IntroductiontoPlasticsEngineering

VijayK.Stokes

ThisWorkisaco-publicationbetweenJohnWiley&SonsLtdandASMEPress

Thiseditionfirstpublished2020

©2020JohnWiley&SonsLtd

ThisWorkisaco-publicationbetweenJohnWiley&SonsLtdandASMEPress

Allrightsreserved.Nopartofthispublicationmaybereproduced,storedinaretrievalsystem,ortransmitted,inanyformorby anymeans,electronic,mechanical,photocopying,recordingorotherwise,exceptaspermittedbylaw.Adviceonhowtoobtain permissiontoreusematerialfromthistitleisavailableathttp://www.wiley.com/go/permissions.

TherightofVijayK.Stokestobeidentifiedastheauthorofthisworkhasbeenassertedinaccordancewithlaw.

RegisteredOffices

JohnWiley&Sons,Inc.,111RiverStreet,Hoboken,NJ07030,USA

JohnWiley&SonsLtd,TheAtrium,SouthernGate,Chichester,WestSussex,PO198SQ,UK

EditorialOffice

TheAtrium,SouthernGate,Chichester,WestSussex,PO198SQ,UK

Fordetailsofourglobaleditorialoffices,customerservices,andmoreinformationaboutWileyproductsvisitusat www.wiley.com.

Wileyalsopublishesitsbooksinavarietyofelectronicformatsandbyprint-on-demand.Somecontentthatappearsinstandard printversionsofthisbookmaynotbeavailableinotherformats.

LimitofLiability/DisclaimerofWarranty

Whilethepublisherandauthorshaveusedtheirbesteffortsinpreparingthiswork,theymakenorepresentationsorwarranties withrespecttotheaccuracyorcompletenessofthecontentsofthisworkandspecificallydisclaimallwarranties,including withoutlimitationanyimpliedwarrantiesofmerchantabilityorfitnessforaparticularpurpose.Nowarrantymaybecreatedor extendedbysalesrepresentatives,writtensalesmaterialsorpromotionalstatementsforthiswork.Thefactthatanorganization, website,orproductisreferredtointhisworkasacitationand/orpotentialsourceoffurtherinformationdoesnotmeanthatthe publisherandauthorsendorsetheinformationorservicestheorganization,website,orproductmayprovideorrecommendations itmaymake.Thisworkissoldwiththeunderstandingthatthepublisherisnotengagedinrenderingprofessionalservices.The adviceandstrategiescontainedhereinmaynotbesuitableforyoursituation.Youshouldconsultwithaspecialistwhere appropriate.Further,readersshouldbeawarethatwebsiteslistedinthisworkmayhavechangedordisappearedbetweenwhen thisworkwaswrittenandwhenitisread.Neitherthepublishernorauthorsshallbeliableforanylossofprofitoranyother commercialdamages,includingbutnotlimitedtospecial,incidental,consequential,orotherdamages.

LibraryofCongressCataloging-in-PublicationData

Names:Stokes,VijayKumar,1939-author.

Title:Introductiontoplasticsengineering/VijayK.Stokes.

Othertitles:Plasticsengineering

Description:Firstedition.|Hoboken,NJ:Wiley,[2020]|Includes bibliographicalreferencesandindex.|

Identifiers:LCCN2018055488(print)|LCCN2019000594(ebook)|ISBN 9781119536543(AdobePDF)|ISBN9781119536529(ePub)|ISBN9781119536574 (hardcover)

Subjects:LCSH:Plastics.|Polymerengineering.

Classification:LCCTA455.P5(ebook)|LCCTA455.P5S7382019(print)|DDC 620.1/923--dc23

LCrecordavailableathttps://lccn.loc.gov/2018055488

CoverDesign:Wiley

CoverImage:(top)courtesyofProfessorJ.Oliveira,UniversityofMinho;(middle)courtesyVijayK.Stokes; (bottom)courtesySABIC

Setin10/12ptTimesLTStdbySPiGlobal,Chennai,India

PrintedintheUKbyBell&BainLtd,Glasgow. 10987654321

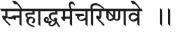

dui biE dOsha bOrsha ka ubi bakO sata dENiE tEi jO pothi apNi ThOldi prOba lE meri Zani ka ubi behTa.

This book is dedicated to my wife Prabha in recognition of over fifty years of loving support.

