WileySeriesinQuality&ReliabilityEngineering

Dr.AndreKleyner

SeriesEditor

TheWileySeriesinQuality&ReliabilityEngineeringaimstoprovideasolid educationalfoundationforboth practitionersandresearchersintheQ&Rfieldandtoexpandthereader’s knowledgebasetoincludethelatest developmentsinthisfield.Theserieswillprovidealastingandpositive contributiontotheteachingandpracticeof engineering. Theseriescoveragewillcontain,butisnotexclusiveto,

● Statisticalmethods

● Physicsoffailure

● Reliabilitymodeling

● Functionalsafety

● Six-sigmamethods

● Lead-freeelectronics

● Warrantyanalysis/management

● Riskandsafetyanalysis

WileySeriesinQuality&ReliabilityEngineering Lead-freeSolderingProcessDevelopmentandReliability byJasbirBath(Editor) 2020

ThermodynamicDegradationScience:PhysicsofFailure,AcceleratedTesting, FatigueandReliability byAlecFeinberg October2016

DesignforSafety byLouisJ.Gullo,JackDixon February2018

NextGenerationHALTandHASS:RobustDesignofElectronicsandSystems byKirkA.Gray,JohnJ.Paschkewitz May2016

ReliabilityandRiskModels:SettingReliabilityRequirements,2ndEdition byMichaelTodinov September2015

AppliedReliabilityEngineeringandRiskAnalysis:ProbabilisticModelsand StatisticalInference byIliaB.Frenkel,AlexKaragrigoriou,AnatolyLisnianski,AndreV.Kleyner September2013

DesignforReliability

byDevG.Raheja(Editor),LouisJ.Gullo(Editor) July2012

EffectiveFMEAs:AchievingSafe,Reliable,andEconomicalProductsandProcesses UsingFailureModes andEffectsAnalysis byCarlCarlson April2012

FailureAnalysis:APracticalGuideforManufacturersofElectronicComponents andSystems byMariusBazu,TituBajenescu April2011

ReliabilityTechnology:PrinciplesandPracticeofFailurePreventioninElectronic Systems byNormanPascoe April2011

ImprovingProductReliability:StrategiesandImplementation byMarkA.Levin,TedT.Kalal March2003

TestEngineering:AConciseGuidetoCost-EffectiveDesign,Developmentand Manufacture byPatrickO’Connor April2001

IntegratedCircuitFailureAnalysis:AGuidetoPreparationTechniques byFriedrichBeck January1998

MeasurementandCalibrationRequirementsforQualityAssurancetoISO9000 byAlanS.Morris October1997

ElectronicComponentReliability:Fundamentals,Modelling,Evaluation,and Assurance byFinnJensen 1995

Editedby Mr.JasbirBath

BathConsultancyLLC 11040BollingerCanyonRoad,#E-122 SanRamon CA94582,USA

Email:Jasbir_Bath@yahoo.com

Thiseditionfirstpublished2020 ©2020JohnWiley&Sons,Inc

Allrightsreserved.Nopartofthispublicationmaybereproduced,storedinaretrievalsystem,ortransmitted, inanyformorbyanymeans,electronic,mechanical,photocopying,recordingorotherwise,exceptas permittedbylaw.Adviceonhowtoobtainpermissiontoreusematerialfromthistitleisavailableathttp:// www.wiley.com/go/permissions.

TherightofJasbirBathtobeidentifiedastheauthorofthisworkhasbeenassertedinaccordancewithlaw.

RegisteredOffice

JohnWiley&Sons,Inc.,111RiverStreet,Hoboken,NJ07030,USA

EditorialOffice 111RiverStreet,Hoboken,NJ07030,USA

Fordetailsofourglobaleditorialoffices,customerservices,andmoreinformationaboutWileyproductsvisit usatwww.wiley.com.

Wileyalsopublishesitsbooksinavarietyofelectronicformatsandbyprint-on-demand.Somecontentthat appearsinstandardprintversionsofthisbookmaynotbeavailableinotherformats.

LimitofLiability/DisclaimerofWarranty

Whilethepublisherandauthorshaveusedtheirbesteffortsinpreparingthiswork,theymakeno representationsorwarrantieswithrespecttotheaccuracyorcompletenessofthecontentsofthisworkand specificallydisclaimallwarranties,includingwithoutlimitationanyimpliedwarrantiesofmerchantabilityor fitnessforaparticularpurpose.Nowarrantymaybecreatedorextendedbysalesrepresentatives,writtensales materialsorpromotionalstatementsforthiswork.Thefactthatanorganization,website,orproductis referredtointhisworkasacitationand/orpotentialsourceoffurtherinformationdoesnotmeanthatthe publisherandauthorsendorsetheinformationorservicestheorganization,website,orproductmayprovide orrecommendationsitmaymake.Thisworkissoldwiththeunderstandingthatthepublisherisnotengaged inrenderingprofessionalservices.Theadviceandstrategiescontainedhereinmaynotbesuitableforyour situation.Youshouldconsultwithaspecialistwhereappropriate.Further,readersshouldbeawarethat websiteslistedinthisworkmayhavechangedordisappearedbetweenwhenthisworkwaswrittenandwhen itisread.Neitherthepublishernorauthorsshallbeliableforanylossofprofitoranyothercommercial damages,includingbutnotlimitedtospecial,incidental,consequential,orotherdamages.

LibraryofCongressCataloging-in-PublicationData

Names:Bath,Jasbir,editor.

Title:Lead-freesolderingprocessdevelopmentandreliability/editedby JasbirBath,BathConsultancyLLC.

Description:Firstedition.|Hoboken,NJ:JohnWiley&Sons,Inc.,2020. |Series:Wileyseriesinquality&reliabilityengineering|Includes bibliographicalreferencesandindex.

Identifiers:LCCN2020004969(print)|LCCN2020004970(ebook)|ISBN 9781119482031(hardback)|ISBN9781119482048(adobepdf)|ISBN 9781119481935(epub)

Subjects:LCSH:Electronicpackaging.|Solderandsoldering.

