Visit to download the full and correct content document: https://ebookmass.com/product/nanocolloids-for-petroleum-engineering-fundamentals -and-practices-baghir-suleimanov/

More products digital (pdf, epub, mobi) instant download maybe you interests ...

Formulas And Calculations For Petroleum Engineering 1st Edition Edition Cenk Temizel

https://ebookmass.com/product/formulas-and-calculations-forpetroleum-engineering-1st-edition-edition-cenk-temizel/

Environmental Engineering Principles and Practices (Water Supply Engineering) N. S. Varandani

https://ebookmass.com/product/environmental-engineeringprinciples-and-practices-water-supply-engineering-n-s-varandani/

Methods and Applications in Petroleum and Mineral Exploration and Engineering Geology Said Gaci

https://ebookmass.com/product/methods-and-applications-inpetroleum-and-mineral-exploration-and-engineering-geology-saidgaci/

Fundamentals of Nuclear Science and Engineering 3rd Edition

https://ebookmass.com/product/fundamentals-of-nuclear-scienceand-engineering-3rd-edition/

Practical Petroleum Geochemistry for Exploration and Production 1st Edition Edition Harry Dembicki (Auth.)

https://ebookmass.com/product/practical-petroleum-geochemistryfor-exploration-and-production-1st-edition-edition-harrydembicki-auth/

Fundamentals of Enhanced Oil Recovery Methods for Unconventional Oil Reservoirs (Developments in Petroleum Science, Volume 67) 1st Edition Dheiaa Alfarge

https://ebookmass.com/product/fundamentals-of-enhanced-oilrecovery-methods-for-unconventional-oil-reservoirs-developmentsin-petroleum-science-volume-67-1st-edition-dheiaa-alfarge/

Engineering Fundamentals: An Introduction to Engineering, SI Edition Saeed Moaveni

https://ebookmass.com/product/engineering-fundamentals-anintroduction-to-engineering-si-edition-saeed-moaveni/

Engineering Fundamentals: An Introduction to Engineering, 6th Edition Moaveni Saeed

https://ebookmass.com/product/engineering-fundamentals-anintroduction-to-engineering-6th-edition-moaveni-saeed/

Surveying fundamentals and practices 6th Edition Jerry A. Nathanson M.S. P.E.

https://ebookmass.com/product/surveying-fundamentals-andpractices-6th-edition-jerry-a-nathanson-m-s-p-e/

NanocolloidsforPetroleum Engineering

NanocolloidsforPetroleumEngineering FundamentalsandPractices

BaghirA.Suleimanov

OilandGasScientificResearchProjectInstitute StateOilCompanyofAzerbaijanRepublic(SOCAR) Baku,Azerbaijan

ElchinF.Veliyev

OilandGasScientificResearchProjectInstitute StateOilCompanyofAzerbaijanRepublic(SOCAR) Baku,Azerbaijan

VladimirVishnyakov UniversityofHuddersfield Huddersfield,UK

Thiseditionfirstpublished2022 ©2022byJohnWiley&SonsLtd.Allrightsreserved.

Allrightsreserved.Nopartofthispublicationmaybereproduced,storedinaretrievalsystem,ortransmitted, inanyformorbyanymeans,electronic,mechanical,photocopying,recordingorotherwise,exceptas permittedbylaw.Adviceonhowtoobtainpermissiontoreusematerialfromthistitleisavailableat http://www.wiley.com/go/permissions.

TherightofBaghirA.Suleimanov,ElchinF.VeliyevandVladimirVishnyakovtobeidentifiedastheauthors ofthisworkhasbeenassertedinaccordancewithlaw.

RegisteredOffices

JohnWiley&Sons,Inc.,111RiverStreet,Hoboken,NJ07030,USA

JohnWiley&SonsLtd,TheAtrium,SouthernGate,Chichester,WestSussex,PO198SQ,UK

EditorialOffice

TheAtrium,SouthernGate,Chichester,WestSussex,PO198SQ,UK

Fordetailsofourglobaleditorialoffices,customerservices,andmoreinformationaboutWileyproductsvisit usatwww.wiley.com.Wileyalsopublishesitsbooksinavarietyofelectronicformatsandbyprint-ondemand.Somecontentthatappearsinstandardprintversionsofthisbookmaynotbeavailableinother formats.

LimitofLiability/DisclaimerofWarranty

Inviewofongoingresearch,equipmentmodifications,changesingovernmentalregulations,andthe constantflowofinformationrelatingtotheuseofexperimentalreagents,equipment,anddevices,thereader isurgedtoreviewandevaluatetheinformationprovidedinthepackageinsertorinstructionsforeach chemical,pieceofequipment,reagent,ordevicefor,amongotherthings,anychangesintheinstructionsor indicationofusageandforaddedwarningsandprecautions.Whilethepublisherandauthorshaveusedtheir besteffortsinpreparingthiswork,theymakenorepresentationsorwarrantieswithrespecttotheaccuracyor completenessofthecontentsofthisworkandspecificallydisclaimallwarranties,includingwithout limitationanyimpliedwarrantiesofmerchantabilityorfitnessforaparticularpurpose.Nowarrantymaybe createdorextendedbysalesrepresentatives,writtensalesmaterialsorpromotionalstatementsforthiswork. Thefactthatanorganization,website,orproductisreferredtointhisworkasacitationand/orpotential sourceoffurtherinformationdoesnotmeanthatthepublisherandauthorsendorsetheinformationor servicestheorganization,website,orproductmayprovideorrecommendationsitmaymake.Thisworkis soldwiththeunderstandingthatthepublisherisnotengagedinrenderingprofessionalservices.Theadvice andstrategiescontainedhereinmaynotbesuitableforyoursituation.Youshouldconsultwithaspecialist whereappropriate.Further,readersshouldbeawarethatwebsiteslistedinthisworkmayhavechangedor disappearedbetweenwhenthisworkwaswrittenandwhenitisread.Neitherthepublishernorauthorsshall beliableforanylossofprofitoranyothercommercialdamages,includingbutnotlimitedtospecial, incidental,consequential,orotherdamages.

Forgeneralinformationonourotherproductsandservicesorfortechnicalsupport,pleasecontactour CustomerCareDepartmentwithintheUnitedStatesat(800)762-2974,outsidetheUnitedStatesat(317)5723993orfax(317)572-4002.

Wileyalsopublishesitsbooksinavarietyofelectronicformats.Somecontentthatappearsinprintmay notbeavailableinelectronicformats.FormoreinformationaboutWileyproducts,visitourwebsiteat ww.wiley.com.