Contents

SeriesPreface xxix

Preface xxxi

PARTIINTRODUCTION 1

OutlinesforChapters1and2

1IntroductorySurvey 3

1.1Background 3

1.2SynergyBetweenMaterialsScienceandEngineering 4

1.3PlasticsEngineeringasaProcess(thePlasticsEngineeringProcess) 7

1.4TypesofPlastics 9

1.4.1PlasticComposites 9

1.4.2RecyclingofPlastics 10

1.5MaterialCharacteristicsDeterminePartShapes 11

1.5.1StoneasaBuildingMaterial 11

1.5.1.1TheEarlyUseofStone 11

1.5.1.2TheInventionoftheArch 14

1.5.1.3VaultsandDomes 14

1.5.1.4SummaryComments 19

1.5.2CastIronasaBuildingMaterial 19

1.5.3SteelasaBuildingMaterial 20

1.5.3.1SummaryComments 20

1.5.4ShapeSynthesisforPlasticParts 21

1.5.4.1PartComplexityandConsolidation 22

1.5.4.2PlasticHinges 24

1.5.4.3SummaryComments 27

1.6PartFabrication(PartProcessing) 27

1.7PartPerformance 28

1.7.1TheRoleofNumericalMethods 29

1.7.2RapidPrototyping 31

1.8Assembly 32

1.9ConcludingRemarks 33

2EvolvingApplicationsofPlastics 35

2.1Introduction 35

2.2ConsumerApplications 36

2.2.1Clothing 36

2.2.1.1ProtectiveClothingforFirefighters 36

2.2.1.2BulletproofClothing 37

2.2.1.3Hook-and-LoopFasteners 39

2.2.2Shoes 42

2.2.2.1AthleticShoes 42

2.2.2.2Firefighters’Boots 44

2.2.3Toothbrushes 46

2.2.4DisposableRazors 48

2.2.5Eyewear 49

2.2.6ContactLenses 51

2.2.7BottleCaps 51

2.2.8Drip-ProofSpouts 53

2.2.9PlasticTopsforPaperContainers 53

2.2.9.1PlasticTopsforCardboardSaltContainers 54

2.2.9.2PlasticTopsforPaperJuiceCartons 54

2.2.10Toys 56

2.2.11ConsumerAudio 57

2.2.11.1RecordingMedia 58

2.2.11.2AudioSystems 60

2.2.12VacuumCleaners 65

2.2.13SmallandMajorAppliances 65

2.3MedicalApplications 67

2.3.1DripBagsandAccessories 67

2.3.2Syringes 68

2.3.3MedicalImagingEquipment 69

2.3.4PlasticModelsforBodyParts 70

2.4AutomotiveApplications 70

2.4.1Bumpers 71

2.4.2Fenders 72

2.4.3ThrottleBodies 72

2.4.4ExhaustManifolds 73

2.4.5GasTanks 74

2.4.6DoorModules 75

2.4.7BootsforConstant-VelocityJoints 76

2.5InfrastructureApplications 77

2.5.1Glazing 77

2.5.2SecurityGlazing 78

2.5.3WaterManagementSystems 79

2.5.4Large-DiameterPiping 83

2.5.5PowerLinePoles 84

2.5.6Bridges 86

2.5.7CompositeSheetPiling 86

2.6WindEnergy 88

2.7AirlineApplications 90

2.8OilExtraction 91

2.9Mining 92

2.10ConcludingRemarks 93

PARTIIMECHANICS 95

OutlinesforChapters3through8

3IntroductiontoStressandDeformation 97

3.1Introduction 97

3.2SimpleMeasuresforLoadTransferandDeformation 97

3.3*StrainsasDisplacementGradients 99

3.4*CouplingBetweenNormalandShearStresses 101

3.5*CouplingBetweenNormalandShearStrains 102

3.6**Two-DimensionalStress 103

3.7ConcludingRemarks 105

4ModelsforSolidMaterials 107

4.1Introduction 107

4.2SimpleModelsfortheMechanicalBehaviorofSolids 107

4.3ElasticMaterials 108

4.4*AnisotropicMaterials 109

4.4.1*OrthotropicMaterials 109

4.5ThermoelasticEffects 111

4.6Plasticity 113

4.7ConcludingRemarks 116

5SimpleStructuralElements 119

5.1Introduction 119

5.2BendingofBeams 119

5.3DeflectionofPrismaticBeams 123

5.3.1DeflectionofaCantileverDuetoanEndLoad 123

5.3.2DeflectionofaSimplySupportedBeamDuetoaCentralLoad 124

5.3.3DeflectionofaSimplySupportedBeamDuetoaNoncentralLoad 125

5.4TorsionofThin-WalledCircularTubes 127

5.5TorsionofThinRectangularBarsandOpenSections 129

5.6TorsionofThin-WalledTubes 130

5.7*TorsionofMulticellularSections 131

5.8IntroductiontoElasticStability 133

5.8.1ConceptofStability 133

5.8.2StabilityofaHingedRigidBar 134

5.8.3*Spring-SupportedRigidBar:StabilityAbovetheCriticalLoad 136

5.9*ElasticStabilityofanAxiallyLoadedColumn 138

5.9.1BucklingLoadforaPin-JointedColumn 139

5.9.2BucklingofaColumnFixedatOneEnd 140

5.10Twist-BendBucklingofaCantilever 142

5.11StressConcentration 142

5.12TheRoleofNumericalMethods 145

5.13ConcludingRemarks 145

6ModelsforLiquids 147

6.1Introduction 147

6.2SimpleModelsforHeatConduction 147

6.2.1Steady-StateHeatConduction 148

6.2.2TransientHeatConduction 149

6.3KinematicsofFluidFlow 149

6.3.1MeasuresforDeformationRates 150

6.4EquationsGoverningOne-DimensionalFluidFlow 151

6.4.1One-DimensionalContinuityEquation 152

6.4.2BalanceofLinearMomentuminOneDimension 153

6.4.3*EnergyBalanceinOneDimension 154

6.5SimpleModelsfortheMechanicalBehaviorofLiquids 157

6.5.1NewtonianLiquids 157

6.5.2Non-NewtonianLiquids 157

6.5.3Temperature-DependentViscosityModels 158

6.6SimpleOne-DimensionalFlows 159

6.6.1Surface-DrivenOne-DimensionalSteadyFlow 159

6.6.2HeatGenerationinOne-DimensionalCouetteFlow 160

6.6.3*One-DimensionalCouetteFlowwithTemperature-DependentViscosity 161

6.6.3.1LinearVariationofViscositywithTemperature 161

6.6.4*DevelopmentofCouetteFlow 162

6.6.5Pressure-DrivenOne-DimensionalSteadyFlow 162

6.6.6Pressure-DrivenRadialFlow 164

6.6.6.1ContinuityEquationforRadialFlow 165

6.6.6.2BalanceofLinearMomentuminRadialFlow 166

6.6.6.3IncompressibleNewtonianRadialFlow 168

6.7PolymerRheology 171

6.7.1DieSwell 171

6.7.2TubelessSiphon 172

6.7.3VibrationofaBallDroppedinaLiquid 172

6.7.4WeissenbergEffect 173

6.8ConcludingRemarks 173

7LinearViscoelasticity 175

7.1Introduction 175

7.2PhenomenologyofViscoelasticity 176