Classification:LCCTK7870.15.L4342020(print)|LCCTK7870.15(ebook) |DDC621.381/046–dc23

LCrecordavailableathttps://lccn.loc.gov/2020004969

LCebookrecordavailableathttps://lccn.loc.gov/2020004970

CoverDesign:Wiley

CoverImage:©PaulKrugman/Shutterstock

Setin9.5/12.5ptSTIXTwoTextbySPiGlobal,Chennai,India

PrintedintheUnitedStatesofAmerica

10987654321

Contents

ListofContributors xix

Introduction xxi

1Lead-FreeSurfaceMountTechnology 1

JenniferNguyenandJasbirBath

1.1Introduction 1

1.2Lead-FreeSolderPasteAlloys 1

1.3SolderPastePrinting 2

1.3.1Introduction 2

1.3.2KeyPastePrintingElements 2

1.4ComponentPlacement 5

1.4.1Introduction 5

1.4.2KeyPlacementParameters 5

1.4.2.1Nozzle 6

1.4.2.2VisionSystem 6

1.4.2.3PCBSupport 6

1.4.2.4ComponentSize,Packaging,andFeederCapacity 6

1.4.2.5FeederCapacity 6

1.5ReflowProcess 7

1.5.1Introduction 7

1.5.2KeyParameters 7

1.5.2.1Preheat 7

1.5.2.2Soak 8

1.5.2.3Reflow 8

1.5.2.4Cooling 9

1.5.2.5ReflowAtmosphere 9

1.6VacuumSoldering 9

1.7PasteinHole 10

1.8RoboticSoldering 11

1.9AdvancedTechnologies 12

1.9.1FlipChip 12

1.9.2PackageonPackage 12

1.10Inspection 13

1.10.1SolderPasteInspection(SPI) 13

1.10.2SolderJointInspection 14

1.10.2.1AutomatedOpticalInspection(AOI) 14

1.10.2.2X-rayInspection 15

1.11Conclusions 16 References 17

2Wave/SelectiveSoldering 19

GerjanDiepstraten

2.1Introduction 19

2.2Flux 19

2.2.1TheFunctionofaFlux 19

2.2.2FluxContents 20

2.3AmountofFluxApplicationonaBoard 20

2.4FluxHandling 21

2.5FluxApplication 21

2.5.1MethodstoApplyFlux(WaveSoldering) 21

2.5.2MethodstoApplyFlux(SelectiveSoldering) 23

2.6Preheat 24

2.6.1PreheatProcess-HeatingMethods 24

2.6.2PreheatTemperatures 27

2.6.3PreheatTime 28

2.6.4ControllingPreheatTemperatures 28

2.6.5BoardWarpageCompensation(SelectiveSoldering) 29

2.7SelectiveSoldering 29

2.7.1DifferentSelectiveSolderingPointtoPointNozzles(Selective Soldering) 29

2.7.2SolderTemperatures(SelectiveSoldering) 30

2.7.3Dip/ContactTimes(SelectiveSoldering) 31

2.7.4DragConditions(SelectiveSoldering) 31

2.7.5NitrogenEnvironment(SelectiveSoldering) 31

2.7.6WaveHeightControls(SelectiveSoldering) 32

2.7.7De-BridgingTools(SelectiveSoldering) 32

2.7.8SolderPot(SelectiveSoldering) 33

2.7.9TopsideHeatingduringSoldering(SelectiveSoldering) 34

2.7.10SelectiveSolderingDipProcesswithNozzlePlates(Selective Soldering) 34

2.7.11SolderTemperaturesforMulti-WaveDipSoldering(Selective Soldering) 35

2.7.12NitrogenEnvironment(SelectiveSoldering) 35

2.7.13WaveHeightControl(SelectiveSoldering) 36

2.7.14DipTime–ContactTimewithSolder(SelectiveSoldering) 36

2.7.15SolderFlowAccelerationandDeceleration(SelectiveSoldering) 37

2.7.16De-BridgingTools(SelectiveSoldering) 37

2.7.17Pallets(SelectiveSoldering) 38

2.7.18Conveyor(SelectiveSoldering) 38

2.8WaveSoldering 39

2.8.1WaveFormers(WaveSoldering) 39

2.8.2Pallets(WaveSoldering) 40

2.8.3NitrogenEnvironment(WaveSoldering) 40

2.8.4ProcessControl(WaveSoldering) 41

2.8.5Conveyor(WaveSoldering) 41

2.9Conclusions 42 References 42

3Lead-FreeRework 43 JasbirBath

3.1Introduction 43

3.2HandSolderingReworkforSMTandPTHComponents 43

3.2.1AlloyandFluxChoices 43

3.2.1.1Alloys 43

3.2.1.2Flux 44

3.2.2SolderingIronTipLife 44

3.2.3HandSolderingTemperaturesandTimes 47

3.3BGA/CSPRework 50

3.3.1AlloyandFluxChoices 50

3.3.1.1Alloys 50

3.3.1.2Flux 50

3.3.2BGA/CSPReworkSolderingTemperaturesandTimes 50

3.3.3ComponentTemperaturesinRelationtoIPC/JEDECJ-STD-020and Component/BoardWarpageStandards 52

3.3.3.1IPC/JEDECJ-STD-020Standard 52

3.3.3.2ComponentWarpageStandards 52

3.3.3.3BoardWarpageStandards 52

3.3.4EquipmentUpdatesforLead-FreeBGA/CSPRework 53

3.3.5AdjacentComponentTemperatures 53

3.4Non-standardComponentRework(IncludingBTC/QFN) 54

3.4.1AlloyandFluxChoices 54

x Contents

3.4.1.1Alloys 54

3.4.1.2Flux 54

3.4.2SolderingTemperaturesandTimes 54

3.4.3Non-standardComponentTemperaturesinRelationtoIPCJEDEC J-STD-020StandardandComponentWarpageStandards 55

3.4.4EquipmentandToolingUpdatesforLead-FreeNon-standard ComponentRework 55

3.4.5AdjacentComponentTemperatures 56

3.4.6Non-standardComponentReworkSolderJointReliability 56

3.5PTH(Pin-Through-Hole)WaveRework 56

3.5.1AlloyandFluxChoices 56

3.5.1.1Alloys 56

3.5.1.2Flux 57

3.5.2SolderingTemperaturesandTimes 57

3.5.3ComponentTemperaturesinRelationtoIndustryandBoardStandards DuringPTHRework 67

3.5.3.1ComponentTemperatureRatingStandards 67

3.5.3.2BareBoardTestingStandardsandMethodsforPTHRework 67

3.5.4EquipmentUpdatesforPTHComponentRework 68

3.5.5AdjacentComponentTemperaturesDuringPTHRework 68

3.5.6PTHComponentReworkSolderJointReliability 68

3.5.6.1CopperDissolution 68

3.5.6.2Holefill 69

3.6Conclusions 69 References 70

4SolderPasteandFluxTechnology 73 ShantanuJoshiandPeterBorgesen

4.1Introduction 73

4.2SolderPaste 75

4.2.1Water-SolubleSolderPaste 75

4.2.2No-CleanSolderPaste 76

4.3FluxTechnology 77

4.3.1Halide-FreeandHalide-Containing 77

4.4CompositionofSolderPaste 79

4.4.1Alloy 79

4.4.2Flux 82

4.4.3SolderPowderType 83

4.4.3.1OxideLayer 84

4.5CharacteristicsofaSolderPaste 84

4.5.1Printing 84

4.5.1.1PrintingParameters 85

4.5.2Reflow 86

4.5.2.1Wetting/SpreadabilityofLead-FreeSolderPaste 86

4.5.2.2Bridging 86

4.5.2.3MicroSolderBalls 86

4.5.2.4Voiding 86

4.5.2.5Head-on-PillowComponentSolderingDefect 88

4.5.2.6Non-WetOpen 90

4.5.2.7Tombstoning 90

4.5.3In-CircuitTest(ICT)ProbeTestability 90

4.5.4FluxReliabilityIssues 91

4.6Conclusions 92 References 92

5LowTemperatureLead-FreeAlloysandSolderPastes 95 RaiyoAspandiar,NileshBadwe,andKevinByrd

