AdvancedConcrete Technology

HongyanMa

ZongjinLi

XiangmingZhou

DongshuaiHou

Thisbookisprintedonacid-freepaper. ♾

Copyright©2023byJohnWiley&Sons,Inc.Allrightsreserved

PublishedbyJohnWiley&Sons,Inc.,Hoboken,NewJersey

PublishedsimultaneouslyinCanada

Nopartofthispublicationmaybereproduced,storedinaretrievalsystem,ortransmittedinanyformorbyanymeans, electronic,mechanical,photocopying,recording,scanning,orotherwise,exceptaspermittedunderSection107or108 ofthe1976UnitedStatesCopyrightAct,withouteitherthepriorwrittenpermissionofthePublisher,orauthorization throughpaymentoftheappropriateper-copyfeetotheCopyrightClearanceCenter,222RosewoodDrive,Danvers,MA 01923,(978)750-8400,fax(978)646-8600,oronthewebat www.copyright.com.RequeststothePublisherfor permissionshouldbeaddressedtothePermissionsDepartment,JohnWiley&Sons,Inc.,111RiverStreet,Hoboken, NJ07030,(201)748-6011,fax(201)748-6008,oronlineat www.wiley.com/go/permissions.

LimitofLiability/DisclaimerofWarranty:Whilethepublisherandauthorhaveusedtheirbesteffortsinpreparingthis book,theymakenorepresentationsorwarrantieswiththerespecttotheaccuracyorcompletenessofthecontentsofthis bookandspecificallydisclaimanyimpliedwarrantiesofmerchantabilityorfitnessforaparticularpurpose.Nowarranty maybecreatedorextendedbysalesrepresentativesorwrittensalesmaterials.Theadviceandstrategiescontained hereinmaynotbesuitableforyoursituation.Youshouldconsultwithaprofessionalwhereappropriate.Neitherthe publishernortheauthorshallbeliablefordamagesarisingherefrom.

Forgeneralinformationaboutourotherproductsandservices,pleasecontactourCustomerCareDepartmentwithinthe UnitedStatesat(800)762-2974,outsidetheUnitedStatesat(317)572-3993orfax(317)572-4002.

Wileypublishesinavarietyofprintandelectronicformatsandbyprint-on-demand.Somematerialincludedwith standardprintversionsofthisbookmaynotbeincludedine-booksorinprint-on-demand.Ifthisbookreferstomedia suchasaCDorDVDthatisnotincludedintheversionyoupurchased,youmaydownloadthismaterialat http://booksupport.wiley.com.FormoreinformationaboutWileyproducts,visit www.wiley.com

LibraryofCongressCataloging-in-PublicationDataAppliedfor

ISBN:9781119806257(Hardcover)

ISBN:9781119806202(ePDF)

ISBN:9781119806196(ePUB)

CoverDesign:Wiley

CoverImage:©graemenicholson/GettyImage

Tostudents,teachers,researchers,andengineersinthefieldofconcrete,whoarethedriving forcesforthedevelopmentofthescienceandtechnologyofconcrete,includingthepersonnel workingontheChina973project,BasicStudyonEnvironmentallyFriendlyContemporary Concrete(2009CB623200)