7.2.1StressRelaxation 176

7.2.2Creep 176

7.3LinearViscoelasticity 179

7.3.1ConstitutiveEquations 180

7.3.2Stress-RelaxationIntegralForm 181

7.3.3CreepIntegralForm 181

7.3.4*RelationshipBetweentheRelaxationModulusandtheCreepCompliance 181

7.4SimpleModelsforStressRelaxationandCreep 182

7.4.1ContinuumElasticElement(ElasticSpring) 183

7.4.2ContinuumViscousElement(Dashpot) 183

7.4.3MaxwellModel 184

7.4.3.1StressRelaxation 185

7.4.3.2Creep 185

7.4.4Kelvin-VoigtModel 185

7.4.4.1StressRelaxation 186

7.4.4.2Creep 187

7.4.5StandardThree-ParameterModel 187

7.5ResponseforConstantStrainRates 189

7.5.1MaxwellModel 189

7.5.2Kelvin–VoigtModel 190

7.5.3StandardThree-ParameterModel 190

7.6*SinusoidalShearing 190

7.6.1DynamicMechanicalAnalysis(DMA) 191

7.6.1.1DMACurvesforThree-ParameterModel 192

7.6.2*EnergyStorageandLoss 192

7.7IsothermalTemperatureEffects 193

7.7.1ThermorheologicallySimpleMaterials 194

7.7.2PhysicalInterpretationforTime-TemperatureShift 195

7.8*VariableTemperatureHistories 195

7.9*CoolingofaConstrainedBar 196

7.10ConcludingRemarks 196

8StiffeningMechanisms 199

8.1Introduction 199

8.2ContinuousFiberReinforcement 199

8.2.1Fiber-MatrixInterphase 202

8.3DiscontinuousFiberReinforcement 203

8.3.1LoadTransferinaDiscontinuousFiber 203

8.3.2DiscontinuousFiberComposite 208

8.3.3ReinforcingFillers 209

8.3.3.1SphericalFillers 209

8.3.3.2CylindricalFillers 210

8.4TheHalpin–TsaiEquations 211

8.5ReinforcingMaterials 211

8.5.1ContinuousFibers 211

8.5.2ChoppedFibers 212

8.5.3Flakes 212

8.5.4Particulates 212

8.5.5RubberToughening 212

8.6ConcludingRemarks 213

FurtherReading 213

PARTIIIMATERIALS 215

OutlinesforChapters9through15

9IntroductiontoPolymers 217

9.1Introduction 217

9.2Thermoplastics 217

9.2.1Polyethylene 217

9.2.1.1LinearPolyethylene 218

9.2.1.2BranchedPolyethylene 220

9.2.2Polypropylene 221

9.2.2.1Tacticity 221

9.2.3 Cis and Trans Isomers 223

9.2.4Polyisoprene 223

9.2.5HomopolymersandCopolymers 224

9.2.6ChainEntanglement 226

9.3MolecularWeightDistributions 226

9.4Thermosets 227

9.4.1Phenolics 227

9.4.2Elastomers 227

9.5ConcludingRemarks 227

10ConceptsfromPolymerPhysics 229

10.1Introduction 229

10.2ChainConformations 229

10.2.1*FreelyJointedChainModels 230

10.2.2*EffectofBondAngleRestriction 231

10.2.3*EffectofStericRestrictions 232

10.3AmorphousPolymers 234

10.3.1PhenomenologyoftheGlassTransition 234

10.3.2PhysicalAging 236

10.3.3ConceptofFreeVolume 236

10.3.4EffectofPressureonGlassTransition 238

10.3.5EffectofChemicalStructureonGlassTransition 239

10.3.6EffectofMolecularWeightonGlassTransition 240

10.4SemicrystallinePolymers 240

10.4.1StructureofPolymerCrystals 240

10.4.2MeltingPhenomenologyofSemicrystallinePolymers 242

10.4.3DegreeofCrystallinity 242

10.5LiquidCrystalPolymers 243

10.5.1LiquidCrystalPhasesandTransitions 244

10.5.2PolymerLiquidCrystals 245

10.6ConcludingRemarks 245

11Structure,Properties,andApplicationsofPlastics 247

11.1Introduction 247

11.2ResinGrades 248

11.3AdditivesandModifiers 248

11.3.1Stabilizers 248

11.3.1.1UVStabilizers 249

11.3.1.2Antioxidants 249

11.3.1.3ThermalStabilizers 249

11.3.1.4FireRetardants 249

11.3.2Modifiers 250

11.3.2.1Colorants 250

11.3.2.2Fillers 250

11.3.2.3ReinforcingFibers 250

11.3.2.4ImpactModifiers 251

11.3.2.5Lubricants 251

11.3.2.6Plasticizers 251

11.4Polyolefins 251

11.4.1Polyethylene 251

11.4.1.1High-StrengthPolyethyleneFibers 253

11.4.2Polypropylene 253

11.4.3Polybutylene 254

11.5VinylPolymers 254

11.5.1Poly(VinylChloride) 254

11.5.1.1Plastisol 255

11.5.2Polyacrylonitrile 255

11.5.3Polystyrene 256

11.5.3.1Poly(Styrene-co-Acrylonitrile)(SAN) 256

11.5.3.2Poly(Styrene-co-MaleicAnhydride)(SMA) 257

11.5.4Poly(MethylMethacrylate) 257

11.5.5Poly(Ethylene-co-VinylAlcohol) 257

11.6High-PerformancePolymers 258

11.6.1Polyoxymethylene 258

11.6.2Poly(PhenyleneOxide) 259

11.6.3Polyesters 259

11.6.4Polycarbonate 260

11.6.5Polyamides 261

11.6.5.1SemicrystallinePolyamides 261

11.6.5.2AmorphousPolyamides 262

11.6.6Fluoropolymers 263

11.6.6.1CopolymersofFluoropolymers 264

11.7High-TemperaturePolymers 265

11.7.1Poly(PhenyleneSulfide) 265

11.7.2Polyetherimide 266

11.7.3Poly(Amide-Imide) 266

11.7.4Polysulfones 267

11.7.4.1Polysulfone 267

11.7.4.2Polyethersulfone 268

11.7.4.3Polyphenylsulfone(Polyarylethersulfone) 268

11.7.5Polyketones 268

11.7.6LiquidCrystallinePolyesters 269

11.7.7AromaticPolyamides(Aramids) 270

11.7.8Polybenzimidazole 271

11.8CyclicPolymers 271

11.9ThermoplasticElastomers 272

11.9.1Polypropylene-EPDMTPE 272

11.9.2ThermoplasticCopolyesterTPE 272

11.9.3ThermoplasticUrethane(TPU) 273

11.10HistoricalNotes 273

11.11ConcludingRemarks 274

12BlendsandAlloys 277

12.1Introduction 277

12.2Blends 278

12.2.1Acrylonitrile-Butadiene-Styrene 278

12.2.2Acrylonitrile-Styrene-Acrylate 279

12.2.3ABS/PVCBlends 279

12.2.4Nylon/ABSBlends 279

12.2.5Polycarbonate/ABSBlends 279

12.2.6Poly(PhenyleneOxide)/PolystyreneBlends 280

12.2.7Polycarbonate/PBTBlends 280

12.2.8Nylon/PPOBlends 281

12.2.9High-TemperatureBlends 281

12.3HistoricalNotes 282

