Food Wastes and By‐products

Nutraceutical and Health Potential

Edited by Rocio Campos‐Vega

Programa de Posgrado en Alimentos del Centro de la República (PROPAC)

Research and Graduate Studies in Food Science

School of Chemistry

Universidad Autónoma de Querétaro

México

B. Dave Oomah

(Retired) Formerly with Summerland Research and Development Centre

Agriculture and Agri‐Food Canada

Summerland, BC, Canada

Haydé Azeneth Vergara‐Castañeda

Facultad de Medicina

Universidad Autónoma de Querétaro

Querétaro, México

This edition first published 2020 © 2020 John Wiley & Sons Ltd

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, except as permitted by law. Advice on how to obtain permission to reuse material from this title is available at http://www.wiley.com/go/permissions.

The right of Rocio Campos‐Vega, B. Dave Oomah, and Haydé Azeneth Vergara‐Castañeda to be identified as the editors of this work has been asserted in accordance with law.

Registered Office(s)

John Wiley & Sons, Inc., 111 River Street, Hoboken, NJ 07030, USA

John Wiley & Sons Ltd, The Atrium, Southern Gate, Chichester, West Sussex, PO19 8SQ, UK

Editorial Office

The Atrium, Southern Gate, Chichester, West Sussex, PO19 8SQ, UK

For details of our global editorial offices, customer services, and more information about Wiley products visit us at www.wiley.com.

Wiley also publishes its books in a variety of electronic formats and by print‐on‐demand. Some content that appears in standard print versions of this book may not be available in other formats.

Limit of Liability/Disclaimer of Warranty

While the publisher and authors have used their best efforts in preparing this work, they make no representations or warranties with respect to the accuracy or completeness of the contents of this work and specifically disclaim all warranties, including without limitation any implied warranties of merchantability or fitness for a particular purpose. No warranty may be created or extended by sales representatives, written sales materials or promotional statements for this work. The fact that an organization, website, or product is referred to in this work as a citation and/or potential source of further information does not mean that the publisher and authors endorse the information or services the organization, website, or product may provide or recommendations it may make. This work is sold with the understanding that the publisher is not engaged in rendering professional services. The advice and strategies contained herein may not be suitable for your situation. You should consult with a specialist where appropriate. Further, readers should be aware that websites listed in this work may have changed or disappeared between when this work was written and when it is read. Neither the publisher nor authors shall be liable for any loss of profit or any other commercial damages, including but not limited to special, incidental, consequential, or other damages.

Library of Congress Cataloging-in-Publication Data is available for this title 9781119534105 (hardback)

Cover image: © Craevschii Family/Shutterstock

Cover design by Wiley

Set in 9.5/12.5pt STIXTwoText by SPi Global, Pondicherry, India

Contents

List of Contributors xv

1 Cereal/Grain By-products 1

Norma Julieta Salazar-López, Maribel Ovando-Martínez, and J. Abraham

Domínguez-Avila

1.1 Introduction 1

1.2 Global Production of Cereals and Crop Residues 2

1.3 Cereal Processing and Production of By-products 5

1.3.1 Cereals Morphology and Composition 5

1.3.2 Cereal Grains Processing 6

1.3.2.1 Milling 6

1.3.2.2 Dry Milling 6

1.3.2.3 Wet Milling 6

1.3.2.4 Pearling 7

1.3.2.5 Malting 8

1.3.2.6 Fermentation 8

1.3.2.7 Others 9

1.4 Cereal Grains By-products 9

1.5 Nutraceutical from Cereal/Grain By-products 11

1.5.1 Classification of Nutraceutical Ingredients in Cereal By-products 12

1.5.1.1 Polyphenols 12

1.5.1.2 Carotenoids 16

1.5.1.3 Dietary Fiber 16

1.5.1.4 Prebiotics 17

1.5.1.5 Lipids and Fatty Acids 17

1.5.1.6 Proteins 18

1.5.1.7 Starch 18

1.6 Health Potential of Cereal/Grain By-products 18

1.6.1 Non- Communicable Diseases 18

1.6.1.1 Dyslipidemia and Cardiovascular Effect 18

1.6.1.2 Diabetes 22

1.6.1.3 Anticancer Effect 23

1.7 Current and Future Perspectives 25

1.8 Concluding Remarks 26

References 26

2 Enrichment and Utilization of Thin Stillage By products 35

Timothy J. Tse and Martin J. T. Reaney

2.1 Introduction 35

2.2 Endemic Bacteria in Wheat‐Based Thin Stillage 37

2.3 Protein and Organic Solute Concentration in Thin Stillage 39

2.4 Bacteriocins 43

2.5 Separation and Purification of Bacteriocins 46

2.6 Conclusion 47

References 48

3 Pulse By-products 59

Iván Luzardo-Ocampo, M. Liceth Cuellar-Nuñez, B. Dave Oomah, and Guadalupe Loarca-Piña

3.1 Introduction 59

3.2 Beans By-products 62

3.3 Pea (Pisum sativum) By-products 68

3.4 Chickpea (Cicer arietinum) and Lentil (Lens culinaris) By-products 71

3.5 Lupin (Lupinus) By-products 72

3.6 Other Pulse By-products 74

3.6.1 Pigeon Pea (Cajanus cajan L.) 74

3.6.2 Broad Beans (Vicia faba) 75

3.7 Concluding Remarks 78 References 86

4 Aquafaba, from Food Waste to a Value-Added Product 93

Rana Mustafa and Martin J. T. Reaney

4.1 Introduction 93

4.2 Plant-based Dairy and Eggs Replacement 94

4.3 History of Use and Etymology 95

4.4 Composition of Chickpea and Aquafaba 96

4.5 Anti-nutritional Compounds 98

4.5.1 Protein Anti-nutritional Compounds 100

4.5.2 Nonprotein Anti-nutritional Compounds 100

4.6 Functional Properties 101

4.6.1 Water Holding Capacity and Oil Holding Capacity 102

4.6.2 Emulsion Stabilizer 103

4.6.3 Foaming Properties 104

4.6.4 Gelling and Thickening Properties 107

4.7 Factors Affecting Functional Properties 108

4.7.1 Effect of Cultivars and Genotypes 108

4.7.2 Effect of Processing Methods 110

4.8 Environmental Impact 112

4.9 Value-added Products for the Food and Pharmaceutical Industries 113

4.10 Current and Future Perspectives 115

4.11 Conclusion 116

References 116

5 Brazilian (North and Northeast) Fruit By-Products 127

Larissa Morais Ribeiro DA Silva, Paulo Henrique Machado de Sousa, Luiz Bruno de Sousa Sabino, Giovana Matias do Prado, Lucicleia Barros Vasconcelos Torres, Geraldo Arraes Maia, Raimundo Wilane de Figueiredo, and Nágila Maria Pontes Silva Ricardo

