ElectrocatalysisforMembraneFuelCells

Methods,Modeling,andApplications

EditedbyNicolasAlonso-VanteandVitoDiNoto

Editors

Prof.NicolasAlonso-Vante UniversityofPoitiers IC2MP-UMR-CNRS7285 4rueMichelBrunet F-86073PoitiersCedex9 France

Prof.VitoDiNoto UniversityofPadova DepartmentofIndustrialEngineering ViaMarzolo9 I-35131Padova Italy

CoverImage: CourtesyofVitoDiNoto, NicolasAlonsoVanteandKetiVezzù

Allbookspublishedby WILEY-VCH arecarefully produced.Nevertheless,authors,editors,and publisherdonotwarranttheinformation containedinthesebooks,includingthisbook, tobefreeoferrors.Readersareadvisedtokeep inmindthatstatements,data,illustrations, proceduraldetailsorotheritemsmay inadvertentlybeinaccurate.

LibraryofCongressCardNo.: appliedfor BritishLibraryCataloguing-in-PublicationData Acataloguerecordforthisbookisavailable fromtheBritishLibrary.

Bibliographicinformationpublishedby theDeutscheNationalbibliothek TheDeutscheNationalbibliotheklists thispublicationintheDeutsche Nationalbibliografie;detailedbibliographic dataareavailableontheInternetat <http://dnb.d-nb.de>

©2024WILEY-VCHGmbH,Boschstraße12, 69469Weinheim,Germany

Allrightsreserved(includingthoseof translationintootherlanguages).Nopartof thisbookmaybereproducedinanyform–by photoprinting,microfilm,oranyothermeans–nortransmittedortranslatedintoamachine languagewithoutwrittenpermissionfromthe publishers.Registerednames,trademarks,etc. usedinthisbook,evenwhennotspecifically markedassuch,arenottobeconsidered unprotectedbylaw.

PrintISBN: 978-3-527-34837-4

ePDFISBN: 978-3-527-83055-8

ePubISBN: 978-3-527-83056-5

oBookISBN: 978-3-527-83057-2

Typesetting: Straive,Chennai,India

Preface xv

PartIOverviewofSystems 1

1System-levelConstraintsonFuelCellMaterialsand Electrocatalysts 3

ElliotPadgettandDimitriosPapageorgopoulos

1.1OverviewofFuelCellApplicationsandSystemDesigns 3

1.1.1System-levelFuelCellMetrics 3

1.1.2FuelCellSubsystemsandBalanceofPlant(BOP)Components 5

1.1.3ComparisonofFuelCellSystemsforDifferentApplications 9

1.2Application-derivedRequirementsandConstraints 10

1.2.1FuelCellPerformanceandtheHeatRejectionConstraint 10

1.2.2Startup,Flexibility,andRobustness 13

1.2.3FuelCellDurability 14

1.2.4Cost 16

1.3MaterialPathwaystoImprovedFuelCells 18

1.4Note 19

Acronyms 20 Symbols 20 References 20

2PEMFuelCellDesignfromtheAtomtotheAutomobile 23

AndrewHaugandMichaelYandrasits

2.1Introduction 23

2.2ThePEMFCCatalyst 27

2.3TheElectrode 32

2.4Membrane 38

2.5TheGDL 42

2.6CCMandMEA 46

2.7FlowfieldandSingleFuelCell 50

2.8StackandSystem 55

Acronyms 57 References 58

PartIIBasics–Fundamentals 69

3ElectrochemicalFundamentals 71

VitoDiNoto,GioelePagot,KetiVezzù,EnricoNegro,andPaoloSgarbossa

3.1PrinciplesofElectrochemistry 71

3.2TheRoleoftheFirstFaradayLaw 71

3.3ElectricDoubleLayerandtheFormationofaPotentialDifferenceatthe Interface 73

3.4TheCell 74

3.5TheSpontaneousProcessesandtheNernstEquation 75

3.6RepresentationofanElectrochemicalCellandtheNernst Equation 77

3.7TheElectrochemicalSeries 79

3.8Dependenceofthe Ecell onTemperatureandPressure 82

3.9ThermodynamicEfficiencies 83

3.10CaseStudy–TheImpactofThermodynamicsontheCorrosionofLow-T FCElectrodes 85

3.11ReactionKineticsandFuelCells 88

3.11.1CorrelationBetweenCurrentandReactionKinetics 88

3.11.2TheConceptofExchangeCurrent 89

3.12ChargeTransferTheoryBasedonDistributionofEnergyStates 89

3.12.1TheButler–VolmerEquation 96

3.12.2TheTafelEquation 100

3.12.3InterplayBetweenExchangeCurrentandElectrocatalystActivity 101

3.13Conclusions 103

Acronyms 104 Symbols 104 References 107

4QuantifyingtheKineticParametersofFuelCell Reactions 111

ViktoriiaA.Saveleva,JuanHerranz,andThomasJ.Schmidt

4.1Introduction 111

4.2ElectrochemicalActiveSurfaceArea(ECSA)Determination 114

4.2.1ECSADeterminationUsingUnderpotentialDeposition 115

4.2.1.1HydrogenUnderpotentialDeposition(HUPD ) 116

4.2.1.2CopperUnderpotentialDeposition(CuUPD ) 117

4.2.2ECSAQuantificationBasedontheAdsorptionofProbeMolecules 118

4.2.2.1COStripping 118

4.2.2.2NO2 ∕NOSorption 119

4.2.3Double-layerCapacitanceMeasurementsandOtherMethods 120

4.2.4ECSAMeasurementsinaPEFC:WhichMethodtoChoose? 120

4.3H2 -OxidationandElectrochemicalSetupsfortheQuantificationof KineticParameters 121

4.3.1RotatingDiscElectrodes(RDEs) 122

4.3.2HydrogenPump(PEFC)Approach 124

4.3.3UltramicroelectrodeApproach 125

4.3.4ScanningElectrochemicalMicroscopy(SECM)Approach 125

4.3.5FloatingElectrodeMethod 127

4.3.6MethodsSummary 128

4.4ORRKinetics 129

4.4.1ORRMechanismStudieswithRRDESetups 129

4.4.2ORRPathwayonMe/N/CORRCatalysts 130

4.4.3ORRKinetics:Methods 132

4.4.3.1Pt-basedElectrodes 132

4.4.3.2Pt-freeCatalysts:RDEvs.PEFCKineticStudies 133

4.5ConcludingRemarks 133 Acronyms 134 Symbols 134 References 135

5AdverseandBeneficialFunctionsofSurfaceLayersFormed onFuelCellElectrocatalysts 149 ShimshonGottesfeld

5.1Introduction 149

5.2CatalystCappinginHeterogeneousCatalysisandin Electrocatalysis 151

5.3PassivationofPGM/TMandNon-PGMHORCatalystsandItsPossible Prevention 156

5.4LiteratureReportsonFuelCellCatalystProtectionbyCapping 161

5.4.1ProtectionofORRPtcatalystsAgainstAgglomerationbyanUltrathin OverlayerofMesoporousSiO2 orMe–SiO2 161

5.4.2ProtectionbyCarbonCapsAgainstCatalystDetachmentandCatalyst PassivationUnderAmbientConditions 162