12.4ConcludingRemarks 282

13ThermosetMaterials 285

13.1Introduction 285

13.2ThermosettingResins 285

13.2.1Phenolics 286

13.2.1.1ResoleResins 287

13.2.1.2NovolakResins 287

13.2.1.3ApplicationsofPhenolics 288

13.2.2Urea-Aldehyde-BasedResins 288

13.2.2.1Urea-Formaldehyde-BasedResin 288

13.2.2.2Melamine-Aldehyde-BasedResins 289

13.2.2.3ApplicationsofUrea-andMelamine-AldehydeResins 291

13.2.3AllylDiglycolCarbonate(CR-39) 291

13.2.4ThermosettingPolyesters 291

13.2.5VinylEsters 293

13.2.5.1ApplicationsofPolyestersandVinylEsters 293

13.2.6Epoxies 293

13.2.6.1ApplicationsofEpoxies 294

13.2.7SheetandBulkMoldingCompounds 294

13.2.8Polyurethanes 295

13.2.8.1ApplicationsofPolyurethanes 296

13.3High-TemperatureThermosets 296

13.3.1CyanateEsters 296

13.3.2Bismaleimides 300

13.3.3Polyimides 302

13.3.3.1PMR-15 302

13.3.3.2LaRCRP-46 303

13.3.4Poly(PhenyleneBenzobisoxazole) 303

13.4ThermosetElastomers 304

13.4.1DieneElastomers 304

13.4.1.1Polyisoprene(NaturalRubber) 304

13.4.1.2Polychloroprene(Neoprene) 305

13.4.1.3Polybutadiene 306

13.4.1.4Poly(Isobutylene-co-Isoprene)(ButylRubber) 306

13.4.1.5Poly(Styrene-co-Butadiene)(SBRRubber) 307

13.4.1.6Poly(Acrylonitrile-co-Butadiene)(NBRRubber) 307

13.4.2Ethylene-PropyleneCopolymer-BasedElastomers 308

13.4.2.1Ethylene-PropyleneRubber(EPR) 308

13.4.2.2Ethylene-Propylene-DieneMonomer(EPDM)Rubber 308

13.4.2.3SiliconeElastomers 308

13.5HistoricalNotes 309

13.6ConcludingRemarks 311

14PolymerViscoelasticity 313

14.1Introduction 313

14.2PhenomenologyofPolymerViscoelasticity 313

14.2.1RelaxationModuliatConstantTemperature 314

14.2.2RelaxationModuliatConstantTime 315

14.2.3RelaxationModuliofSeveralResins 316

14.2.3.1EffectofMolecularWeight:RelaxationModuliofPolystyrene 316

14.2.3.2EffectsofCrystallinity:RelaxationModuliofSeveralResins 317

14.2.3.3EffectsofPlasticizers:RelaxationModuliofPVC 318

14.3Time-TemperatureSuperposition 319

14.3.1ExperimentalCharacterizationoftheMasterCurve 319

14.3.2CorrectionstotheTime-TemperatureCorrespondenceRelations 321

14.3.3TheWLFEquation 322

14.3.4PhysicalInterpretationfortheTime-TemperatureShift 322

14.3.5Summary 322

14.4SinusoidalOscillatoryTests 323

14.4.1DMADataforHigh-PerformanceThermoplastics 324 14.5ConcludingRemarks 328

15MechanicalBehaviorofPlastics 331

15.1Introduction 331

15.2DeformationPhenomenologyofPolycarbonate 332

15.2.1Constant-Displacement-RateTensileTest 333

15.2.2*ConsidèreTreatmentofYield 336

15.2.3*UniaxialExtensionofWidePCSpecimens 338

15.2.4*DefinitionandMeasurementofInitialYielding 341

15.2.5*MechanicalBehaviorofNeckedPC 342

15.2.6*CompositeStress-StretchCurveforPC 343

15.2.7*CreepofPCatHighLoads 343

15.2.8*Deformation-RateandTemperatureEffects 346

15.2.9*BiaxialStretchingofClampedCircularPCSheetsbyFluidPressure 349

15.2.10ThermallyInducedRecoveryfromaMechanicallyYieldedState 355

15.2.11Large-DeformationApplications 358

15.3TensileCharacteristicsofPEI 360

15.3.1Constant-Displacement-RateTensileTest 360

15.3.2*Deformation-RateandTemperatureEffects 362

15.4DeformationPhenomenologyofPBT 363

15.4.1Constant-Displacement-RateTensileTest 363

15.4.2*DefinitionandMeasurementofInitialYieldinginPBT 364

15.4.3*MechanicalBehaviorofNeckedPBT 366

15.4.4*CompositeStress-StretchCurveforPBT 367

15.4.5*Deformation-RateandTemperatureEffects 368

15.4.6*Post-YieldBehaviorPriortoNecking 371

15.4.7*LoadHistoryandFinalPermanentDeformation 372

15.4.8Large-DeformationApplications 375

15.5Stress-DeformationBehaviorofSeveralPlastics 376

15.5.1Thermoplastics 376

15.5.2Thermosets 380

15.5.3ThermoplasticElastomers 383

15.6PhenomenonofCrazing 387

15.7*MultiaxialYield 393

15.7.1MaximumPrincipalStressTheory 394

15.7.2MaximumShearStressTheory 394

15.7.3MaximumPrincipleStrainTheory 396

15.7.4StrainEnergyofDistortionTheory 396

15.7.5ComparisonofFailureTheories 399

15.7.6FailureTheoriesforPlastics 400

15.8*Fracture 401

15.9Fatigue 403

15.9.1TheS-NCurve 404

15.9.2*Fatigue-CrackPropagation 406

15.9.3TheRoleofHystereticHeating 412

15.10ImpactLoading 412

15.10.1InstrumentedImpactTest 412

15.10.2Ductile-BrittleTransition 414

15.11Creep 419

15.12Stress-DeformationBehaviorofThermosetElastomers 419

15.13ConcludingRemarks 420

FurtherReading 420

PARTIVPARTPROCESSINGANDASSEMBLY 421 OutlinesforChapters16through21

16ClassificationofPartShapingMethods 423

16.1Introduction 423

16.2PartFabrication(Processing)MethodsforThermoplastics 424

16.2.1ProcessesUsingDouble-SidedMolds 426

16.2.2ProcessesUsingSingle-SidedMolds 426

16.3EvolutionofPartShapingMethods 429

16.4EffectsofProcessingonPartPerformance 431

16.5BulkProcessingMethodsforThermoplastics 439

16.5.1FiberSpinning 439

16.5.2FilmBlowing 439

16.5.3SheetExtrusion 439

16.5.4ProfileExtrusion 439

16.6PartProcessingMethodsforThermosets 440

16.6.1ProcessesUsingDouble-SidedMolds 440

16.6.1.1ProcessesUsingPowderResin 441

16.6.1.2ProcessesUsingSheetandBulkMoldingCompounds 442

16.6.1.3ProcessesUsingLiquidResin 442

16.6.2ProcessesUsingSingle-SidedMolds 442

16.7PartProcessingMethodsAdvancedComposites 442

16.7.1Pultrusion 442

16.7.2FilamentWinding 442