5.1 Introduction 127

5.2 Coproducts’ Origin 131

5.3 Types of Waste Processing 131

5.4 Bioactive Compounds 132

5.4.1 Vitamin C 133

5.4.2 Phenolic Compounds 134

5.4.3 Antioxidant Activity in Fruit Coproducts 136

5.4.4 Phytosterols in Fruit Coproducts 141

5.5 Brazilian Fruit By-products from the North and Northeast as a Source of Colorants 141

5.6 Brazilian North and Northeast Fruit By-products as Source of Polysaccharides 144

5.7 Brazilian North and Northeast Fruit By-products as Source of Fibers 145

5.8 Conclusions 149

References 149

6 Health Benefits of Mango By-products 159

Abraham Wall-Medrano, Francisco J. Olivas-Aguirre, Jesus F. Ayala-Zavala, J. Abraham Domínguez-Avila, Gustavo A. Gonzalez-Aguilar, Luz A. HerreraCazares, and Marcela Gaytan-Martinez

6.1 Introduction 159

6.2 Mango Agro wastes and Industrial By-products 161

6.2.1 Impacts of Generating Mango Wastes and By-products 162

6.2.1.1 Economic Impact 163

6.2.1.2 Environmental Impact 163

6.2.2 Research and Development (R&D) 164

6.3 Nutritional and Functional Value of Mango Wastes and By-products 165

6.3.1 Nutritional and Functional Value of Mango Wastes and By-products 165

6.3.1.1 Macro/Micronutrients 165

6.3.1.2 Dietary Fiber 166

6.3.1.3 Phenolic Compounds 168

6.3.2 Metabolic Fate of Phytochemicals from Mango By-products 170

6.4 Potential Health Benefits of Mango Wastes and By-products 171

6.4.1 Infectious Diseases 171

6.4.1.1 Antibiotic Effect: Planktonic Cells 172

6.4.1.2 Antibiotic Effect: Biofilms 174

6.4.1.3 Prebiotic Effects 176

6.4.2 Noncommunicable Chronic Diseases (NCCDs) 176

6.4.2.1 Obesity 177

6.4.2.2 Diabetes Mellitus 177

6.4.2.3 Cardiovascular Diseases (CVDs) 179

6.4.2.4 Cancer 180

6.4.2.5 Inflammatory Diseases 181

6.4.2.6 Neurological Diseases 182 Acknowledgements 182 References 183

7 Citrus Waste Recovery for Sustainable Nutrition and Health 193

Adriana Maite Fernández-Fernández, Eduardo Dellacassa, Alejandra Medrano-Fernandez, and María Dolores Del Castillo

7.1 Introduction 193

7.2 Citrus By-products: Natural Sources of Health-Promoting Food Ingredients 194

7.2.1 Polyphenols 196

7.2.2 Antioxidant dietary fiber 198

7.3 Health-Promoting Effects 200

7.4 Food Applications 208

7.5 Safety 210

7.6 Conclusions 210 Acknowledgments 210 References 211

8 Vegetable By-products 223

L. Gabriela Espinosa-Alonso, Maribel Valdez-Morales, Xochitl AparicioFernandez, Sergio Medina-Godoy, and Fidel Guevara-Lara

8.1 Introduction 223

8.2 Global and/or by Region Vegetable Food Production and Postharvest Waste 226

8.2.1 Tomato 227

8.2.2 Chili 229

8.2.3 Broccoli and Cauliflower 229

8.2.4 Zucchini 230

8.2.5 Cucumber 230

8.3 Global and/or Regional Vegetable Industrialization and By-Product Generation 231

8.3.1 Tomato 231

8.3.2 Chili 232

8.3.3 Broccoli and Cauliflower 235

8.4 Nutraceutical Composition 236

8.4.1 Tomato 236

8.4.2 Chili 237

8.4.3 Broccoli and Cauliflower 238

8.4.4 Zucchini 239

8.4.5 Cucumber 241

8.5 Proven Nutraceutical In Vitro and In Vivo Bioactivity 242

8.5.1 Tomato 242

8.5.2 Chili 243

8.5.3 Broccoli and Cauliflower 245

8.5.4 Zucchini 245

8.5.4.1 Fruit 245

8.5.4.2 Peel 246

8.5.4.3 Leaves and Stems 247

8.5.5 Cucumber 247

8.5.5.1 Fruit 248

8.5.5.2 Seeds 249

8.5.5.3 Peel 250

8.5.5.4 Leaves and Stems 250

8.6 Methods and Strategies Used by the Food Sector and Other Industries 251

8.7 Commercialization or Transformation in Value-Added Products 253

8.7.1 Tomato 253

8.7.2 Seed Chili 254

Contents x

8.7.3 Broccoli and Cauliflower 255

8.7.4 Zucchini 256

Acknowledgments 256

References 256

9 Flaxseed By-products 267

B. Dave Oomah

9.1 Introduction 267

9.2 Flaxseed Protein 269

9.2.1 Extraction 269

9.2.2 Composition 272

9.2.3 Amino Acid Profile 273

9.2.4 Product Application 275

9.3 Advanced Processing 276

9.4 Mucilage 277

9.5 Current Trends and Perspectives 278

Acknowledgments 283

References 283

10 Seed Hull Utilization 291

E.E. Martinez-Soberanes, R. Mustafa, Martin J.T. Reaney, and W.J. Zhang

10.1 Introduction 291

10.2 Seed Hull Production 292

10.3 Seed Hull Composition 294

10.3.1 Dietary Fiber (DF) 295

10.3.2 Phytochemicals 297

10.3.3 Protein and Other Minor Components 303

10.4 Dehulling Technology 304

10.4.1 Seed Dehulling 304

10.4.2 Dehulling Technology 305

10.5 Recovery of Compounds from Seed Hull 308

10.5.1 Traditional Solvent Extraction 309

10.5.2 Ultrasonic-Assisted Extraction 310

10.5.3 Microwave-Assisted Extraction 312

10.5.4 Supercritical Fluid Extraction 313

10.5.5 Membrane Separation 314

10.5.6 Seed Hull in Value-Added Food Products 316

10.6 Prospects and Challenges 316

References 317

11 Health Benefits of Spent Coffee Grounds 327

Norma Julieta Salazar-López, Carlos Vladimir López-Rodríguez, Diego Antonio Hernández-Montoya, and Rocio Campos-Vega