5.5OtherMeansforImprovingthePerformanceStabilityofSupported Electrocatalysts 166

5.5.1ReplacementofCarbonSupportsbyCeramicSupports 166

5.5.2ProtectionofPtCatalystsbyEnclosureinMesopores 167

5.6Conclusions 170 Abbreviations 171 References 171

PartIIIStateoftheArt 175

6DesignofPGM-freeORRCatalysts:FromMoleculartothe StateoftheArt 177

NaomiLevyandLiorElbaz

6.1Introduction 177

6.2TheInfluenceofMolecularChangesWithintheComplex 179

6.2.1TheRoleoftheMetalCenter 179

6.2.2AdditionofSubstituentstoMCs 183

6.2.2.1Beta-substituents 184

6.2.3Meso-substituents 186

6.2.4AxialLigands 187

6.3CooperativeEffectsBetweenNeighboringMCs 190

6.3.1BimetallicCofacialComplexes–“Packman”Complexes 191

6.3.2MCPolymers 191

6.4ThePhysicaland/orChemicalInteractionsBetweentheCatalystandIts SupportMaterial 193

6.5EffectofPyrolysis 194

Acronyms 196 References 196

7RecentAdvancesinElectrocatalystsforHydrogenOxidation ReactioninAlkalineElectrolytes 205 IndraN.PulidindiandMeitalShviro

7.1Introduction 205

7.2MechanismoftheHORinAlkalineMedia 206

7.3ElectrocatalystsforAlkalineHOR 212

7.3.1PlatinumGroupMetalHORElectrocatalysts 212

7.3.2Non-platinumGroupMetal-basedHORElectrocatalysts 214

7.4Conclusions 220 Acronyms 221 References 221

8MembranesforFuelCells 227

PaoloSgarbossa,GiovanniCrivellaro,FrancescoLanero,GioelePagot, AfaafR.Alvi,EnricoNegro,KetiVezzù,andVitoDiNoto

8.1Introduction 227

8.2PropertiesofthePEseparators 228

8.2.1BenchmarkingofIEMs 229

8.2.2Ion-exchangeCapacity(IEC) 229

8.2.3WaterUptake(WU),SwellingRatio(SR),andWaterTransport 231

8.2.4IonicConductivity(�� ) 233

8.2.5GasPermeability 234

8.2.6ChemicalStability 235

8.2.7ThermalandMechanicalStability 237

8.2.8CostoftheIEMs 239

8.3ClassificationofIon-exchangeMembranes 240

8.3.1Cation-exchangeMembranes(CEMs) 240

8.3.1.1PerfluorinatedMembranes 240

8.3.1.2NonperfluorinatedMembranes 245

8.3.2Anion-exchangeMembranes(AEMs) 246

8.3.2.1FunctionalizedPolyketones 247

8.3.2.2Poly(VinylBenzylTrimethylAmmonium)(PVBTMA)Polymers 248

8.3.2.3Poly(sulfones)(PS) 249

8.3.3HybridIon-exchangeMembranes 249

8.3.3.1HybridMembraneswithSingleCeramicOxoclusters[P/(Mx Oy )n ] 250

8.3.3.2HybridMembranesComprisingSurface-functionalizedNanofillers 254

8.3.3.3HybridMembranesDopedwithhierarchical “Core–Shell” Nanofillers 254

8.3.4PorousMembranes 257

8.3.4.1PorousMembranesasHostMaterial 257

8.3.4.2PorousMembranesasSupportLayer 258

8.3.4.3PorousMembranesasUnconventionalSeparators 259

8.4MechanismofIonConduction 259

8.5SummaryandPerspectives 268

Acronyms 271 Symbols 272 References 272

9SupportsforOxygenReductionCatalysts:Understandingand ImprovingStructure,Stability,andActivity 287 IwonaA.Rutkowska,SylwiaZoladek,andPawelJ.Kulesza

9.1Introduction 287

9.2CarbonBlackSupports 288

9.3DecorationandModificationwithMetalOxideNanostructures 289

9.4CarbonNanotubeasCarriers 291

9.5Doping,Modification,andOtherCarbonSupports 293

9.6GrapheneasCatalyticComponent 293

9.7MetalOxide-containingORRCatalysts 296

9.8PhotodepositionofPtonVariousOxide–CarbonComposites 299

9.9OtherSupports 301

9.10AlkalineMedium 302

9.11TowardMoreComplexHybridSystems 303

9.12StabilizationApproaches 306

9.13ConclusionsandPerspectives 307

Acknowledgment 308

Acronyms 308 References 308

Contents

PartIVPhysical–ChemicalCharacterization 319

10UnderstandingtheElectrocatalyticReactionintheFuelCell byTrackingtheDynamicsoftheCatalystbyX-rayAbsorption Spectroscopy 321

DittyDixon,AiswaryaBhaskar,andAswathiThottungal

10.1Introduction 321

10.2AShortIntroductiontoXAS 323

10.3ApplicationofXASinElectrocatalysis 325

10.3.1 ExSitu CharacterizationofElectrocatalyst 325

10.3.2 Operando XASStudies 330

10.4 �� XANESAnalysistoTrackAdsorbate 334

10.5Time-resolved Operando XASMeasurementsinFuelCells 338

10.6Fourth-generationSynchrotronFacilitiesandAdvanced CharacterizationTechniques 340

10.6.1Total-reflectionFluorescenceX-rayAbsorptionSpectroscopy 341

10.6.2ResonantX-rayEmissionSpectroscopy(RXES) 341

10.6.3CombinedXRDandXAS 342

10.7Conclusions 342

Acronyms 343 References 344

PartVModeling 349

11UnravelingLocalElectrocatalyticConditionswithTheoryand Computation 351

JunHuang,MohammadJ.Eslamibidgoli,andMichaelH.Eikerling

11.1LocalReactionConditions:WhyBother? 351

11.2FromElectrochemicalCellstoInterfaces:BasicConcepts 352

11.3CharacteristicsofElectrocatalyticInterfaces 355

11.4MultifacetedEffectsofSurfaceChargingontheLocalReaction Conditions 356

11.5TheChallengesinModelingElectrifiedInterfacesusingFirst-principles Methods 358

11.5.1ComputationalHydrogenElectrode 359

11.5.2Unit-cellExtrapolation,ExplicitSolvatedProtons,andExcess Electrons 360

11.5.3CounterChargeandReferenceElectrode 361

11.5.4EffectiveScreeningMediumandmPBTheory 361

11.5.5Grand-canonicalDFT 362

11.6AConcertedTheoretical–ComputationalFramework 362

11.7CaseStudy:OxygenReductionatPt(111) 364

11.8Outlook 367 Acronyms 367 Symbols 368 References 368 PartVIProtocols 375

12QuantifyingtheActivityofElectrocatalysts 377 KarlaVega-GranadosandNicolasAlonso-Vante