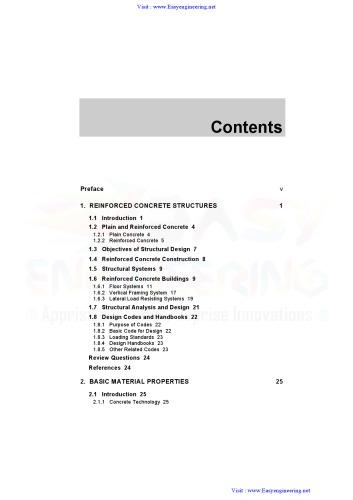

CONTENTS

Preface xi

1IntroductiontoConcrete1

1.1ConcreteDefinitionandHistoricalDevelopment1

1.2ConcreteasaStructuralMaterial7

1.3CharacteristicsofConcrete11

1.4TypesofConcrete14

1.5FactorsInfluencingConcreteProperties18

1.6ApproachestoStudyConcrete21 DiscussionTopics23 References23

2MaterialsforMakingConcrete25

2.1AggregatesforConcrete25

2.2CementitiousBinders38

2.3Admixtures86

2.4Water98 DiscussionTopics101 Problems102 References103

3FreshConcrete109

3.1Introduction109

3.2WorkabilityandRheology109

3.3MixDesign124

3.4ManufactureofConcrete149

3.5DeliveryofConcrete150

3.6ConcretePlacing152

3.7CuringofConcrete160

3.8Early-AgePropertiesofConcrete164

DiscussionTopics166

Problems167

References168

4MaterialsStructureofConcrete171

4.1Introduction171

4.2ClassificationofMaterialsStructuralLevels172

4.3StructureofConcreteatNanometerScale:TheC–S–HStructure176

4.4StructureofConcreteattheMicro-Scale191

4.5TheTransitionZoneinConcrete194

4.6Nano-andMicro-StructuralEngineering198

DiscussionTopics208

References209

5PropertiesofHardenedConcrete213

5.1StrengthsofHardenedConcrete213

5.2Stress–StrainRelationshipandConstitutiveEquations238

5.3DimensionalStability—ShrinkageandCreep246

5.4Durability265

DiscussionTopics297

Problems298 References299

6AdvancedCementitiousComposites305

6.1Fiber-ReinforcedCementitiousComposites305

6.2High-StrengthCementitiousComposites324

6.3Ultra-High-StrengthConcrete331

6.4PolymersinConcrete336

6.5Shrinkage-CompensatingConcrete347

6.6Self-CompactingConcrete350

6.7EngineeredCementitiousComposite364

6.8ConfinedConcrete366

6.9High-VolumeFlyAshConcrete369

6.10StructuralLightweightandHeavyweightConcrete371

6.11SeaSandandSeaWaterConcrete372

6.12The3DPrintedConcrete374

DiscussionTopics380 Problems381 References382

7ConcreteFractureMechanics393

7.1Introduction393

7.2LinearElasticFractureMechanics397

7.3TheCrackTipPlasticZone404

7.4CrackTip-OpeningDisplacement407

7.5FractureProcessinConcrete408

7.6NonlinearFractureMechanicsforConcrete413

7.7Two-ParameterFractureModel415

7.8SizeEffectModel422

7.9TheFictitiousModelbyHillerborg431

7.10 R-CurveMethodforQuasi-BrittleMaterials436

7.11Double-K Criterion441

7.12TheApplicationofFractureMechanicsintheDesignCodeofConcrete Structures448

DiscussionTopics453

Problems453

References457

8NondestructiveTestinginConcreteEngineering461

8.1Introduction461

8.2ReviewofWaveTheoryfora1DCase474

8.3ReflectedandTransmittedWaves483

8.4AttenuationandScattering485

8.5MainCommonlyUsedNDT-CETechniques486

8.6NoncontactingResistivityMeasurementMethod536

8.7AnInnovativeMagneticCorrosionDetectionTransducers546

DiscussionTopics557

Problems557

References560

9TheFutureandDevelopmentTrendsofConcrete565

9.1SustainabilityofConcrete565

9.2DeepUnderstandingoftheNatureofHydration577

9.3IntegratedMaterialsandStructuralDesign580

9.4High-Tensile-StrengthandHigh-ToughnessCement-basedMaterials584

9.5ApplicationofNanotechnologyinConcrete586

9.6DataScienceandArtificialIntelligenceinConcreteTechnology588 References589

INTRODUCTIONTOCONCRETE

1.1CONCRETEDEFINITIONANDHISTORICALDEVELOPMENT

Concreteisaman-madebuildingmaterialthatlookslikestone.Theword“concrete”isderived fromtheLatin concretus,meaning“togrowtogether.”Concreteisacompositematerialcomposed ofcoarsegranularmaterial(theaggregateorfiller)embeddedinahardmatrix(cementorbinder) thatfillsthespaceamongtheaggregateparticlesandbindsthemtogether.Alternatively,wecan saythatconcreteisacompositematerialthatconsistsessentiallyofabindingmediuminwhich areembeddedparticlesorfragmentsofaggregates.Thesimplestdefinitionofconcretecanbe writtenas

concrete = filler + binder(1-1)

Dependingonthetypesofbinderused,concretecanbenamedindifferentways.Forinstance, ifconcreteismadewithnonhydrauliccement,itiscallednonhydrauliccementconcrete;ifconcrete ismadeofhydrauliccement,itiscalledhydrauliccementconcrete;ifconcreteismadeofasphalt, itiscalledasphaltconcrete;ifconcreteismadeofpolymer,itiscalledpolymerconcrete.Both nonhydraulicandhydrauliccementneedwatertomixinandreact.Theydifferhereintheability togainstrengthinwater.Nonhydrauliccementcannotgainstrengthinwater,whilehydraulic cementcan.

Nonhydrauliccementconcretesaretheoldestconcreteusedinhumanhistory.Asearlyas around6500bc,nonhydrauliccementconcreteswereusedbytheSyriansandspreadthrough Egypt,theMiddleEast,Crete,Cyprus,andancientGreece.However,itwastheRomanswho refinedthemixture’suse.Thenonhydrauliccementsusedatthattimeweregypsumandlime.The Romansusedaprimalmixfortheirconcrete.Itconsistedofsmallpiecesofgravelandcoarse sandmixedwithhotlimeandwater,andsometimesevenanimalblood.TheRomanswereknown tohavemadewideusageofconcreteforbuildingroads.Itisinterestingtolearnthattheybuilt some5300milesofroadsusingconcrete.Concreteisaverystrongbuildingmaterial.Historical evidencealsopointsoutthattheRomansusedpozzolana,animalfat,milk,andbloodasadmixtures formakingconcrete.Totrimdownshrinkage,theywereknowntohaveusedhorsehair.Historical evidencealsoshowsthattheAssyriansandBabyloniansusedclayasthebondingmaterial.Lime wasobtainedbycalcininglimestonewithareactionof

andisthenfurtherreactedwithCO2 toformlimestoneagain:

TheEgyptiansusedgypsummortarinconstruction,andthehalf-watergypsumwasobtainedby calciningtwo-watergypsumwithareactionof:

Whenmixedwithwater,half-watergypsumcouldturnintotwo-watergypsumandgainstrength:

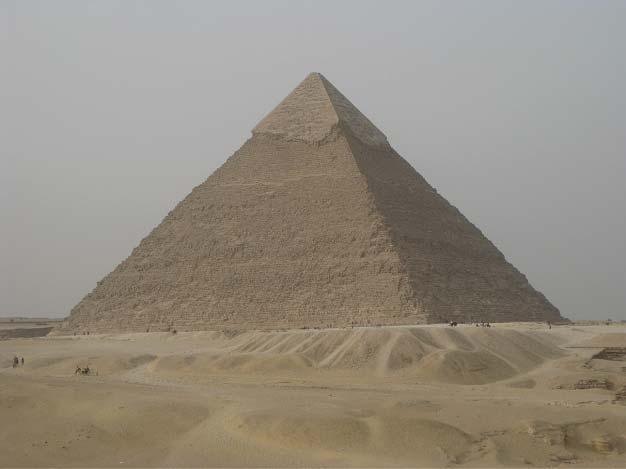

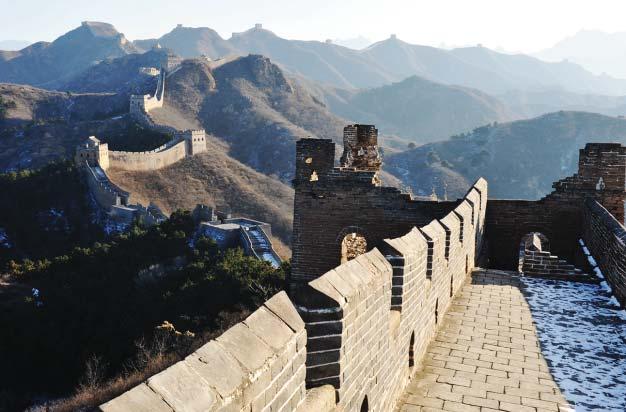

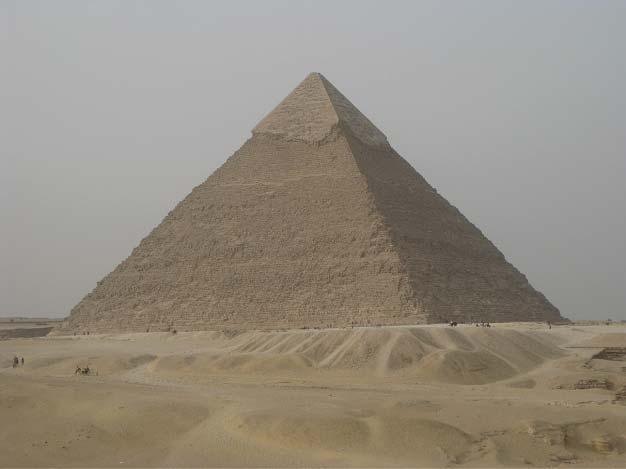

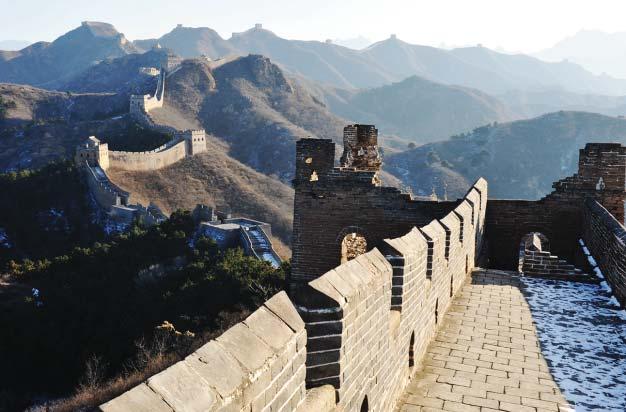

TheEgyptiansusedgypsuminsteadoflimebecauseitcouldbecalcinedatmuchlower temperatures.Asearlyasabout3000bc,theEgyptiansusedgypsummortarintheconstructionof thePyramidofCheops.However,thispyramidwaslootedlongbeforearcheologistsknewabout thebuildingmaterialsused.Figure1-1showsapyramidinGiza.TheChinesealsousedlimemortar tobuildtheGreatWallintheQindynasty(220bc)(seeFigure1-2).

AhydrauliclimewasdevelopedbytheGreeksandRomansusinglimestonecontaining argillaceous(clayey)impurities.TheGreeksevenusedvolcanicashfromtheislandofSantorini, whiletheRomansusedvolcanicashfromtheBayofNaplestomixwithlimetoproducehydraulic lime.Itwasfoundthatmortarmadeofsuchhydrauliclimecouldresistwater.Thus,hydrauliclime mortarswereusedextensivelyforhydraulicstructuresfromthesecondhalfofthefirstcenturybc tothesecondcenturyad.However,thequalityofcementingmaterialsdeclinedthroughoutthe MiddleAges.Theartofburninglimewasalmostlostandsiliceousimpuritieswerenotadded. High-qualitymortarsdisappearedforalongperiod.In1756,JohnSmeatonwascommissioned torebuildtheEddystoneLighthouseoffthecoastofCornwall,England.Realizingthefunction ofsiliceousimpuritiesinresistingwater,Smeatonconductedextensiveexperimentswithdifferent limesandpozzolans,andfoundthatlimestonewithahighproportionofclayeymaterialsproduced thebesthydrauliclimeforthemortartobeusedinwater.Eventually,Smeatonusedamortar

Figure1-2 TheGreatWallbuiltintheQindynasty(PhotoprovidedbyTongboSui) preparedfromahydrauliclimemixedwithpozzolanimportedfromItaly.Hemadeconcreteby mixingcoarseaggregate(pebbles)andpowderedbrickandmixeditwithcement,verycloseto theproportionsofmodernconcrete.TherebuiltEddystoneLighthouselastedfor126yearsuntil itwasreplacedwithamodernstructure.

AfterSmeaton’swork,hydrauliccementdevelopedveryfast.JamesParkerofEnglandfiled apatentin1796foranaturalhydrauliccementmadebycalciningnodulesofimpurelimestone containingclay.VicatofFranceproducedartificialhydrauliclimebycalciningsyntheticmixtures oflimestoneandclay.PortlandcementwaspatentedbyJosephAspdinofEnglandin1824.The namePortlandwascoinedbyAspdinbecausethecolorofthecementafterhydrationwassimilarto thatoflimestonequarriedinPortland,atowninsouthernEngland.Portlandcementwasprepared bycalciningfinelygroundlimestone,mixingitwithfinelydividedclay,andcalciningthemixture againinakilnuntiltheCO2 wasdrivenoff.Thismixturewasthenfinelygroundandusedas cement.However,thetemperatureclaimedinAspdin’sinventionwasnothighenoughtoproduce truePortlandcement.ItwasIsaacJohnsonwhofirstburnedtherawmaterialstotheclinkeringtemperaturein1845toproducemodernPortlandcement.Afterthat,theapplicationofPortlandcement spreadquicklythroughoutEuropeandNorthAmerica.ThemainapplicationofPortlandcementis tomakeconcrete.ItwasinGermanythatthefirstsystematictestingofconcretetookplacein1836. Thetestmeasuredthetensileandcompressivestrengthofconcrete.Aggregatesareanothermain ingredientofconcrete,whichincludesand,crushedstone,clay,gravel,slag,andshale.PlainconcretemadeofPortlandcementandaggregateisusuallycalledthefirstgenerationofconcrete.The secondgenerationofconcretereferstosteelbar-reinforcedconcrete.FrançoisCoignetinFrance wasapioneerinthedevelopmentofreinforcedconcrete.(DayandMcNeil,1996).Coignetstarted experimentingwithiron-reinforcedconcretein1852andwasthefirstbuilderevertousethistechniqueasabuildingmaterial(EncyclopaediaBritannica,1991).Hedecided,asapublicitystunt andtopromotehiscementbusiness,tobuildahousemadeof bétonarmé ,atypeofreinforced concrete.In1853,hebuiltthefirstironreinforcedconcretestructureanywhere;afour-storyhouse at72RueCharlesMichelsinSt.Denis(Sutherlandetal.,2001).Thislocationwasnearhisfamily cementplantinSt.Denis,acommuneinthenorthernsuburbsofParis.Thehousewasdesigned bylocalarchitectTheodoreLachez(Collins,2004).