11.1 Introduction 327

11.2 Coffea Arabica L. Generalities 328

11.3 Coffee Processing and By-products 329

11.3.1 Coffee Husks 330

11.3.2 Coffee Pulp 330

11.3.3 Coffee Silverskin 331

11.3.4 Spent Coffee Grounds 331

11.4 Physicochemical Characteristics in SCG 331

11.5 Nutritional Properties of SCG 333

11.5.1 Carbohydrates 334

11.5.2 Proteins 336

11.5.3 Lipids 336

11.5.4 Minerals 337

11.5.5 Feed Quality 337

11.6 Nutraceuticals in SCG 338

11.6.1 Dietary Fiber 339

11.6.2 Resistant Starch 339

11.6.3 Antioxidant Compounds 340

11.6.4 Antioxidant Dietary Fiber 341

11.7 Health Benefits of Spent Coffee Grounds 341

11.7.1 Weight Management and Obesity 342

11.7.2 Cardiovascular Diseases 344

11.7.3 Gastrointestinal Diseases 345

11.7.4 Cancer 346 References 348

12 Health Benefits of Silverskin 353

Amaia Iriondo-DeHond, Teresa Herrera, and María Dolores Del Castillo

12.1 Introduction 353

12.2 Improvement of Gastrointestinal Health 358

12.3 Prevention of Metabolic Disorders 359

12.3.1 Obesity and Dyslipemia 360

12.3.2 Diabetes 362

12.4 Improvement of Skin Health 363

12.5 Conclusions 366

Acknowledgements 366

References 367

13 Cocoa By‐products 373

Karen Haydeé Nieto Figueroa, Nancy Viridiana Mendoza García, and Rocio Campos-Vega

13.1 Introduction 373

13.2 Cocoa Bean Shell 376

13.2.1 Chemical Composition 376

13.2.2 Nutraceutical Composition 377

13.2.2.1 Dietary Fiber 377

13.2.2.2 Phenolic Compounds 378

13.2.2.3 Methylxanthines 379

13.2.2.4 Other Compounds 380

13.2.3 Applications 381

13.2.3.1 Feedstuff 381

13.2.3.2 Agriculture 382

13.2.3.3 Biofuels 382

13.2.3.4 Adsorbent 382

13.2.3.5 Dye 383

13.2.3.6 Food Products 383

13.2.3.7 Cocoa Shell Tea 383

13.2.3.8 Cocoa Hulls Polyphenols as a Functional Ingredient for Bakery Applications 383

13.2.3.9 Bio‐Recyclable Paper Packaging 384

13.2.3.10 Cocoa Shell Extracts 384

13.3 Cocoa Pod Husk 386

13.3.1 Chemical Composition 387

13.3.2 Drying Methods 387

13.3.3 Nutraceutical Composition 388

13.3.3.1 Dietary Fiber 388

13.3.3.2 Antioxidants 390

13.3.3.3 Theobromine 391

13.3.3.4 Other Compounds 392

13.3.4 Applications 393

13.3.4.1 Animal Feed 393

13.3.4.2 Soap Making 394

13.3.4.3 Activated Carbon 394

13.3.4.4 Fertilizer and Soil Organic Matter 394

13.3.4.5 Paper Making 395

13.3.4.6 Biofuels and Chemical Industry 395

13.3.4.7 Gums 396

13.3.4.8 Source of Enzymes 396

13.4 Cocoa Mucilage/Pulp/Sweating 396

13.4.1 Chemical Composition 397

13.4.2 Nutraceutical Composition 398

13.4.2.1 Dietary Fiber 398

13.4.2.2 Phenolic Content 398

13.4.3 Applications 399

13.4.3.1 Cocoa Juice 399

13.4.3.2 Cocoa Alcoholic Products 399

13.4.3.3 Pectin 400

13.4.3.4 Marmalade 400

13.4.3.5 Cocoa Jelly 401

13.4.3.6 Other Products 401

13.5 Technological Properties of Cocoa By‐products 402

13.5.1 Water (WHC)‐ and Oil (OHC)‐Holding and Swelling Capacities (SWC) 402

13.6 Concluding Remarks 402

References 403

14 Emerging and Potential Bio-Applications of Agro-Industrial By-products Through Implementation of Nanobiotechnology 413 Hayde Azeneth Vergara-Castañeda, Gabriel Luna-Bárcenas, and Héctor Pool

14.1 Introduction 413

14.2 Green Synthesis of Metallic Nanoparticles Mediated by Agro-Industrial Wastes 414

14.2.1 Gold Nanoparticles 417

14.2.2 Silver Nanoparticles 419

14.2.3 Quantum Dots 422

14.3 Agro-Industrial Wastes as Platforms for Biofunctional Nanocomposite Production 425

14.4 Nano-Drug Delivery Systems for Encapsulation, Protection, and Controlled Release of Bioactive Agents Extracted from Agro-Industrial Wastes 431

14.5 Concluding Remarks 435

References 436

Index 445

List of Contributors

J. Abraham Domínguez-Avila

Cátedras CONACyT‐Centro de Investigación en Alimentación y Desarrollo, A.C., Sonora, México

Xochitl Aparicio-Fernandez

Centro Universitario de los Lagos, Universidad de Guadalajara, Lagos de Moreno, Jalisco, México

Jesus F. Ayala-Zavala

Departmento de Tecnologia de Alimentos de Origen Vegetal, Centro de Investigacion en Alimentacion y Desarrollo, A.C., Hermosillo, Sonora, México

Rocio Campos-Vega

Programa de Posgrado en Alimentos del Centro de la República (PROPAC), Research and Graduate Studies in Food Science, School of Chemistry, Universidad Autónoma de Querétaro (UAQ), Querétaro, México

María Dolores del Castillo

Department of Bioactivity and Food Analysis, Instituto de Investigación en Ciencias de la Alimentación (CIAL) (CSIC-UAM), Campus de la

Universidad Autónoma de Madrid, Madrid, Spain

Eduardo Dellacassa

Departamento de Química Orgánica, Facultad de Química, Universidad de la República, Montevideo, Uruguay

Paulo Henrique Machado De Sousa Institute of Culture and Art, Federal University of Ceará, Fortaleza, Brazil

Adriana Maite Fernández-Fernández Departamento de Ciencia y Tecnología de Alimentos, Facultad de Química, Universidad de la República, Montevideo, Uruguay Department of Bioactivity and Food Analysis, Instituto de Investigación en Ciencias de la Alimentación (CIAL) (CSIC‐UAM), Campus de la Universidad Autónoma de Madrid, Madrid, Spain

Raimundo Wilane De Figueiredo

Department of Food Engineering, Federal University of Ceará, Fortaleza, Ceará, Brazil

List of Contributors

L. Gabriela Espinosa-Alonso

Departamento de Biotecnología

Agrícola, Alimentos Funcionales

Instituto Politécnico Nacional, Centro Interdisciplinario de Investigación para el Desarrollo Integral Regional Unidad Sinaloa, Guasave, Sinaloa, México

Marcela Gaytan-Martinez

Posgrado en Ciencia y Tecnología de los Alimentos, Facultad de Química, Universidad Autónoma de Querétaro, Santiago de Querétaro, México

