ExtractablesandLeachables

DennisJenke

Thiseditionfirstpublished2022 ©2022JohnWiley&Sons,Inc.

Allrightsreserved.Nopartofthispublicationmaybereproduced,storedinaretrievalsystem,ortransmitted,inanyformorbyanymeans, electronic,mechanical,photocopying,recordingorotherwise,exceptaspermittedbylaw.Adviceonhowtoobtainpermissiontoreusematerial fromthistitleisavailableathttp://www.wiley.com/go/permissions.

TherightofDennisJenketobeidentifiedastheauthoroftheeditorialmaterialinthisworkhasbeenassertedinaccordancewithlaw.

RegisteredOffice

JohnWiley&Sons,Inc.,111RiverStreet,Hoboken,NJ07030,USA

EditorialOffice

9600GarsingtonRoad,Oxford,OX42DQ,UK

Fordetailsofourglobaleditorialoffices,customerservices,andmoreinformationaboutWileyproductsvisitusatwww.wiley.com.

Wileyalsopublishesitsbooksinavarietyofelectronicformatsandbyprint-on-demand.Somecontentthatappearsinstandardprintversionsof thisbookmaynotbeavailableinotherformats.

LimitofLiability/DisclaimerofWarranty

Whilethepublisherandauthorshaveusedtheirbesteffortsinpreparingthiswork,theymakenorepresentationsorwarrantieswithrespectto theaccuracyorcompletenessofthecontentsofthisworkandspecificallydisclaimallwarranties,includingwithoutlimitationanyimplied warrantiesofmerchantabilityorfitnessforaparticularpurpose.Nowarrantymaybecreatedorextendedbysalesrepresentatives,writtensales materialsorpromotionalstatementsforthiswork.Thefactthatanorganization,website,orproductisreferredtointhisworkasacitation and/orpotentialsourceoffurtherinformationdoesnotmeanthatthepublisherandauthorsendorsetheinformationorservicesthe organization,website,orproductmayprovideorrecommendationsitmaymake.Thisworkissoldwiththeunderstandingthatthepublisheris notengagedinrenderingprofessionalservices.Theadviceandstrategiescontainedhereinmaynotbesuitableforyoursituation.Youshould consultwithaspecialistwhereappropriate.Further,readersshouldbeawarethatwebsiteslistedinthisworkmayhavechangedordisappeared betweenwhenthisworkwaswrittenandwhenitisread.Neitherthepublishernorauthorsshallbeliableforanylossofprofitoranyother commercialdamages,includingbutnotlimitedtospecial,incidental,consequential,orotherdamages.

LibraryofCongressCataloging-in-PublicationData

Names:Jenke,Dennis,author.

Title:Extractablesandleachables:characterizationofdrugproducts, packaging,manufacturinganddeliverysystems,andmedicaldevices/ DennisJenke.

Description:Hoboken,NJ:Wiley,2022.|Includesbibliographical referencesandindex.

Identifiers:LCCN2022015986(print)|LCCN2022015987(ebook)|ISBN 9781119605072(cloth)|ISBN9781119605089(adobepdf)|ISBN 9781119605102(epub)

Subjects:MESH:DrugPackaging–standards|DrugDelivery Systems–standards|DrugContamination–prevention&control|Drug Stability|ConsumerProductSafety

Classification:LCCRS159(print)|LCCRS159(ebook)|NLMQV825|DDC 615.1/8–dc23/eng/20220525

LCrecordavailableathttps://lccn.loc.gov/2022015986

LCebookrecordavailableathttps://lccn.loc.gov/2022015987

CoverDesign:Wiley

CoverImage:©KJ_Photography/Shutterstock

Setin9.5/12.5ptSTIXTwoTextbyStraive,Chennai,India

Contents

Preface xii Acknowledgments xvi

1IntroductionandEssentialConcepts 1

1.1GeneralDiscussion 1

1.2Regulations,Guidelines,Standards,andRecommendationsforChemicalCompatibilityAssessments 5

1.3WhyChemicalAssessment? 8

1.4AnOverviewoftheChemicalCompatibilityAssessmentProcess 10

1.5LookingAhead 13 References 14

2GeneralPrinciplesofChemicalCompatibilityAssessment:ExtractionandLeaching 15

2.1KeyDefinitionsandConcepts,Extractables,andLeachables 15

2.2ExtractionStudies 23

2.2.1KeyDefinitionsandConcepts 23

2.2.2TypesofExtractions 24

2.2.3ExamplesofExtractionSequences 29

2.2.4Required/RecommendedExtractions 34

2.2.5PrinciplesofExtraction 34

2.2.5.1ThermodynamicsandKineticsofExtractionandLeaching 34

2.2.5.2ExtractionSolvents,Polarity 37

2.2.5.3ExtractionSolvents,pH 43

2.2.5.4TemperatureandDuration 51

2.2.5.5Stoichiometry 54

2.2.5.6AdditionalFactorstoConsider 59

2.2.6CompromisedExtracts 62

2.3LeachingStudies 64

2.4VariationinExtractionandLeachingStudies 66 References 69

3GeneralPrinciplesofChemicalAssessment:AnalyticalTestingforExtractablesandLeachables; OrganicCompounds 73

3.1KeyDefinitionsandConcepts 73

3.2OrganicSubstanceAnalysis,Screening 76

3.2.1RelevantAnalyticalMethods 76

3.2.2SurveyofChromatographicScreeningMethods 76

3.2.3DerivationandUseoftheAnalyticalEvaluationThreshold(AET) 79

3.2.3.1DefinitionsandConcepts 79

3.2.3.2SampleAETCalculations 82

3.2.3.3UncertaintyAdjustmentstotheAET 84

3.2.3.4SelectingtheBasisfortheAET 91

3.2.3.5TheRelationshipBetweentheAETandOtherMeasuresofAnalyticalSensitivity 91

3.2.4Discovery 93

3.2.5IdentificationandIdentificationCategories 94

3.2.6TheIdentificationProcess 98

3.2.7“Quantitation” 99

3.2.8UncertaintyAdjustmentstoEstimatedQuantitativeData 104

3.2.9ReducingVariationviaProcessOptimization 105

3.2.10ScreeningErrorsandTheirMitigation–TheExtractables/LeachablesDatabase 109

3.2.10.1ErrorofOmission(Discovery) 109

3.2.10.2ErrorofInexactIdentification 113

3.2.10.3ErrorofInaccurateandImpreciseQuantitation 113

3.2.10.4Reducing,Mitigating,andEliminatingErrorsinE&LScreening 116

3.2.11MethodQualification 117

3.3OrganicSubstanceAnalysis:Targeting 119

3.3.1IntentandPurpose 119

3.3.2SelectionandJustificationofTargets 119

3.3.3EstablishingReportingPractices 120

3.3.4MethodValidation 121

3.4OrganicSubstanceAnalysis:TargetedScreening 122

3.5Extractables/LeachablesCorrelations 123

3.5.1LinkingExtractablesandLeachables 123

3.5.2AHierarchyforLinkagesBetweenExtractablesandLeachables 124

3.5.3DecisionsConcerningtheRequiredRigorforLinkages 125

3.5.4CircumstancesRequiringtheLinkingofExtractablesandLeachables 126

3.5.5ExamplesofLinkagesBetweenExtractablesandLeachables 127

3.5.6PracticalRealitiesAssociatedwithLinkingExtractablesandLeachables 129

3.6Intra-laboratoryVariationinExtractables/LeachablesProfiles 132

3.6.1PQRIControlledExtractionStudy 134

3.6.2InvestigationofLab-to-LabVariationBetweenFourTestingLaboratories 136

3.6.3InvestigationofExtractionConditionsforMedicalDevices 138

3.6.4IfYouPlayThisGameLongEnough,YouAreBoundtoRepeatYourself 141

3.6.5AddressingVariationinEnvironmentalTesting 142

3.6.6ConcludingThoughts 144 References 145

4GeneralPrinciplesofChemicalAssessment:AnalyticalTestingforExtractablesandLeachables; Elements,Anions,andGeneralTesting 147

4.1ElementalAnalysis 147

4.1.1TheMandateforExtractableElementTesting 147

4.1.2IdentifyingProperArticlesforExtractedElementsTesting 148

4.1.3EstablishingProperTestParameters 149

4.1.3.1GeneratingtheExtract 149

4.1.3.2TestingtheExtract 150

4.1.4SelectingTargetElements 151

4.1.5ReportingandInterpretingExtractedElementsResults 152

4.1.6OtherConsiderations 153

4.1.6.1ExtractedElementsandtheProductLifecycle 153

4.1.6.2GlobalStandardsforExtractableElementsTesting 153

4.1.6.3UseandValueofVendor-SuppliedInformation 153

4.1.7ExistingKnowledgeConcerningExtractedElementsinMaterialsandSystems 154

4.2IonicExtractables 156

4.3ScoutingviaGeneralChemicalAnalysis 157

4.3.1GeneralDiscussion 157

4.3.2pH 158

4.3.3UVAbsorbance 159

4.3.4TOC 159

4.3.4.1UseofTOCinScreening 159

4.3.4.2PerformingaTOCReconciliation 160

4.3.4.3UsingTOCReconciliationtoJudgetheCompletenessofExtractablesProfiling 160

4.3.4.4UsingUnreconciledTOCtoEstimatetheLevelsofUnknownExtractables 160 References 161

5Extractables,Leachables,andtheProductLifecycleThroughProductApprovalandLaunch 163

5.1Introduction 163

5.2Situation 163

5.3Definitions 165

5.4TheChemicalCompatibilityAssessmentProcess 166

5.4.1MaterialSelection 166

5.4.2SystemQualification 166

5.4.3ProductQualification 167

5.4.4ProductMaintenanceandChangeControl 167

5.4.5ComponentTesting 167

5.5ElementsoftheChemicalAssessmentStrategy 168

5.5.1Stage1:MaterialSelection 168

5.5.1.1GeneralDiscussion 168

5.5.1.2VendorInformation 168

5.5.1.3MaterialAssessment 171

5.5.1.4TheMaterialCharacterizationandSelectionReport 172

5.5.2SupportingProductDevelopmentBetweenStages1and2 172

5.5.2.1RevisionControlDuringProductDevelopment 172

5.5.2.2SupplementalTestingDuringProductDevelopment 173

5.5.3Stage2:SystemQualification 173

5.5.3.1Discussion 173

5.5.3.2TheSystemQualificationProcess 173

5.5.3.3ExtractablesProfiling 174

5.5.3.4ImpactAssessmentoftheExtractablesProfile 176

5.5.3.5TheAnalyticalEvaluationThreshold(AET) 176

5.5.4Stage3:ProductQualification 177

5.5.4.1Discussion 177

5.5.4.2TheConceptofTargetLeachables 178

5.5.4.3ProductQualificationviaaTargetedMigrationStudyPerformedonStability 179

5.5.4.4ImpactAssessmentofTargetLeachables 180

5.5.4.5LeachablesScreening 180

5.6AdvancedTopicsinChemicalCompatibilityAssessment 180

5.6.1ApplicationofDesignSpaceConceptstoChemicalCompatibilityAssessment 180

5.6.2MigrationModelingtoReduceStudyDuration 181

5.6.3ExtractablesandLeachablesDatabasetoFacilitatetheTransitionfromScoutingtoProfiling 182