LibraryofCongressCataloging-in-PublicationDataappliedfor: HardbackISBN:9781119889595

CoverDesign:Wiley

CoverImage:©sharply_done

Setin9.5/12.5ptSTIXTwoTextbyStraive,Pondicherry,India

Contents

Acknowledgments ix

Introduction xi

PartANanocolloids – AnOverview 1

1NanocolloidClassification 3

1.1WhatisaColloid? 3

1.1.1ColloidClassification 3

1.1.2ColloidEvaluation 4

1.2WhatisaNanocolloid? 5

2NanocolloidProperties 7

2.1DifferentKindsofInteractionsinNanocolloids 7

2.1.1VanderWaalsInteractions 7

2.1.2ElectrostaticInteraction 7

2.1.3Elastic–StericInteraction 8

2.1.4HydrophobicInteraction 8

2.1.5SolvationInteraction 8

2.1.6DepletionInteraction 8

2.1.7MagneticDipole–DipoleInteraction 8

2.1.8OsmoticRepulsion 9

2.2TheStabilityofNanocolloids 9

2.3RheologyofNanocolloids 10

2.3.1EffectofNanoparticleInteractionontheColloidRheology 10

2.3.2EffectofNanoparticleMigrationontheColloidRheology 14

2.4SurfaceTension.Wettability 21

2.4.1WettabilityAlteration 21

2.4.2SurfaceTension 23

Nomenclature 25 References 27

PartBReservoirDevelopment 33

3ReservoirConditionsforNanocolloidFormation 35

3.1In-SituFormationofNanogasEmulsions 35

3.1.1StabilityoftheSubcriticalGasNuclei 35

3.2In-SituFormationofNanoaerosoles 38

3.2.1StabilityoftheSubcriticalLiquidNuclei 39

4NanogasEmulsionsinOilFieldDevelopment 41

4.1HydrodynamicsofNanogasEmulsions 41

4.1.1FlowMechanismofGasifiedNewtonianLiquids 41

4.1.2FlowofGasifiedNewtonianLiquidsinPorousMediaatReservoirConditions 52

4.2HydrodynamicsofNanogasEmulsionsinHeavyOilReservoirs 60

4.2.1FlowMechanismofGasifiedNon-NewtonianLiquids 60

4.2.2FlowofGasifiedNon-NewtonianLiquidsinPorousMediaatReservoir Conditions 66

4.3FieldValidationofSlippagePhenomena 73

4.3.1Steady-StateRadialFlow 73

4.3.2UnsteadyStateFlow 86

4.3.3ViscosityAnomalyNeartothePhaseTransitionPoint 95

5NanoaerosolesinGasCondensateFieldDevelopment 107

5.1StudyoftheGasCondensateFlowinaPorousMedium 107

5.2MechanismoftheGasCondensateMixtureFlow 111

5.2.1RheologyMechanismoftheGasCondensateMixtureDuringSteady-State Flow 112

5.2.2MechanismofPorousMediumWettabilityInfluenceontheSteady-StateGas CondensateFlow 120

5.2.3MechanismofPressureBuild-UpattheUnsteady-StateFlowoftheGas Condensate 121

5.2.4ConcludingRemarks 124

Nomenclature 125 References 127

PartCProductionOperations 131

6AnOverviewofNanocolloidApplicationsinProductionOperations 133

7NanosolforWellCompletion 137

7.1TheInfluenceoftheSpecificSurfaceAreaandDistributionofParticlesonthe CementStoneStrength 139

7.2TheInfluenceofNano-SiO2 andNano-TiO2 ontheCementStoneStrength 140

7.3RegressionEquation 141

7.4ConcludingRemarks 142

8NanogasEmulsionforSandControl 145

8.1FluidizationbyGasifiedFluids 145

8.1.1CarbonDioxideGasifiedWaterasFluidizingAgent 146

8.1.2NaturalGasorAirGasifiedWaterasFluidizingAgent 149

8.2ChemicalAdditivesImpactontheFluidizationProcess 151

8.2.1Water–AirMixtureswithSurfactantAdditivesasFluidizingAgent 151

8.2.2FluidizationbyPolymerCompositions 152

8.3MechanismofObservedPhenomena 153

9VibrowaveStimulationImpactonNanogasEmulsionFlow 157

9.1ExactSolution 158

9.2ApproximateSolution 161

9.3ConcludingRemarks 162

Nomenclature 165 References 167

PartDEnhancedOilRecovery 171

10AnOverviewofNanocolloidApplicationsforEOR 173

10.1CoreFloodingExperimentsFocusedonDispersionPhaseProperties 174

10.2CoreFloodingExperimentsFocusedonDispersionMediumProperties 175

11Surfactant-BasedNanofluid 177

11.1NanoparticleInfluenceonSurfaceTensioninaSurfactantSolution 177

11.2NanoparticleInfluenceontheSurfactantAdsorptionProcess 178

11.3NanoparticleInfluenceonOilWettability 179

11.4NanoparticleInfluenceonOpticalSpectroscopyResults 179

11.5NanoparticleInfluenceontheRheologicalPropertiesofNanosuspension 182

11.6NanoparticleInfluenceontheProcessesofNewtonianOilDisplacementin HomogeneousandHeterogeneousPorousMediums 183

11.7ConcludingRemarks 186

12NanofluidsforDeepFluidDiversion 187

12.1Pre-formedParticleNanogels 187

12.1.1NanogelStrengthEvaluation 189

12.1.2KineticMechanismofGelation 191

12.1.3CoreFloodingExperiments 192

12.1.4ConcludingRemarks 197

12.2ColloidalDispersionNanogels 197

12.2.1Rheology 198

12.2.2AgingEffect 200

12.2.3InterfacialTension 200

12.2.4ZetaPotential 202

12.2.5ParticleSizeDistribution 203

Contents

12.2.6ResistanceFactor/ResidualResistanceFactor 204

12.2.7ConcludingRemarks 206

13NanogasEmulsionsasaDisplacementAgent 207

13.1OilDisplacementbyaNewtonianGasifiedFluid 207

13.2OilDisplacementbyaNon-NewtonianGasifiedFluid 208

13.3MechanismofObservedPhenomena 210

13.4FieldApplication 213

Nomenclature 217

References 219

14MetalStringComplexMicroandNanoFluids 227

14.1WhatareMetalStringComplexes? 227

14.2ThermalConductivityEnhancementofMicrofluidswithNi3(μ3-ppza)4Cl2 Metal StringComplexParticles 228

14.2.1MicroparticlesofMSCNi3(μ3-ppza)4Cl2 229

14.2.2Ni3 Microfluid 230

14.2.3FluidStability 230

14.2.4ThermalConductivity 232

14.2.5Rheology 235

14.2.6SurfaceTension 235

14.2.7FreezingPoints 236

14.2.8ConcludingRemarks 237

14.3ThermophysicalPropertiesofNano-andMicrofluidswithNi5(μ5-pppmda)4Cl2 MetalStringComplexParticles 237

14.3.1MicroparticlesoftheMetalStringComplexNi5(μ5-pppmda)4Cl2 238

14.3.2Micro-andNanofluidPreparations 239

14.3.3FluidStability 240

14.3.4ThermalConductivity 242

14.3.5Rheology 245

14.3.6SurfaceTension 245

14.3.7FreezingPoints 249

14.3.8ConcludingRemarks 249

Nomenclature 251 References 253

AppendixADeterminationofDispersed-PhaseParticleInteractionInfluenceon theRheologicalBehavior 259

AppendixBDeterminationofInflectionPoints 263 References 267 Index 269

Acknowledgments Theauthorswouldliketorecognizethecontributioninexperimentalstudiesofthe followingpeople:Dr.ElhanM.Abbasov,Dr.HakimF.Abbasov,Dr.OlegA.Dyshin, andDr.RayyetH.Ismayilov.

Theauthorsalsothanktheirfamiliesforthesupport,patience,andunderstandingthey haveshownduringthepreparationofthisbook.

Introduction Incontemptofgrowinginvestmentsinrenewableenergy,theoilindustrystillstaysthe mainsourceofenergyintheworld.Itiswellknownthatthegreatestpartofoilresources isstillmarkedasunrecoverableduetothelimitationofconventionaloilrecoverymethods. Thenumberofexploredoilfieldsalreadyovertakethefieldstobeexplored.Inthisregard, theincrementinoilproductionofmatureoilfieldsisverycrucial.Theoilindustrytodayis standinginthefrontierofnewpioneeringachievements.Withahighprobabilityitcanbe arguedthattheseachievementswillbemadeandhavealreadybeencommittedtolaboratories.Anoilpricedecreasehasalreadyreducedeconomicbenefitsofenhancedoilrecovery (EOR)methodsduetoCAPEXincrements.Thesamechallengesarelyingaheadofall upstreamtechnologies,suchascompletion,workover,sandcontrol,etc.Theapplication ofnewnano-basedmaterialscouldopennewopportunitiesandfindnewdecisionsforconventionalproblems.

