SustainableMetalExtractionfromWaste

Streams

GarimaChauhan

PerminderJitKaur

K.K.Pant

K.D.P.Nigam

Authors

Dr.GarimaChauhan UniversityofAlberta DepartmentofChemical&Materials Engineering 9211-116StreetNW EdmontonAB,T6G1H9 Canada

Dr.PerminderJitKaur IndianInstituteofTechnology CenterforRuralDevelopmentand Technology HauzKhas NewDelhi110016

India

Prof.K.K.Pant IndianInstituteofTechnology DepartmentofChemicalEngineering HauzKhas NewDelhi110016 India

Prof.K.D.P.Nigam IndianInstituteofTechnology DepartmentofChemicalEngineering HauzKhas NewDelhi110016

India

Cover AerialtopviewWatertreatmentplant, shutterstock1239611791/Avigator Fortuner.

Allbookspublishedby Wiley-VCH arecarefullyproduced.Nevertheless, authors,editors,andpublisherdonot warranttheinformationcontainedin thesebooks,includingthisbook,to befreeoferrors.Readersareadvised tokeepinmindthatstatements,data, illustrations,proceduraldetailsorother itemsmayinadvertentlybeinaccurate.

LibraryofCongressCardNo.: appliedfor

BritishLibraryCataloguing-in-Publication Data

Acataloguerecordforthisbookis availablefromtheBritishLibrary.

Bibliographicinformationpublishedby theDeutscheNationalbibliothek TheDeutscheNationalbibliotheklists thispublicationintheDeutsche Nationalbibliografie;detailed bibliographicdataareavailableonthe Internetat <http://dnb.d-nb.de>.

©2020Wiley-VCHVerlagGmbH& Co.KGaA,Boschstr.12,69469 Weinheim,Germany

Allrightsreserved(includingthoseof translationintootherlanguages).No partofthisbookmaybereproducedin anyform–byphotoprinting, microfilm,oranyothermeans–nor transmittedortranslatedintoa machinelanguagewithoutwritten permissionfromthepublishers. Registerednames,trademarks,etc.used inthisbook,evenwhennotspecifically markedassuch,arenottobe consideredunprotectedbylaw.

