Cold-FormedSteelDesign

FifthEdition

Wei-WenYu

MissouriUniversityofScienceandTechnology Rolla,Missouri

RogerA.LaBoube

MissouriUniversityofScienceandTechnology Rolla,Missouri

HelenChen

AmericanIronandSteelInstitute Washington,DC

Thiseditionfirstpublished2020

©2020JohnWiley&Sons,Inc.

EditionHistory

JohnWiley&Sons(2e,1991),JohnWiley&Sons(3e,2000),JohnWiley&Sons(4e,2010)Allrightsreserved.

Nopartofthispublicationmaybereproduced,storedinaretrievalsystem,ortransmitted,inanyformorbyanymeans,electronic,mechanical, photocopying,recordingorotherwise,exceptaspermittedbylaw.Adviceonhowtoobtainpermissiontoreusematerialfromthistitleisavailableat https:// www.wiley.com/go/permissions

TherightofWei-WenYu,HelenChen,andRogerA.LaBoubetobeidentifiedastheauthorsofthisworkhasbeenassertedinaccordancewithlaw.

RegisteredOffice

JohnWiley&Sons,Inc.,111RiverStreet,Hoboken,NJ07030,USA

EditorialOffice

111RiverStreet,Hoboken,NJ07030,USA

Fordetailsofourglobaleditorialoffices,customerservices,andmoreinformationaboutWileyproductsvisitusat www.wiley.com

Wileyalsopublishesitsbooksinavarietyofelectronicformatsandbyprint-on-demand.Somecontentthatappearsinstandardprintversionsofthis book maynotbeavailableinotherformats.

LimitofLiability/DisclaimerofWarranty

Whilethepublisherandauthorshaveusedtheirbesteffortsinpreparingthiswork,theymakenorepresentationsorwarrantieswithrespecttotheaccuracyor completenessofthecontentsofthisworkandspecificallydisclaimallwarranties,includingwithoutlimitationanyimpliedwarrantiesofmerchantabilityor fitnessforaparticularpurpose.Nowarrantymaybecreatedorextendedbysalesrepresentatives,writtensalesmaterialsorpromotionalstatements forthis work.Thefactthatanorganization,website,orproductisreferredtointhisworkasacitationand/orpotentialsourceoffurtherinformationdoesnotmean thatthepublisherandauthorsendorsetheinformationorservicestheorganization,website,orproductmayprovideorrecommendationsitmaymake. This workissoldwiththeunderstandingthatthepublisherisnotengagedinrenderingprofessionalservices.Theadviceandstrategiescontainedherein maynot besuitableforyoursituation.Youshouldconsultwithaspecialistwhereappropriate.Further,readersshouldbeawarethatwebsiteslistedinthis workmay havechangedordisappearedbetweenwhenthisworkwaswrittenandwhenitisread.Neitherthepublishernorauthorsshallbeliableforanylossofprofitor anyothercommercialdamages,includingbutnotlimitedtospecial,incidental,consequential,orotherdamages.

LibraryofCongressCataloging-in-PublicationData

Names:Yu,Wei-Wen,author. | LaBoube,RogerA.,author. | Chen, Helen,author.

Title:Cold-formedsteeldesign/Wei-WenYuandRogerA.LaBoube,MissourUniversityofScience andTech;HelenChen,AmericanIronandSteelInstitute.

Description:Fifthedition. | Hoboken:Wiley,2020. | Includes bibliographicalreferencesandindex.

Identifiers:LCCN2019023220(print) | LCCN2019023221(ebook) | ISBN 9781119487395(cloth) | ISBN9781119487388(adobepdf) | ISBN 9781119487418(epub)

Subjects:LCSH:Building,Ironandsteel. | Sheet-steel. | Thin-walled structures. | Steel—Coldworking.

