Biomass-Based Supercapacitors

Design, Fabrication and Sustainability

Edited by Md. Abdul Aziz

Interdisciplinary Research Center for Hydrogen and Energy Storage, King Fahd University of Petroleum and Minerals, Dhahran, Saudi Arabia

Syed Shaheen Shah

Department of Material Chemistry

Graduate School of Engineering, Kyoto University Nishikyo-ku, Kyoto, Japan

This edition first published 2023 © 2023 John Wiley & Sons Ltd

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, except as permitted by law. Advice on how to obtain permission to reuse material from this title is available at http://www.wiley.com/go/permissions.

The right of Md. Abdul Aziz and Syed Shaheen Shah to be identified as the authors of this editorial material in this work has been asserted in accordance with law.

Registered Offices

John Wiley & Sons, Inc., 111 River Street, Hoboken, NJ 07030, USA

John Wiley & Sons Ltd, The Atrium, Southern Gate, Chichester, West Sussex, PO19 8SQ, UK

Editorial Office 9600 Garsington Road, Oxford, OX4 2DQ, UK

For details of our global editorial offices, customer services, and more information about Wiley products visit us at www.wiley.com.

Wiley also publishes its books in a variety of electronic formats and by print-on-demand. Some content that appears in standard print versions of this book may not be available in other formats.

Trademarks: Wiley and the Wiley logo are trademarks or registered trademarks of John Wiley & Sons, Inc. and/or its affiliates in the United States and other countries and may not be used without written permission. All other trademarks are the property of their respective owners. John Wiley & Sons, Inc. is not associated with any product or vendor mentioned in this book.

Limit of Liability/Disclaimer of Warranty

While the publisher and authors have used their best efforts in preparing this work, they make no representations or warranties with respect to the accuracy or completeness of the contents of this work and specifically disclaim all warranties, including without limitation any implied warranties of merchantability or fitness for a particular purpose. No warranty may be created or extended by sales representatives, written sales materials or promotional statements for this work. The fact that an organization, website, or product is referred to in this work as a citation and/or potential source of further information does not mean that the publisher and authors endorse the information or services the organization, website, or product may provide or recommendations it may make. This work is sold with the understanding that the publisher is not engaged in rendering professional services. The advice and strategies contained herein may not be suitable for your situation. You should consult with a specialist where appropriate. Further, readers should be aware that websites listed in this work may have changed or disappeared between when this work was written and when it is read. Neither the publisher nor authors shall be liable for any loss of profit or any other commercial damages, including but not limited to special, incidental, consequential, or other damages.

Library of Congress Cataloging-in-Publication Data

Names: Aziz, Md. Abdul (Research scientist), author. | Shah, Syed Shaheen, author.

Title: Biomass-based supercapacitors : design, fabrication and sustainability / Abdul Aziz, Syed Shaheen Shah.

Description: Hokoben, NJ : Wiley, 2023.

Identifiers: LCCN 2023017541 | ISBN 9781119866404 (hardback) | ISBN 9781119866428 (epub) | ISBN 9781119866435 (ebook) | ISBN 9781119866411 (pdf)

Subjects: LCSH: Supercapacitors. | Biomass.

Classification: LCC TK7872.C65 A95 2023 | DDC 621.31/5--dc23/eng/20230501

LC record available at https://lccn.loc.gov/2023017541

Cover images: © edge69/Getty Images, © browndogstudios/iStockphoto, © petovarga/Adobe Stock, © chombosan/Shutterstock, © ksyproduktor/Shutterstock, Pixabay, © Elnur/Shutterstock

Cover design by Wiley

Contents

About the Editors ix

Preface xi

List of Contributors xiii

Part 1 Biomass 1

1 Introduction to Biomass 3

Md. Almujaddade Alfasane, Ashika Akhtar, Nasrin Siraj Lopa, and Md. Mahbubur Rahman

2 Environmental Aspects of Biomass Utilization in Supercapacitors 23

Runa Akter, Jaber Bin Abdul Bari, Saidur R. Chowdhury, Muhammad Muhitur Rahman, and Syed Masiur Rahman

3 Biomass Utilization in Supercapacitors for the Circular Economy 41

Runa Akter, Md. Raquibul Hassan Bhuiyan, Saidur R. Chowdhury, Muhammad Muhitur Rahman, and Syed Masiur Rahman

Part 2 Fundamentals of Supercapacitors 61

4 Introduction to Supercapacitors 63

Syed Shaheen Shah, Mohammad Rezaul Karim, Md. Abdul Wahab, Muhammad Ali Ehsan, and Md. Abdul Aziz

5 Electrochemical Techniques for Supercapacitors 81

Syed Shaheen Shah, Md Abdul Aziz, and Munetaka Oyama

6 Types of Supercapacitors 93

Syed Shaheen Shah, Md. Abdul Aziz, Wael Mahfoz, and Md. Akhtaruzzaman

Part 3 Biomass Derived Electrode Materials for Supercapacitors 105

7 Non-activated Carbon for Supercapacitor Electrodes 107

Md. Akib Hasan, Mohammad Anikur Rahman, and Md. Mominul Islam

8 Carbon from Pre-Treated Biomass 121

Syeda Ramsha Ali, Mian Muhammad Faisal, and K.C. Sanal

9 Carbonate Salts-activated Carbon 143

Syed Shaheen Shah , Md. Abdul Aziz , Laiq Zada, Haroon Ur Rahman, Falak Niaz, and Khizar Hayat

10 KOH/NaOH-activated Carbon 161

Nasrin Siraj Lopa, Biswa Nath Bhadra, Nazmul Abedin Khan, Serge Zhuiykov, and Md. Mahbubur Rahman