16.7.3LaminatedComposites 443

16.7.3.1Prepregs 443

16.7.3.2VacuumBagConsolidation 443

16.7.3.3CompressionMolding 443

16.8ProcessingMethodsforRubberParts 443

16.8.1RubberCompounding 443

16.8.2DryRubberCompounding 444

16.8.2.1MoldingProcesses 444

16.8.2.2Extrusion 444

16.8.2.3Calendering 444

16.8.2.4ReinforcedandCoatedRubberSheet 444

16.8.3WetRubberPartFabrication 444

16.8.3.1DipMolding 444

16.8.3.2DipCoating 444

16.9ConcludingRemarks 445

17InjectionMoldingandItsVariants 447

17.1Introduction 447

17.2ProcessElements 447

17.2.1MoldFilling 453

17.2.1.1FillingofanOff-CenterGatedMoldCavity 453

17.2.1.2FillingofaDouble-GatedCavity 453

17.2.1.3EffectsofMaterialDifferencesonFlowinaDouble-GatedCavity 454

17.2.1.4EffectsofSlitsinaMoldCavity 455

17.2.1.5FlowinaDouble-GatedCavitywithInserts 457

17.2.2PartThickness 458

17.2.3MoldClampForces 460

17.2.4MoldCooling 460

17.3FountainFlow 462

17.3.1MeldSurfacesandKnitLines 465

17.3.1.1Head-onWeldingofTwoFlowFronts 465

17.3.1.2MeldingofFlowFrontsAroundaPin 467

17.3.1.3EffectsofGates,PartGeometries,andMaterialsonKnitLines 469

17.3.2TheRoleofNumericalSimulation 472

17.4PartMorphology 473

17.5PartDesign 475

17.5.1PartStiffeningMechanisms 475

17.5.2Molding-DrivenFeatures 476

17.5.2.1PartThicknessDistribution 476

17.5.2.2PartShrinkage 478

17.5.2.3PartWarpage 480

17.5.2.4DraftAngles 482

17.5.2.5BossGeometries 482

17.5.2.6Molded-InInserts 484

17.5.3PlasticHinges 485

17.6Large-VersusSmall-PartMolding 493

17.6.1Thin-WallMolding 493

17.6.2Micromolding 496

17.7MoldingPractice 504

17.7.1Two-PlateCold-RunnerMold 505

17.7.2Three-PlateCold-RunnerMold 508

17.7.3MoldsforPartswithUndercuts 508

17.7.4MoldswithCollapsibleCores 508

17.7.5Hot-RunnerMolds 513

17.7.6Sprues,Runners,andGates 515

17.7.6.1RunnerConfigurations 515

17.7.6.2ImbalancesfromFlowAsymmetry 518

17.7.7GateTypes 520

17.7.7.1SprueGate 521

17.7.7.2EdgeGate 521

17.7.7.3FanGate 521

17.7.7.4DiaphragmGate 522

17.7.8Jetting 522

17.7.9MoldVenting 523

17.7.10MoldCooling 525

17.7.11SummaryComments 525

17.8VariantsofInjectionMolding 526

17.8.1MethodsforReducingInjectionPressure 526

17.8.1.1SequentialGating 526

17.8.1.2Injection-CompressionMolding 527

17.8.2StructuralFoamMolding 529

17.8.2.1AlternativeFoamMoldingProcesses 533

17.8.2.2Advantages,Disadvantages,andApplications 534

17.8.3MicrocellularFoamMolding 535

17.8.4MultimaterialMolding 538

17.8.4.1CoinjectionMolding 538

17.8.4.2Overmolding 538

17.8.5HollowParts 540

17.8.5.1Fusible-CoreMolding 540

17.8.5.2Gas-AssistedInjectionMolding 541

17.8.5.3SummaryComments 548

17.8.6KnitandMeldLineEstheticsandIntegrity 549

17.8.6.1Multiple-Live-FeedInjectionMolding 549

17.8.6.2Push-PullInjectionMolding 550

17.8.7In-MoldDecorationandLamination 552

17.9ConcludingRemarks 553

References 553

18DimensionalStabilityandResidualStresses 555

18.1Introduction 555

18.2ProblemComplexity 556

18.3ShrinkagePhenomenology 556

18.4Pressure-TemperatureVolumetricData 563

18.4.1QuantificationofPVTData 564

18.5SimpleModelforHowProcessingAffectsShrinkage 567

18.5.1ConstantPacking-PressureHistory 569

18.5.2EffectofGateFreeze-Off 572

18.5.3EffectofPackingDuration 576

18.5.4SummaryComments 577

18.6*SolidificationofaMoltenLayer 578

18.6.1*FreezingofaMoltenLayer 578

18.6.2*FluidtoElastic-SolidFreezingModel 579

18.6.3*NumericalExamplefora3-mm-ThickPlaque 581

18.6.4*EffectivePressureasanIndependentVariable 583

18.6.5*SummaryComments 585

18.7**ViscoelasticSolidificationModel 585

18.7.1ViscoelasticMaterialModel 585

18.7.2TemperatureDistributioninaSolidifyingMelt 586

18.7.3EvolutionofShrinkageandResidualStresses 588

18.7.4EffectsofPacking-PressureLevel 590

18.7.5EffectofPacking-PressureDuration 593

18.7.6EffectofGateFreeze-OffTime 594

18.7.7SummaryComments 599

18.8**WarpageInducedbyDifferentialMold-SurfaceTemperatures 602

18.8.1TemperatureDistributioninaSolidifyingMelt 602

18.8.2ConstantPacking-PressureLevel 602

18.8.3EffectofPacking-PressureLevel 604

18.8.4EffectofGateFreeze-Off 605

18.8.5SummaryComments 606

18.9ConcludingRemarks 609

19AlternativestoInjectionMolding 615

19.1Introduction 615

19.2Extrusion 615

19.2.1FiberSpinning 616

19.2.2FilmBlowing 618

19.2.3SheetExtrusion 618

19.2.3.1CastFilmExtrusion 619

19.2.3.2CalenderedSheetExtrusion 620

19.2.4ProfileExtrusion 620

19.2.4.1OpenProfiles 621

19.2.4.2ClosedProfiles 624

19.2.5Coating 626

19.3BlowMolding 627

19.3.1ExtrusionBlowMolding 627

19.3.1.1ParisonProgramming 629

19.3.1.2Deep-DrawBlowMolding 631

19.3.1.3FlashlessBlowMoldingofTubularParts 633

19.3.1.4MultilayerExtrusionBlowMolding 634

19.3.1.5BlowMoldingwithEncasedModules 637

19.3.2InjectionBlowMolding 640

19.3.3PartStiffening 642

19.3.4SummaryComments 642

19.4RotationalMolding 643

19.4.1Rock-and-RollRotationalMolding 650

19.4.2AdvantagesandLimitations 651

19.4.3PartMorphology 654

19.4.4PartDesign 655

19.4.4.1ApproachestoPartStiffening 655

19.5Thermoforming 659

19.5.1VacuumForming 659

19.5.2PressureForming 662

19.5.3Plug-AssistedThermoforming 662

19.5.4Twin-SheetForming 665

19.5.5AdvantagesandLimitations 667