Classification:LCCTA684.Y7872020(print) | LCCTA684(ebook) | DDC 624.1/821—dc23

LCrecordavailableathttps://lccn.loc.gov/2019023220

LCebookrecordavailableathttps://lccn.loc.gov/2019023221

CoverDesign:Wiley

CoverImage:CourtesyofSteelFramingAlliance

Setin10/12ptTimesLTStdbySPiGlobal,Chennai,India

10987654321

CHAPTER1INTRODUCTION1

1.1GeneralRemarks1

1.2TypesofCold-FormedSteelSectionsandTheirApplications2

1.3MetalBuildingsandIndustrializedHousing7 1.4MethodsofForming13

1.5ResearchandDesignSpecifications15

1.6GeneralDesignConsiderationsofCold-FormedSteelConstruction21

1.7EconomicDesignandOptimumProperties26

1.8DesignBasis27

1.9Serviceability35

CHAPTER2MATERIALSUSEDINCOLD-FORMEDSTEELCONSTRUCTION37

2.1GeneralRemarks37

2.2YieldStress,TensileStrength,andStress–StrainCurve44

2.3ModulusofElasticity,TangentModulus,andShearModulus45

2.4Ductility45

2.5Weldability47

2.6FatigueStrengthandToughness48

2.7InfluenceofColdWorkonMechanicalPropertiesofSteel48

2.8UtilizationofColdWorkofForming51

2.9EffectofTemperatureonMechanicalPropertiesofSteel53

2.10TestingofFullSectionsandFlatElements54

2.11ResidualStressesDuetoColdForming55

2.12EffectofStrainRateonMechanicalProperties57

CHAPTER3STRENGTHOFTHINELEMENTSANDDESIGNCRITERIA59

3.1GeneralRemarks59

3.2DefinitionsofTerms59

3.3StructuralBehaviorofCompressionElementsandEffectiveWidthDesign Criteria61

3.4PerforatedElementsandMembers97

3.5DirectStrengthMethodandConsiderationofLocalandDistortional Buckling100

3.6PlateBucklingofStructuralShapes117

3.7AdditionalInformation117

CHAPTER4FLEXURALMEMBERS119

4.1GeneralRemarks119

4.2BendingStrengthandDeflection119

4.3DesignofBeamWebs183

4.4BracingRequirementsofBeams209

4.5TorsionalAnalysisofBeamsandCombinedBendingandTorsionalLoading216

4.6AdditionalInformationonBeams216

CHAPTER5COMPRESSIONMEMBERS217

5.1GeneralRemarks217

5.2ColumnBuckling218

5.3LocalBucklingInteractingwithYieldingandGlobalBuckling226

5.4DistortionalBucklingStrengthofCompressionMembers228

5.5EffectofColdWorkonColumnBuckling228

5.6NorthAmericanDesignFormulasforConcentricallyLoadedCompression Members230

5.7EffectiveLengthFactor K 234

5.8Built-UpCompressionMembers236

5.9BracingofAxiallyLoadedCompressionMembers237

5.10DesignExamples238

5.11CompressionMembersinMetalRoofandWallSystems247

5.12AdditionalInformationonCompressionMembers250

CHAPTER6COMBINEDAXIALLOADANDBENDING251

6.1GeneralRemarks251

6.2CombinedTensileAxialLoadandBending251

6.3CombinedCompressiveAxialLoadandBending(Beam–Columns)253

6.4MemberForcesConsideringStructuralStability261

6.5NorthAmericanDesignCriteriaforBeam–ColumnCheck265

6.6DesignExamples266

6.7AdditionalInformationonBeam–Columns283

CHAPTER7CLOSEDCYLINDRICALTUBULARMEMBERS285

7.1GeneralRemarks285

7.2TypesofClosedCylindricalTubes285

7.3FlexuralColumnBuckling285

7.4LocalBuckling286

7.5NorthAmericanDesignCriteria289

7.6DesignExamples293

CHAPTER8CONNECTIONS297

8.1GeneralRemarks297

8.2TypesofConnectors297

8.3WeldedConnections297

8.4BoltedConnections316

8.5ScrewConnections327

8.6Power-ActuatedFasteners331

8.7OtherFasteners334

8.8RuptureFailureofConnections336

8.9I-orBox-ShapedCompressionMembersMadebyConnectingTwo C-Sections337

8.10I-BeamsMadebyConnectingTwoC-Sections340

8.11SpacingofConnectionsinCompressionElements342

CHAPTER9SHEARDIAPHRAGMSANDROOFSTRUCTURES345

9.1GeneralRemarks345

9.2SteelShearDiaphragms345

9.3StructuralMembersBracedbyDiaphragms358

9.4ShellRoofStructures367

9.5MetalRoofSystems378

9.6ShearWalls380

CHAPTER10CORRUGATEDSHEETS381

10.1GeneralRemarks381 10.2Applications381

10.3SectionalPropertiesandDesignofArc-andTangent-Type CorrugatedSheets381

10.4SectionalPropertiesandDesignofTrapezoidal-TypeCorrugated Sheets386

CHAPTER11COMPOSITEDESIGN389

11.1GeneralRemarks389

11.2Steel-Deck-ReinforcedCompositeSlabs389 11.3CompositeBeamsorGirdersWithCold-FormedSteelDeck390

CHAPTER12LIGHT-FRAMECONSTRUCTION393

12.1GeneralRemarks393 12.2FramingStandards393 12.3DesignGuides406

APPENDIXATHICKNESSOFBASEMETAL407

APPENDIXBTORSION409

APPENDIXCFORMULASFORCOMPUTINGCROSS-SECTIONALPROPERTY �� y 421

APPENDIXDDEFINITIONSOFTERMS423 NOMENCLATURE429

ACRONYMSANDABBREVIATIONS443

CONVERSIONTABLE445 REFERENCES447 INDEX513

PREFACE

Thisfiftheditionofthebookhasbeenpreparedtoprovide readerswithabetterunderstandingoftheanalysisanddesign ofthethin-walled,cold-formedsteelstructuresthathave beensowidelyusedinbuildingconstructionandotherareas inrecentyears.Itisarevisedversionofthefirstauthor’s book, Cold-FormedSteelDesign, fourthedition,published byJohnWiley&Sons,Inc.in2010.Alltherevisionsare basedonthe2016editionoftheNorthAmericanSpecification,whichincorporatedtheDirectStrengthMethod intothemainbodyoftheSpecification,andreorganized thechapterstobeconsistentwithhot-rolledsteeldesign specification,1.411 publishedbyAmericanInstituteofSteel Construction.

Thematerialwasoriginallydevelopedforgraduate coursesandshortcoursesintheanalysisanddesignof cold-formedsteelstructuresandisbasedonexperiencein design,research,anddevelopmentoftheAmericanIronand SteelInstitute(AISI)andNorthAmericandesigncriteria.

Throughoutthebook,descriptionsofthestructural behaviorofcold-formedsteelmembersandconnections aregivenfromboththeoreticalandexperimentalpointsof view.Thereasonsandjustificationforthevariousdesign provisionsoftheNorthAmericanspecificationarediscussed atlength.Consequentlythetextnotonlywillbeinstructive forstudentsbutalsocanserveasamajorsourceofreference forstructuralengineersandresearchers.

Toreflectthechangeinformatandtheinclusionofthe DirectStrengthMethodintothemainbodyoftheSpecification,allchaptershavebeencompletelyrevisedaccordingto thereorganizedlayoutoftheNorthAmericanSpecification andframingstandards.

Chapter1includesageneraldiscussionoftheapplication ofcold-formedsteelstructuresandareviewofpreviousand recentresearch.Italsodiscussesthedevelopmentofdesign specificationsandthemajordifferencesbetweenthedesign

ofcold-formedandhot-rolledsteelstructuralmembers. Becauseofthemanyresearchprojectsinthefieldthat havebeenconductedworldwideduringthepast43years, numerouspapershavebeenpresentedatvariousconferences andpublishedinanumberofconferenceproceedingsand engineeringjournals.Atthesametime,newdesigncriteria havebeendevelopedinvariouscountries.Thesenewdevelopmentsarereviewedinthischapter.NewSections1.8and 1.9discusstheAISISpecification’sdesignbasisforstrength andserviceability.

Sincematerialpropertiesplayanimportantroleinthe performanceofstructuralmembers,thetypesofsteeland theirmostimportantmechanicalpropertiesaredescribedin Chapter2.ThemechanicalpropertiesofASTMA1063steel sheetsareaddedinTable2.1.

InChapter3,thestrengthofthinelementsanddesign criteriaarediscussedtoacquaintthereaderwiththefundamentalsofbucklingmodestobeconsideredincold-formed steeldesign,suchaslocalanddistortionalbucklingandpostbucklingstrengthofthinplates,andwiththebasicconcepts usedindesign.Theanalyticalandnumericalapproaches fordetermininglocalanddistortionalbucklingstrengthsare discussedinthischapter.Thischapteralsointroducesthe definitionsofcommonlyusedtermsincold-formedsteel design.TheconceptsoftheEffectiveWidthMethodandthe DirectStrengthMethodarediscussedwiththelimitsofapplicabilityofthesemethods.

Chapter4dealswiththedesignofflexuralmembers. Thecontentshavebeenreorganizedtobeconsistentwith the2016editionoftheNorthAmericanSpecification.This chapterdiscussestheflexuralmemberstrengthsduetoglobal buckling,localbucklinginteractingwithglobalbuckling, anddistortionalbuckling.Italsoincludesnewandrevised designprovisionsoninelasticreservecapacityofbeams, memberswithholes,shearstrengthofwebs,webcrippling

strengthandcombinationwithbending,bearingstiffeners inC-sectionbeams,bracingrequirements,combinationof bendingandtorsion,andbeamshavingoneflangeattached toametalroofsystem.

Thedesignproceduresforcompressionmembersare discussedinChapter5.Thecontentshavebeenreorganized tobeconsistentwiththe2016editionoftheNorthAmericanSpecification.Thischapterdiscussesthecompressive memberstrengthsduetoglobalbuckling,localbuckling interactingwithglobalbuckling,anddistortionalbuckling. Italsoincludesprovisionsaboutthedesignofbuilt-up members,bracingrequirements,andcompressionmembers havingoneflangeattachedtoametalroofsystem.

Inthe2016editionoftheNorthAmericanspecification, theDirectAnalysisMethodwasintroducedtoconsiderthe second-ordereffectinstructuralanalysis.ThisDirectAnalysisMethodisdiscussedinChapter6.Inaddition,revisions havebeenmadeonthedesignofbeam–columnsusingASD, LRFD,andLSDmethods.

Chapter7coversthedesignofclosedcylindricaltubes. Thisrevisedchapterreflectstherearrangementofdesign provisionsintheNorthAmericanspecification.

Likethememberdesign,thedesignofconnectionshas beenupdatedinChapter8usingtheASD,LRFD,and LSDmethodswithadditionalandreviseddesignprovisionsforbearingstrengthbetweenboltsandconnected parts,combinedshearandtensioninfasteners,blockshear strength,reviseddesigninformationonscrewconnections, andpower-actuatedfasteners.

Becausevarioustypesofstructuralsystems,suchas sheardiaphragmsandshellroofstructures,havebecome increasinglypopularinbuildingconstruction,Chapter9 containsdesigninformationonthesetypesofstructural systems.RevisionsaremadereflectingthenewNorthAmericanstandardofAISIS310forprofiledsteeldiaphragm panels.

Thesectionalpropertiesofstandardcorrugatedsheetsare discussedinChapter10becausetheyhavelongbeenusedin buildingsforroofing,siding,andotherapplications.Minor revisionshavebeenmadeinthechapter.