5.1Introduction 95

5.1.1DefinitionofLowTemperatureSolders 95

5.1.2BenefitsofLowTemperatureSoldering 97

5.1.2.1ReducedManufacturingCost 98

5.1.2.2PowerUseSavings 98

5.1.2.3EnvironmentalBenefits 99

5.1.2.4ManufacturingYieldImprovements 100

5.1.3Drawbacks 103

5.1.3.1Brittleness 103

5.1.4OtherLowTemperatureMetallurgicalSystems 103

5.2DevelopmentofRobustBismuth-BasedLowTemperatureSolder Alloys 105

5.2.1Bismuth-Tin(Bi-Sn)PhaseDiagram 105

5.2.2MechanicalProperties 107

5.2.3PhysicalProperties 108

5.2.4AlloyDevelopmentProgress 108

5.2.5FluxesforLowTemperatureSolders 109

5.3SMTProcessCharacterizationofSn-BiBasedSolderPastes 111

5.3.1Printability 111

5.3.2ReflowProfiles 112

5.3.3Rework 113

5.4PolymericReinforcementofSn-BiBasedLowTemperature Alloys 114

5.4.1CurrentPolymericReinforcementStrategies 114

5.4.2JointReinforcedPastes(JRP) 118

5.4.3PolymericReinforcementSummary 128

5.5MixedSnAgCu-BiSnBGASolderJoints 128

5.5.1FormationMechanism 128

5.5.2MicrostructuralFeaturesandKeyCharacteristics 133

5.5.3SolderingProcessOptimization 134

5.5.4PossibleDefects 135

5.6SolderJointReliability 140

5.7Conclusions 145

5.8FutureDevelopmentandTrends 146 References 149

6HighTemperatureLead-FreeBondingMaterials–TheNeed, thePotentialCandidatesandtheChallenges 155 HongwenZhangandNing-ChengLee

6.1Introduction 155

6.2SolderMaterials 159

6.2.1Gold-BasedSolders 159

6.2.2Bismuth-RichSolders 160

6.2.2.1DesignofBismuth-RichSolders 160

6.2.2.2MechanicalBehaviorofBiAgX 163

6.2.2.3MicrostructureandMicrostructuralEvolutionofBiAgXJoint 167

6.2.3Tin-Antimony(Sn-Sb)HighTemperatureSolders 174

6.2.4Zinc-AluminumSolders 176

6.3Silver(Ag)-SinteringMaterials 178

6.4TransientLiquidPhaseBondingMaterials/Technique 181

6.5Summary 182 Acknowledgment 185 References 185

7Lead(Pb)-FreeSoldersforHighReliabilityand High-PerformanceApplications 191 RichardJ.Coyle