12.1Introduction:TowardaSystematicProtocolforActivity Measurements 377

12.2MaterialsConsideration 378

12.2.1PGMGroup 378

12.2.2LowPGMandPGM-freeApproaches 379

12.2.3ImpactofSupportEffectsonCatalyticSites 381

12.3ElectrochemicalCellConsiderations 382

12.3.1CellConfigurationandMaterial 382

12.3.2Electrolyte 385

12.3.2.1Purity 385

12.3.2.2Protonsvs.HydroxideIons 386

12.3.2.3InfluenceofCounterions 388

12.3.3ElectrodePotentialMeasurements 388

12.3.4PreparationofElectrodes 391

12.3.5Well-definedandNanoparticulatedObjects 395

12.4ParametersDiagnosticofElectrochemicalPerformance 396

12.4.1SurfaceArea 396

12.4.2HydrogenUnderpotentialDepositionIntegration 397

12.4.2.1SurfaceOxideReduction 398

12.4.2.2COMonolayerOxidation(COStripping) 400

12.4.2.3UnderpotentialDepositionofMetals 401

12.4.2.4Double-layerCapacitance 402

12.4.3ElectrocatalystsSiteDensity 402

12.4.4DataEvaluation(Half-CellReactions) 404

12.4.5The E1/2 and E ( jPt (5%))Parameters 405

12.5StabilityTests 407

12.6DataEvaluation(AuxiliaryTechniques) 409

12.6.1SurfaceAtomsvs.Bulk 410

12.7Conclusions 411 Acknowledgments 412 Acronyms 412 Symbols 413 References 414

13DurabilityofFuelCellElectrocatalystsandMethodsfor PerformanceAssessment 429 BiancaM.CeballosandPiotrZelenay

13.1Introduction 429

13.2FuelCellPGM-freeElectrocatalystsforLow-temperature Applications 431

13.3PGM-freeElectrocatalystDegradationPathways 432

13.3.1Demetallation 432

13.3.2CarbonOxidation 436

13.3.3MicroporeFlooding 439

13.3.4NitrogenProtonationandAnionicAdsorption 439

13.4PGM-freeElectrocatalystDurabilityandMetrics 440

13.4.1PerformanceandDurabilityEvaluationinAir-suppliedFuelCell Cathode 440

13.4.2AssessmentofCarbonCorrosioninNitrogen-purgedCathode 443

13.4.3DeterminationofPerformanceLossuponCyclingCathodeCatalystin Nitrogen 443

13.4.4RecommendationsforORRElectrocatalystEvaluationinRRDEinO2 andinanInertGas 446

13.4.5ElectrocatalystCorrosion 447

13.5Low-PGMCatalystDegradation 447

13.5.1PtDissolution 449

13.5.2CarbonSupportCorrosion 452

13.5.3PtCatalystMEAActivityAssessmentandDurability 454

13.5.4PGMElectrocatalystMEAConditioninginH2 /Air 454

13.5.5AcceleratedStressTestofPGMElectrocatalystDurability 456

13.6Conclusion 457 Acronyms 459 References 460

PartVIISystems 471

14ModelingofPolymerElectrolyteMembraneFuelCells 473

AndreaBaricci,AndreaCasalegno,DarioMaggiolo,FedericoMoro, MatteoZago,andMassimoGuarnieri

14.1Introduction 473

14.2GeneralEquationsforPEMFCModels 474

14.2.1AnalyticalandNumericalModeling 474

14.2.2ReversibleElectromotiveForce 476

14.2.3FuelCellVoltage 477

14.2.4ActivationOverpotential 478

14.2.5OhmicOverpotential–PEMModel 479

14.2.6ConcentrationOverpotential 480

14.2.7ExamplesofFuelCellModeling 482

14.3MultiphaseWaterTransportModelforPEMFCs 483

14.4FluidMechanicsinPEMFCPorousMedia:From3DSimulationsto1D Models 488

14.4.1FromMicro-toMacroscopicModels 490

14.4.2PorousMediumAnisotropy 491

14.4.3Fluid–FluidViscousDrag 492

14.4.4SurfaceTensionandCapillaryPressure 492

14.5Physical-basedModelingforElectrochemicalImpedance Spectroscopy 496

14.5.1ExperimentalMeasurementandModelingApproaches 496

14.5.2Physical-basedModeling 497

14.5.2.1CurrentRelaxation 497

14.5.2.2LaplaceTransform 498

14.5.3TypicalImpedanceFeaturesofPEMFC 498

14.5.4ApplicationofEISModelingtoPEMFCDiagnostic 500

14.5.5Approximationsof1DApproach 501

14.6ConclusionsandPerspectives 502 Acronyms 503 Symbols 504 References 507

15Physics-basedModelingofPolymerElectrolyteMembrane FuelCells:FromCelltoAutomotiveSystems 511 AndreaBaricci,MatteoZago,SimoneBuso,MarcoSorrentino,and AndreaCasalegno

15.1PolymerFuelCellModelforStackSimulation 511

15.1.1GeneralCharacteristicsofaFuelCellSystemforAutomotive Applications 511

15.1.2AnalysisoftheChannelGeometryforStackPerformanceModeling 514

15.1.3AnalysisoftheAirandHydrogenUtilizationforStackPerformance Modeling 516

15.1.4IntroductiontoTransientStackModels 518

15.2AuxiliarySubsystemsModeling 519

15.2.1AirManagementSubsystem 519

15.2.2HydrogenManagementSubsystem 521

15.2.3ThermalManagementSubsystem 522

15.2.4PEMFCSystemSimulation 522

15.3ElectronicPowerConvertersforFuelCell-poweredVehicles 525

15.3.1PowerConverterArchitecture 527

15.3.2LoadAdaptability 527

15.3.3PowerElectronicSystemComponents 528

15.3.3.1PortInterfaceConverters 530

15.3.3.2ThePEMFCInterfaceConverter 530

15.3.3.3TheMotorInterfaceConverter 530

15.3.3.4TheEnergyStorageInterface 531

15.3.3.5SupervisoryControl 531

15.4FuelCellPowertrainsforMobilityUse 532

15.4.1TransportApplicationScenarios 532

15.4.2ToolsfortheCodesignofTransportFuelCellSystemsandEnergy ManagementStrategies 534

15.4.2.1AutomotiveCaseStudy:OptimalCodesignofanLDVFCHV Powertrain 535

Acronyms 540 Symbols 541 References 541

Index 545

Preface

Inelectrochemicalenergyconverterssuchaslow-temperaturemembranefuelcells, theslowkineticsofoxygenreduction(ORR)representsoneofthemainreasons forahighoverpotentialinafuelcell,e.g.polymerelectrolytemembrane(PEM) type.Despitethisinherentphenomenon,inthesesystems,fuelcellsconstitute(i) acornerstoneintheenergytechnologiesofthepresenttwenty-firstcenturyfor transportationandstationaryapplicationsand(ii)oneofthetwopillars,together withelectrolyzers,ofthefutureGreenHydrogenEconomyoftheworld.These scenariosarecomfortedbytherapidadvancesinthedevelopmentofmaterials basedonnobleandnon-nobleelectrocatalyticmaterialsthatencompassabunch ofapplicationsoperatinginawidepHrange(acidicandalkaline).Inthiscontext, inordertofindautility,totheknowledgeobtainedtodate,forcurrentand futureresearchersinthisfieldofactivity,therepositoryofsuchanavalancheof informationisthusacentralresourcetobetransmittedwithaglobalperspective. Itisforthisreasonthatthepresentbookaimstoconsolidateandtransmitthis knowledgewhileprovidingthenecessaryforumtocomplementwhatispublished dailyinspecializedjournals.Thus,thecontributionsofexpertsworkinginboth academicandindustrialresearchanddevelopmentwillserveasareferencesource forthefundamentalsandapplicationsoffuelcells,establishingthestate-of-the-art anddisseminatingresearchadvanceswithinascopecorrespondingtotextbooksfor undergraduateandgraduatestudents.

