironusagefollowedthatofbronze,thelatterbeingeasiertorefineandcast.Additionally, copper-bearingmineralsweremoreeasilyidentifiableduetothecolorfulmineralforms.

Itwasmostlikelymankind’saggressiveandassertivebehaviorthatdrovetheearlygrowthand discoveryofworkingwithiron.Oncemankindfiguredouthowtocastandshapethismetal,it soonsupplantedcopperandthecopperalloy,bronze,asthematerialofwar.Thealchemistusedthe symbolofadiagonalarroworthesymbolforman–whichisalsothesymbolforMars,thegodof war.SeeFigure1.4.

TheHittitesaresaidtohavebeenoneofthefirstcivilizationstomineandworkthemetalby smeltingore.TheHittitecivilization,alsoreferredtoasthe KingdomofHatti, controlledtheregion aroundAnatoliabackin1700 BCE.TheywererivalstotheEgyptians.Theiruseofironpredates othercivilizations,andbecausetheywereoftenatwar,onecanonlypresupposetheadvantageof

1 Giauque,G.,‘Thehistoryofcarbonsteels’, TheBookofSteel,LavoisierPublishing,1997,p.4.

FIGURE1.4 Symbolofironusedbytheearlyalchemists.

thisharderandstrongermaterialpresentedtotheHittites.TheChalybeswereatribesubjecttothe Hittites.TheylivedalongtheshoresoftheBlackSea.Thistribeiscreditedwithbeingsomeofthe firsttoworkwithiron.

TherearesitesinAfricathatcouldbeevenolder;however,controversysurroundstheirexact date.Thus,iron,enteringtherealmofman,ismostoftenattributedtothecentralAsianregion. InIndia,wherecastingandworkingwithironwasarefinedart,excavationsintheMiddleGanga Valleyshowironworkingbeganasearlyas2800 BCE.TheMughalEmpireofthiserawasprolific intheexploitationofironandtheearlyunderstandingofcastingthismetal.Themetalworkersof theMughalperiodwereexpertsandweresomeofthefirsttoworkwiththelostwaxtechniqueof casting.Theywereknownforcastingnear-perfectironsphereswithnoseams.

Ithasbeenwellestablishedthatpeopleofthisregionexhibitedsignificantprowessintheproductionofironandlatersteelasearlyas300 BCE.Forthenext500years,high-qualitysteelwasbeing producedbythepeopleofthisregion.Theyusedamethodreferredtodayasthe crucibletechnique toproducethishigh-qualitysteel.ThesteelproducedwasofsuchgreatqualitythatKingPorusof Indiaoffered15kgofirontoAlexandertheGreatasagift.

Thecrucibletechniqueinvolvedheatinghigh-puritywroughtironmixedwithcharcoaland glass.Thesiliconintheglasswouldattachtoimpuritiesinthewroughtironandfloattothetop, whilesomeofthecarbonwouldbeabsorbedintotheirontocreatesteel.Thissteelwasknownby theArabsas fülåd, andinEuropeitwascalled wootz.

ThepeopleofthisregiontradedwiththeGreeksandRomans,aswellastheeasterncultures. Theexchangeofthescienceofmetallurgyslowlypercolatedoutofthisregiontootherpartsofthe knownworld.

TheknowledgeandabilitytotempersteelwaswellknowntothemetalworkersofancientIndia. Theywereknownformakingincredibleswordsandbladessuperiortoanythingatthetime.Even today,someoftheartofcreatingthesespecialbladeshasyettobeuncovered.

Onespecializedprocesswastheproductionofthe Damascussword,alsocalleddamascene. Damascene standsforthedecorativeprocessofproducingwavylinesinmetalbyinlayingother metalsorbyetchingthesurfaceofmetals.Figure1.5showswhatdamascenesteellookedlike.The Damascusswordwasmadefromsteelproducedthisway.

ThedamascenesteeltechniqueswerebelievedtobefirstdevelopedinIndia.Decorativeetching andmetalinlaymethodswereperfectedinIndiainthefirstmillennia BCE.RomanstradedwithIndia toobtainswordsandcutlerymadefromtheirspecializedironworks.