Thisbookaimstocoveratheoreticalandpracticalbackgroundrelatedtonanocolloid applicationexperiencegainedoverthelastdecades.Nanocolloidsareadmittedbythe majorityofresearchersasanewperspectiveandapromisinginvestigationtopic.Thehigh surfaceareaofdispersionphasecausesamorereactivebehaviorcomparedtoconventional counterpartsandsignificantlychangesthepropertiesofcolloidsystems.Forinstance,the propagationabilityofnanogelsconsiderablyincreasesanopeningofnewopportunitiesfor in-depthfluiddiversiontechniquesaswellasgeldurabilityinreservoirconditions.The bookconsistsoffivepartsdividedintochapterstomaketheexperienceofreadingthebook morereader-friendly.Theparagraphsthatfollowbrieflydescribeeachpartandhighlight themaindiscussedtopics.

PartA.Nanocolloids – AnOverview consistsoftwochaptersdevotedtoabrief introductionandclassificationofcolloidsystems.Itwaspresentedandexplainedtheterm “nanocolloid. ” Thechaptersdescribethemainpropertiesofnanocolloidscrucialfor practicalapplicationsinpetroleumengineering:forexample,stability,rheological behavior,surfacetension,andwettability.

PartB.ReservoirDevelopment consistsofthreechaptersdevotedtonanocolloid applicationsinreservoirengineering.Thechaptersdescribereservoirconditionsnecessary fornanocolloidformation.Nanogasemulsionhydrodynamicsatreservoirconditionshave beendescribedindetail.Fieldvalidationresultsoftheproposedkineticmechanisms accompaniedbytechnicalrecommendationsforsuccessfulimplementationwerealso presented.

PartC.ProductionOperations consistsoffourchaptersdevotedtonanocolloid applicationsinproductionoperations.Thechaptersdescribethemechanismofthe nanoscaledispersionphaseimpactonphysicalpropertiesofconventionalsubstances utilizedinupstreamprocesses.Particularly,themechanismofPortlandcementreinforcementinthepresenceofnanoparticleswasdescribedandverified.Nanogasemulsionswere investigatedintermsofsandcontrolapplicationsbasedonfluidizationphenomena.The vibrowavestimulationimpactonnano-gasemulsionflowwasalsoreported.

PartD.EnhancedOilRecovery consistsoffourchaptersdevotedtonanocolloidapplicationsforEOR.Thechaptersdescribetheimpactofnanoparticlesonconventionaldisplacementagents.Forinstance,theadditionofnanoparticlessignificantlychanges surfaceandrheologicalbehaviorinsurfactantaqueoussolutions.Themechanismofthe observedphenomenahasbeenexplainedandspecified.Deepflowdiversionagentsdemonstrateimprovedstabilityandenhancedphysicalpropertiesintheexistenceofnanoparticles inthedispersionphase.Enhancedflowbehaviorofnanogelsimprovesconformancecontrol duetodeeperin-situpropagationandincreasedthermalstability.Fieldapplicationresults encouragestatingnanogasemulsionsaseffectiveandprofitabledisplacementagentsforoil recovery.Explainedmechanismsandreporteddatareferringtoobservedphenomenacould beagoodtheoreticalandpracticalbasisforfutureinvestigations.

PartE.NovelPerspectiveNanocolloids describesnewperspectivematerialsfor petroleumengineering.Metalstringcomplexesduetotheexistenceofextrametalions andpaddlewheelgeometryhavelargevarietiesofmetal–metalbondsthatleadtosignificant changesinphysicalproperties.Colloidstabilityandthermalconductivityhavebeen sustainablyimprovedinthepresenceofmetalstringcomplexes.Theoverallreportedresults allowthesecompoundstobeshownasapromisingareaforfuturestudiesandapplications inthepetroleumindustry.

Thebookisbasedonmaterialsfrommanysources,includingacademicpapers,publicationsfromtheindexedpetroleumjournals,academicinstitutionslaboratoryreportdata,as wellastheexperienceofServiceandNationalOilCompaniesgainedoverthelastthree decades.Tomakethisbookausefulandeffectiveguideintothenanocolloids,applied andtheoreticalbasisofthedetailedobservedresultswereprovided.

NanocolloidClassification 1.1WhatisaColloid? Acolloid(colloidalsystemormixture)isaheterogeneousmatterinwhichonephaseplaysa hostrole(dispersionmedia)andanotherphaseispresentasastabledistinguishabledispersed(dispersion)entity(wecanalsosayparticlesifthedispersionisfromasolidphase). Thedispersionphasecanhavesizesbetween1and1000nm[1].Theshapecanvaryovera very broadrange.Itisassumedthatacolloidshouldbethermodynamicallystableandthat thedispersedphase(entities)remainsevenlydistributedthroughoutthecolloid. Ifthedispersedentitiesaretoosmall,itwouldnotbepossibletodefinethemasaphase. At the otherextreme,iftheyaretoobigthenthesystemwouldnotbestable. Infact,twocommonmethodsexisttodeterminewhetheramixtureisacolloidornot:

1) The Tyndalleffect.Thisisbasedonlightscatteringbyparticlesinacolloidoraveryfine suspension.Thelightpasseseasilythroughatruesolutionbutincolloidsthedispersed phasescattersitinalldirections,makingithardlytransparent.

2) Filtrationofthecolloidthroughasemipermeablemembrane.Infact,thedispersion phasecannotpassthroughthemembraneandisfilteredoutofadispersionmedium.

Therearethreemainclassificationsofcolloidsaccordingtodifferentpropertiesofthe dispersed phaseandmedium[2,3]

1.1.1ColloidClassification 1) Classificationbasedonthephysicalstateofthedispersionmediumandofthe dispersedphase. Usingthesecriteria,colloidscanbedividedasshowninTable1.1.

2) Classificationbasedonthenatureoftheinteractionbetweenthedispersion mediumandthedispersedphase. Usingthiscriterion,colloidscanbeclassifiedas eitherlyophilicorlyophobic.

• Lyophilic(intrinsiccolloids ).Ahighforceofattractionexistsbetweenadispersed phaseandthedispersionmedium.Thesetypesofcolloidsareverystableanddo notrequirespecialmixingrequirements.Examplesarestarch,rubber,protein,etc.

4 1NanocolloidClassification

Table1.1 Themaintypesofnanocolloid.

DispersedphaseDispersedmediumNameofcolloidalsolutionCommonexamples

Solid Gas Solidaerosol

Smoke,dust

Solid Liquid Sol,gel,suspensionPaints,inks,jellies

Solid Solid Solidsol Alloys,opals

Liquid Gas Liquidaerosol Dust,smog,clouds

Liquid Liquid Emulsion Butter,cream,milk

Liquid Solid Solidemulsion(gel)Butter,cheese,curd

Gas Liquid Gasemulsion,foamWhippedcream,suds

Gas Solid Solidfoam Cake,marshmallow,lava

• Lyophobic(extrinsiccolloids).Averyweakforceofattractionexistsbetweenthe dispersedphaseandthedispersionmedium.Thesetypesofcolloidsareunstablewithouttheapplicationofstabilizingagentsandrequirespecialmixingprocedures.Examplesaresolsofmetalslikesilverandgold.