PrintISBN: 978-3-527-34755-1

ePDFISBN: 978-3-527-82672-8

ePubISBN: 978-3-527-82671-1

oBookISBN: 978-3-527-82670-4

Typesetting SPiGlobal,Chennai,India PrintingandBinding

Printedonacid-freepaper 10987654321

Contents

GraphicalAbstract xi

Preface xiii

1IntroductiontoSustainabilityandGreenChemistry 1

1.1Introduction 1

1.2Defining“Sustainability” 2

1.3DimensionsofSustainability 3

1.4NewConceptualFrameworkstoDefineSustainability 5

1.4.1FiveDimensionFramework 5

1.4.2FourForceModel 5

1.4.3CorporateSustainableManagement 7

1.5GreenValueStreamMapping(GVSM) 7

1.6“GreeningtheWaste” 8

1.7GreenChemistryTerminology 10

1.8GreenWaysofMetalExtraction:CoreoftheBook 11 Questions 13

2WasteHandlingandPre-treatment 15

2.1Introduction 15

2.2WasteCategorization 17

2.2.1WasteElectricalandElectronicEquipment(WEEE) 17

2.2.2Agro-ResidueWaste 20

2.2.3IndustrialWaste 21

2.3LegislationsandRegulationsforHazardousWastes 27

2.4Handling/ManagementofHazardousWaste 28

2.4.1SecuredLandfilling 29

2.4.2Incineration 30

2.4.3RecyclingofHazardousWaste 31

2.5ACallforMetalRecoveryfromWaste 31

2.5.1ThreattoHumanHealthandEnvironment 31

2.5.2Waste:AnArtificialOre 32

2.5.3“Waste”toWealth 33

2.6PretreatmentofWaste 34

2.6.1DisassemblingtheWaste 34

2.6.2SizeReduction(Comminution) 34

2.6.3Screening/Sieving 35

2.6.4Classification 36

2.6.5Segregation 36

2.6.6CalcinationandChemicalPretreatment 37

2.7SummaryandOutlook 37 Questions 38

3ConventionalTechnologiesforMetalExtractionfrom Waste 39

3.1Introduction 39

3.2PyrometallurgicalOperations 40

3.2.1PyrometallurgicalTreatmentofIndustrialWaste 40

3.2.2PyrometallurgicalTreatmentofWEEE 45

3.2.3MajorChallengesAssociatedwithPyrometallurgicalOperations 49

3.3HydrometallurgicalTreatmentofWaste 50

3.3.1LeachingofMetalsinAcidicMedium 50

3.3.2LeachingofMetalsinAlkaliMedium 57

3.3.3LeachingwithLixiviants(Cyanide,Thiourea,Thiosulfate) 60

3.3.4HalideLeaching 66

3.4SummaryandOutlook 69 Questions 70

4EmergingTechnologyforMetalExtractionfromWaste: I.GreenAdsorption 71

4.1Introduction 71

4.2Adsorption 71

4.2.1HydrophilicCompounds 72

4.2.2HydrophobicCompounds 72

4.2.3PolymerMatrix 73

4.3GreenAdsorption 74

4.4ParametersAffectingtheAdsorptionCapacityofGreen Adsorbents 75

4.4.1InfluenceofpH 75

4.4.2InfluenceofTemperature 76

4.4.3EffectofInitialConcentration 76

4.4.4EffectofAdsorbentDosage 76

4.4.5EffectofCo-ions 77

4.5AdsorptionKineticModels 77

4.6MechanismofMetalUptake 78

4.7GreenAdsorbents:RelevantLiterature 79

4.7.1AgriculturalResources 79

4.7.2Zeolites 81

4.7.3Clay 84

4.7.4IndustrialWaste 85

4.7.5ModifiedBiopolymers 88

4.8InnovativeApplicationsofAdsorption 88

4.9CaseStudy 89

4.10SummaryandOutlook 90 Questions 91

5EmergingTechnologiesforExtractionofMetalsfromWasteII. Bioleaching 93

5.1Introduction 93

5.2BioleachingProcessDescription 94

5.3FactorsAffectingtheProcessEfficiency 95

5.3.1TypesofMicroorganisms 95

5.3.1.1Mesophiles 95

5.3.1.2Thermophiles 96

5.3.1.3HeterotrophicMicrobes 97

5.3.2AffinityBetweenMicroorganismsandMetalSurfaces 97

5.3.3PhysicochemicalFactors 98

5.3.3.1SurfaceProperties 98

5.3.3.2OxygenandCarbonDioxideContent 98

5.3.3.3pHValueofSolution 99

5.3.3.4Temperature 99

5.3.3.5MineralSubstrate 99

5.3.3.6SurfaceChemistryofMetals 99

5.3.3.7SurfactantandOrganicExtractants 100

5.3.4ReactorDesign 100

5.4MechanismofBioleachingProcess 101

5.4.1BiochemicalReaction(Directvs.Indirect)Mechanism 102

5.4.2MechanismofMetalSulfideDissolution(PolysulfidePathway) 103

5.5EngineeringPracticesinBioleachingProcess 104

5.5.1BatchProcess 105

5.5.2ContinuousProcess 106

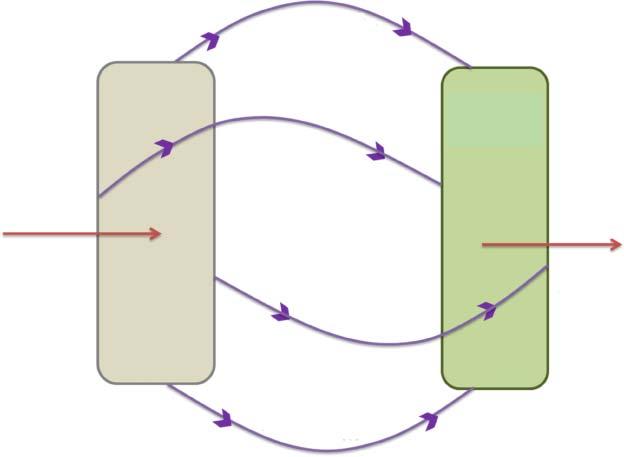

5.5.3HybridProcesses 110

5.6ApplicationofBioleachinginExtractingMetalsfromWaste 110

5.6.1ExtractionofMetalsfromWEEE 111

5.6.2ExtractionofMetalsfromIndustrialWaste 115

5.6.3ExtractionofMetalsfromMineralWaste 118

5.6.4ExtractionofMetalsfromMunicipalSewageSludge 119

5.7TechnoeconomicOpportunitiesandChallenges 119

5.8SummaryandOutlook 121 Questions 122

6FutureTechnologyforMetalExtractionfromWaste: I.ChelationTechnology 123 Abbreviations 123

6.1Introduction 123

6.2Defining“Chelation” 124

6.3ClassificationofLigands 124

6.4ChemistryAssociatedwithChelation 127

6.4.1TheoriesDerivedforMetal–LigandComplexation 127

6.4.2AttributesofMetalIonsforComplexation 129

6.4.3Metal–ChelateComplexFormation 130

6.4.4TheChelateEffect 132

6.5ChelationProcessforExtractionofMetals 133

6.5.1FrameworkforChelatingAgentAssistedMetalExtractionfromSolid Waste 133

6.5.2ProcessParametersAffectingtheMetalExtractionProcess 135

6.5.2.1EffectofReactionpH 135

6.5.2.2EffectofMolarConcentrationofChelatingAgent 138

6.5.2.3EffectofReactionTemperature 140

6.5.2.4PresenceofCompetingIonsinReactionZone 141

6.5.3FactorsAffectingStabilityofMetal–LigandComplex 142

6.6NovelApplicationsofChelatingAgents 143

6.6.1ChelatingAgentsUsedforMetalExtractionfrom Metal-ContaminatedSoil 144

6.6.1.1HydrometallurgicalRouteofChelationProcess(DirectUse) 144

6.6.1.2Phyto-remediationofSoilsinPresenceofChelatingAgents 145

6.6.2ChelatingAgentsUsedforMetalExtractionfromIndustrial Waste 147

6.6.3ChelatingAgentsUsedforMetalExtractionfromWEEE 149

6.7EcotoxicologicalConcernsandBiodegradability 151

6.8SummaryandOutlook 155 Questions 155

7FutureTechnologyforMetalExtractionfromWaste:II.Ionic Liquids 157 Abbreviation 157

7.1Introduction 158

7.2WhatAreIonicLiquids? 158

7.3CharacteristicPropertiesofIonicLiquids 161

7.3.1MeltingPoint 162

7.3.2VaporPressureandNonflammability 162

7.3.3ThermalStability 163

7.3.4Density 164

7.3.5Viscosity 164

7.3.6Polarity 166

7.3.7CoordinationAbility 166

7.3.8Conductivity 167

7.3.9Solubility 167

7.4ClassificationofIonicLiquids 169

7.5EnvironmentalScrutinyofIonicLiquids 171

7.6ApplicationsofIonicLiquids 173

7.6.1ExtractionofMetalsfromAqueousMedia 173

7.6.2ExtractionofMetalsfromIndustrialSolidWaste/Ores 176

7.6.3ExtractionofMetalsfromWEEE 177

7.7SummaryandOutlook 179 Questions 179

8Scale-upProcessforMetalExtractionfromSolidWaste 181 Nomenclature 181

8.1Introduction 182

8.2ProcessIntensification 183

8.3IntensificationofMetalExtractionProcesses 185

8.3.1Centrifugation 185

8.3.2Liquid–LiquidExtraction 185

8.3.3Mixing 186

8.3.4Reactors 188

8.3.5Comminution 188

8.3.6Drying 189

8.4ScalingUpfromBatchtoContinuousProcess 189

8.4.1ProcessDesignFabrication 190

8.4.2DesigningofPilotPlant 191

8.4.2.1MaterialBalance 191

8.4.2.2DevelopmentofComminutionCircuit 193

8.4.3ReactorSizingandAgitatorSelection 197

8.4.4DesignofFiltrationSystem 199

8.4.5DesignofHeatExchanger 201

8.4.6DesignofPrecipitatorUnit 202

8.4.7BatchScheduling 203

8.5SummaryandOutlook 204 Questions 205

9ProcessIntensificationforMicro-flowExtraction:Batchto ContinuousProcess 207 JogenderSingh,LoveleenSharma,andJamalChaouki Abbreviations 207