5.6.4RegulatoryStatus 182

References 183

6Extractables,Leachables,andtheProductDevelopmentLifecycle:ChangeControl 185

6.1Stage4:LifecycleManagementandChangeControlviaaComparabilityProtocol 185

6.1.1ATieredApproachtoChangeControl 185

6.1.2Tier0AssessmentforTwoLevelsofChange 187

6.1.2.1MaterialLevelChanges(Tier0) 187

6.1.2.2ItemLevelChanges(Tier0) 188

6.1.3Tier1Assessment 188

6.1.4Tier2Assessment 189

6.1.5AdditionalLifecycleManagementConsiderations 189

6.1.5.1RefreshingaSystem’sExtractablesProfile 189

6.1.5.2ControlofIncomingMaterials 190

6.2Stage4:Life-CycleManagementandChangeControlviaaRisk-BasedApproach 190

6.2.1Discussion 190

6.2.2Definitions 192

6.2.3EssentialPrinciplesofChangeCategorization 193

6.2.4UnderstandingtheAbsoluteRisk 193

6.2.5Stage1Categorization:UseofPriorKnowledgetoDriveCategorization 193

6.2.6Stage2Categorization:GeneralProcess 195

6.2.6.1ChangeDimensions 195

6.2.6.2Dimension1,WhereinthePackagingSystemIstheChangeBeingMade? 195

6.2.6.3Dimension2,WhatTypeofChangeIsBeingConsidered? 196

6.2.6.4Dimension3,howIsthePackagingSystemBeingChanged? 197

6.2.6.5Dimension4,WhatIstheMagnitudeoftheChange? 198

6.2.7CompletingStage2Categorization 199

References 203

7Applications–PharmaceuticalDrugProducts–Packaging 205

7.1ClassificationofPackagingSystemsandComponents 205

7.2PharmacopeialMonographs 210

7.2.1TheRoleofthePharmacopeiainSettingStandardsforChemicalCharacterizationofPackaging 211

7.2.2PharmacopeialGuidanceviaCompendialMonographs 211

7.2.3TheUnitedStatesPharmacopeia(USP)MonographsonPackagingMaterialsandSystems 211

7.2.3.1GeneralDiscussion 211

7.2.3.2PlasticPackagingSystemsandTheirMaterialsofConstructions, <661>

7.2.3.3PlasticPackaging:ExtractablesandLeachables, <1663> and <1664> 217

7.2.3.4Containers–Glass, <660> and <1660> 223

7.2.3.5ElastomericComponents, <381> and <1381> 223

7.2.4TheEuropeanPharmacopeia(PharmEur)MonographsonPackagingMaterialsandSystems 225

7.2.5OtherPharmacopeia 228

7.3RegulatoryGuidance 230

7.3.1TheFDA1999ContainerClosureGuidance 230

7.3.2TheFDAGuidanceforOIDNP 234

7.3.3TheEMEAGuidelineonPlasticImmediatePackaging 235

7.4BestPracticeRecommendations 237

7.4.1PQRIRecommendationsforOrallyInhaledorNasalDrugProducts(OINDP) 237

7.4.2PQRIRecommendationsforParenteralDrugProducts(PDP) 241

7.4.3PQRIRecommendationsforOphthalmicDrugProducts(ODP) 244

7.5RiskClassificationofPackagingSystems 244

7.6AssessmentsofDrugProducts,PackagingSystems,andMaterialsofConstructionBasedonRisk Classification 256

7.7CaseStudies 260

7.7.1InjectableDrugProducts 261

7.7.2OtherDosageForms 264 References 265

8Applications–PharmaceuticalDrugProducts–ManufacturingComponentsandSystems 269

8.1Introduction 269

8.2IndustryPerspectives 272

8.2.1VendorPerspective,Bio-ProcessSystemsAlliance(BPSA) 272

8.2.2UserPerspective,BioPhorumOperationsGroup(BPOG) 275

8.2.2.1GeneralDiscussion 275

8.2.2.2PerformingExtractions 276

8.2.2.3AnalysisofExtracts 278

8.2.2.4ReportingExtractablesTestResults 279

8.2.2.5Leachables 280

8.3CompendialGuidance,USP <665> and <1665> 280

8.3.1PerspectivesontheDevelopmentofaUSPMonographfortheChemicalCharacterizationofPharmaceutical Plastics 280

8.3.2ObjectivesandScope 282

8.3.3TheConceptofaComparator:InitialAssessment 284

8.3.4RiskAssessmentandRiskClassification 285

8.3.5Risk-BasedTestingofPlasticComponentsandSystems 286

8.3.6TheStandardExtractionProtocolperUSP <665> 288

8.4FlexibilityintheImplementationofUSP <665> 290

8.5RiskClassificationofManufacturingComponents 291

8.5.1GeneralRequirementsperUSP <665> 291

8.5.2AScientificallyRigorousRiskEvaluationMatrix 292

8.5.3BioPhorumLeachablesRiskEvaluationMatrix 293

8.5.4USPRiskEvaluationMatrixper <1665> 294

8.6CaseStudies 299 References 301

9Applications–MedicalDevices 303

9.1Introduction 303

9.2RegulatoryLandscape:ISO10993;GeneratinganExtract 305

9.2.1ISO10993:12(2012) 305

9.2.2ISO10993:18(2020) 307

9.2.3ReconcilingtheExtractionConditionsContainedinParts12and18 311

9.3LinkingExtractionConditionstoMedicalDeviceCategories 312

9.4ChemicalTestingofExtracts 315

9.4.1TestMethods 315

9.4.2TestMethodQualification 318

9.4.3ReportingofTestData 319

9.5TheChemicalCharacterizationProcessforMedicalDevicesperISO10993:18(2020) 320

9.5.1TheChemicalCharacterizationFlowChart 320

9.5.2CompositionalAssessment 322

9.5.3ExtractablesAssessment 324

9.5.4LeachablesAssessment 325

9.6FDARecognitionofPart18 326

9.7MedicalDevicePackaging 328

9.8CaseStudies 329 References 332

10GeneralPrinciplesforRiskAssessmentofExtractablesandLeachables 333

10.1ToxicologicalSafetyRiskAssessmentofExtractablesandLeachables 333

10.1.1Introduction 333

10.1.2KeyDefinitionsandConcepts 333

10.1.3TheToxicologicalSafetyRiskAssessmentProcessSimplified 334

10.1.4ToxicologicalSafetyRiskAssessmentofPharmaceuticalPackaging 335

10.1.5ToxicologicalSafetyRiskAssessmentofMedicalDevices 340

10.1.6ToxicologicalSafetyRiskAssessmentofManufacturingComponents 343

10.1.7ToxicologicalSafetyRiskAssessmentofIncompletelyIdentifiedCompounds 344

10.2TheSpecialCaseofBiologics 345

10.3BiologicalSafetyRiskAssessment 347

10.3.1KeyDefinitionsandConcepts 347

10.3.2BiologicalTestsandTestMethods 347

10.4TheUseofAuxiliaryInformationinSafetyRiskAssessment 349

10.5AreOrganicExtractablesandLeachablesInherentlyUnsafe? 350

10.6AssessingRisksOtherThanPatientSafety 355

References 357

11FocusonEmergingConcepts 359

11.1ADoseofReality 359

11.2DesigningandImplementingBetterExtractions 360

11.3AchievingBetterAnalyticalOutcomes 364

11.3.1Re-statingtheCaseforStandardizedMethods 364

11.3.2Reducing,Mitigating,andEliminatingErrorsandVariationinE<esting 366

11.3.2.1DetectingandReportingaCompound 366

11.3.2.2MathematicalToxicologicalSafetyAssessmentSimplified 367

11.3.2.3IdentifyingaCompound 368

11.3.2.4QuantifyingaCompound 369

11.3.2.5Conclusion 369

11.3.3TheFinalWordonSettingtheUncertaintyFactor,UF,forAETAdjustment 370

11.4InformationSharingfortheCommonGood 373

11.4.1ReductionofRedundantTesting 374

11.4.2EliminationofUnnecessaryTesting 375

11.5ReplacingtheLabwithaComputer(MathematicalModeling) 378

11.6ConsidertheImpactofaResultBeforeAttemptingtoImproveIt 378

11.7RecentPublications 379

11.8USPBiologicalReactivityTesting 384

11.9I’llPassonThat 386

11.10TheEndofE&L? 387 References 388

APrinciplesforIdentifyingOrganicExtractablesandLeachables 391

A.1IdentificationClasses,Processes,andPractices 391

A.1.1Introduction 391

A.1.2Identification 391

A.1.3IdentificationProcesses 392

A.1.3.1MassSpectralMatching 392

A.1.3.2ManualMassSpectralInterpretation–StructuralElucidation 392

A.1.3.3AdditionalEvidences–SecuringtheIdentitywiththeHighestConfidence 392

A.1.4PracticalConsiderationsinIdentification 392

A.2IdentificationviaMassSpectralMatching 393

A.2.1IntroductiontoMassSpectralMatching 393

A.2.2RelevanceofExternalMassSpectralLibrariesforIdentification 394

A.2.3DetectionandDiscriminationofAnalyteSignals(Spectra)forIdentification 394

A.2.4EvaluationofMassSpectralMatchingResults 395

A.2.5ExamplesofIdentificationbyMassSpectralMatching 395

A.2.5.1Example1:CorrectIdentificationforBestHit(MF > 900);GC/MS 395

A.2.5.2Example2:CorrectIdentificationforBestHit(800 < MF < 900);HS-GC/MS 397

A.2.5.3Example3:IncorrectIdentificationforBestHit(800 < MF < 900);GC/MS 400

A.2.5.4Example4:FalsePositiveIdentificationforBestHit(700 < MF < 800);GC/MS 402

A.2.6ClosingComments 404

A.3IdentificationbyMassSpectralInterpretation 404

A.3.1IntroductiontoMassSpectralInterpretation 404

A.3.2IdentificationoftheMolecularFormula 404

A.3.3InterpretationofIsotopicData 405

A.3.4InterpretationofMassFragments: DeNovo StructuralElucidation 406

A.3.5SecuringPartialIdentities 407

A.4AdditionalEvidencesSupportingHigherLevelIdentifications 407

A.4.1RetentionTime/IndexMatching 407

A.4.2TandemMassSpectrometry 409

A.4.3AdditionalEvidencesfromOrthogonalTechniques 409

A.4.4Derivatization 410

A.4.5IndirectInferences 411

A.4.6TheUseofaDatabasetoCapturetheIdentificationEfforts 412

A.4.7Conclusion 412

A.5FinalThoughts 414 References 414

GlossaryandAbbreviations 415 Index 423

Preface

Iadmitit,IwatchrerunsoftheoriginalStarTraktelevision seriesasawaytounwindfromaharddayatwork.NowI amnotsuchafanaticthatIknowalltheepisodesandthatI immediatelyrecognizedialogueandminorcharacters,but certainthingshavestuckwithme.Pertinenttothisbookis aquotethatisattributedtoScotty,theEnterprise’sirascible ChiefEngineer.NowIcannotremembertheepisodeorthe circumstancesbutinoneoftheseeminglyendlessimpossiblesituationsScottyfindshimselfin,henotes“Foolme once,shameonyou,foolmetwice,shameonme.”