11 Chloride Salt-activated Carbon for Supercapacitors 179

Eman Gul, Syed Adil Shah, and Syed Niaz Ali Shah

12 CO2-activated Carbon 201

Salman Farsi, Thuhin Kumar Dey, Mushfiqur Rahman, and Mamun Jamal

13 Steam-activated Carbon for Supercapacitors 213

Madhusudan Roy and Hasi Rani Barai

14 Biomass-Derived Hard Carbon for Supercapacitors 237

Himadri Tanaya Das, Swapnamoy Dutta, Muhammad Usman, T. Elango Balaji, and Nigamananda Das

15 Carbon Nanofibers 249

Nasrin Sultana, Ahtisham Anjum, S. M. Abu Nayem, Syed Shaheen Shah, Md. Hasan Zahir , A. J. Saleh Ahammad, and Md. Abdul Aziz

16 Biomass-Derived Graphene-Based Supercapacitors 269

Nafeesa Sarfraz, Ibrahim Khan, and Abdulmajeed H. Hendi

17 Biomass-derived N-doped Carbon for Electrochemical Supercapacitors 289

Syed Niaz Ali Shah, Eman Gul, Narayan Chandra Deb Nath, and Guodong Du

18 Biomass Based S-doped Carbon for Supercapacitor Application 315

S. M. Abu Nayem, Santa Islam, Syed Shaheen Shah, Nasrin Sultana, Wael Mahfoz, A. J. Saleh Ahammad, and Md. Abdul Aziz

19 Biomass-derived Carbon and Metal Oxides Composites for Supercapacitors 329 Muhammad Ammar, Himadri Tanaya Das, Awais Ali, Sami Ullah, Abuzar Khan, Abbas Saeed Hakeem, Naseem Iqbal, Muhammad Humayun, Muhammad Zahir Iqbal, and Muhammad Usman

20 Composites of Biomass-derived Materials and Conducting Polymers 347

Wael Mahfoz, Abubakar Dahiru Shuaibu, Syed Shaheen Shah, Md. Abdul Aziz, and Abdul-Rahman Al-Betar

21 Composite of Biomass-derived Material and Conductive Material Excluding Conducting Polymer Material 367

Nasrin Sultana, Ahmar Ali, S. M. Abu Nayem, Syed Shaheen Shah, Md. Hasan Zahir, A. J. Saleh Ahammad, and Md. Abdul Aziz

Part 4 Binding Materials, Electrolytes, Separators, and Packaging Materials from Biomass for Supercapacitors 383

22 Biomass-based Electrolytes for Supercapacitor Applications 385

S. M. Abu Nayem, Santa Islam, Syed Shaheen Shah, Nasrin Sultana, M. Nasiruzzaman Shaikh, Md. Abdul Aziz, and A. J. Saleh Ahammad

23 Biomass-based Separators for Supercapacitor Applications 403

S. M. Abu Nayem, Santa Islam, Syed Shaheen Shah, Abdul Awal, Nasrin Sultana, A. J. Saleh Ahammad, and Md. Abdul Aziz

24 Binding Agents and Packaging Materials of Supercapacitors from Biomass 417 Md. Mehedi Hasan and Md. Rajibul Akanda

Part 5 Biomass-Based Supercapacitors: Future Outlooks and Challenges 435

25 Biomass-based Supercapacitors: Lab to Industry 437

Syed Shaheen Shah, Md. Abdul Aziz, Muhammad Usman, Abbas Saeed Hakeem, Shahid Ali, and Atif Saeed Alzahrani

26 Future Directions and Challenges in Biomass-Based Supercapacitors 461

Syed Shaheen Shah, Md. Abdul Aziz, Muhammad Ali, Muhammad Usman, Sikandar Khan, Farrukh Shehzad, Syed Niaz Ali Shah, and Sami Ullah

Index 485

About the Editors

Dr. Md. Abdul Aziz is a Research Scientist-II (Associate Professor) at the Interdisciplinary Research Center for Hydrogen and Energy Storage (IRC-HES), King Fahd University of Petroleum & Minerals (KFUPM), Saudi Arabia. He also served as research scientist-III (Assistant Professor) at the Center of Research Excellence in Nanotechnology (CENT), KFUPM. He worked as a postdoctoral fellow of the Japan Society for the Promotion of Science (JSPS) in the Department of Material Chemistry, Kyoto University, from 2009–2011. He is a serving editorial board member of ChemistrySelect-Wiley; Current Nanomaterials – Bentham Science and served/serving as guest editor of The Chemical Record-Wiley; Chemistry-an Asian Journal-Wiley; Chemistry – a European Journal-Wiley.

Dr. Aziz has authored 187 papers in well-reputed peer-reviewed journals in addition to numerous numbers of conference proceedings/presentations/book chapters, and holds 30 US patents. His research interests are the preparation and characterization of nanomaterial and carbonaceous materials for different electrochemical applications such as energy storage and generation, sensor, CO2 conversion, water splitting, sensors etc. Dr. Aziz received his B.Sc. in Chemistry in 1999 and M.Sc. in organic chemistry in 2001 from University of Dhaka, Bangladesh. In 2009, he earned his PhD in chemistry from BioMEMS and Nanoelectrochemistry Laboratory, Department of Chemistry, Pusan National University, Republic of Korea.

Dr. Syed Shaheen Shah is a JSPS Post-Doctoral Fellow in the Department of Material Chemistry, Graduate School of Engineering, Kyoto University, Japan. Dr. Shah received his Bachelor’s degree in 2015 and Master’s degree in 2017 from the Department of Physics, University of Peshawar, Pakistan. He earned his PhD degree in 2022 from the Physics Department, King Fahd University of Petroleum & Minerals, Saudi Arabia. His research interests focus on the development and mechanistic investigation of advanced nanomaterials for energy harvesting and storage applications, such as supercapacitors, electrochemical water splitting, and electrochemical sensors.