Coignethadanexhibitatthe1855ParisExpositiontoshowhistechniqueofreinforcedconcrete.Attheexhibit,heforecastthatthetechniquewouldreplacestoneasameansofconstruction. In1856,hepatentedatechniqueofreinforcedconcreteusingirontirants.In1861,hepublished histechniquesofreinforcedconcrete.

ReinforcedconcretewasfurtherdevelopedbyHennebiqueattheendofthe19thcentury, anditwasrealizedthatperformancecouldbeimprovedifthebarscouldbeplacedintension,thus keepingtheconcreteincompression.Earlyattemptsworked,withthebeamsshowingareduced tendencytocrackintension,butafterafewmonths,thecracksreopened.Agooddescriptionof thisearlyworkisgiveninLeonhardt(1964).Thefirstreinforcedconcretebridgewasbuiltin1889 intheGoldenGateParkinSanFrancisco,California.

Toovercomethecrackingprobleminreinforcedconcrete,prestressedconcretewasdevelopedandwasfirstpatentedbyaSanFranciscoengineernamedP.H.Jacksonasearlyas1886. Prestressedmeansthatthestressisgeneratedinastructuralmemberbeforeitcarriestheservice load.Prestressedconcretewasreferredtoasthethirdgenerationofconcrete.Prestressingisusuallygeneratedbythestretchedreinforcingsteelinastructuralmember.Accordingtothesequence ofconcretecasting,prestressingcanbeclassifiedaspretensioningorpost-tensioning.Pretensioningpullsthereinforcingsteelbeforecastingtheconcreteandprestressisaddedthroughthebond builtupbetweenthestretchedreinforcingsteelandthehardenedconcrete.Inthepost-tensioning technique,thereinforcingsteelortendonisstretchedafterconcretecastingandthegainingofsufficientstrength.Inpost-tensioning,steeltendonsarepositionedintheconcretespecimenthrough prereservedholes.Theprestressisaddedtothememberthroughtheendanchorage.Figure1-3 showsthesequenceofthepretensioningtechniqueforprestressedconcrete.

PrestressedconcretebecameanacceptedbuildingmaterialinEuropeafterWorldWarII, partlyduetotheshortageofsteel.NorthAmerica’sfirstprestressedconcretestructure,theWalnut LaneMemorialBridgeinPhiladelphia,Pennsylvania,wascompletedin1951.Nowadays,withthe developmentofprestressedconcrete,long-spanbridges,tallbuildings,andoceanstructureshave beenconstructed.TheBarriosdeLuraBridgeinSpainiscurrentlythelongest-spanprestressed concrete,cable-stayedbridgeintheworld,withamainspanof440m,whiletheShibanpoYangtze

(1)Pre-stressrebar

(2)Castconcrete

(3)Releaserebar

Figure1-3 Pretensioningsequenceforprestressedconcrete

Rebar

Concrete

Anchor Jack

Bridgeistheworld’slongestprestressedconcretegirderbridgewiththemainspanof330m. InCanada,theprestressedTorontoCNtowerreachesaheightof553m.

Asastructuralmaterial,thecompressivestrengthatanageof28daysisthemaindesign indexforconcrete.Thereareseveralreasonsforchoosingcompressivestrengthastherepresentativeindex.First,concreteisusedinastructuremainlytoresistthecompressionload.Second, themeasurementofcompressivestrengthisrelativelyeasier.Finally,itisthoughtthatotherpropertiesofconcretecanberelatedtoitscompressivestrength.Pursuinghighcompressivestrength hasbeenanimportantdirectionofconcretedevelopment.Asearlyas1918,DuffAdamsfound thatthecompressivestrengthofconcretewasinverselyproportionaltothewater-to-cement(w/c) ratio.Hence,ahighcompressivestrengthcouldbeachievedbyreducingthe w/c ratio.However,to keepconcreteworkable,thereisaminimumrequirementontheamountofwater;hence,the w/c ratioreductionislimited,unlessothermeasuresareprovidedtoimproveconcrete’sworkability. Forthisreason,progressinachievinghighcompressivestrengthwasveryslowbeforethe1960s. Atthattime,concretewithacompressivestrengthof30MPawasregardedashigh-strengthconcrete.Sincethe1960s,thedevelopmentofhigh-strengthconcretehasmadesignificantprogress duetotwomainfactors:theinventionofwater-reducingadmixturesandtheincorporationofmineraladmixtures,suchassilicafume,flyash,andslag.Water-reducingadmixtureisachemical admixturethatcanenableconcretewithgoodworkabilityunderaverylow w/c ratio;thelatter arefinermineralparticlesthatcanreactwithahydrationproductinconcrete,calciumhydroxide, tomakeconcrete’smicrostructuredenser,henceimprovingconcrete’sproperties.Silicafumealso hasapackingeffecttofurtherimprovethematrixdensity.In1972,thefirst52-MPaconcretewas producedinChicagoforthe52-storyMid-ContinentalPlaza.In1972,a62-MPaconcretewasproduced,alsoinChicago,forWaterTowerPlace,a74-storyconcretebuilding,thetallestintheworld atthattime(seeFigure1-4).Inthe1980s,theindustrywasabletoproducea95-MPaconcrete tosupplytothe225WestWackerDrivebuildingprojectinChicago,asshowninFigure1-5.The highestcompressivestrengthof130MPawasrealizedinthe220-m-high,58-storybuilding,the UnionPlaza,constructedinSeattle,Washington(Caldarone,2009).

Concreteproducedafterthe1980susuallycontainsasufficientamountofflyash,slag,or silicafumeaswellasmanydifferentchemicaladmixtures,soitshydrationmechanism,hydration products,andothermicrostructurecharacteristicsareverydifferentfromtheconcreteproduced withouttheseadmixtures.Moreover,themechanicalpropertiesarealsodifferentfromtheconventionalconcrete;hence,suchconcretesarereferredtoascontemporaryconcretes.