19.5.6PartStiffening 667

19.5.7MechanicalForming 668

19.6ExpandedBeadandExtrudedFoam 669

19.6.1ExpandedBeadFoamMolding 669

19.6.2ExtrudedFoam 670

19.73DPrinting 670

19.8ConcludingRemarks 672

20FabricationMethodsforThermosets 675

20.1Introduction 675

20.2GelPointandCuring 675

20.2.1ShelfLifeofPrecursors 678

20.3CompressionMolding 678

20.3.1CompressionMoldingofThermoplastics 680

20.4TransferMolding 681

20.5InjectionMolding 681

20.5.1Injection-CompressionMolding 683

20.6ReactionInjectionMolding(RIM) 683

20.6.1ReinforcedReactionInjectionMolding(RRIM) 684

20.6.2StructuralReactionInjectionMolding(SRIM) 685

20.7OpenMoldForming 685

20.8FabricationofAdvancedComposites 686

20.8.1Pultrusion 687

20.8.2FilamentWinding 688

20.8.3LaminatedComposites 692

20.8.3.1Prepregs 693

20.8.3.2VacuumBagConsolidation 693

20.8.3.3CompressionMolding 693

20.8.3.4PressureBagMolding 693

20.8.3.5Liquid-ResinTransferMolding 694

20.8.3.6SandwichStructureswithPrepregSkins 697

20.9FabricationofRubberParts 698

20.9.1RubberCompounding 699

20.9.2DryRubberPartFabrication 699

20.9.2.1MoldingProcesses 699

20.9.2.2Extrusion 699

20.9.2.3Calendering 700

20.9.2.4ReinforcedandCoatedRubberSheet 700

20.9.3WetRubberPartFabrication 700

20.9.3.1DipMolding 701

20.9.3.2DipCoating 703

20.9.4ManufactureofReinforcedRubberParts 703

20.9.4.1Tires 703

20.9.4.2ConveyorBelts 708

20.9.4.3PressureHoses 708

20.10ConcludingRemarks 708

21JoiningofPlastics 711

21.1Introduction 711

21.2ClassificationofJoiningMethods 712

21.3MechanicalFastening 713

21.3.1SnapFits 713

21.3.2UseofScrews 715

21.4AdhesiveBonding 721

21.4.1SolventBonding 722

21.5Welding 722

21.6ThermalBonding 723

21.6.1Hot-GasWelding 723

21.6.2ExtrusionWelding 723

21.6.3Hot-Tool(Hot-Plate)Welding 723

21.6.3.1WeldMorphology 729

21.6.3.2WeldStrength 732

21.6.4InfraredWelding 737

21.6.5LaserWelding 738

21.7FrictionWelding 741

21.7.1SpinWelding 742

21.7.2VibrationWelding 742

21.7.2.1WeldMorphology 746

21.7.2.2WeldStrength 749

21.7.3OrbitalWelding 753

21.7.4UltrasonicWelding 753

21.7.4.1UltrasonicStaking,SpotWelding,Swaging,Insertion,and Embedding 756

21.8ElectromagneticBonding 762

21.8.1Resistance(Implant)Welding 762

21.8.2InductionWelding 763

21.8.3DielectricWelding 770

21.9ConcludingRemarks 770

PARTVMATERIALSYSTEMS 771

OutlinesforChapters22through25

22Fiber-FilledMaterialMaterials–MaterialswithMicrostructure 773

22.1Introduction 773

22.2FiberTypes 773

22.3ProcessingIssues 774

22.4MaterialComplexity 774

22.5TensileandFlexuralModuli 780

22.5.1HomogeneousBarinTensionandBending 780

22.5.2NonhomogeneousBarinTension 781

22.5.3BendingofNonhomogeneousBarintheLowerStiffnessMode 781

22.5.4BendingofNonhomogeneousBarintheHigherStiffnessMode 783

22.6Short-Fiber-FilledSystems 784

22.6.1TensileModulus 785

22.6.1.1TestProcedures 785

22.6.1.2DirectionalandSpatialModulusVariation 787

22.6.1.3RepeatabilityofModulusData 790

22.6.1.4EffectsofPlaqueThicknessontheTensileModulus 791

22.6.1.5EffectsofInjectionSpeedontheTensileModulus 799

22.6.2TensileandFlexuralStrength 801

22.6.2.1TestProcedures 803

22.6.2.2DirectionalTensileandFlexuralStrengths 805

22.6.2.3VariationsinTensileandFlexuralStrengths 808

22.6.3EffectsofFiberAspectRatio 812

22.6.4EffectsofMatrixResin 813

22.6.5SummaryofMechanicalCharacteristicsofShort-FiberSystems 815

22.7Long-FiberFilledSystems 817

22.7.1TensileModulus 819

22.7.1.1TestProcedures 819

22.7.1.2TensileandFlexuralTests 820

22.7.1.3StrengthVariationStudy 822

22.7.1.4In-PlaneTensileModulusVariations 822

22.7.2SpatialandDirectionalVariationsoftheTensileModulus 826

22.7.3FlowandCross-FlowMechanicalPropertiesofInjection-MoldedPlaques 828

22.7.4VariationsinStrength 831

22.7.5MechanicalPropertiesforDesign 832

22.8*FiberOrientation 833

22.8.1*OrientationofaSingleFiber 833

22.8.2*FiberOrientationDistributionFunction 835

22.8.3**OrientationTensors 836

22.8.4*FiberOrientationMeasurement 839

22.8.4.1DirectMeasurement 839

22.8.4.2Through-ThicknessVariationsofOrientationTensorComponents 841

22.8.4.3IndirectMeasurement 844

22.8.5**FiberOrientationModels 846

22.8.5.1Jeffery’sModel 847

22.8.5.2Dinh–ArmstrongModel 848

22.8.5.3Folgar–TuckerModel 850

22.8.6**FiberOrientationPrediction 851

22.9ConcludingRemarks 851

23StructuralFoams–MaterialswithMillistructure 853

23.1Introduction 853

23.2MaterialComplexity 855

23.3FoamsasNonhomogeneousContinua 856

23.3.1NonhomogeneousBarinTension 856

23.3.2BendingofaNonhomogeneousBarintheStiffMode 857

23.3.3BendingofaNonhomogeneousBarinaReducedStiffnessMode 858

23.4EffectiveBendingModulusforThin-WalledPrismaticBeams 860

23.4.1I-SectionBeam 862

23.4.2T-SectionBeam 862

23.5Skin-CoreModelsforStructuralFoams 863

23.5.1Four-ParameterModel 863

23.5.2Three-ParameterModel 864

23.6StiffnessandStrengthofStructuralFoams 866

23.6.1TestProcedureforAcquiringStiffnessandStrengthData 867

23.6.2Plaque-to-PlaqueandIn-PlaqueVariationsofMaterialProperties 868

23.6.3EffectofDensityonMechanicalProperties 873

23.6.4DependenceofMechanicalPropertiesonPlaqueThickness 875

23.6.5SummaryComments 877