Preface

Due to recent technological developments energy demands are rising with time, and our planet currently faces enormous energy-related challenges, including fossil fuel consumption and CO2 emission. Renewable energy resources provide a considerable alternative to meet global energy demands. However, due to its time-dependent operations, a powerful energy storage system is required that can store vast amounts of energy in a short time. In this regard, supercapacitors based on biomass materials have recently received tremendous attention. A supercapacitor is an energy storage device with high energy and power densities and can be completely charged in seconds. Supercapacitors can be developed to store renewable energy on a larger scale by carefully selecting electrode materials and electrolytes and using cost-effective and simple preparation methods. Supercapacitors are now a reality in the market and are used in various wearable and automobile systems. When intermittent renewable sources are added to the energy mix, supercapacitors can also help stabilize the output energy and power. Supercapacitors are currently commercially accessible; however, they still need to be improved, mainly to increase their energy density. In addition to enhancing electrode materials, electrolytes present, and system integration, a thorough comprehension of their properties and precise operating principles is required. All of these issues over the decade greatly influenced both academia and business.

One fundamental technical and financial development is turning biomass into energy, transport, and storage. R&D and industrial applications for collecting all types of biomass resources have made significant progress in recent years. All the non-fossilized biological materials on Earth are referred to as biomass, including animal and plant wastes, agricultural residues, industrial residues, food wastes, municipal wastes, forest residues, and agricultural residues. Biomass has been utilized as a renewable resource for both energy and non-energy purposes, including the production of fuels and power as well as uses in agriculture and industry. As a result, biomass meets roughly 10% of the global energy demand and 35% of that in developing nations. Biomass and its derivatives have increased as science and technology have advanced, not only for use in producing energy and fuel but also in applications such as energy storage, sensors, and catalysis. Producing electrodes, electrolytes, binder materials, separators, and packaging materials from biomass has sparked a prospective interest in developing electrochemical supercapacitors.

Our book, Biomass-Based Supercapacitors, provides extensive knowledge about the developments of supercapacitors, with a complete package of using biomass-based materials and

their various industrial applications. No other thorough book has dealt extensively with the subject of biomass-based supercapacitors. A comprehensive study is necessary due to the new concepts that have emerged over the last few years, including a better explanation of how biomass can efficiently be utilized in developing high-performance supercapacitors. This book has been specifically designed to satisfy the academic and scientific needs of students, aspiring researchers, and material scientists working in the area of biomass-based materials and their numerous applications in the field of electrochemical energy storage devices. The book was written in collaboration with experts in the field of supercapacitors from around the world, and state-of-the-art studies are covered in detail. This book is structured into several sections that discuss different aspects of biomass in the field of supercapacitors. We are confident that this book will satisfy all of needs and expectations. There are 26 chapters in the book: the first three chapters being devoted to an introduction to biomass, the environmental aspects for utilization in supercapacitors, and circular economy. The next three chapters explain the basic concepts, fundamental electrochemical principles, electrochemical characterization methods, and fundamental supercapacitor attributes to enable reading the book without any prior knowledge. Afterward, fifteeen chapters are devoted to very important component of supercapacitors i.e., biomass-derived carbonaceous electrode materials, including non-activated carbon, carbon from pretreated biomass, carbonate salts-activated carbon, KOH/NaOH-activated carbon, chloride salt-activated carbon, CO2-activated carbon, steam-activated carbon, hard carbon, carbon nanofibers, graphene, nitrogen-doped carbon, sulfur-doped carbon, composites of biomass-derived carbon and metal oxides, composites of biomass-derived materials and conducting polymers, and composites of biomass-derived materials and conductive materials excluding conducting polymers. Next, three further chapters explains the production of supercapacitor’s electrolytes, separators, binding agents, and packaging materials from biomass, and the last two chapters provide a comprehensive insight into the industrial applications, future directions, and challenges in biomass-based supercapacitors. Each chapter strives to provide the most comprehensive information possible using everyday language.

We are pleased that we were able to bring together the top experts in biomass-based supercapacitors research and technology in one book. They all graciously consented to offer their time to write chapters, for which we are grateful. We would also like to thank the Wiley team for their patience and for providing us with this amazing opportunity to provide an excellent platform for researchers and students working in electrochemical energy storage. Finally, we would like to dedicate this book to our teachers and parents, who would be incredibly proud of our small contributions to assist in resolving global issues facing humanity.

Dr. Md. Abdul Aziz

Dr. Syed Shaheen Shah

List of Contributors

A. J. Saleh Ahammad

Department of Chemistry

Jagannath University

Dhaka, Bangladesh

Md. Rajibul Akanda

Department of Chemistry

Jagannath University

Dhaka, Bangladesh

Ashika Akhtar

Department of Botany

University of Dhaka

Dhaka, Bangladesh

Md. Akhtaruzzaman

Solar Energy Research Institute (SERI)

Universiti Kebangsaan

Malaysia

Runa Akter

Institute of Forestry and Environmental Sciences

University of Chittagong

Chittagong, Bangladesh

Md. Almujaddade Alfasane

Department of Botany

Curzon Hall Campus

University of Dhaka

Dhaka, Bangladesh

Syeda Ramsha Ali

Universidad Autónoma de Nuevo León

UANL, Facultad de Ciencias Químicas

Av. Universidad, Cd. Universitaria

San Nicolás de los Garza

Nuevo León, México

Awais Ali

Department of Chemical Engineering

Technology

Government College University

Faisalabad, Pakistan

Ahmar Ali

Physics Department

King Fahd University of Petroleum & Minerals

Dhahran, Saudi Arabia

Muhammad Ali

Interdisciplinary Research Center for Hydrogen and Energy Storage (IRC-HES)

King Fahd University of Petroleum & Minerals

Dhahran, Saudi Arabia

Shahid Ali

Interdisciplinary Research Center for Hydrogen and Energy Storage (IRC-HES)