Gustavo A. Gonzalez-Aguilar

Departmento de Tecnologia de Alimentos de Origen Vegetal, Centro de Investigacion en Alimentacion y Desarrollo, A.C., Hermosillo, Sonora, México

Fidel Guevara-Lara

Departamento de Química, Centro de Ciencias Básicas, Universidad Autónoma de Aguascalientes, Aguascalientes, Aguascalientes, México

Diego Antonio Hernández-Montoya

Programa de Posgrado en Alimentos del Centro de la República (PROPAC) Research and Graduate Studies in Food Science, School of Chemistry Universidad Autónoma de Querétaro (UAQ), Querétaro, México

Teresa Herrera

Department of Bioactivity and Food Analysis, Instituto de Investigación en Ciencias de la Alimentación

(CIAL) (CSIC‐UAM), Campus de la Universidad Autónoma de Madrid, Madrid, Spain

Luz A. Herrera-Cazares

Posgrado en Ciencia y Tecnología de los Alimentos, Facultad de Química, Universidad Autónoma de Querétaro, Santiago de Querétaro, México

Amaia Iriondo-DeHond

Department of Bioactivity and Food Analysis, Instituto de Investigación en Ciencias de la Alimentación (CIAL) (CSIC‐UAM), Campus de la Universidad Autónoma de Madrid, Madrid, Spain

M. Liceth Cuellar-Nuñez

Programa de Posgrado en Alimentos del Centro de la República (PROPAC) Research and Graduate Studies in Food Science, School of Chemistry

Universidad Autónoma de Querétaro, Querétaro, México

Guadalupe Loarca-Piña

Programa de Posgrado en Alimentos del Centro de la República (PROPAC) Research and Graduate Studies in Food Science, School of Chemistry

Universidad Autónoma de Querétaro, Querétaro, México

Carlos Vladimir López-Rodríguez

Programa de Posgrado en Alimentos del Centro de la República (PROPAC) Research and Graduate Studies in Food Science, School of Chemistry

Universidad Autónoma de Querétaro (UAQ), Querétaro, México

Gabriel Luna-Bárcenas

Centro de Investigación y Estudios

Avanzados del Instituto Politécnico Nacional (CINVESTAV‐IPN), Querétaro, México

Iván Luzardo-Ocampo Programa de Posgrado en Alimentos del Centro de la República (PROPAC)

Research and Graduate Studies in Food Science, School of Chemistry Universidad Autónoma de Querétaro, Querétaro, México

Geraldo Arraes Maia

Department of Food Engineering, Federal University of Ceará, Fortaleza, Ceará, Brazil

E.E. Martinez-Soberanes

Department of Plant Sciences, University of Saskatchewan, Saskatoon, Saskatchewan, Canada Department of Mechanical Engineering, University of Saskatchewan, Saskatoon, Canada

Sergio Medina-Godoy Departamento de Biotecnología Agrícola, Alimentos Funcionales, Instituto Politécnico Nacional, Guasave, Sinaloa, México

Alejandra Medrano-Fernandez

Departamento de Ciencia y Tecnología de Alimentos, Facultad de Química, Universidad de la República, Montevideo, Uruguay

Nancy Viridiana Mendoza García

School of Chemistry, Universidad Autónoma de Querétaro, Santiago de Querétaro, Qro, México

Rana Mustafa

Department of Plant Sciences, University of Saskatchewan, Saskatoon, Saskatchewan, Canada Prairie Tide Diversified Inc., Saskatoon, Saskatchewan, Canada

Karen Haydeé Nieto Figueroa Programa de Posgrado en Alimentos del Centro de la República (PROPAC), Research and Graduate Studies in Food Science, School of Chemistry, Universidad Autónoma de Querétaro, Santiago de Querétaro, Qro, México

Francisco J. Olivas-Aguirre Departmento de Ciencias de la Salud, Universidad de Sonora (campus Cajeme), Ciudad Obregon, Sonora, México

B. Dave Oomah (Retired) Formerly with Summerland Research and Development Centre, Agriculture and Agri‐Food Canada, Summerland, BC, Canada

Maribel Ovando-Martínez Departamento de Investigaciones Científicas y Tecnológicas, Universidad de Sonora, Sonora, México

Héctor Pool

División de Investigación y Posgrado, Facultad de Ingeniería, Universidad Autónoma de Querétaro, Querétaro, México

List of Contributors

Giovana Matias Do Prado

Department of Food Engineering, Federal University of Ceará, Fortaleza, Ceará, Brazil

Martin J. T. Reaney Department of Plant Sciences, University of Saskatchewan, Saskatoon, Saskatchewan, Canada Prairie Tide Diversified Inc., Saskatoon, Saskatchewan, Canada, Guangdong Saskatchewan Oilseed Joint Laboratory, Department of Food Science and Engineering, Jinan University, Guangzhou, Guangdong, China

Nágila Maria Pontes Silva Ricardo Department of Organic and Inorganic Chemistry, Fortaleza, Brazil

Luiz Bruno De Sousa Sabino Department of Chemical Engineering, Federal University of Ceará, Fortaleza, Brazil

Norma Julieta Salazar-López

Programa de Ingeniería en Horticultura, Universidad Estatal de Sonora (UES), Hermosillo, Sonora, México

Larissa Morais Ribeiro DA Silva Department of Food Engineering, Federal University of Ceará, Fortaleza, Ceará, Brazil

Lucicleia Barros Vasconcelos Torres Department of Food Engineering, Federal University of Ceará, Fortaleza, Ceará, Brazil

Timothy J. Tse Department of Plant Sciences, University of Saskatchewan, Saskatoon, Saskatchewan, Canada

Maribel Valdez-Morales Departamento de Biotecnología

Agrícola, CONACyT‐Instituto Politécnico Nacional, Guasave, Sinaloa, México

Haydé Azeneth Vergara-Castañeda Department of Biomedical Sciences, Faculty of Medicine, Universidad Autónoma de Querétaro, Querétaro, México

Abraham Wall-Medrano

Instituto de Ciencias Biomedicas, Universidad Autonoma de Ciudad Juarez, Ciudad Juarez, Chihuahua, México

W.J. Zhang

Department of Mechanical Engineering, University of Saskatchewan, Saskatoon, Saskatchewan, Canada

Cereal/Grain By-products

Norma Julieta Salazar-López1, Maribel Ovando-Martínez2, and J. Abraham Domínguez-Avila3

1 Programa de Ingeniería en Horticultura, Universidad Estatal de Sonora (UES), Hermosillo, Sonora, México

2 Departamento de Investigaciones Científicas y Tecnológicas, Universidad de Sonora, Sonora, México

3 Cátedras CONACyT-Centro de Investigación en Alimentación y Desarrollo A.C., Sonora, México

1.1 Introduction

By‐products are generated during harvesting and processing of different cereals worldwide as wheat, rice, maize, barley, oat, millet, sorghum, and other cereal grains, cereal crop residues, and cereal brans as food waste. The cereal crop residues are used for ethanol production from lignocellulosic biomass, animal feed, or burned in the soil with emissions that negatively impact the environment [1].