Thisbook,devotedtofuelcellelectrocatalysis,will,wehope,furtherthedevelopmentandapplicationofthisexcitingtechnologyontheroadtothesuccessful establishmentofacleanandsustainableenergyeconomyinthetwenty-first century.Forthereader’sconvenience,thisbook,withatotalof15chapters,is organizedinsevensections,namelyOverview,Fundamentals,StateoftheArt, Physical–ChemicalCharacterization,Modeling,Protocols,andSystems.

Thefirstchapterdiscusseshowapplicationrequirementsandsystem-levelconsiderationscreateconstraintsonfuelcellmaterialsandelectrocatalysts,withthe goalofinformingmorestrategicandimpactfulresearchanddevelopmentefforts.In thesecondchapter,thediscussioniscenteredonhowanatomicallydesignedcatalystsurfaceefficientlyproducesprotonsandelectronsfromhydrogenontheanode andwaterfromoxygen,protons,andelectronsonthecathode.Inthethirdchapter, insightsareprovidedonhowfundamentalelectrochemistrycanbeexploitedto guidefuelcellresearch,whereasthefourthchapterdisclosesthequantificationof thekineticdescriptorsthatdeterminetheactivityandstabilityoftheanodeand cathodeelectrocatalysts,providinganalyticalmethodsandelectrochemicalset-ups

assupports.Moreover,inChapter5,theauthordiscussessomemeansforprotecting catalyticsitesinordertomaintainhighperformanceinthelightofrecentdata fromtheliterature.Chapter6,furthermore,putsintorelevancethestate-of-the-art ofplatinumgroupmetal(PGM)-freeORRcatalysts.Herein,theauthorsprovide anoverviewofimportantparametersthatinfluencethecatalysisofORRwith well-definedORRcatalysts.InChapter7,recentdevelopmentinelectrocatalysts forthehydrogenoxidationreaction(HOR)isputonthefloor,emphasizingthe state-of-the-artPGM-andnon-PGM-basedelectrocatalystsfortheHORinalkaline conditions.Animportantingredientintheprotonexchangemembranefuelcell (PEMFC)systemisthepolymericelectrolyte.Inthiscontext,Chapter8describesthe featuresthatamembranemustexhibittobeimplementedinafuelcell.Thischapter endswithacomprehensiveoverviewofthemechanismsofionconductionproposed forfuelcellmembranes,followedbyabriefsummaryoutliningtheperspectives oftheresearchinthisfield.ThecharacteristicsofORRelectrocatalystsupport (carbon-basedandoxide-based)havebeenanalyzedinChapter9.Ofimportance,in allinterfaceresearch,isthe inoperando technique,and/orprobingunderrealfuel celloperatingconditionsisofferedinChapter10withtheuseofX-rayabsorption spectroscopy(XAS).Theoreticalmodelingandcomputationtounravelthelocal reactionenvironmentaregiveninChapter11.Thischapteraddressesthiscomplex issuebyintroducingsomebasicconceptsofelectrochemicalinterfaces,especially thesurfacechargingrelation.Theauthorshighlighttheelectrocatalyticinterfaces pertainingtotheroleofchemisorption-inducedsurfacedipolesthatcouldcause nonmonotonicityinthesurfacechargingbehavior.Theelectrocatalyticmaterials researchprotocolsforinvestigatingfuelcellreactionsaredeployedinChapters12 and13.Insum,thecorrectevaluationoffuelcellreactions,selectionofreference electrodes,durabilitytestsofPGM-freematerials,andfuelcelltestingprocedures areputforwardinthelightofthemostadvancedliteraturedataresearch.The lastsectionofthebookpresentsChapters14and15.Thesechaptersanalyzethe fundamentalsoffuelcellsimulationbymeansofamono-dimensionalanalytical modelconsideringmultiphasewatertransportaffectingtheelectricalconductivity propertiesofthecellmembrane,whereasChapter15analyzestheoptimizationof theoperativeconditionsandthepredictionofthesystemdurabilitythatbackthe designofthePEMFCstackandcomponentsofthebalanceoftheplant.

Theeditorsappreciatethecontributingauthorsofthisbook,whomaintainedhigh scientificstandards.

N.Alonso-VanteacknowledgesfinancialsupportfromtheEuropeanUnion (ERDF)and“RégionNouvelleAquitaine.”

V.DiNotothanksthefinancialsupportofEITRawMaterials,projectAlpe,and GrapheneFlagship,Core3,oftheEuropeanUnion.

NicolasAlonso-Vante UniversityofPoitiers,IC2MP-UMRCNRS7285 Poitiers,France

VitoDiNoto UniversityofPadova,DepartmentofIndustrialEngineering Padova,Italy

System-levelConstraintsonFuelCellMaterialsand Electrocatalysts

ElliotPadgettandDimitriosPapageorgopoulos

HydrogenandFuelCellTechnologiesOffice,OfficeofEnergyEfficiencyandRenewableEnergy,U.S. DepartmentofEnergy,1000IndependenceAve.,SW,Washington,D.C.,20585,USA

1.1OverviewofFuelCellApplicationsandSystem Designs

Fuelcellsareanticipatedtoplayanimportantroleinthefuturecleanenergy economyasversatileenergyconversiondevicesacrossmanyapplicationsand sectors.Fuelcellshaveimportantcurrentandpotentialapplicationsinthreebroad areas:(i)transportationpowertrains,invehiclessuchascars,buses,trucks,rail locomotives,ships,andaircraft;(ii)stationarypowersystems,suchasdistributed powergeneration,backuppower,andcombinedheatandpower(CHP)systems; and(iii)specialtyapplicationssuchasmaterialhandlingequipmentaswellas portablesystemsforauxiliarypowerordevicessuchaspersonalelectronicsor mobilecommunicationsequipment.Whilefuelcellsforthesediverseapplicationshavesomecommonfoundations,thesystemsforeachapplicationhave differentrequirementsandpriorities,whichcallfordifferentsystemdesignsand technologiestomeetthem.Thedevelopmentofadvanced,application-relevant materialsandelectrocatalystsisessentialtoovercomingthetechnicalchallenges thatremaintobringfuelcellsintowidespreadadoptionandrealizationoftheir potential.Thischapterdiscusseshowapplicationrequirementsandsystem-level considerationscreateconstraintsonfuelcellmaterialsandelectrocatalysts,withthe goalofinformingmorestrategicandimpactfulresearchanddevelopmentefforts. Theprimaryfocuswillbeontransportationapplicationsandpolymerelectrolyte membrane(PEM)fuelcells,butotherapplicationsandfuelcelltypeswillalsobe includedforcontextandcomparison.