So,whatdoesthishavetodowithmysecondbookon thesubjectofchemicalcharacterization,popularlyknown andmis-representedas“extractableandleachables?”Well, intheprefaceofmyfirstbookonthissubject,Iindicateda certaintrepidationatevenstartingthatproject,recognizing thedifficultyintryingtobringacertaindegreeofordertoa subjectwheretherewaslittleconsensus,imperfectknowledge,andminimalmeaningfulguidance.Intheend,IultimatelydecidedthatwhileIcouldnotbringthesubjectto closure,Icouldmovetheballjustalittleclosertotheendzone.

AsIsuspectedwouldbethecasewhenIwrotethefirst bookandashasbeenverifiedbyongoingandrecentdevelopments,thefieldhaschangeddramaticallyinthedecade sincethepublicationofthatbook.Facilitatedbyboth scientificpublicationandmorecasual“wordofmouth,” many(butnotall)questionsofsciencehavebeenengaged, addressedand,toacertainextent,answered.Basedonthe evolvingunderstandingofgoodsciencepracticallyapplied, experimentalandlaboratorystrategies,tactics,andpracticeshavebeenimprovedsothatbetterinformationis moreroutinelyobtainedinamoreeffective,efficient, andreproduciblemanner.Amultitudeofnewcasestudies haveopenedoureyestonewthreatsandnewopportunities whileatthesametimeputtingsomeoftheoldmonsters backunderthebedwheretheybelong.Throughthehard andlargelythanklessworkofregulators,standardsetting bodies,andprofessionalorganizations(andthevolunteers whoselflesslygiveoftheirtimeandtalent),someprogress hasbeenmadeintermsofconsensus-buildingthatseeksto

findtheproperrisk-basedbalancebetweentheivorytower ofscienceandthepracticalrealitiesofdeveloping,registering,regulating,marketing,andsupportingsafe,effective, andappropriatelyinexpensivepharmaceuticalandmedical productsthatsave,sustain,andimprovelives.Toacertain extent,thisconsensus-buildinghasreachedthepoint whereactionableandappropriatelyconservativeregulations,guidelines,andbestpracticerecommendationshave beendeveloped,published,andexecuted.Unfortunately, intoomanywaysitis“stillthewildwestoutthere.”

So,itistimetogetbackinthesaddleagainandwrite anewtextconsideringtheongoingandever-changingscientificandpracticalendeavorthatwecall“E&L.”Notto throwouttheoldtextsasinvalid,irrelevant,imperfect,and incorrectbutrathertosay“givenwhatweknowtoday,we canimproveonwhatwehadinthepast.”Foolmetwice, indeed!

Mostofthereaderswillbefamiliarwiththephrase“what happensinVegasstaysinVegas,”whichgivespeopleat leasttheimpressionthattheycan“walkabitonthewild side”whilevisitingVegaswithnosignificantconsequence. ThecorrespondingexpressionintheE&Lworldgosomethinglike“Whatstartsintheitemshouldstayintheitem.” Yousee,asIhavenotedpreviously,drugproductsdonot justmagicallyappeartotheuserattimeofuse.Rather,drug productsmustbemanufacturedfromtheirindividualraw materialsandingredients.Oncemanufactured,drugproductsmustbepackagedforprotectionandpreservationduringdistributionandstorage.Attimeofuse,drugproducts mustbeadministeredtotheuser,eitherbytheactionof thestoragecontainerortheactionofadrugadministration device.

Eachoftheseactivities,manufacturing,storage,and delivery,includescontactbetweenthedrugproduct (and/oritsprecursors)andoneormoreitems.Forexample, processsolutionsencountervariousitemsincludingmixing andstoragecontainers,tubing,filters,gaskets,connectors, sensors,etc.,astheyareconvertedintothefinaldrugproduct.Duringstorageanddistribution,thedrugproductisin contactwithcomponentsofitspackagingsystem.During

administration,thedrugproductisincontactwiththat medicaldevicethatservesastheintermediarybetweenthe packagingandthepatient.

Eachcontactdescribedaboveprovidesanopportunity forthedrugproduct(oritsprecursors)andthecontacted itemtochemicallyinteract.If,duringthatinteraction, “whatstartsintheitemstaysintheitem,”thenlifeis good.Thedrugproductisnotalteredbythecontactand everyonegoesawaysafeandhappy.

Unfortunately,drugproductsandtheitemstheycontact arequitedifferentchemicallyandthussomeextentofdrug productalterationwilloccurasaresultofthatcontact.On theonehand,substancesinthecontactitemwillbedriven byaconcentrationgradienttomovefromtheitemandinto thedrugproduct.Inthisway,substancesleachfromthe itemandintothedrugproduct,therebybecomingforeign impuritiesinthedrugproduct.Asforeignimpuritiesin thedrugproduct,thesesubstancesmayhaveanunwanted effectonthedrugproduct,forexamplerenderingitless stable.Alternatively,theforeignimpuritiesmaybetoxic andthustheyrepresentasafetyhazardtodrugproduct users.Inanyevent,characterizationofthedrugproduct forforeignimpurities(leachables)and/orcharacterizationofthecontactitemforpotentialforeignimpurities (extractables)becomesapre-requisiteforestablishingthat adrugproductissuitableforitsintendeduse.

Ofcourse,“foreveryactionthereisanequalandoppositereaction.”Forleaching,thisoppositeactionissorption. Whileleachinginvolvesthemovementofsubstancesfrom anitemandintothedrugproduct,sorptioninvolvesthe movementofsubstancesfromthedrugproductandinto thecontactitem.Asitisrarethatdrugproductsareformulatedwithsuperfluousingredients,lossofaningredientcan haveasignificantadverseeffectondrugproductpotency, efficacy,and/orstability.

However,sorptionisatopicforanotherauthorand anotherbook.Inthisbookwewillfocusstrictlyonthose interactionsthataddsubstancestothedrugproducts and/ortheirprecursors.Whenonetestsitemstoestablish “whatcouldcomeout,”oneisperforminganextractables orextractionstudy.Whenoneteststhedrugproduct(or precursorsolution)forforeignimpuritiesderivedfromthe items,oneisperformingaleachablesorleachingstudy. Generally,throughacombinationofbothextractablesand leachablestesting,oneproducesthedatasetwithwhich theimpactoftheinteractiononthepatient,thedrug product,andtheitemcanbeassessed.

Asimilardiscussioncanbeheldforamedicaldevice, wherechemicalspresentinthedevicecanleachoutinto thatmediumbywhichthedevicedirectlyorindirectly interacts(or“communicates”)withthedevice’suser.

Previousworksinthisfieldhavefocusedonprovidinganswerstotwoimportantquestions:“Whathasto bedone?”and“Whendoesithavetobedone?”While providingupdatedanswerstothesequestionsisstillan importantobjectiveofthisbook,wewillalsoconsiderand addresstwoadditionalpoints:“Howdowedowhatwe needtodo?”and“Whydowedoitthatway?”Although afifthquestionisrelevant,specifically,“Wheredoeswhat needstobedonegetdone?”ispertinent,thisquestionwill notbeaddressedtoanygreatextentasitsanswerislargely anindividualorganization’sprerogative.

Afewwordsabouttheconstructionofthisbookare appropriate.Actually,thehardestpartaboutwritingthis bookisnotcollectingthecontentsbutratherorganizing theconceptsandcontentsinalogicalandappropriate manner.Itischallengingtoconstructatextthatstarts fromthebeginning,establishingessentialconceptsand principles,andthentakesthesebasicbuildingblocksand turnsthemintoafinishedstructure.Nevertheless,the bookisroughlyconstructedinthismanner,startingwith conceptsandendingwithtactics,strategies,andprocesses.

Chapter1servesastheintroductiontotheissueof chemicalcompatibility.InadditiontoprovidingaProblem Statement,Chapter1speakstotheevolutionofchemical assessmentasanareaofinterest,asascientificdiscipline,andasaregulatory“topicofinterest.”Chapter1 willdelineatethosesignificantissuesfacingthevarious stakeholdersinvolvedwithdesigning,implementing, interpreting,reporting,andreviewingchemicalcharacterizations,settingthestagefortheanswersthatwillbe providedintheensuingChapters.

Chapters2through4aretheplaceswhereweestablish thebuildingblocksuponwhichchemicalcharacterization willbebuilt.AsIamconvincedthatoneofthedifficulties inaddressingchemicalcharacterizationisasloppyuse ofanevolvingbutdisjointednomenclature,definitions, derivedfromandconsistentwithemergingstandards,will beprovidedforallrelevanttermsandconcepts.Extraction andleachingstudieswillbedescribedanddiscussed, intermsofbothbasicscientificprinciplesandpractical applications.Bothtypesofstudieswillbediscussedin termsoftheirtwoessentialaspects,generatingthetest article(Chapter2)andperformingtheactualchemical testing(Chapters3and4).Conceptsimportantfororganic compounds,suchasscreeningversustargeting,“howlow doyougo?”(theAET),identification,quantitation,and qualification(validation),areaddressedinChapter3.The importanceanduseofextractables–leachablescorrelationswillalsobediscussedandexamplesofthevarious levelsofcorrelationwillbeprovided.Extractedelements, anions,andgeneralchemicaltestingarealladdressed inChapter4.

Thepremiseofmypreviousbookwasthatthereisa logical,effective,andefficientprocessperformingthe variousactivitiesinvolvedinchemicalcharacterizations andthebookwasconstructedonthebasisofthatprocess. Chapters5and6buildonthatpremisebyfocusingonthe fourmajorstagesofaproduct’slifecycle,development, optimization,registration,andlifecycle(postapproval) management.Activitiesandactionsthatarerelevantto andappropriateforeachstageintheproduct’slifecycle aredelineatedanditwillbeestablishedanddemonstrated thatchemicalcharacterizationisnotaseriesoflargely unrelatedtasksbutratheralogicalsequenceoftasks,each oneservinganecessaryandspecificpurpose,mostappropriatelyperformedataspecifictimeintheprocess.Specific attentionwillbegiventothetopicofmanagingchange controlonceadrugproductanditsrelateditemshave beenapprovedforandimplementedinthecommercial marketplace(Chapter6).