Therehavebeentwoinnovativedevelopmentsincontemporaryconcrete:selfcompactingconcrete(SCC)andultra-high-performanceconcrete(UHPC).SCCisatype ofhigh-performanceconcrete(HPC).High-performanceconcreteisaconceptdevelopedinthe 1980s.Itisdefinedasaconcretethatcanmeetspecialperformanceanduniformityrequirements, whichcannotalwaysbeachievedroutinelybyusingonlyconventionalmaterialsandnormal mixing,placing,andcuringpractices.Therequirementsmayinvolveenhancementofthe characteristicsofconcrete,suchasplacementandcompactionwithoutsegregation,long-term mechanicalproperties,higherearly-agestrength,bettertoughness,highervolumestability,or longerservicelifeinsevereenvironments.

Self-compactingconcreteisatypicalexampleofhigh-performanceconcretethatcanfillin formworkinacompactedmannerwithouttheneedofmechanicalvibration.SCCwasinitially developedbyProfessorOkamuraandhisresearchgroupinJapaninthelate1980s(Ozamaetal., 1989).Atthattime,concreteconstructionwasbloomingeverywhereinJapan.SinceJapanisin anearthquakezone,concretestructuresareusuallyheavilyreinforced,especiallyatbeam-column joints.Hence,duetolowflowability,conventionalconcretecouldhardlyflowpasttheheavily reinforcedrebars,leavingpoor-qualitycastconcreteandleadingtopoordurability.Sometimes,the

reinforcingsteelwasexposedtoairimmediatelyafterdemolding.Tosolvetheproblem,Professor Okamuraandhisresearchgroupdevelopedconcretewithveryhighflowability.Withthehelp oftheinventionofthehigh-rangewaterreducerorplasticizer,suchhighlyflowableconcretewas finallydeveloped.Theyweresoexcitedthattheycalledthisconcrete“high-performanceconcrete” inthebeginning.ItwascorrectedlatertoSCC,asHPCcoversbroadermeanings.Durabilityisa mainrequirementofHPC.Ithasbeenfoundthatmanyconcretestructurescouldnotfulfillthe servicerequirement,duenottolackofstrength,buttolackofdurability.Forthisreason,concrete withhighperformancetomeettherequirementofprolongingconcreteservicelifewasgreatly needed.

Inthe1990s,anewtypeof“concrete”withacompressivestrengthhigherthan200MPawas developedinFrance.Duetothelargeamountofsilicafumeincorporatedinsuchamaterial,it wasinitiallycalledreactivepowderconcreteandlateronthenamechangedtoultra-high-strength (performance)concrete(UHSC),duetoitsextremelyhighcompressivestrength(Richardand Cheyrezy,1995).Theultra-high-strengthconcretehasreachedacompressivestrengthof800MPa withheatingtreatment.However,itisverybrittle,hence,incorporatingfibersintoUHSCisnecessary.Afterincorporatingfinesteelfibers,aflexuralstrengthof50MPacanbereached.Thefirst trialapplicationofUHSCwasafootbridgebuiltinSherbrooke,Canada(Aitcinetal.,1998).

Figure1-4

WaterTowerPlaceinChicago,USA(PhotoprovidedbyXiaojianGao)

Figure1-5 The225WestWackerbuildinginChicago,USA(PhotoprovidedbyXiaojianGao)

1.2CONCRETEASASTRUCTURALMATERIAL

Inthisbook,thetermconcreteusuallyreferstoPortlandcementconcrete,ifnototherwisespecified.Forthiskindofconcrete,thecompositionscanbelistedasfollows:

Portland cement + water (&admixtures) → cement paste + fineaggregate → mortar + coarseaggregate → concrete

Hereitshouldbenotedthatadmixturesareusedinalmostallmodernpracticeandthus havebecomeanessentialcomponentofcontemporaryconcrete.Admixturesaredefinedasmaterialsotherthanaggregate(fineandcoarse),water,andcementthatareaddedintoaconcrete batchimmediatelybeforeorduringmixing.Theuseofadmixturesiswidespread,mainlybecause manybenefitscanbeachievedbytheirapplication.Forinstance,certainchemicaladmixturescan

Chapter1IntroductiontoConcrete modifythesettingandhardeningcharacteristicsofcementpastebyinfluencingtherateofcement hydration.Water-reducingadmixturescanplasticizefreshconcretemixturesbyreducingthesurfacetensionofthewater.Air-entrainingadmixturescanimprovethedurabilityofconcrete,and mineraladmixturessuchaspozzolans(materialscontainingreactivesilica)canreducethermal cracking.AdetaileddescriptionofadmixturesisgiveninChapter2.

Concreteisthemostwidelyusedconstructionmaterialintheworld,anditspopularitycan beattributedtotwoaspects.First,concretecanbeusedformanydifferentstructures,suchas dams,pavements,buildingframes,orbridges,muchmorethananyotherconstructionmaterial. Second,theamountofconcreteusedismuchmorethananyothermaterial.Itsworldwideproductionexceedsthatofsteelbyafactorof10intonnageandbymorethanafactorof30involume.

Inaconcretestructure,therearetwocommonlyusedstructuralmaterials:concreteandsteel. Astructuralmaterialisamaterialthatcarriesnotonlyitsself-weight,butalsotheloadpassing fromothermembers.

Steelismanufacturedundercarefullycontrolledconditions,alwaysinahighlysophisticated plant;thepropertiesofeverytypeofsteelaredeterminedinalaboratoryanddescribedinamanufacturer’scertificate.Thus,thedesignerofasteelstructureneedonlyspecifythesteelcomplying witharelevantstandard,andtheconstructorneedsonlytoensurethatthecorrectsteelisusedand thatconnectionsbetweentheindividualsteelmembersareproperlyexecuted(NevilleandBrooks, 1993).

Ontheotherhand,concreteisproducedinacruderwayanditsqualityvariesconsiderably. Eventhoughthequalityofcement,thebinderofconcrete,isguaranteedbythemanufacturerin amannersimilartothatofsteel,thequalityofconcreteishardlyguaranteedbecauseofmany otherfactors,suchasaggregates,mixingprocedures,andtheskilloftheoperatorsofconcrete production,placement,andconsolidation.