1.1.1System-levelFuelCellMetrics

Itisusefultobeginbycoveringthetypicalhigh-levelmetricsforfuelcellsystems, whichprovideabasisforcomparingdifferentfuelcelltypes,applicationrequirements,andalternativetechnologiesaswellasforbenchmarkingtechnological ElectrocatalysisforMembraneFuelCells:Methods,Modeling,andApplications,FirstEdition. EditedbyNicolasAlonso-VanteandVitoDiNoto. ©2024WILEY-VCHGmbH.Published2024byWILEY-VCHGmbH.

1System-levelConstraintsonFuelCellMaterialsandElectrocatalysts

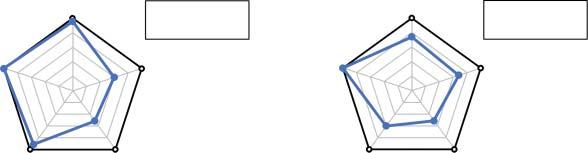

Figure1.1 Diagramssummarizingthecurrentstatusofautomotivefuelcellsystems (a)andstacks(b)relativetoDOEtargets.Source:ReproducedfromU.S.Departmentof energy[4]/https://www.hydrogen.energy.gov/pdfs/20005-automotive-fuel-cell-targetsstatus.pdf/Publicdomain.

progress.Thesemetricsarecommonlyusedasspecificationsforfuelcellproducts andtargetsforfuelcellresearch,development,anddemonstration(RD&D) programs[1–3].Forinstance,systemandstack-leveltargetsforautomotivefuel cellssetbytheU.S.DepartmentofEnergy(DOE),alongwithrespectivestatus estimates,areillustratedinFigure1.1[4].Themostusedmetriccategoriesinclude cost,durability,efficiency,systemsize,andflexibility.Eachofthese,aswellas specificmetrics,willbedescribedbelow.

Thereareseveraldifferentmetricsincommonusethatdescribethesizeoffuelcell systems,combiningthepoweroutputandphysicalmassorvolumeofthesystem. Poweroutputmaybegivenasgrosspower–thetotalelectricalpoweroutputofthe fuelcellstack–orasnetpower–thepoweroutputofthestackminusthepower consumptionofthesupportingbalanceofplant(BOP).Thisdistinctionmustbe specifiedtoavoidconfusionandmaybeincludedinthepowerunits(askWgross or kWnet ,forexample).Toaddressapplication-drivensystemsizeandweightrestrictions,thepoweroutputcanbegivenasanabsolutetotal,perunitweightofthe system(thisisknownasthespecificpower,withunitssuchaskWkg 1 ),orperunit volumeofthesystem(thisisknownasthepowerdensity,withunitssuchaskWl 1 ).

Theenergyconversionefficiencyofafuelcellsystemcanbespecifiedineither theelectricalpoweroutputperfuelinput(e.g.kWhkg 1 H2 )orasapercentageofthe fuel’slowerheatingvalue.Fuelcellsgenerallyaremoreefficientatlowpowerthan athighpower,andtheefficiencyiscloselytiedtothefuelcellperformance,as thesamemechanismsofvoltagelossdecreaseboth.Therearethereforedifferent definitionsforsystemefficiencyspecifiedatdifferentperformancelevels,most commonlyatthepeakefficiency(atlowpower),peakorratedpower,oranaverage efficiencyoveraparticulardutycycle.

Fuelcelldurabilityorlifetimeiscommonlyspecifiedasthenumberofhoursof operationbeforeacertainlevelofdegradationisreached.While,inpractice,the tolerablelevelofdegradationwillvarydependingontheuser’sneeds,itisalsouseful tousestandardizedendoflifedefinitionssuchas10%voltagedegradationatrated powerforbenchmarkingpurposes.Itisalsoimportanttorecognizethatdegradation

1.1OverviewofFuelCellApplicationsandSystemDesigns 5 ratesandlifetimesforfuelcellsystemswilldependonthedutycycleandstressors ofeachapplication.

Thecostofafuelcellsystemisanimportantmetricbutismorechallengingto determinethanothermetricsthatarerootedinthephysicalorengineeringparametersofthesystem.Theactualcostofdeployedfuelcellsystemsisofinterestinbusinesstransactionsandtoassesscurrentmarketcompetitiveness.Theprojectedcostof fuelcellsystemsusingearlierstage,lab-demonstratedtechnologies,andlargermanufacturingscalesisalsousefulfortrackingadvancesintechnologyandinforming researchanddevelopment(R&D)needs.Thecostoffuelcellsystemsiscommonly specifiedperpoweroutput(e.g.$kWnet 1 )althoughthismetricdependsonboththe systemsizeandthedefinitionofthesystemboundaries(fuelstorage,powerelectronics,andothercomponentsarecommonlyexcludedfromthefuelcellsystem, althoughsystemdefinitionsvary).

Flexibilityandrobustnessareumbrellaconceptsthatencompassmanydifferent potentialmetricsfortheabilityofthefuelcellsystemtoadjusttoprovidepowerasit isrequired.Theseincludethetimerequiredtostartthefuelcellsystem,itscapability tostartandsustainpowerundercoldorhotconditions,itsabilitytoquicklyadjust tovaryingpowerdemands,andthereliabilityofthesystem.

Itisimportanttorecognizethatthevariousaspectsoffuelcellsystemsthatare describedbythesemetricsareinterrelated.Forinstance,analterationtoafuelcell systemthatlowersitscostmayalsoimpactitspoweroutput,efficiency,anddurability.Compositemetricsthatconstrainrelatedmetricsinaparticularwaycanthereforealsobeuseful.Forexample,DOEhasintroduceda“durability-adjustedcost” metricforautomotivefuelcells,whichdescribesthecostofan80-kWnet fuelcell systemthatalsomeetstherequirementsfor8000houron-roaddurability[5].

1.1.2FuelCellSubsystemsandBalanceofPlant(BOP)Components

FuelcellsrequiresupportingBOPequipmenttoprovidehighperformanceanddurability,includingthesupplyofairandfuel,cooling,andsystemmonitoringandcontrol.Itisimportanttounderstandthecommonsubsystemsandcomponentsusedfor thesepurposes.State-of-the-artfuelcellsystemdesignsaregenerallyproprietary, butrepresentativemodelsystemshavebeendevelopedtoprovidepublicinformation.Forinstance,theDOEhasfundedthedevelopmentofamodelautomotive fuelcellsysteminacollaborationbetweenStrategicAnalysis,Inc.andArgonne NationalLaboratoryandwithfeedbackfromtheU.S.DRIVE(DrivingResearchand InnovationinVehicleefficiencyandEnergysustainability)Partnership[6,7].This modelsystemisausefulresourceforunderstandingthesubsystemsandcomponentsintransportationfuelcellsystems.Similarmodelsystemsarebeingdeveloped formedium-andheavy-dutyvehicles[8–10]andhavealsobeendevelopedforstationaryandotherfuelcelltypes[11–14].