9.1Introduction 208

9.2MiniaturizedExtractionDevices 208

9.2.1IntensificationinMiniaturizedExtractionDevices 209

9.2.2ApplicationofMiniaturizedExtractionDevices 211

9.3CFIforContinuousMicro-flowExtraction 212

9.3.1DesigningCFIasanExtractor 216

9.3.2ExtractionParameters 218

9.3.3MethodologyandSetupforMicro-flowExtraction 218

9.3.4Liquid–LiquidMicro-flowExtraction 220

9.3.4.1TypicalFlowPatterns 220

x Contents

9.3.4.2ExtractionEfficiency 222

9.3.4.3EffectofAqueousPhaseVolumeFractionsonExtraction Efficiency 223

9.3.5Micro-flowExtractionofCoandNi 225

9.3.5.1EffectofpH 225

9.3.5.2EffectofResidenceTime 225

9.3.5.3EffectofExtractantConcentration 229

9.4SummaryandFutureChallenges 229 Questions 229

Bibliography 231

Index 273

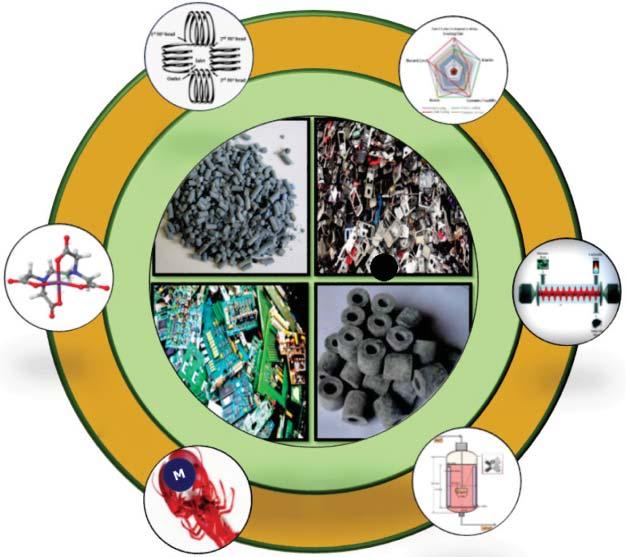

GraphicalAbstract

Preface

Environmentfriendlytechnologiesandimprovedresourceintensityisthecall ofthepresentdaywherevarioustypesofwastesposemanyhazardsforthe eco-system.Thekeyconceptofwritingthisbookistodemonstratetransdisciplinaryresearchasanexecutabledirectiontoachievesustainablegovernance ofnaturalresourcesandsolidwastemanagement.Differentaspectsassociated withsolidwastemanagementincludingtypesofsolidwaste,conventionalwaste disposalmethodologies,rulesandregulationsforwastedisposal,andtheglobal scenarioforsolidwastegenerationarediscussedinbrief.Recoveryandrecycling ofheavymetalsfromsolidwastecanalwaysbeagoodoptiontoreducefresh inputsandhazardouswasteoutput.Thisbookprimarilyfocusesonshowcasing variousrecenttechnologicalinnovationsthathavethepotentialtoextractmetals fromsolidwasteandthustoofferanswerstochallengesinthefieldofresource optimization.

Whilemanybooksandresearcharticleshavealreadybeenpublishedhighlightingthedevelopmentsinthefieldofsolidwastemanagement,information abouttheemergingprocessesofwastetreatmentthatwouldbeintheforefront innearfutureisscanty.Theconceptofdevelopingsustainablepracticesfor wasteminimizationdefinesthethemeofourbook.Thisbookprovidesa comprehensivecollectionoftheconventional,emergingandfuturetechnologies formetalextractionfromindustrialwasteandwasteelectricalandelectronic equipment(s)inasustainableway.Variousaspectsofthenovelprocesses rangingfrombasicconcepts,benchmarkperformanceofthesetechnologies onlaboratoryscale,recentresearchtrendsinmetalextraction,challengesto theimplementationoftheseatlargescale,andthefutureperspectiveshave beensummarizedinthisbook.Processintensificationisanotherinteresting researchareathathasnotbeendealtwithextensivelyintheliterature.Thisbook presentsadedicatedsectiononscale-upandprocessintensificationofmetallurgicalprocesses.Coveringavarietyofinterdisciplinarytopicsonresource optimizationandwasteminimizationmakesitonebookforallthatservesasan excellentreadingmaterialforengineers,sciencestudents,entrepreneurs,and organizationswhoareworkinginthefieldofwastemanagementandwishto gaininformationonupcomingsustainableprocesses.

Thechaptersofthisbookpresentvariousnoveltechnologiesthatshowthe potentialofmetalextractioninagreenerwayandofferseveralnewopportunitiestoattainsustainability.Itisimportanttounderstandhowcrucialitisto

learnaboutsolidwastemanagementinthepresentcontext.Chapter1provides anoverviewofsustainability-relatedconstructsandillustratestheprerequisites forsustainablemanagementofwastestreams.Chapter2coversthebasicsofsolid wastehandlingrangingfromananalysisoftherelevance,categoriesofwastes, consequencesofuntreatedwastedisposalintotheenvironment,governmentinitiatives,managementstrategies,andunitoperationsforpretreatmentofwastes. Someofthewidelyacceptedconventionaltechnologiesformetalextraction suchashydro-andpyrometallurgicalmethodsarediscussedinChapter3.Next, thebookbringsoutthepossibilityofsustainablegreenprocessesformetal extraction.Chapters4and5discusstheapproaches(adsorption,bioleaching) thathavebeeninvestigatedalreadyatindustrial/pilotscaleforseveralapplicationsandthatarenowbeinginvestigated(slowtobeadapted)toexploretheir novelapplicationsinthefieldofwastemanagement(especiallytheextractionof metalsfromwaste)andareincludedinthecategoryof“emergingtechnology.” Chelationtechnologyandionicliquids(Chapters6and7)havebeenincluded inthelistoffuturetechnologies.Theseapproachesarestillintheirinfancy andhavebeentestedonlyatthelaboratoryscale(onlyacademic).Chapter8 addressestheextentofcommercializationoftheprocessesdiscussedthrough scaling-upofthebenchscaleprocesses.Acasestudyisillustratedtoprocess alargeamountofindustrial/electronicwastewhilescalingupvariousunit operationsusedintheprocessing.Abriefinsighthasbeenprovidedonthetechnicalcomplexitiesandeconomicfeasibilityoftheaforementionedeco-friendly processesofmetalextractionfromwaste.Chapter9introducescoiledflow inverter,arecentexampleofprocessintensificationthathasbeenusedearlier forheattransfer/masstransferapplicationsandthatisnowbeingexploredfor recoveryofmetalsfromtheaqueousandsolidwastestream.Iftheseprocesses aredeployedonalargescale,certainlyitwilldeepentheirimpact.

Eachnewbookgivesrecognitiontothosewhosenameappearsonthetitle page,yetabookis,infact,acollectiveeffortofmanymoreindividualswho havecontributedeitherdirectlyorindirectlytoitssuccessfulcompletion.The authorswouldliketoextendtheirgratitudetoeveryindividualfortheirsupport andmotivationthroughoutthejourney.Themostobviousdebtiscertainlytothe researcher(s)whoareconstantlyworkingtofindoutnewsustainableapproaches forthebettermentofhumanlivesandfuturegenerations.Theauthorswouldalso liketoacknowledgeDr.JogenderSingh,Dr.LoveleenSharma,andProf.Jamal ChaoukifortheirhelpincompletingChapter9.

GarimaChauhan,PerminderjitKaur , NewDelhi,India

June01,2019 K.K.Pant,andK.D.P.Nigam

IntroductiontoSustainabilityandGreenChemistry

“Weneedanewsystemofvalues,asystemoftheorganicunitybetween humankindandnatureandtheethicofglobalresponsibility.”