The milling of cereals is one of the main processing methods, and its objective is to obtain flour (endosperm) as the main product and generate as by‐products the bran, germ, protein, hull, broken grain, fiber, husk, and others; most of these cereal brans contain the pericarp, testa, aleurone and subaleurone layers, and part of the starchy endosperm. Depending on the cereal grain, the bran is around 3–30% of the kernel weight on dry basis [2]. During the eighties, the effluent from wheat starch–gluten production was high in biological oxygen demand (BOD). So, the wheat industry was concerned with pretreatments to control the wastewater effluent [3]. In this regard, wheat flour solubles (WFS) obtained by ultrafiltration and spray drying of an industrial gluten–wheat starch plant effluent performed well in yellow layer cake (50% whole egg substitution), cookies (up to 25%substitution cookie formulation), and wieners (6% level) [3]. Nowadays,

Food Wastes and By-products: Nutraceutical and Health Potential, First Edition. Edited by Rocio Campos-Vega, B. Dave Oomah, and Haydé Azeneth Vergara-Castañeda.

© 2020 John Wiley & Sons Ltd. Published 2020 by John Wiley & Sons Ltd.

the cereal food industry is interested in the recovery of starch, protein, lipids, dietary fiber, and bioactive compounds from these by‐products. Such recovery targets to produce nutraceutical ingredients for the production of functional foods. In order to achieve this aim, it is important to understand the biological properties and human health‐related benefits of the extracted bioactive compounds from the cereal grains waste and by‐products.

1.2 Global Production of Cereals and Crop Residues

Annual global production (2008–2016) of cereals averaged about 3200 million tons of grains including wheat, maize, sorghum, barley, rice, oat, rye, and millet (Table 1.1) [4]. The global production of cereals increased 14.3% over the last nine years. During that period, the maize crop showed the highest increase (29.8%) in production compared to wheat, sorghum, barley, rice, oat, rye, and millet crops.

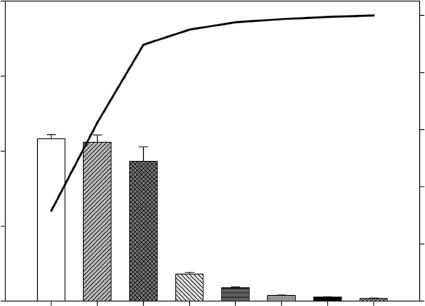

Crop residues of cereals are a source of nutrients. The Pareto figure depicts the average cereal crop residues expressed as million‐tons of nutrients (2008–2016), indicating that over 80% of nutrients contained in crop residues come from rice (paddy), maize, and wheat crops (Figure 1.1).

According to Santos et al. [5], lignocellulosic biomass is the most abundant renewable resource, which could be used to obtain biofuels and with the advantage of not generating emissions of CO2 as fossil fuels. Regarding each million

Table 1.1 Global production of cereals

a Other cereals include sorghum, barley, oat, rye, and millet.

b Total production includes wheat, maize, sorghum, barley, rice, oat, rye, and millet production. Source: adapted from [4]. Reproduced with permission of The Food and Agriculture Organization Corporate Statistical Database.

(millions of tons).

Figure 1.1 Crop residues of cereals expressed as millions of tons of nutrients (2008–2016). Source: adapted from [4]. Reproduced with permission of The Food and Agriculture Organization Corporate Statistical Database.

tons of rice, maize, and wheat produced, about 114, 186, and 119 thousand tons of biomass (dry matter), respectively, are burned (Table 1.2). In the analyzed period, biomass burned from rice, maize, and wheat crops increased by 8.5%. However, the maize crop generated higher quantity of burned dry matter compared to wheat and rice crops.

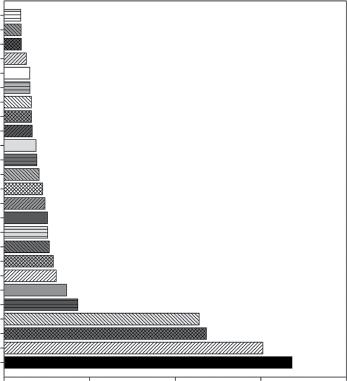

On the other hand, statistical analysis showed that mainly four countries produced the highest proportion of cereal crop residues (2008–2016) (Figure 1.2). China and India are the two countries generating crop residues of cereals production with 672.7 and 604.7 thousand tons of nutrients, respectively, followed by Indonesia and United States of America with 472.9 and 455.9 thousand tons of nutrients, respectively. So, these statistics indicate that the challenge would be the search for alternative use of the cereal biomass from cereals crops (mainly maize, rice, and wheat). The aforementioned countries together with Vietnam, Russian Federation, Canada, Brazil, and others should study the use of cereal crop residues as a source of biofuels, nutrients, and phytochemicals, among others.

Cereals

Rice, paddy Wheat

Sorghum

Table 1.2 Crop residues expressed as biomass burned (dry matter), in millions of tons.

(dry

a Total production of maize, rice, and wheat expressed as millions of tons; Biomass burned (dry matter) expressed as millions of tons.

Source: adapted from [4]. Reproduced with permission of The Food and Agriculture Organization Corporate Statistical Database.

Figure 1.2 Global production of crop residues, in 2008–2016. Source: adapted from [4]. Reproduced with permission of The Food and Agriculture Organization Corporate Statistical Database.

1.3.1 Cereals

Morphology and Composition

Cereal grains belong to the Poaceae family [6] and includes wheat, rye, barley, oat rice, millet, corn, sorghum, and triticale (hybrid of wheat and rye); corn, rice, wheat, barley, oat, and rye are the most produced cereals around the world [7]. Cereal grains are consumed worldwide as staple food and most of their nutritional importance come from the grain composition [8]. The main structural components of cereal grains are the bran, germ, and endosperm, the latter found in high proportion [9, 10]. Brown rice has highest endosperm content among four cereal grains (corn, brown rice, wheat, and barley), followed by barley, corn, and wheat [9]. However, wheat had the highest bran content, while corn presented the highest germ content.

The cereal bran consists of hemicellulose type cell walls rich in arabinoxylans and mixed‐linkage β‐glucan [6], cellulose, vitamins, and minerals [2, 9]. The endosperm is rich in starch, proteins, and small amount of dietary fiber, minerals [6, 9], and unsaturated fatty acids [11]. Finally, the germ contains lipids, proteins, and vitamins [8, 9]. The cell wall composition among cereal grains varies, especially in the polysaccharide composition and the morphology of the endosperm. The starchy endosperm plays an important role in the morphological form of the grains giving different shapes and sizes [6]. The cell wall morphology of wheat, barley, rye, and oat grains differs because of their arabinoxylans and β‐glucan content, both of them components of the cereal dietary fiber [12]. The staining techniques demonstrated that arabinoxylans are concentrated in nucellar epidermis and aleurone cells, while β‐glucan is concentrated in the subaleurone cells. In addition, cells in the starchy endosperm have a thinner cell wall compared to the aleurone cell layers. Apart from the aforementioned compounds, other bioactive compounds have been mostly determined in the cereal bran and germ [11, 13].