3) Classification based onthetypesofparticlesofthedispersedphasecolloids. Usingthesecriteria,colloidscanbedividedinto:

• Multimolecularcolloids. Theseareformedbyacolloidalrangeaggregationof atomsorsmallmoleculesthathaveaparticlesizelessthanthecolloidalrange(i.e. withadiameterlessthan1nm)inadispersionmedium.Forexample,goldconsists ofvarioussizedparticlescomposedofseveralatomsofgold.

• Macromolecularcolloids. Thesearecomposedofmacromoleculeshavingstrong chemicalbondsbetweenmoleculesandofasizeinthecolloidalrange.Theyarevery stable.Examplesarestarch,proteins,cellulose,etc.

• Associatedcolloids. Thesearesubstancesthatbehaveaselectrolytesatlowconcentrations,butshowcolloidalpropertiesathighconcentrationsdueto a micelle formation.

1.1.2ColloidEvaluation

Colloidsareusuallyevaluatedbythefollowingdispersioncharacteristics[4]:

• Particleaggregate. Aninter-particleforcecausestheaggregationofthedispersion phaseinsmallspecies,wheretwotypesofaggregatesoccur.:

a) Nanoparticleagglomerationindrypowderform. It isveryhardtosegregate them,evenwithultrasonication.

b) Nanoparticlesincolloidsformalargecluster. Thistypeofclusterrequiresmore thanoneproceduretodispersethem.

1.2WhatisaNanocolloid? 5

Table1.2 Stabilityofsuspensionswithrelationtothezetapotential[5].

Zetapotential

This is anelectrokineticvalueforadispersedphase.Thepotentialis stronglyrelatedtothecolloidstability.

Stabilitycharacteristics

Maximumagglomerationandprecipitation

Averagezeta potentialinmV

0to+3

Rangeofstrongagglomerationandprecipitation +5to 5

Thresholdofagglomeration 10to 15

Thresholdofdelicatedispersion 16to 30

Moderatestability 31to 40

Fairlygoodstability 41to 60

Verygoodstability 61to 80

Extremelygoodstability 81to 100

• Particlestructure(sizeandshape). Dispersionphaseparticledimensionsandshapes haveahugeimpactoncolloidsproperties.Examplearethermophysicalproperties,rheologicalbehavior,etc.

• Polydispersity. Ingeneral,acolloidwouldhavevarioussizedparticlesactingasthedispersionphase.Apolydispersityindexisameasureoftheparticlesizevariationandranges from0to1.Accordingtointernationalstandards,thevalueoftheindexbelow0.05is characteristicofmonodisperseddistribution(allparticleshavethesamesize),while theindexvaluesabove0.7indicateabroadlypolydispersesystem.

• Zetapotential. Thisisanelectrokineticvalueforadispersedphase.Thepotentialis stronglyrelatedtothecolloidstability(seeTable1.2).

1.2WhatisaNanocolloid? Thetermnanocolloidisrelativelynewandconsidersacolloidthathasnanoparticlesasa dispersionphase[4,6].Nanocolloidshavethefollowingmainfeatures:

– Thedispersionphaseisestablishedbycompoundsintheamorphousorcrystallinestate, either organic orinorganic,andmaydemonstratecollectivebehaviorandconsistsofparticlesinthe1–100nmrange.

– Repulsionforcesactasthemainforcetopreventamacroscopicphaseseparation.

Mean while itshouldbementionedthatthedispersionmediumisalsoaverycriticalfactoraswellasaninterfaciallayercoveringthedispersionmedium.Thestabilityofthe obtainedcolloidsdependsstronglyonthefactorsmentionedabove.Thiswillbediscussed andillustratedfurtherlaterinthebook.

Table1.3 showsthemaintypesofnanocolloidoftenfoundinpetroleumengineering.

6 1NanocolloidClassification

Table1.3 Themaintypesofnanocolloidoftenfoundinpetroleumengineering.

Dispersed phase Dispersed mediumNameofcolloidalsolution

Applicationsinpetroleum engineering

SolidLiquidNanogel,nanosuspension (nanofluid) [6–49]

SolidSolid Nanosol [12,50,51]

LiquidGas Nanoaerosol [12]

LiquidLiquidNanoemulsion [6,12,52–54]

Gas LiquidNanogasemulsion,nanofoam[6]

NanocolloidProperties 2.1DifferentKindsofInteractionsinNanocolloids

Asmentionedearlier,theaggregationofnano-sizedparticlesisthemainchallengeinadiscussionofcolloidstability.Inparticular,flocculationismostoftenobservedasakindof aggregation.Inthisregard,dominationofattractiveforcesisdefinedasundesirable,while repulsionisfoundtobepositiveforcolloidstability.However,collectivepropertiesofnanoparticlesthatarenotpresentedinindividualparticlesshouldalsobetakenintoaccount[4].

2.1.1VanderWaalsInteractions VanderWaalsforcesareintermolecularforcesthatgenerallydemonstrateattractivebehavior.Insomecases,however,theycoulddisplayrepulsivebehaviorbetweendissimilarmaterialsinathirdmedium.Inhydrocarbonliquids(i.e.inertpolar),uncoatednanoparticles favortheformationofaggregates.

TheVanderWaalsinteractionpotentialbetweentwoparticlescanbecalculatedusingthe HamakertheorysimplifiedbytheDerjaguinapproximation:

where c = R1 + R2 + h andisthecenter-to-centerdistance, h isthedistanceofseparation, and A istheHamakerconstant.ParticlesthathaveahighHamakerconstantvalueshowa strongeraggregationbehaviorincomparisonwithparticlesthathavealowervalueof Hamakerconstant.

2.1.2ElectrostaticInteraction Electrostaticinteractionsaretheattractiveorrepulsiveinteractionsbetweenchargedmoleculesandparticles.Therearevariousmechanismsdefiningthesurfacecharginginliquids byadsorption,ionization,etc.[55].

Tocalculatetheelectrostaticinteractionpotential,eitherDerjaguinapproximation(DA) orlinear-superpositionapproximation(LSA)isusuallyused.Theenvironmentalconditions shouldbetakenintoaccountforeverycaseasthesolutionpH,electrolytemedia,andionic strengthhaveastrongimpactonthesetypesofinteraction.

NanocolloidsforPetroleumEngineering:FundamentalsandPractices,FirstEdition. BaghirA.Suleimanov,ElchinF.Veliyev,andVladimirVishnyakov. ©2022JohnWiley&SonsLtd.Published2022byJohnWiley&SonsLtd.

2.1.3Elastic

–StericInteraction Stericstabilizationistheprocessbywhichadsorbednonionicsurfactantsorpolymersproducestrongrepulsionbetweenparticlesinadispersion[56].Basedonthismechanism,polymerchainsbecomeadsorbedontothesurfaceofcolloidalparticlesinordertoavoidthe flocculationdrivenbyVanderWaalsforces.

2.1.4HydrophobicInteraction

Hydrophobicinteractionsincolloidsaredefinedasinteractionsthatoccurbetweenwater andlowwater-solublemolecules(i.e.hydrophobes).Thisprocessismainlyassociatedwith anentropydecreaseintheliquidduetosolubilizationofnonpolarmolecules.However,it shouldbenotedthathydrophobicinteractionsarestronglydependentonelectrostatic forces(i.e.thepresenceofions,chargeoftheinterface,etc.)[55].

2.1.5SolvationInteraction

Theprocessofattractionandassociationofsolventmoleculeswithsolutemolecules/ions involvesbondingandVanderWaalsforces.Inthecaseofwatertheprocessiscalledhydration.Solvationforcesdependonphysicochemicalproperties,suchasthewettabilityangle, surfacemorphology,etc.[57].

