Visit to download the full and correct content document: https://ebookmass.com/product/waste-valorisation-waste-streams-in-a-circular-econo my-carol-sze-ki-lin/

More products digital (pdf, epub, mobi) instant download maybe you interests ...

Waste Biorefinery: Integrating Biorefineries for Waste Valorisation Thallada Bhaskar (Editor)

https://ebookmass.com/product/waste-biorefinery-integratingbiorefineries-for-waste-valorisation-thallada-bhaskar-editor/

Sustainable Metal Extraction from Waste Streams Chauhan

https://ebookmass.com/product/sustainable-metal-extraction-fromwaste-streams-chauhan/

Circular Economy: From Waste Reduction to Value Creation Karen Delchet-Cochet

https://ebookmass.com/product/circular-economy-from-wastereduction-to-value-creation-karen-delchet-cochet/ Waste-to-Resource System Design for Low-Carbon Circular Economy Siming You

https://ebookmass.com/product/waste-to-resource-system-designfor-low-carbon-circular-economy-siming-you/

Building materials in a circular economy: The case of wood waste as CO2-sink in bio concrete Lucas Rosse Caldas

https://ebookmass.com/product/building-materials-in-a-circulareconomy-the-case-of-wood-waste-as-co2-sink-in-bio-concrete-lucasrosse-caldas/

Biomass, Biofuels, Biochemicals: Circular Bioeconomy: Technologies for Waste Remediation Sunita Varjani

https://ebookmass.com/product/biomass-biofuels-biochemicalscircular-bioeconomy-technologies-for-waste-remediation-sunitavarjani/

Advanced Materials from Recycled Waste Sarika Verma https://ebookmass.com/product/advanced-materials-from-recycledwaste-sarika-verma/

Concepts of Advanced Zero Waste Tools: Present and Emerging Waste Management Practices Chaudhery Mustansar Hussain

https://ebookmass.com/product/concepts-of-advanced-zero-wastetools-present-and-emerging-waste-management-practices-chaudherymustansar-hussain/

A Thermo-Economic Approach to Energy from Waste Anand Ramanathan

https://ebookmass.com/product/a-thermo-economic-approach-toenergy-from-waste-anand-ramanathan/

WasteValorisation WileySeries in RenewableResources SeriesEditor:

ChristianV.Stevens,FacultyofBioscienceEngineering,GhentUniversity,Belgium

TitlesintheSeries:

WoodModification:Chemical,ThermalandOtherProcesses

CallumA.S.Hill

Renewables-BasedTechnology:SustainabilityAssessment

JoDewulf,HermanVanLangenhove

Biofuels

WimSoetaert,ErikVandamme

HandbookofNaturalColorants

ThomasBechtold,RitaMussak

SurfactantsfromRenewableResources

MikaelKjellin,IngegärdJohansson

IndustrialApplicationsofNaturalFibres:Structure,PropertiesandTechnicalApplications JörgMüssig

ThermochemicalProcessingofBiomass:ConversionintoFuels,ChemicalsandPower

RobertC.Brown

BiorefineryCo-Products:Phytochemicals,PrimaryMetabolitesandValue-AddedBiomass Processing

ChantalBergeron,DanielleJulieCarrier,ShriRamaswamy

AqueousPretreatmentofPlantBiomassforBiologicalandChemicalConversiontoFuelsand Chemicals

CharlesE.Wyman

Bio-BasedPlastics:MaterialsandApplications

StephanKabasci

IntroductiontoWoodandNaturalFiberComposites

DouglasD.Stokke,QinglinWu,GuangpingHan

CellulosicEnergyCroppingSystems

DouglasL.Karlen

IntroductiontoChemicalsfromBiomass,2ndEdition

JamesH.Clark,FabienDeswarte

LigninandLignansasRenewableRawMaterials:Chemistry,TechnologyandApplications FranciscoG.Calvo-Flores,JoseA.Dobado,JoaquínIsac-García,FranciscoJ.Martin-Martínez

SustainabilityAssessmentofRenewables-BasedProducts:MethodsandCaseStudies

JoDewulf,StevenDeMeester,RodrigoA.F.Alvarenga

CelluloseNanocrystals:Properties,ProductionandApplications WadoodHamad

Fuels,ChemicalsandMaterialsfromtheOceansandAquaticSources FrancescaM.Kerton,NingYan

Bio-BasedSolvents

FrançoisJérôme,RafaelLuque

NanoporousCatalystsforBiomassConversion Feng-ShouXiao,LiangWang

ThermochemicalProcessingofBiomass:ConversionintoFuels,ChemicalsandPower, 2ndEdition

RobertC.Brown

TheChemicalBiologyofPlantBiostimulants

DannyGeelen,LinXu

ChitinandChitosan:PropertiesandApplications LambertusA.M.vandenBroek,CarmenG.Boeriu

BiorefineryofInorganics:RecoveringMineralNutrientsfromBiomassandOrganicWaste ErikMeers,EviMichels,RenéRietra,GerardVelthof

ProcessSystemsEngineeringforBiofuelsDevelopment AdriánBonilla-Petriciolet,GadeP.Rangaiah

WasteValorisation:WasteStreamsinaCircularEconomy CarolSzeKiLin,GuneetKaur,ChongLi,XiaofengYang

ForthcomingTitles: BiobasedPackaging:Material,EnvironmentalandEconomicAspects MohdSapuanSalit,RushdanAhmadIlyas

High-PerformanceMaterialsfromBio-basedFeedstocks

AndrewJ.Hunt,NontipaSupanchaiyamat,KaewtaJetsrisuparb,JesperT.N.Knijnenburg

WasteValorisation WasteStreamsinaCircular Economy Editedby

CAROLSZEKILIN SchoolofEnergyandEnvironment,CityUniversityofHongKong, TatCheeAvenue,KowloonTong,HongKong

GUNEETKAUR DepartmentofBiology,HongKongBaptistUniversity, KowloonTong,HongKong and DepartmentofCivilEngineering,YorkUniversity,Toronto,Canada

CHONGLI ShenzhenBranch,GuangdongLaboratoryforLingnanModernAgriculture, GenomeAnalysisLaboratoryoftheMinistryofAgriculture, AgriculturalGenomicsInstituteatShenzhen, ChineseAcademyofAgriculturalSciences,Shenzhen,China

XIAOFENGYANG SchoolofBiologyandBiologicalEngineering, SouthChinaUniversityofTechnology,Guangzhou,China

Thiseditionfirstpublished2021

©2021JohnWiley&SonsLtd

Allrightsreserved.Nopartofthispublicationmaybereproduced,storedinaretrievalsystem,ortransmitted,inanyformorby anymeans,electronic,mechanical,photocopying,recordingorotherwise,exceptaspermittedbylaw.Adviceonhowtoobtain permissiontoreusematerialfromthistitleisavailableat http://www.wiley.com/go/permissions

TherightofCarolSzeKiLin,GuneetKaur,ChongLi,andXiaofengYangtobeidentifiedastheauthorsoftheeditorialmaterial inthisworkhasbeenassertedinaccordancewithlaw.

RegisteredOffices

JohnWiley&Sons,Inc.,111RiverStreet,Hoboken,NJ07030,USA

JohnWiley&SonsLtd,TheAtrium,SouthernGate,Chichester,WestSussex,PO198SQ,UK

EditorialOffice

TheAtrium,SouthernGate,Chichester,WestSussex,PO198SQ,UK

Fordetailsofourglobaleditorialoffices,customerservices,andmoreinformationaboutWileyproductsvisitusat www.wiley .com

Wileyalsopublishesitsbooksinavarietyofelectronicformatsandbyprint-on-demand.Somecontentthatappearsinstandard printversionsofthisbookmaynotbeavailableinotherformats.

LimitofLiability/DisclaimerofWarranty

Inviewofongoingresearch,equipmentmodifications,changesingovernmentalregulations,andtheconstantflowof informationrelatingtotheuseofexperimentalreagents,equipment,anddevices,thereaderisurgedtoreviewandevaluatethe informationprovidedinthepackageinsertorinstructionsforeachchemical,pieceofequipment,reagent,ordevicefor,among otherthings,anychangesintheinstructionsorindicationofusageandforaddedwarningsandprecautions.Whilethepublisher andauthorshaveusedtheirbesteffortsinpreparingthiswork,theymakenorepresentationsorwarrantieswithrespecttothe accuracyorcompletenessofthecontentsofthisworkandspecificallydisclaimallwarranties,includingwithoutlimitationany impliedwarrantiesofmerchantabilityorfitnessforaparticularpurpose.Nowarrantymaybecreatedorextendedbysales representatives,writtensalesmaterialsorpromotionalstatementsforthiswork.Thefactthatanorganization,website,orproduct isreferredtointhisworkasacitationand/orpotentialsourceoffurtherinformationdoesnotmeanthatthepublisherandauthors endorsetheinformationorservicestheorganization,website,orproductmayprovideorrecommendationsitmaymake.This workissoldwiththeunderstandingthatthepublisherisnotengagedinrenderingprofessionalservices.Theadviceand strategiescontainedhereinmaynotbesuitableforyoursituation.Youshouldconsultwithaspecialistwhereappropriate. Further,readersshouldbeawarethatwebsiteslistedinthisworkmayhavechangedordisappearedbetweenwhenthisworkwas writtenandwhenitisread.Neitherthepublishernorauthorsshallbeliableforanylossofprofitoranyothercommercial damages,includingbutnotlimitedtospecial,incidental,consequential,orotherdamages.