FIGURE1.5 DamasceneSteelThedamasceneswordtechniqueswerebelievedtobefirstdevelopedinIndia. DecorativeetchingandmetalinlaymethodswereperfectedinIndiainthefirstmillenniaBC.

Source: L.WilliamZahner

Thisearlysteelwasknownaswootzsteelforthecarboncontent.DevelopedinsouthernIndia aroundthesixthcentury BCE,wootzisasteelcreatedusingthisearlycruciblemeltingprocess. UsedinIndia,thenDamascusandtheregionaroundToledo,Spain,thisearlyprocessusedsand, glass,andothersubstancesasafluxtoaidinmeltingiron.Theresultingsteelwasofveryhighquality.Wootzishighincarbonandcontainedbandsofpearlite,martensite,andferrite.Tomakewootz, orewouldbecookedinsideasealedclaycrucibleoveracharcoalfire.Earlycruciblesteelwoulduse thehighwindsfromstormstoforceairintothecharcoalinordertoachievethenecessaryheat.

Littleremainsofearlyironarticlesduetothepropensityofironarticlestocorrodewhenexposed tomoistureandoxygen.Oncecorrosionwouldstart,itwasdifficulttostop.Theresimplywereno goodmeansofinhibitingironfromwantingtocombinewithoxygenandformironoxideorrust.

Mostcertainly,muchoftheearlyironwascollectedfrommeteorites.Thisfactcanbededuced fromthelanguageoftheregions.TheGreekwordforironis sideros, translatedtomean,“fromthe stars.”TheEgyptianwordforironis baaenepe, or“giftfromheaven.”Tomeltiron,however,requires ablastfurnacetoachievethetemperaturesneeded.

Eventually,itwasdeterminedthatifironwereheatedforlongperiodsoftimeinacrudefurnace, afurnacesetsothatairwouldrushthroughtheburningmassofcharcoalandore,aspongylumpof metalwouldform.Thismalleableironcouldbehammeredandflattened.Reheatingwouldsoften itor,ifleftforlongperiodsoftimeinhotcharcoal,theoutersurfacewouldhardenascarbonwas absorbed–processestodaycalled annealing and casehardening.

Castirontechniquesdevelopedoutofthecastingofbronzeworkashighertemperatureswere achievedascastingprocessesimproved.Withtheinclusionofsmallquantitiesofcarbon,say2–4%, themeltingpointofironisreduced.Manydiverseancientculturespracticedandimprovedtheart ofcastingmetals.TheChinesemadevarioussmallfarmingutensilsasfarbackas500 BCE,whilein Indiaexceptionalcastingtechniqueshadbeenindevelopmentcenturiesearlier.Indiantechniques wereacceptedandadoptedbythePersiansandtheRomansassuperiorsourcesofironproducts; bothcastandwroughtcouldbeproduced.

AnexampleoftheprowessoftheIndianmetallurgyistheIronPillarofDelhi.SeeFigure1.6. Thisamazingstructureis8mtallandweighs7tons.ItwascastduringtheChandraguptaIIreign sometimearoundthefourthcentury CE.Tothisday,this1600-year-old,high-purityironformshows littlesignsofcorrosion.

FIGURE1.6 IronPillarofDelhi,IndiaEarlyArchitecturalUsesIn1849,thedesignerJamesBogardus,created thefirstself-supportingglassandironcurtainwalls

Source: ByShutterstock

EARLYARCHITECTURALUSES

In1849,thedesignerJamesBogarduscreatedthefirstself-supportingglassandironcurtainwalls. Thesecurtainwallsofiron,castinsandmolds,wouldstackandbolttogetherintomultistory buildingfronts.Theironcurtainwallproliferatedinthenewmoderncitiesofeasternseaboard. In1853,thegrandCrystalPalacewaserectedusingthisnewbolt-uptechniqueofironsupporting glasswalls.Theseintricatelydetailedcurtainwallsofironandglassweremoreeconomicaland

quickertoconstruct.Theyprovidedbothanaestheticappearanceandafire-resistantfronttomany buildingsinthesecondhalfofthenineteenthcentury.Severalmajoriron-castingcompaniessprang upacrossAmericaandEuropetotakeadvantageofthedesignsthatcouldbedevelopedusingcast iron.ExamplesofcastironstructuralcolumnsandcastironcurtainwallareshowninFigure1.7.