Steeldecksarewidelyusedinbuildingconstruction. ConsequentlytheupdatedinformationinChapter11on theiruseinsteel-deck-reinforcedcompositeslabsand compositebeamsistimely.

In2015,theAISIdesignstandardsforcold-formedsteel framingwereconsolidated.Thesestandardsarespecifically applicableforresidentialandcommercialconstruction.As aresult,Chapter12hasbeencompletelyrewrittenbasedon newandconsolidatedAISIstandards.

Itisobviousthatabookofthisnaturewouldnothave beenpossiblewithoutthecooperationandassistanceof

manyindividuals,organizations,andinstitutions.Itisbased primarilyontheresultsofcontinuingresearchprogramson cold-formedsteelstructuresthathavebeensponsoredby theAmericanIronandSteelInstitute(AISI),theASCE, theCanadianSheetSteelBuildingInstitute(CSSBI),the Cold-FormedSteelEngineersInstitute(CFSEI)oftheSteel FramingAlliance(SFA),theMetalBuildingManufacturers Association(MBMA),theMetalConstructionAssociation (MCA),theNationalScienceFoundation(NSF),theRack ManufacturersInstitute(RMI),theSteelDeckInstitute (SDI),theSteelFramingIndustryAssociation(SFIA),the SteelStudManufacturersAssociation(SSMA),andother organizationslocatedintheUnitedStatesandabroad.The publicationsrelatedtocold-formedsteelstructuresissued byAISIandotherinstitutionshavebeenveryhelpfulforthe preparationofthisbook.

Thefirstauthorisespeciallyindebtedtohisteacher,the lateDr.GeorgeWinterofCornellUniversity,whomade contributionsofpronouncedsignificancetothebuilding professioninhisoutstandingresearchoncold-formedsteel structuresandinthedevelopmentofAISIdesigncriteria.A considerableamountofmaterialusedinthisbookisbased onDr.Winter’spublications.

OursincerethanksgotoMr.RobertJ.Wills,VicePresident,ConstructionMarketDevelopment,SteelMarket DevelopmentInstitute(abusinessunitoftheAmericanIron andSteelInstitute),forpermissiontoquotefreelyfrom theNorthAmericanSpecification, Commentary, Design Manual, FramingStandards, DesignGuides,andotherAISI publications.Anexpressionofappreciationisalsodueto themanyorganizationsandindividualsthatgrantedpermissionforthereproductionofquotations,graphs,tables,and photographs.Creditsfortheuseofsuchmaterialsaregiven inthetext.

WeareverygratefultoMrs.ChristinaStratmanforher kindassistanceinthepreparationofthisbook.Thefinancial assistanceprovidedbytheMissouriUniversityofScience andTechnologythroughthefirstauthor’sCurators’ProfessorshipandthesponsorsfortheWei-WenYuCenterfor Cold-FormedSteelStructuresisappreciated.

Thisbookcouldnothavebeencompletedwithoutthehelp andencouragementoftheauthors’wives,Yueh-HsinYuand KarenLaBoube,andhusband,ChunweiHuang,aswellas fortheirpatience,understanding,andassistance.

Wei-WenYu RogerA.LaBoube Hong(Helen)Chen Rolla,Missouri March2019

CHAPTER1 Introduction

1.1GENERALREMARKS

Insteelconstruction,therearetwomainfamiliesofstructuralmembers.Oneisthefamiliargroupofhot-rolled shapesandmembersbuiltupofplates.Theother,less familiarbutofgrowingimportance,iscomposedofsections coldformedfromsteelsheet,strip,plate,orflatbarin roll-formingmachinesorbypressbrakeorbendingbrake operations.1.1,1.2,1.3 ∗ Thesearecold-formedsteelstructural members.Thethicknessofsteelsheetorstripgenerally usedincold-formedsteelstructuralmembersrangesfrom 0.0149in.(0.378mm)toabout 1 4 in.(6.35mm).Steelplates andbarsasthickas1in.(25.4mm)canbecoldformed successfullyintostructuralshapes.1.1,1.4,1.314,1.336,1.345

Althoughcold-formedsteelsectionsareusedincar bodies,railwaycoaches,varioustypesofequipment,storage racks,grainbins,highwayproducts,transmissiontowers, transmissionpoles,drainagefacilities,andbridgeconstruction,thediscussionsincludedhereinareprimarilylimited toapplicationsinbuildingconstruction.Forstructuresother thanbuildings,allowancesfordynamiceffects,fatigue,and corrosionmaybenecessary.1.314,1.336,1.345,1.417

Theuseofcold-formedsteelmembersinbuilding constructionbeganinaboutthe1850sinboththeUnited StatesandGreatBritain.However,suchsteelmembers werenotwidelyusedinbuildingsuntilaround1940.The earlydevelopmentofsteelbuildingshasbeenreviewedby Winter.1.5–1.7

Since1946theuseandthedevelopmentofthin-walled cold-formedsteelconstructionintheUnitedStateshave beenacceleratedbytheissuanceofvariouseditionsof the“SpecificationfortheDesignofCold-FormedSteel StructuralMembers”oftheAmericanIronandSteelInstitute (AISI).1.267,1.345 Theearliereditionsofthespecificationwere basedlargelyontheresearchsponsoredbyAISIatCornell UniversityunderthedirectionofGeorgeWinter.Ithasbeen revisedsubsequentlytoreflectthetechnicaldevelopments andtheresultsofcontinuingresearch.1.267,1.336,1.346,1.416,1.417 Ingeneral,cold-formedsteelstructuralmembersprovide thefollowingadvantagesinbuildingconstruction:

1.Ascomparedwiththickerhot-rolledshapes, cold-formedlightmemberscanbemanufactured forrelativelylightloadsand/orshortspans.

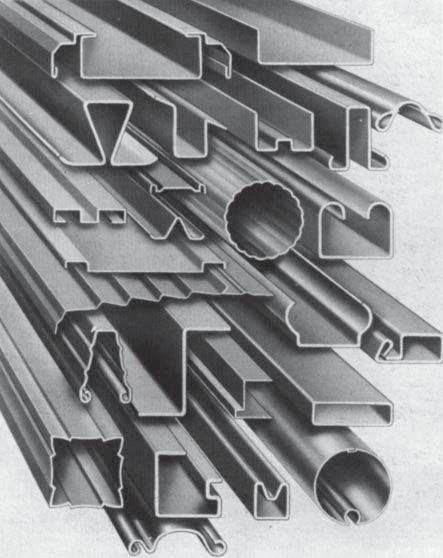

2.Unusualsectionalconfigurationscanbeproduced economicallybycold-formingoperations(Fig.1.1), andconsequentlyfavorablestrength-to-weightratios canbeobtained.

3.Nestablesectionscanbeproduced,allowingfor compactpackagingandshipping,aswellasfor developingefficientstructuralapplications.

∗ Thereferencesarelistedatthebackofthebook.

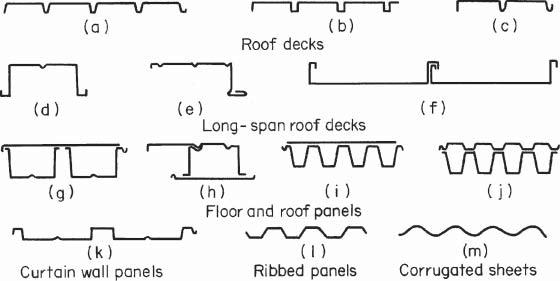

Figure1.1 Variousshapesofcold-formedsections.1.1

4.Load-carryingpanelsanddeckscanprovideuseful surfacesforfloor,roof,andwallconstruction,andin othercasestheycanalsoprovideenclosedcellsfor electricalandotherconduits.

5.Load-carryingpanelsanddecksnotonlywithstand loadsnormaltotheirsurfaces,buttheycanalsoactas sheardiaphragmstoresistforceintheirownplanesif theyareadequatelyinterconnectedtoeachotherandto supportingmembers.

