Petroleum Refining Design and Applications Handbook

Volume 4

• Heat Transfer

• Pinch Analysis

• Process Safety Incidents

A. Kayode Coker

This edition first published 2023 by John Wiley & Sons, Inc., 111 River Street, Hoboken, NJ 07030, USA and Scrivener Publishing LLC, 100 Cummings Center, Suite 541J, Beverly, MA 01915, USA

© 2023 Scrivener Publishing LLC

For more information about Scrivener publications please visit www.scrivenerpublishing.com.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, except as permitted by law. Advice on how to obtain permission to reuse material from this title is available at http:// www.wiley.com/go/permissions.

Wiley Global Headquarters

111 River Street, Hoboken, NJ 07030, USA

For details of our global editorial offices, customer services, and more information about Wiley products visit us at www.wiley.com.

Limit of Liability/Disclaimer of Warranty

While the publisher and authors have used their best efforts in preparing this work, they make no representations or warranties with respect to the accuracy or completeness of the contents of this work and specifically disclaim all warranties, including without limitation any implied warranties of merchant-ability or fitness for a particular purpose. No warranty may be created or extended by sales representatives, written sales materials, or promotional statements for this work. The fact that an organization, website, or product is referred to in this work as a citation and/or potential source of further information does not mean that the publisher and authors endorse the information or services the organization, website, or product may provide or recommendations it may make. This work is sold with the understanding that the publisher is not engaged in rendering professional services. The advice and strategies contained herein may not be suitable for your situation. You should consult with a specialist where appropriate. Neither the publisher nor authors shall be liable for any loss of profit or any other commercial damages, including but not limited to special, incidental, consequential, or other damages. Further, readers should be aware that websites listed in this work may have changed or disappeared between when this work was written and when it is read.

Library of Congress Cataloging-in-Publication Data

ISBN 9781119827528

Cover image: Heat Transfer, provided by Kayode Coker

Cover design: Kris Hackerott

Set in size of 11pt and Minion Pro by Manila Typesetting Company, Makati, Philippines

Printed

Companion Web Page

This multi-volume set includes access to its companion web page, from which can be downloaded useful software, spreadsheets, and other value-added products related to the books. To access it, follow the instructions below:

1. Go to https://scrivenerpublishing.com/coker_volume_four/

2. Enter your email in the username field

3. Enter “Refining” in the password field

In Loving Memory of My Parents

Gabriel Shodipo Coker and

Modupe Ajibike Coker

For their fortitude and kindness in paving the path for being a worthwhile person. Wishing them the Almighty Father's mercy, grace and blessings, the most wonderful and beautiful journey in the Luminous Realm of joyful activities in the beyond.

Gratitude to the Elemental and Created beings in higher realms, faithfully fulfilling the Will of the Almighty father.

“God wills that His Laws working in Creation should be quite familiar to man, so that he can adjust himself accordingly, and with their help can complete and fulfill his course through the world more easily and without ignorantly going astray.”

Abd-ru-shin (In the Light of Truth)

The Laws of Creation

The Law of Motion

The Law of the Attraction of Homogeneous Species

The Law of Gravitation

The Law of Reciprocal Action

“What is Truth?”

“Only the truth is simple.”

“Woe to the people to whom the truth is no longer sacred!”

Pilate (John 18, 38)

Sebastian Haffner

Friedrich Christoph Schlosser

“Truth does not conform to us, dear son but we have to conform with it.”

Matthias Claudius

“Nothing will give safety except truth. Nothing will give peace except the serious search for truth.”

Blaise Pascal

“Truth is the summit of being; justice is the application of it to affairs.”

Ralph Waldo Emerson

“The ideals which have lighted my way, and time after time have given me new courage to face life cheerfully, have been Kindness, Beauty and Truth.”

Albert Einstein

“It irritates people that the truth is so simple.”

Johann Wolfgang von Goethe

“Aglow with the Light of the Divine, I surrender my whole attention to the Presence of Truth that guides my path.”

Michael Bernard Beckwith

“Truth means the congruence of a concept with its reality.”