7.1EvolutionofCommercialLead(Pb)-FreeSolderAlloys 191

7.1.1FirstGenerationCommercialPb-FreeSolders 191

7.1.2SecondGenerationCommercialPb-FreeSolders 192

7.1.3ThirdGenerationCommercialPb-FreeSolders 196

7.2ThirdGenerationAlloyResearchandDevelopment 196

7.2.1LimitationsofSn-Ag-CuSolderAlloys 196

7.2.2EmergenceofCommercialThirdGenerationAlloys 202

7.2.2.1TheGenesisof3rdGenerationAlloyDevelopment 202

7.2.2.2AnExpandingClassof3rdGenerationAlloys 202

7.2.3MetallurgicalConsiderations 203

7.2.3.1Antimony(Sb)AdditionstoTin(Sn) 206

7.2.3.2Indium(In)AdditionstoTin(Sn) 207

7.2.3.3Bismuth(Bi)AdditionstoTin(Sn) 209

7.3ReliabilityTestingThirdGenerationCommercialPb-FreeSolders 210

7.3.1ThermalFatigueEvaluations 210

7.3.2iNEMI/HDPUGThirdGenerationAlloyPb-FreeThermalFatigue Project 213

7.3.3MicrostructureandReliabilityofThirdGenerationAlloys 219

7.4ReliabilityGapsandSuggestionsforAdditionalWork 223

7.4.1RootCauseofInterfacialFractures 223

7.4.2EffectofComponentAttributesonThermalFatigue 224

7.4.3EffectofSurfaceFinishonThermalFatigue 224

7.4.4ThermomechanicalTestParametersandTestOutcomes 225

7.4.4.1ThermalCyclingDwellTime 225

7.4.4.2Preconditioning(IsothermalAging) 225

7.4.4.3ThermalCyclingofMixedMetallurgyBGAAssemblies 226

7.4.4.4ThermalShockorAggressiveThermalCycling 226

7.4.5ReliabilityUnderMechanicalLoading:Drop/Shock,and Vibration 227

7.4.6SolderAlloyMicrostructureandReliability 230

7.4.7SummaryofSuggestionsforAdditionalInvestigation 231

7.5Conclusions 232 Acknowledgments 234 References 234

8Lead-FreePrintedWiringBoardSurfaceFinishes 249 RickNichols

8.1Introduction:WhyaSurfaceFinishIsNeeded 249

8.2SurfaceFinishesintheMarket 250

8.3ApplicationPerspective 255

8.4ADescriptionofFinalFinishes 261

8.4.1HotAirSolderLeveling(HASL) 263

8.4.1.1ProcessComplexity 263

8.4.1.2ProcessDescription 265

8.4.1.3IssuesandRemedies 267

8.4.1.4Summary 267

8.4.2HighTemperatureOSP 267

8.4.2.1ProcessComplexity 267

8.4.2.2ProcessDescription 269

8.4.2.3IssuesandRemedies 270

8.4.2.4Summary 270

8.4.3ImmersionTin 271

8.4.3.1ProcessComplexity 271

8.4.3.2ProcessDescription 273

8.4.3.3IssuesandRemedies 275

8.4.3.4Summary 276

8.4.4ImmersionSilver 276

8.4.4.1ProcessComplexity 277

8.4.4.2ProcessDescription 279

8.4.4.3IssuesandRemedies 280

8.4.4.4Summary 281

8.4.5ElectrolessNickelImmersionGold(ENIG) 281

8.4.5.1ProcessComplexity 281

8.4.5.2ProcessDescription 283

8.4.5.3IssuesandRemedies 285

8.4.5.4Summary 286

8.4.6ElectrolessNickel/ElectrolessPalladium/ImmersionGold (ENEPIG) 287

8.4.6.1ProcessComplexity 287

8.4.6.2ProcessDescription 289

8.4.6.3IssuesandRemedies 290

8.4.6.4Summary 291

8.4.7ElectrolessNickelAutocatalyticGold(ENAG) 291

8.4.7.1ProcessComplexity 292

8.4.7.2ProcessDescription 293

8.4.7.3IssuesandRemedies 295

8.4.7.4Summary 295

8.4.8ElectrolessPalladiumAutocatalyticGold(EPAG) 295

8.4.8.1ProcessComplexity 295

8.4.8.2ProcessDescription 297

8.4.8.3IssuesandRemedies 298

8.4.8.4Summary 299

8.4.9ElectrolyticNickelElectrolyticGold 299

8.4.9.1ProcessComplexity 299

8.4.9.2ProcessDescription 301

8.4.9.3IssuesandRemedies 301

8.4.9.4Summary 302

8.5Conclusions 303 References 304

9PCBLaminates(IncludingHighSpeedRequirements) 307 KarlSauterandSilvioBertling

9.1Introduction 307

9.2ManufacturingBackground 307

9.3PCBFabricationDesignandLaminateManufacturingFactors AffectingYieldandReliability 308

9.3.1HighFrequencyLoss 308

9.3.2MixedDielectric 308

9.3.3Back-Drilling 309

9.3.4AspectRatio 309

9.3.5PCBFabrication 309

9.3.6PressLamination 310

9.3.7MoistureContent 310

9.3.8LaminateMaterial 311

9.4AssemblyFactorsAffectingYieldsandLong-TermReliabilityfor LaminateMaterials 311

9.4.1ReflowTemperature 311

9.4.2AssemblyComponents 312

9.4.3ThermalStress 312

9.5CopperFoilTrends(bySilvioBertling) 312

9.6HighFrequency/HighSpeedandOtherTrendsAffectingLaminate Materials 316

9.6.1HighSpeedStandards 316

9.6.2AdhesionTreatment(PriortoPressLamination) 317

9.6.3LaminateMaterialFillerContent 317

9.6.4GlassWeaveEffect 317

9.6.5Halogen-Free 318

9.7Conclusions 318 References 319

10UnderfillsandEncapsulantsUsedinLead-FreeElectronic Assembly 321 BrianJ.Toleno

10.1Introduction 321

10.2Rheology 322

10.2.1RheologicalResponseandBehavior 323

10.2.1.1Thixotropy 325

10.2.2MeasuringRheology 327

10.2.2.1SpindleTypeViscometry 327

10.2.2.2ConeandPlateRheometry 328

10.3CuringofAdhesiveSystems 330

10.3.1ThermalCure 330

10.3.2Ultraviolet(UV)LightCuring 335

10.3.3MoistureCure 338

10.4GlassTransitionTemperature 339

10.5CoefficientofThermalExpansion(CTE) 341

10.6Young’sModulus(E) 343

10.7Applications 344

10.7.1Underfills 344

10.7.1.1CapillaryUnderfill 345

10.7.1.2Fluxing(No-Flow)Underfill 348

10.7.1.3Removable/ReworkableUnderfill 349

10.7.1.4StakingorCornerBondUnderfill 349

10.7.2EncapsulantMaterials 350

10.7.2.1GlobTop 351

10.7.2.2ComponentEncapsulation 351

10.7.2.3Application 353

10.7.2.4Low-PressureMolding 355

10.8Conclusions 355 References 355

11ThermalCyclingandGeneralReliability Considerations 359 MaximSerebreni

11.1IntroductiontoThermalCyclingofElectronics 359

11.1.1InfluenceofSolderAlloyCompositionandMicrostructureonThermal CyclingReliability 362

11.2InfluenceofPackageTypeandThermalCyclingProfile 363

11.2.1InfluenceofBoardandPadDesign 366

11.3FatigueLifePredictionModels 371

11.3.1EmpiricalModelsandAccelerationFactors 371

11.3.2Semi-empiricalModels 372

11.3.3FiniteElementAnalysis(FEA)BasedFatigueLifePredictions 373

11.4Conclusions 376 References 377

12IntermetallicCompounds 381

AlyssaYaeger,TravisDale,ElizabethMcClamrock,GaneshSubbarayan, andCarolHandwerker

12.1Introduction 381

12.1.1Solders 382

12.1.2InteractionwithSubstrates 382

12.2SettingtheStage 384

12.2.1MechanicalandThermomechanicalResponseofSolderJoints 386

12.3CommonLead-FreeSolderAlloySystems 392

12.3.1SolderJointsFormedBetweenSn-Cu,Sn-Ag,andSn-Ag-CuSolder AlloysandCopperSurfaceFinishes 396

12.3.1.1Sn-CuSolderonCopper 396

12.3.1.2Sn-AgandSn-Ag-CuSolderAlloysonCopper 399

12.3.2SolderJointsFormedBetweenSn-Cu,Sn-Ag,andSn-Ag-CuAlloysand NickelSurfaceFinishes 408