Starch, proteins, dietary fiber, and other bioactive compounds such as minerals, trace elements, vitamins, carotenoids, polyphenols, tocopherols, phytosterols, alkylresorcinols, betaine, choline, sulfur amino acids, phytic acid, lignans, and others are found mainly located in the bran and germ fractions of the grain [8, 11, 13–15]. Cereal grain composition has been related with the prevention or reduction of some types of cancer, cardiovascular diseases, diabetes, and obesity [8]. These health benefits attributed to cereal grains were first associated with the dietary fiber content, but recently, such benefits are also related to the bioactive compounds, which are unique in phytochemical composition. So, the knowledge of the distribution of a specific component in the grain structure is important to the food industry to recover specific compounds after grain processing [9]. However, such composition is affected by the processing method in the production of cereal‐based foods [16].

1.3.2 Cereal Grains

Processing

Most of the whole and refined cereal grains produced worldwide are subjected to specific processes to convert them into more desirable food ingredients with improved flavor, color, texture, appearance, and shelf life [17]. In addition, cereal grain processing is based on the composition of the main structural parts of the grain and its use in different cereal‐based foods [18]. The processing of grains in the food production chain includes milling, pearling, malting, and fermentation as the most important processes and others such as heat processing, extrusion, and puffing [7, 17, 18].

1.3.2.1 Milling

This is the oldest way for cereal grains processing [19]. Since most of the inner volume of the cereal grains contains starch, the main purpose of milling is to separate the bran and germ from the starchy endosperm to reduce it into flour [18]. During this process, fractions of aleurone, pericarp, and testa are obtained, whereas some components such as dietary fiber and phytate are removed from the grains [17]. The milling grain process is classified in dry and wet milling, which could generate high amount of cereal grains waste and by‐products [8].

1.3.2.2 Dry Milling

It is used to separate the seed coat, aleurone and subaleurone layers, and the germ from the white endosperm [7]. This process is mainly used in grains such as wheat, corn, rice, and barley [17]. Dry milling has been adopted in the maize food chain to produce refined endosperm products with different particle sizes and other by‐products depending on the degermination system [20]. The main products obtained from corn dry milling are grits, meals, and flour [17]. On the other hand, before the rice and barley milling process, pretreatments are used to separate the bran and husks from the grain (cleaning, shelling, or pulling), and then the remaining milled grain is considered as the endosperm to obtain the flour. In rice milling, husk, bran, and “brokens” are generated by the use of abrasive scouring or pearling [17, 18]; bran and broken grains are the main by‐products [21, 22]. Nowadays, dry milling is performed in tempering–degerming systems to aid fractioning [19]. With tempering, the grain is cleaned, adjusted to certain moisture content depending on the grain, and placed in a tempering bin. Later, the grains are processed in a degerminator to take off the pericarp and germ from the endosperm using crude abrasion. Finally, these grain components are separated by aspirators and gravity tables [17].

1.3.2.3 Wet Milling

Wronkowska [23] defines this process as the separation of the main components of cereal grains through physical, chemical, biochemical, and mechanical

1.3 CPCbG PluClslstonng bonof Ploductlon lof ByopPloducls 7

operations. Wet milling is generally used for corn and wheat; however, it can be used in the processing of other cereals such as sorghum, barley, oats, or rice. In general, this process is used to separate starch, germ, bran, and gluten [7], especially to extract the highest amount of undamaged starch granules, and generate germ, bran, and gluten as by‐products in cereal grains [8]. Bran and germ are the by‐products generated in high amount during corn wet milling, followed by the gluten and steep liquor [8]. Additionally, with the corn wet milling, starch, syrups, and dextrose are obtained as food ingredients [17]. The main by‐products are starch fractions and gluten in wet milling wheat, after the formation and agglomeration of gluten, and following separation of starch from this gluten mass by water washing [24]. The use of wet milling has been increasing especially to obtain compounds used in the production of industrial ethanol; however, it is important to take into account use of the by‐products generated by this process [23]. For example, functional soluble protein‐fiber products have been obtained from cereal grains using enzymatic starch digestion, ultrapurification, and concentration. The high‐protein and high fiber products from cereal grains can be dissolved in water and used to improve the nutritional and functional properties of a wide range of products, including food bars, soups, baked goods, breakfast cereals, sport drinks, and health‐promoting foods and beverages [25].

1.3.2.4

Pearling

This technology is well known by its application in rice milling as mentioned above. However, it is also applied before durum wheat milling and is also known as debranning [7, 26]. Pearling is an abrasive process to remove the testa and pericarp, aleurone and subaleurone layers, and the germ of the grain. The grain obtained by this process can be converted into flour by roller milling. The abrasion helps to reduce the microbial load and the concentration of contaminants such as mycotoxins and heavy metals [26]. In the case of barley, pearled barley has been used as rice extenders and it can be milled for its application in bakery, pasta, and other products where its β‐glucan content is required in the food industry. Despite this, barley pearling should be improved to avoid altering the physical properties of the grain, as well as the particle size of the flour after milling [27]. The same concern applies to pearled wheat, because during this process, the generated wheat fractions differ in composition due to decreasing particle size of each fraction, presumably because of reduced enzyme activity by pearling of the bran [26]. This process in pearled barley is important to recover different grain fractions with unique composition [28]. Additionally, pearling also offers the opportunity to decrease the free fatty acids and lipase activity from the wheat bran, improving the storage stability of the bran [29]. The tangential abrasive dehulling device (TADD) was designed to gradually remove (abrade) layers from

barley and sorghum and simultaneously measure grain hardness. The abrasive hardness index of 31 sorghum samples ranged from 5 to 12.8 with extraction rates from 69 to 98% [30]. Several iterations of this device have been developed, including batch and industrial scale machinery used in many countries to dehull cereal grains [31].

1.3.2.5 Malting

This is another process for cereal grains used in the production of beer and other type of alcoholic beverages through the steeping, germination, and kilning of the grains [7, 18]. Malting is induced by many complex biochemical processes, where cereal cell wall, proteins, and starch granules are degraded and modified. The main purpose of this process is the production of enzymes essential for the degradation of the compounds aforementioned. The enzymatic degradation of the cereal endosperm produces soluble peptides and amino acids, which are substrates for the synthesis of proteins and the growing embryo [32]. Barley is the most common cereal grain used in this process, especially for the brewing industry. During malting, barley is steeped to ensure good water absorption by the grain. Later, germination helps to maintain the embryo growth, enzyme synthesis, and limited endosperm breakdown. An incomplete germination process is applied, where barley kernel endosperm is enzymatically degraded. As a result of this degradation, the cell wall of the barley endosperm is degraded and the starch granules are released from the endosperm matrix. As mentioned, during malting, the germination process ensures a physical and biochemical change into the grain, which is later stabilized by drying; finally, the kilning ensures product stability [33]. This process has also been applied to common wheat [32], rice [34], sorghum, and buckwheat [35].