Ironisdistinguishedfromsteelinthatironisanelementwheresteelisanalloyofiron.Ironis rarelyusedinitspureform.Usually,asmallamountofcarbonispresent.Ironusedinartcomesin severalforms,thepredominatebeingcastandwrought.Castisanyironthathasbeenpouredinto amoldtocreateitsformorshape,whereaswroughtironisironthathasbeenheatedandshaped withtooling.

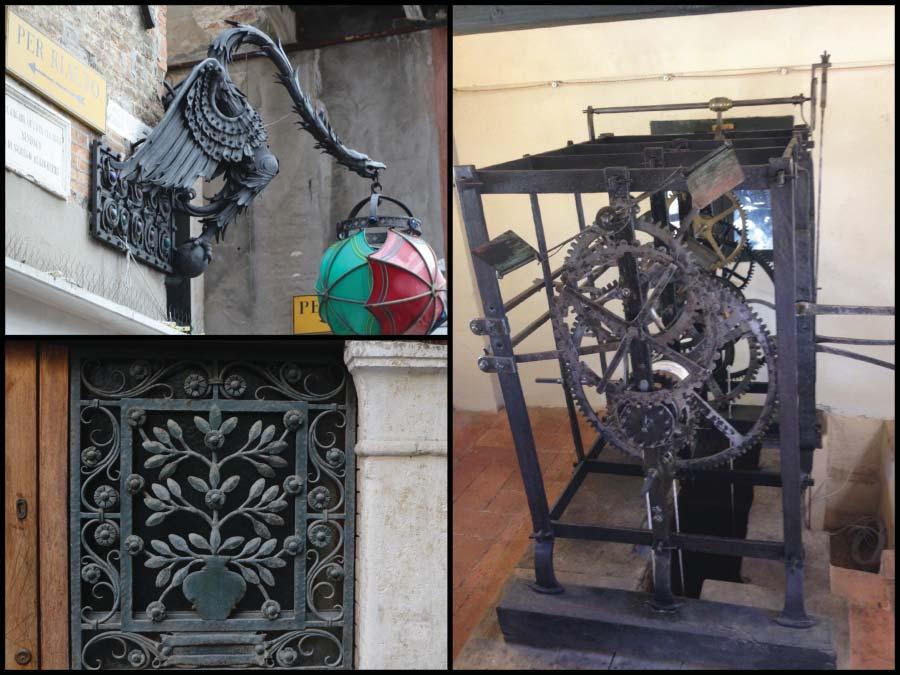

Figure1.8showsexamplesofearlywroughtiron.Theupperleftisadecorativesculpturalform, thelowerleftagrillemadefromwroughtiron,andtherightimageisanearlyclockmechanism madefromwroughtiron.

Inthelate1700s,techniquesofcastingironcolumnsweredevelopedandtheuseofironasa structuralsupportmemberproliferated.Castironcolumnsprovidedexcellentcompressivestrength,

FIGURE1.7 Castironcolumnsandcurtainwall.

Source: L.WilliamZahner

Source: L.WilliamZahner

anddesignersusedirontocreatethinsupportingstorefronts,balconysupports,andeveninterior columnsupports.Theyweremoreresistanttofirethanconventionalwoodcolumnsandtookupless spacethanstonesupports,providingbetterviewingintoshopswiththeirsmallercrosssection.Iron columnscouldbecastwithdecorativefeaturesandcouldbeboltedquicklyintoornamentalassemblies.Thesecastironfacadesprovidedtheneededcompressivestrength,stiffness,andhardness. Theycouldnotbeforgedorshapedbecauseoftheirinherentbrittleness,andcatastrophefollowed iftheyweresubjectedtobendingandtensionstresses.