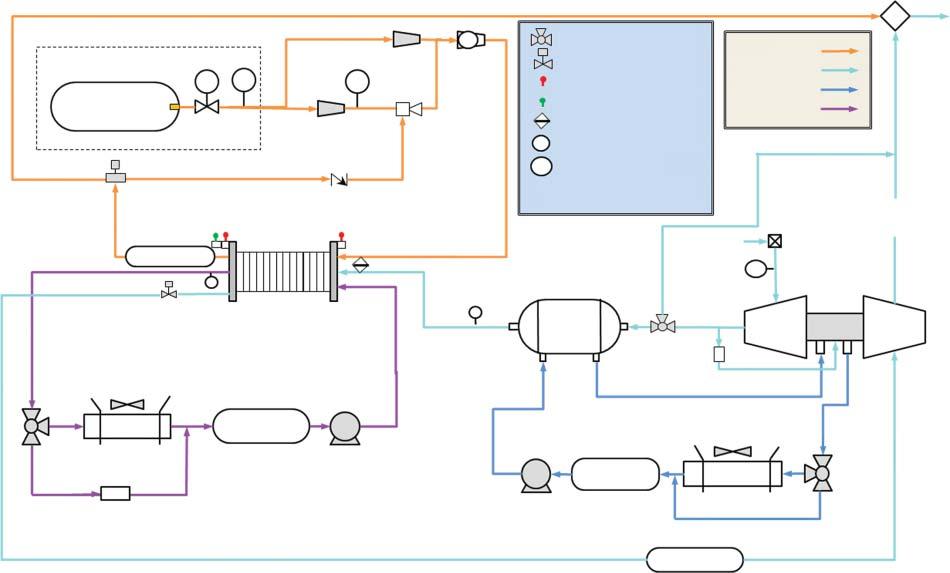

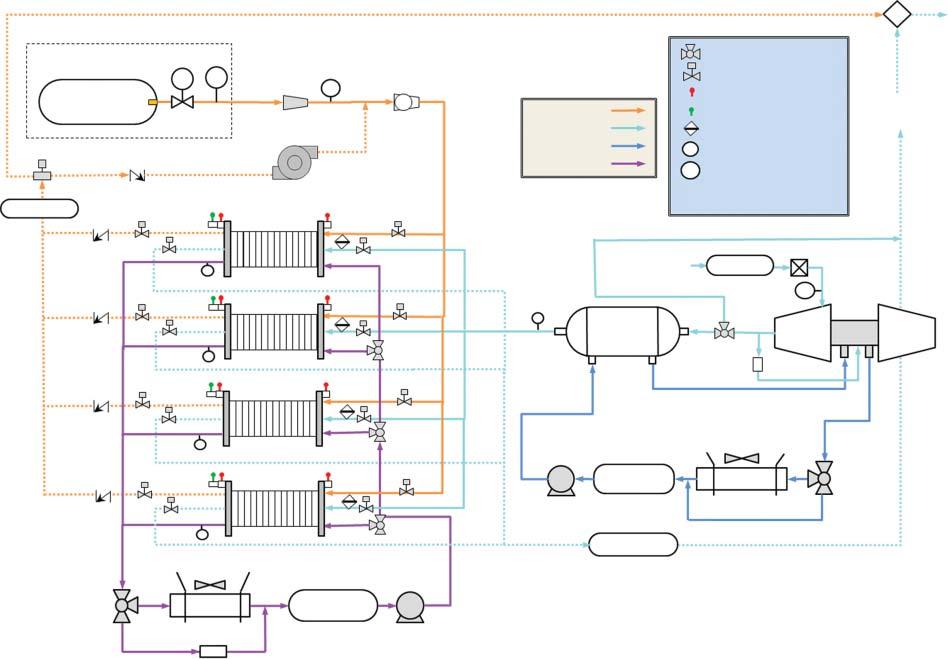

Examplediagramsoffuelcellsystemsforautomotiveandheavy-dutyvehicle applicationsareshowninFigure1.2.Thesediagramsprovidearepresentative illustrationoftypicalBOPcomponentsandsubsystemsintransportationfuelcell systems.

80-kW Automotive System

Differential

Anode

Figure1.2 Schematicsofrepresentativefuelcellsystemdesignsforautomotive(top)andheavy-dutyvehicle(HDV)applications(bottom)illustrating majorbalanceofplantcomponentsandsubsystems.Source:ReproducedfromRef.[6].

275-kW HDV System

Hydrogen from tanks

Compressed hydrogen tank

coolant loop

Differential

8 1System-levelConstraintsonFuelCellMaterialsandElectrocatalysts

Asthepower-producingcomponent,thestackistheheartofthefuelcellsystem. Thestackisacollectionofindividualgalvaniccells,eachofwhichprovides <1V whenoperating,connectedinseriestocreateapowerdevicethatprovidesahigher, moreusefulvoltage.Insomeapplications,multiplestacksmaybeusedtogetherfor modular,higherpowersystems.Eachcellcontainsamembraneelectrodeassembly (MEA),whichistheelectrochemicallyactivestackcomponent,withdiffusionmedia (gasdiffusionlayersandmicroporouslayers)oneachelectrodeencouraginguniform distributionofreactantsovertheMEAandremovalofwater.MEAsareconnected inthestackbyelectricallyconductivebipolarplatestocollecttheelectriccurrent produced,whichincludeflowchannelsfacingtheMEAstodeliverreactantstothe electrodes.Bipolarplateassembliesalsoincludecoolantchannelsrunningbetween (andseparatedfrom)theMEAstoremovewasteheatfromthestack.Gasmanifoldsdistributegasesbetweenthecellsinthestack,andgasketsareincludedtoseal gaswithinthedesiredelectrodes.Thestackalsoincludesstructuralcomponents, includingtierodsthatholdthecellstogetherandhousingthatenclosesthestack.

Fuelmustbesuppliedandpreparedforthefuelcellsystem,requiringdifferent BOPcomponentsdependingonthetypeoffuel.Ifhydrogenisthefuel,the preparationrequiredisminimal:thepressureandflowrateofhydrogentothe stackmustbecontrolled,andinsomecasesthehydrogenmaybehumidified. Unusedhydrogenmayalsoberecirculated.Morecomplexmolecules,suchas alcoholsorhydrocarbons,mayalsobeusedasfuelfordifferenttypesoffuelcell systems.High-temperaturefuelcells(e.g.solidoxide)canusecomplexfuelsdirectly, reformingtheminternallyinthestack.Low-temperaturefuelcellsmayincludean externalreformer,whichproduceshydrogenfromthefuelandmustalsoremove by-products,suchascarbonmonoxide,thatareharmfultothefuelcell.

Fuelcellsystemsalsorequireairtobesuppliedtothefuelcellstack.Toenable high-powerperformance,theairistypicallypressurizedbyacompressor,which maybeasimplecompressororacompressor-expandermodule,whichrecoups someenergyfromthepressurizedoutletstreamtoimproveoverallefficiency.Compressionheatstheairsupply,soprecoolingmaybenecessarybeforetheairenters thestack.Theairsupplymayalsobehumidifiedtoensureoptimalperformanceof membraneandelectrodes,andairmustbefilteredtoremovepotentiallyharmful contaminants.