MikhailGorbachev

1.1Introduction

Thegrowingnecessityinthepastfewdecadeshasinitiatedamechanical thinking.Rapidindustrializationhastheimpetustoincreasetheconsumption ofnaturalresourcesandconsequentlytodegradetheenvironmentbydisposing offindustrialeffluentsintothesoil–water–aircontinuuminacavaliermanner. Theseactivitiesresultinchangeinweatherpatterns,globalwarming,foodborne contamination,andincreasingrateofhealthrisk,whichhaveledtosignificant concernofresearcherstowardtheconceptofsustainabledevelopment(SD). Acallforsustainabilityisrequiredforpreservingnonrenewablenatural resourcesandimprovingindustrialeconomy.

TheWorldCommissiononEnvironmentandDevelopment(WCED)launched theconceptofSDtoillustratenewschemesorientatedtoeconomic,social,and ecologicalbenefits.AmajorsteptowardSDwasinitiatedin1987byacommissionundertheChairofGroHarlemBrundtland(WCED1987),convenedbythe UnitedNationsin1983.Thereportwascommissionedtoaddressissuessuchas theacceleratingrateofdeteriorationoftheenvironmentandnaturalresources anditsconsequencesoneconomicandsocialdevelopment.IntheBrundtland report,SDwasdefinedas“Thedevelopmentthatmeetstheneedsofpresent generationwithoutcompromisingtheabilityoffuturegenerationstomeettheir ownneeds.”ThiswidelypopulardefinitionofSDposedseveralchallengesto researchersandindustrialiststoequilibratetheecological,economic,andtechnicaldevelopment.Eventually,inordertorespondtothischallenge,theconcept ofGreenChemistrywasnurtured.

Greenchemistryisdefinedas“Theprocessofmanufacturingofchemical productinwhichrawmaterialsareenvironmentfriendly,withoutuseofany hazardousortoxicchemicals,energyefficient,inherentlysaferprocessesand involvesminimumproductionofwaste.”

Althoughtheterms“Greenchemistry”and“Sustainability”aresimilar constructsthatareusedinterchangeablyingeneral,itisbelievedthatthegoal ofsustainabilityisachievedusingGreenchemistryapproaches.Anoverview ofsustainability-relatedconstructsisprovidedinthischaptertoencourage readers,payingparticularattentiontotheuseofthesetermsintheirstudies. DimensionsofsustainabilityandnewframeworkstodefineSDarealsooutlined. Greenchemistryterminologyandvaluestreammapping(VSM)arediscussed inbrieftomakereadersawareofthebasicconceptsofthegreenprocesses.A sectionattheendintroducesthereaderstothecorethemeofthebook,which iscenteredaroundtherecoveryofmetalsfromwasteinasustainablemanner usinggreenchemistryapproaches.

1.2Defining“Sustainability”

Sustainabilitycanbedefinedas“Theexpectationsofimprovingthesocialand environmentalperformanceofthepresentgenerationwithoutcomprisingthe abilityoffuturegenerationstomeettheirsocialandenvironmentalneeds”(Hart andMilsten2003).Sustainabilitywascitedinvariouswaysintheliteraturebased onthesource;however,thecoreconceptalwaysreferstothesocietyandtheenvironment.ArasandCrowther(2009)referredtoitasafundamentalandcomplex constructthatmandatesthebalanceofseveralfactorsontheplanettocontinuallyexist.Thisconstructisalsodelineatedasabeliefofthepreservationofnatural resources.

Sustainabilityalsoconsidersthefinancialadvantagesinthepresentalongwith theassuranceofbenefitsforthefuturegenerations.Elkington(2005)suggested “economics”asanintegralfactoralongwithsocialandenvironmentalfactorsto attainsustainabilityandcoinedtheterm“triplebottomline(TBL).”Thistermwas citedasthepracticalframeworkofsustainabilitybyRogersandHudson(2011). TheeconomiclineofTBLframeworkconcernsthecapabilityofeconomytosurviveandevolveintothefutureinordertosupportfuturegenerations.Industrial practicesthatarebeneficialandfairtothehumancapitalandtothecommunity areincludedinthesocialline(Elkington2005).Environmentallinereferstothe efficientuseofenergyresourcesandreducingtheenvironmentalpollution.A complexbalanceamongtheeconomy,environment,andsocietyistheconstruct thatleadstoSD.TheseaspectsofSDareessentialtobeconsideredbyindividuals andindustries.

However,thelackofarigidframeworkandpoorinterpretationoftheterm “sustainability”confrontedinconsistencyinitsusage.Somesustainabilitystudies arecenteredononelineonlywhereassomeauthorstriedtoincludetwoormore linesintheirstudies.Yanetal.(2009)employedtheterm“sustainability”torefer totheenvironmentalline,whereasthesociallinewasemphasizedbyBibri(2008). Someoftheliteraturestudiesincludedtheimportanceoftheeconomiclineinto theterm“sustainability”(Collinsetal.2007).Althoughveryfewstudiesmanaged tousethistermtorefertoallthreebottomlinestogether(MarcusandFremeth 2009),effortsarebeingmadeacrosstheworldtoemphasizeSDatnationaland

internationallevels.Severalorganizations/industriesaretryingtoincorporate thesethreelinesofsustainabilityintheirpoliciesandcultures.Forexample,the InternationalOrganizationforStandardization(ISO)providesEcolabelsto marketproductsundervariouscategoriesasfollows:

Type1(ISO14024:Environmentlabelsanddeclaration):Thistypeofproducts areinaccordancewithenvironmentalcriteriareleasedbyathirdpartyorganization.Forinstance,EuropeanEcolabelsareawardedonthebasisoflifecycle assessment(LCA)ofaproductunderthesupervisionoftheEcolabelCommittee.Theselabelsareconsideredasaclearsignofenvironmentalexcellence.The productslabeledundertheEuropeanEcolabelcanbecomeaproductofchoice fortheconsumerswhoareconcernedforsustainability.

TypeII(ISO14021:Self-declaredenvironmentalclaims):Theselabelsare self-declaredbycompaniesorproducers,basedonenvironmentalperformancesoftheirproducts,forexample,therecyclabilityatendoftheproduct life.

TypeIII(ISO14025:Environmentlabelsanddeclaration):Theselabelsrequire aquantifieddeclarationofthelifecycleoftheproduct,whichcanbeverified byathirdpartyorganization.Thishelpstoprovidetransparentinformationto theconsumerforcomparisonpurposes.

Theselabelsconsiderthesourceofrawmaterial,processinginvolvedinthe preparationofthefinalproduct,use,andendoflifeoftheproduct.Moreover, theseinternationalenvironmentsustainabilitylabelsarealsobasedonthefollowingaspectsofaproduct:

i.Amountofenergyandnaturalresourcesconsumedduringtheproduction process

ii.Emissionoftoxicsubstancestotheenvironment

iii.Impactofprocessonhabitatandnaturalresourcessuchaswater,air,andsoil iv.Wastemanagementpracticesfollowedbytheorganization.

Therefore,hereithasbecomenecessarytounderstandthedimensionsofsustainabilityinordertomaximizeprofitsaswellastohandleallthesocialand environmentalresponsibilities.