12.3.2.1Ni-Sn 408

12.3.2.2Sn-AgSolderAlloysonNickel 411

12.3.2.3Spalling 415

12.3.2.4EffectsofPhosphorusConcentrationinENIGonSolderJoint Reliability 416

12.3.3Au-Sn 417

12.4HighLead–Exemption 422

12.5Conclusions 423 References 423

13ConformalCoatings 429 JasonKeeping

13.1Introduction 429

13.2Environmental,Health,andSafety(EHS)Requirements 430

13.3OverviewofTypesofConformalCoatings 430

13.3.1TypesofConformalCoatings 431

13.3.1.1AcrylicResins(TypeAR) 432

13.3.1.2UrethaneResins(TypeUR) 433

13.3.1.3EpoxyResins(TypeER) 433

13.3.1.4SiliconeResins(TypeSR) 435

13.3.1.5Para-xylylene(TypeXY) 436

13.3.1.6SyntheticRubber(TypeSC) 437

13.3.1.7Ultra-Thin(TypeUT) 438

13.4PreparatoryStepsNecessarytoEnsureaSuccessfulCoating Process 440

13.4.1AssemblyCleaning 440

13.4.2AssemblyMasking 440

13.4.3PrimingandOtherSurfaceTreatments 441

13.4.3.1MeasuringSurfaceEnergy 441

13.4.3.2WaterDropContactAngle 447

13.4.4Bake-Out 448

13.5VariousMethodsofApplyingConformalCoating 449

13.5.1ManualCoating 449

13.5.2Dip 449

13.5.3HandSpray 450

13.5.4AutomaticSpray 451

13.5.5SelectiveCoating 451

13.5.6VaporDeposition 451

13.6AspectsforCure,Inspection,andDemasking 453

13.6.1Cure 453

13.6.1.1SolventEvaporation 453

13.6.1.2RoomTemperatureVulcanization(RTV) 454

13.6.1.3HeatCure 454

13.6.1.4UVCure 454

13.6.1.5Catalyzed 454

13.6.2UVInspection 455

13.6.3Demasking 455

13.7RepairandReworkProcesses 456

13.7.1Chemical 456

13.7.2Thermal 456

13.7.3Mechanical 457

13.7.4Abrasion(Micro-Abrasion) 457

13.7.5PlasmaEtch 457

13.8DesignGuidanceonWhenandWhereConformalCoatingisRequired, andWhichPhysicalCharacteristicsandPropertiesareImportantto Consider 457

13.8.1IsConformalCoatingRequired? 458

13.8.1.1WhyUseIt? 458

13.8.1.2WhyNotUseConformalCoating? 459

13.8.2DesirableMaterialProperties 459

13.8.3AreastoMask 461

13.9Long-TermReliabilityandTesting 462

13.10Conclusions 462

13.11FutureWork 463 References 463

Index 467

ListofContributors

RaiyoAspandiar IntelCorporation

Hillsboro,OR USA

NileshBadwe IntelCorporation

Hillsboro,OR USA

JasbirBath BathConsultancyLLC SanRamon,CA USA

SilvioBertling Mesa Arizona,USA

PeterBorgesen IntegratedElectronicsEngineering Center

BinghamtonUniversity,State UniversityofNewYork,NY USA

KevinByrd IntelCorporation Hillsboro,OR USA

RichardJ.Coyle NokiaBellLaboratories MurrayHill,NJ USA

TravisDale SchoolofMechanicalEngineering PurdueUniversity WestLafayette,IN USA

GerjanDiepstraten VitronicsSoltec Oosterhout,TheNetherlands

CarolHandwerker SchoolofMaterialsEngineering PurdueUniversity WestLafayette,IN USA

xx ListofContributors

ShantanuJoshi KokiSolderAmerica

Cincinnati,OH

USA

JasonKeeping CelesticaInc. Toronto Canada

Ning-ChengLee IndiumCorporation Clinton,NY USA

ElizabethMcClamrock SchoolofMaterialsEngineering PurdueUniversity WestLafayette,IN USA

JenniferNguyen Flex Milpitas,California USA

RickNichols Atotech Berlin Germany

GaneshSubbarayan SchoolofMechanicalEngineering PurdueUniversity WestLafayette,IN USA

KarlSauter OracleCorporation SantaClara,California USA

MaximSerebreni DepartmentofMechanical Engineering UniversityofMaryland CollegePark,MD USA

BrianJ.Toleno Microsoft MountainView,California USA

AlyssaYaeger SchoolofMaterialsEngineering PurdueUniversity WestLafayette,IN USA

HongwenZhang IndiumCorporation Clinton,NY USA

Introduction

Withthemovementtolead-freesolderinginelectronicsmanufacturingproduction,thereisaneedforanupdatedreviewofvarioustopicsinthisareaforpracticingprocess,qualityandreliabilityengineersandmanagerstobeabletouseto addressissuesinproduction.

Thebookgivesupdatesinareasforwhichresearchisongoing,andaddresses newtopicswhicharerelevanttolead-freesoldering.Itcoversalistofkeytopics includingdevelopmentsinprocessengineering,alloys,printedcircuitboard(PCB) surfacefinishes,PCBlaminates,andreliabilityassessments.

Chapter1discusseslead-freesurfacemounttechnology(SMT)withreviewof thesurfacemountprocessforlead-freesoldering,includingprinting,component placement,reflow,inspection,andtest.

Chapter2coverslead-freeselectiveandwavesolderingintermsoffluxandpreheatprocessesaswellasthesimilaritiesanddifferencesoftheseprocesses.

Chapter3discussestheissuesduringlead-freereworkfortheassembledcomponentsbasedonthehigherlead-freesolderingtemperaturesandtherangeofsmall andlargecomponentstoreworkaswellastemperatureandmoisturesensitivitywithcomponentsandboards.Thechapterreviewsupdatesinlead-freerework technologyincludinghandsoldering,ballgridarray/chipscalepackageBGA/CSP rework,andPTH(PinThroughHole)rework.

Chapter4discusseslead-freesolderpasteandfluxtechnologyandthecharacteristicsneededforthesematerialstoensuregoodsolderpasteperformance.Italso reviewsthedefectswhichcanoccurduringelectronicsmanufacturing,includingmicrosolderballs,voiding,tombstoning,bridging,opens,head-on-pillow,and non-wetopens.

Chapter5coverslowtemperaturelead-freealloysandpastes,withanemphasis ontheBi-Snsystemandthedevelopmentworkongoinginthisarea.

Chapter6discussessoldermaterials,silver-sinteringmaterials,andTLPB(transientliquidphasebonding)materialsasthethreepotentialcandidatetypesfor lead-free,high-temperature,die-attachmentmaterials.

Chapter7coversthedrivers,benefits,andconcernsassociatedwiththedevelopmentandimplementationofthirdgeneration,highreliabilitylead-freesolders.

Chapter8reviewslead-freesurfacefinishalternatestotheelectrolyticnickel immersiongoldsurfacefinishinrelationtoperformancecharacteristicsandcost, withselectionofafinalboardsurfacefinishbeingofsignificancetotheassembly andreliabilityoftheproduct.

Chapter9discussesseveralcriticalfactorsrelatingtoPCBlaminatematerials anddescribeswhytheyareimportanttoensuringthatthefinishedboardperformancerequirementsaremet.

Chapter10reviewstheuseofadhesivesinthemanufacturingofhigh-density lead-freesurfacemountassemblies,withadiscussionofthetwoadhesiveapplicationsusedwidelyforincreasedreliability:underfillsandencapsulants.

Chapter11overviewsthermalcyclingreliabilityinrelationtolead-freesolder joints,withthereliabilityofsolderinterconnectsinfluencedbyallaspectsofthe electronicassembly,rangingfromthecomponentpackagestyleandcircuitboard constructiontothesoldercomposition.