LibraryofCongressCataloging-in-PublicationData

NamesSzeKiLin,Carol,1977-editor.Kaur,Guneet,1985-editor.Li, Chong,1986-editor.Yang,Xiaofeng,1987-editor.

TitleWastevalorisationwastestreamsinacirculareconomyeditedby CarolSzeKiLin,CityUniversityofHongKong,HongKong,GuneetKaur DepartmentofBiology,HongKongBaptistUniversity,KowloonTong,HongKong andDepartmentofCivilEngineering,YorkUniversity,Toronto,Canada,ChongLi,ShenzhenBranch, GuangdongLaboratoryforLingnanModernAgriculture,GenomeAnalysis LaboratoryoftheMinistryofAgriculture,AgriculturalGenomics InstituteatShenzhen,ChineseAcademyofAgriculturalSciences, Shenzhen,China,XiaofengYang,SouthChinaUniversityofTechnology, Guangzhou.

DescriptionFirstedition.Hoboken,NJJohnWiley&Sons,Inc.,2021. SeriesWileyseriesinrenewableresourcesIncludesbibliographical referencesandindex.

IdentifiersLCCN2020016810(print)LCCN2020016811(ebook)ISBN 9781119502708(cloth)ISBN9781119502692(adobepdf)ISBN 9781119502746(epub)

SubjectsLCSHBiomassenergyindustries.Biomassenergy–Economic aspects.

ClassificationLCCHD9502.5.B542W372021(print)LCCHD9502.5.B542 (ebook)DDC338.4766288–dc23

LCrecordavailableathttpslccn.loc.gov2020016810

LCebookrecordavailableathttpslccn.loc.gov2020016811

CoverDesign:Wiley

CoverImages:Frontcoverdesignandimages:X’ianShangyuanNetworkCo.Ltd;Globeimage©IngramPublishing/Alamy StockPhoto

Setin10/12ptTimesLTStdbySPiGlobal,Chennai,India

PrintedandboundbyCPIGroup(UK)Ltd,Croydon,CR04YY 10987654321

ListofContributorsxiii

SeriesPrefacexvii Prefacexix

1OverviewofWasteValorisationConceptsfromaCircularEconomy Perspective1

JinhuaMou,ChongLi,XiaofengYang,GuneetKaurandCarolSzeKiLin

1.1Introduction1

1.2Developmentof(Bio)ChemicalProcessforUtilizationofWasteasa Bioresource4

1.2.1MechanicalPretreatment5

1.2.2PhysicalPretreatment5

1.2.3ChemicalPretreatment5

1.2.4BiologicalPretreatment6

1.3ProcessIntegrationforWaste-BasedBiorefinery6

1.3.1FoodWasteBiorefinery7

1.3.2AgriculturalWasteBiorefinery7

1.3.3IndustrialWasteBiorefinery8

1.3.4WastewaterBiorefinery8

1.4ClosedLoopRecirculationinaBio-basedEconomy8

1.5ConclusionsandFutureTrends9 References10

2WasteasaBioresource13

GayatriSuresh,JosephSebastianandSatinderKaurBrar

2.1Introduction13

2.2WasteStreamsandTheirSuitabilityasFeedstockforValorisation:Is AllWasteaResource?14

2.3(Bio)diversityandVariabilityofWasteFeedstock16

2.3.1Agro-industrialWastes16

2.3.2MunicipalSolidWastes18

2.3.3LivestockWastes19

2.3.4IndustrialWastes21

2.4Drivers,Policies,andMarketsforValue-addedWaste-derived Products23

2.5ConclusionsandFutureTrends25 Acknowledgements26 References26

3TreatmentofWaste33 RavindranBalasubramani,VasanthyMuthunarayanan,KarthikaArumugam, RajivPeriakaruppan,ArchanaSingh,SoonWoongChang,Thamaraiselvi Chandran,GopalShankarSinghandSelvakumarMuniraj

3.1Introduction33

3.2SolidWasteManagement34

3.2.1E-wasteManagement34

3.2.2HazardousWasteManagement35

3.2.3BiomedicalWasteManagement35

3.2.4PlasticWasteManagement35

3.2.5SolidWasteManagementOptions35

3.3GeneralApproachforWasteTreatmentandConversionto Value-addedProducts:Biochemical,Mechanical,and Thermochemical36

3.3.1ConventionalTreatment36

3.3.2Biological/BiochemicalTreatment37

3.3.3ThermalMethods40

3.3.4OpenBurning40

3.3.5MechanicalTreatment40

3.4FactorsInfluencingSelectionofanAppropriateValorisation TechniqueforSpecificWasteTypes42

3.4.1CaseStudyofPaperWasteRecycling42

3.4.2DeinkingProcess42

3.4.3PaperDeinkingResidue43

3.5ConventionalandNovelTechniques:OverallComparisoninTermsof EnergyConsumption,WasteStreamGenerationandCost44

3.5.1Pyrolysis44

3.5.2Gasification44

3.5.3Incineration44

3.6EnergyConsumption,WasteStreamGeneration,andCostsof ConventionalandNovelWasteTreatmentTechnologies45

3.7ConclusionsandFutureTrends45 Acknowledgement46 References46

4ValorisationofAgriculturalWasteResidues51 SrinivasMettu,PobitraHalder,SavankumarPatel,SazalKundu,Kalpit Shah,ShunyuYao,ZubeenHathi,Khai LunOng,SandyaAthukoralalage, NamitaRoyChoudhury,NabaKumarDuttaandCarolSzeKiLin 4.1Introduction51

4.2AgriculturalWasteDefinition,Composition,Variability,and AssociatedPoliciesandRegulations53

4.2.1AgriculturalWastefromFarming55

4.2.2AgriculturalWastesfromLivestock56

4.2.3AgriculturalWasteAvailability57

4.3ConventionalTechniques–AnaerobicDigestion,Pyrolysis, Gasification,andSolventTreatment/Extraction58

4.3.1AnaerobicDigestion58

4.3.2SolventTreatment63

4.3.3Gasification65

4.3.4Pyrolysis67

4.4NovelTechniquesandEnvisionedProductStreams:ANew Perspective71

4.5CaseStudy:YardWasteManagement74

4.5.1BackgroundofYardWasteinHongKong74

4.5.2ConventionalYardWasteReductionandTreatmentStrategy75

4.5.3NovelTechniquesandStrategiesforYardWasteTreatment76

4.6ConclusionsandFutureTrends76 Acknowledgements77 References77

5ValorisationofWoodyBiomass87 MdKhairulIslam,ChengyuDong,Hsien-YiHsu,CarolSzeKiLinand Shao-YuanLeu

5.1GenerationofWoodyBiomass87

5.2GeneralClassificationandPropertiesofWoods88

5.3WoodChemistry89

5.3.1Cellulose89

5.3.2Hemicelluloses90

5.3.3Lignin91

5.3.4Extractives92

5.4ChemicalCompositionAnalysis93

5.4.1StructuralCarbohydratesandLignin93

5.4.2Extractives94

5.5Pretreatment94

5.6SaccharificationandFermentation97

5.7NewFunctionsofWoodResidues100

5.7.1Wood–PlasticCompositeforConstructionPurposes100

5.7.2CelluloseNanomaterials100

5.7.3WoodExtractives102

5.8ConclusionsandFutureTrends102 Acknowledgement102 References103

6RecoveryofNutrientsandTransformationsofMunicipal/Domestic FoodWaste109 DivyaniPanwar,ParmjitS.Panesar,GishaSingla,MeenaKrishaniaand AvinashThakur

6.1Introduction109

6.2CharacteristicsofFoodWasteanditsSupplyChain111

6.2.1CharacteristicsofWasteGeneratedfromFoodIndustries113

6.2.2FoodWasteSupplyChain114

6.3RecoveryofValuableProductsfromAnaerobicDigestionof FoodWaste116

6.3.1Biogas118

6.3.2Digestate119

6.4NovelApproachesandObtainableProducts:Biotechnological ProcessesandChemicalTransformations124

6.4.1ChemicalTransformations125

6.4.2BiotechnologicalApproaches130

6.5CaseStudy:ProductionofMethaneviaAnaerobicDigestionofFood Waste139

6.5.1AnaerobicDigestion140

6.5.2TEAMDigesterforDomesticFoodWasteDigestion143

6.6ConclusionsandFutureTrends144 References145

7BioconversionofProcessingWastefromAgro-FoodIndustriesto Bioethanol:CreatingaSustainableandCircularEconomy161 DeepakKumarandVijaySingh