“Truth is the revealing gloss of reality.”

G.W. Friedrich Hegel

Simone Well

“We are the Multi-dimensional Universe becoming aware of Itself. Live in this One Truth – That God is Real As your very Life!”

Michael Bernard Beckwith

“Truth is a torch, but a tremendous one. That is why we hurry past it, shielding our eyes, even terrified of getting burnt.”

Johann Wolfgang von Goethe

“Truth is the spirit’s sun.”

Marquis de Vauvenargues

You will recognise the Truth, and the truth will set you free John, 8:32

“Truth is the Eternal – Unchangeable! Which never changes in its form, but is as it has been eternally and will ever remain, as it is now. Which can therefore never be subjected to any development either, because it has been perfect from the very beginning. Truth is real, it is ‘being’! Only being is true life. The entire Universe is “supported” by this Truth!”

Abd-ru-shin

Truth

To honour God in all things and to perform everything solely to the glory of God

Abd-ru-shin

(In the Light of Truth)

Keep the heart of your thoughts pure, by so doing you will bring peace and be happy.

Love thy neighbour, which means honour him as such!

Therein lies the adamantine command: You must never consciously harm him, either in his body or in his soul, either in his earthly possessions or in his reputation!

He who does not keep this commandment and acts otherwise, serves not God but the darkness, to which he gives himself as a tool!

Honour be to God Who only sows Love! Love also in the The Law of the destruction of the darkness!

Abd-ru-shin

(In the Light of Truth)

Love & Gratitude

Crystal Images © Office Masaru Emoto, LLC

Awake!

Petroleum refining is a complex industry that worldwide produces more than $10 billion worth of refined products. Improvements in the design and operation of these facilities can deliver large economic value for refiners. Furthermore, economic, regulatory and environmental concerns impose significant pressure on refiners to provide safe working conditions and at the same time optimize the refining process. Refiners have considered alternative processing units and feedstocks by investing in new technologies.

The United States, Europe and countries elsewhere in the world are embarking on full electrification of automobiles within the next couple of decades. Furthermore, the current pandemic of the coronavirus with lock downs in many countries has restricted the movement of people, less use of aviation fuel and motor gasoline. This has resulted in the barrel of crude being sold at $42.0 per barrel presenting problems to oil producers and refiners. The venture of electrification still poses inherent problems of resolving rechargeable batteries and fuel cells and providing charging stations along various highways and routes. Oil and natural-gas will for the foreseeable future form an important part of everyday life. Their availability has changed the whole economy of the world by providing basic needs for mankind in the form of fuel, petrochemicals and feedstocks for fertilizer plants and energy for the power sector.

Recently, the prices of Brent crude and WTI have now risen to $113.1 and $109.8 respectively, caused by various factors such as the war between Russia and Ukraine. Refining capacity is the maximum volume of crude oil that refineries can produce in a day. Setting the US as a benchmark for the world, it had 135 operable petroleum refineries and a total of refining capacity of 19 millions barrels per day in 2020 to 128 operable refineries with a total crude distillation capacity of 17.9 million barrels per day, a loss of 1.1 million barrels. In the same period of time the world lost a total of 3.3 millions barrels of daily refining capacity, and about 1/3 of these losses occurred in the US.

With this realignment, and planned refining openings and capacity expansions in Asia, trade press reports suggest China will overtake the US as the country with the most refining capacity by the end of 2022.

World Economic Situation

Russia’s war in Ukraine is further expected to advance economic consensus’s expectations for higher price inflation and slower global GDP growth.

On Oil

As solid global oil demands is expected to reach record highs in 2023 per International U.S. Energy Information Administration (EIA), supply challenges have persisted for oil and natural gas production. The global demand of 98.8 million barrels per day (mb/d) in Q2, 2022 is projected to grow to a record high 102.7 mb/d in December 2023 per (EIA).

Uncertainties: This results in effective Russian production losses; potential OPEC and US growth.