Theconceptandrealityofchemicalassessmentare relevantandappropriateforthreemajorclassesofpharmaceuticalcontactitems,pharmaceuticalpackaging, componentsusedinthemanufacturingofpharmaceuticals,andmedicaldevices,particularlythoseusedtodeliver apharmaceuticalproducttothepatient.Whilethesethree classesofitemssharecommonmaterialsofconstruction andmayhaveasimilarlifecycleintermsofdevelopment, optimization,registration,andmaintenance,thesimple factremainsthatapharmaceuticalpackagingsystemis notthesameasapharmaceuticalmanufacturingcomponent,whichinturnisnotthesameasamedicaldevice. Althoughoftentimestheyareconstructedfromsimilar materialclasses(forexample,polyethylene),compositionalsimilarityisnotalwaysthecaseand,furthermore, theycandiffergreatlyinconfiguration,theydodiffer greatlyintermsofprocessing,andtheirconditionsofuse varywidely.Thus,itislogical,appropriate,andnecessary thattheprocessofchemicalconsiderationdiffers,packagingversusmanufacturingcomponentsversusmedical devices.Therefore,Chapters7through9onApplications considereachoftheseitemsseparately,startingwitha reviewoftheemergingregulatorylandscape,considering particularlyrecentdevelopmentsincompendialmonographsandinternationalstandards.Characteristicsthat differentiatethevariousitemsarediscussed,specifically inthecontentofhowthedifferencestranslateintodifferentchemicalcharacterizationstrategiesandtactics. Theconceptofa“risk-basedapproach,”meaningthatthe amountandtypeofchemicalcharacterizationsshould dependontheriskthataparticularitemcouldhavean adverseeffect,isintroducedandappliedtoeachitemclass, resultinginariskclassificationofitemswithineachclass. Forexample,theprocessforclassifyingmanufacturing

componentsintermsofthechemicalrisktheyrepresent willbedescribedandthenatureandextentofchemical characterizationrequiredineachriskcategorywillbe established.Lastly,chemicalcharacterizationstrategiesfor eachclassofpharmaceuticalitemswillbeillustratedin selectedcasestudies.

Tothatpoint,thebookwillhaveconsideredonlyone aspectofchemicalassessment,thegatheringandgenerationofchemicalinformation.Althoughinformation gatheringandgenerationisthefoundationofchemical assessment,byitselfitisameanswithoutanend,an activitywithoutanimpact.Ultimatelyandappropriately, informationgatheringandgenerationservesthesole purposeofenablinginformationinterpretation.Forpharmaceuticalitems,thekeyconceptthatmustbeinterpreted isimpact;thatis,whatimpactwillthechemicalsthathave beenidentifiedandquantifiedduringthetestingcomponentofchemicalcharacterizationhaveonakeyquality attributeoftheitemsundergoingcontact?Forpackagingas anexample,whatimpactwillleachableshaveonthesafety, efficacy,stability,purity,andcompendialcomplianceofthe packageddrugproduct?Furthermore,whatimpactwill leachinghaveonthepackagingsystem’sabilitytoperform itsessentialfunctionofcontainment,preservation,and protection?Establishingtheimpactofleachingonboththe sourceitemoftheleachablesaswellastheitemreceiving theleachablesistermedriskassessment.Chapter10providesanoverviewofriskassessment.Firstandforemost, theChapterconsiderstheadverseimpactthatleachables canhaveonthehealthandsafetyofthepatientwhois exposedtotheleachablesasaresultofamedicaltherapy. Thegeneralconceptsandprinciplesoftoxicologicalsafety riskassessmentareconsideredataveryhighleveland themeansoftoxicologicallyassessingextractablesand leachablesarediscussed.Thechallengesassociatedwith toxicologicallyassessingincompletelyidentifiedextractablesorleachablesareconsideredandtheuseofauxiliary information(suchascompendialcompliance)intoxicologicalriskassessmentisaddressed.Biologicalsafety riskassessment,whichistheprocessofperformingand interpretingbiologicaltestingtoaddresssafetyimpact,is consideredasanalternatetochemicalcharacterization andthecomplementarynatureofchemicalandbiological testingisestablished.

Althoughitisappropriateforpatientsafetytobeof paramountconcern,thedirectandadverseimpactof leachablesonhealthisnottheonlyconcernapatient couldhaveaboutleachables.Forexample,ifaleachable reactswiththedrugproduct’sactiveingredient,drugproductefficacy,andthereforethepositivetherapeuticbenefit, canbelessened.Furthermore,interactionsbetweena leachableandadrugproductingredientcanshortenthe

shelf-lifebyanumberofmeans,increasingthecostofdrug products.Additionally,theproductsofareactionbetween aleachableandthedrugsubstancemayhaveadversesafety consequences.

Moreover,someleachablesimpactitemsotherthan thedrugproductitself.Forexample,leachingofsilicone oilfromthebarrelofapre-filledsyringecanmakeit moredifficulttomovethesyringe’splunger,preventing thesyringefromperformingitsdrugdeliveryfunction. Additionally,process-relatedleachablesfrommanufacturingcomponentscanadverselyimpacttheefficiency ofupstreammanufacturingsteps.Thus,Chapter10also considerstheriskassessmentofleachableswithrespectto productqualityattributesotherthansafety.

Lastly,theriseofbiopharmaceuticalshasputaspotlight oneffectsofleachablesotherthandirecttoxicity.Because oftheirchemicalnature,biologicaldrugsubstancesare muchmorelikelytochemicallyandphysicallyinteract withleachablesthanaretheirmoretraditional“small molecule”drugsubstancecounterparts,anditismore likelythatsuchaninteractionwouldhaveameaningful effectonthekeyqualityattributesofthebiopharmaceuticaldrugproducts.Thus,Chapter10includesadiscussion ofthespecialcaseofbiopharmaceuticals.

Istartedthisprefacewiththeobservationthatmuchhas happenedinthechemicalcharacterizationworldinthelast 10yearsorso.Itisshortsightedtothinkthattheevolution inthescienceandpracticeofchemicalcharacterizationis overoreventhattherateofevolutionhasslowed.Thus,I spendtimeinChapter11describingandadvocatingforthe “futureofE&L.”Firstandforemost,theChapteradvocates forbetterscience.Inthisvein,itaddressesinherent“errors” thatareapartofgenerallyestablishedchemicalcharacterizationpractices,suchasidentificationandquantitation, andadvocatesforameansofreducingthefrequencyof occurrenceandthemagnitudeofsucherrors.Additionally, Iconsiderhowbettersciencecanresultinbetter(more consistent,reproducible,andrelevant)extractions.Lastly, Iadvocateforthemorepervasiveuseofsoundscientific principles(asopposedtohighlygeneralizedandfrequently incorrect“rulesofthumb”orpocketsof“commonknowledge)todesignandjustifychemicalcharacterization studies.

TheChapterthenmovesontothepracticalrealityof the“siloapproach”thatisthecurrentbusinessmodelfor chemicalcharacterization.Generallyspeaking,the“silo approach”recognizesthefactthatchemicalcharacterizationisadisjointedandinsulatedactivity.Itisdisjointed astherearefewstandardmethods,bothintermsofhow extractionsareperformedandhowextracts(anddrug products)aretested.Thus,itispossiblefortwocompanies

tousethesameiteminthesamemannerbuttosupport theitemwithchemicalcharacterizationsthatdifferin tacticsandthusdifferinoutcomes.Itisinsulatedbecause eachcompanyisresponsiblefortheregistrationofitsown productsandbecauseeachcompanytreatsitschemical characterizationaspartofitsintellectualproperty.Insuch anenvironmentwherethereislittleinformationsharing, oneimaginesthatredundant(andthereforeunnecessary) testingistheruleratherthantheexception.Thus,Iadvocateforinformationsharingasthemeansofreducing redundantandunnecessarytestingandconsidermeansby whichsuchinformationgatheringcanbeaccomplished.

GivenfutureadvancesinscienceandpracticeandprojectingthatsomeoftheitemsIhaveadvocatedforcometo fruition,thenthetheoryandpracticeofchemicalcharacterizationasitispracticedtomorrowwillbearlittleresemblancetowhatweknowittoday.Chapter11closeswith thepredictionof“theendofE&L”andadescriptionofa collaborativeenvironmentwheretheapplicationofsound science,temperedwithpracticalrealitiesandtheproper balanceofriskandreward,hasledachemicalcharacterizationprocessthatisconsistent,credible,efficient,effective, andreliable.

Thelastsectioncontainsanabbreviationskeyandaglossaryofthecriticaltermsusedthroughoutthebook.

IfyouwatchStarTrakre-runslikeIdo,thenyouhave invariablyseenthosecommercialsthatgo“Butwait,there’s more.”Sojustwhenwethinkthatthebookhasreached itslogicalending,thereisthis“butwait,thereismore!” Herethe“more”isanAppendix,devotedtoadiscussion ofgoodidentificationpracticesfororganicextractablesand leachables.HereIconsiderthevariouscategoriesofidentification,definethecategoriesintermsoftheamountand numberof“dimensions”ofcorroboratingdataanddescribe themeansbywhichidentitiesare“elevated”tohigherconfidencecategories.Identificationpracticessuchasspectral matchingandstructureelucidationarediscussedandillustratedbyexamples.Moreover,theuseandapplicationof “additionalevidences”tosupportandsecurehighconfidenceidentitiesarediscussed.

Inoteinclosingthatthereadermayfindthetextto beredundanttoacertainpoint.Thereasonforthisis thatIwantconceptsandsuchtobeunderstoodnotonly conceptuallybutalsoincontext.Thus,conceptsthatare relevantinseveralcontexts(forexample,theAET)are repeatedlyaddressedinthosemultiplesituationsandin multiplechapters.Ipersonallyfinditfrustratingtorun acrossaconceptinatextandthentohavetogoandsearch foritsdefinitionandexplanationsomewhereelse.Thus, Ihavechosentoberedundantandapologizeup-frontto thosewhofinditexcessive.

Acknowledgments

Ihopeyoufindthisbooktobeuseful,well-designed, logicallyorganized,understandable,andeffective.Those whoknowmeandmyworkwellwillunderstandthatI couldnotproducesuchabookwithoutconsiderablehelp. IthankArunaPragasam,JonathonRose,andtheentire editorialstaffatJohnWiley&SonsInc.,notonlyforthe considerableimprovementstheyhavemadetothisbook butalsofortheirhelpandencouragementthroughoutthis process.WithoutJonathon’sgentlepersistence,itislikely thebookwouldhavenevergonepasteventheconcept phase.

Theexpressionthat“anarmytravelsonitsstomach” hasbeenattributedtonolessorindividualsthanNapoleon Bonaparte,FredericktheGreatofPrussia,andClaudius Galen,chiefphysiciantotheRomanarmy.Andyet, betweenyouandme,itisrarethatthecooksaretheones thatgetthemedalsandthepromotions.

Thereisasimilarconceptinsciencethatstates“science advancesonthebacksoftheindividualscientists.”Science advancesonlywhenindividualscientistsacceptthechallenge,responsibility,andburdenofthescientificendeavor andshouldertheirobligationto“thegreatergood”bysharingtheoutcomeoftheirefforts,regardlessofmotivation andbenefit.Thepharmaceuticalindustry’sabilitytohave apositiveimpactonthehumanconditionshasprogressed, insomesmallbutdiscernibleway,duetoadvancesin thetheoryandpracticeofchemicalcharacterizationand theseadvanceshavebeenhardwonbythosescientists, academic,industry,andregulatory,whohaveacceptedthe challengeandembracedtheirresponsibility.Althoughit isasmallrewardindeed,thesescientistshavemyutmost respectandadmirationandmysincereandheart-felt thanks.WhileIamtemptedtomentionindividualsby name,IfearthatImightinadvertentlyleavesomeoneout, andinsodoingdamagethecommitmentanddedication thatIamtryingtosupport.Youknowwhoyouareand youandIbothknowwhatitisthatyouhavesacrificedand accomplished.