23.7TheAverageDensityandtheEffectiveTensileandFlexuralModuliofFoams 879

23.7.1TestProcedure 879

23.7.2In-PlaneDensityVariations 881

23.8DensityandModulusVariationCorrelations 884

23.8.1Density-ModulusCorrelationfor6.35-mmThickFoam 884

23.8.2Density-ModulusCorrelationfor4-mmThickFoam 886

23.9FlexuralModulus 887

23.10**TorsionofNonhomogeneousBars 890

23.10.1**BasicEquationsforModifiedSaintVenant’sTheory 891

23.10.2**TorsionofThin-WalledRectangularBars 893

23.10.3**TorsionofThin-WalledOpenPrismaticSections 895

23.10.4**TorsionofThin-WalledTubes 895

23.11ImplicationsforMechanicalDesign 898

23.12ConcludingRemarks 899

24RandomGlassMatComposites–MaterialswithMacrostructure 901

24.1Introduction 901

24.2GMTProcessing 901

24.3ProblemComplexity 904

24.4EffectiveTensileandFlexuralModuliofNonhomogeneousMaterials 906

24.4.1TensileTest 906

24.4.2Three-PointFlexuralTest 908

24.5InsightsfromModelMaterials 909

24.5.1ModelMaterialwithSinusoidallyVaryingModulus 909

24.5.1.1EffectiveTensileModulus 909

24.5.1.2EffectiveFlexuralModulus 911

24.5.1.3EffectofGaugeLengthonModulusDistributionMeasurement 913

24.5.2ModelMaterialwithRectangularWaveModulusVariation 918

24.5.3SummaryofLessonsLearnedfromModelMaterials 919

24.6CharacterizationoftheTensileModulus 921

24.6.1Cross-Machine-DirectionTensileModuli 921

24.7CharacterizationoftheTensileStrength 924

24.7.1TestProcedure 924

24.7.2Machine-DirectionTensileModulusandStrengthData 925

24.7.3Cross-Machine-DirectionTensileModulusandStrengthData 929

24.7.4ComparisonofMachine-andCross-MachineDirectionStrengthData 932

24.8StatisticalCharacterizationoftheTensileModulusExperimentalData 934

24.8.1HistogramsforTensileModulusData 935

24.8.2*MomentsoftheTensileModulusDistributions 935

24.8.3ProbabilityDensityFunctionfortheTensileModulus 940

24.8.4HigherOrderMoments 941

24.9StatisticalPropertiesofTensileModulusDataSets 943

24.9.1CorrelationBetweentheLeftandRightModuli 943

24.9.2LinearCombinationofTwoIndependentRandomVariables 944

24.10Gauge-LengthEffectsandLarge-ScaleMaterialStiffness 946

24.10.1SampleSize:TheoreticalConsiderations 947

24.10.2SampleSize:NumericalExperiments 948

24.11MethodologyforPredictingtheStiffnessofParts 951

24.11.1*EffectiveStructuralStiffness 957

24.11.2NumericalProcedure 959

24.11.3SomeNumericalResults 960

24.12*StatisticalApproachtoStrength 962

24.12.1*StateofMaterialLoading 962

24.12.2*InterpretationofMeasuredStrains:LeftandRightModuli 963

24.12.3*CorrelationofStrengthwithTensileModulus 964

24.12.4*FailureofLongDog-BoneTensileSamples 965

24.12.5*CorrectionsfortheRandomnessoftheStressField 967

24.12.6SummaryComments 968

24.13ImplicationsforMechanicalDesign 969

24.14ConcludingRemarks 969

25AdvancedComposites–MaterialswithWell-DefinedReinforcementArchitectures 973

25.1Introduction 973

25.2Resins,Fibers,andFabrics 974

25.2.1MatrixResins 974

25.2.2ReinforcingFibers 974

25.2.2.1GlassFibers 974

25.2.2.2CarbonFibers 975

25.2.2.3AramidFibers 976

25.2.2.4PolyethyleneFibers 976

25.2.2.5NylonFibers 976

25.2.3ReinforcingTapesandFabrics 976

25.3AdvancedComposites 977

25.3.1PultrudedCompositeSections 977

25.3.2Filament-WoundComposites 977

25.3.3LaminatedComposites 981

25.3.3.1MechanicalPropertiesofaLaminae 981

25.3.3.2MechanicalPropertiesofLaminaeStacks 982

25.3.3.3AnalysisofLaminateStructures 983

25.3.3.4DefectsandFailureModes 984

25.3.4ResinTransferMoldedComposites 985

25.3.5SandwichStructures 987

25.3.5.1DefectsandFailureModes 987

25.3.6SummaryComments 989

25.4Rubber-BasedComposites 990

25.4.1Tires 990

25.4.1.1AutomotiveTires 990

25.4.1.2DeformationofTires 992

25.4.1.3TreadDesign 995

25.4.1.4LargeHeavy-DutyTires 999

25.4.2ReinforcedRubberConveyorBelts 1000

25.4.3PressureHoses 1003

25.4.4SummaryComments 1008

25.5ConcludingRemarks 1008

Index 1011

SeriesPreface

TheWiley-ASMEPressSeriesinMechanicalEngineeringbringstogethertwoestablishedleadersin mechanicalengineeringpublishingtodeliverhigh-quality,peer-reviewedbookscoveringtopicsof currentinteresttoengineersandresearchersworldwide.

Theseriespublishesacrossthebreadthofmechanicalengineering,comprisingresearch,designand development,andmanufacturing.Itincludesmonographs,referencesandcoursetexts.

ProspectivetopicsincludeemergingandadvancedtechnologiesinEngineeringDesign;ComputerAidedDesign;EnergyConversion&Resources;HeatTransfer;Manufacturing&Processing;Systems &Devices;RenewableEnergy;Robotics;andBiotechnology.

Preface

Thisbookisanintroductiontoplasticsengineering,theprocessforconvertingplasticsintousefulproducts.Itisinfluencedbymechanicalengineeringthathasevolvedoveraperiodof150yearsintoan efficientprocessforconvertingmaterials,mainlymetals,intoalargenumberofusefulproducts.Anovel featureofthisbookisitssynergisticfocusonallaspectsofmaterialsuse–concepts,mechanics,materials,partdesign,partfabrication,andassembly–requiredforconvertingplasticmaterials,mainlyin theformofsmallpellets,intoproducts.Anditintegratestheapplicationsoffourdisparatepolymer types–thermoplastics,thermosets,elastomers,andadvancedcomposites–thatnormallyaretreatedas separatesubjects.