2.1.6DepletionInteraction

Largeparticlessuspendedindilutesolutionsofsmallersolutesgenerateanattractiveforce calledthedepletionforce[58].Forexample,thesearesolutionsthatcontainnonadsorbing polymers.Thedepletionpotentialcanbecalculatedbythefollowingformula:

where P istheosmoticpressureand LD isthedepletionlayerthickness(roughlytwicethe radiusofgyration).

2.1.7MagneticDipole–DipoleInteraction Magneticdipole–dipoleinteractionisobservedasadirectinteractionbetweentwomagnetic dipoles(e.g.alsocalleddipolarcoupling).Thefollowingformulaexpressesthedipole –dipoleinteractionpotential:

where M isthemagnetizationofthematerial, a theradiusoftheparticles, s thedistance betweenthesurfacesoftwointeractingparticles,and μ0 isthepermeabilityofthe vacuum[59].

2.2TheStabilityofNanocolloids 9

2.1.8OsmoticRepulsion Osmoticrepulsionisbasedonthelocalincreaseofosmoticpressureduetoariseinthe polymerconcentrationwhileoverlappingofpolymerligandsincolloidstakesplace[60].

2.2TheStabilityofNanocolloids Asdescribedpreviously,thestabilityofacolloidstronglydependsoninterparticleinteractions.Tocharacterizeinteractionpotentialbetweenparticlesandevaluateanaggregation tendency,theDerjaguin–Landau–Verwey–Overbeek(DLVO)theoryisthemostwidely used[61].

Thetheorystatesthatcolloidstabilityisdefinedbythetotalpotentialenergyoftheparticles(VT),whichisthesumoftheattractive(i.e.VanderWaals) VA andrepulsive(i.e.electrostatic) VR potentials:

V T = V A + V R

Theexpressionfortheattractivepotentialenergy VA is

V A = Ar 12x

where A istheHamakerconstant, r istheradiusoftheparticles(applicableforthespherical particleorapproximation),and x isthedistancebetweenthesurfaces.

Theexpressionfortherepulsivepotentialenergyis

V R =2

2 e kx where ε isthedielectricconstantofthesolvent, ε0 isthevacuumpermittivity, ζ isthezeta potential,and k isafunctionoftheionicconcentration(while k 1 isthecharacteristic lengthoftheelectricdoublelayer,orEDL).

However,someassumptionsofDLVOtheorythathavebeenfoundtobecriticalfornanocolloidsshouldbenotedandarepresentedbelow[62,63]:

1) Allparticlesconsideredtobesimilarintermsofsurfaceandshapemorphologyare describedasspherical.However,inthecaseofnanoparticlesthisitisnotcorrect.

2) Thedispersionmediumsinsideandoutsideofaparticleareconsideredtobehomogeneous.However,thisdoesnotapplyinthecaseoftheinterfaciallayer.Forthenanosizeddispersionphase,theinterfaciallayercouldbecomparableandevengreaterthan theparticlediameter,whichcouldhaveagreatimpactontheagglomerationproperties ofthenanoparticles.

3) Therepulsionandattractiveforcesarepresumedtobeindependentforces.However,on nanoscaledimensions,thisisnotanaccurateassumption.Forexample,polarizability increasesthecouplingbetweendifferentforces.

4) Electrostaticpropertiesaredistributeduniformlyonthedispersionphasesurfaces.

5) Brownianmotionandelectrostaticforcesgovernthedistributionofions.

Furthermore,Suleimanovetal.hadshownthat,apartfromthepotentialenergyoftotal particles,thegravityandbuoyancyforcesshouldbetakenintoconsideration[22].

Theauthorsdemonstratedthatparticleaggregationsizesandconsequentlythecolloidstabilitystronglydependonequilibriumbetweenthementionedforces.

Thevalueofdispersionphaseparticledensityatwhichcolloidstabilizationisachieved canbedeterminedfromtheconditionofbuoyancywhenthegravityactingontheparticles aggregationisbalancedbythebuoyancy:

where g isgravitationalacceleration, N istheaveragenumberofparticlesintheassembly, rp istheaverageradiusofthemicroparticles, H isthethicknessoftheassociatedsurrounding liquidlayer, ρp isthedensityofthedispersionphase, Ra istheaverageradiusoftheassembly,and ρbf isthedensityofthedispersionmedium.

Thedensityofmicroparticlesiscalculatedasfollows:

Thisshowsthattheparticlesizedistributionandmorphologyofparticlesshouldbeconsideredintermsofnanocolloidstabilization.ItisimportanttonotethattheParticleSize DistributionAnalyzerandScanningElectronMicroscopeshouldbeusedtoobtaintheparametersmentionedintheequations.

2.3RheologyofNanocolloids Innanocolloidswithaliquiddispersionmedium,whereariseinnanoparticleconcentrationleadstoswitchinginrheologyfromNewtoniantonon-Newtonian(e.g.nanofluidsor nanosuspension,gasemulsions,emulsions)behavior,Suleimanovetal.reportedtheflow characteristicalterationofasurfactantaqueoussolutionfromaNewtoniantoanonNewtonianstateinthepresenceofnon-ferrousmetalnanoparticles[49].However,the mechanismbehindthatdeviationhasstillnotbeensufficientlystudied.Thefollowingsubsectiondiscussesthemechanismofnanoparticleinteractionandtheimpactofmigrations ontherheologyofnanocolloids.

2.3.1EffectofNanoparticleInteractionontheColloidRheology

Nonlineareffectsobservedindispersesystemswithtime-dependentrheologicalproperties (e.g.self-oscillationsandrandomoscillationsofrheologicalcharacteristics)couldbe explainedbyspecificfeaturesoftheinteractionbetweentheirstructuralelements.The interactionofdispersedphaseparticlesinpurelyviscousnon-Newtoniansystemsdoes notnotablyaffectthedynamicbehaviorofrheologicalcharacteristicsbutrathermanifests itselfintheirsteady-statevalues.Thereasonsaretherelativelysmallsize(~10 μm)ofthe dispersedphaseparticlesandtheabsenceofanydevelopedthree-dimensionalstructure. Thespecificfeaturesoftherheologicalbehaviorofpurelyviscousnon-Newtoniansystems canbeexplainedbyusingthedataontheiropticalcharacteristicsmeasuredintheprocess offlow.

2.3RheologyofNanocolloids 11

Theinvestigationscouldbeconductedonanexperimentalsetupsimilartothoseusedin references[64] and[65].Lightispassedthroughacylindricallayer(cell)ofthesolutionin question.Thesolutionflowsataconstantspeed,e.g.theshearrate.Theintensityofthe transmittedlight,registeredasavoltagefromaphotomultiplier,isrecorded.Thisallows thetimedependenceofthesolutiontransparencytobeobserved.Thetransparencychanges whenaggregatesofthedispersedphaseparticlesareformedordestroyed.Therefore,itis possibletoestimatethedynamicsoftheinteractionbetweenthedispersedphaseparticles bymeasuringthesystemtransparency.

Example Thesolutionofa2wt.%partiallyhydrolyzedpolyacrylonitrile(PAN)wasinvestigated.Itsflowdependenceat20 CisshowninFigure2.1.Itisapparentfromthefigure thattheflowhasaninitialportionofpseudoplasticcharacter,whichisreplacedbyadilatantflow(e.g.anincreaseofviscositywiththeshearrate)afterthethresholdrate(ataround γ =600s 1)isexceeded.