Likewise,Iofferaspecialthankstothosewhotakeupthe challengeofapplyingtheirgoodjudgmentandtechnical expertisetoconverttheoryintopractice,tobuildconsensusfromchaos,andtofindthecommongoodamong individualself-interest,forthepurposeofestablishing standards,creatingregulatoryguidance,anddeveloping bestdemonstratedpracticesforchemicalcharacterization. Thetaskisdifficult,theexpectationsareunattainable,the requiredeffortissubstantial,andthepersonalrewardsare minimal.Despitethesechallenges,youhavepersevered andelevatedthestandardofregulatorypracticetothepoint thatitenables,asopposedtoretards,thedevelopment, commercialization,andclinicalapplicationofsafeand effectivepharmaceuticalandmedicalproducts.

Ihavebeenblessedtohaveworkedwithfriendsand colleagueswhohavebeenaconstantsourceofsupport, encouragement,insight,knowledge,andinspiration. Whenyoufindthegoodthatisinthisbook,Iamsureyou willseereflectionsofyourselfandyourcontributions.It hasbeenmygoodfortunetobeassociatedwithorganizationssuchasBaxterHealthcareandNelsonLabs,which haveprovidedmewiththesupport,bothtangibleand intangible,thathasmadeitpossibletotakethejourney thatIcallmyE&Lexperience.

Thejobisnotdoneandyetmylegoftheraceisjustabout over.Withhighhopesandgreatexpectations,Ihandthe batonovertothe“nextgeneration”ofpractitionerswho willcontinueto“runthehardrace”and“fightthegood fight”untilitcantrulybesaidthatchemicalassessment isastrongenablerofthedevelopment,qualification,and commercializationofpharmaceuticalandmedicalproductsthatsaveandsustainlives.IwishyouGodspeedand goodluckinthisendeavor.

DennisR.Jenke ChiefExecutiveScientist TriadScientificSolutions,LLC

IntroductionandEssentialConcepts

1.1GeneralDiscussion

Materialssuchasplastics,elastomers,glasses,andmetals arewidelyusedinmedicalandpharmaceuticalitems suchascontainers,packagingsystems,sets,transferand transportsystems,manufacturingsystems/equipment, andmedicaldevices.Thephysicalandchemicalnature ofthesematerialsprovidesmedicalandpharmaceutical productswiththeirnecessaryanddesirableperformance characteristics.Anumberofmedicalproductsinvolve items,constructedinwholeorinpartfrommaterials, whoseprimarypurposeisthegeneration,production,protection,transport,storage,delivery,and/oradministration oftherapeuticproductsthatareusedeitherdirectlyor indirectlybypatientstoproduceadesirabletherapeutic outcome.Additionally,suchitemsmaybeusedforthe samepurposeswithprecursorsofthetherapeuticproduct,suchasmanufacturingprocessstreams.Lastly,such itemsthemselvesmayprovidethetherapeuticbenefit(e.g. medicaldevices).

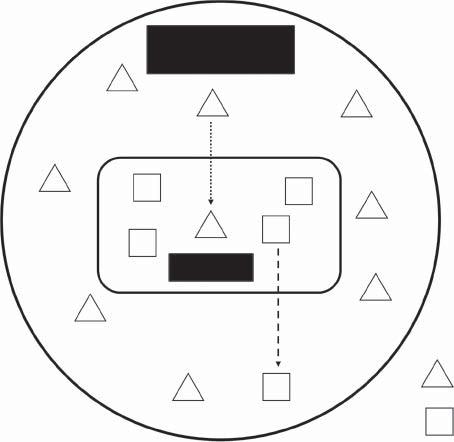

Whileanimportantperformancecharacteristicofmaterialsusedinmedicalandpharmaceuticalapplications ischemicalinertness,itisanunfortunaterealitythata completelyinertmaterialhasyettobedeveloped.Wheneveramaterialisputintocontactwithanotherentitythat ischemicallydifferentthanthematerial,aninteraction mustoccurbetweenthematerialandthecontactingentity. Thus,interactionsbetweenamaterialandthepharmaceuticalproductitcontactsarewelldocumented.These interactionsinvolvethetransferofsubstancesbetweenthe materialandthepharmaceuticalproductandincludesorption(binding),thetransferofproductcomponents(such astheactiveingredient)intothematerial,orleaching,the transferofmaterialcomponents(suchasplasticadditives) intothepharmaceuticalproduct(Figure1.1).

Throughoutthistext,Iwillrefertothetwoitemsthat comeintocontactasamaterialandapharmaceuticalproduct.Iusethesetermstoavoidtheawkwardnessoftermslike “item1anditem2”or“constructandtherapeuticproduct.” Ipointoutthattheirintentistobecompletelygenericand

toavoidexclusion.Thus,forexample,theterms“material” and“pharmaceuticalproduct”aremeanttocapturethose contactsituationswhichcanoccurbetweenadrugproduct anditspackaging,betweenamedicaldeviceandthebody fluidorpartitcontacts,andbetweenamanufacturingcomponentandamanufacturingprocesssolution.

Ifthetransferofsubstancesbetweenthematerialand thepharmaceuticalproductweremerelyofacademic interestthentherewouldbelittlepracticalneedtostudy andquantifythesetransferprocessesandestablishtheir effects.However,boththematerialandthepharmaceutical productwereformulatedsothateachandeveryingredient ineitherthematerialortheproductperformsanessential function.Ifingredientsarelostfromanitembytransfer,it islogicaltoassumethatthelosswouldhaveanundesirable effectontheitem’sabilitytoperformitsintendedfunction. Thus,forexample,ingredientsinthepharmaceuticaldrug productprovideeitherthetherapeuticbenefit(theactive substance),stabilizetheproduct(pHbuffers,solubilizing agents,metalchelatingagents)orproduceacosmetic effect(flavors,dyes,etc.).Lossoftheseingredientscould seriouslyaffectthepharmaceuticalproduct’spotency,efficacy,compositionalcompliance,andstability.Inasimilar way,ingredientsarepresentinmaterialstoperforma specificfunctionwithinthematerial.Forexample,materialadditivesprovidethematerialwithdesirablephysical properties(e.g.plasticizersandfillers),promotethematerial’sstability(e.g.antioxidants,acidscavengers),give thematerialscertaindesirableproperties(e.g.colorants, flameretardants,antimicrobialagents),andimprovethe material’sprocessing(e.g.anti-staticagents,slipagents). Lossoftheseingredientscouldalterthematerial’sstability, processability,integrity,and/orfunctionality.

Furthermore,additionofunintentionalsubstances(foreignimpurities)toeitherapharmaceuticalproductora materialcouldadverselyaffectakeyqualityattributeofthe itemand/ortheitem’ssuitabilityforintendeduse.Addition ofanunintentionalsubstance(foreignimpurity)toapharmaceuticalproductamountstoadulterationofthatproduct andtheeffectofthatadulterationmustbeascertained.For ExtractablesandLeachables:CharacterizationofDrugProducts,Packaging,ManufacturingandDeliverySystems,andMedicalDevices, FirstEdition.DennisJenke. ©2022JohnWiley&Sons,Inc.Published2022byJohnWiley&Sons,Inc.

example,additionofunintentionalreactivesubstancesto pharmaceuticalproducts(foreignimpurities)couldalter theproducts’stability(reducedshelf-life),efficacy(active ingredientdegradationorinactivation),andphysical acceptability(e.g.precipitation,discoloration,flavoring). Moreover,theforeignimpuritymaybeinherentlytoxic, andthuspossessesthepotentialtoadverselyaffectpatient healthandsafety(directsafetyimpact).Furthermore, interactionsbetweenareactiveforeignimpurityanda product’sactiveingredientcouldproducesubstancesthat themselveshaveanadverseeffectonpatienthealthand safety(forexample,drugsubstance/leachedsubstances reactionproductsactingasadjuvants,therebytriggering animmuneresponse).

Althoughsorptionofpharmaceuticalproductingredientsbyamaterialcouldconceivablyhaveaneffecton thematerial’sabilitytoperformitsintendedfunction, examplesofthisphenomenonhavebeenrarelydocumentedanditislikelythattheyarequiteuncommon. However,adulterationofamaterialwithpharmaceutical productingredientscertainlyimpactsthesuitabilityofthe materialforreuse.Onceamaterialisadulteratedwitha pharmaceuticalproductingredient,itbecomesapotential sourceofthatingredientshouldthematerialbeusedagain. Thus,forexample,anadulteratedmaterialthatisreused withasecondpharmaceuticalproductcanbethemeansby whichpharmaceuticalproductsarecross-contaminated.

Aswasnotedpreviously,iftheinteractionsofsorption andleachingweresufficientlysmallthattheireffects wereminorandinconsequential,thentheneedtostudy, quantify,andimpactassesstheseprocesseswouldbe purelyacademic.However,instanceswheresorptionand leachinghaveresultedinseriousandimpactfuleffects

Figure1.1 Interactionsbetweenamaterialanda pharmaceuticalproduct.Suchinteractionsinclude leaching,thetransferofmaterial-related componentstothepharmaceuticalproductand sorption,thetransferofpharmaceuticalproduct ingredientstothematerial.Bothprocessesimpact thematerial’sandthepharmaceuticalproduct’s keyqualityattributesandabilitytoperformtheir intendedfunction(suitabilityforintendeduse).

arewell-documented.Consideringleachingspecifically, anoften-citedcaseinvolvedtheleachingofavulcanizing agentfromuncoatedstoppersusedinpre-filledsyringes, whichhasbeenproposedasamechanismcontributingto adverseclinicaleventsassociatedwithEPREX® [1].Precipitationofphosphatesaltsinphosphate-buffereddrug solutionsduetotheleachingofdivalentcations(e.g.Ca+2 , Zn+2 )fromrubberstoppersiswell-documented[2].Other examplesofleachablesexertinganundesirableinfluence ontherapeuticbiologicproteinproductsinclude[3]:

• Leachingofadivalentmetalcationfromavial’s rubberstopper,whichactivatedametalloprotease process-relatedimpurityinthedrugproductcausing N-terminaldegradationofthedrugsubstance,

• Leachingofanorganicsolventfromthepartiallydried epoxyglueusedtocementaneedletoasyringebarrel, whichcausedanincreaseinproteinoxidationfollowed byaggregationviadisulfideswitching,

• Leachingofresidualaluminumoxidefromaglass vial,whichprecipitatedasaluminumphosphateinthe phosphate-buffereddrugproduct.