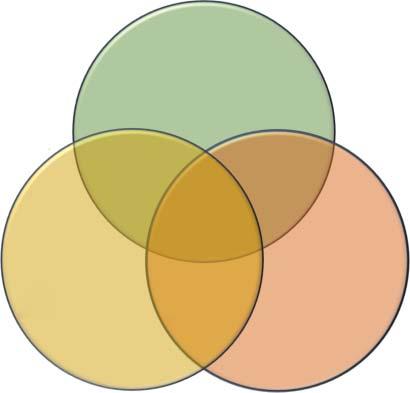

1.3DimensionsofSustainability

Threefundamentalfactors,i.e.People,Planet,andProfit(thethreePs)associated withtheTBLconstruct,canbeaccountedasthedimensionsofsustainabilityand outlinedhereasthetraditionalsustainablegovernance.Sustainabilityofanyprocessthusbanksupontheeconomic,social,andenvironmentalpillarsasshown inFigure1.1.Ifanyofthesepillarsisweakthentheprocesscannotbeconsideredasustainablepractice.Theinterlockingcirclesindicatethatthesethree dimensionsshouldbeintegratedinsuchawayastobeabletomaintainbalancebetweenallthefactors.Itisobservedthatevenmostofthedistinguished organizationsfocusononlyonedimensionatatime.TheUnitedNationsEnvironmentProgramme(UNEP),theEnvironmentalProtectionAgencies(EPAs)of

Socio-environmental

e.g. Environmental regulation, safety and health, water management

Social progress (“People”)

e.g. Business ethics, skill enhancement, local economical impact, social investment Environmental stewardship (“Planet”)

Dimensionsofsustainability(threePs).

Eco-efficiency

e.g. Life cycle management, product stewardship, resource efficiency

Economic growth (“Profit”)

manynations,andenvironmentalnongovernmentalorganizations(NGOs)focus onlyontheenvironmentalpillar.Ontheotherhand,theprimaryfocusareaofthe WorldTradeOrganization(WTO)andtheOrganizationforEconomicCooperationandDevelopment(OECD)iscenteredoneconomicgrowth.Itisdifficult toincludeallthethreepillarsinoneprocess;stilleffortsshouldbemadeinthis directionforthecontinuanceofnaturalresourcesindefinitelyinfuture.

Economicpillar(the“profit”factor)ofsustainabilityisreferredtoasthe conditionofnecessaryeconomicbenefitsprojectedindefinitelyintothefuture. Economicallysustainableindustryshouldfocusonthemaximizationofprofit perunitofproduct,maintenanceofastrongcompetitivepositionintheindustry, andhighlevelofoperationalefficiencyalongwithbeingconsistentlyprofitable. Carroll(1991)presentedacorporatesocio-economicmodelthatsuggeststhat “initiatingastrategyonsocio-economicresponsibilityisthefoundationon whichotherthreedimensionsarebasedon.”Anynewconceptforsustainability shouldconsiderthecostsofimplementingsustainabilityandidentifypotential benefitstoensurelong-termfinancialbenefits.Thus,economicfeasibilityand processproductivityarethemostdesiredcharacteristicstodefinesustainable practices.

Socialdimensionofsustainability(the“people”factor)referstoasharedsense ofsocialpurposetofostersocialintegrationandcohesion.Anorganizationwith socialresponsibilitymustensurethatitcontributestheresourcestothecommunityandimprovesqualityoflife.Socialresponsibilitiesarealsoconnectedto theenvironmentalpillarinordertoprovideahealthyecosystemtothesociety.In thisregard,safety,healthcare,environmentalregulations,accesstopotablewater,

Figure1.1

1.4NewConceptualFrameworkstoDefineSustainability 5 crisismanagement,andmanyotherenvironmentalpracticesbecomeapartofthe socialpillartoachievesustainability.

Thecontributionoftheenvironment(the“planet”factor)totheeconomyand societyisperceivedtobethroughtheoperationofawiderangeofenvironmentalfunctions.DeGroot(1992),defines“environmentalfunctions”as“thecapacity ofnaturalprocessesandresourcestoprovideservicesinordertosatisfyhuman needs.”Also,anaturalprocessisbasedoncomplexinteractionsbetweenlivingorganisms,i.e.bioticcomponentsandchemicalandphysicalcomponentsof ecosystemsthroughtheuniversaldrivingforcesofmatterandenergy.

Insupportoftheaforementioneddefinition,preservationofnaturalresources isoneofthemajorresponsibilitiesofthescientificcommunity,whichis furtherextendedtothethreeRs(Reduce,Recycle,Reuse)schemetoachieve sustainability.Severalresearcheffortsarebeingmadeinordertodevelopnovel environment-friendlytechnologies,minimizewastegeneration,useopen-and closed-looprecyclingprocesses,usealternativeenergysources,effectivelyutilize renewable/nonrenewableresources,andfosterharmonybetweensupplychains andnature.

1.4NewConceptualFrameworkstoDefine Sustainability

1.4.1FiveDimensionFramework

TheaforementionedWCEDdefinition(WCED1987)iswidelyacceptedto delineatetheterm“sustainability”;however,someauthorscontendedthe anthropocentrismoftheWCEDdefinition.Anthropocentrismindicatesthat thegratificationofhumanneedsinherentlycontraveneswithenvironmental constraintsand,therefore,societyandenvironmentarerepresentedasseparate “pillars”todefinethedimensionsofsustainability.

Seghezzo(2009)consideredthislimitationoftheWCEDsustainabilitydefinitionandproposedanewconceptualframeworkthatincludesfivedimensionsof sustainability.Territorial(place),temporal(permanence),andpersonal(persons) aspectsofdevelopmentwerecoveredinthisnewdefinitionofsustainabilityas showninFigure1.2.Placecontainsthethreedimensionsofspace,Permanenceis thefourthdimensionoftime,andthePersonscategoryrepresentsafifth,human dimension.Theimportanceofeconomyisalsoconsideredtobeoverestimated intheWCEDdefinition,whichhasalsobeenaddressedintheSeghezzoframework.Spatialandtemporalboundariesmustalsobetakenintoaccounttoassess sustainability,whichhasbeenignoredintheWCEDdefinitionofsustainability. Theimportanceoftimeinthecomplexitiesassociatedwithproblemsolvingis alsoacknowledged.

1.4.2FourForceModel

Aconceptualframework,the“FourForceModel,”assistsinthetransformation ofunsustainabledevelopment(USD)toSD.Itisastructuredapproachtoidentify

Figure1.2 Thenew five-dimensional sustainabilitytriangle.Source: Seghezzo(2009).Reproduced withpermissionofTaylor& Francis.