Comparedwithothermaterialssuchastimberand concrete,thefollowingqualitiescanberealizedfor cold-formedsteelstructuralmembers1.8,1.9 :

1.Lightness

2.Highstrengthandstiffness

3.Easeofprefabricationandmassproduction

4.Fastandeasyerectionandinstallation

5.Substantialeliminationofdelaysduetoweather

6.Moreaccuratedetailing

7.Nonshrinkingandnoncreepingatambienttemperatures

8.Formworkunneeded

9.Termiteproofandrotproof

10.Uniformquality

11.Economyintransportationandhandling

12.Noncombustibility

13.Recyclablematerial

Thecombinationoftheabove-mentionedadvantagescan resultincostsavingsinconstruction(www.buildsteel.org).

1.2TYPESOFCOLD-FORMEDSTEELSECTIONS ANDTHEIRAPPLICATIONS

Cold-formedsteelstructuralmemberscanbeclassifiedinto twomajortypes:

1.Individualstructuralframingmembers

2.Panelsanddecks

Thedesignandtheusageofeachtypeofstructural memberhavebeenreviewedanddiscussedinanumberof publications.1.5–1.75,1.267–1.285,1.349,1.358,1.418

1.2.1IndividualStructuralFramingMembers

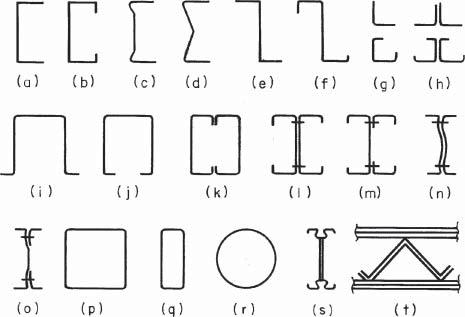

Figure1.2showssomeofthecold-formedsectionsgenerally usedinstructuralframing.Theusualshapesarechannels

Figure1.2 Cold-formedsectionsusedinstructuralframing.1.6 (C-sections),Z-sections,angles,hatsections,I-sections, T-sections,andtubularmembers.Previousstudieshave indicatedthatthesigmasection(Fig.1.2d)possessesseveral advantages,suchashighload-carryingcapacity,smaller blanksize,lessweight,andlargertorsionalrigidityas comparedwithstandardchannels.1.76

Ingeneral,thedepthofcold-formedindividualframing structuralmembersrangesfrom2to16in.(50.8to406mm), andthethicknessofmaterialrangesfrom0.0329to0.1180 in.(0.836to2.997mm).Insomecases,thedepthofindividualmembersmaybeupto18in.(457mm),andthethicknessofthemembermaybe 1 2 in.(12.7mm)orthickerin transportationandbuildingconstruction.Cold-formedsteel platesectionsinthicknessesofuptoabout 3 4 or1in.(19.1or 25.4mm)havebeenusedinsteelplatestructures,transmissionpoles,andhighwaysignsupportstructures.

Inviewofthefactthatthemajorfunctionofthistype ofindividualframingmemberistocarryload,structuralstrengthandstiffnessarethemainconsiderations indesign.Suchsectionshavecommonlybeenusedas primaryframingmembersinbuildingshavingmultiple storiesinheight.1.278 In2000,the165-unitHolidayInnin FederalWay,Washington,utilizedeightstoriesofaxialload bearingcold-formedsteelstudsastheprimaryload-bearing system.1.357 Figure1.3showsamid-riseconstruction building.Cold-formedsteelformid-riseconstructionhas becomepopularforthesebuildingsthattypicallymay rangefrom4to12storieshigh.Chapter12providesadditionaldiscussionofcold-formedsteelapplicationsforlowandmid-riseconstruction.Additionalinformationmay alsobeobtainedat www.buildsteel.org.Intallmultistory buildingsthemainframingistypicallyofheavyhot-rolled

Figure1.3 Buildingcomposedentirelyofcold-formedsteelsections.CourtesyofDonAllen.

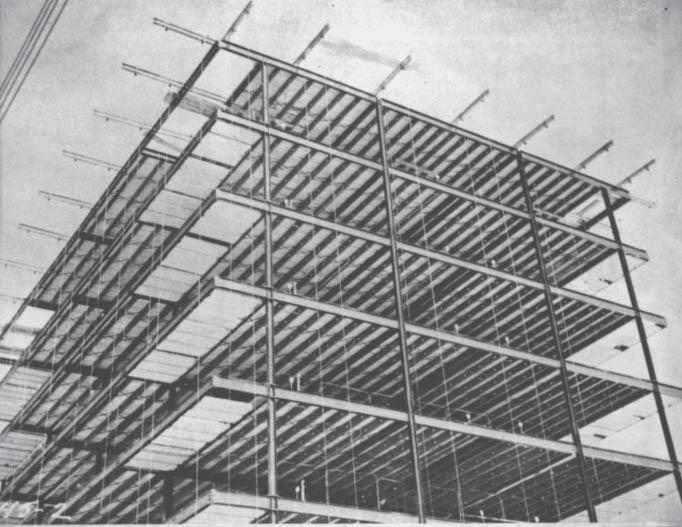

shapesandthesecondaryelementsmaybeofcold-formed steelmemberssuchassteeljoists,studs,decks,orpanels (Figs.1.4and1.5).Inthiscasetheheavyhot-rolledsteel shapesandthecold-formedsteelsectionssupplementeach other.1.264

AsshowninFigs.1.2and1.6–1.10,cold-formedsections arealsousedaschordandwebmembersofopenwebsteel joists,spaceframes,arches,andstorageracks.

1.2.2PanelsandDecks

Anothercategoryofcold-formedsectionsisshownin Fig.1.11.Historically,thesesectionsaregenerallyusedfor roofdecks,floordecks,wallpanels,sidingmaterial,and bridgeforms.Recently,profileddeckhasbeenusedfor shearwall.Somedeeperpanelsanddecksarecoldformed withwebstiffeners.

Compositetruss–panelsystemprefabricatedbyLacledeSteelCompany.

Figure1.5 Cold-formedsteeljoistsusedtogetherwithhot-rolledshapes.CourtesyofStran-Steel Corporation.

Thedepthofpanelsgenerallyrangesfrom9/16to7 1 2 in. (14.2to191mm),andthethicknessofmaterialsranges from0.018to0.075in.(0.457to1.91mm).Thisisnotto suggestthatinsomecasestheuseof0.012-in.(0.305-mm) steel-ribbedsectionsasload-carryingelementsinroofand wallconstructionwouldbeinappropriate.

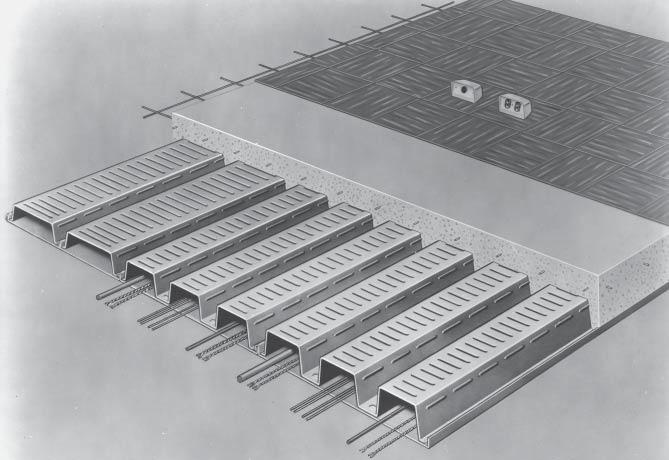

Steelpanelsanddecksnotonlyprovidestructural strengthtocarryloads,buttheyalsoprovideasurfaceon whichflooring,roofing,orconcretefillcanbeapplied, asshowninFig.1.12.Theycanalsoprovidespacefor

electricalconduits,ortheycanbeperforatedandcombined withsoundabsorptionmaterialtoformanacoustically conditionedceiling.Thecellsofcellularpanelsarealso usedasductsforheatingandairconditioning.