Earlyusesofironwereofthewroughtironform.Wroughtironwasinpredominantuseearly becauseitdidnotrequirefullymeltingtheore.Tofullymelttheorewouldrequireveryhigh temperatures,soinsteadahotmassofironandothersubstances,usuallycarbonfromcharcoal usedintheovenandslagmaterialsfromtheheat,wouldbehammeredaparttorevealsmall globulesofiron.Theseglobuleswouldbecollectedandreheated,andthenforgedtogetherby furtherhammering.Theabilitytoreheatandhammertheseglobulesofirontogethertoformlarger elementswaskeytothesuccessofironinantiquity.Objectscouldbeshapedthiswaywithblows

FIGURE1.8 Earlywroughtironwork.

fromahammer,essentially“welding”thepiecestogether.Theironwouldjoinintoalargermass andwouldbethinnedandshapedintoallsortsofimplements,fromswordstofarmingimplements.

Wroughtironhasalong,lineargrainappearance,asopposedtotheregulargrainsofthecast irons.Whenbroken,thegrainshaveafibrousorwood-likeappearance.Wroughtironhaslower carbonthancastironandhasinclusionsfromslagandoxidesthatareintegratedbythehammering andextendingofthemetalgrains.Byintegratingtheslag,amorefibrousstructurecanbeobtained, whichimprovesflexibility.

Sometelltalesignsusedtodistinguishthedifferencebetweencastironandwroughtironartifactsare,first,thatcastironusuallyisthemoredetailedofthetwo.Additionally,moldlinesand detailarethedomainofcastings.Castironassembliesarebolted,whereaswroughtironassembles arerivetedorheatforgedtogether.

Wroughtironhasbetterstrengthcharacteristicsthancastiron.Wroughtironisolderthancast ironbecauseitcouldbecreatedfromthespongybloomofironintheoldcharcoalfurnaces.These oldfurnacescouldnotreachthetemperaturesneededtosmeltironcompletefromtheore.Instead theywouldarriveatacarbonrichporouslumpofironmixedwithvariousothersubstances.This lumpwouldbehammeredrepeatedlytoremovephysicalimpurities.Thelargerphysicalimpurities wouldspallawayasthelumpbecamethinner.Iron-richprillscouldbeextractedfromthemassasthe outershellofglassyoxidesarebrokenaway.Theprillswereofrichinironandwouldbehammered andfoldedintoalarger,workablemassofwroughtiron.Ashammeringandfoldingcontinued,the irongrainswouldstretchandelongatecreatingmorestrengthwhileallowinggoodductilitywithout thebrittlenessofacastiron.Wroughtironhasinclusionsofslagandothersubstancesthatgiveita distinctivesurfaceappearance.Thisgrain-likestructurerunsthroughwroughtironandiscreated bystretchingandextendingthesefibersthroughtheironasitishammeredandfolded.Wrought ironhasgoodstrength,corrosionresistanceandthecarboncontentareless.Aswithcastiron,today mostwroughtironisactuallyasteelalloy,generallyalow-carbonformofmildsteel.Steelreplaced wroughtironinthenineteenthcenturyasnewprocesseswereintroducedinthemanufactureof ferrousgoods.

Improvementsinthemanufacturingofsteelstartedintheearly1800s.Mostironwassmelted bythecruciblemethod.Thismethodofsteelproductionusedcharcoalandlatercoketoproduce steelfrompigiron.

Bythesecondhalfofthenineteenthcentury,theneedforsteelincreased,andanewprocess, calledtheBessemerprocess,wasdeveloped.HenryBessemerinEnglandandWilliamKellyinthe UnitedStatesdevelopedamethodofblastingairtochangepigironintowroughtiron.Thiswould removecarbon,butthecarboncouldbeaddedbackinamorecontrolledmannertomakesteel.The processisstillused,anditcarriesthenameBessemer,whoappliedforapatentontheprocessin 1856.However,Kelly,claimedthathehadalsodevelopedtheprocessinKentucky,in1851.Kelly laterfiledforapriorityclaimfortheprocessintheUnitedStatesandwasawardedapatent,essentiallyforthesameprocess,in1857.TheBessemerprocessdevelopedbecauseoftheneedofmassive amountsofconsistentrailroadtrack.Priortothat,itwasmadefromcastiron.TheBessemerprocess revolutionizedsteelmaking.

Thecommercialmanufactureofwroughtironislefttosmallartfoundries.Thelastmajor commercialfoundryceasedmakingwroughtironintheearly1970s.Today,whatwecallwrought