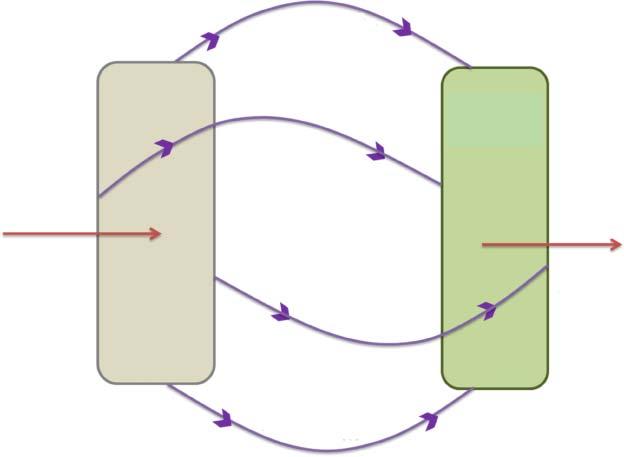

theneed,cause,andprocesstoaccomplishSD.Fiveissues,i.e.currentUSD,environmentaldegradation,futureSD,greeningforce,andgreeningprocess,have beenemphasizedinthismodel(Gandhietal.2006).Themodelsuggeststhatthe moveofanenterpriselowerendsolutiontoahigherendsolutionleadstoagreen process.Byenhancingtheresourceutilization,recycling,andextractionofmaximumvaluablecomponentsfromwastestreams,anorganizationcaneasilymeet thetargetofminimumwasteandgreenprocess.Withincreasinginternational cooperationandtechnologytransfer,itispossibletominimizewastewithout causinganyharmtotheenvironment.

Figure1.3illustratesthelinkbetweencurrentgrowthwithUSDandthemost requisiteSDinfuture.Theback-castingapproachutilizesaparticularfuture scenariotobeconsideredinitially.Backwarddirectionwasdefinedbyfulfilling theneededoutcomesinordertolinkthefuturewiththepresent.Thefourforce modeldefinesthefourindicatorsofenvironmentasthedrivingforce,state, reactiveresponse,andproactiveresponse(Banerjee2002).Themodelshows thepresentstateasenvironmentdegradation.Thefuturestateistargetedas SDusingeitherproactiveorreactiveresponses.Itisalsoknownasaprocessof determiningthestepstobetakenoreventstoberealizedfortheneededfuture. Inthepresentcontext,environmentaldegradationisthemajoroutcomeof thecurrentUSD.Industrialgrowthoccursbyextractingandutilizingnatural resourcesandthereforenatureshrinkswiththeexpansioninindustrialactivities andeconomics.Certainfactorssuchasrapidindustrialization,increaseinper capitaincome,subsequentchangesinresourceconsumptionpattern,exponentialincreaseinpopulation,andcontinuousdepletionofnonrenewableresources areresponsiblefortheincreasingrateofenvironmentaldegradation.Thegreeningprocessmaybeeitherreactiveorproactiveresponsestothefourdriving forces.Thesefourdrivingforcesincludethreeexternalforces(regulatory,community,andconsumerforce)andoneinternalforce(financialadvantage).These

Figure1.3 Fourforcemodel.Source:Gandhietal.(2006).Reproducedwithpermissionof EmeraldGroupPublishingLimited.

forcesexertextremepressureontheindustriestoadoptgreenprocesses,which mayleadfromUSDtonovelsustainabletechnologiesandproducts.

1.4.3CorporateSustainableManagement

Corporatesustainablemanagementisaverynewconceptthatisadoptedbyseveralindustriestoinvolvetheirownframeworktomanagesustainabilityissues. Companiesareconstantlymakingeffortstodifferentiatetheirproductsonthe basisofsustainabilitypractices.Somecompanieshavedevelopedthe“carbon neutral”programs,whereasotherindustriesareworkingtominimizehazardous gasemissionsandwastegenerationfromthesource.Corporatesustainability indexisalsoanemergingideatomeasuresustainabilityperformance.Theindex providesvitalandtimelyinformationtocustomersandshareholdersontheenvironmentalhealthandsustainabilityofcompanies.Industriesarecoercedtopay sincereattentiontominimizeenvironmentalimpactssuchaswastegeneration, greenhousegasemissions,deforestation,andotherenvironmentalhazardsdue toindustrialactivities.

1.5GreenValueStreamMapping(GVSM)

Thesequenceofactivitiestodevelopnovelgreenproductsandservicesplaysan importantroleinattainingsustainability.Therefore,aprocessmappingmethod namedasthe“valuestreammapping(VSM)”iscompiledtounderstandthe sequenceofactivities,toidentifyandeliminatethenon-value-addedactivities,

andtostreamlinetheprocess.Constrainedenvironmentalruleshaveextended theconventionalVSMtoincludebotheco-friendlygreenelementsinitsmappingtechnique.Greenvaluestreammapping(GVSM)isanextensiontoachieve thesamegoalbyrulingoutthenon-value-addedmaterials,reducingcosts, identifyingwaystominimizewastegeneration,andascertainingopportunities toimproveperformance.Itfocusesonexcessusageofenergy,water,andraw material;releaseofpollutants,andhazardousandsolidwastedischargeintothe ecosystem;useofhazardoussubstancesintheproductionprocess,etc.

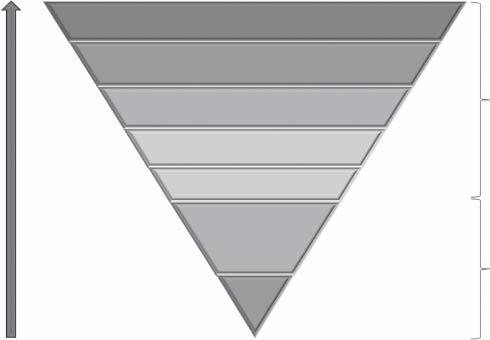

1.6“GreeningtheWaste”

“Greeningthewaste”conceptreferstoanapproachinwhichindustryshiftsfrom lesspreferredmethodsofwastetreatmentincludingtreatmentwithtoxicchemicalsandincinerationtowardthe“threeR:Reduce,Reuse,andRecycle”principle ofsustainability.Further,researchersareawareofthefourthdimensionofsustainability,Recovery.Byintegrationoftheconstructof“recovery”insolidwaste management,wecanmoveinthedesiredupstreamdirectioninsolidwastemanagementhierarchy.

Thiscallsfortheintegratedsolidwastemanagement(ISWM)approach, basedonappropriatewastetreatmentandrecoverytechnology,tobridgethe gapbetweencommunityandwastemanagementauthorities.Considerations regardingtheenvironmentalimpacts,socialimpact,andfinancialconstraints havetofactoredinwhiledesigningtherelevantISWMstrategy(Figure1.4).