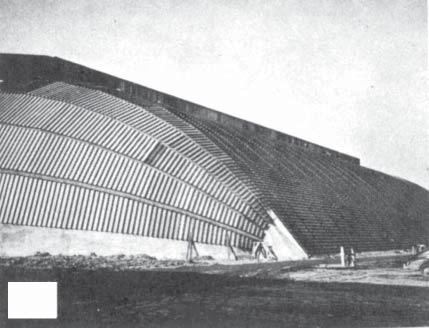

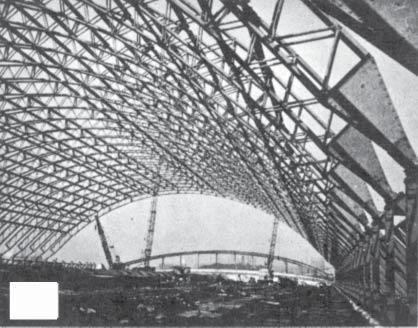

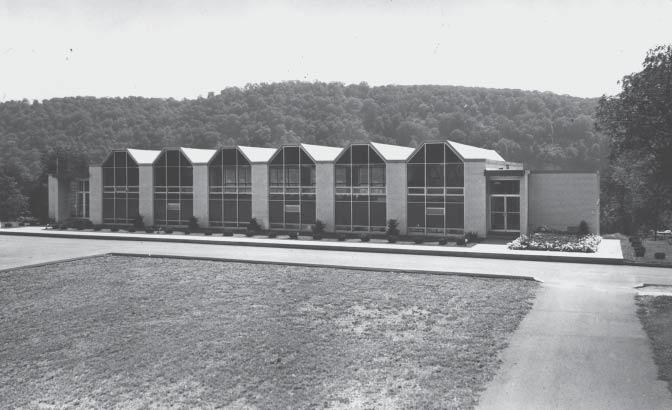

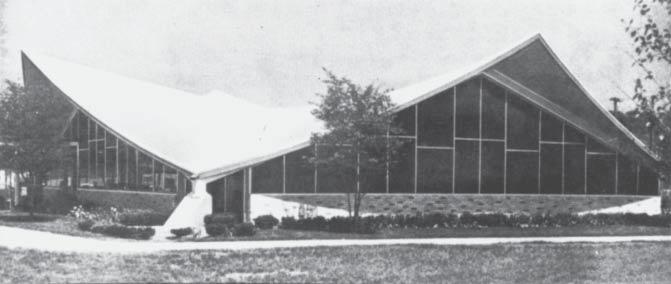

Inthepast,steelroofdecksweresuccessfullyused infolded-plateandhyperbolicparaboloidroofconstruction,1.13,1.22,1.26,1.30,1.34,1.35,1.72,1.77–1.84 asshownin Figs.1.13and1.14.Oneoftheworld’slargestcold-formed steelprimarystructuresusingsteeldeckingforhyperbolic paraboloids,designedbyLevZetlinAssociates,isshownin

Figure1.4

Figure1.6 Cold-formedsteelsectionsusedinspaceframes.CourtesyofUnistrutCorporation.

Figure1.7 Cold-formedsteelmembersusedinspacegridsystem.CourtesyofButlerManufacturingCompany.

Figure1.8 Cold-formedsteelmembersusedina100 × 220 × 30-ft(30.5 × 67.1 × 9.2-m)triodetic arch.CourtesyofButlerManufacturingCompany.

Figure1.9 Hangar-typearchstructuresusingcold-formedsteelsections.CourtesyofArmcoSteel Corporation.1.6

Fig.1.15.1.82 Roofdecksmaybecurvedtofittheshapeofan archedroofwithoutdifficulty.Someroofdecksareshipped tothefieldinstraightsectionsandcurvedtotheradiusofan archedroofatthejobsite(Fig.1.16).Inotherbuildings,roof deckshavebeendesignedasthetopchordofprefabricated openwebsteeljoistsorrooftrusses(Fig.1.17).1.85,1.86 In Europe,TRP200decking(206mmdeepby750mmpitch) hasbeenusedwidely.IntheUnitedStates,thestandingseam metalroofhasanestablishedtrackrecordinnewconstructionandreplacementforbuilt-upandsingle-plysystemsin manylow-risebuildings.

Figure1.11alsoshowscorrugatedsheets,whichareoften usedasrooforwallpanelsandindrainagestructures.Theuse ofcorrugatedsheetsasexteriorcurtainwallpanelsisillustratedinFig.1.18a.Ithasbeendemonstratedthatcorrugated

sheetscanbeusedeffectivelyinthearchedroofsofundergroundsheltersanddrainagestructures.1.87–1.89

Thepitchofcorrugationsusuallyrangesfrom1 1 4 to3in. (31.8to76.2mm),andthecorrugationdepthvariesfrom 1 4 to1in.(6.35to25.4mm).Thethicknessofcorrugated steelsheetsusuallyrangesfrom0.0135to0.164in.(0.343to 4.17mm).However,corrugationswithapitchofupto6in. (152mm)andadepthofupto2in.(50.8mm)arealsoavailable.SeeChapter10forthedesignofcorrugatedsteelsheets basedontheAISIpublications.1.87,1.88 Unusuallydeep corrugatedpanelshavebeenusedinframelessstressed-skin construction,asshowninFig.1.18b.Theself-framing corrugatedsteelpanelbuildingprovedtobeaneffective blast-resistantstructureintheNevadatestsconductedin 1955.1.90

(b) (a)

Figure1.19showstheapplicationofstandingseamroof systems.Thedesignofbeamshavingoneflangefastenedtoa standingseamroofsystemandthestrengthofstandingseam roofpanelsystemsarediscussedinChapter4. Inthepastfourdecades,cold-formedsteeldeck hasbeensuccessfullyusednotonlyasformworkbut alsoasreinforcementofcompositeconcretefloorand roofslabs.1.55,1.91,1.103 Thefloorsystemsofthistypeof

compositesteeldeck-reinforcedconcreteslabarediscussed inChapter11.

1.3METALBUILDINGSANDINDUSTRIALIZED

HOUSING

Single-storymetalbuildingshavebeenwidelyusedin industrial,commercial,andagriculturalapplications.Metal

Figure1.10 Rackstructures.CourtesyofUnarcoMaterialsStorage.

Figure1.11 Decks,panels,andcorrugatedsheets.

Figure1.12 Cellularfloorpanels.CourtesyofH.H.RobertsonCompany.

Figure1.13 Cold-formedsteelpanelsusedinfolded-plateroof.CourtesyofH.H.Robertson Company.

Figure1.14 Hyperbolicparaboloidroofofweldedlaminatedsteeldeck.Reprintedfrom ArchitecturalRecord, March1962.CopyrightbyMcGraw-HillBookCo.,Inc.1.79

Figure1.15 SuperbayhangarforAmericanAirlinesBoeing747sinLosAngeles.1.82 Courtesyof LevZetlinAssociates,Inc.

Figure1.16 Archedroofcurvedatjobsite.CourtesyofDonnProductsCompany.

Figure1.17 Steeldeckisdesignedasthetopchordofprefabricatedopenwebsteeljoists.Courtesy ofInland-RyersonConstructionProductsCompany.