Leachingoftungstenfromthebarrelsofsyringeshasbeen linkedtoaggregationofproteinsinbiopharmaceutical drugproductsbynumerousauthors[4,5],whileacrylic acid,leachedfromtheacrylicadhesiveusedtobonda syringeneedletoitsglassbarrel,hasbeendemonstrated tointeractwiththerapeuticproteins,modifyingtheir structureandsurfacechargedistribution[6].Anotherdocumentedcaseofleachablesadverselyaffectingthestability ofprotein-basedbiopharmaceuticalproductsinvolved theabilityofleachablesassociatedwithrubberstoppers tofacilitatetheformationofsolubleandinsolublehigh molecularweightaggregatesofmodelproteinsincluding

IgGandEPO[7].Asalastexample,extractablesfrom sterilizingfiltersusedinbiopharmaceuticalmanufacturingwerefoundtobedestabilizing,causingincreasesin (protein)aggregation,oxidation,andacidicspecies[8].

Casesofadverseeffectsofleachablesarenotlimited todrugproductsandtheirassociatedcontainerclosure systems.Forexample,anantioxidant-relatedleachable associatedwithsingle-usebioprocesscontainershasbeen demonstratedtoreducecellgrowthrate,andthusdrug substanceyields,duringcellculture[9].Aleachablefrom polycarbonateshakerflaskshasbeenshowntoinhibitthe growthofCHOcells,interferingwithbiologicaltesting results[10].Asimilarabilityofpolypropylene-related leachablesfrommicroplatestoadverselyaffecttheresults ofbiologicaltestresultshasbeenreported[11].

Theserecentexamplesaugmentalonghistoryof instanceswherethesafetyorefficacyofapharmaceuticalproducthasbeencompromisedbyitsinteraction withanitemassociatedwithitsmanufacturing,storage/distribution,andadministration.

Althoughthepreviouscitationshaveestablishedthe adverseeffectofleachables,itisinterestingtonotethat positiveeffectshavealsobeenascribedtoleachables. Theabilityofdi-(2-ethylhexyl)phthalate(DEHP)leached fromplasticizedpolyvinylchloride(PVC)storagebagsto stabilizestoredbloodandincreaseitsstorageshelf-lifeis well-documented[12–14].Diphenylguanidine,leached fromrubberclosures,hasbeenestablishedtoimprove thestabilityofanoxytocindrugproductformulatedin anacetate-bufferedsolutionbybindingwiththepeptide andsuppressingintermoleculardegradationreactions involvingoxytocin’sdisulfidebond[15].

Thus,contactbetweenamaterialandpharmaceutical product(oritsrelatedprecursors)isanopportunityforthat materialorproducttobealteredasaresultofthatcontact. Thepurposeofa compatibilityassessment istoassess themagnitudeandimpact,ifany,ofsuchaninteraction anditsassociatedalteration.Thus,thefollowingdefinition isoffered:

Compatibilityassessment. Thisistheprocessbywhich theinteractionbetweentwocontactingitems(forexample, amaterialandapharmaceuticalproduct)isinvestigated, quantified,andassessedforimpact.

Logically,then,a chemicalcompatibilityassessment isacompatibilityassessmentthatfocusesonthechemical interactionthatoccursbetweentwoitemsincontact.

Byconvention,ifthedegreeofalterationissmalland hasnomeaningfuladverseeffect,thenitisconcludedthat thematerialandthepharmaceuticalproductarecompatible.Toestablishifthereisthepotentialforameaningful

adverseeffect,acompletecompatibilityassessmentconsidersnumerouspotentialoutcomesofthematerial/product interaction,asillustratedinFigure1.2.Inthemostgeneralsense,specificaspectsofacompatibilityassessment addresseithertheissuesofapharmaceuticalproduct’sefficacy(doestheproductperforminamannerconsistentwith itslabelingandindicationandthusprovidetheexpected therapeuticoutcome),stability(doesthepharmaceutical productprovidetheexpectedtherapeuticoutcomeand/or remainwithincompositionalspecificationsoveritslabeled shelf-life),compositionalcompliance(doesitscomposition complywithcompositionalspecificationsincludinglabelingandrelevantcompendialmonographs),orsafety(does theproductproduceanunanticipatedandadversepatient response).Consideringefficacy,whilesorption(lossof ingredientfromthedrugproductduetotheingredient’s uptakebythematerial)isthemosttypicallydocumented efficacy-impactinginteraction,leachinginteractionsand effectsarepossibleandsignificant.Forexample,aleachableandthedrugsubstanceinthepharmaceuticalproduct couldinteractchemically,resultingintheingredient’s decompositionand/orinactivation,therebyreducingits potencyandefficacy.Alternatively,theleachablemayaffect somechemicalpropertyofthepharmaceuticalproductto theextentthatthedrugsubstancebecomesdestabilized. Forexample,anacidicleachablecouldlowerthepHofan unbufferedaqueouspharmaceuticalproducttoanextent sufficientthattherateofacidhydrolysisofthedrugproduct isincreased.Itisnotedthatefficacydoesnotsolelyreflecta substance’sabilitytodeliveritsspecifiedtherapeuticdose. Iftheactiveingredientisdeactivated,thensurelyadrug product’sefficacyhasbeencompromised.

Toacertainextent,theaspectsofefficacy,stability,and compositionalcompliancearerelated.Aspotencyofthe pharmaceuticalproductisastability-indicatingattribute, anyinteractionthataffectsefficacyalsoaffectsstability.However,efficacy(potency)isnottheonlystabilityindicatingattributeofadrugproduct,andthusleaching canaffectproductstabilitybyothermeans.Forexample, aleachablemayimpactachemicalpropertyofthepharmaceuticalproduct(suchaspH)whosechangeincreases therateofdrugsubstancedegradation,therebyreducing shelf-life.Alternatively,aleachablemayreactwithastabilizingagentinthepharmaceuticalproduct,limitingthe agent’sstabilizingabilityandshorteningshelf-life.Lastly, ascompositionalcomplianceisastability-indicating productattribute(thatis,aproductmustcomplywith compositionalspecifications,suchasthoseappearingin relevantcompendialmonographsoveritsentireshelf-life), anyleachablethataffectscompositionaland/orcompendialcomplianceisalsoaleachableeffectthatimpacts stability(shelf-life).Forexample,theaccumulationof

coloredleachablesmayaffectproductstabilitybycausing compendialappearanceandcolorspecificationlimitstobe exceededearlierthanwouldbethecaseintheabsenceof leaching.

Theaspectofcompendialcompliancehasbeenlargely addressedinthepreviousdiscussion.Sincethelevelofthe drugsubstanceandlimitsonimpuritylevelsaretypically specifiedinapharmaceuticalproduct’scompendialmonograph,accelerateddegradationaffectstheaspectofcompendialcomplianceinthesamewaythatitaffectsefficacy andstability.Ascompendialmonographstypicallycontain specificationsforgeneralproductattributes,suchaspH, UVabsorbance,andlevelofparticulatematter,aleachable effectontheseattributescanbecomeanissueofcompendialcompliance.

ThefinalaspectlistedinFigure1.2ispatientsafety. Whenapatienteitherreceivesapharmaceuticalproduct orusesamedicaldeviceaspartofaclinicaltherapy,the patientisexposedtoleachablespresentinthepharmaceuticalproductorleachablesleachedfromthemedical deviceduringitsuse.Iftheleachableistoxic,thenpatient health(safety)maybedirectlyandadverselyaffected,with themagnitudeoftheadverseeffectbeingproportionalto themagnitudeofexposure(amountoftheleachableto whichthepatientisexposed),thefrequencyofexposure, therouteofexposure,andtheinherenttoxicityriskposed byaspecificleachable.

Additionally,aleachablemayproduceanadversehealth effectindirectly,meaningthatitisnottheleachableitself

thatisthesafetyhazardbutrathereitherapharmaceuticalproductingredientthathasbeenalteredviaachemical interactionwiththeleachablesothatitisnowtoxicora toxicdegradationproductthatisformedviathechemical interactionoftheleachableandapharmaceuticalproduct ingredient.

Lastly,itisalsonotedthattheaccumulationofleachables inapharmaceuticalproductcanhaveramificationsoutsideofthecontextofthepharmaceuticalproduct’sperformanceandkeyqualityattributes.Forexample,leachables cancomplicatethechemicalanalysisoftheproductbyproducinganalyticalresponses(forexample,chromatographic peaks)thateitherdirectlyinterferewithtargetedanalyte quantitationorindirectlycomplicatetheinterpretationof theanalyticalinformation.

Thepreviousdiscussionestablishesthosedrugproduct aspectsthatareincludedinthecompatibilityassessment butdonotaddresstheprocessofperformingthecompatibilityassessment.Clearly,compatibilityassessment consistsoftwodistinctparts:informationcollectionand informationinterpretation(seeFigure1.3).Thecollected informationmayincludeexistinginformationthatis gathered(forexample,acertificateofcompendialcompliance)ornewinformationthatisgenerated(forexample, datafromanextractionstudy).Processesandtechniques forinformationinterpretationvarydependingonthe effectbeingconsidered;however,generallyspeaking,the interpretationiseitherdirectorindirect.Forexample,a drugproductstabilitystudyperformedintheproduct’s

Leachable affects, product property (e.g., pH), increasing degradation, thereby reducing drug levels and shortening shelf-life Sorption of drug substance or ingredients causes levels to be below specification limits Typically little to no effect Sorption of stabilizing ingredients causes accelerated and/or increased level of degradation

reacts, directly or indirectly, with drug substance, causing drug substance levels to decrease due to degradation and shortening shelf-life Leachable reacts with stabilizing ingredient, causing ingredient to be less effective and shortening shelf-life Leachable causes drug product properties to fall outside of specification limits (e.g., pH, color, particulates) Leachable degradation of drug substance causes level to be below specification limits Leachable degradation of drug substance causes degradate levels to exceed specification limits Leachable itself is toxic (direct effect) Reaction product between the leachable and the drug substance is toxic (indirect effect)

Figure1.2 Dimensionsofcompatibilityassessment.Thecompletecompatibilityassessmentincludestheaspectsofefficacy,stability, compendialcompliance,andsafety,allofwhichcanbeinfluencedbyeithersorptionorleaching.

1.2Regulations,Guidelines,Standards,andRecommendationsforChemicalCompatibilityAssessments

Figure1.3 Thechemicalcompatibilityassessment process.Collectedinformation,obtainedbyeither gatheringorgeneration(orboth),isinterpretedto establishitseffectonkeyproductquality attributes,consideringbothinteractingentities (drugproductandmaterial).

marketedpackagingsystemwilldirectlyestablishtheeffect ofleachablesonproductstability.However,aleachable’s probableeffectonpatientsafetyisinferred,indirectly,by theprocessoftoxicologicalsafetyriskassessment.

Inanycircumstance,theprocessesofinformationcollectionandinformationinterpretationarediscussedingreater detailelsewhereinthebook(forexample,Chapters2and3 forinformationgenerationandChapter10forinformation interpretation).