7.1Introduction161

7.2BioconversionTechnologiesforBioethanolProduction164

7.2.1EthanolProductionfromStarchyFeedstock (First-GenerationBioethanol)164

7.2.2EthanolfromLignocellulosicBiomass(Second-Generation Bioethanol)167

7.3UseofProcessingWastetoProduceEthanol170

7.3.1CitrusPeelWaste(CPW)170

7.3.2PeelResidueWastefromOtherFoodIndustries171

7.3.3WastefromtheBrewingIndustry172

7.3.4OtherProcessingWastes173

7.4UseofProcessingWastetoEnhanceEthanolYields174

7.4.1ImprovingFermentationofDryFractionatedCorn174

7.4.2ProcessingofDDGStoEnhanceEthanolYields177

7.5ConclusionsandFutureTrends178 References179

8ChallengeswithBiomassWasteValorisation183 GuihuaYan,YunchaoFeng,SishiLong,XianhaiZeng,YongSun,XingTang andLuLin

8.1Introduction183

8.2ThePre-PreparationTechnologiesofBiomassWaste184

8.2.1“Cellulose-First”BiorefineryTechnologies185

8.2.2“Lignin-First”BiorefineryTechnologies185

8.2.3“LigninandHemicellulose-First”BiorefineryTechnologies186

8.2.4“CelluloseandHemicellulose-First”Biorefinery Technologies186

8.3HandlingofEmergingBiomassWastesbyNewlyDeveloped Techniques188

8.3.1CatalyticChemistryTechnologies188

8.3.2ThermochemicalConversionTechnologies189

8.3.3BiochemicalTechnologies190

8.3.4IntegrationwithExistingTechnologiesandEconomic Viability190

8.4TransformingBiomassWastetoCellulosebyNewTechniques191

8.4.1CelluloseExtractionorPurificationTechniquesfrom BiomassWaste192

8.4.2CelluloseMicro/NanomerizationTechnologies192

8.5TransformingBiomassWastetoLigninbyNewTechnologies197

8.6ConclusionsandFutureTrends198 Acknowledgements199 References199

9LifecycleApproachesforEvaluatingTextileBiovalorisationProcesses: SustainableDecision-makinginaCircularEconomy203 KarpagamSubramanian,ShauhratS.Chopra,CakinEzgi,XiaotongLiand CarolSzeKiLin

9.1Introduction203

9.2LiteratureReview206

9.2.1CircularEconomyandSustainableDevelopment206

9.2.2TextileIndustry–SustainabilityIssuesandRecycling206 9.3Methods208

9.3.1DescriptionofEnvironmentalAssessment208

9.3.2DescriptionofSocialAssessment209 9.4CaseStudy211

9.4.1RecoveryofPETFiberfromCotton–PolyesterBlended TextileWaste211

9.4.2SystemDescriptionoftheBiorecyclingMethod212

9.4.3LifeCycleInventory214

9.5ResultsandDiscussion215

9.5.1EnvironmentalSustainabilityofBio-basedPETFiber215

9.5.2SocialandEconomicSustainabilityofBio-basedPETFiber217

9.6ConclusionsandFutureTrends218 Acknowledgement219 References219

10CircularWaste-BasedBiorefineryDevelopment223 RaffelDharmaPatria,XiaotongLi,HuaiminWang,ChenyuDu,CarolSzeKi LinandGuneetKaur

10.1Introduction223

10.2TransitioningfromCurrentLineartoStrongerCircularEconomy Models226

10.2.1IntegrationofCircularEconomyandSustainable Development226

10.2.2RequirementsforTransitiontoaCircularEconomy227

10.3CaseStudy1:CircularTextileWaste-basedBiorefineryforProduction ofChemicals,Materials,andFuels229

10.3.1NeedforaCircularTextileWaste-basedBiorefinery229

10.3.2CircularTextileBiorefinery230

10.4CaseStudy2:CircularFoodWaste-basedBiorefineryforProduction ofChemicals,Materials,andFuels233

10.4.1CircularBioconversionofFoodWasteintoPolyethylene Furanoate(PEF)235

10.4.2CircularBioconversionofFoodWasteintoBiosurfactant240

10.5ConclusionsandFutureTrends246 Acknowledgements246 References247

ListofContributors KarthikaArumugam DepartmentofBiotechnology,KalasalingamUniversity,India

SandyaAthukoralalage ChemicalandEnvironmentalEngineering,RMITUniversity, Australia

RavindranBalasubramani DepartmentofEnvironmentalEnergyandEngineering, KyonggiUniversityYoungtong-Gu,SouthKorea

SatinderKaurBrar INRS-ETE,UniversitéduQuébec,Canada DepartmentofCivilEngineering,LassondeSchoolofEngineering,YorkUniversity, Canada

ThamaraiselviChandran DepartmentofBiotechnology,MotherTeresaWomen’s University,India

SoonWoongChang DepartmentofEnvironmentalEnergyandEngineering,Kyonggi UniversityYoungtong-Gu,SouthKorea

ShauhratS.Chopra SchoolofEnergyandEnvironment,CityUniversityofHong Kong,HongKong

NamitaRoyChoudhury ChemicalandEnvironmentalEngineering,RMITUniversity, Melbourne,Australia

ChengyuDong DepartmentofCivilandEnvironmentalEngineering,HongKongPolytechnicUniversity,HongKong

ChenyuDu SchoolofAppliedSciences,UniversityofHuddersfield,UnitedKingdom

NabaKumarDutta ChemicalandEnvironmentalEngineering,RMITUniversity, Australia

CakinEzgi SchoolofEnergyandEnvironment,CityUniversityofHongKong, HongKong

YunchaoFeng CollegeofEnergy;FujianEngineeringandResearchCenterofClean andHigh-valuedTechnologiesforBiomass;andXiamenKeyLaboratoryofCleanand High-valuedApplicationsofBiomass,XiamenUniversity,PRChina

PobitraHalder ChemicalandEnvironmentalEngineering,RMITUniversity,Australia

ZubeenHathi SchoolofEnergyandEnvironment(SEE),CityUniversityofHongKong, HongKong

Hsien-YiHsu SchoolofEnergyandEnvironment,CityUniversityofHongKong, HongKong

MdKhairulIslam DepartmentofCivilandEnvironmentalEngineering,HongKong PolytechnicUniversity,HongKong

GuneetKaur DepartmentofBiology,HongKongBaptistUniversity,KowloonTong, HongKongandDepartmentofCivilEngineering,YorkUniversity,Canada

MeenaKrishania CenterofInnovativeandAppliedBioprocessing,India

DeepakKumar DepartmentofChemicalEngineering,StateUniversityofNewYork CollegeofEnvironmentalScienceandForestry,USA

SazalKundu ChemicalandEnvironmentalEngineering,RMITUniversity,Australia

Shao-YuanLeu DepartmentofCivilandEnvironmentalEngineering,HongKongPolytechnicUniversity,HongKong

ChongLi ChineseAcademyofAgriculturalSciences,China

XiaotongLi SchoolofEnergyandEnvironment,CityUniversityofHongKong, HongKong

CarolSzeKiLin SchoolofEnergyandEnvironment,CityUniversityofHongKong, HongKong

LuLin CollegeofEnergy;FujianEngineeringandResearchCenterofCleanand High-valuedTechnologiesforBiomass;andXiamenKeyLaboratoryofCleanand High-valuedApplicationsofBiomass,XiamenUniversity,PRChina

SishiLong CollegeofEnergy;FujianEngineeringandResearchCenterofClean andHigh-valuedTechnologiesforBiomass;andXiamenKeyLaboratoryofCleanand High-valuedApplicationsofBiomass,XiamenUniversity,PRChina

SrinivasMettu SonochemistryGroup,SchoolofChemistry,UniversityofMelbourne, Parkville,Australia

ChemicalandEnvironmentalEngineering,RMITUniversity,Australia SchoolofEnergyandEnvironment(SEE),CityUniversityofHongKong,HongKong

JinhuaMou SchoolofEnergyandEnvironment(SEE),CityUniversityofHongKong, HongKong

SelvakumarMuniraj WaterandSolidWasteProcessingLab,DepartmentofEnvironmentalBiotechnology,BharathidasanUniversity,India

VasanthyMuthunarayanan WaterandSolidWasteProcessingLab,Departmentof EnvironmentalBiotechnology,India.