US petroleum net exports reached a record high as 94.3%, 7.3% above its 5-year average. Presently US refineries are operating at or near maximum utilization and about 1/3 of recent refining capacity loss is due to conversions to biofuels plants (e.g., renewables fuels and oxygenaged plants (Volume 5 of these volume series)).

US refiners is a long-cycle business and where refiners could bring more refining capacity on line despite these challenges, the result could be higher demand and higher costs for crude oil.

Presently, the world economy runs on oil and natural gas, and the processing of these feedstocks for producing fuels, and value-added products has become an essential activity in modern society. The availability of liquefied natural gas (LNG) has enhanced the environment, and recent development in the technology of natural gas to liquids (GTL) has further improved the availability of fuel to transportation and other sectors.

The complex processing of petroleum refining has created a need for environmental, health, and safety management procedures and safe work practices. These procedures are established to ensure compliance with applicable regulations and standards such as hazard communications (PHA, HAZOPS, MoC, and so on), emissions, Waste Management (pollution that includes volatile organic compounds (VOC), carbon monoxide, sulfur oxides (SOx), nitrogen oxides (NOx), particulates, ammonia (NH3), hydrogen sulfide (H2S), and toxic organic compounds) and waste minimization. These pollutants are often discharged as air emissions, wastewater or solid wastes. Furthermore, concerns over issues such as the depletion of the ozone layer that results in global warming is increasingly having a significant impact on earth’s nature and mankind, and carbon dioxide (CO2) is known to be the major culprit of global warming. Other emissions such as H2S, NOx, and SO x from petroleum refining have adversely impacted the environment, and agencies such as Occupational Safety and Health Administration (OSHA), and Environmental Protection Agency (EPA), Health and Safety Executive (U.K. HSE) have imposed limits on the emissions of these compounds upon refiners.

Flaring has become more complicated and concerns about its efficiency have been increasing and discussed by experts. The OSHA, EPA and HSE have imposed tighter regulations on both safety and emission control, which have resulted in higher levels of involvement in safety, pollution, emissions and so on.

Petroleum refining is one of the important sectors of the world economy, and it’s playing a crucial and pivotal role in industrialization, urbanization, and meeting the basic needs of mankind by supplying energy for industrial and domestic transportation, feedstock for petrochemical products as plastics, polymers, agrochemicals, paints, and so on. Globally, it processes more materials than any other industry, and with a projected increase in population to around 8.1 billion by 2025, increasing demand for fuels, electricity and various consumer products made from the petrochemical route is expected via the petroleum and refining process.

Petroleum Refining Design and Applications Handbook, Volume Four, is a continuation of the previous volumes; comprising of two chapters including extensive case studies of process safety incidents in the refineries, a revised glossary of petroleum and technical terminology, process data sheets, and Excel spreadsheet programs, computer developed programs, UniSim – Design

simulation software excises, cases studies and a Conversion Table.

Chapter 21, “Heat Transfer” provides types of heat exchanger equipment terminology, fouling of exchangers, and crude oil fouling models, fouling mitigation and monitoring, prevention and control of liquid/ gas side fouling; design and rating of shell and tube exchangers; design of double pipe including finned tube exchangers, plate frame heat exchangers, design techniques for difficult condensing situations and for the application of thermosiphon reboilers, design of air-coolers, heat tracer requirements for pipeline and heat loss from insulated pipelines, troubleshooting of heat exchangers and case studies of heat exchanger failures.

The chapter provides computer/software programs for the design/rating of these exchanger types.

Chapter 22, “Process Integration (PI)” reviews PI in heat exchanger networks involving a systematic and oriented approach to heating and cooling and power generation to process design, and optimization that exploits the interaction between different units, exchangers and utilities in order to employ resources effectively and minimize costs. The chapter uses the Honeywell UniSim Design software with an Appendix F that reviews the steps to determine pinch temperature, cold and hot pinch temperatures, hot and cold composite curves, grand composite curve, hot and cold utility requirements. The program further produces graphical outputs of pinch temperatures, hot and cold utility requirements at varying ΔTmin.