1.2Regulations,Guidelines,Standards, andRecommendationsforChemical CompatibilityAssessments

Thegenerationofsafeandeffectivepharmaceuticalproductsandmedicaldevicesisanobligationforcompanies thatparticipateinthepharmaceuticalandmedicalmarketplaces.Nevertheless,itisonethingforacompanyto acknowledgethat“wemustgenerateasafeandeffective product”andanotherthingaltogetherforthatcompanyto understandtheprocessbywhichaproductisdemonstrated tobesafeandeffective.Consideringsafetyspecifically,itis onethingtosaythat“ourproductmeetsourowninternally developedstandardsforsafety”andanotherthingaltogethertohavetheproductdeclaredtobesafebasedonan independent,scientificallyrigorousandunbiasedregulatoryanalysisofthesafetyassessmentprocessandoutcome. Chemicalcompatibilityassessmentisacomplexand challengingendeavor.Thesinglereasonthisbookand manyothersimilarresourcesexististoaddressandsimplifythiscomplexityandreducethechallenge.Theaspect thatmakeschemicalcompatibilityassessmentsochallengingisnotamatterofcompaniesrecognizingandaccepting theirobligationtoperformanassessment.Rather,the challengesassociatedwithchemicalsafetyassessmentlie inthedifficultyinestablishingwhatrepresentsanefficient andeffective(andthereforeacceptable)assessmenttoall therelevantstakeholders.Thatistosaythatthelargest

issuestandinginthewayofperformingchemicalcompatibilityassessmentisnotacceptingtheresponsibilityfor performingtheassessmentbutratherthelackofastandardizedprocessfordesigning,implementing,reporting, andinterpretinganassessment.Theissueisnot“DoI accepttheresponsibilityforperforminganassessment?” butrather“Idonotknowhowtoperformanefficient, effectiveandacceptableassessment.”

Thisdifficultyanduncertaintyariseduetocertain unavoidabletruthsassociatedwithpharmaceuticaland medicalproducts:

a.Thegreatdiversityofpharmaceuticalandmedicalproducts,

b.Thegreatdiversityintheconditionsunderwhichpharmaceuticalandmedicalproductsareusedtoproducea positiveclinicaloutcome,

c.Thescientificcomplexityofchemicalinteractions,

d.Thedifficultyinattributingeffecttoacause(thatis,the difficultyinestablishingtheeffectthatachemicalwill produceonceithasbeenestablishedthatthechemical isrelevanttotheinteractionbeinginvestigated).

Letusbeclear.Theidealcircumstanceinanyassessment isthat:

1.Theprocessforperformingtheassessmenthasbeen establishedandclearlycommunicated.

2.Theprocessforperformingtheassessmenthasbeen standardizedtotheextentthataminimumnumber ofprocessvariationscoverthemaximumnumberof circumstanceslikelytorequireassessment.

3.Theprocessforperformingtheassessmentisrelatively easilyachievedwithareasonabledegreeofknowledge andskill.

4.Theprocessforperformingtheassessmentcanbe performedusinguniversallyavailabletoolsthatare relativelyinexpensivetoprocure,maintain,andoperate.

5.Theprocessforperformingtheassessmentislogicaland canbeexplainedtoindividualsgenerallyschooledin theart.

6.Theassessmentitselfprovidesatangibleandrecognizableoutcomethatisacceptabletoandacceptedbyall stakeholders.

7.Theassessmentprocessandtheoutcomeoftheassessmentisreproducible.

Itisfinetounderstandthecharacteristicsofthe“ideal” chemicalcompatibilityassessment.However,practically speaking,itisinfinitelymoreimportant(anduseful)that theidealchemicalsafetyassessmentexistsasadocument (ordocuments)thatcontainsanddescribestheprocessof chemicalcompatibilityassessment.Suchadocument(or seriesofdocuments)would:

–Definethoseactionsthatneedtobetakentoperformthe assessment,

–Establish,inaclearandunmistakablemanner,howto accomplishthoseactions,

–Provideameanstoverifythattheactionswereproperly taken,

–Delineatehowtheresultsoftheactionstakencanbe interpretedinthecontextofestablishingeffectand impact.

Thiswouldbeaveryshortbookindeedifallthatwas requiredatthispointwastolistexistingchemicalcompatibilityassessmentdocumentsthatachievetheidealcaseand say“heretheyare,goreadthemanddowhattheysay.” Thecircumstancethatthisbookisaslongasitisandthat thereissomuchdiscussionandcontroversyaroundchemicalcompatibilityassessmentverifiestherealitythatideal chemicalcompatibilityassessmentdocumentsdonotcurrentlyexist.

However,thatisnottosaythatstakeholdersareleftto fendforthemselveswithoutaidandguidance.Resources thataddresschemicalsafetyassessmenttoacertainextent existandcanprovideaninterestedpartywithvaluable insights,recommendedpracticesandactionableprocesses. Theseresourcesinclude(seealsoTable1.1):

• RegulatoryGuidelinesandGuidances.Asafundamentalresponsibilityofagovernmentistoprotectits people,itisnecessarilythecasethattherequirements forcompatibilityassessmentsarecontainedwithin thecontextoflaws,legislation,andassociatedregulationsandthatsuchlaws,legislation,andregulations areupheldandenforcedbyappropriategovernmental authoritiessuchastheUSFoodandDrugAdministration(FDA),theEuropeanMedicinesAgency(EMEA), HealthCanada,China’sNationalMedicalProducts Administration(NMPA),andothernationalMinistries ofHealth.Tofacilitateenforcementandcompliance, suchgovernmentalauthoritiespublishGuidelinesor

provideGuidancethatessentiallyestablishtheauthorities’expectationswithrespecttocompatibilityand, toacertainextent,delineatethemeansforfulfilling thoseexpectations.Becausepharmaceuticalandmedicalproductsmustberegisteredwiththeregulatory authoritiesbeforetheycanbemarketed(meaningin essencethattheproductsmustbe“approved”bythe authoritybeforetheycanbesoldwithintheauthority’s jurisdiction),regulatoryguidancesandguidelinescarry significantweightandaretypicallyviewedasproviding theultimateauthorityon“whattodoandhowtodoit.”

• NationalandInternationalStandards.Giventhecomplexitiesinvolvedwithestablishingguidelinesand providingguidance,organizationswhosesolepurpose isthegenerationandmaintenanceofguidanceand guidelineshaveevolved,suchas,forexample,the InternationalCouncilforHarmonizationofTechnical RequirementsforPharmaceuticalsforHumanUse (ICH).Theseso-called“standards-settingorganizations”haveassembledappropriateteamsofexperts andstakeholderswhoarechargedwiththeresponsibilityofgeneratingstandards.Additionally,these “standards-setting”organizationshavedevelopedprocessesbywhichthegeneratedstandardsarereviewed andultimately“approved”bythelargerglobalcommunityofexpertsandstakeholders.Inthisway,the standardsrepresenttheconsensusopinionamong expertsandstakeholders.Equallyimportant,theseorganizationshavedevelopedcontent,quality,andformat requirementsfortheirstandardsandhaveestablished processesfortheperiodicmaintenance(reviewand revision)ofthestandards.

Generallyspeaking,these“standards-setting”organizationshavenodirectregulatoryauthorityandthusno abilitytoenforcecompliancetotheirstandards.These standardsbecomeenforceableeitherviaformalrecognitionbyregulatoryauthorities(thatis,theregulatory authoritieswillprovideastatementthatcommunicates theirstanceontheuseandutilityofthestandard)orby theinformalrecognitionbythecommunityofstakeholdersthat“thisistherightwaytodothingsandthusthis isthewaywearegoingtodoit.”Inthisway,thestandardsarecrediblebecausetheorganizationsgenerating thestandardsarecredible.

• CompendialMonographs.Toaidinthedevelopment, marketing,andcontrolofsafeandeffectivepharmaceuticalsandmedicaldevices,manynationalities haveestablishedaPharmacopeia(acompendiumfor druginformation)whosepurposeis“toprovidestandardsofidentity,strength,quality,andpuritythatcan helpsafeguardtheglobalsupplyofmedicines,dietary supplements,andfoodingredients”(UnitedStates

Table1.1 Sourcesofguidanceandadviceonchemicalcompatibilityassessment.

Regulatory Guidanceor Guideline

Nationalor International Standard

GuidanceforIndustryContainer ClosureSystemsforPackaging HumanDrugsandBiologics,US DepartmentofHealthandHuman Services,FoodandDrug Administration,Rockville,MD,May 1999

ISO10993-1:2018.Biological evaluationofmedicaldevices–Part 1:Evaluationandtestingwithina riskmanagementprocess. AssociationfortheAdvancementof MedicalInstrumentation(AAMI), Arlington,VA,2018

Compendial Monographs

Best Demonstrated Practice Recommendations

USP <661> PlasticPackaging SystemsandTheirMaterialsof Construction.USP42/NF37, pp.6812–6818.OfficialMay1,2019

Directlegalandenforceable requirementsformarketing approval

Safetythresholdsandbestpractices forextractablesandleachablesin orallyinhaledandnasaldrug products.PQRILeachablesand ExtractablesWorkingGroup. September8,2006

PublicationsD.R.JenkeandB.E.Rabinow.Proper AccountingforSurfaceAreato SolutionVolumeRatiosin ExaggeratedExtractions. PDAJ. Pharm.Sci.Technol.71(3):225–233 (2017).

Indirectlylegaland enforceablerequirements pendingadoptionby regulatoryauthorities. Recognizedandadoptedas consensusbestpractice

Legalandenforceable requirementsatthediscretion ofregulatoryauthorities; mandatorycompliancefor productssolabeled

Consensusadviceprovidedby apanelofexperts.Maybe incorporatedintoregulations, standardsandmonographs.

Adviceprovidedbyindividual experts,whichmaybe incorporatedintoregulations, standards,andmonographs byreference.

Generalconceptswithwide applicability;focusismoreonwhatto doandlessonhowtodoit.Maycontain somespecificsonmethodologyand acceptancecriterion.Typicallycontains littleexplanationorjustificationof requirements.

Generalconceptswithwide applicability;focusismoreonwhatto doandlessonhowtodoit.Maycontain somespecificsonmethodologyand acceptancecriterion.Typicallycontains minimalexplanationorjustificationof requirements.

Generalconceptswithwide applicability;providesabalanceofwhat todoandhowtodoit.Typically containsbothgeneralitiesandspecifics onmethodologyandacceptance criteria.Typicallycontainslittle explanationorjustificationofmethods andrequirements.a)

Containsbothgeneralconceptsand specificrecommendedpractices.Equal focusonbothwhattodo,howtodoit andwhyitshouldbedonethatway. Typicallycontainsextensive justificationandexplanation.

Focusedonaspecificcircumstanceor aspect.Typicallydefinesasetof circumstancesandreflectstheactions theauthortookunderthose circumstances.

a)RecentenforceableUSPmonographsarenowsupportedbyinformationalmonographsthatcontainmoreexplanationorjustificationofthe contentsoftheassociatedenforceablemonographandwhichserveas“usermanuals”fortheassociatedenforceablemonograph.

Pharmacopeia).ThePharmacopeia“establisheswritten (documentary)andphysical(reference)standardsfor medicines,foodingredients,dietarysupplementproducts,andingredients.”Thegeneration,publication,and themaintenanceofthePharmacopeiaisentrustedto anorganizationchargedwiththesetasks,forexample, theUnitedStatesPharmacopeialConvention(USP). Toacertainextent,theseorganizationsandtheirprocessesaresimilartothoseofthestandards-setting organizationsdiscussedpreviously.