KhaiLunOng SchoolofEnergyandEnvironment(SEE),CityUniversityofHong Kong,HongKong

ParmjitS.Panesar FoodBiotechnologyResearchLaboratory,DepartmentofFood EngineeringandTechnology,SantLongowalInstituteofEngineeringandTechnology, India

DivyaniPanwar FoodBiotechnologyResearchLaboratory,DepartmentofFoodEngineeringandTechnology,SantLongowalInstituteofEngineeringandTechnology,India

SavankumarPatel ChemicalandEnvironmentalEngineering,RMITUniversity, Australia

RaffelDharmaPatria SchoolofEnergyandEnvironment,CityUniversityofHong Kong,HongKong

RajivPeriakaruppan DepartmentofBiotechnology,KarpagamAcademyofHigher Education,India

JosephSebastian INRS-ETE,UniversitéduQuébec,Canada

KalpitShah ChemicalandEnvironmentalEngineering,RMITUniversity,Australia

ArchanaSingh InstituteofEnvironmentandSustainableDevelopment,BanarasHindu University,India

GopalShankarSingh InstituteofEnvironmentandSustainableDevelopment,Banaras HinduUniversity,India

VijaySingh AgriculturalandBiologicalEngineeringDepartment,UniversityofIllinois atUrbana-Champaign,USA

GishaSingla CenterofInnovativeandAppliedBioprocessing,India

KarpagamSubramanian SchoolofEnergyandEnvironment,CityUniversityofHong Kong,HongKong

YongSun CollegeofEnergy;FujianEngineeringandResearchCenterofClean andHigh-valuedTechnologiesforBiomass;andXiamenKeyLaboratoryofCleanand High-valuedApplicationsofBiomass,XiamenUniversity,PRChina

GayatriSuresh INRS-ETE,UniversitéduQuébec,Canada

XingTang CollegeofEnergy;FujianEngineeringandResearchCenterofClean andHigh-valuedTechnologiesforBiomass;andXiamenKeyLaboratoryofCleanand High-valuedApplicationsofBiomass,XiamenUniversity,PRChina

AvinashThakur DepartmentofChemicalEngineeringSantLongowalInstituteofEngineeringandTechnology,India

HuaiminWang SchoolofEnergyandEnvironment,CityUniversityofHongKong, HongKong

xviListofContributors

XiaofengYang SouthChinaUniversityofTechnology,China

GuihuaYan CollegeofEnergy;FujianEngineeringandResearchCenterofClean andHigh-valuedTechnologiesforBiomass;andXiamenKeyLaboratoryofCleanand High-valuedApplicationsofBiomass,XiamenUniversity,PRChina

ShunyuYao SonochemistryGroup,SchoolofChemistry,UniversityofMelbourne, Parkville,Australia

XianhaiZeng CollegeofEnergy;FujianEngineeringandResearchCenterofClean andHigh-valuedTechnologiesforBiomass;andXiamenKeyLaboratoryofCleanand High-valuedApplicationsofBiomass,XiamenUniversity,PRChina

SeriesPreface Renewableresources,theiruseandmodificationareinvolvedinamultitudeofimportant processeswithamajorinfluenceonoureverydaylives.Applicationscanbefoundinthe energysector;paintsandcoatings;andthechemical,pharmaceutical,andtextileindustries, tonamebutafew.

Theareainterconnectsseveralscientificdisciplines(agriculture,biochemistry,chemistry,technology,environmentalsciences,forestry),whichmakesitverydifficulttohave anexpertviewonthecomplicatedinteraction.Therefore,theideatocreateaseriesofscientificbooks,focusingonspecifictopicsconcerningrenewableresources,hasbeenvery opportuneandcanhelptoclarifysomeoftheunderlyingconnectionsinthisarea.

Inaveryfast-changingworld,trendsarenotonlycharacteristicoffashionandpoliticalstandpoints;sciencetooisnotfreefromhypesandbuzzwords.Theuseofrenewable resourcesisagainmoreimportantnowadays;however,itisnotpartofahypeorafashion. Asthelivelydiscussionsamongscientistscontinueabouthowmanyyearswewillstillbe abletousefossilfuels–opinionsrangingfrom50to500years–theydoagreethatthe reserveislimited,andthatitisessentialnotonlytosearchfornewenergycarriersbutalso fornewmaterialsources.

Inthisrespect,thefieldofrenewableresourcesisacrucialareainthesearchforalternativesforfossil-basedrawmaterialsandenergy.Inthefieldofenergysupply,biomass-and renewables-basedresourceswillbepartofthesolutionalongsideotheralternativessuch assolarenergy,windenergy,hydraulicpower,hydrogentechnology,andnuclearenergy. Inthefieldofmaterialsciences,theimpactofrenewableresourceswillprobablybeeven bigger.Integralutilizationofcropsandtheuseofwastestreamsincertainindustrieswill growinimportance,leadingtoamoresustainablewayofproducingmaterials.Although oursocietywasmuchmore(almostexclusively)basedonrenewableresourcescenturies ago,thisdisappearedintheWesternworldinthenineteenthcentury.Nowitistimeto focusagainonthisfieldofresearch.However,itshouldnotmeana“retouràlanature,” butshouldbeamultidisciplinaryeffortonahighlytechnologicalleveltoperformresearch towardnewopportunities,todevelopnewcropsandproductsfromrenewableresources. Thiswillbeessentialtoguaranteeanacceptablelevelofcomfortforthegrowingnumber ofpeoplelivingonourplanet.Itis“the”challengeforthecominggenerationsofscientists

todevelopmoresustainablewaystocreateprosperityandtofightpovertyandhungerin theworld.Aglobalapproachiscertainlyfavored.

Thischallengecanonlybedealtwithifscientistsareattractedtothisareaandarerecognizedfortheireffortsinthisinterdisciplinaryfield.Itis,therefore,alsoessentialthat consumersrecognizethefateofrenewableresourcesinanumberofproducts.Furthermore,scientistsdoneedtocommunicateanddiscusstherelevanceoftheirwork.Theuse andmodificationofrenewableresourcesmaynotfollowthepathofthegeneticengineering conceptinviewofconsumeracceptanceinEurope.Relatedtothisaspect,theserieswill certainlyhelptoincreasethevisibilityoftheimportanceofrenewableresources.Being convincedofthevalueoftherenewablesapproachfortheindustrialworld,aswellasfor developingcountries,Iwasmyselfdelightedtocollaborateonthisseriesofbooksfocusing onthedifferentaspectsofrenewableresources.Ihopethatreadersbecomeawareofthe complexity,theinteractionandinterconnections,andthechallengesofthisfield,andthat theywillhelptocommunicateontheimportanceofrenewableresources.

IcertainlywanttothankthepeopleofWiley’sChichesteroffice,especiallyDavid Hughes,JennyCossham,andLynRoberts,inseeingtheneedforsuchaseriesofbookson renewableresources,forinitiatingandsupportingit,andforhelpingtocarrytheprojectto theend.

Last,butnotleast,Iwanttothankmyfamily,especiallymywifeHildeandchildren PaulienandPieter-Jan,fortheirpatience,andforgivingmethetimetoworkontheseries whenotheractivitiesseemedtobemoreinviting.

ChristianV.Stevens FacultyofBioscienceEngineering,GhentUniversity,Belgium SeriesEditor,“RenewableResources” June2005

Preface Globaleconomicdevelopmentisbeingconfrontedwiththeissuesoflimitationofnaturalresources,endlessdemandsfromtheenvironment,andincreasedgenerationofwaste streams.Theexplorationofcirculareconomyprinciplestocapturevalue,intheformofthe energy,nutrientsandmaterialsembodiedinthesestreams,wouldcontributetorestoring thenaturalcapital.

Thisbookaimstogiveanoverviewofwastevalorisationstrategiesundertheconceptof circulareconomy.Theincreasingamountofwastegeneratedfromhumanactivitiesattracts globalattention,andinnovativebiotechnologiesforgreenandsustainableresourcemanagementarebeingcloselyandextensivelystudiedinbothacademicandindustrial-scale research.Technology-integratedbiorefineriesfocusonthematerialrecoveryapproachto resolvethetwinproblemsoftheglobalwasteburdenandresource/energyconcernsin ordertotransformrenewableresourcesfromwastestreamsintovalue-addedproducts.New researchandexplorationsarerapidlyemergingtoleadthewaytowardabio-basedeconomy.Boththeoryandpracticeofwastevalorisationisatopicofincreasingimportancein the2030SustainableDevelopmentAgenda.