1.3.2.6

Fermentation

Fermentation is a process carried out since antiquity for the conservation and improvement of the organoleptic properties of food. This consists of controlled processing realized by different microorganisms (fungi, lactic acid bacteria, and yeasts) added or native to the food. The fermentation of cereals causes the rupture of grain structures and changes characteristic in texture, flavor, and smell, besides improving the accessibility of nutrients and phytochemicals [36, 37]. The fermentation of cereal by‐products enables generation of traditional foods such as porridges, slurry, ogi, and alcoholic beverage, breads and different foods based on underutilized cereals [36, 37]. Currently, fermentation is used to produce functional metabolites from cereal by‐products; for example, the fermentation of wheat bran and rice bran improves the bioaccessibility of their phenolic compounds, mainly ferulated compounds, and promotes the growth of butyrogenic bacteria and colonic health benefits [38, 39].

1.3.2.7

Others

Among other cereal grain processes, in pre‐milling rice, also known as husking, the awns of the paddy are separated from the rice grain. The efficiency of husking depends on the tightness of the husk bound to the rice variety and grain humidity. Other process for rice grains is the polishing, performed by a mild fraction or abrasion, where under gentle brushing, the remaining bran in the cereal grain is removed to improve grain translucency. On the other hand, a grading process separates rice pieces by sieving and air aspiration. In the case of oat grains, before milling, other processes such as thermal treatment and dehulling are used to produce naked caryopses known as groats [7]. In respect to corn, the grains are submitted to dry‐grind process, where the whole grains are ground into a coarse powder and fermented for ethanol production [40, 41]. Flaking is another process where oat groats are flaked. This process involves cleaning, heat treatment, dehulling, cutting, and flaking, all of them used to deactivated enzymes and avoid breakage of the oat groat produced by rolling oats [42]. Heat treatment primarily used to deactivate lipase activity in the commercial production of oat flour also influences the starch and protein components. Conditioning (steam injection at 96–100 °C) of oat groats alters protein solubility, lipase activity, and pasting and thermal characteristics [43].

Different processes can be applied to the main cereal crops worldwide depending on the cereal grain morphology and structure, as well as composition, to obtain bran, germ, gluten, oil, hull, and others. Cereal processing will depend on the cereal fraction of interest and the targeted food application of the grain. However, it is important to consider that this cereal processing will produce waste and by‐products, which could be related to environmental problems and losses to the food industry and farmers. So, it should be important to consider the nutritional compounds present in these by‐products, to take advantage and recover them to increase the added value.

1.4 Cereal Grains By-products

During cereal grain processing, recovered by‐products may have functional and nutritional attributes [28] applicable not only for animal feed. Among the main cereal grain by‐products obtained with different processing methods are the bran, germ, protein, hull, fiber, husk, and others (Table 1.3). Most of the by‐products generated by the cereal processing are germ and bran, the latter constituted by aleurone and subaleurone layer, pericarp, and endosperm [9]. These fractions are sources of insoluble and soluble dietary fibers, oil, and other phytonutrients as reported in wheat, corn, and rice [44]. Bran (25% of the grain weight) is the most important wheat fraction, and it includes the starchy endosperm and aleurone

Table 1.3 Main cereal grains processing by-products.

CerealProcessingBy-products

WheatDry millingBran (25% of wheat grain), germ (2–3% of wheat grain)

References

[8, 15, 44, 45]

Wet millingStarch, fiber, gluten protein [23]

MaltingBran, starch, protein [32]

PearlingBran (7–15% of wheat grain) [26]

CornDry millingBran (6–7% of corn grain), distiller’s dried grains (DDG), distiller’s dried with solubles (DDGS), distiller’s solubles

Wet millingGluten feed, gluten meal, fiber (8–11% of corn grain), germ oil, sleeping solids, germ meal, molasses, liquefied corn product, condensed fermented corn extractives, hydrolyzed protein

RiceDry millingPaddy (70% of rice grain), husk (20%), bran (8–12%), germ (2%), oil from bran (18–22% of the bran), bran layers, fine brokens plus bran (brewer’s rice)

[7, 8]

[7, 8, 23]

[8, 15, 46]

Wet millingHull, bran, oil from rice bran [23]

Dry millingBroken rice (88% starch), maltodextrin.[22]

MaltingFiber [34]

PearlingHusk (20% of the rice grain) [46]

OatDry millingBran [15]

Wet millingBran [23]

PearlingBran [42, 47]

BarleyDry millingBran, germ [15]

Wet millingFiber (8% of de barley grain), hull, protein [23, 48]

MaltingBrewers’ spent grain (85% of total by‐products) [9, 15, 49]

PearlingHull (30–49% of the barley grain) [15, 26, 50]

Note: The percentage of each by‐product was not found in all cereal grains.

layers. Wheat bran fraction is generally used for feed products [45], but it represents a good source of ferulic acid, β‐glucan, arabinoxylans, cellulose, lignin, sterols, vitamin B, and minerals [15, 44, 45]. On the other hand, rice bran fraction, also used as animal feed, contains lipids, fiber, protein, steryl ferulate esters

(oryzanols), polyphenols, and tocopherols [15, 46]. In the case of corn, its by‐products represent a source of proteins, oil, fiber, vitamins, and minerals; however, these compounds are being consumed only by animals [7, 40, 41]. Whole stillage of corn generates wet distillers’ grains, condensed distillers’ solubles and wet distillers’ grains with solubles and dried distillers’ grains in ethanol production [40]. These fractions represent a source of protein, fat, minerals, vitamins, and starch [41, 51].

About other by‐products, the germ fraction of cereal grains processing also represents a source of phytonutrients. For example, rice germ is a source of vitamin E as α‐tocopherol, vitamins B1, B2, and B6, dietary fiber, and γ‐aminobutyric acid (GABA) [46]. Besides the rice germ, brewer’s rice generated during rice dry milling also has nutritional importance; however, it is used as animal feed and brewing material. Among the compounds found in this fraction are carbohydrates, protein, oil, minerals, fatty acids, and bioactive compounds such as γ‐oryzanol, phytic acid, vitamin E, polyphenols, and dietary fiber [46]. Broken rice is a source of starch and maltodextrin, which has healing application [22]. Besides, rice by‐products obtained by controlled debranning can be used for production of probiotic strains and promote a healthy alternative [21].