Figure1.18 (a)Exteriorcurtainwallpanelsemployingcorrugatedsteelsheets.1.87 (b)Frameless stressed-skinconstruction.CourtesyofBehlenManufacturingCompany.

buildingsystemshavealsobeenusedforcommunity facilitiessuchasrecreationbuildings,schools,and churches.1.104,1.105 Metalbuildingsprovidethefollowing majoradvantages:

1.Attractiveappearance

2.Fastconstruction

3.Lowmaintenance

4.Easyextension

5.Lowerlong-termcost

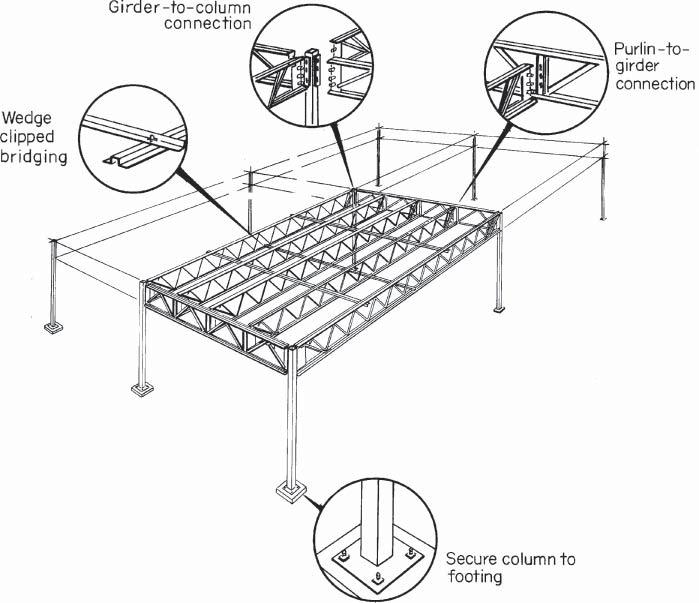

Ingeneral,smallerbuildingscanbemadeentirely ofcold-formedsections(Fig.1.20),andrelativelylarge buildingsareoftenmadeofweldedsteelplaterigidframes withcold-formedsectionsusedforgirts,purlins,roofs,and walls(Fig.1.21).

Thedesignofpre-engineeredmetalbuildingsisoften basedonthe MetalBuildingSystemsManual issuedbythe MetalBuildingManufacturersAssociation(MBMA).1.360 The2012editionoftheMBMAmanualisarevisedversion ofthepreviousmanual.Thenewmanualincludes(a)load

Figure1.19 Applicationofstandingseamroofsystems.Courtesy ofButlerManufacturingCompany.

applicationdata[InternationalBuildingCode(IBC)2006 loads],(b)craneloads,(c)serviceability,(d)common industrypractices,(e)guidespecifications,(f)AISC-MB certification,(g)windloadcommentary,(h)fireprotection, (i)wind,snow,andraindatabyU.S.county,(j)aglossary,(k)anappendix,and(l)abibliography.Inaddition, MBMAalsohaspublishedthe MetalRoofSystemsDesign Manual 1.361 Itincludessystemscomponents,substrates, specificationsandstandards,retrofit,commonindustry practices,design,installation,energy,andfireprotection.Additionalinformationmaybelocatedat www.mbma .com.

Thedesignofsingle-storyrigidframesistreatedextensivelybyLeeetal.1.107 InCanadathedesign,fabrication,and

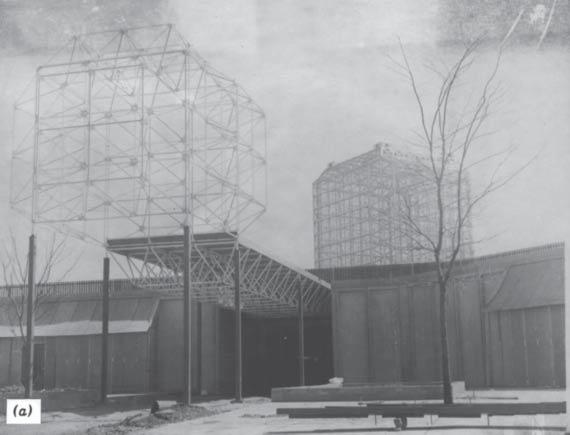

erectionofsteelbuildingsystemsarebasedonastandardof theCanadianSheetSteelBuildingInstitute(CSSBI).1.108 Industrializedhousingcanbesubdividedconveniently into(1)panelizedsystemsand(2)modularsystems.1.109,1.278 Inpanelizedsystems,flatwall,floor,androofsections areprefabricatedinaproductionsystem,transportedto thesite,andassembledinplace.Inmodularsystems, three-dimensionalhousingunitsegmentsarefactorybuilt, transportedtothesite,liftedintoplace,andfastenedtogether. Inthe1960s,undertheSchoolConstructionSystems DevelopmentProjectofCalifornia,fourmodularsystemsof schoolconstructionweredevelopedbyInlandSteelProductsCompany(modularsystemasshowninFig.1.17), MacomberIncorporated(V-Lokmodularcomponentsystem asshowninFig.1.22),andRheem/DudleyBuildings(flexiblespacesystem).1.110

In1970RepublicSteelCorporationwasselectedbythe DepartmentofHousingandUrbanDevelopmentunderthe OperationBreakthroughProgramtodevelopamodular systemforhousing.1.111 Panelsconsistingofsteelfacings withaninsulatedcorewereusedinthissystem.

Buildinginnovationalsoincludestheconstructionof unitizedboxes.Theseboxesareplannedtobeprefabricated ofroomsize,fullyfurnished,andstackedinsomemanner tobeahotel,hospital,apartment,orofficebuilding.1.25,1.112 Formultistorybuildingstheseboxescanbesupportedbya mainframingmadeofheavysteelshapes.

Inthepast,cold-formedsteelstructuralcomponents havebeenusedincreasinglyinlow-risebuildingsand residentialsteelframing.Considerableresearchand

Figure1.20 Smallbuildingmadeentirelyofcold-formedsections.CourtesyofStran-Steel Corporation.1.6

Figure1.21 Standardizedbuildingmadeoffabricatedrigidframewithcold-formedsectionsfor girts,purlins,roofs,andwalls.CourtesyofArmcoSteelCorporation.

Figure1.22 V-Lokmodularcomponentsystem.CourtesyofMacomberIncorporated.

developmentactivitieshavebeenconductedcontinuouslybynumerousorganizationsandsteelcompanies.1.21,1.25,1.27,1.28,1.113–1.116,1.280–1.301 Inadditiontothestudy oftheload-carryingcapacityofvariousstructuralcomponents,recentresearchworkhasconcentratedon(1)joining methods,(2)thermalandacousticalperformanceofwall panelsandfloorandroofsystems,(3)vibrationalresponse ofsteeldecksandfloorjoists,(4)foundationwallpanels,(5) trusses,and(6)energyconsiderations.Chapter12provides someinformationonrecentdevelopments,designstandards,anddesignguideforcold-formedsteellight-frame construction.

InEuropeandothercountriesmanydesignconcepts andbuildingsystemshavebeendeveloped.Fordetails,see Refs.1.25,1.140–1.143,1.117,1.118,1.268,1.270,1.271, 1.273,1.275,1.290,1.293,and1.297.

1.4METHODSOFFORMING

Threemethodsaregenerallyusedinthemanufactureof cold-formedsectionssuchasillustratedinFig.1.1:

1.Coldrollforming

2.Pressbrakeoperation

3.Bendingbrakeoperation

1.4.1ColdRollForming1.1,1.119

Themethodofcoldrollforminghasbeenwidelyusedfor theproductionofbuildingcomponentssuchasindividual structuralmembers,asshowninFig.1.2,andsomeroof, floor,andwallpanelsandcorrugatedsheets,asshownin Fig.1.11.Itisalsoemployedinthefabricationofpartitions, framesofwindowsanddoors,gutters,downspouts,pipes, agriculturalequipment,trucks,trailers,containers,railway passengerandfreightcars,householdappliances,andother products.Sectionsmadefromstripsupto36in.(915mm) wideandfromcoilsmorethan3000ft(915m)longcanbe producedmosteconomicallybycoldrollforming.