Inordertoapplytheconceptof“Greeningthewaste,”the“three3R”principlesofsustainabilityshouldbeapplied:reusetheresourcewhereverpossibleto abstainfromthewasteofvirginresources.Recyclethewastebyconvertingwaste intosuitableproductsandrecovertheenergyfromwasteusingpertinenttechniques.Useofresourceoptimizationtechniquesassistsinminimizingresource wastage.Propercollectionandsegregationofwasteatsourceensuresefficient wastetreatment.Further,resourcesshouldbereservedandbeusedprudently toaverttheiroverconsumption.Landfillingofthewasteshouldbeavoidedas leachatesfromitarehazardoustonearbyenvironment.Resourceoptimization techniquesneedtobeappliedtoimprovetheconsumptionofresources.

Thegreeningofthewastesectorshouldbefacilitatedbysignificantbreakthroughsintechnologiesrequiredforcollection,reprocessing,andrecycling ofwaste,extractingenergyfromorganicwaste,andefficientgascapturefrom landfills.Recoveringenergyandotherusefulproductsfromwasteisbeing enabledbyconsiderabletechnologicalbreakthroughs.Manycountrieshave movedfromincinerationtoenergygenerationasapartofwastetreatment. Mechanicalandbiologicaltreatment(MBT)andbiomethanationarealsobeing recognizedassuitableforprocessingorganicwetwasteindevelopingcountries. However,incompletesegregationofdryandwetorganicwastehasbeenamajor barriertothewidespreadsuccessfuladoptionofthesetechnologiesinthese countries.Techniquessuchasvermi-compostingandrapidcompostinghaveled toconversionoforganicwasteintousefulagriculturalmanureatapacefaster

Figure1.4 Wastemanagementhierarchy.

thannaturaldecomposition.Advancedtechnologiesareemployedtoconvert wasteintovalue-addedproducts.Forinstance,wastewithhighcalorificvalueis usedtogeneraterefusederivedfuel(RDF).

Inspiteoftheeffortsmadebyresearchersinthefieldofvalorizationofwaste, nospecifictargetsforgreeningthewastesectorshavebeenestablishedbyinternationalconventions.AppreciableeffortshavebeenmadebynorthernEurope, theRepublicofKorea,andSingapore,bysubjectingover50%ofwastematerialstothematerialrecoveryprocess(GaillochetandChalmin2009).ManyAsian countries,suchasJapan,haveinitiatedeffortstoevaluatetheyearlydevelopmentsinrecyclingratesbysettingmaterialflowindicatorsunderthreecategories,i.e.“input,”“cycle,”and“output.”Basedonindicatorssuchasresource productivity(increasedfrom210000yen/tonnein1990to390000yen/tonnein 2010),recycleuserate(increasedfrom8%in1990to14%in2010),andfinaldisposalamount(decreasedfrom110milliontonnesin1990to28milliontonnes in2010),recyclingofmaterialisencouraged(MinistryofEnvironment,GovernmentofJapan2008).Similarly,theconceptofcirculareconomy(CE)hasbeen includedinthe11thfive-yearlyplansofChina.Effortsonthepracticeofthree Rspolicy–Reduce,Reuse,andRecyclearemadeinEuropeancountriestofoster sustainablematerialsmanagement.Earlierin2011,citiesoftheUnitedKingdom, especiallyLondon,draftedapolicytomanagewastebysettingup70%commercial/industrialwaste’srecycling/compostingby2020and95%reuseandrecycling ofwasteby2020(MayorofLondon2010).However,TheNetherland’swastemanagementpolicy(alsoknownasthe“Lansink’sLadder”)isbasedontheconcept ofthewiseuseofexistingresources,alongwiththereductionofwastegenerationandrecoveryofresourcesandenergyfromwaste(ZimringandRathje2012). ThecountryusesstonywastethatmeetsthecriteriaofDutchBuildingMaterialsDecreeforconstructionapplications(Liuetal.2015).TheUnitedStatestoo, throughtheEPA,haslawstodealwithreleaseofwastethataretoxicforpublic health,welfare,andenvironment.Quantitativeriskassessmentpolicyisfollowed inthecountrytoevaluatetheeffectofwasteonpublichealthandenvironment.

1IntroductiontoSustainabilityandGreenChemistry

Thus,globalawarenessaboutincreasingwastegenerationandpotentialof resourcerecoveryfromwastehasgivenrisetotheterm“Greeningthewaste.” Thevariousaspectsofvalorizationofproductareeconomicbenefits(energy generation,newbusinessavenues,creationofjobs,secondarysourcesofmetals), environmentalprotection(resourceconservation,reductioningreenhouse gases(GHG)),andsocialbenefitssuchascompostproductionsupporting organicagriculture,contributionstoequity,andpovertyeradication.Better managementofwasteimprovespublichealthandtheconditionofwaterbodies. Thisconsequentlyleadstoreducedhealthcosts,whichisanimportantstream ofbenefitsof“GreeningtheWaste.”

1.7GreenChemistryTerminology

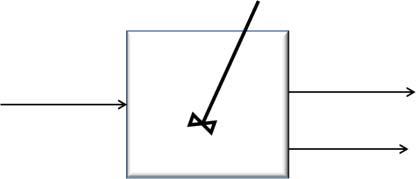

Ingreenchemistry,environmentfactor(E-factor)isanimportanttermtoillustratetheprocessefficiency.Figure1.5illustratesageneralprocessflowdiagram demonstratinginputofrawmaterial,whichinturnresultsinproductandwaste generation.

Todefinetheenvironmentalefficiency,E-factorisdefinedasthemassratioof wasteproduced(excludingwater)tothedesiredproduct.E-factorisrelatedto theyieldoftheprocessasdefinedinEq.(1.1):

E-factor = massofwaste massofdesiredproduct

ItisrecommendedthataprocessshouldbedesignedtominimizetheE-factor. TherearevariousfactorsthataffectthevalueoftheE-factor,includingthefollowing:

i.Yieldofthedesiredproduct

ii.Reagentsused

iii.Numberofstepsandreactionsequences

iv.Extractionandpurificationsolvents.

TheaverageE-factorvariesfortheoilrefining(<0.1)tobulkchemical(1–5),to finechemical(5–50),topharmaceuticalindustries(25–>100).

Inaddition,thereisanothertermknownas“atomefficiency.”Itisdefinedasthe ratioofmolecularweightofthedesiredproducttothesumofmolecularweights ofallsubstancesproducedinastoichiometricequation.

Atomefficiency = molecularweightofdesiredproduct sumofmolecularweightofallproducts × 100% (1.2)

Figure1.5 Generalchemical processshowinginputand output.

Figure1.6 Exampleofanatom-efficientreaction.

Atomefficiencyisatooltoshowtheefficiencyofaprocesstoutilizeallatoms involved.Itisusefultocomparedifferentpathwaystoobtainthedesiredproduct, withoutconsideringtheyield.

Baylis–Hillmanreaction,showninFigure1.6,isa100%atom-efficientprocess. Inthisreaction,anactivatedalkenederivativereactswithanaldehyde,catalyzed byatertiaryamine(forexample,DABCO = 1,4-diazabicyclo[2,2,2]octane).No co-productsareknowntobeformed.Allatomsareefficientlyconvertedintothe desiredproduct,resultingincompleteefficiencyoftheprocess.