Itispossibletoobtainconcreteofspecifiedqualityfromaready-mixsupplier,but,evenin thiscase,itisonlytherawmaterialsthatareboughtforaconstructionjob.Transporting,placing, and,aboveall,compactinggreatlyinfluencethequalityofacastconcretestructure.Moreover, unlikethecaseofsteel,thechoiceofconcretemixesisvirtuallyinfiniteandthereforetheselection hastobemadewithasoundknowledgeofthepropertiesandbehaviorofconcrete.Itisthusthe competenceofthedesignerandspecifierthatdeterminesthepotentialqualitiesofconcrete,and thecompetenceofthesupplierandthecontractorthatcontrolstheactualqualityofconcretein thefinishedstructure.Itfollowsthattheymustbethoroughlyconversantwiththepropertiesof concreteandwithconcretemakingandplacing.

Inaconcretestructuralelement,concretesmainlycarrythecompressivestressandshear stresswhilethesteelcarriesthetensionstress.Moreover,concreteusuallyprovidesstiffnessfor structurestokeepthemstable.

Asatypeofstructuralmaterial,concretehasbeenwidelyusedtobuildvariousstructures. High-strengthconcretehasbeenusedinmanytallbuildingconstructions.InHongKong,grade90 concrete(i.e.,compressivestrengthof90MPa)wasusedinthecolumnsofthetallestbuildingin theregion,i.e.,the108-storyInternationalCommerceCentre(seeFigure1-6),whichwasbuiltin 2010andstands484m(1588ft)tall.

Concretehasalsobeenwidelyusedinbridgeconstruction.Figure1-7showstheSutong BridgethatcrossestheYangtzeRiverinChinabetweenNantongandChangshu,asatellitecity ofSuzhou,inJiangsuprovince,eastChina.Itisacable-stayedbridgewiththethird-longestmain span,1088meters,intheworldaftertheRusskybridge(1104m)andtheHutongYangtzeRiver bridge(1092m).Itstwosidespansare300m(984ft)each,andtherearealsofoursmallcable spans.

Figure1-6 InternationalCommerceCentre,HongKong.(Source:Wing1990hk/ WikimediaCommons/CCBY-SA3.0)

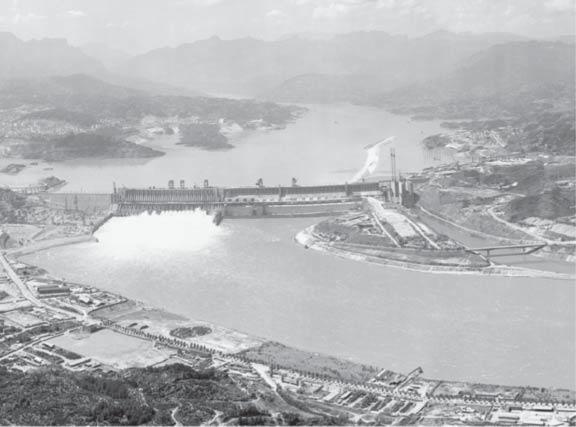

Damconstructionisanotherpopularapplicationforconcrete.Thefirstmajorconcretedams, theHooverDamandtheGrandCouleeDam,werebuiltinthe1930sandtheyarestillstanding.The largestdameverbuiltistheThreeGorgesDaminHubeiprovince,China,asshowninFigure1-8. Thetotalconcreteusedforthedamwasover22millionm3 .

Concretehasalsobeenusedtobuildhigh-speedrailways.Shinkansen,theworld’sfirstcontemporaryhigh-volume(initially12-carmaximum),“high-speedrail,”wasbuiltinJapanin1964. InEurope,high-speedrailwasfirstintroducedduringtheInternationalTransportFairinMunichin June1965.Nowadays,high-speedrailconstructionisbloominginChina.With37,900kilometers oflinesby2021,Chinahastheworld’slargestnetworkofhigh-speedrailways.Accordingtoplanning,70,000kmofhigh-speedrailwillbebuiltinChinaby2035.Figure1-9showsahigh-speed railsysteminChina.

Inaddition,concretehasbeenwidelyappliedintheconstructionofairportrunways,tunnels, highways,pipelines,andoilplatforms.Uptonow,theannualworldconsumptionofconcretehas reachedavaluesuchthatiftheconcretewereedible,everypersonontheEarthwouldhave2000kg peryearto“eat.”Youmaywonderwhyconcretehasbecomesopopular.

Figure1-7 SutongBridgeinSuzhou,Jiangsu,China(PhotoprovidedbyXiaoyanLiu)

Figure1-8 ThreeGorgesDam,Hubei,China(PhotoprovidedbyZhenHe)

Figure1-9 HighspeedrailinChina(PhotoprovidedbyGuotangZhao)

1.3.1AdvantagesofConcrete

(a) Economical:Concreteisthemostinexpensiveandthemostreadilyavailablematerialinthe world.Thecostofproductionofconcreteislowcomparedwithotherengineeredconstructionmaterials.Thethreemajorcomponentsinconcretearewater,aggregate,andcement. Comparedwithsteels,plastics,andpolymers,thesecomponentsarethemostinexpensive, andareavailableinalmosteverycorneroftheglobe.Thisenablesconcretetobeproduced worldwideataverylowcostforlocalmarkets,thusavoidingthetransportexpensesand associatedcarbonemissionformostothermaterials.

(b) Ambienttemperature-hardenedmaterial:Becausecementisalow-temperaturebondedinorganicmaterialanditsreactionoccursatroomtemperature,concretecangainitsstrengthat ambienttemperature.Normally,nohightemperaturecuringisneeded.

(c) Abilitytobecast :Freshconcreteisflowablelikealiquidandhencecanbepouredintovarious formworkstoformdifferentdesiredshapesandsizesrightonaconstructionsiteoraprecast plant.Hence,concretecanbecastintomanydifferentconfigurations.Onegoodexampleto showconcretecastabilityistheBaha’iTemplelocatedinWilmette,Illinois,USA,asshown inFigure1-10.Theverycomplexconfigurationsofthedifferentshapesofflowersinthewall androofwereallcastbyconcrete.