Theflowcelltransparencymeasurementswereconductedatfourshearrates:inthe regionofpseudoplasticflow(γ =400s 1),attheinflectionpointoftheflowcurve (γ =600s 1),neartheinflectionpointintheregionofthedilatantflow(γ =800s 1), andintheregionofthedevelopeddilatantflow(γ =1200s 1).AFourierspectralanalysis wassubsequentlyperformedforthesemeasurementsandtheresultsarepresentedasthe powerspectraldensity.

Intheregionofthepseudoplasticflow,thetransparencydidnotchangewithtime,i.e.the flowofthedispersionwassteady.Attheinflectionpoint,thesteadyflowisdisturbedand thereareperiodictransparencyoscillations(seeFigure2.2).Furtherinthetransitional regiontothedilatantflow,onecanobservecomplexperiodicvariationsinthetransparency, withthreecharacteristicfrequencies.Intheregionofthedevelopeddilatantflow,thetransparencyvariesinaquasi-randommanner,asindicatedbythepresenceofmanyharmonics inthepowerspectraldensitygraph(Figure2.2c).

Onthedatabasisprovided,onecouldarriveatthefollowingconclusion:whenthesteady flowofthedispersionisdisrupted,thehydraulicresistanceincreasesand,accordingly,the

Powerspectraldensity.(a) γ =600, (b)800,and(c)1200s–1

apparentviscosityofthesystemalsoincreases.Eachnewlevelofinteractionbetweenthe structuralelementsofthesystemischaracterizedbyanewvalueofitsapparentviscosity.

Themajorityofresearchersconsidertheobservedphenomenontobequietrare.Accordingtoreferences[66] and[67],thedilatancyisobservedinsystemswithahighconcentration of thesolidphaseandincoarsedispersions.Dilatantflowforsuchsystemsisexplained onthebasisofthetheoryofan “excluded-volume.” Itisassumedthattheeffectiveconcentrationofthesolventintheprocessofflowconstantlydecreasesduetoitshighermobility, thedryfrictionbetweendispersedphaseparticlesincreasesasaresult,and,hence,the apparentviscosityofthesystemincreases.

Figure2.2

2.3RheologyofNanocolloids

Inreference[68] itwasshownthatstrongdilatancymaybeobservedinacolloidwitha dispersionphasesmallerthan5 μm.Itisexplainedbypreferentialparticlemigrationtothe wallsofthecapillary,whichleadstoanincreaseintheapparentviscosityofthesystem.

Inreference[69],adilatantflowwasobservedinapolymersolutionofpolymethacrylic acid.Theflowbehaviorwasexplainedbythemechanisminvolvingunfoldingofthemacromoleculechainswithanincreaseinshearrateandanincreaseinparticleinteraction.In somecolloidsthetransitionfromalowtoahighshearratewasassociatedwiththetransitionfromapseudoplasticflowtoadilatant(e.g.forpolyvinylchloride,hydrolyzedPAN).

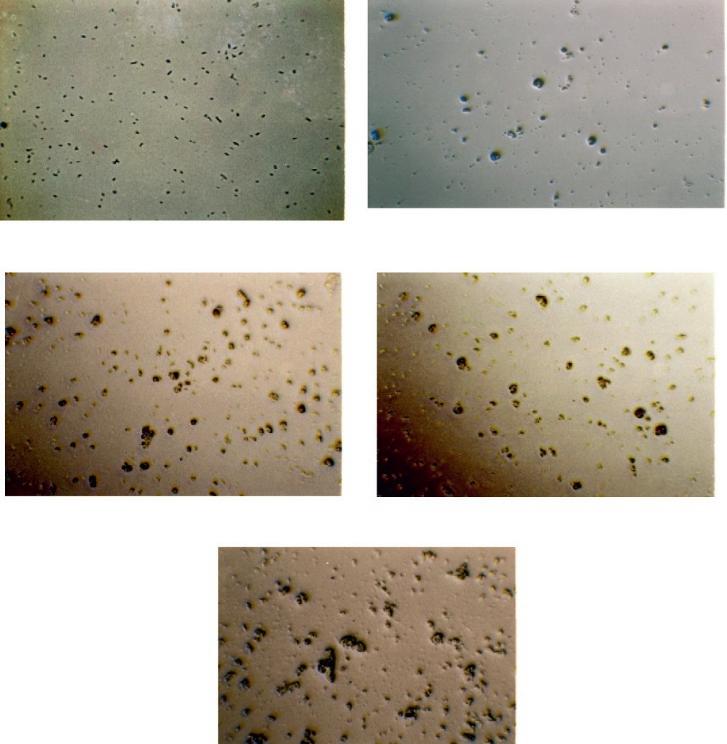

ThesteadypseudoplasticflowofthedispersedphaseisnotdisruptedwhentheconcentrationofthepartiallyhydrolyzedPANintheaqueoussolutionisbelow1wt.%.Therefore, thedisruptionofthesteadyflowisinitiatedbyintensificationofinter-particleinteraction, whichisusuallyobservedwithincreasingconcentrationofthedispersedphaseandmanifestsintheformationofdispersedphaseparticleagglomerates.Toverifythisassumption, thestructureofthedispersionatvariouspolymerconcentrationshasbeeninvestigated usinganopticalmicroscope.Atlowconcentrations(upto0.05wt.%),thedispersedphase consistsofseparatedeformablerandomlyorientedelongated(rod-shaped)formswithasize ofabout100nm.Astheconcentrationincreasestoandabove1wt.%,theagglomerates (mostlycircularoroval)withsizesof5–10 μmareobserved(Figure2.3).Inaddition,the averagetransparencydecreaseswithanincreasingshearrate.

Inordertodeterminetheuniformityofparticledistributionfrommicrophotographs,the dependencesoftheparticlenumber n inacirclewitharbitraryselectedradius r, n(r),was measured.Basedontheobtainedfunction,thefractaldimensionalityofthesystem’sgeometricalstructurewasdeterminedinlinewithreference[70].Figure2.4showsthefractal

dimensionality D functiononthepolymerconcentration.Ascanbeseenfromthefigure,at concentrationsupto1%thegeometricalstructureofthesystemishomogeneousandthe fractaldimensionalitycorrespondstotheEuclideandimensionalityofthearea.Afurther increaseintheconcentrationleadstoadecreaseinthefractaldimensionalityoftheinhomogeneities,butatthe2%concentrationitinsignificantly(by8%)differsfromtheEuclideandimensionalityofthesurface.Atlowpolymerconcentrationsitispossibleinthefirst approximationtoconsiderthespatialdistributionofthedispersedphaseashomogeneous.

Itisclearthattheobservedchangesinthetransparencyofsheareddispersionaredueto processesoftheassociateddestructionandformation.Theabsenceofasteadystateforthese processesisevidentlyattributedtothespecificityoftheeffectofsingleparticlesandassociates onthehydrodynamicstressesthatdevelopinthedispersionwhenundergoingshearflowin theregionofdilatancy.Inordertobuildakineticmodelthatwouldexplaintheobserveddispersiontransparencyoscillations,thenatureofthedilatantbehaviorshouldbestudied.

Theprocessesinconcentrateddispersedsystemsmainlyshowdynamicbehaviorthat leadstoasituationwhenthetheoreticalstudy,withaccountingforcoagulationeffectseven forthesimplestcases,becomesmathematicallyintricate.Theconstructionofsimplified modelsthatprovidesufficientaccuracyforpracticalapplicationisverycritical.

Inreferences[71–79],basedonthekineticapproach,thixotropicprocessesindispersed systems were investigated.Itwasshownthatitispossibletopredicttherheologicalpropertiesofadispersedsolutionwithacceptableaccuracy.However,theauthorsdidnotconsider motiondynamicsofthedispersemediumandtheinfluenceofdispersed-phaseparticle interactionontherheologicalbehavior.SeeAppendix1foranillustrationofasimplemodel thattakesintoaccounttheabove-mentionedissues.