Thethermalmanagementsubsystemremoveswasteheatfromthefuelcellsystem,usingcoolanttotransferheatfromthestack(andotherBOPcomponents, suchasthecompressor,asneeded)totheradiator.Thermalmanagementsubsystemstypicallyconsistofpumps,coolantlines,andradiators,althoughtheradiator issometimesconsideredtobeexternaltothefuelcellsystem.Multiplethermalmanagementsubsystemsmaybeused,suchasahigh-temperatureloopforthefuelcell stackandalow-temperatureloopfortheairprocessingsubsystem.

Thefuelcellsystemalsoincludescomponentsusedtomonitorandcontrolthe system.Numeroussensorsareusedinfuelcellsystems,includingstackvoltageand currentmonitors,pressureandtemperaturesensorsatdifferentpointsinthesystem,andhydrogensensorstodetectleaks.Thesesensorsprovideinformationto thesystemcontroller,whichdirectsthesystemtodeliverrequestedpower,while maintainingsafeoperationandavoidingconditionsthatmaydegradethefuelcell.

1.1OverviewofFuelCellApplicationsandSystemDesigns 9

Severalothersystemsandcomponentscommonlyaccompanythefuelcellsystem, butarenotconsideredapartofit,suchasthefuelstoragesystem,powerelectronics, andhybridbatteries.Theboundariesbetweenthefuelcellsystemandtheseother systemsnecessaryforapplicationsareoftennotdefinedconsistently.However,these externalsystemshaveminimalimpactonthechoiceoffuelcellmaterialsandsowill notbecoveredinthischapter.

1.1.3ComparisonofFuelCellSystemsforDifferentApplications

Thedesignoffuelcellsystemsandthetechnologiesusedvarysignificantlybetween differentapplications.Fortransportationfuelcellsystems,flexibilityandfaststartup arecritical,makingPEMfuelcellsthepreferredtechnology.Forautomotiveapplications,thefuelcellsystemistypicallysizedtoprovidearound100kWratedpower andisusuallyaccompaniedbyahybridenergystoragebatterytosupporttransient andpeakpowerdemands.Largerfuelcellsystems(hundredsofkWtoseveralMW) withmultiplestacksareusedforheavy-dutyvehicles,whilesmaller(uptotensof kW)butsimilarsystemsareusedformaterialhandlingvehiclessuchasforklifts. Transportationfuelcellsystemsaretypicallydirecthydrogenfueled,makingthefuel supplysubsystemrelativelysimple.Thecompressedairsupplyandheatrejectionare bothveryimportanttoenablehighpowerdensityandspecificpower.Alowcostis importantforthefuelcellsystemtocompetewithincumbentcombustionengine technologies.Durabilityisalsoakeyconcernfortransportationfuelcells,aspowertrainsarerequiredtoendurethousandsofhoursofoperationforautomobilesand tensofthousandsofhoursforheavy-dutyvehicles.Therelativeimportanceofdifferentsystemmetricsvariessignificantlybetweendifferenttransportationapplications aswell.Forexample,automotivefuelcelldevelopersprioritizeloweringcapitalcost andimprovinghigh-powerperformancetoenablesystemsizeandcostreductions. Incontrast,fulllifecyclecostsareimportantforcommercial,heavy-dutyvehicles, makingdurabilityandefficiencyimportantpriorities.Furthermore,forheavy-duty vehicleapplicationsthatcarryheavyloads,thefuelcellsystemneedstobedesigned todeliverhighpowerformoresustainedperiods,whichcancreatemoreharshconditionsforfuelcellmaterials.

Stationaryfuelcellsystemsvarywidelyinscalefrom <1kW“micro-CHP”residentialsystemstolargemultimegawattsystems.Forbackuppowersystems,flexibilityandresponsivenessarecritical,soPEMfuelcellsaretypicallyused.Because backuppowersystemsoperateonlyasmallfractionofthetime,capitalcostdominatestheiroverallcost.FordistributedpowerandCHPapplications,systemsare typicallyoperatedcontinuouslyforverylongperiods,makingdurabilityandefficiencyveryimportant.Thefuelprocessingsystemisalsoimportantforstationary fuelcellsystemsfueledbymethane(naturalgasorbiogas).Stationaryfuelcellshave minimalconstraintsonthesystemsizeorweight.

Forspecialtyapplicationssuchasmaterialhandling,fuelcellsmustprovideat leastequivalentperformancewithoutsignificantchangesinfunctionality,size, andcounterbalanceweightcomparedtotheincumbenttechnology.Theymust provideshortbursts(15–20seconds)ofhighpowerforliftingaheavyload,plus

1System-levelConstraintsonFuelCellMaterialsandElectrocatalysts

sustainedpowertodrivetheequipment.Ontheotherhand,portablefuelcell systemstypicallyhavelowpowerrequirements.However,theyaresubjectto extremesystemsizeandweightlimitations,andoftenaredesignedtominimize therequiredBOP,forexamplebyoperatingatornearambientpressure.Because theseconstraintsimpactthefuelstoragesystemaswell,liquidfuelsareofinterest fortheseapplications.Costmayormaynotbeaseriousconstraintdependingon theapplication;forconsumerelectronics,lowcostsarerequiredtocompetewith Li-ionbatteries,whichhaveseenrapidlyfallingpricesinrecentyears.However,for militaryorotherspecialtyapplicationshighcostsmaybeacceptable.

1.2Application-derivedRequirementsandConstraints

Thissectioncoversconstraintsonfuelcelloperationandmaterialchoicesthatare imposedbythesystemandapplicationrequirements.Fuelcellmaterialsmustmeet allsystem-levelrequirementssimultaneously,whichmakessomeotherwisepromisingmaterialsinfeasible.Themostfundamentalrequirementofafuelcellsystem istoprovidethepowerdemandedbytheapplication.Thisrequirementincludes twobroadcategories:(i)maximumpowerperformance,eitherinstantaneousor sustained,and(ii)flexibilitytodeliverpowerunderavarietyofconditionsandin responsetochangingdemand.Thefuelcellsystem,components,andmaterials mustalsobedurabletoprovidetherequiredperformancenotonlyinitiallybutalso afterextensiveuseandexposuretopotentiallydamagingconditions.Finally,fuel cellsystemsmustbeavailableatlowcosttobecompetitivewithalternativepower systems,consideringbothinitialcapitalandoperatingcosts.Itisimportanttonote thatperformance,durability,andcostareinterrelated,whichallowsfortrade-offs betweenthethree,dependingonthelifecyclerequirementsoftheapplication.

1.2.1FuelCellPerformanceandtheHeatRejectionConstraint

Cell-levelperformanceisafundamentalissueunderlyingthesystem-levelpower density,specificpower,cost,andefficiency.Thefuelcellsystemmustbesizedto deliverthepowerrequireddependingonthenatureoftheapplicationandthesystemarchitecture.Forafuel-cell-dominanthybridizationscheme,thefuelcellmust delivertherequiredsustainedmaximumpower,astherelativelysmallbatterycan addtothepeakpowerforalimitedperiodoftime.Forabattery-dominanthybridizationscheme,thefuelcellinsteadmustdelivertheaveragepowerrequired,withthe batterysupplyingpowerforpeakdemand.Forexample,fuel-cell-dominantautomotivefuelcellsoperatemostofthetimeatlow-powerconditions,wherethesystem ismostefficient,butoccasionallyrequireahighratedpower(suchasforhighway merging).Thismakesratedpowerimportantbecauseitdrivessystemsizerequirementsandisdirectlyrelatedtocost.