(d) Energy-efficient :Comparedtosteel,theenergyconsumptionofconcreteproductionislow. Theenergyrequiredtoproduceplainconcreteisonly450–750kWh/tonandthatofreinforcedconcreteis800–3200kWh/ton,whilestructuralsteelrequires8000kWh/tonormore tomake.

(e) Excellentwaterresistance:Unlikewood(timber)andsteel,concretecanhardeninwater andcanwithstandtheactionofwaterwithoutseriousdeterioration,whichmakesconcrete anidealmaterialforbuildingstructurestocontrol,store,andtransportwater,suchas

Figure1-11 Pipelineunderconstruction(PhotoprovidedbyZhulinZhang)

pipelines(Figure1-11),dams,andsubmarinestructures.Atypicalexampleofapipeline applicationistheCentralArizonaProject,whichprovideswaterfromtheColoradoRiver tocentralArizona.Thesystemcontains1560pipesections,each6.7mlong,7.5moutside diameter,and6.4minsidediameter.Contrarytopopularbelief,waterisnotdeleteriousto concrete,eventoreinforcedconcrete;itisthechemicalsdissolvedinwater,suchaschlorides, sulfates,andcarbondioxide,thatcausedeteriorationofconcretestructures.

(f) High-temperatureresistance:Concreteconductsheatslowlyandcanstoreconsiderable quantitiesofheatfromtheenvironment.Moreover,themainhydratethatprovidesbinding toaggregatesinconcrete,calciumsilicatehydrate(C–S–H),willnotbecompletely dehydrateduntil910o C.Thus,concretecanwithstandhightemperaturesmuchbetterthan woodandsteel.Eveninafire,aconcretestructurecanwithstandheatfor2–6hours,leaving sufficienttimeforpeopletoberescued.Thisiswhyconcreteisfrequentlyusedtobuildup protectivelayersforasteelstructure.

(g) Abilitytoconsumewaste:Withthedevelopmentofindustry,civilization,andurbanization, moreandmoreby-productsorwastehavebeengenerated,whichcausesaseriousenvironmentalpollutionproblem.Tosolvetheproblem,peoplehavetofindawaytoconsume suchwastes.Ithasbeenfoundthatmanyindustrialwastescanberecycledasasubstitute (replacement)forcementoraggregate,suchasflyash,slag(GGBFS = groundgranulated blast-furnacesslag),wasteglass,andgroundvehicletiresinconcrete.Productionofconcretewiththeincorporationofindustrialwastenotonlyprovidesaneffectivewaytoprotect ourenvironment,butalsosometimesleadstothebetterperformanceofaconcretestructure. Duetoalargeamountofconcreteproducedannually,itispossibletoconsumemostofthe industrialwasteintheworldinconcreteproduction,providedthatsuitabletechniquesfor individualwasteincorporationareavailable.

(h) Abilitytoworkwithreinforcingsteel:Concretehasasimilarvaluetosteelforthecoefficient ofthermalexpansion(steel1.2 × 10 5 ;concrete1.0–1.5 × 10 5 ).Concreteproducesgood

protectiontosteelduetotheexistenceofCHandotheralkalis(thisisfornormalconditions). Therefore,whilesteelbarsprovidethenecessarytensilestrength,concreteprovidesaperfect environmentforthesteel,actingasaphysicalbarriertotheingressofaggressivespeciesand givingchemicalprotectioninahighlyalkalineenvironment(pHvalueisabout13.5),in whichblacksteelisreadilypassivated.

(i) Lessmaintenancerequired :Undernormalconditions,concretestructuresdonotneedcoating orpaintingasprotectionforweathering,whileforasteelorwoodenstructure,itisnecessary tohaveaprotectivelayer.Moreover,thecoatingsandpaintingshavetobereplacedeveryfew years.Thus,themaintenancecostforconcretestructuresismuchlowerthanthatforsteelor woodenstructures.

1.3.2Limitations

(a) Quasi-brittlefailuremode:Thefailuremodeofmaterialscanbeclassifiedintothreecategories:brittlefailure,quasi-brittlefailure,andductilefailure,asshowninFigure1-12.Glass isatypicalbrittlematerial.Itwillbreakassoonasitstensilestrengthisreached.Materialsexhibitingastrain-softeningbehavior(Figure1-12b)arecalledquasi-brittlematerials. Bothbrittleandquasi-brittlematerialsfailsuddenlywithoutgivingalargedeformationas awarningsign.Ductilefailureisafailurewithalargedeformationthatservesasawarningbeforethecollapse,suchaslow-carbonsteel.Concreteisatypeofquasi-brittlematerial withlowfracturetoughness.Usually,concretehastobeusedwithsteelbarstoformso-called reinforcedconcrete,inwhichsteelbarsareusedtocarrytensionandtheconcretecompressionloads.Moreover,concretecanprovideastructurewithexcellentstability.Aselaborated previously,reinforcedconcreteisrealizedasthesecondgenerationofconcrete.

(b) Lowtensilestrength:Concretehasdifferentvaluesincompressionandtensionstrength. Itstensilestrengthisonlyabout1/10ofitscompressivestrengthfornormal-strengthconcrete,evenlowerforhigh-strengthconcrete.Toimprovethetensilestrengthofconcrete, fiber-reinforcedconcreteandpolymerconcretehavebeendeveloped.

(c) Lowtoughness(ductility):Toughnessisusuallydefinedastheabilityofamaterialtoconsume energy.Toughnesscanbeevaluatedbytheareaofaload–displacementcurve.Comparedto steel,concretehasverylowtoughness,withavalueonlyabout1/50to1/100ofthatofsteel, asshowninFigure1-13.Addingfibersisagoodwaytoimprovethetoughnessofconcrete.

(d) Lowspecificstrength(strength/densityratio):Fornormal-strengthconcrete,thespecific strengthislessthan20,whileforsteelitisabout40.Therearetwowaystoincreaseconcrete specificstrength:oneistoreduceitsdensityandtheotheristoincreaseitsstrength.Hence, lightweightconcreteandhigh-strengthconcretehavebeendeveloped.