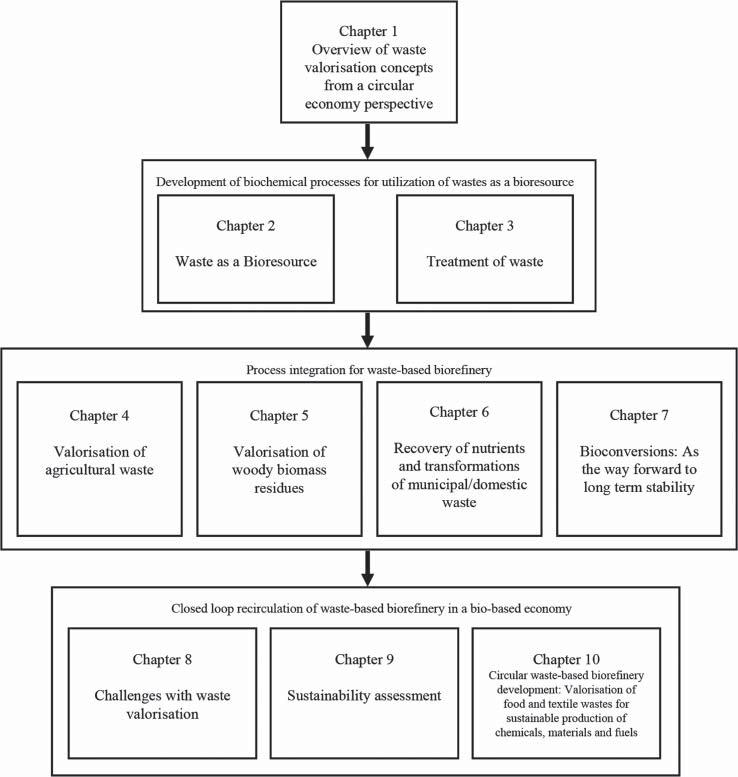

Thisbookgivesadetailedpresentationofvalorisationschemesforvarioustypesofwaste streams.Sustainabilityanalysis,circulareconomydevelopmentandfuturetrendsarealso included.Inthisbook,wewillreviewthedevelopmentofbiochemicalprocessesforutilisationofwastesasbioresources(Chapters2and3),processintegrationforawaste-based biorefinery(Chapters4–7),andclosedlooprecirculationofawaste-basedbiorefineryina bio-basedeconomy(Chapters8–10).

Aseditorsofthisbook,wesincerelyhopeitcansuccessfullydemonstratetheapplicationoftheintegratedwaste-basedbiorefinery,whichhasastrongpotentialtoprovide solutionstocombatclimatechange.Basedonthesesolutionsoncirculareconomyprinciples,cascadedbenefitsforfoodsecurity,humanhealth,andenvironmentalprotectionare anticipated.Wehopethisbookcanpromoteandaccelerateaninnovativewaste-basedbioeconomy,andinspiremoreresearchandpracticeonwastemanagementstrategiesinorder tomakeasignificantcontributiontotheUNSustainableDevelopmentGoals.

Wewouldliketotakethisopportunitytoacknowledgeallcontributorsfortheirgreat effortsinexcellentandtimelycontributionsandefficientcollaboration.Theco-editors wouldliketoexpresstheirsincereappreciationandgratitudetotheSeriesEditorProf.

ChristianStevensfromGhentUniversity,Belgium,forhiskindrecommendationforsubmissionofabookproposaltotheWileySeriesinRenewableResources.Also,wewouldlike toextendourgratitudetotheWileyCoverTeamfortheirgreateffortinpreparationofthe bookcover.Lastbutnotleast,wesincerelythankthepublishingeditorSarahHigginbotham, projecteditorArunaPragasam,andassistanteditorEmmaStrickland,whopatientlyand kindlytookusthroughthedevelopmentofthisbookoverthepastthreeyearstoachieve thisimpressivefinalresult,whichwouldnothavebeenpossiblewithouttheirsupport.

Sincerewishesforanenjoyableread!

CarolSzeKiLin,GuneetKaur,ChongLiandXiaofengYang HongKongSpecialAdministrativeRegionofthePeople’sRepublicofChina

March2020

1 OverviewofWasteValorisation ConceptsfromaCircular EconomyPerspective JinhuaMou1 ,ChongLi2 ,XiaofengYang3 ,GuneetKaur4 andCarol SzeKiLin1

1 SchoolofEnergyandEnvironment,CityUniversityofHongKong,TatCheeAvenue,KowloonTong, HongKong

2 ShenzhenBranch,GuangdongLaboratoryforLingnanModernAgriculture,GenomeAnalysis LaboratoryoftheMinistryofAgriculture,AgriculturalGenomicsInstituteatShenzhen,ChineseAcademy ofAgriculturalSciences,Shenzhen,China

3 SchoolofBiologyandBiologicalEngineering,SouthChinaUniversityofTechnology,Guangzhou,China

4 DepartmentofBiology,HongKongBaptistUniversity,KowloonTong,HongKong

1.1Introduction

Petroleumisoneofthemostimportantreservesusedasafundamentalrawmaterialfor variousindustries.Ithasbeeninapredominantpositionintheworldenergyconsumptionstructuresincethe1970s.Petroleum-derivedproducts,suchasplastics,syntheticfiber, andsyntheticrubber,arewidelyutilizedintheagricultural,chemical,andpharmaceuticalsectors,andhavealreadybecomenecessitiesinourdailylife.Mostindustries,likethe chemicalindustriesandtransportation,areheavilydependentuponpetroleumandother fossilresources.

However,thisfossil-basedeconomyisfacingtwoseriousproblems.Ononehand, fossilresourcesarenotrenewable–theyhavelimitedavailabilityonourplanetandare

WasteValorisation:WasteStreamsinaCircularEconomy,FirstEdition. EditedbyCarolSzeKiLin,GuneetKaur,ChongLiandXiaofengYang. ©2021JohnWiley&SonsLtd.Published2021byJohnWiley&SonsLtd.

runningoutatarapidrate.Ontheotherhand,theindustrialutilizationoffossilresources hasalreadycausedmanyenvironmentalproblems,suchasgreenhouseeffects,andair, water,andsoilpollution.Theseriousenergyandenvironmentalcrisishasarousedglobal concernsandreflections.Theworldneedstofindsubstitutesforfossilresourcestochange thecurrentenergy-intensiveandenvironmentallyunfriendlyeconomicmodel.Therefore, alow-consumptionandhigh-value-addedsustainablecirculareconomysystemneeds tobeestablished.Suchacirculareconomycanreplacethelineareconomymodelof “make-use-dispose”witha“circular”model,inwhichthevalueofresourcesandproducts ismaintainedinthesystemforalongperiod.Theefficientuseofwasteorsidestreams fromproductionprocessesisanotherimportantaspectofacirculareconomy.

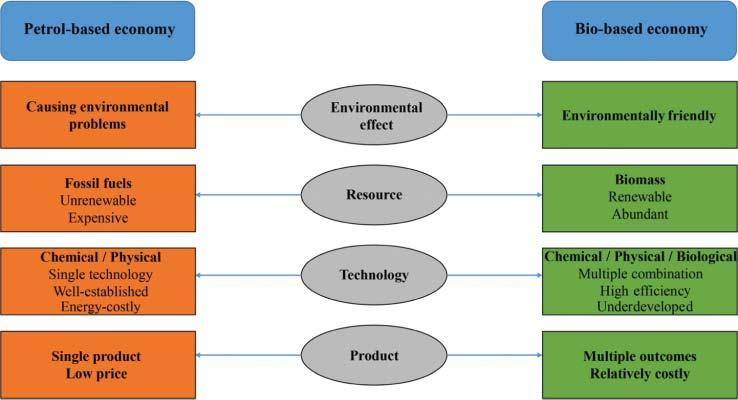

Whiletraditionalenergyresources,suchaspetroleumandnaturalgas,arenon-renewable andwillbedepletedinthenearfuture,thesubstitutionofemergingresources(energyand materials)andawarenessofenvironmentalprotectionoutweighseekingonlyeconomic profitsandhasbecomeasignificantworldwideissue.Besidestheutilizationofsolarenergy andwindenergy,biomassenergy,asanalternativeformofenergyderivedfromsolar energy,hasattractedanincreasingamountofattention.DatafromtheUSEnergyInformationAdministrationshowthatthepercentageofbiomassenergyintotalenergyconsumption hasincreasedrapidlyinrecentyears.Forinstance,in2016,biomassenergycontributed 5.8%tothesourceofUSenergyconsumption.Biomassenergyisarenewable(theonly renewablecarbonresource),clean(littlepollution,lowcarbonemissions),andabundant resource(Fieldetal.2008).Itwillgreatlyeasetheenergyandenvironmentburdenif biomassenergycouldbewidelyacceptedandutilizedinindustriesorinourdailylife,and replacefossilresourcesasthepreferenceinenergyconsumption.Infact,aglobalindustrialrevolutionhasalreadybegunasthefoundationsofeconomicdevelopmentchangefrom hydrocarbontocarbohydrate,i.e.,thetransitionfromapetrol-basedeconomytoabio-based economy,whichisasignificanttrendforsustainabledevelopment(BozellandPetersen 2010)(Figure1.1).