2.3.2EffectofNanoparticleMigrationontheColloidRheology Experimentsonvariousdispersesystemshaveproventhatrheologicalflowdependences cannotbeuniversallydescribedbytheexponentiallaw.Indeed,inthecaseofflowthrough tubeswithvariablecross-sections,therheologicalfunctiondoesnotobeytheexponential law.Moreover,thefunctionoftheapparentviscosityupontheflowratehasanonmonotoniccharacter.Similareffectsarealsoobservedintubeswithvariablecross-sectionsfor non-Newtonianoils.

Figure2.4 Fractaldimensionofassociatesasafunctionofthepolymerconcentration C insolution.

2.3RheologyofNanocolloids 15

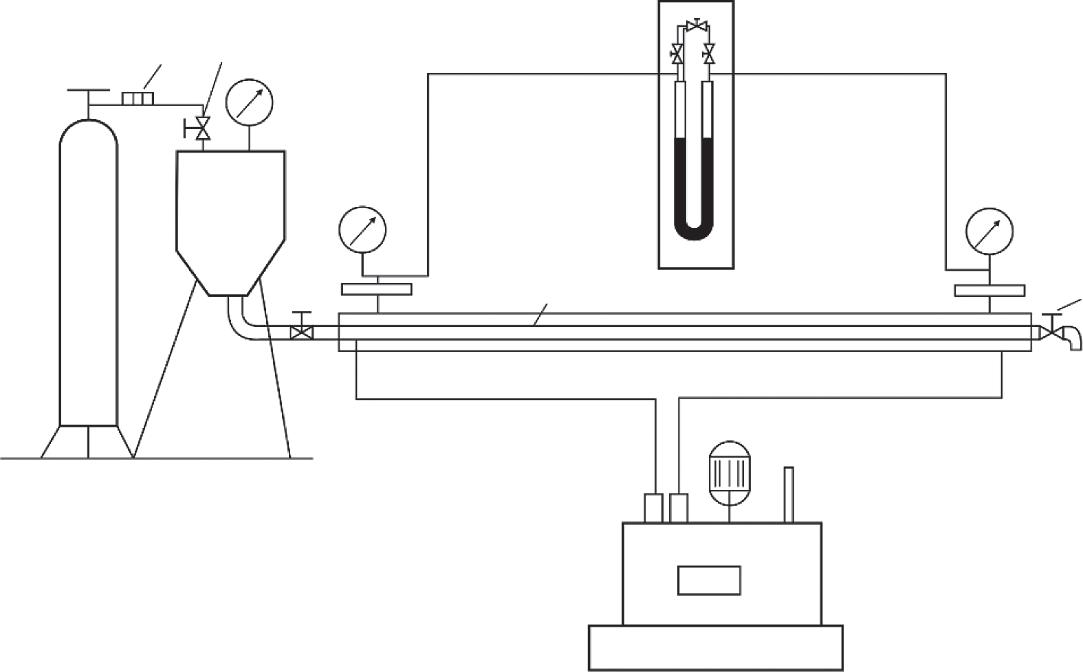

However,fielddataonoiltransportindicatesthattheseeffectscanalsobeobservedin tubeswithconstantdiameters,e.g.duringthetransportofwater–oilemulsions.Moreover, anomalousphenomenaalsooccurwhensuspensionswithsolidparticlesareflowing throughthetubes.Experimentalinvestigationsofnon-Newtonianoilrheologyaswellas suspensionswithsolidparticleswerecarriedoutinordertostudytheseproblemsindetail. Heavygradesofoilwithacomplicatedrheologicalbehaviorwereobtainedfromthe GryazevayaSopkaandBusachidepositsfortheinvestigation.Adispersesystemmodelconsistingofaclay(bentonite)slurrymixedwithaddedquartzsand(densityof2600kg/m3) invariousfractions(withaverageparticlesizeof10 4 m)wasalsoexamined(Table2.1). TheexperimentalsetupshowninFigure2.5wasused.

Table2.1 Basicphysicalcharacteristicsofthesystemsstudied.

Characteristicsandunitsof measurement Oilsamplefromthe GryazevayaSopkadeposit Oilsamplefromthe Busachideposit

Figure2.5 Schematicdiagramoftheexperimentalsetup,where(7)isahigh-pressurevessel,(2)an electricalstirrervessel(forthesystemsunderinvestigation),(3)atubeofconstantdiameter(4or 16×10 3 m)withanexchangeablehorizontal2.7mlongsection,(4)standardpressuregauges,(5)agas pressureregulator,(6)adifferentialpressuregauge,(7)anultra-thermostat,(8)one-wayvalves,(9)a lockingvalve,and(10)separatingcompensators.

Throughoutalltheexperiments,aconstanttemperature(287K)andlaminarflowwere maintained.Therheologicalcurvesortime-dependentflow-ratecharacteristicswere recorded.Figure2.6 showsarheologicalcurvefortheoilsamplesfromtheBusachideposit, which wasusedtoplotthedependenceofthedimensionlessapparentviscosityagainstthe valueoftheshearrateaveragedoverthecross-sectionofthetube(Figure2.7).Ascanbe seenfromthesefigures,therheologicalcurveisS-shaped,whereasthecorresponding dependenceoftheapparentviscosityupontheshearrateisnonmonotonic.Attheinflection point(pointAinFigures2.6and2.7),thedilatantbehaviorbecomespseudo-plastic(inthis case, γ ≈ 160s 1).SimilarresultswereobtainedfortheoilsamplestakenfromtheGryazevayaSopkadeposit.

Thedispersedphaseofoilsystemsisknowntobecomposedmainlyofasphaltenes,which tend to formsupermolecularstructuresofthesize10 6 m.Thesestructuresmaybe deformedundertheinfluenceofexternalforces(forexample,shearstress).Inaccordance withthemicrorheologicalstudydescribedinreference[80],duringthelaminarflowofa suspension, solidparticlesmovepredominantlynearthetubewalls,whereasthedeformed particlesmigratetothecenteroftheflow.Hence,therheologicalcurvesfortheoilswitha non-Newtonianbehaviormaybedescribedbythefollowingkineticmechanism.Ata

Figure2.6 RheologicalcurvefortheoilsamplefromtheBusachideposit,obtainedinexperiments witha tube4×10 3mindiameter.

Figure2.7 Dependenceofthedimensionlessapparentviscosityontheshearrateaveragedoverthe cross-sectionof thetube.

2.3RheologyofNanocolloids 17

relativelylowshearrate,theparticlesofadispersedphasethatarechaoticallydistributedin aliquidarenotdeformed(similartosolidparticles)andaregraduallyconcentrated(predominantlynearthewallsofthecylindricaltube),thusresultinginanincreaseintheapparentviscosityofthesystem.Then,afterattainingacertainthresholdshearrate,theparticles becomedeformed,whichleadstoanadditionalperturbationofthefieldofliquidvelocities, andtheymigratetowardthecenteroftheflow.Thisisreflectedbyadecreaseintheapparentviscosityofthesystem.Infact,ashasbeenshownabove,thecharacterofflowisaltered at γ ≈ 160s 1,whichisconsistentwiththeresultsofstudy[80].Accordingtoit,adispersed particle10 6 minsizestartstobecomedeformedwhentheshearrate γ averagedoverthe cross-sectionofthetubeexceeds150s 1 .