Themachineusedincoldrollformingconsistsofpairs ofrolls(Fig.1.23)whichprogressivelyformstripsintothe finalrequiredshape.Asimplesectionmaybeproducedby asfewassixpairsofrolls.However,acomplexsectionmay requireasmanyas15setsofrolls.Rollsetuptimemaybe severaldays.

Thespeedoftherollingprocesstypicallyrangesfrom 20to300ft/min(6to92m/min).Theusualspeedisinthe rangeof75–150ft/min(23–46m/min).Atthefinishend,the completedsectionmaybecuttorequiredlengthsbyanautomaticcutofftoolwithoutstoppingthemachine.Maximum

cutlengthsareusuallybetween20and40ft(6and12m).The flatsheetmaybecuttolengthpriortotherollingprocess.

Asfarasthelimitationsforthicknessofmaterialare concerned,carbonsteelplateasthickas 3 4 in.(19mm)canbe rollformedsuccessfully,andstainlesssteelshavebeenroll formedinthicknessesof0.006–0.30in.(0.2–7.6mm).The sizerangesofstructuralshapesthatcanberollformedon standardmill-typecold-roll-formingmachinesareshownin Fig.1.24.

Thetolerancesinrollformingareusuallyaffectedbythe sectionsize,theproducttype,andthematerialthickness. ThefollowinglimitsweregivenbyKirkland1.1 asrepresentativeofcommercialpractice,butdonotnecessarilyrepresent currentindustrytolerances:

Piecelength,using automaticcutoff ± 1 64 1 8 in.(0.4–3.2mm)

Straightnessandtwist ± 1 64 1 4 in.(0.4–6.4mm)in 10ft(3m)

Cross-sectionaldimensions

Fractional ± 1 64 1 16 in.(0.4–1.6mm)

Decimal ±0.005–0.015in. (0.1–0.4mm)

Angles ±1∘ –2∘

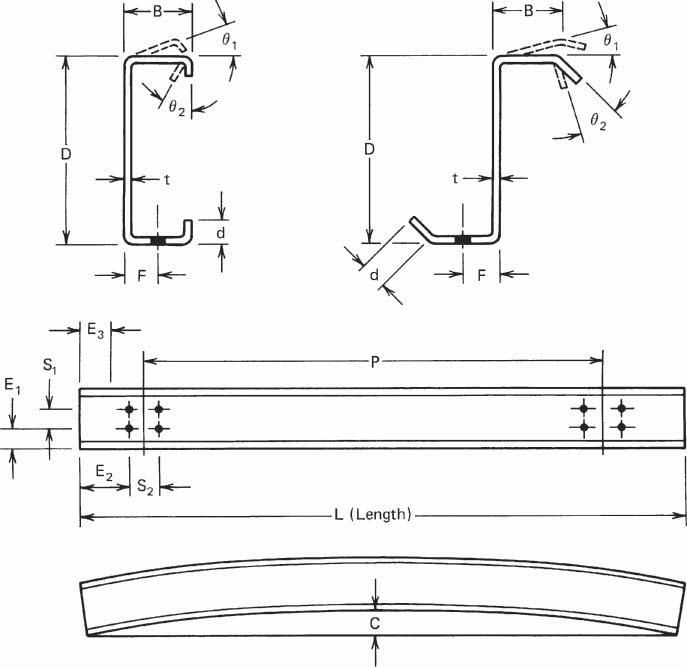

Table1.1givesthefabricationtolerancesasspecifiedby theMBMAforcold-formedsteelchannelsandZ-sections tobeusedinmetalbuildingsystems.1.360 Allsymbols usedinthetablearedefinedinFig.1.25.ThesametolerancesarespecifiedinthestandardoftheCSSBI.1.108 For lightsteelframingmembers,theAISIframingstandard S240-151.400,1.432 includesmanufacturingtolerancesfor structuralmembers.Thesetolerancesforstudsandtracks arebasedontheAmericanSocietyforTestingandMaterials (ASTM)standardC955-11.SeeTable1.2andFig.1.26.For additionalinformationonrollforming,seeRef.1.119.

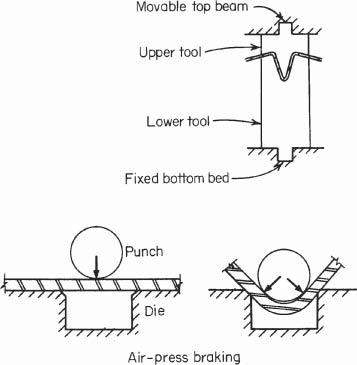

1.4.2PressBrake

Thepressbrakeoperationmaybeusedunderthefollowing conditions:

1.Thesectionisofsimpleconfiguration.

2.Thereisasmallrequiredquantity.

Theequipmentusedinthepressbrakeoperationconsists essentiallyofamovingtopbeamandastationarybottom bedonwhichthediesapplicabletotheparticularrequired productaremounted,asshowninFig.1.27.

Figure1.23 Cold-roll-formingmachine.

Figure1.24 Sizerangesoftypicalroll-formedstructuralshapes.1.1

Table1.1MBMATableonFabricationTolerances1.360 Tolerances,in.

Note: 1in. = 25.4mm.

Simplesectionssuchasangles,channels,andZ-sections areformedbypressbrakeoperationfromsheet,strip,plate, orbarinnotmorethantwooperations.Morecomplicated sectionsmaytakeseveraloperations.

Itshouldbenotedthatthecostofproductsisoftendependentuponthetypeofthemanufacturingprocessusedin production.Reference1.120indicatesthatinadditiontothe strengthanddimensionalrequirementsadesignershould alsoconsiderotherinfluencingfactors,suchasformability, costandavailabilityofmaterial,capacityandcostofmanufacturingequipment,flexibilityintooling,materialhandling, transportation,assembly,anderection.

1.5RESEARCHANDDESIGNSPECIFICATIONS

1.5.1UnitedStates

1.5.1.1Research Duringthe1930s,theacceptanceand developmentofcold-formedsteelmembersfortheconstructionindustryintheUnitedStatesfaceddifficultiesduetothe lackofanappropriatedesignspecification.Variousbuilding codesmadenoprovisionforcold-formedsteelconstruction atthattime.

Sincecold-formedsteelstructuralmembersareusually madeofrelativelythinsteelsheetandcomeinmany differentgeometricshapesincomparisonwithtypical hot-rolledsections,thestructuralbehaviorandperformance ofsuchthin-walled,cold-formedstructuralmembersunder loadsdifferinseveralsignificantrespectsfromthatof

Figure1.25 SymbolsusedinMBMAtable.1.360

Stiffening Lip Length

Figure1.26 Manufacturingtolerances.1.400,1.432

Width

Table1.2ASTMC955-11ManufacturingTolerancesforStructuralMembers1.400,1.432

Dimension

�� ItemCheckedStuds,in.(mm)Tracks,in.(mm)

ALength +3/32(2.38) +1/2(12.7) –3/32(2.38)–1/4(6.35)

B�� WebDepth +1/32(0.79) +1/32(0.79) –1/32(0.79) +1/8(3.18)

CFlare +1/16(1.59) +0(0)

Overbend–1/16(1.59)–3/32(2.38)

DHoleCenterWidth +1/16(1.59)NA –1/16(1.59)NA

EHoleCenterLength +1/4(6.35)NA –1/4(6.35)NA

FCrown +1/16(1.59) +1/16(1.59) –1/16(1.59)–1/16(1.59)

G�� Camber1/8per10ft(3.13per3m)1/32perft(2.60perm)1/2max(12.7)

H�� Bow1/8per10ft(3.13per3m)1/32perft(2.60perm) 1/2max(12.7)

ITwist1/32perft(2.60perm)1/32perft(2.60perm) 1/2max(12.7)1/2max(12.7)

JFlangeWidth +1/8(3.18) +1/4(6.35) –1/16(1.59)–1/16(1.59)

KStiffeningLipLength +1/8(3.18)NA –1/32(0.79)

�� Allmeasurementsaretakennotlessthan1ft(305mm)fromtheend.SeeFig.1.26forsymboldefinitions.