King Fahd University of Petroleum & Minerals

Dhahran, Saudi Arabia

List of Contributors

Abdul-Rahman Al-Betar

Chemistry Department

King Fahd University of Petroleum and Minerals

Dhahran, Saudi Arabia

Interdisciplinary Research Center for Hydrogen and Energy Storage (IRC-HES)

King Fahd University of Petroleum & Minerals

KFUPM, Dhahran, Saudi Arabia

Atif Saeed Alzahrani

Interdisciplinary Research Center for Hydrogen and Energy Storage (IRC-HES)

King Fahd University of Petroleum & Minerals

Dhahran, Saudi Arabia

Materials Science and Engineering Department

King Fahd University of Petroleum & Minerals

Dhahran Saudi Arabia

Muhammad Ammar

Department of Chemical Engineering

Technology

Government College University

Faisalabad, Pakistan

Ahtisham Anjum

Physics Department

King Fahd University of Petroleum & Minerals

Dhahran, Saudi Arabia

Abdul Awal

Department of Chemistry

Jagannath University

Dhaka, Bangladesh

Md. Abdul Aziz

Interdisciplinary Research Center for Hydrogen and Energy Storage

King Fahd University of Petroleum and Minerals

Dhahran, Saudi Arabia

K. A. CARE Energy Research and Innovation Center

King Fahd University of Petroleum & Minerals

Dhahran, Saudi Arabia

T. Elango Balaji

Department of Chemistry

Utkal University

Bhubaneswar

Odisha, India

Hasi Rani Barai

Department of Mechanical Engineering

School of Mechanical and IT Engineering

Yeungnam University

Republic of Korea

Jaber Bin Abdul Bari

Department of Oceanography

Noakhali Science and Technology University

Noakhali, Bangladesh

Biswa Nath Bhadra

International Center for Materials

Nanoarchitectonics (WPI-MANA)

National Institute for Materials Science (NIMS)

Tsukuba, Ibaraki, Japan

Md. Raquibul Hassan Bhuiyan Department of Architecture

Bangladesh University of Engineering and Technology

Dhaka

Saidur R. Chowdhury

Department of Civil Engineering

College of Engineering

Prince Mohammad Bin Fahd University (PMU)

Al khobar

Saudi Arabia

SC Environmental Solutions

Toronto ON, Canada

List of Contributors

Himadri Tanaya Das

Centre for Advance Materials and Applications

Utkal University

Bhubaneswar, Odisha, India

Nigamananda Das

Department of Chemistry

Utkal University

Bhubaneswar, Odisha, India

Thuhin Kumar Dey

Department of Leather Engineering

Khulna University of Engineering & Technology

Khulna, Bangladesh

Guodong Du Department of Chemistry University of North Dakota

Grand Forks, North Dakota

United States

Swapnamoy Dutta

Bredesen Center for Interdisciplinary Research and Graduate Education University of Tennessee Knoxville, TN, USA

Muhammad Ali Ehsan

Interdisciplinary Research Center for Hydrogen and Energy Storage (IRC-HES)

King Fahd University of Petroleum & Minerals

Dhahran, Saudi Arabia

Mian Muhammad Faisal

Universidad Autónoma de Nuevo León

UANL, Facultad de Ciencias Químicas

Av. Universidad, Cd. Universitaria

San Nicolás de los Garza

Nuevo León, México

Salman Farsi

Department of Materials Science & Engineering

Khulna University of Engineering & Technology

Khulna, Bangladesh

K.C. Sanal

Universidad Autónoma de Nuevo León

UANL, Facultad de Ciencias Químicas

Av. Universidad, Cd. Universitaria

San Nicolás de los Garza Nuevo León, México

Eman Gul Institute of Chemical Sciences University of Peshawar Peshawar, Pakistan

Md. Akib Hasan Department of Chemistry University of Dhaka Bangladesh

Abbas Saeed Hakeem

Interdisciplinary Research Center for Hydrogen and Energy Storage (IRC-HES)

King Fahd University of Petroleum and Mineral

Dhahran, Saudi Arabia

Md. Mehedi Hasan

Department of Chemistry

Jagannath University

Dhaka, Bangladesh

Khizar Hayat

Department of Physics Abdul Wali

Khan University

Mardan, Khyber Pakhtunkhwa

Pakistan

List of Contributors

Muhammad Humayun

Wuhan National Laboratory for Optoelectronics

Huazhong University of Science and Technology

Wuhan, China

Abdulmajeed H. Hendi

Physics Department

King Fahd University of Petroleum and Minerals

Dhahran, Saudi Arabia

Md. Mominul Islam

Department of Chemistry

Faculty of Sciences

Dhaka University

Bangladesh

Santa Islam Department of Chemistry

Jagannath University

Dhaka, Bangladesh

Naseem Iqbal

U.S. Pakistan Center for Advanced Studies in Energy (USPCAS−E)

National University of Sciences and Technology (NUST)

Islamabad, Pakistan

Muhammad Zahir Iqbal

Nanotechnology Research Laboratory

Faculty of Engineering Sciences

GIK Institute of Engineering Sciences and Technology

Topi, Khyber Pakhtunkhwa, Pakistan

Mamun Jamal

Department of Chemistry

Khulna University of Engineering & Technology (KUET)

Khulna, Bangladesh

Mohammad Rezaul Karim

Center of Excellence for Research in Engineering Materials (CEREM)

Deanship of Scientific Research (DSR)