Chapter12discussesintermetalliccompounds(IMCs)formedinthelead-free solderjointswithadiscussionoftherolesthatIMCsplayindeterminingsolder jointreliability,andhowthoseroleschangeasaresultofagingordamageinduced bythermalcycling.Itcoverstheperformanceofcommonlead-freesolderalloys incombinationwithmetallizationsandsurfacefinishestounderstandwhatto expectinthesespecificsystemsandtheproblemsthatmayarisewhencombining newsolderalloysandsurfacefinishes/metallizationsandthemethodologiesthat canbeusedtoseparateoutthedifferentpossiblerootcauses.

Thefinalchapter(Chapter13)coversindustryupdatesintheuseofconformal coatingsandtheiruseinelectronicsmanufacturingandtheireffectonreliability.Variousaspectsofconformalcoatingsarediscussed,includingEnvironmental HealthandSafety(EHS)requirements,thefivebasicconformalcoatingtypesand newemergingmaterials,preparation,application,cure,andinspectionofconformalcoatings,repairandrework,anddesignguidanceonwhenandwherecoatings arerequired,andwhichphysicalcharacteristicsandpropertiesareimportantto consider.

Lead-FreeSurfaceMountTechnology

JenniferNguyen 1 andJasbirBath 2

1 Flex,Milpitas,California,USA

2 BathConsultancyLLC,SanRamon,CA,USA

1.1Introduction

Surfacemounttechnology(SMT)involvestheassemblyorattachmentofsurface mountdevices(SMDs)ontotheprintedcircuitboard(PCB).Today,themajority oftheproductsarebuiltusingsurfacemounttechnologyandlead-freeprocess. Thischapterwillreviewthesurfacemountprocessforlead-freesoldering,includingprinting,componentplacement,reflow,inspection,andtest.Thechapteralso discussessomeadvancedminiaturizationtechnologiesusedintheSMTprocess.

1.2Lead-FreeSolderPasteAlloys

Today,thereareavarietyoflead-freesolderpastealloysavailableinthemarket. SnAgCu(SAC)materialswith3.0–4.0%Agand0.5–0.9%CuandremainderSn arewidelyacceptedwithintheindustry.Amongthem,Sn3.0Ag0.5Cu(SAC305) isstillthemostcommonalloyusedintheSMTprocess.TheseSnAgCualloys havetheliquidustemperatureofaround217 ∘ C.AsthecostofAghasincreased overthepastyears,theuseoflowAgalloymaterialssuchasSn0.3-1.0AgCuor SnCu/SnCuNihasincreased.Thesealloyshaveapproximately10 ∘ ChighermeltingtemperaturethanSAC305andmayneedtobeprocessedatslightlyhigher temperatureduringthereflowprocess.

Lowtemperaturelead-freealloyswhichcontainSnBi/SnBiAgarealsoused. Thesealloyshavemeltingtemperaturearound140 ∘ Candcanbeprocessedat 170–190 ∘ C.Theselowtemperaturealloysusuallyhavehighbismuthcontentand theycreatesomereliabilityconcerns,especiallyonmechanicalreliability.These Lead-freeSolderingProcessDevelopmentandReliability, FirstEdition.EditedbyJasbirBath. ©2020JohnWiley&Sons,Inc.Published2020byJohnWiley&Sons,Inc.

1Lead-FreeSurfaceMountTechnology

lowtemperaturealloysareusedoncertainapplicationssuchaslight-emitting diode(LED)/TVproducts.Inrecentyears,thereisadesireforlowtemperature lead-freealloyalternativeswithbetterreliability.Thedriversfortheselow temperaturealloysincludecomponentwarpage,lowenergyconsumption,and componentorboardsensitivitytothehighertemperaturelead-freeprocess.These alloystypicallyhavehigherliquidustemperaturethantraditionalSnBi/SnBiAg alloys,buttheystillhavelowerliquidustemperaturethanSAC305.Thesealloys havegainedalotofinterestintheindustryintherecentyears,andsomeare availableinthemarketandusedinproduction.

1.3SolderPastePrinting

1.3.1Introduction

OneofthemostimportantprocessesofthesurfacemountassemblyistheapplicationofsolderpastetothePCB.Thisprocessmustaccuratelydepositthecorrectamountofsolderpasteontoeachofthepadstobesoldered.Screen-printing thesolderpastethroughafoilorstencilisthemostcommonlyusedtechnique, althoughothertechniquesuchasjetprintingisalsoused.

Thereisnomajorchangetosolderpasteprintingforlead-freeprocesses.The sameprintercanbeusedfortin-leadandlead-freeprinting.Ingeneral,thesame stencildesignguidelinescanbeusedforlead-freeprocess.

1.3.2KeyPastePrintingElements

Solderpasteprintingprocessisoneofthemostimportantprocessesinsurface mounttechnology.Thisprocesscanaccountforthemajorityoftheassembly defectsifitisnotcontrolledproperly.Foreffectivesolderpasteprinting,the followingkeyfactorsneedtobeoptimizedandcontrolled:

● PCBsupport

● Squeegee(type,speed,pressure,angle)

● Stencil(thickness,aperture,cleanliness,snapoff,separationspeed)

● Solderpaste(includingtype,viscosity)

PCBsupportisimportanttotheprintingprocess.GoodPCBsupportholdsthe PCBflatagainstthestencilduringthescreen-printingprocess.PCBsupportisgenerallyprovidedwiththescreen-printingmachines.Iftheboardisnotproperly supported,solderdefectssuchasbridging,insufficientsolder,andsoldersmearingcanbeseen.Forfinepitchprintingsuch0.3/0.4mmpitchchipscalepackage (CSP),0201/01005(Imperial)chipcomponent,adedicatedcustom-madefixture forprintingorvacuumsupportshouldbeused.

Squeegees,squeegeepressure,andspeedareothercriticalparametersinthe screen-printingprocess.Metalsqueegeesarecommonlyusedforprintingsolder paste,andrubberorpolyurethanesqueegeesareusedforepoxyprinting.A squeegeeangleof60 ∘ Ctothestencilistypicallyused[1].Squeegeespeedand squeegeepressurearecriticalforgoodprinting.Thespeedofthesqueegeedetermineshowmuchtimethesolderpastecanrollandsettleintotheaperturesofthe stencilandontothepadsofthePCB.Inthebeginningoflead-freeconversion, aslowerprintingspeedwasusedbecausethelead-freesolderpastewasstickier thantin-leadsolderpaste.Today,manylead-freesolderpastescanprintwellat highspeed.