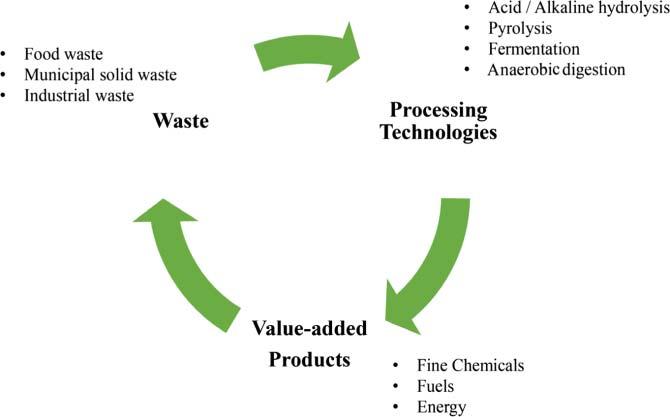

Withtherapiddevelopmentofindustriesandimprovementinlivingstandards,thegenerationofwasteisalsoincreasing,whichhasalreadycausedmanyenvironmentalandsocial problems(Sharholyetal.2008).Landfillandincinerationarethemostcommonlyused methodsofwastemanagementatpresent.However,theyarenotidealsolutionsowingtothe damagetotheenvironmentandhumanhealth.Inparticular,organicwastes,characterized byputrescibility,lowheatvalueandhighorganicmatter,couldbecomeagreatthreattopublichealth,becauseoftheemissionoftoxicgases(e.g.,oxole,dioxine)andthetransmission ofpathogenicmicro-organismswhenimproperlytreatedbyconventionalmethods(PolprasertandKoottatep2017).But“wastes”canberegardedasvaluableresourcesduetothe functionalcomponentsarepresentwithinthem(Ongetal.2018).Itallowsfortheirtransformationintohigh-valueproductsratherthanbeingdiscardedasuselessandunwanted. Overall,thisprovidessolutionstobothefficientwastemanagementandprovisionoffeedstockforindustriallyimportantproducts,whicharefundamentalsolutionsforsustainable development(Figure1.2).

Togetherwithincreasingdemandinbothsubstanceandspirit,theworldtodayisfacing manyproblemsrelatedtofoodsecurity,energyconsumption,andenvironmentalprotection.Thedevelopmentofbiomass-basedindustriescouldbeoneofthegreateffortsmade inordertochangethissituation.Biorefinery,aimedatsustainabledevelopmentthroughutilisationofrenewable(and/orwaste)resourcesandintegrationofhigh-efficiencytechnologies,canplayanincreasinglyimportantroleinachievingagreen,circular,andsustainable economy.

Inthisbook,wewilltakeanoverviewofthedevelopmentofbiochemicalprocesses fortheutilizationofwastesasabioresource(Chapters2and3),processintegrationfor waste-basedbiorefinery(Chapters4–7),andclosedlooprecirculationofwaste-basedbiorefineryinabio-basedeconomy(Chapters8–10)(Figure1.3).

Figure1.2 Conceptofwastevalorisationtohigh-valueproducts.

Booklayout.

1.2Developmentof(Bio)ChemicalProcessforUtilizationofWasteasa Bioresource

Wastesareoftendefinedassubstancesthatarenolongerusefultotheholder.Therapid industrialandeconomicdevelopmentofrecentyearshasseenahugeamountofwastegeneratedfromhumanactivities,whichhascausedmanyenvironmentalandsocialproblems. Infact,mostofthewasteswearetalkingabouthavethepotentialforfurtherprocessingandutilization.Themainreasonshinderingtheeffectiverecyclingofthewastesare improperhandlingstrategiesandinadequatetechnologiesinrelatedindustries.Sustainable wastemanagementshouldbecarriedoutforbothenvironmentalandeconomicbenefits. Awastestreamistheflowofaspecificwaste,referringtothelifecyclefromitssource torecovery,recycling,ordisposal.Ingeneral,wastestreamsaremainlydividedintotwo

Figure1.3

Table1.1 Suitablewastestreamsforbiorefineries.

WastestreamExamples

Municipal/domesticwasteFoodwaste,Wastecookingoil,Sewage,Leather,Textiles AnimalwasteFats,Blood,Meat,Manure ForestrywasteLeaves,Straw,Wood AgriculturalwasteCropwaste,Ricestraw,Citruswaste IndustrialwastePulpandpaperindustrywaste,Sugarindustrywaste,Coffeeindustrywaste

groups:material-relatedstreams(e.g.,metals,plastics,bio-waste)andproduct-related streams(e.g.,e-waste,constructionwaste)(Bourguignon2015).Whentalkingaboutthe biorefineryconceptinwastevalorisation,itaimstoutilizewasteasabioresource,sowe aremoreinterestedintheorganic(orbiodegradable)partsamongthewholewastestream. Basically,thesuitablesourcesforwastebiorefineriesaremunicipal/domesticwaste, agriculturalwaste,industrialwaste,forestrywaste,andanimalwaste(Table1.1).

Inmostcases,itisnotefficienttoconvertthewastedirectlyintoproducts.Hence, beforetheyarereadyassubstratesforbiorefineries,certainpretreatmentsormodifications arerequiredtomakethemaccessibletothefollowingdownstreamreactions,which mayimprovetheconversionefficiency.Pretreatmentmethodsaremainlyclassifiedinto mechanical,physical,chemicalandbiologicaltypes,andeachmethodhasitsadvantages anddisadvantagesdependingonthecharacteristicsofthewasteorspecificneedofthe subsequentconversion(orproduction)process.Thus,itisanimportantconsiderationfor thebiorefinerymanagementtodecidethebestpretreatmentoption.Abriefsummaryof pretreatmentmethodsisprovidedbelow.

1.2.1MechanicalPretreatment

Themainpurposeofmechanicalpretreatmentisthereductionoftheparticlesizeorcrystallinityofthematerials.Itincreasesthesurfaceareaandreducesthedegreeofpolymerization,whichcanbenefitthedownstreamconversionprocess,forexample,byimproving enzymatichydrolysis(TaherzadehandKarimi2008).Grinding,milling,andchippingare commonlyused,althoughtheirpowerrequirementisrelativelyhigh.

1.2.2PhysicalPretreatment Physicalpretreatmentisusuallyproposedunderspecifictemperatureandpressureconditions.Theextractionmethodcouldachieveeffectiveisolationandfractionationofvaluable productsduetotheuniquepropertiesofasolvent(Azmiretal.2013).Ammoniafiber explosionmakeshydrolysisofmaterialseasier,increasesthesurfaceareaforenzymatic conversion,andactsasanitrogensourceformicrobesindownstreamprocessing(Alizadeh etal.2005).

1.2.3ChemicalPretreatment Themainobjectivesofchemicalpretreatmentarebreakingupanyresistantstructures, removalofunwantedfractions,andselectivedissolution.Forexample,acidhydrolysiscan

effectivelyremoveligninandhemicelluloseduringwoodbiomasstreatment,andhydrolyze celluloseintoglucose.Themajordrawback,however,isthepotentialinhibitioneffectof thebyproductsonthedownstreamprocess(GalbeandZacchi2012).Alkalinehydrolysis isarelativelymildprocessthatcanbeusedinbiomasstreatmentssuchasdelignification, whilesomeobviousissuessuchasthecorrosionproblemduringtheprocessneedtobe tackled(Chenetal.2013).

1.2.4BiologicalPretreatment Thebestexampleofthispretreatmentisfungalbiodegradation,whichisawidelyused methodfordelignificationoflignocellulosicbiomass,woodchipsandwheatstrawfor instance.Whiterotfungiarewellstudiedandhaveshownahighdegradationefficiency becauseoftheextracellularenzymestheysecrete,suchasligninperoxidases,manganese peroxidases,andlaccases(Alviraetal.2010).Thisbiologicalapproachisamoreenvironmentallyfriendlypretreatmentprocessthatissaferandcheaper,butmoretimeconsuming incomparisontotheconventionalpetrochemicalproductionprocess.

1.3ProcessIntegrationforWaste-BasedBiorefinery Theconceptof“biorefinery”wasfirstputforwardin Science in1982(Bungay1982). Derivedfrompetroleumrefinery,biorefineryaimstoproduceavarietyofvaluablechemicals,materials,andenergybymaximizingtheconversionefficiencyandminimizingcost andwastegeneration.Whatmakesitdifferentfrompetroleum-basedbiorefineryisthecombinationoffacilitiesusingbiomassasfeedstocksinsteadoffossilresources.Biorefinery overturnsthestereotypeofproducingoneproductfrombiomass,asfoundintraditional chemicalindustries.Instead,itmakesthemostofeverycomponentofsubstratesandconvertsthemintovariousproductsinordertoachievefullresourceutilizationandvalue maximization.Biomassconversionisthecoreprocedureofthebiorefinery.Physical,chemical,andbiologicalmethodsplayimportantrolesinthisconversionprocess,suchasmixing, separation,pyrolysis,modification,fermentation,andenzymecatalysis.