College of Engineering

King Saud University

Riyadh, Saudi Arabia

K.A. CARE Energy Research and Innovation Center

King Saud University

Riyadh, Saudi Arabia

Nazmul Abedin Khan

Department of Mathematical and Physical Sciences

East West University

Dhaka, Bangladesh

Ibrahim Khan

School of Chemical Engineering & Materials Science

Chung-Ang University

Seoul, Republic of Korea

Syed Niaz Ali Shah

Center for Integrative Petroleum Research

King Fahad University of Petroleum and Minerals

Dhahran, Saudi Arabia

Sikandar Khan

Department of Mechanical Engineering

King Fahd University of Petroleum and Minerals

Dhahran, Saudi Arabia

Abuzar Khan

Interdisciplinary Research Center for Hydrogen and Energy Storage (IRC-HES) King Fahd University of Petroleum and Minerals

Dhahran, Saudi Arabia

Nasrin Siraj Lopa

Center for Environmental & Energy Research

Ghent University Global Campus

Incheon, Republic of Korea

List of Contributors

Wael Mahfoz

Chemistry Department

King Fahd University of Petroleum & Minerals

Dhahran, Saudi Arabia

Narayan Chandra Deb Nath

Department of Chemistry University of North Dakota

Grand Forks, North Dakota, United States

S.M. Abu Nayem

Department of Chemistry

Jagannath University

Dhaka, Bangladesh

Munetaka Oyama

Department of Material Chemistry

Graduate School of Engineering

Kyoto University

Kyotodaigaku Katsura

Nishikyo-ku, Kyoto, Japan

Md. Mahbubur Rahman

Department of Energy and Materials

Konkuk University

Chungju, Republic of Korea

Mushfiqur Rahman

Department of Materials Science & Engineering

Khulna University of Engineering & Technology

Khulna, Bangladesh

Muhammad Muhitur Rahman

Department of Civil and Environmental Engineering

College of Engineering

King Faisal University

Al-Ahsa, Saudi Arabia

Madhusudan Roy

Department of Physics

National Taiwan University

Taipei, Taiwan

Falak Niaz

Materials Research Laboratory Department of Physics University of Peshawar Peshawar, Pakistan

Syed Masiur Rahman

Applied Research Center for Environment & Marine Studies

King Fahd University of Petroleum & Minerals

Dhahran, Eastern Province

Saudi Arabia

Mohammad Anikur Rahman Department of Chemistry University of Dhaka Dhaka, Bangladesh

Haroon Ur Rahman

Department of Physics

Abdul Wali Khan University

Mardan, Khyber Pakhtunkhwa Pakistan

Nafeesa Sarfraz

School of Chemical Engineering & Materials Science

Chung-Ang University Seoul, Republic of Korea

Syed Adil Shah

National Laboratory of Solid-States Microstructures

Department of Physics

Nanjing University

Nanjing, China

Syed Shaheen Shah

Department of Material Chemistry

Graduate School of Engineering

Kyoto University, Nishikyo-ku Kyoto, Japan

List of Contributors

M. Nasiruzzaman Shaikh

Interdisciplinary Research Center for Hydrogen and Energy Storage (IRC-HES)

King Fahd University of Petroleum & Minerals Dhahran

Saudi Arabia

Farrukh Shehzad

Department of Chemical Engineering

King Fahd University of Petroleum & Minerals

Dhahran, Saudi Arabia

Abubakar Dahiru Shuaibu

Material Science and Engineering Department

King Fahd University of Petroleum and Minerals

Dhahran, Saudi Arabia

Nasrin Sultana

Department of Chemistry

Jagannath University

Dhaka, Bangladesh

Sami Ullah

K. A. CARE Energy Research and Innovation Center

King Fahd University of Petroleum & Minerals

Dhahran, Saudi Arabia

Muhammad Usman

Interdisciplinary Research Center for Hydrogen and Energy Storage

King Fahd University of Petroleum and Minerals

Dhahran, Saudi Arabia

Md. Abdul Wahab

Australian Institute for Bioengineering and Nanotechnology (AIBN)

The University of Queensland St. Lucia, QLD, Australia

Laiq Zada

Department of Microbiology

Faculty of Biological Sciences

Quaid-i-Azam University

Islamabad, Pakistan

Md. Hasan Zahir

Interdisciplinary Research Center for Renewable Energy and Power Systems (IRC-REPS)

King Fahd University of Petroleum & Minerals

Dhahran, Saudi Arabia

Serge Zhuiykov

Center for Environmental & Energy Research

Ghent University Global Campus

Yeonsu-gu, Incheon, South Korea

Part 1

Biomass

1

Introduction to Biomass

Md. Almujaddade Alfasane1,*, Ashika Akhtar1, Nasrin Siraj Lopa2, and Md. Mahbubur Rahman3,*

1 Department of Botany, University of Dhaka, Dhaka-1000, Bangladesh

2 Center for Environmental & Energy Research, Ghent University Global Campus, 119–5 Songdomunhwa-ro,Yeonsu-gu, Incheon 21985, Republic of Korea

3 Department of Applied Chemistry, Konkuk University, Chungju 27478, Republic of Korea

* Corresponding authors

1.1 Introduction

Biomass refers to the organic materials that come from biological bodies [1]. Carbon, hydrogen, oxygen, and nitrogen are the major elements of biomass-based organic compounds that can be derived from plants, animals, and microorganisms in both terrestrial and aquatic ecosystems [1, 2]. Terrestrial biomass consists of various plants, animals, and microorganisms, whereas aquatic biomass mainly comprises micro-/macro-algae, phytoplankton, zooplankton, aquatic plants and animals, and other microorganisms [3–5]. Biomass encompasses different compounds such as cellulose, hemicelluloses, starches, sugars, lipids, proteins, lignin, hydrocarbons, and trace amounts of Si, Na, K, Mg, Al, Fe, Mn, Ca, P, and S contained in inorganic ash [6–8]. Among them, lignocellulosic materials, including cellulose, hemicellulose, and lignin, are the major compounds of the biomass (Figure 1.1) [6–8].