Thespeedsettingiswidelyvariedfromatypicalrangeof20–100mm/s 1 dependingonthesizeoftheaperture,thesizeofPCB,andthequantityofboards beingassembled,etc.Printingspeeduseddependsonthesolderpastesupplier orisoptimizedbyaDesignofExperiment(DOE).Itistypicallybetween40and 80mms 1 .Duringthesolderpasteprinting,itisimportanttoapplysufficient squeegeepressureandthispressureshouldbeevenlydistributedacrossthe entiresqueegees.Toolittlepressurecancauseincompletesolderpastetransfer tothePCBorpastesmearing.Toomuchpressurecancausethepastetosqueeze betweenthestencilandthepad.

Stencilisanotherkeyfactorinthesolderpasteprinting.Metalstencilsareused insolderpasteprinting.Stainlesssteelmaterialiscommonlyused;however,metal stencilscanbemadeofcopper,bronze,ornickel[2].Thereareseveraltypesof screen-printingstencil,includingchemicaletch,lasercut,andelectroformed[2].

Thethicknessofthestencilistypically125 μm(5mil)or150 μm(6mil).Stencils withthethicknessof100 μm(4mil)orthinnerhavebecomemorepopularwith thehighdensityandfinepitchcomponentssuchas0201/01005(Imperial)chip componentsor0.4/0.3mmpitchCSPorquadflatno-leads/bottomtermination component(QFN/BTC)components.Thickerstencilsthan150 μmaretypically usedwhenmorepasteisneeded.Stencilthicknessandaperturesizedeterminethe amountofpastedepositedonthepad.Ingeneral,stencilaperturemustbethree timesandpreferablyfivetimesthediameterofthesolderparticles.Toensurethe properpastereleaseandefficientprinting,theaspectratioshouldbegreaterthan 1.5,andthearearatioshouldbegreater0.66.

TheaspectratioisdefinedbyEq.(1.1),andthearearatioisshowninEq.(1.2).

Aspectratio = ApertureWidth∕StencilThickness(1.1)

AreaRatio = AreaoftheAperture (L × W)∕AreaofApertureWalls (2 ×(L + W)× T) (1.2)

Snapoffandstencilseparationspeedarealsoimportantforgoodprintingquality.SnapoffisthedistancebetweenthestencilandthePCB.Formetalstencil

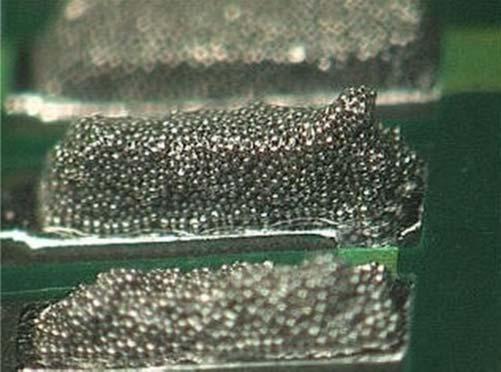

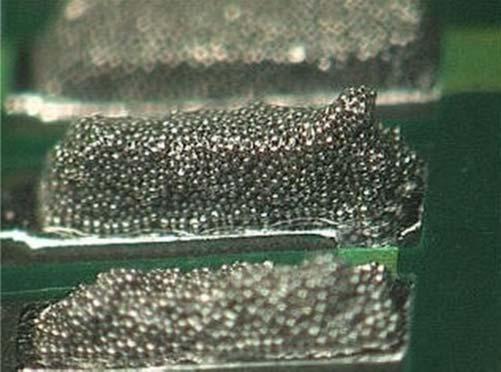

Exampleoftailingattheedgeofthepasteduetohighseparationspeed. printing,thesnapoffshouldbezero.Thisisalsocalledcontactprinting.Ahigh snapoffwillresultinathickerlayerofsolderpaste.Stencilseparationspeedisthe speedofseparationbetweenthestencilandPCBafterprinting.Traditionally,high separationspeedwillresultincloggingofthestencilaperturesortailingatedges aroundthesolderpastedeposited(Figure1.1).However,lead-freepastestendto haveahigheradherencethantin-leadpastesandmaypreferhighseparationspeed thantin-leadsolderpaste.Separationspeedvariesdependingonthesolderpastes anditssupplier,andthesupplier’srecommendationshouldgenerallybefollowed. Lastbutnotleast,thecorrectsolderpastetypeandmaterialshouldbeused.The correcttypeofsolderpasteshouldbeselectedbaseduponthesizeoftheapertures withinthestencil.Type3wascommonlyusedinthetin-leadprocess;however, Type4hasbecomeamorecommonlead-freesolderpastetypeintherecentyears duetotheincreaseinminiaturizedcomponentsontheprintedcircuitboard.The

Figure1.1

Table1.1 Generalsolderpaste typeandparticlesizes.

releasefromtheaperturesofthestencilisaffectedbytheparticlesizewithinthe selectedsolderpaste.Table1.1liststheparticlesizeofdifferentsolderpastetype. Bothtin-leadandlead-freesolderpasteshouldberefrigeratedwhilebeingstored tomaintainitsshelflifebutmustbebroughttoroomtemperaturebeforeuseto maintainquality.Somenewlead-freesolderpastesrequirenorefrigerationand canbestoredatroomtemperature.Thesolderpasteshouldbemixedproperly beforeusetoensureevendistributionofanyseparatedmaterialthroughoutthe paste.Itisrecommendedtofollowthesolderpastemanufacturer’srecommendationsforstorageandhandlingconditions.

1.4ComponentPlacement

1.4.1Introduction

Afterthecorrectamountofsolderpasteisapplied,componentsareplacedonthe PCBatthespecificlocations.Thecomponentplacementprocessincludesboard loadingandregistration,fiducialvisionalignment,componentpick-up,componentinspection,andalignmentandplacement.Thecomponentplacementmust bepreciseandinaccordancewiththeschematics.Pickandplacemachinesare usedinthisprocess.Therearedifferenttypesofpickandplacementmachineavailableinthemarket.Somemachinesaredesignedspecificallyforspeedwhereas othersaremorefocusedonflexibility.Themachinesdesignedforspeedaregenerallyreferredtoas“chipshooters”andcanachievecomponentplacementrates ofupto100000cph(componentsperhour).Theflexiblepickandplacemachine canhandlecomponentsrangingfrom01005(Imperial)chipstolargecomponents suchasballgridarrays(BGAs),connectors,etc.Flexiblemachinestypicallyhave slowerpickandplacespeedthanthechipshooter.Themachinesareselected dependingonthetypes,sizes,andvolumesofthesurfacemountcomponents.The samepickandplaceequipmentcanbeusedfortin-leadandlead-freecomponents.