The Excel spreadsheet program from Ian C. Kemp's text has been used to determine the pinch temperature, cold and hot pinch temperatures, hot and cold composite curves, grand composite curve, hot and cold utility requirements. The program further produces graphical outputs of pinch temperatures, hot and cold utility requirements at varying ΔTmin.

Appendix H reviews the failure scenarios of heat transfer equipment. Potential safety systems are categorized as inherently safer/passive, active and procedural in decreasing order of robustness and reliability. The appendix provides description of these systems thus ensuring the design engineer to take a very broad and holistic approach to complete design, thereby accounting for the many different, and often competing, objectives which the design must accomplish. Safety, environmental impact, loss prevention, health effects, economic and business factors, product quality, technical feasibility and many other factors must be considered.

Finally, there are case studies of process safety incidents in this volume, which the author hopes will spur readers to process safety management, investigating the root causes and near misses of incidents in the refinery plants, finding ways in mitigating these incidents in the future thereby saving lives of personnel in the refinery facilities and chemical process industries worldwide.

The US Chemical Safety and Hazard Investigation Board (www.csb.gov) has provided case studies of process safety incidents with animations, and recently the U.K. Institution of Chemical Engineers (IChemE) (www.icheme.org) from IChemE Safety and Loss Prevention Special Interest Group (SIG) has published

case studies of lessons learned database (LLD). It provides major process safety incident vs. root cause map matrix in a quick reference guide (https://lnkd.in/ dm3t5VPe) in process safety incidents. Readers are advised to view these websites and will find them educational and informative.

Finally, the volume provides a glossary of petroleum and technical terminology, process datasheets, and a conversion table, developed Microsoft Excel spreadsheet programs and developed programs including UniSim design software programs that can be readily accessed from the publisher’s website using a password.

A. Kayode Coker (www.akctechnology.com)

21 Heat Transfer

21.1 Introduction

The escalating cost of energy in recent years has resulted in increased attention being given to conservation and efficient energy management. Other types of technology, for example, energy management and pinch technology (Chapter 22) have been employed in the energy integration of process plants and of heat exchangers, in particular. This has resulted in an improved performance of the plants at reduced operation costs. Heat transfer is perhaps the most important, as well as the most applied process, in refining, gas processing, chemical and petrochemical plants. The economics of plant operation is controlled by the effectiveness of the use and recovery of heat or cold (refrigeration). The service functions of steam, power, refrigeration supply, and the like are dictated by how these services or utilities are used within the process to produce an efficient conversion and recovery of heat.

Shell and tube heat exchanger types are widely employed and generally, they are custom designed for any capacity and operating conditions, including from high vacuums to ultra-high pressures over 15,000 psig (100 MPa), from cryogenics to high temperatures ~ 2000°F (1100°C), and any temperature and pressure differences between the fluids, limited by the materials of construction. They can be designed for special operating conditions: heavy fouling, highly viscous fluids, erosion, corrosion, toxicity, multicomponent mixtures, vibration, etc. They are the most versatile exchanger types made from a variety of metals (e.g., Admiralty, copper, alloys, monel, nickel, aluminum, carbon/ stainless steel, etc.) and nonmetal materials (e.g., graphite, glass and Teflon) and in various sizes from 1 ft2 (0.1 m2) to 106 ft2 (105 m2). They are extensively employed as process heat exchangers in petroleum refining, petrochemicals and chemical industries; as boiler feed water heaters, phase change heat exchangers (e.g., reboilers and condensers), evaporators, steam generators, and oil coolers in power plants, in some air conditioning and refrigeration applications; in waste heat recovery applications with heat recovery from liquids and condensing fluids and in environmental control. The tube side is for corrosive, heavy fouling, scaling, hazardous, high temperature and pressure, and more expensive fluids, while the shell side is for cleaner, more viscous, lower flow rate, evaporating and condensing fluids. When a gas or vapor is used as an exchanger fluid, it is typically introduced through the shell side and viscous liquids, for which the pressure drop for flow through the tubes is high, are introduced on the shell side.