Humans have utilized biomass since time immemorial and its use has fostered the birth of civilization. Among all the sources of biomass, plant-derived biomasses are significantly used for energy and fuel production. Plants produce biomass by absorbing solar energy through photosynthesis and converting carbon dioxide (CO2) and water into carbohydrates [1, 2]. This chemical energy produced by biomass can be converted to usable heat and electrical energy or can be processed into biofuel through pyrolysis [9]. Thus, biomass is currently regarded as the fourth energy source in the world after oil, coal, and natural gas. With the world’s increasing energy demand, biomass utilization has been growing substantially to fulfill a significant proportion of this demand as one of the cheap, available, and renewable energy sources [10]. For example, in 2019, biomass satisfied approximately 10% of the energy requirement worldwide [11]. However, biomass has not been utilized equally by the world’s countries for energy production. Developing countries depend more on

Biomass-Based Supercapacitors: Design, Fabrication and Sustainability, First Edition. Edited by Md. Abdul Aziz and Syed Shaheen Shah.

© 2023 John Wiley & Sons Ltd. Published 2023 by John Wiley & Sons Ltd.

biomass-based energy than industrialized countries due to their limited technology, infrastructure, and poor economies [12]. For instance, almost half of the energy supply in Africa comes mainly from biomass-based sources, whereas in Europe, only about 10% of the energy supply comes from renewables, the lowest among the continents [13]. Meanwhile, considering the total global production of biomass (~150 billion tons/year), a large amount of these biomasses is still underutilized for energy and fuel production [14]. Interestingly, most of them are generally considered waste materials, commonly to be decomposed or subjected to waste management methods.

Awareness and concern among the world population have increased regarding the use and valorization of biomass not only for energy and fuel production but also for synthesizing nanomaterials and dyes for various applications [15, 16]. The utilization of biological residue materials obtained from biomass represents ecologically friendly and considerably higher-value alternatives to conventional fossil fuels [17]. For example, peanut shells, which was previously considered waste and was given low value, has the potential to be applied to hydrogen, biodiesel, bioethanol, carbon nano-sheet, and dye production [18, 19].

Another example is phytoplankton, which was earlier considered a disturbance and a hazardous ecosystem component. It is now being commercially cultured for biofuels, bioactive pigments, lipids, and energy production [20]. Similarly, many examples of biomass that have never been considered valuable previously are now valorized as precious materials. Accordingly, researchers’ interest in using biomass for energy production increased steeply, as is evident from the number of publications that appeared in the last decade (Figure 1.2).

Figure 1.1

The main compounds and the chemical structures of lignocellulosic biomass.

Figure 1.2 The number of publications having keywords of “biomass for energy production”, “biomass for supercapacitors”, and “activated carbon from biomass for supercapacitors” from 2013 to October 17, 2022. Source: Scopus

In addition to energy and fuel production, biomass can be utilized to produce biochar (BC), a lightweight black carbon residue, through the carbonization processes (e.g., pyrolysis and hydrothermal carbonization) [21]. The biochar can be treated for producing activated carbon (AC) through various chemical, physical, and mechanical activation methods [22, 23]. Moreover, AC can be produced from biomass using a single step [23]. These ACs derived from biomass could solve environmental problems such as air and water pollution and the accumulation of industrial, food, and agricultural wastes. Furthermore, using ACs from lignocellulosic biomass instead of fossil fuels such as coal can reduce global warming effects. ACs derived from lignocellulosic biomass can potentially be utilized in various industrial sectors such as chemical processes, petroleum refining, wastewater and air pollution treatment, volatile organic compounds adsorption, catalysis, gas separation, deodorization, and purification [24]. This is due to the rich carbon content of ACs derived from BC with high surface area, microporous structure, and favorable pore size [24, 25]. Along with this improved physical property, facile controlling of the dimensions and structures, heteroatom doping, chemical functionalization, and enhanced degree of graphitization of ACs prepared from suitable biomass help to increase its electrical conductivity, which is beneficial for the development of high-performance electrochemical energy storage devices such as electrochemical supercapacitors (ESCs) and batteries [26–30].

In particular, the application of ACs derived from biomass has increased sharply for ESC applications, as is evident from the number of publications that appeared in the last decade (Figure 1.2). ESCs have received tremendous recognition as energy storages device in recent years due to their intermediate energy density between battery and capacitor [31]. The ultra-high-power density, extended life cycles, and prompt charge/discharge rate of ESC widen its application in various technologies, including consumer electronics, voltage stabilizers, micro-grids, low-power equipment, etc [32]. Principally, ESCs fabricated using carbons or ACs store the charge by reversible adsorption of ions in a non-Faradaic process and are commonly known as electric double-layer capacitors (EDLCs) [33, 34]. To develop high-performance ESCs based on ACs derived from biomass, the optimal pores corresponding to the size of the electrolyte ions, high degree of graphitization for improved electrical conductivity, heteroatom doping (e.g., N and P), and chemical functionalization

Introduction to Biomass

(e.g., carboxylic, carbonyl, and hydroxyl) are significantly important [35, 36]. Moreover, enduring cyclic stability and capacitance retention in ESCs can be obtained by tuning the structural stability of the AC framework [29, 37–40]. All other main parts of supercapacitors, including binder, electrolyte, and membrane (separator), can be produced via biochar and biomass derivatives [41–45]. Therefore, biomass could be considered a complete material source for the fabrication of efficient energy storage devices, supercapacitors, and for future research (Figure 1.2). Considering the importance of biomass for energy and fuel production and ESCs applications, this chapter briefly discusses the fundamentals of biomass by highlighting its classification, environmental and energy aspects, and pyrolysis process. Additionally, the application of biomass for ESCs is discussed briefly by highlighting the current challenges and future directions.