Thedifferencebetweenplasticsengineeringascurrentlyunderstoodintheplasticsindustry–mainly focusedonmaterialsscienceaspectsofplastics–andtheparadigmdevelopedinthisbook,isbest explainedbythesynergyanddifferencesbetweenmaterialsscienceandengineering.Materialsscience, ascience-baseddiscipline,ismainlyconcernedwithsynthesizingandmodifyingthepropertiesofmaterialstoobtaindesirablecharacteristics.Thisprocessrequiresanunderstandingofhowthemolecular structureofamaterialaffectsitsmicrostructurethat,inturn,affectsitsmacrocontinuumproperties. Incontrast,theengineeringprocess,concernedwithconvertingmaterialsintousefulproducts,usesthe principlesofmechanics,orengineeringscience,asthebasictoolforunderstandingpartdesign,part performance,andpartfabricationissues.Forusingmaterials,materialsscienceandengineeringareseparatebutcomplementarydisciplinesthatrequiredifferentskillsetsandtraining.Thematerialaspects formetalswereearliercoveredbymetallurgy,thedisciplinefromwhichmodernmaterialssciencehas evolved.Mechanicalengineering,concernedwiththedesignandfabricationofstructuralcomponents ofthewidestvarietyofproducttypes,providedtheengineeringtoolsforrationallyconvertingmetals intousefulproducts.Inaddition,electricalengineeringdevelopedtoexploittheelectricalandmagnetic propertiesofmaterials.

Forhistoricalreasons,thecurrentparadigmforplasticsengineering–whichemphasizesmaterials aspectswithsomeconsiderationofprocessingissues,andmainlydrawsonchemicalengineeringto providerheological(fluidflow)principlesforprocessing–isheavilybiasedtowardmaterialsscience, andhasnotbenefitedfrommechanics-basedengineering(engineeringscience)principlesthatroutinely areusedfordesigningmetalparts.Plasticsengineering,ascurrentlyunderstoodintheplasticsindustry, doesnotrationallyaddressimportantissuesformechanicaldesign,partperformance,andpartfabrication.Mostapplicationshaveevolvedbyusingiterativebuild-and-testmethods.Thehighertoolingcosts oflargerpartsandtheneedtoreducetheproductdevelopmentcycle–especiallyhigherload-bearing partssuchasautomotivebumpers–aredrivingtheincreasinguseofbasicengineeringprinciples.

Preface

Thisbookprovidesaself-containedintroductiontoplasticsengineering,synergisticallyencompassingmaterialsandengineeringaspects.Thisparadigmisanadaptationofmechanicalengineering methodologytoplasticsmaterials,requiringasystematicincorporationofmechanicsprinciplesand aconsiderationofshapesynthesisforplasticparts.Eachfacetofplasticsengineeringispresentedat anelementarylevel,sothatportionsofthebookmayappearoverlysimplistictospecialists.However, althoughelementary,portionsmaybesomewhatdifficultforsome.

Tofacilitatetheintegrationofmaterialsandengineeringaspectsofplasticsengineeringthebookis dividedintofiveparts:Introduction–whichincludesaconsiderationofevolvingconceptsforplastics use–Mechanics,Materials,PartProcessingandAssembly,andMaterialSystems.Inaddition,asaguide tothebook,eachpartisprecededbyaseparatorwithoutlinesofthechaptersinthatpart.

InPartI,Chapter1providesabroadsurveyofplasticsengineering,essentiallyasummaryofthebook: Whatplasticsareandwhytheyarebecomingimportantengineeringmaterials,thesynergybetween materialsscienceandengineering,theeffectofmaterialtypeonpartshape,theroleofengineeringscience inpartdesignandpartprocessing,andtheroleofassemblymethods.Italsoisasummaryreferencefor readersastheyprogressthroughthesucceedingchapters.

Thesecondchapterinthispartfocusesonevolvingconceptsforplasticsuse;awiderangeofapplicationshavebeendescribedtodemonstratehowmuchplasticshavepenetratedalmosteverysphereof humanactivity.Understandingtheprocessforselectingappropriatepartshapes–anontrivialexercisefor plasticsthatrequireslookingbeyondshapesappropriateformetals–isimportantbecausefirstattempts atusingplasticsconsistedofone-for-onemetalpartreplacement.Thisstrategyfailedbecauseitdidnot accountfortheenormouscomplexitythatcanbebuiltintosingleplasticparts,whichiswhatmakesthe useofotherwiseexpensiveplasticseconomical.Plasticsusedinanassemblycancostmorethanthecost ofthemetalsreplaced.Itisthroughinnovativedesignsandcost-effectivefabrication(partprocessing) techniquesthat,inmanyapplications,plasticshaveanedgeovermetals.

PartIIofthebookisaself-containedintroductiontoallsimpleprinciplesrequiredforunderstanding theroleofmechanicsinplasticsengineering.Whilemechanicalengineersarewellgroundedinthe fundamentalsandapplicationsofmechanics,thelackofanadequateexposuretomechanicscanbe amajorbarrierforplasticsengineerstolookbeyondamaterialsmindset.Becauseanunderstanding ofmechanicsprinciplesisanimportantaspectoftheplasticsengineeringparadigmdiscussedinthis book,conceptssuchasstress,strain,andconstitutiverelationsareintroducedataveryelementary, one-dimensionallevel.However,elementarydifferentialandintegralcalculusareprerequisites.Some relativelyadvancedtwo-dimensionaltopicsareprecededbyanasterisk;stillmoreadvancedtopicsare indicatedbytwoasterisks.Whilesuchtopicsarenotessentialforunderstandingthemoreelementary discussions,theydogiveanideaofthelevelofmathematicsrequiredforthenextlevelofanalyses fordesigningandprocessingactualparts.Simplematerialmodelsareusedtoanalyzethebehaviorof structuralelementssuchasbeams,torsionmembers,andcolumns.

Anotherchapteraddressesmodelsforthebehavioroffluids.And,inviewofitsimportanceandcomplexity,one-dimensionalviscoelasticityisdiscussedinaseparatechapter.

ThelastchapterinPartIIdiscussesmechanicsprinciplesunderlyingthestiffeningofplasticsbyembeddedfibers.Forprovidingabettermotivation,thischaptercouldalsohavebeenplacedafterthegross behaviorofplasticshasbeenintroducedinPartIII.

PartIIIaddressesmaterialsissues:Thechemicalstructureandclassificationofpolymers,howstructureaffectsproperties,andthemodificationofpropertiesthroughadditives.However,polymersynthesis andrelatedchemistryissuesarenotaddressed,asarenotmethodsforcharacterizingthepropertiesof polymericmaterials.