Generally, shell and tube exchanger types are non-compact exchangers, and the heat-transfer area per unit volume ranges from 15 to 30 ft2/ft3 (50–100 m2/m3). Therefore, they require a considerable amount of space, support structure, capital and installation costs. As a result, they are often replaced with compact heat exchangers (e.g., plate exchangers, spiral plate heat exchangers) in those applications where the operating conditions permit it. For the equivalent cost of the shell and tube exchangers, compact heat exchangers provide high effectiveness and are more efficient in heat (energy) transfer.

Although many excellent references [1−14] are available, and the technical literature contains important details of good heat transfer design principles and good approaches to equipment design, an unknown factor still enters into every design. This factor is the scale or fouling from the fluids being processed and is wholly dependent on the fluids, their temperature and velocity, and to a certain extent, the nature of the heat-transfer tube surface and its chemical composition. Due to the unknown nature of the assumptions, these fouling factors can markedly affect the design of heat transfer equipment. We shall review this aspect with others such as the pressure drop later in the chapter as these could have deleterious effects on the performance of heat exchangers resulting in high operating costs of millions of US dollars per annum. Conventional practice is presented here; however, Kern and Seaton [15] have proposed thermal concepts that may offer new approaches.

The most popular and reliable software packages for the design or rating of shell and tube heat exchangers are:

• BJAC: USA based company.

• HEI: Heat Exchange Institute, USA

• HTRI: Heat Transfer Research Institute (www.HTRI.net) USA

• HFTS: Heat Transfer Fluid Flow Services (HTFS programs are part of Aspen Technology’s Aspen Engineering Suite and Honeywell’s UniSim Design Suite).

Generally, the design methods and equations used by these companies and institutes are proprietary and therefore, are not provided in open literature. Tinker [16, 17] published the first detailed stream analysis method for predicting shell and tube heat transfer coefficients and pressure drop, and his model has been used as the basis for the proprietary computer methods developed by these institutes and companies. Tinker’s method is difficult and tedious to apply in manual calculations. However, it has been simplified by Devore [18, 19], using standard tolerances for commercial exchangers and only a limited number of baffle cuts. Devore presented nomographs that facilitate the application to the method in manual calculations. Mueller [20] has further simplified Devore’s method and provides an illustrative example. Bell [21, 22] provided a semi-analytical method based on research programs carried out on shell and tube exchangers at the University of Delaware, where his results accounted for the major bypass and leakage streams.

This text provides the designer with a basis for manually checking the expected equations, coefficients, etc., enabling him/her to accept or reject the computed results. The text provides a basis for completely designing the process heat transfer equipment, and (except for specialized items such as fired heaters, steam boiler/generators, cryogenic equipment, and some other process requirements) and sizing (for mechanical dimensions/details, but not for pressure strength) the mechanical hardware that will accomplish this function. Additionally, the text presents research studies on fouling in shell and tube heat exchangers, and, in particular, to pre-heat trains in the refining of crude oil.