1.2 Categories of Biomass

A wide range of materials, including agricultural and forest residues, food wastes, animal wastes, wastes of the wood processing industry, wastes of the zoo-technical industry, biodegradable industrial/household solid wastes, and algal and other aquatic organisms with varying compositions of lignocellulosic compounds are termed as biomass [46–48]. Accordingly, biomass can be mainly classified as plant and organic wastes/residues (Figure 1.3).

1.2.1 Plant Biomass

Plants are the largest biomass energy source worldwide and can be categorized mainly as woody and non-woody biomass based on the plant’s origin and chemical compositions [49]. Woody biomass is primarily derived from stems and branches of trees and shrubs or their residue products [50]. The proportions of lignocellulosic compounds are not the same

Figure 1.3 Types of biomasses based on the sources.

1.2 Categories of Biomass 7 in all woody biomass. Accordingly, woody biomass can be reclassified as hardwoods and softwoods [51]. Hardwoods generally contain higher proportions of cellulose and hemicelluloses than softwoods, but the amount of lignin is higher in softwoods (Table 1.1) [52]. Generally, hardwoods contain approximately 35% hemicelluloses and 22% lignin by dry weight. In contrast, softwoods have a composition of approximately 43% cellulose, 28% hemicelluloses, and 29% lignin by dry weight [50, 52].

In contrast, non-woody biomass is described as those plants with weak stems, such as herbaceous plants, grasses, and agricultural crops. In non-woody biomass, the proportion of hemicellulose is generally higher, with a low proportion of lignin [52]. However, the chemical composition of non-woody plants is highly dependent on the soil properties and climate conditions. Furthermore, their chemical compositions are also varied based on the structure of cell walls, species, and maturity. Other than lignocellulosic compounds, nonwoody biomass is richer in silicate and various nutrient contents than is woody biomass [53]. Also, the plant biomass’s chemical composition depends on the plant’s type and portions (e.g., root, leaves, trunk). For example, Albizia procera leaves contain a significant amount of protein and lignocellulosic components [54]. It is well known that protein is used to develop bioelectrolyte for supercapacitor fabrication.

1.2.2 Organic Wastes and Residues-based Biomass

Organic wastes and residues from different sources, such as forest products, agricultural, industrial, municipal and urban activities, and animals, produce a massive amount of biomass, more than 13 × 109 tons/year [55]. Based on the sources, this type of biomass can be generated in different stages of its processing, growing, production, and uses. For example, agricultural wastes are produced during crop harvesting, such as wheat straw, rice husk, rice straw, etc. Industrial waste, such as sawdust, is produced in the timber and furniture industry. All these different forms of organic waste biomass are also rich in lignocellulosic materials (Table 1.2) and are potential energy sources. Among all these sources, residues from agriculture account for 87% of the total supply of organic wastes and residues-based biomass, while municipal and industrial wastes occupy 5% [13]. However, almost 99% of this form of biomass remains unused due to the lack of proper knowledge and ability to commercialize it [56].

Table 1.1 Chemical composition of lignocellulosic hardwood and softwood biomass.

Reproduced with permission [52]. Reproduced under the terms of the CC BY 3.0 license. Copyright 2015, Isikgor et al., Royal Society of Chemistry

Table 1.2 Composition of different organic waste biomass.

1.3 Utilization of Biomass

Biomass can be utilized as an energy and non-energy source to produce fuels and power, and for agricultural and industrial uses (Figure 1.4). For example, woody biomass is mainly used for household heating, cooking, and electricity generation, and for producing paper, particle boards, and furniture. Moreover, woody biomass is also used as animal food and as a raw material for chemical synthesis. While fast-growing vegetal species, which are not fit for agriculture, are generally cultivated for biofuel production [70]. Agricultural biomass residue is widely applied in generating electric and thermal energies [71]. Other than the production of energy and fuels, biomass is extensively used to produce animal feed and food, construction materials, compost, and composite materials. In particular, composites from natural fibers have gained considerable attention in the manufacturing industry, particularly for transportation, automotive, and electronics applications [72–84]. This is due to their light weight, resistance to corrosion, abundance, and biodegradability [85].

Furthermore, biomass polymer composites can provide a sustainable, eco-friendly, and cheap structural material with improved mechanical properties different from traditional polymer-reinforced glass and carbon composite materials [85]. For instance, carbon derived from feedstock waste or undervalued sources such as coir fibers, shell particles, coffee ground powder, and olive seed flour can be used to prepare carbon/poly(propylene) as an effective composite for automobile parts with light weight and low-cost [86–89]. Binoj et al. reported that an optimized amount of tamarind fruit fiber incorporated into polyester resins substantially improves the thermal stability and aquatic properties suitable for lightweight automotive and marine applications [90]. Biomass/polymer composites are also used to produce hybrid particle boards with improved mechanical properties. For example, a hybrid particle board was

1.4 Biomass as an Energy Source

Figure 1.4 Utilization of biomass for practical applications.

prepared by reinforcing rice straws/coir fibers in phenol formaldehyde resin [91]. This particle board possibly improves the toughness, vibration damping, and flame retardancy compared to the board made with only phenol formaldehyde resin. Some other researchers embedded celery root fibers, poplar seed hair fibers, and hazelnut shell flour into the polylactic acid matrix to prepare biodegradable plastic films, bottles, and medical devices [92, 93].

1.4 Biomass as an Energy Source

The resources that meet the basic needs of energy demand for humans and civilizations can be divided into primary resources (renewable and non-renewable energy resources) and secondary resources obtained by converting primary energy resources [94]. Primary energy sources can be classified as non-renewable (e.g., coal, natural gas, oil) and renewable

energy sources (e.g., solar, hydrothermal, biomass, etc.) [95–97]. Biomass is a renewable energy source that can provide a sustainable energy supply at a low cost and mitigate global warming by reducing greenhouse gas emissions. Energy generation from biomass is growing faster due to the quick depletion of conventional fossil fuels. Plants, rice husks, waste plastics, sawdust, algae, and trees are the common biomass sources for producing different energy and products (Figure 1.4). Currently, biomass energy sources produce 50 × 1018 J, accounting for 10% of the world’s energy demand and 35% of that of developing countries [98]. These sources include the production of electrical and thermal energy, fuels (gaseous, liquid, and solid), and valuable chemicals (e.g., ethanol and methanol) through thermal (e.g., pyrolysis, gasification, and combustion) and chemical treatments.