�� Outsidedimensionfor stud;insidefor track

�� 1/8inchper10feetrepresentsL/960maximumforoverallcamberandbow.Thus,a20-foot-longmemberhas1/4-inchpermissible maximum;a5-foot-longmemberhas1/16-inchpermissiblemaximum.

heavyhot-rolledsteelsections.Inaddition,theconnections andfabricationpracticeswhichhavebeendevelopedfor cold-formedsteelconstructiondifferinmanywaysfrom thoseofheavysteelstructures.Asaresult,designspecificationsforheavyhot-rolledsteelconstructioncannotpossibly coverthedesignfeaturesofcold-formedsteelconstruction completely.Itsoonbecameevidentthatthedevelopmentof anewdesignspecificationforcold-formedsteelconstruction washighlydesirable.

Realizingtheneedforaspecialdesignspecificationand theabsenceoffactualbackgroundandresearchinformation, theAISICommitteeonBuildingResearchandTechnology (thennamedtheCommitteeonBuildingCodes)sponsoreda researchprojectatCornellUniversityin1939forthepurpose ofstudyingtheperformanceoflight-gagecold-formedsteel structuralmembersandofobtainingfactualinformationfor

Figure1.27 Pressbraking.1.2,1.16

theformulationofadesignspecification.Researchprojects havebeencarriedoutcontinuouslyatCornellUniversityand otheruniversitiessince1939.

Theinvestigationsonstructuralbehaviorofcold-formed steelstructuresconductedatCornellUniversitybyProfessor GeorgeWinterandhiscollaboratorsresultedinthedevelopmentofmethodsofdesignconcerningtheeffectivewidth forstiffenedcompressionelements,thereducedworking stressesforunstiffenedcompressionelements,webcripplingofthin-walledcold-formedsections,lateralbucklingof beams,structuralbehaviorofwallstuds,bucklingoftrusses andframes,unsymmetricalbendingofbeams,welded andboltedconnections,flexuralbucklingofthin-walled steelcolumns,torsional–flexuralbucklingofconcentrically andeccentricallyloadedcolumnsintheelasticandinelastic ranges,effectsofcoldformingonmaterialproperties,performanceofstainlesssteelstructuralmembers,shearstrength oflight-gagesteeldiaphragms,performanceofbeamsand columnscontinuouslybracedwithdiaphragms,hyperbolic paraboloidandfolded-plateroofstructures,influenceof ductility,bracingrequirementsforchannelsandZ-sections loadedintheplaneoftheweb,mechanicalfastenersfor cold-formedsteel,interactionoflocalandoverallbuckling,ultimatestrengthofdiaphragm-bracedchannelsand Z-sections,inelasticreservecapacityofbeams,strengthof perforatedcompressionelements,edgeandintermediate stiffeners,rackstructures,probabilityanalysis,andC-and Z-purlinsunderwinduplift.1.5–1.7,1.31,1.121,1.122,1.133–1.136

TheCornellresearchunderthedirectionofProfessor TeomanPekozincludedtheeffectofresidualstresson columnstrength,maximumstrengthofcolumns,unified designapproach,screwconnections,distortionalbucklingofbeamsandcolumns,perforatedwallstuds,storage racks,loadeccentricityeffectsonlipped-channelcolumns, bendingstrengthofstandingseamroofpanels,behaviorof longitudinallystiffenedcompressionelements,probabilistic examinationofelementstrength,direct-strengthprediction ofmembersusingnumericalelasticbucklingsolutions, laterallybracedbeamswithedge-stiffenedflanges,steel memberswithmultiplelongitudinalintermediatestiffeners, designapproachforcomplexstiffeners,unlippedchannel inbendingandcompression,beam–columns,cold-formed steelframedesign,andsecond-orderanalysisofstructural systemsandothers.1.220,1.273,1.302–1.308,1.346,1.362,1.363

InadditiontotheCornellwork,numerousresearch projectsoncold-formedsteelmembers,connections,and structuralsystemshavebeenconductedatmanyindividual companiesanduniversitiesintheUnitedStates.1.121.1.143, 1.267,1.302–1.305,1.309,1.311,1.346,1.362–1.366,1.419–1.423 Forty-three universitieswerelistedinthefirsteditionofthisbook publishedin1985.1.352 Researchfindingsobtainedfrom

theseprojectshavebeenpresentedatvariousnationaland internationalconferencesandarepublishedintheconferenceproceedingsandthejournalsofdifferentengineering societies.1.43,1.117,1.118,1.124–1.132,1.144–1.147,1.272–1.276,1.302–1.308, 1.367–1.377

Previously,theASCECommitteeonCold-Formed Membersconductedsurveysofcurrentresearchoncoldformedstructuresandliteraturesurveys.1.133–1.134,1.135,1.136, 1.139–1.141 Thirty-eightresearchprojectswerereportedin Ref.1.136.InRef.1.141,about1300publicationswere classifiedinto18categories.Thesereportsprovideauseful referenceforresearchersandengineersinthefieldof cold-formedsteelstructures.

In1990,theCenterforCold-FormedSteelStructureswas establishedattheUniversityofMissouri–Rollatoprovide anintegratedapproachforhandlingresearch,teaching,technicalservices,andprofessionalactivity.1.312 In1996,the CenterforCold-FormedSteelStructuresconductedasurvey ofrecentresearch.Reference1.309lists48projectscarried outinsevencountries.InOctober2000,thecenterwas renamedtheWei-WenYuCenterforCold-FormedSteel Structures(CCFSS)attheFifteenthInternationalSpecialty ConferenceonCold-FormedSteelStructures.1.378

1.5.1.2AISIDesignSpecifications Asfarasthedesign criteriaareconcerned,thefirsteditionof“Specification fortheDesignofLightGageSteelStructuralMembers” preparedbytheAISITechnicalSubcommitteeunderthe chairmanshipofMiltonMalewasissuedbytheAISIin 1946.1.5 Thisallowablestressdesign(ASD)specification wasbasedonthefindingsoftheresearchconductedat CornellUniversityuptothattimeandtheaccumulatedpracticalexperienceobtainedinthisfield.Itwasrevisedbythe AISIcommitteeunderthechairmanshipsofW.D.Moorehead,TappanCollins,D.S.Wolford,J.B.Scalzi,K.H. Klippstein,S.J.Errera,andR.L.Brockenbroughin1956, 1960,1962,1968,1980,1986,1996,2001,2007,2012,and 2016toreflectthetechnicaldevelopmentsandresultsof continuingresearch.

In1991,thefirsteditionoftheloadandresistancefactor design(LRFD)specification1.313 wasissuedbyAISIunder thechairmanshipofR.L.BrockenbroughandthevicechairmanshipofJ.M.Fisher.Thisspecificationwasbasedonthe researchworkdiscussedinRef.1.248.In1996,theAISI ASDSpecification1.4 andtheLRFDSpecification1.313 were combinedintoasinglespecification1.314 underthechairmanshipofR.L.Brockenbroughandthevicechairmanship ofJ.W.Larson.Therevisionsofvariouseditionsofthe AISISpecificationarediscussedinRef.1.267.InRef.1.315, Brockenbroughsummarizedthemajorchangesmadeinthe 1996AISISpecification.SeealsoRef.1.316foranoutlineof