Effectivemassyieldisalsousedtodefinethe“greenness”ofareaction.This termcanbeexplainedas

Effectivemassyield = massofdesiredproducts massofnon-benignreagents × 100% (1.3)

1.8GreenWaysofMetalExtraction:CoreoftheBook

Itisclearfromthepreviousdiscussionthatsustainablemanagementisofutmost importancefortheaccomplishedgrowthofanyindustry.Environmentisone ofthepillarsofthesustainabilitytrianglethatisgenerallyignoredbyvarious industriesinordertoaddfinancialbenefits.However,thesedays,theconstrained environmentalregulationsareforcingindustriestopaysincereattentiontoward wasteminimizationandresourceoptimization.Wasteminimizationisaprocess ofincreasingresourceutilizationandextractingmaximumfromthewastebefore finaldisposal.Withthenewtechnologicalinnovations,theconceptofwasteminimizationcanbedirectlyreferredtoasGreenTechnologyDevelopment,which includesenergygeneration,resourceextraction,pollutionprevention,andrecyclingofresourcesanddisposalwithenergyrecovery.

Thecoreofthisbookisbasedonthebeliefthattransdisciplinaryresearch canbeconsideredastheexecutabledirectiontoachievethesustainable governanceofnaturalresourcesandsolidwastemanagement.Thedominant wastestreams,i.e.electronicwaste(wasteelectricalandelectronicequipment [WEEE]),agro-residuewaste,andindustrialwasteoriginatedfrompetrochemical/fertilizer/textileindustries,havebeencoveredindetailintheChapters3–7 toillustratevariousconventional,emerging,andfuturetechnologiesforthe recoveryofmetalsfromthesewastestreams.

Thegrowingproportionofheavymetalsinsoilandwaterisathreatto humanhealth.Someofthenegativeimpactsofheavymetalsonplantsinclude decreaseofseedgerminationandlipidcontentbycadmium,decreasedenzyme activityandplantgrowthbychromium,theinhibitionofphotosynthesisby copperandmercury,thereductionofseedgerminationbynickel,andthe

reductionofchlorophyllproductionandplantgrowthbylead.Theimpacts onanimalsincludereducedgrowthanddevelopment,cancer,organdamage, nervoussystemdamage,andinextremecases,death.Inaddition,metalsare alsoanineluctablecontributorintheindustrialdevelopment.Globally,scarcity ofheavymetalresourcesisanimportantmatterofconcern,keepinginview theincreasingrateofindustrializationTherefore,recoveryofmetalsfrom waste(industrial/agricultural/electronic)isofsignificantimportancefromthe environmentalaswellasindustrialperspectives.Numerousapproacheshave beenwidelyreportedintheliteratureforrecoveryofmetalsfromcontaminated sites.Adsorptionhasbeenconsideredagoodalternativeforefficientextraction ofmetalsfromindustrialwastewater.Membraneseparation,electrotreatment, photocatalyticprocesses,andabsorptionbyaquaticplantshavealsobeen employedtoremovemetalsandotherpollutantsfromwater.Varioustechniques suchasvitrification,excavation,removalofcontaminatedsoillayer,phytoremediation,andsoilwashingusingsurfactants,acids,alkalis,andchelatingagents havebeeninvestigatedforsoilremediation.Varioushydrometallurgical(leaching,solventextraction,andbiologicalmethods)andpyrometallurgicalprocesses suchascalcinationfollowedbyleachingorroastingathightemperatureshave beenemployedforextractionofheavymetalsfromspentcatalysts,soil,and otherindustrialwastes.Alltheseprocesseshaveshownpotentialinremoving metalsfromindustrialwastes;however,useofhazardouschemicals,secondary pollutionpossibilitybythesechemicals,lessacceptanceofbiologicalprocesses intheenvironment,andhighprocesscostrestricttheiruseonalargescale.

Thisexcogitationisnowassistingresearcherstomovetowardgreener approachessuchaschelationtechnology,ionicliquids(ILs),andothergreen extractants.Anewterm“GreenAdsorption”hasalsobeenintroducedrecently formetalextractionfromwastewater,whichincludeslow-costecofriendly materialsoriginatedfromagriculturalsourcesandby-products(fruits,vegetables,food),agriculturalresidues,andwastes.Severalauthorsemployednatural bentoniteandzeolites,rice/peanuthuskandflyash,bananaandorangepeel,and anaerobicgranularsludgesformetalextraction.Someauthorsalsoemployed modifiedbiopolymeradsorbentsderivedfromchitin,chitosan,andstarchfor metalremovalfromcontaminatedsites.Chelationtechnology,evolvedover thecenturyforbeingusedinmetalintoxication,hasalsoemergedasagreen chemicalengineeringapproachformetalextractionfromcontaminatedsites (soil,wastewater,spentcatalyst)inrecentyears.Itisbelievedthattechnical applicability,operationalsimplicity,andeconomicfeasibilityarethekeyfactors inselectingthemostsuitabletechnologyformetalextraction.

Inthefollowingchaptersofthisbook,thetechnicalapplicabilityofvariousnew greenerapproachesformetalremovalfromsolidwasteandcontaminatedsites willbeidentified.Recentdevelopmentsrelatedtothesenewtechnologiesinorder toaccomplishtheconceptof“GreeningtheWaste”willalsobediscussed.

1 Howdoyoudefinetheterminology“Sustainability”and“Greenchemistry”?

2 ExplainthedimensionsofsustainabilityonthebasisofTBL?

3 Doesthefivedimensionalframeworkdefineadditionalinformationto“Sustainability”?Ifyes,pleaseexplainhow.

4 Explainhowthefourforcemodelillustratesconnectingdotsbetweencurrent USDandthefutureSD.

5 Discusstheconceptof“GreeningtheWaste.”

6 Followingtwodifferentroutesillustratetheformationofmaleicanhydride: a. Oxidationofbenzene: + 9 2 O2 O O O + 2CO2 + 2H2O (Yield: 65%)

b. Oxidationofbut-1-ene: O O O 3H2O (Yield: 55%) + 3O2 +

i.Assumingthateachreactionisperformedinthegasphaseonlyandthat noadditionalchemicalsarerequired,calculate(i)theatomeconomyand (ii)theeffectivemassyieldofbothreactions.YoushouldassumethatO2 , CO2, andH2 Oarenottoxic.

ii.Whichroutewouldyourecommendtoindustry?Outlinethefactors thatmightinfluenceyourdecision.

7 CalculatetheE-factorforthefollowingreaction:

K2 PtCl4 (4.5g) + C2 H4 (∼2g) + HCl (inwater) (8.21g) SnCl2 (40mg) →

K[PtCl3 (C2 H4 )] H2 O (3.86g) + KCl + C2 H4 (unreacted)