Basedonthecomplexityoffeedstock,combinationoftechnologiesandvarietyofoutcomes,biorefineriesaredividedintothreetypes:(I)singlefeedstock,singleprocessand singlemajorproduct;(II)singlefeedstock,multipleprocesses,andmultiplemajorproducts;(III)multiplefeedstocks,multipleprocesses,andmultiplemajorproducts(Fernando etal.2006).Biorefineriesarecapital-intensiveprojects,anditwouldbeverydifficult,and alsocostly,toincreasetheproductivityorconversionefficiencywhenthedesignerputtoo muchweightonjustoneconversiontechnology.Obviously,typeIIIbiorefineriesarethe mostadvancedandoptimal,becausetheycanefficientlyproducemultipleoutcomesto meetmarketdemandsandachieveprofitability.Also,theyarecapableofusingdifferent substrateswhenrequiredafterstructuraladjustment,whichmakesthemflexibleinindustrialpractice.However,thereisstillalongwaytogoforthecommercialexistenceofsuch integratedbiorefineries.Itisnoteasytoachievethecombinationofmultipleinputsand considerableoutputsonalargescale,andinoneplatform.Nevertheless,thereareextensiveworksunderwayinmanyplacesonthedesignandfeasibilityofsuchfacilities(Clark andDeswarte2008).

Alongwithincreasingpopulationandurbanization,wastegenerationaswellasits accompanyingproblemshasbecomeaglobalconcern.Wastebiorefineriesareabletooffer

satisfyingwastemanagementsolutionsgiventhecurrentcircumstances.Althoughthereis nostandardclassificationforexistingwastebiorefineries,inmostcaseswedividewaste biorefineriesintodifferenttypesaccordingtotheoriginoffeedstocks.Forexample,there arebiorefineriesbasedonfoodwaste,agriculturalwaste,industrialwaste,andwastewater.

1.3.1FoodWasteBiorefinery Foodwasteisthefoodmassleftbeforeorafterhumanconsumptionthroughoutthesupply chain,includingthosearisingfromproduction,handling,storageanddisposal.Itisamong themostwidelygeneratedbiowastesintheworld,amountingtoabout1.3billiontonnes globallyeveryyear(Paritoshetal.2017).Foodwastecanberoughlydividedintotwo groups:avoidablefoodwasteandunavoidablefoodwaste.Avoidablefoodwasteisedible beforebeingdiscarded,andwecanusuallydecreasethiswastebychangingconsumption strategies;whileunavoidablefoodwastemainlyoriginatesfromfood(processing)industriesandneedstobeproperlydisposedoforrecycled.

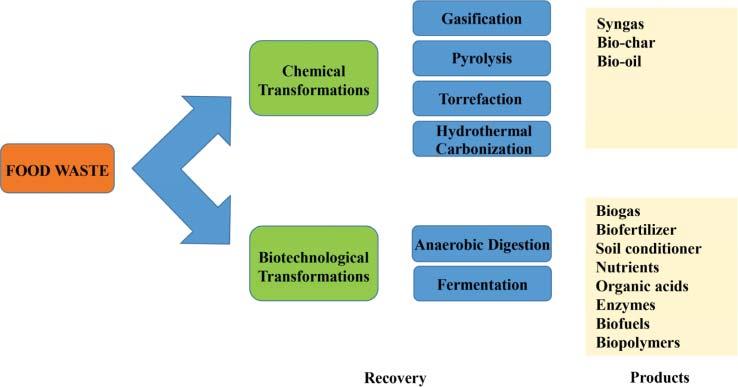

Theorganicfractionisthedominantcomponentoffoodwaste–carbohydrates,proteins andlipidsthatcanbeconvertedintosimplecompoundslikeglucose,aminoacidsandfatty acidsthroughfurtherconversionprocesses.Anaerobicfermentationisthemostpromisingprocessforfoodwastevalorisationtoproducebiogasandvolatilefattyacids(Dahiya etal.2018).Metabolite-richeffluentsaregeneratedduringthesespecificprocesses.They havegreatpotentialtoimprovetheconversionefficiencythroughintegratingwithother bio-processestoobtainadditionalproductssuchasbiopolymers,bioelectricity,andanimal feed(Figure1.4).

1.3.2AgriculturalWasteBiorefinery Commonagriculturalresiduesorbiomassincludecropwaste,wheatstraw,seed,andwood chips.Theyarepromisingsubstratesforbiogasandbiofuelproduction.Forinstance,the

hydrolysateofwheatstrawafterhydrothermalpretreatmentisrichinhemicellulose,which canbeutilizedinbiohydrogenproduction,andbioethanolproductionisalsoachieved throughthecellulose-richsolidfraction(Kaparajuetal.2009).Leavesandwoodwaste arerichsourcesofligninandcellulose.Thermochemicaltreatment,suchasliquefaction, gasification,pyrolysis,andtorrefaction,canhelpconvertbiomassintoproductslikebiochar andsyngas(Lametal.2015).

1.3.3IndustrialWasteBiorefinery Thesludgeproducedbythepaperandpulpindustrieshasahighmoisturecontent,anditis alsorichincarbohydrates,whichmakespossibletheproductionofcellulose-derivedfuels andhigh-valuechemicalslikebioethanol,biohydrogen,andfattyacidsbyhydrolysisor fermentationtechniques.Integrationoftwoormoreprocesses,athermalprocessandbioprocessforinstance,hasprovedtocreatehigherenergyoutputsandchemicalconversion yields.Onestudydemonstratedthatextratreatmentoffermentation,togetherwithpyrolysis,improvedenergyconversioncomparedwithsolopyrolysisinpapersludgetreatment (Gottumukkalaetal.2016).Also,thecharproducedfromthermochemicalconversionof sludgehasthepotentialforuseasactivatedcarbonorbiochar.

1.3.4WastewaterBiorefinery Wastewatermanagementisinefficientintheworldatpresent,asmostofthewastewater isdirectlydischargedintothenaturalwaterenvironment.Untreatedwastewatercan damageboththeenvironmentandhumanhealth.Hence,thereisanurgentneedforgreen wastewatertreatment.Renewableenergyproduction,hydrogenbeingatypicalexample, wouldbeapromisingapproachforwastewaterbiorefineries.Microbialelectrolysiscell technologyhashigherhydrogenproductivitycomparedwithconventionalelectrolysisor fermentation.Researchshowsthatacellutilizingwastewaterasthesubstratehasahigh removalratefororganicmatter(Khanetal.2017).Ifchallengesofthistechnologycould beresolved,suchaslowenergyefficiency,andcompetitionandgrowthinhibitionbetween microbialcommunities,itwouldhaveasignificantimpactonwastewatertreatment plants.

1.4ClosedLoopRecirculationinaBio-basedEconomy Landfillandincinerationhavebeenwidelyacceptedaswastemanagementstrategiesfor alongtime.However,drawbacksofthesetraditionalwastemanagementmethodshave alreadyemerged.Landfillingisaseriouswasteoflandresources,andwithouttreatment,the buriedwastescouldresultinseriousproblemsinthefuture,suchasheavymetalpollution, groundwaterpollution,andfatalbacterial/viraldiseases.Similarly,thedisadvantagesof incinerationincludepublichealthproblemsandsecondaryenvironmentalpollution(e.g., airpollutionandacidrain).

Incontrast,wastebiorefinerieshavemoreopportunitiesincompetitionwithtraditional strategies.Withthesupportofrichfeedstocksandsuperiortechnologies,itrealizes sustainableconceptsbyeffectiveutilizationofbiomassresourcesandachievesnumerous value-addedoutputs.Developingwastebiorefineriescouldcontributetoimproving

environmentalconditionsthroughashiftintheconsumptionmodel,fromfossilfuelsto renewableresources,andefficientwastemanagement.Environmentalbenefitsthatwaste biorefineriesbring,suchastheabatementofgreenhousegasemissionsandincreasing energysavings,wouldhaveapositiveimpactoneconomicdevelopment,especiallyin developingcountries.

Undoubtedly,wastebiorefinerycouldbetheoptimalsolutionforacost-effectiveand environmentallyfriendlyeconomyinsucharapiddevelopingera.Asanewconcept, however,itstillfacesmanychallengescomparedwithtraditionalindustriesinamature, petroleum-dominanteconomy.

Abundantavailabilityoffeedstockisoneoftheoutstandingadvantagesforwastebiorefinery.Butinmostcases,theseresourcesareseason-dependentandwidelydistributed. Collection,transportationandstoragewouldbemajorissuesfortheearlystagesofwaste management.Inaddition,technologiesbasedonbiologystillneedpracticalexamination. Theyareusuallymorecomplicatedthanchemicaltechnologies,whichmakesitdifficultfor bio-basedsubstratestoachievehighconversionefficienciesandconsiderableproductivity. Furthermore,despitethefactthatmanybioproductsarecost-competitive,lowyields andlowproductivitiesincreasetheirpriceandlimittheirpopularity.Thismeansthat petroleum-derivedproductsarestillinthedominantpositioninthemarket,despiteahigh oilprice,thankstowelldevelopedandhighlyefficientprocessingtechnologies.Therapid realizationofeconomicbenefitsfurthermakesthefossil-basedindustriesmorefavorable, whileincreasingcompetitivepressuresforbio-basedprocessesandproducts.

Nevertheless,theincreasingdemandforenvironmentalprotectionandsustainable resourceutilization,andimprovementsinefficiencyandproductivityofbio-basedprocesses,willsoonoutweighthequickyetnon-sustainablebenefitsofthepetroleum-based processes.Thiswillpromotethedevelopmentofabio-basedeconomythatisboth environmentallyandeconomicallysustainable.