Consideringthatforanoildispersesystemthedensitiesofthedispersedphaseandthe dispersionmediumarepracticallyequal,thefollowingviscosityfunctionwassuggested[81]:

hc = 1 η c + A r 2 c

where η(c)isthefunctionofviscosityversusconcentration, r isthecylindricalcoordinate, c istheconcentrationofthedispersedphase,and A isaconstant.Inaccordancewithreference[81], A [0, ∞], r [0,1],and c [0,1].Thevalueofthefunction c(r)isdefinedso that h(c)and,accordingly,theflowratearemaximal.

Assumingthatthefunction η(c)isexpressedbytheEinsteinequation,weobtainthefollowingexpression:

= 1

BydifferentiatingEquation(2.1) withrespectto c,thefollowingexpressionscanbe obtained: h c = a 1+ ac 2 + A r 2 h c = 2a2 1+ ac 3

AnanalysisofEquation(2.2) indicatesthatthefunction h(c)acquiresitsmaximumvalue eitherat c =0orat c =1.Determiningthefunction h(c)atthesevaluesof c,

h 1 = 1 1+ a + A r 2 , h 0 1

Sincefunction h(1)decreaseswithincreasing r, cm(r)forthedistributionoftheconcentrationoverthecross-sectionofthetube,thusprovidingthefollowingmaximumflowrate, couldbeexpressedasfollows:

cm r = 1,0< r <1+ a A a 0,1+ a A a < r ≤ 1 2 3

Fortheconcentrationaveragedoverthecross-section,

i.e.at A (0, a/(1+ a)2)and F (0,1/2)thedistributionexpressedbyEquation(2.3) is validandthesystemiscompletelyseparated.

Itshouldbenotedthat,intheconsideredexample,whenthedispersedphaseismoving nearthetubewall,completeseparationisnotobtained.However,accordingtoreference [80],astheparticlesmovefromthecenterofthetubetoitswalls,anincreaseintheconcentrationand,accordingly,intheviscositytakesplace.

Thenextstepisaninvestigationintotheimpactoftheobtaineddistributionontheliquid flowrate.Inthisregard,assumethattwoviscousincompressibleliquidswithdifferentviscositiesaremovinginthefollowingmanner – oneoftheliquidsismovinginanannulusnear thetubewallsandtheotherliquidismovinginthecenteroftheflux.Theflowratesofthese liquidsaredeterminedbythefollowingformula:

where ΔP/l isthepressuregradient, ηi istheviscosityofaliquid,and ai and bi areconstants. Theliquidnearthewallisdenotedbythesubscriptindex1andthecore,thesubscript index2.

SolvingEquation(2.4) undertheboundaryconditions

where R1 isthetuberadiusand R2 istheradiusoftheinterfacebetweenthetwoliquids,we obtainthefollowingexpressionforthetotalflowrate:

where δ isthethicknessofthelayernearthewall(δ =1 R2/R1)and ε = η2/η1.

Ananalysisofrelationship(2.5) indicatesthatat ε >1,i.e.whenalayerwithalowerviscositymovesnearthetubewalls,theflowrateoftheliquidincreaseswiththethicknessof thelayernearthewall,whereasat ε <1,theflowrateoftheliquiddiminisheswiththe increasingthicknessofthislayer.

InFigure2.8,thedependenceoftheflowrateonthetimeisrepresentedataconstant pressuredropof1.1×104Paforaclayslurrywithaddedquartzsand.Itcanbeseenthat theflowrateisadescendingfunction,virtuallyvanishingoveracertainperiodoftime. Thescatterofexperimentaldata,whichisobservedbeforethesteadystateisattained, maybeattributedtoagradualredistributionofthedispersedphase.Notethatasimilarscatterisalsoobservedduringtheflowofrheopecticsuspensions.

2.3RheologyofNanocolloids

Figure2.8 Dependenceoftheclayslurryflowratewithaddedquartzsandontimeataconstant pressuredropof1.1×104Pa,obtainedinexperimentswithatube1.6×10 2m indiameter.

Anincreaseintheinputpressureofupto1.3×104Paresultsincontinuedflowofthe system.Thesuspensionunderinvestigationpossessesareasonablyhighsedimentationstabilityduetothesmallaveragesizeoftheparticlesofthedispersedphaseandtherelatively highviscosityofthedispersionmediumwithacomparativelysmalldifferenceindensities, aswellasduetothepresenceofyieldshearstress.Thiswassupportedbythefactthatthe concentrationofsandintheoutflowoftheslurryremainsvirtuallyconstant.

Thedependencesoftheyieldshearstressandthestructuralviscosityontheconcentration forthesuspensionunderconsiderationhavealsobeenstudied.Ithasbeenestablishedthat theyieldshearstressandstructuralviscosityincreaserapidlywithconcentration.

Thedecreaseobservedintheflowrateafterstoppingtheflowmaybeexplainedasfollows.Afteracertainperiodoftime,inthetubewherethesuspensionhasbeenflowing adistributionofthedispersedphaseisestablishedsothatitsconcentrationincreaseswith proximitytothetubewall.This,inturn,resultsinanincreaseintheyieldshearstressofthe system.

Thenextstepistoobtainaqualitativeconformationofthesuggestedmodel.Abbasov foundthatadensitydifferencebetweenthedispersephaseandthedispersionmediumcannotbeneglected.Then,transformingthefunctionobtainedinreference[81] fortheinstant case,thefollowingexpressionwasachieved:

where ρ(c)isthefunctionofthedensityoverconcentration.Forthefunction c(r),wefinda valuethatresultsinminimizationoftheflowrateoftheliquidafterthefunction h(c)is maximized.Forthefunctionofdensityversusconcentration,thisisassumedtobe

where b istheratioofthedensityofthedispersionmediumtothatofthedispersedphase. Thefunctionofviscosityversusconcentrationisexpressedbytheformula[82]

Thenthefunction h(c) takesthefollowingform: hc = c a b +1 b c 2a + A 1 r 2 c

Differentiatingthiswithrespectto c wasobtainedas h c = 2c a 1 b + b 2a + A 1 r 2 h c = 1 b a 2 6

Ananalysisofthisequationshowsthatfunction h(c) attainsitsmaximumateither c =0 or c =1.Determiningthisfunctionatthesevaluesof c wasobtainedusingthefollowing expressions:

=

Sincefunction h(1)decreaseswith r,[a > b/(1 b)]dr wasobtainedas

r =

Theexpressionfortheaveragedconcentration

1

i.e.at A = a 1 b b 2a , F =(0,1/2)thedistributionaccordingtoEquation(2.7) is observed,andthesystemiscompletelyseparated.Notethat,inpractice,thecompleteseparationofaliquiddoesnotoccur.Therefore,itwouldbenaturaltoassumethatarelatively thinlayernearthewall(δ =0.3 0.5)willexhibitaconsiderablyhigherconcentrationof thesolidphaseand,accordingly,ahigherviscositythanthosewithauniformlydistributed dispersedphase.

Intheliquidflowrateevaluationwehadassumedthattwovisco-plasticliquidsflow throughacylindricaltubeinacircularmode:aviscous-plasticliquidwiththestructural viscosity η1 andyieldshearstress τ 1 isflowingnearthetubewalls,whereasanotherviscous-plasticliquidwith η2 and τ 2 flowsinthecenterofthetube.Inthiscase, η1 > η2 and τ 1 > τ 2.Assumingthattheradiusoftheflowcoreisrelativelysmall,asimplifiedapproach hasbeenapplied,inaccordancetowhichtheequationofmotionfortheviscous-plasticliquidholdsthroughouttheentirerangeof r values.Theflowrateofviscous-plasticliquidsis determinedfromtheknownformula(usingthenotationsintroducedearlier)