In other processes such as malting and brewing, the brewer’s spent grain, obtained from the residual solid fraction of barley malt generated after the production of wort, is rich in protein and generally used in animal feed as a good source of protein and fiber [33]. This by‐product also contains phenolic acids such as p‐coumaric acid, ferulic acid, hydroxycinnamic acid, caffeic acid, and tocols, as well as arabinoxylans and β‐glucans [15, 33, 49]. In addition, the pearled barley fractions also contain starch, protein, soluble and insoluble dietary fibers, β‐glucans, tocopherols, tocotrienols, and polyphenols, all with nutritional significance [28, 50].

Despite the use of by‐products as animal feed, it is necessary to add value to cereal grain by‐products. Because of this, the milling industry is seeking to increase application of these by‐products in the pharmaceutical and food industry as nutraceutical ingredients and functional foods due to the presence of bioactive compounds and in other agroindustries due to the presence of fiber, protein, oil, minerals, and starch [16]. So, it is important to study the nutraceutical and functional ingredients contained in these by‐products for their extraction, considering the cereal processing, by‐products generated, and phytonutrients profile.

Most of the cereal grain by‐products represent a source of different phytonutrients and bioactive compounds, which could be used in the development of food products or extraction of nutraceutical ingredients. Nowadays, consumers are

more interested in the consumption of products with human health‐related benefits [52]. Therefore, it should be important to classify these compounds based on the main structural components of cereal grain by‐products, to understand their localization and concentration as described in Table 1.4.

1.5.1 Classification of Nutraceutical Ingredients in Cereal By-products

1.5.1.1

Polyphenols

The bran layer as a protective tissue is a rich source of polyphenols in cereal grain by‐products [53, 60]. Polyphenols are also known as potent antioxidants and can be classified according to their structure in phenolic acids (benzoic and cinnamic acids), flavonoids (anthocyanidins, quinones, flavonols, flavones, flavanones), and tannins [14]. Some of them were identified in cereal grain by‐products (Table 1.4).

1.5.1.1.1

Phenolic Acids

Most phenolic acids are bound, mainly linked to polysaccharides by ester bonds, to lignin by ether bonds and proteins. However, there are soluble phenolic acids (free, soluble esterified and glycosylated forms) that contribute to the flavor and antioxidant capacity [60]. Among the phenolic acids found in cereal grain bran, aleurone, and husk are p‐hydroxybenzoic acid, chlorogenic acid, syringic acid, vanillic acids, vanillin, p‐coumaric acid, ferulic acid, salicylic acid, and caffeic acids [56]. Ferulic acid is mostly found in the bran linked to the cell wall polysaccharides (hemicellulose) or to lignin through ester and ether bonds [53], while vanillic acids and p‐coumaric acids are found in the husk [8]. Additionally, p‐coumaric acid could indicate the presence of aleurone cell walls in cereal grain by‐products [56]. On the other hand, ferulic acid may be responsible for the antioxidant properties of the cereal grain fractions [56]. Wheat bran contains high levels of phenolics (two to three folds), those in their respective flours depending on wheat cultivars. The phenolic‐rich kernel tissues (e.g. bran and shorts) are separated from the flour stream as a result of the milling process [61].

1.5.1.1.2 Flavonoids Among flavonoids, anthocyanins are located in a specific layer of the cereal grain. In wheat, anthocyanins are concentrated in the pericarp and aleurone layer of purple and blue wheat grain varieties, respectively. The main anthocyanins found in purple wheat are peonidin and cyanidin glycosides [52]. In blue wheat, delphinidin‐3‐O‐rutinoside and cyanidin‐3‐O‐rutinoside, cyanidin‐3‐O‐glucoside, delphinidin‐3‐O‐glucoside, and peonidin‐3‐O‐rutinoside were detected. Brewers’ spent grains contain flavonoids [59].

1.5.1.1.3 Tannins These compounds are covalently linked to the cell wall polymers as cellulose, hemicellulose, lignin, pectin, and rod‐shaped structural proteins. Since they are in bound form, tannins cannot be digested by human enzymes, remaining intact during the digestion process in the upper

Table 1.4 Classification of nutraceutical ingredients in some cereal grain by-products.

Localization (by-product)CerealNutraceutical ingredients

BranWheatTotal dietary fiber (45–56%), soluble dietary fiber, insoluble dietary fiber, alkylresorcinols (0.27%), ferulic acid monomer (0.5–0.7%), ferulic acid dimer (0.8–1%), sinapic acid (0.02%), p‐coumaric acid (0.01%), flavonoids (28 μg/100 g), total β‐glucans (2–2.6%), total arabinoxylans (10–30%), lignin (5.6%), sterols, protein (13–22%), phytosterols (0.16–0.17%), α‐linoleic acid (0.16%), starch (13–27%), cellulose (6.5–11%), lipids (1–4%), minerals (3.4%), betaine (0.87%), vitamins (0.04%)

Durum wheat

Wheat: roller‐milled and pearled fractions

p‐Hydroxybenzoic acid (281–897 μg/g), chlorogenic acid (0.8–1.7 μg/g), syringic acid (4.83–46.2 μg/g), vanillic acid (8.8–53.2 μg/g), vanillin (5.08–46.7 μg/g), p‐coumaric acid (17.3–147 μg/g), ferulic acid (421–2102 μg/g), salicylic acid (24.3–114 μg/g), fiber content (10–35%)

Content among red, white, yellow, purple and blue wheat types:

Protein (12–17%), total dietary fiber (26–34%), β‐glucan (0.66–2%), free phenolic acids (4–18 mg/kg), total anthocyanins (140–271 mg/kg), lutein (1.6–3 mg/kg), zeaxanthin (0.28–0.91 mg/kg)

BarleyStarch (32.31%), protein (16.23%), fat (8.57%), ash (2.79%), total dietary fiber (35.10%), soluble dietary fiber (14.67%), insoluble dietary fiber (20.43%), total β‐glucan (4.78%)

RiceProtein (10–17%), crude fat (5–20%), crude fiber (7–19%), calcium (0.08–1.4%), phosphorus (1.3–2.9%), cellulose (30%), hemicellulose (20%), lignin (20%), γ‐oryzanol (0.93–13.8 mg/g), tocopherols (27–770 μg/g), tocotrienols (17–460 μg/g), total phenolics (14–20 g GAE/kg), total anthocyanins (55 mg/g), total proanthocyanidins (67 mg/g), protocatechuic acid (168–5777 μg/g), vanillic acid (34–1568 μg/g), p‐coumaric acid (424–517 μg/g), ferulic acid (20–1995 μg/g), 4‐hidroxibenzoic acid (427–673 μg/g), caffeic acid (111–157 μg/g), sinapic acid (2039–2544 μg/g)

References

[26, 45, 53–55]

[56]

[52]

[50]

[46]

(Continued )