AswasthecasewithStandardsand“standards-setting” organizations,pharmacopeialorganizationsgenerally havenoclearregulatoryauthorityandthuslittleor noabilitytoenforcecompliancetotheirCompendial standards.Thereisan“understanding,”sometimes reinforcedbylawandlegislationtoacertainextent,

thattheCompendialstandardsareenforcedbythe localregulatoryauthorities.ConsideringtheUSPasan example,theUSPworkscloselywithgovernmentagencies,ministries,andregulatoryauthoritiesaroundthe worldtohelpsafeguardtheglobalsupplyofmedicines, dietarysupplements,andfoodingredientsandUSP standardsareusedbyregulatoryagenciesandmanufacturerstohelptoensurethattheseproductsareof theappropriateidentity,strength,quality,purity,and consistency.

• BestPracticesRecommendations.Itisanaturalcircumstanceinanyandallareasofexpertisethatexperts routinelygettogetherand“talkshop.”Professionaland tradeorganizationshavebeenorganizedtofacilitate andformalize“shoptalk”andtoharnessthetalkfor productivepurposes.Tobehonest,afairportionof

that“shoptalk”revolvesarounddeficiencies,realand perceived,inregulations,standards,andCompendial monographs.Althoughthetopicsandfocusofthese discussionsvary,itisoftenthecasethattheexpert’sconcernisthattheregulations,standards,andmonographs areinsufficientlydetailedtoprovideactionableguidance inthecircumstancethattheexpertsfindthemselvesin. Certainorganizationshaveembracedandaccepted theresponsibilityforaddressingandremediating suchdeficienciessoastomoregenerallyimprove thechemicalcompatibilityassessmentandrelatedprocesses.Theyaccomplishthis,inthesamewaythatthe “standards-setting”andCompendialorganizationsdo, byassemblingapanelofexperts,chargingtheexpertsto writeapositionpaper,vettingthewrittenpaperwitha wideraudienceorexperts,stakeholders,andinterested parties,andthenpublishingthepositionpaper.Because theseorganizationshavenoregulatoryauthorityand cannotclaimevenatangentialrelationshipwithregulators,thepositionpapersaregenerallyknownas“best demonstratedpracticerecommendations”thatserve thepurposeofproviding“consensusexpertadvice.” Theserecommendationsderivetheir“authority”onthe basisoftheircredibilityandpracticalityand,inisolated cases,byinformalrecognitionbyregulatoryauthorities.Examplesofsuchbestdemonstratedpractice recommendationsinclude:

–Safetythresholdsandbestpracticesforextractables andleachablesinorallyinhaledandnasaldrug products,submittedtotheProductQualityResearch Institute(PQRI)DrugProductTechnicalCommittee,PQRISteeringCommittee,andUSFoodand DrugAdministrationbythePQRILeachablesand ExtractablesWorkingGroup,September8,2006.

–RecommendationsforExtractablesandLeachables Testing,publishedbytheExtractablesandLeachables SubcommitteeoftheBio-ProcessSystemsAlliance (BPSA)in2008toaddresssingle-usemanufacturing systems.

–StandardizedExtractablesTestingProtocolforSingleUseSystemsinBiomanufacturing(Ding,W.,Madsen, G.,Mahajan,E.,O’Connor,S.,andWong,K., Pharm. Eng 34(6):1–6(2014)),developedinconjunctionwith theExtractablesWorkGroupoftheBioPhorumOperationsGroup(BPOG).

–Assessingsafetyofextractablesfrommaterials andleachablesinpharmaceuticalsandbiologics–Currentchallengesandapproaches(Broschard,T., Glowiemke,S.,Bruen,U.S.,Nagao,L.N.,Teasdale, A.,Studlts,C.L.M,Li,K.L.,Iceik,L.A.,Erexson,G., Martin,E.A.,andBall,D.J. Reg.ToxandPharm 81:201–211(2016))developedinconjunctionwith

theExtractablesandLeachablesSafetyInformation Exchange(ELSIE).

• IndividualPublications.Thegenerallyemployedmeans forindividualauthors(orsmallgroupsofauthors)to sharetheirexperiencesandinsights,communicate(and defend)theiropinions,advocateforparticularstrategies ortactics,andcommunicatescientificadvancesisvia publicationofscholarlydocuments.Whereasthepreviouslydiscussedguidances,standards,monographs,and recommendationstendtobebroadscopeandstrategic,individualpublicationstendtofocusonaspecific circumstanceorconceptfromatacticalperspective. Thus,whereguidances,standards,monographs,and recommendationstendtofocusonthe“whatneedstobe done,”thefocusinindividualpublicationsismoreonthe “howtodoit.”Forexample,anindividualmanuscript maydescribeaspecifictestprocedureforperforming acertainaspectofchemicalcompatibilityassessment (suchaschromatographicallyscreeninganextractfor organicextractables).Othermanuscriptsmightdiscuss andenumeratethescientificprinciplesrelevanttoaspecificaspectofchemicalcompatibilityassessment(such ashowtoselectandjustifytheappropriateextraction vehicle).Casestudy-typemanuscriptsdescribeaparticularcircumstance,chronicletheauthor’sactionsinthose circumstancesandpresenttheresultsofthoseactions. Reviewscollectandsummarizetheavailablerelevant informationandmayusethatcollectedinformationto advocateforaspecificconceptoraction(forexample, summarizingavailableinformationonextractablemetalsfromplasticsandusingtheinformationtosupport theproposalthatextractablemetalsarelowriskand thereforeextensivetestingisnotrequired).

Regardlessofthenatureofthepublication,itisclear thatthepublicationitselfisadviceratherthanguidance. Thus,thepublicationitselfisnotdirectlyenforceable andimplementationofanystrategiesandtacticspresentedinthepublicationsmayormaynotaddressand fulfillregulatoryrequirements.Ofcourse,itisarealistic expectationthatguidances,standards,monographs,and recommendationsembracemeritoriouspublications, eitherbyreferenceordirectassimilation.

1.3WhyChemicalAssessment?

Inthepreviousdiscussionweestablishedthatcompatibilityassessmentisnecessaryasitcanreasonablybeinferred thatamaterialandapharmaceuticalproductareincompatibletoacertainextent.Thatis,whenthematerialand thepharmaceuticalproductcomeintocontact,theywill interactanditispossible,ifnotlikely,thattheinteraction

willhaveanadverseimpactonacriticalqualityattributeof eitherthematerialorthepharmaceuticalproduct(orboth). Thus,anassessmentisnecessarytoquantifytheimpactand toestablishtheacceptabilityoftheimpact.

However,wehaveyettoestablishwhythepropercompatibilityassessmentisachemicalassessment.Infact,itis logicaltosuggestthatachemicalcompatibilityassessment isnottheassessmentmethodoffirstchoice.Thisistruefor thesimplereasonthatchemicalcompatibilityassessment isanindirectassessmentmethodwherecompatibilityis generallyinferred,notmeasured.Specifically,thechemical compatibilityassessmentinvolvesthecollectionofchemicaldatarelevanttotheinteractionfollowedbyinferring theimpactbasedonthechemicaldata(datageneration followedbydatainterpretation).Thus,the“accuracy”of thechemicalcompatibilityassessmentisbasedonthe quantityandqualityofthechemicaldataandthecertainty intheinference.Aninaccurateassessmentisproduced wheneitherinsufficientorsubstandarddataisthebasisof theassessmentand/oriftheinferenceisirrelevant(e.g.an “applestooranges”comparison)orbasedonquestionable science.Anaccurateassessmentistheoutcomeonlyif thechemicaldataissufficientand“highquality”andthe inferenceisbasedonrelevantgoodscience.

Forthesereasons,adirectdeterminationofcompatibilityistheassessmentmethodofchoice.However,the practicalissueisthatmanykeyqualityattributescannot beassesseddirectlyor,iftheycanbeassesseddirectly,the directassessmentissub-optimal.Forexample,considerthe keyqualityattributeofpharmaceuticalproductstability. Conceptually,itisrelativelystraightforwardtodirectly establishtheeffectofapharmaceuticalproduct’spackagingsystemonpharmaceuticalproductstability.Twosetsof pharmaceuticalproductunitsarestoredsidebysideover thecourseofastabilitystudy,onesetbeingthepharmaceuticalproductinitspackagingsystem(thetestsystem)and thesecondsetbeingthepharmaceuticalproductstoredin aninertcontainer(thecontrolsystem).Stability-indicating attributesofthepharmaceuticalproductaremeasured inbothsetsofunitsovertheshelf-lifeandtheresults arecompared,testversuscontrol.Anydifferencesin thestability-indicatingattributes,testversuscontrol,are attributedtopharmaceuticalproduct/packagingsystem incompatibilities.

Althoughthisexperimentalapproachisstraightforward enoughinconcept,therearepracticalissuestoconsider. Forpharmaceuticalproductswithlongshelf-livesand/or numerouscriticalqualityattributes,suchastudywould representaconsiderableinvestmentofresources.Furthermore,itislikelythatsuchastudywouldbeperformed onlyafteraconsiderabledevelopmentprocessandeffort forboththepharmaceuticalproductanditspackaging.

Itwouldbemostunfortunateindeedtodiscoverameaningfulincompatibilityatthislatestageoftheproduct developmentcycle.

Theproblemassociatedwithdirectcompatibilityassessmentisevenclearerifthequalityattributebeingconsidered ispatientsafety.Letususethesameexampleofapharmaceuticalproductanditspackagingsystem.Certainly,one waytoestablishthesafetyofpackaging-relatedleachables wouldbetoperformthestabilitystudynotedaboveand dosepatientswithanagedproductatcertaintimesover itsshelf-lifeusingandthenobservingtherelatedeffecton patienthealth.Evenasonereadsthisoneunderstandsthe practicalandethicalissuesassociatedwithsuchadirect approachofwhatamountstoaclinicaltrial.

Thus,oneunderstandsthattheindirectapproachof chemicalcompatibilityassessmentisoftenemployed becausemoredirectapproacheshaveirreconcilabledifficulties.

Furthermore,ifadirectchemicalapproachtocompatibilityassessmentisnotpossible,thenwhataboutalternate directapproachestocompatibilityassessment?Thesimple truthisthatformanycriticalqualityattributes,thereisno alternate,direct,andnon-chemicalapproachor,ifthere isanalternatedirect,non-chemical,approach,ittoohas itsownissues.Reconsiderthecaseofproductstability. Productinstabilityisgenerallychemistry-based;thatisa pharmaceuticalproduct’singredientschemicallydegrade overitsshelf-life,causingtheproducttoeither(i)become sub-potent,(ii)haveexcessivelevelsofdegradationproducts,or(iii)exhibitanundesirablecosmeticproperty(e.g. discoloration).Becausethemodeofactionoftheincompatibilityischemical,therearenoalternativeassessment methodsversuschemicalassessment.