1.4.2KeyPlacementParameters

Componentplacementisanimportantfactorinsurfacemountassembly.Itaffects notonlytheassemblytimebutalsothereliabilityofthesolderjoint.Placement accuracyandplacementspeedarecriticalinthisprocess.Toachieveaccurate placementandhighoutput,thefollowingfactorsneedtobeconsidered:

● Nozzle

● Visionsystem

● PCBsupport

● Componentsize,packaging

● Feedercapacity

1.4.2.1Nozzle

Itisveryimportantthatthecorrectnozzlebeselectedforeachdifferentpartto beplacedtoensureaccurateandconsistentplacement.Therearemanydifferenttypesofnozzleforpickandplacecomponents.Mostnozzlesuseavacuumto holdthecomponents.Forhandlingsmallcomponents,positivepressureisoften suppliedinadditiontovacuumatthemomentofplacementsothatthecomponentwouldbecompletelyreleasedfromthenozzle.Componentflatnessatthetop surfaceisimportantforthepickandplaceprocess.Certaincomponentssuchas connectorsthatdonothaveaflattopsurfacecanhaveapick-uppadinsertedor pre-attachedbythesupplierforpickandplacepurposes.Somealternativenozzles haveagripper,whichgripsthecomponentsidesinstead.Thegripperistypically forplacingsomeodd-shapedcomponents.However,theplacementspeedistypicallyslowerascomparedtothenozzlesthatholdthecomponentbyvacuum.In addition,extraspaceisrequiredbetweenthecomponentstoaccommodatethe grippers.

1.4.2.2VisionSystem

Thevisionsysteminspectseverycomponentbeforeplacement.Itchecksthepart dimensionsandanycomponentdamagebeforeplacement.Itisimportanttoprogrameachcomponentwiththecorrecttoleranceparameterstoallowthemachine todetermineifanincorrectparthasbeenloadedandalsonottorejectacceptable components.

1.4.2.3PCBSupport

ThePCBneedstohaveadequatesupportduringcomponentplacement.Improper PCBsupportcancausecomponentmisalignmentormissingcomponents.

1.4.2.4ComponentSize,Packaging,andFeederCapacity

ThesurfacemountcomponentsonthePCBwilldifferinsize.Itiscommontohave smallcomponentspositionedclosetolargecomponentsinhighdensitydesign.All smallcomponentsneedtobeplacedbeforelargercomponentssothatthelarger componentsdonotgetdisturbedandmisalignedduringplacement.

Thesurfacemountcomponentsaresuppliedindifferentways.Themostcommoncomponentpackagesaretapeandreel,tubes,andtrays.

1.4.2.5FeederCapacity

Feedersareusedtofeedcomponentstoafixedlocationforthepick-upmechanism.Feedertypesincludetapeandreelfeeder,matrixtrayfeeder,bulkfeeder, andtubefeeder.Thetapeandreelfeederscomeindifferentsizesandarethemost commonfeederforplacinglargequantitiesofsmallcomponents.Thenumberof tapefeedersthatcanbeloadedintothemachineatatimewillplayanimportant

roleindeterminingthespeedofcomponentplacement.Thematrixtrayfeedersare typicallyusedforlargeand/orexpensivecomponentssuchasBGAorQFN/BTC components.Thetrayholdsthecomponentssecurelywithoutdamagingthebody orleads.However,thepickandplaceprocessforthetrayfeederisoftenslower thanthetapefeeder.

1.5ReflowProcess

1.5.1Introduction

Inreflowsoldering,thesolderpasteandsolderballsforthecaseofaBGAcomponentmustbeheatedsufficientlyaboveitsmeltingpointandbecomecompletely molten,inordertoformreliablejoints.Inthecaseofcomponentswithleads,the solderpastemustwettheplatingoncomponentleadstoformthedesiredheeland toefillets.

Thereisnoonebestreflowprofileforallboardassemblies.Ideally,areflow profilemustbecharacterizedforeachboardassemblyusingthermocouplesat multiplelocationsonandaroundthecomponentdevicesandboard.Thesolder pastetype,component,andboardthermalsensitivitymustbeconsideredinreflow profiledevelopment.

Lead-freesolderstypicallyprocessathighertemperaturethantin-leadsolder duetothehighmeltingtemperatureoftypicallead-freesolders.Lead-freesolder suchasSAC305(Sn3Ag0.5Cu)haveaninitialmeltingpointof217 ∘ Candafinal meltingpointof220 ∘ C.Lead-freereflowtypicallyhasanarrowerprocesswindowthantin-leadreflowduetothecomponentorboardmaximumtemperature limitations.

1.5.2KeyParameters

Solderjointformationdependsontemperatureandtimeduringreflow.Thereare fourphasesofareflowprocess,includingpreheat,soak,reflow,andcooling.In addition,reflowatmosphereplaysanimportantroleinthereflowprocess.The keyparametersforreflowwillbediscussedinthefollowingsections.

1.5.2.1Preheat

ThepreheatphasepreparesthePCBandcomponentsforactualreflow.Ithelps toreducethethermalshockandtemperaturedifferencebetweenthePCBand componentsandreflowtemperature.Aquickramprateduringthepreheatcan damagethecomponent.Ingeneral,arampratebetween1.0and3.0 ∘ C/s 1 isrecommended,andthetemperaturechangeshouldbeevenlydistributedthroughout thePCB.Preheatalsoremovessomefluxvolatilesandpreparesthesolderpaste materialforreflow.

1.5.2.2Soak

Soakisalsoknownasthepre-reflowphase.Inthisphase,thefluxinthesolder pastegetsactivated,andthishelpstoremoveoxidationonthecomponentleads, PCBpadsoronthesolderparticles’surface.Also,soakingphaseallowsthe thermalgradientacrossthePCBtoequilibratepriortoreflow.Inthisway,the entireassemblyseesnearlythesamereflowconditionstoformconsistentsolder bonds.Forlargeboardsorboardswithalargerangeofcomponentsizes,alonger soaktimeisusuallyhelpfultoachievesuccessfulassemblytohelpensurethe deltaTemperatureacrosstheboardisreduced.Soakprofilesarealsousedto minimizevoidingwhenassemblingsuchcomponentsasBGA,landgridarray (LGA),andQFN/BTC.

1.5.2.3Reflow

Asthesolderreachesthesoldermeltingtemperature,theboardentersthereflow phase.Peaktemperatureandtimeaboveliquidustemperatureareimportantfactorsinthisphase.Thepeaktemperatureisgenerally20–30 ∘ Cabovetheliquidus temperatureofthealloy,andreflowtimeistypically30–90secondsinorderto formagoodsolderjointandproperintermetallicformationattheinterfaces. AtypicalreflowprofilechartisshowninFigure1.2,andtypicalprofileparametersarelistedinTable1.2.

Time 25°C to Peak

Figure1.2 Reflowprofilechart[3].Copyright2019byIPCInternational,Inc.andisused withIPC’spermission.Thisimagemaynotbealteredorfurtherreproducedwithoutthe priorwrittenconsentofIPC.