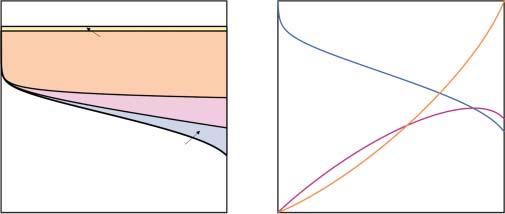

Thevoltagelossmechanismsthatdeterminefuelcellperformance,illustratedin Figure1.3a,havebeenthoroughlydescribedinmanyothertextsonfuelcellsand electrochemistry[15,16],sowewillonlybrieflyrecapthemhere.Theidealpotential

Figure1.3 Illustrationsof(a)thevoltagelossmechanismsthatcontributetothefuelcell polarizationcurveand(b)therelationshipamongthefuelcellvoltage,electricalpower production,andwasteheatthatmustberejected.

(foraperfectlyreversibleprocess)isdeterminedbytheoverallthermodynamics ofthefuelcellreaction,correspondingto1.23Vforahydrogen-oxygenfuelcell atstandardambienttemperatureandpressure[15].Nonstandardthermodynamic conditionsmodifythispotentialasdescribedbytheNernstequation,butthe correctionisgenerallysmall(ontheorderof10mV)forPEMfuelcells.Theactual voltageofanoperatingfuelcelldependsonthecurrentdensityandisdetermined byvoltagelossesfromreactionkinetics,Ohmicresistance,andmasstransport.

Thelargestlossforlow-temperaturefuelcellsundertypicalconditionsisdue totheslowkineticsoftheoxygenreductionreaction(ORR)onthecathode.ORR kineticsforPEMfuelcellsarewelldescribedbytheTafelapproximation[17]and havearoughlylogarithmicdependenceonthecurrentdensity,growingrapidlyat lowcurrentdensityandthenvaryingslowlyatmoderatetohighcurrentdensities. ORRkineticlossesareimpactedbytheintrinsicactivityofacatalystmaterial,the activesurfaceareainthefuelcellelectrode,andinteractionswiththepolymer electrolyteintheelectrode(theionomer),whichmaycoattheactivesurface.By contrast,thekineticsofthehydrogenoxidationreaction(HOR)atthefuelcell anodeareextremelyrapid,andHORkineticlossesforPEMfuelcellsaretypically negligible,evenwithextremelylowcatalystloadings.Forhigh-temperaturefuel cellskineticchallengesareminimal.

Ohmiclossesincreaselinearlywithcurrentdensityinproportiontotheoverallresistanceofthecell.InPEMfuelcellsthemembraneistypicallytheprimary sourceofohmicresistance,withtheelectrodeionomeralsocontributingsignificantlyundersomeconditions.Thecarbon-basedmaterialscommonlyusedforgas diffusionmediaandcatalystsupportscontributeminimalresistance,althoughcontactresistancesandless-conductive,corrosion-resistantalternativematerialsmay contributesignificantohmiclosses.Forhigh-temperature,solidoxidefuelcells,the ohmicresistanceoftheceramicelectrolytetypicallydominatesoveralllosses.

Masstransport-relatedlossesarenegligibleatlowcurrentdensitybutgrowrapidly athighcurrentdensity.Theprimarysourceoftransportlossesforhydrogen-airfuel cellsisoxygendiffusioninthecathode.Thisincludesbothbulkoxygentransport throughtheelectrodeandlocaloxygentransportresistanceassociatedwithoxygen

1System-levelConstraintsonFuelCellMaterialsandElectrocatalysts

diffusiontoalimitednumberofcatalyticallyactivesites,whichisaparticularly importantandchallengingproblemforlow-platinumgroupmetal(PGM)-loaded electrodes[18].Inadequateremovalofproductwatercanalsoleadtocondensationor“flooding,”leadingtosignificantmasstransportlosses.Theeffectivenessof masstransportisdeterminedbytheporousstructureofthediffusionmediaand electrodes,includingthecatalystsupportstructureandionomerdispersion.

Beyondsimplesingle-cellperformance,heatrejectionputsanimportantconstraintonperformance.AsillustratedinFigure1.3b,asthevoltagelossesincrease athighercurrentdensities,theefficiencyofenergyconversioninthefuelcell declines.Consequently,theincreaseinpoweroutputslows,eventuallyreachinga peakathighcurrentdensityandhighvoltageloss.Thisalsoleadstoanaccelerating growthintheamountofwasteheatproducedbythefuelcell.

Duringsteady-stateoperation,thefuelcellsystemmustremoveallwasteheatproducedbythefuelcellsstack.Forbriefperiods,thestackcanbeallowedtogenerate excessiveheatifitisatarelativelylowtemperature,sohigherpowerispossible intransientoperationthanthecontinuouspowerrating.Theheat Q rejectedfrom radiatorcanbesimplydescribedbyNewton’slawofcooling:

Q = hAΔT

where h istheheattransfercoefficient, A issurfacearea,and ΔT = T c T a isthe differencebetweenthecoolanttemperature T c andtheambienttemperature T a .For agivenradiator, h and A arefixed,so Q/ΔT muststaybelowacertainvalue.This makesaparticularvalueof Q/ΔT ametrictodescriberadiatorcapacity,whichis limitedforvehicleapplications.Tomeetthisheatrejectionconstraint,itispossibleto eitherlowertheamountofwasteheatproducedorraisetheoperatingtemperature. Thissetsapracticallimitonthefeasiblefuelcelloperatingconditions[19].

Asimpleformularelatesthe Q/ΔT heatrejectionmetrictorated(continuous) poweroperatingconditions,particularlythecellvoltage V r ,whichdeterminesthe fractionofenergyconvertedtowasteheat,andthestackcoolantoutlettemperature T c ,whichdetermineshoweffectivelythatheatcanberejectedthroughtheradiator: Q ΔT = P

g isthegrosspowerratingofthestack,and V i istheidealcellvoltage. ThisrelationshipisillustratedinFigure1.4,whichshowsthedependenceofthe cellvoltageatratedpower V r on T c and Q/ΔT ,usingstandardassumptions[20]for anautomotivefuelcellsystem(90kWgross ratedpower,40 ∘ Cambienttemperature, and1.23Videalcellvoltage).Ingeneral,lowervoltages(andthereforehighercurrentandpowerdensities)canbeusedwitheitherahighercoolanttemperatureor higher Q/ΔT (i.e.radiatorsize).TheDOEhassetatargetforfuelcellheatrejection of Q/ΔT ≤ 1.45kWper ∘ Ctoenableuseofpracticallysizedautomotiveradiatorsfor fuelcellvehicles.

Meetingthisautomotiveheatrejectionconstraintcreatesastrongmotivationfor usinghighertemperature(e.g.94 ∘ C)andhigherpressure(e.g.2.5bar)operating conditionsatratedpower[19].Raisingthetemperatureallowshighercurrent