(e) Formworkisneeded :Conventionalfreshconcreteisinaliquidstateandneedsformworkto holditsshapeandtosupportitsweight.Formworkcanbemadeofsteelorwood,asshown

Brittle

Quasi-brittle

inFigure1-14.Theformworkisexpensivebecauseitislabor-intensiveandtime-consuming tobuildanddemoldit.Toimproveefficiency,precast,extrusion,and3Dprintingtechniques havebeendeveloped.

(f) Longcuringtime:Thedesignindexforconcretestrengthisthe28-daycompressionstrength. Hence,fullstrengthdevelopmentneedsamonthatambienttemperature.Theimprovement measurethatisabletoreducethecuringperiodissteamcuringormicrowavecuring.

(g) Workingwithcracks:Evenforreinforcedconcretestructuremembers,thetensionsidehas aconcretecovertoprotectthesteelbars.Duetothelowtensilestrength,theconcretecover cracks.Tosolvethecrackproblem,prestressedconcreteisdeveloped,anditisalsorealized asathird-generationconcrete.Mostreinforcedconcretestructureshaveexistingcrackson theirtensionsideswhilecarryingtheserviceload.

1.4TYPESOFCONCRETE

1.4.1ClassificationinAccordancewithUnitWeight

Accordingtotheunitweightofconcretes,theycanbeclassifiedintofourcategories,as showninTable1-1.Ultra-lightweightconcretecanonlybeusedtobuildupnonstructural members.Lightweightconcretecanbeusedtobuildbothnonstructuralandstructuralmembers,

Figure1-13 Stress-straincurvesofsteelandconcrete

Figure1-14 Formworkforconcretecasting

Table1-1 Classificationofconcreteinaccordancewith unitweight

ClassificationUnitweight(kg/m3 )

Ultra-lightweightconcrete < 1,200

Lightweightconcrete1,200 < UW < 1,800

Normal-weightconcrete ≈ 2,400

Heavyweightconcrete > 3,200

Table1-2 Concreteclassifiedinaccordancetocompressive strength

ClassificationCompressivestrength(MPa)

Low-strengthconcrete < 20

Moderate-strengthconcrete20 ∼ 50

High-strengthconcrete50 ∼ 150

Ultrahigh-strengthconcrete > 150

dependingonitsspecifiedcomposition.Normal-weightconcretesarecommonlyusedconcretes intheconstructionofinfrastructuresandbuildings.Heavyweightconcreteisusedtobuildsome specialstructures,suchaslaboratories,hospitalexaminationrooms,andnuclearplants,where radioactiveprotectionisneededtominimizeitsinfluenceonpeople’shealth.

Themaincomponentthatmakesaconcreteunitweight(UW)differenceistheaggregate.As discussedinChapter2,thefourtypesofconcretedifferentiatedbyUWcorrespondtofourdifferent typesofaggregates,i.e.,ultra-lightweightaggregatesforultra-lightweightconcretes,lightweight aggregatesforlightweightconcretes,normal-weightaggregatesfornormal-weightconcreteswhile heavyweightaggregatesforheavyweightconcretes.

1.4.2ClassificationinAccordancewithCompressiveStrength

Accordingtoitscompressivestrength,concretecanbeclassifiedintofourcategories,aslistedin Table1-2.Low-strengthconcreteismainlyusedtoconstructmassconcretestructures,subgrades ofroads,andpartitions.Moderate-strengthconcretesarethemostcommonlyusedconcretesin buildings,bridges,andsimilarstructures.High-strengthconcretescanbeusedtobuildtallbuilding columns,bridgetowers,andshearwalls.Ultra-high-strengthconcreteshavenotyetbeenwidely usedinstructuralconstructions.Onlyafewfootbridgesandsomestructuralsegments,suchas girders,havebeenbuiltusingsuchconcretes.

1.4.3ClassificationinAccordancewithAdditives

Accordingtothematerialsotherthancement,aggregate,andwaterthatareaddedintoconcrete mixturesasadditives,concretescanbeclassifiedintodifferentcategories.Fourexamplesare showninTable1-3.Fiber-reinforcedconcrete(FRC)isatypeofconcretewithfibersincorporated.Manydifferentfibershavebeenusedtoproducefiber-reinforcedconcrete,includingsteel, glass,polymerics,andcarbon.Thepurposeofincorporatingfibersintoconcreteincludestoughnessenhancement,tensionpropertyimprovement,shrinkagecontrol,anddecoration.Detailed informationregardingFRCcanbefoundinChapter6.Macro-defect-free(MDF)isacement-based compositethatincorporatesalargeamountofwater-solublepolymer,producedinatwin-roll

Table1-3 Concreteclassificationsinaccordanceto additives

ClassificationAdditives

MDFPolymers

FiberreinforcedconcreteDifferentfibers

DSPconcreteLargeamountsilicafume

PolymerconcretePolymers

Figure1-15 3Dprintingtechnology(PhotoprovidedbyZhendiWang)

mixingprocess.Itwasdevelopedtoenhancethetensileandflexuralpropertiesofconcrete.ConcretethathasbeendensifiedwithsmallparticlesiscalledDSPconcretewhichhasincorporated alargeamountofsilicafume,amineraladmixturewithverysmallparticles.DSPconcretehas excellentabrasionresistanceandismainlyusedtoproducemachinetoolsandindustrialmolds. Threemethodshavebeendevelopedtoincorporatepolymersintoconcrete:(1)usingthepolymer asabinder;(2)impregnatingnormalPortlandcementconcretememberswiththepolymer;and (3)usingthepolymerasanadmixtureinnormalPortlandconcrete.MDF,DSP,andpolymerin concretearediscussedindetailinChapter6.

1.4.4ClassificationinAccordancewithConstructionMethods

Apartfromthecommoncastingmethod,therearesomespecialtypesofconcretemadebydifferentconstructionmethods.Associatedwiththesedifferentconstructionmethods,theseconcretes possessspecifiedpropertiesandthusrequirespecialdesign.Someinclude3Dprintableconcrete, sprayableconcrete,androller-compactingconcrete.

3Dconcreteprinting(3DCP)(Figure1-15)isanewconstructiontechnologydevelopedin recentyears.Itadoptsthelayer-by-layerdepositionmethodtoconstructthedesiredstructureas percomputer-aideddesign.Comparedwiththecommoncastingmethod,3Dconcreteprinting