1.5ConclusionsandFutureTrends Wastebiorefineryisfullofpotentialtoachievegreenandsustainablewastemanagement andbringconsiderableenvironmentalandeconomicbenefits.Environmentalbenefits includeabatementofgreenhousegasemissions,naturalresourcesconservation,and eliminationofotherdetrimentalimpactsontheenvironmentcausedbytraditionalwaste disposal.Asforeconomicbenefits,wastebiorefineryhelpstobreakawayfromthe fossilfuel-dependentsituationanddecreasetheutilizationofrawmaterialsowingto widelyavailablerenewablewasteresources.Thedevelopmentofinnovativeandoptimal technologiescouldcontributetorealizingcost-efficientoutputsofenergyrecoveryand value-addedproductsfrombio-basedrefineriesinacirculareconomy.Thisclosed-loop approachaddressessustainabledevelopmentgoalsandwillleadmanyeconomiestomove towardsanenvironmentallyfriendlydevelopmentmodel,whichisthereflectionofa transitionaltrendtoacirculareconomy.

Thecirculareconomyorganizeseconomicactivitiesintoafeedbackprocessof“resources–products–renewableresources,”comparedwiththe“make-use-dispose”process ofthelinear-increaseeconomicmodeloftraditionalindustries.Itischaracterizedbylow exploitation,highutilization,andlowemissions,andallthesubstratesandenergyunder

thisconceptcanberationallyandcircularlyutilizedforthelongterm.Thecirculareconomyminimizestheimpactofeconomicactivitiesontheenvironment,andcombinesgreen productionwithwasteutilization,whichinessenceisaformofecologicaleconomy.Core principlesofthiseconomicmodelfacilitatetherecyclingandreuseofmaterialthoughintegratedsustainableapproaches(Mainaetal.2017).

However,asupcominggreenindustries,wastebiorefineryshouldbepreparedforthe opportunitiesandchallengeswhencompetingwithtraditionalindustries.Thetransition fromthecurrentpetrol-dominanteconomytoabio-basedeconomywillrequireasystematic processinvolvingmanyaspects.Fromtheperspectiveofindustrialchains,wastebiorefinery showsitsadvantagesduringtheadjustmentoffeedstocks,energystructure,andtechnology integration.Changingtorenewablewasteresourcesrelievestheeconomic,environmental, andsocialburdenscausedbythetraditionallineareconomy.Integrationofvariousprocessesenhancestheefficiencyofresourceutilizationandachievesconsiderableoutcomes. However,therearestillmanyproblems,suchasunderdevelopedtechnologies,imperfect policies,andcommercializationdifficulties.Thus,inthissignificantperiodofsocialtransformationtowardamoresustainable(economic)system,thoseworkingintheareaofwaste biorefinerymustbefullyawareofitsdevelopmentneeds,graspopportunities,andstrivein thecompetition.Finally,theobjectiveisgreenandsustainablemanagement,andthekey aspectistofindabalancebetweeninnovationandregulation.

Toallowoptimalresourceutilizationandmaximumeconomicbenefit,apriority-hierarchy modelcouldbeestablished.Thismodeladoptsawastebiomassutilizationsequencebased ontherankingofthevaluechain.Forexample,highvalue-addedindustries,suchasthe chemicalindustrialchain,havethehighestpriorityinthewastebiomassdistributionin ordertoincreasetheoverallsubstrateutilizationefficiencyandeconomicvalue.Material andbiofuelproductionwouldbethenext.Subsequently,theresidualbiomassafter distributioncanbeutilizedinheatingandelectricityproduction.Additionally,“green policies”areneededtosupportandguidetheseindustries,especiallyatthebeginningofthe researchstageand/orindustrialization.Thesepolicieswouldinvolveinnovativeresearch, greenpurchase,taxes,andgreenconsumption,andtheywillcontributetopromotingthe developmentofbio-basedindustries,raisepublicawarenessofbioproducts,andstimulate greenbehaviorandconsumption.

Theaboveaspectsoftransitioningtoacirculareconomybasedonvalorisationof resourcesinabiorefineryschemearediscussedindetailinsubsequentchaptersof thisbook.

References

Alizadeh,H.,Teymouri,F.,Gilbert,T.I.,andDale,B.E.(2005).Pretreatmentofswitchgrassbyammonia fiberexplosion(AFEX). Appl.Biochem.Biotechnol. 124 (1–3):1133–1141.

Alvira,P.,Tomás-Pejó,E.,Ballesteros,M.,andNegro,M.(2010).Pretreatmenttechnologiesforanefficient bioethanolproductionprocessbasedonenzymatichydrolysis:areview. Bioresour.Technol. 101 (13): 4851–4861.

Azmir,J.,Zaidul,I.,Rahman,M.etal.(2013).Techniquesforextractionofbioactivecompoundsfrom plantmaterials:areview. J.FoodEng. 117 (4):426–436. Bourguignon,D.(2015). UnderstandingWasteStreams.TreatmentofSpecificWaste.EuropeanParliamentaryResearchService.

Bozell,J.J.andPetersen,G.R.(2010).Technologydevelopmentfortheproductionofbiobasedproducts frombiorefinerycarbohydrates–theUSDepartmentofEnergy’s“Top10”revisited. GreenChem. 12 (4):539–554.

Bungay,H.R.(1982).Biomassrefining. Science 218 (4573):643–646.

Chen,Y.,Stevens,M.A.,Zhu,Y.etal.(2013).Understandingofalkalinepretreatmentparametersforcorn Stoverenzymaticsaccharification. Biotechnol.Biofuels 6 (1):8.

Clark,J.H.andDeswarte,F.E.(eds.)(2008).Thebiorefineryconcept–anintegratedapproach.In: IntroductiontoChemicalsfromBiomass,2e,1–29.Chichester:Wiley.

Dahiya,S.,Kumar,A.N.,Sravan,J.S.etal.(2018).Foodwastebiorefinery:sustainablestrategyforcircular bioeconomy. Bioresour.Technol. 248:2–12.

Fernando,S.,Adhikari,S.,Chandrapal,C.,andMurali,N.(2006).Biorefineries:currentstatus,challenges, andfuturedirection. EnergyFuel 20 (4):1727–1737.

Field,C.B.,Campbell,J.E.,andLobell,D.B.(2008).Biomassenergy:thescaleofthepotentialresource. TrendsEcol.Evol. 23 (2):65–72.

Galbe,M.andZacchi,G.(2012).Pretreatment:thekeytoefficientutilizationoflignocellulosicmaterials. BiomassBioenergy 46:70–78.

Gottumukkala,L.D.,Haigh,K.,Collard,F.-X.etal.(2016).Opportunitiesandprospectsof biorefinery-basedvalorisationofpulpandpapersludge. Bioresour.Technol. 215:37–49.

Kaparaju,P.,Serrano,M.,Thomsen,A.B.etal.(2009).Bioethanol,biohydrogenandbiogasproduction fromwheatstrawinabiorefineryconcept. Bioresour.Technol. 100 (9):2562–2568.

Khan,M.,Nizami,A.,Rehan,M.etal.(2017).Microbialelectrolysiscellsforhydrogenproductionand urbanwastewatertreatment:acasestudyofSaudiArabia. Appl.Energy 185:410–420.

Lam,W.C.,Kwan,T.H.,Budarin,V.L.etal.(2015).Pretreatmentandthermochemicalandbiologicalprocessingofbiomass.In: IntroductiontoChemicalsfromBiomass,2e(eds.J.ClarkandF.Deswarte), 53–88.Chichester:Wiley.

Maina,S.,Kachrimanidou,V.,andKoutinas,A.(2017).Aroadmaptowardsacircularandsustainable bioeconomythroughwastevalorisation. Curr.Opin.GreenSustainableChe. 8:18–23.

Ong,K.L.,Kaur,G.,Pensupa,N.etal.(2018).Trendsinfoodwastevalorisationfortheproductionof chemicals,materialsandfuels:casestudySouthandSoutheastAsia. Bioresour.Technol. 248:100–112.

Paritosh,K.,Kushwaha,S.K.,Yadav,M.etal.(2017).Foodwastetoenergy:anoverviewofsustainable approachesforfoodwastemanagementandnutrientrecycling. Biomed.Res.Int.:1–19. https://doi.org/ 10.1155/2017/2370927

Polprasert,C.andKoottatep,T.(2017). OrganicWasteRecycling:Technology,ManagementandSustainability.IWAPublishing.

Sharholy,M.,Ahmad,K.,Mahmood,G.,andTrivedi,R.(2008).Municipalsolidwastemanagementin Indiancities–areview. WasteManag. 28 (2):459–467.

Taherzadeh,M.andKarimi,K.(2008).Pretreatmentoflignocellulosicwastestoimproveethanolandbiogas production:areview. Int.J.Mol.Sci. 9 (9):1621–1651.