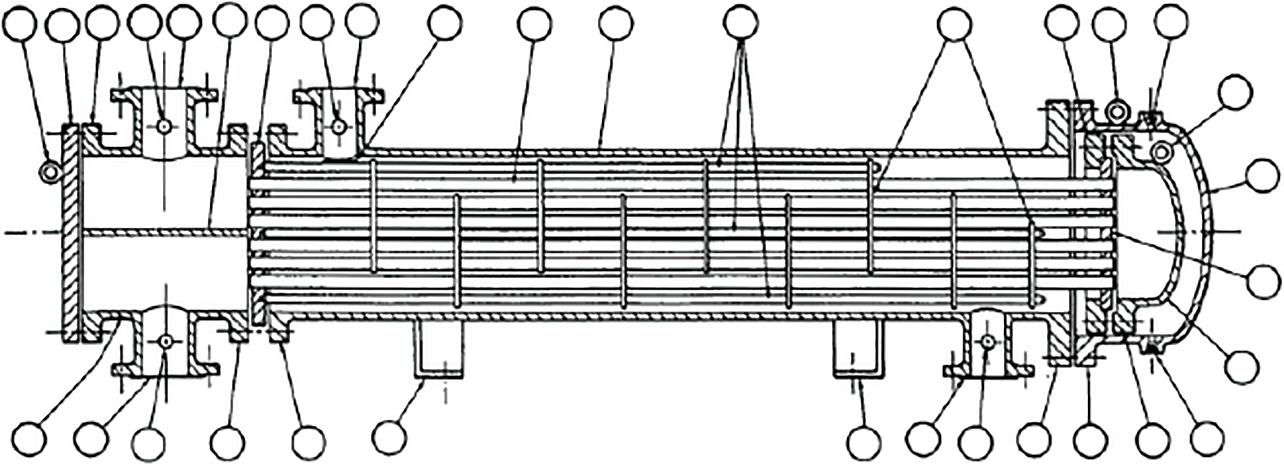

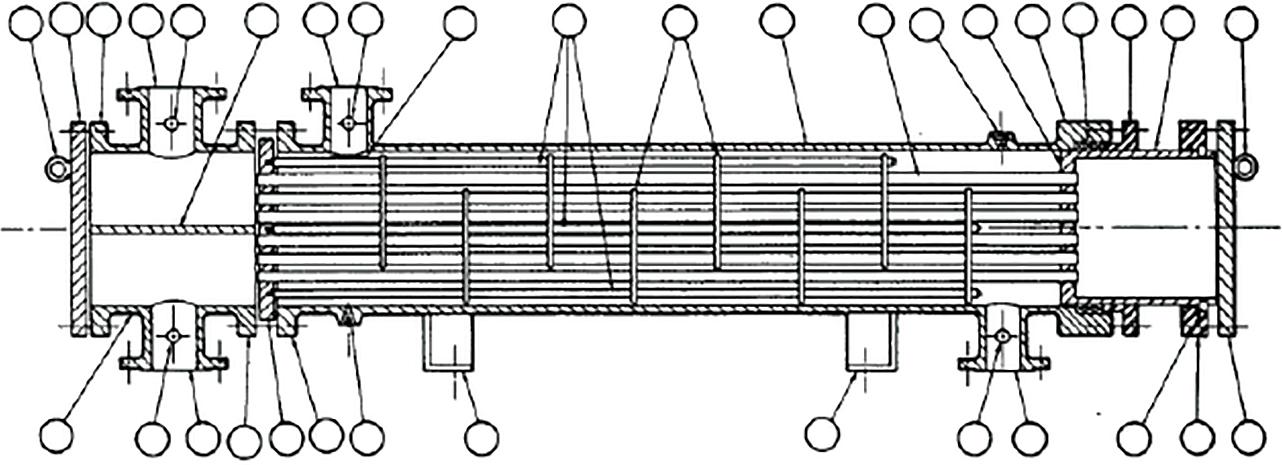

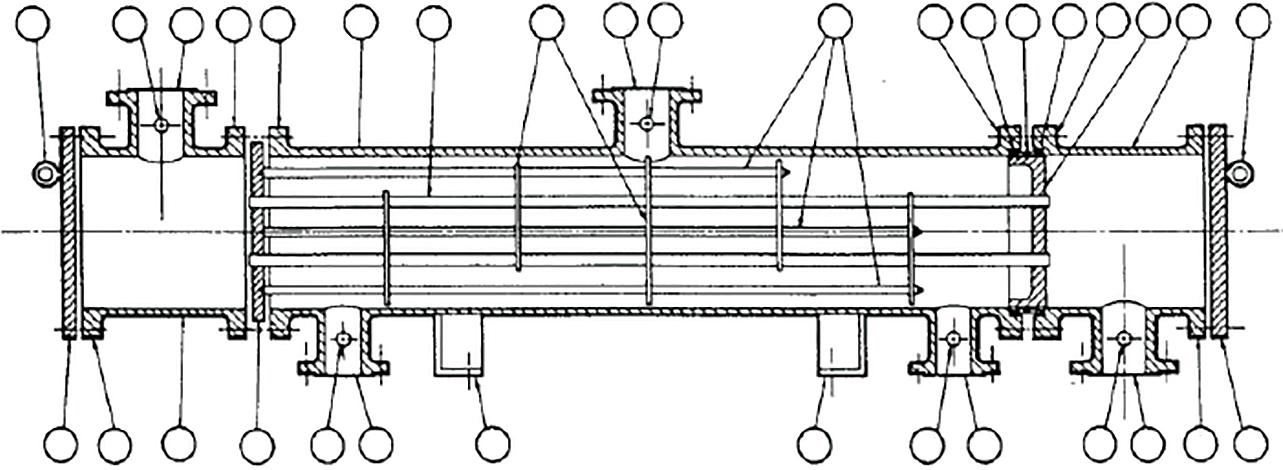

21.1.1 Types of Heat Transfer Equipment Terminology

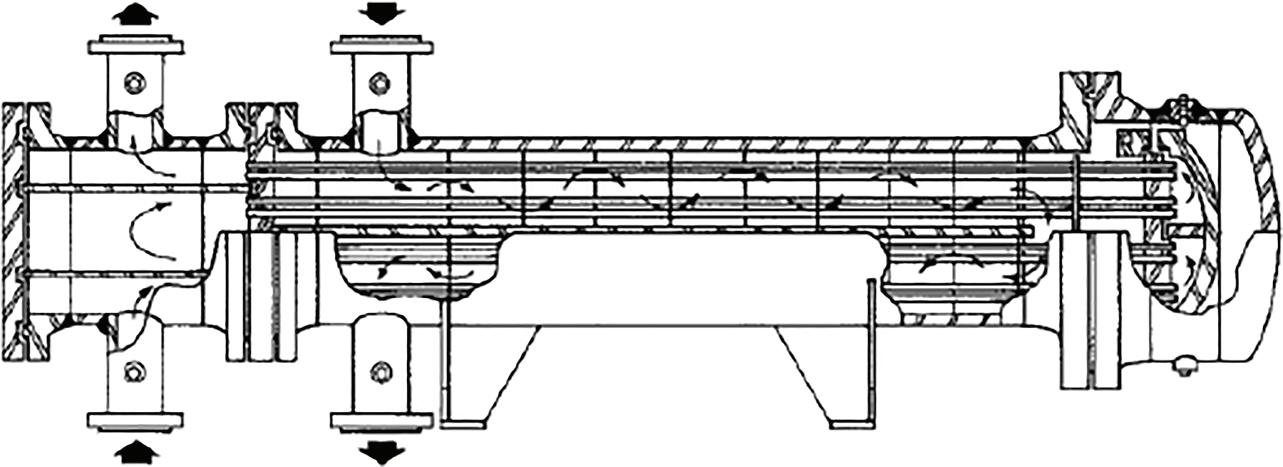

The chemical process industries (CPIs) require heat exchanger types to transfer heat from a hot stream to a cold stream. This heat transfer equipment must meet various codes/standards to deal with the thermal, mechanical, operational, installation and maintenance demands on the process. The optimal heat exchanger design should minimize operating costs and maximize product output. Shell and tube heat exchangers (Figures 21.1B–D) consist of a bundle of tube inside a cylindrical shell. One fluid (the tube side fluid) flows inside the tubes whilst the other fluid (the shell side fluid) flows through the shell and around the tubes. Heat is transferred across the tube wall separating the hot and cold streams. The shell type has a significant effect on the flow configuration and thermal performance of the heat exchangers. Shell and tube heat exchangers use baffles to transport heat to or from tube side process fluids by directing the shell side fluid flow. The increased structural support that baffles provide is essential to the tube stability, as they prevent the tube from sagging due to structural weight and also minimize vibration due to cyclic flow forces. Baffles improve heat transfer at the expense of increased pressure drop. Tubesheets seal the ends of the tubes, ensuring separation between the two streams.

The process engineer needs to understand the terminology of the heat-transfer equipment manufacturers in order to properly design, specify, evaluate bids, and check drawings for this equipment.