Considering the chemical compositions of biomass and fossil oils, biomass’s main disadvantage in producing biofuels is its higher oxygen content with less carbon and hydrogen ratio (C/H) [99]. To replace fossil oils with biofuels, the C/H ratio in biomass must be improved by removing oxygen from the biomass in the form of H2O, CO, and CO2 [100]. This is challenging and costly since pyrolysis, gasification, combustion, and chemical processes for energy production and the enhancement of C/H ratio are still required for using other primary and secondary energy sources and chemical reagents. However, the high O/C atomic ratio in lignocellulosic biomass is advantageous for synthesizing valuable chemicals and residues.

1.5 Pyrolysis of Biomass

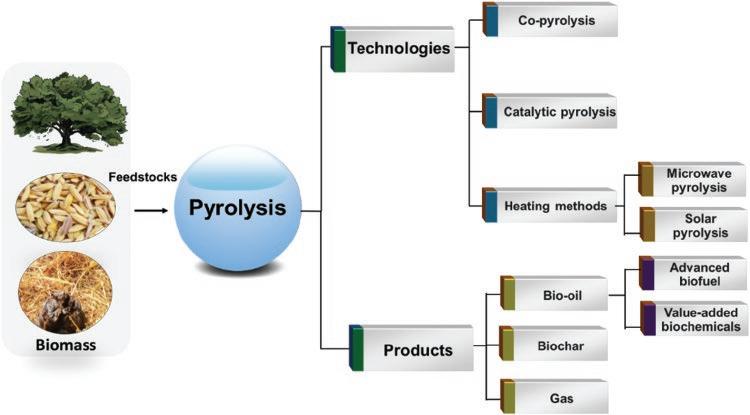

Pyrolysis is a process that decomposes the lignocellulosic polymer chains in biomass by thermal treatment in the absence of air or an inert atmosphere [101]. This led to the use of BC to generate solid fuels, bio-oil as liquid fuels, and non-condensable gases (Figure 1.5) [102, 103]. In the process of biomass pyrolysis, first the biomass feed materials are

Figure 1.5 Schematic representation of the products and technologies of the pyrolysis of biomass.

1.6 Biomass-derived Carbon for Electrochemical Supercapacitors 11 decomposed by the removal of moisture contents [104]. This also induces the breaking of bonds in lignocellulosic polymers and the formation of CO, CO2, and residues [105–107]. The remaining compounds or materials are further converted to secondary BC, crude biooil, and gases using cracking and polymerization processes. The pyrolysis products and their yields are highly dependent on the conditions and parameters of the pyrolysis technologies and biomass sources. These include the reactor’s temperature, gas flow rate, heating rate, residence time, catalysts, and reactor configurations [105, 106].

Depending on the operating conditions, the pyrolysis process can be categorized as either slow, fast, or flash pyrolysis [108]. In the slow pyrolysis process, lower temperature (550–950 K), slow heating rate, and long residence time (several hours to days) are applied to prepare BC as the primary product [109]. While in the fast pyrolysis method, moderate temperature (850–1250K), high heating rates (on the order of 100 οC/sec), and short residence time are used to prepare bio-oil with a maximum yield of ~75% [109]. The prepared crude pyrolytic bio-oil can be further upgraded and purified to advanced biofuels or biochemicals through fast pyrolysis. In contrast, flash pyrolysis is based on heat treatment at a higher temperature (1050–1300 K) for less than two seconds producing a higher yield of bio-oil than gas and BC [109]. However, bio-oil produced by flash pyrolysis is acidic, unstable, and highly viscous, and contains solids and dissolved water [110, 111]. Hence, reducing the oxygen content in the final product (bio-oil) is essential by using advanced methods, such as hydrogenation and catalytic cracking. To improve the yield and properties of biooil, BC, and gas-derived from biomass, many pyrolysis techniques, including co-pyrolysis [112], catalytic pyrolysis [113], microwave pyrolysis [114], and solar pyrolysis [115] have already been developed (Figure 1.5).

1.6 Biomass-derived Carbon for Electrochemical Supercapacitors

The main component of an ESC consists of two electrodes separated by a thin and porous insulator soaked in an electrolyte. Various materials are used to fabricate ESC electrodes, including metal oxides, carbon-based compounds, and conducting polymers [116]. The energy storage mechanism in ESCs depends on the types and properties of electrode materials, broadly classified as EDLC and pseudocapacitor (Figure 1.6) [117]. In particular, both non-activated carbon (NAC) and AC derived from biomass sources are attractive materials for fabricating high-performance EDLC-type ESCs due to their low cost, easy processing, availability, and improved physicochemical properties [118–120]. NAC and AC materials can be prepared from a wide variety of biomass sources such as coffee beans, rice husk, coffee endocarp, bamboo species, apricot shell, sugarcane bagasse, rubberwood sawdust, jute stick, wood, anthracite, bitumen charcoal, peat shells, date seeds, coconut, etc [23, 29, 120, 121]. NAC, which is generally obtained from biomass by simple hydrothermal/pyrolysis method, generally exhibits inferior physical and chemical properties and energy storage capacity in ESCs compared to the ACs [119]. For example, Saini et al. compared the energy storage capacity of AC and NAC derived from sugar [119]. Results demonstrated that the sugar-derived AC exhibited a 35% improved energy storage capacity compared to the NAC. This research further revealed a significantly high capacity of ACs compared to the reduced