FRONT END STATIONARY HEAD TYPES

CHANNEL AND REMOVABLE COVER

BONNET (INTEGRAL COVER)

CHANNEL INTEGRAL WITH TUBESHEET AND REMOVABLE COVER

PASS SHELL WITH

RAFFLE

REAR END HEAD TYPES

CHANNEL INTEGRAL WITH TUBESHEET AND REMOVABLE COVER

FLOW

PASS SHELL FIXED TUBESHEET LIKE “A” STATIONARY HEAD FIXED TUBESHEET LIKE “B” STATIONARY HEAD FIXED TUBESHEET LIKE “N” STATIONARY HEAD OUTSIDE PACKED FLOATING HEAD FLOATING HEAD WITH BACKING DEVICE PULL THROUGH FLOATING HEAD U-TUBE BUNDLE EXTERNALLY SEALED FLOATING TUBESHEET

Figure 21.1A Nomenclature for Heat Exchanger Components. Figures 21.1A–G used by permission: Standards of Tubular Exchanger Manufacturers Association, 7th Ed., © 1988. Tubular Exchanger Manufacturers Association, Inc.

The shell and tube exchanger consists of four major parts:

• Front header—this is where the fluid enters the tube-side of the exchanger. It is sometimes referred to as the stationary header.

• Rear header—this is where the tube-side fluid leaves the exchanger or where it is returned to the front header in exchangers with multiple tube-side passes.

Figure 21.1B Floating head (© 1988 by Tubular Exchanger Manufacturers Association, Inc.).

Figure 21.1C Fixed tubesheet (© 1988 by Tubular Exchanger Manufacturers Association, Inc.).

Figure 21.1D Floating head—outside packed (© 1988 by Tubular Exchanger Manufacturers Association, Inc.).

Figure 21.1E Removable U-bundle (© 1988 by Tubular Exchanger Manufacturers Association, Inc.).

Figure 21.1F Kettle reboiler (© 1988 by Tubular Exchanger Manufacturers Association, Inc.).

Figure 21.1G Divided flow-packed tubesheet (© 1988 by Tubular Exchanger Manufacturers Association, Inc.).

Partnership).

Figure 21.1H Fixed tubesheet, single-tube pass vertical heater or reboiler (used by permission: Engineers & Fabricators, Inc. Houston).

SECTION “A” ”A”

SEAL STRIP

BAFFLE CUT

CHANNEL CHANNEL

Figure 21.1I Floating head, removable type (used by permission: Yuba Heat Transfer Division of Connell Limited

21.1J Split-ring removable floating head, four-pass tube-side and two-pass shell side (used by permission: Engineers & Fabricators, Inc., Houston).

21.1K U-tube exchanger (used by permission: Yuba Heat Transfer Division of Connell Limited Partnership).

an inlet nozzle on the shell-side in preparation for pressure testing.

Figure

CHANNEL

CHANNEL

Figure

Figure 21.1L A shell and tube heat exchanger showing

Figure 21.1M Reactor effluent vertical shell and tube heat exchangers in series of a hydrocracking unit.

Figure 21.1N A shell and tube heat exchanger showing the nozzles on the shell and tube sides and nozzles at the rear end.

• Tube bundle—this comprises of the tubes, tubesheets, baffles, and tie rods, etc., which hold the bundle together.

• Shell—this contains the tube bundle.

The standards of the Tubular Exchanger Manufacturers Association (TEMA) [23, 24] is the only assembly of unfired mechanical standards, including selected design details and Recommended Good Practice and is used by all reputable exchanger manufacturers in the U.S. and many manufacturers in other countries who supply U.S. plant equipment. These standards are developed, assembled, and updated by a technical committee of association members. The standards are updated and reissued every 10 years. They do not designate or recommend thermal design methods or practices for specific process applications, but they do outline basic heat transfer fundamentals, and list suggested fouling factors for a wide variety of fluid or process services.

Figure 21.1O Heat exchanger tube bundles with baffles.

Figure 21.1P A tube bundle with segmental baffles.