Notes on the Screen Presentation

You are reading this e-book in a file format (EPUB or Mobi) that makes the book content adaptable to the display options of your reading device and to your personal needs. That’s a great thing; but unfortunately not every device displays the content in the same way and the rendering of features such as pictures and tables or hyphenation can lead to difficulties. This e-book was optimized for the presentation on as many common reading devices as possible.

If you want to zoom in on a figure (especially in iBooks on the iPad), tap the respective figure once. By tapping once again, you return to the previous screen. You can find more recommendations on the customization of the screen layout on the Service Pages.

Table of Contents

Notes on Usage

Table of Contents

Preface

1 Introduction to Extended Warehouse Management

1.1 What Is Extended Warehouse Management?

1.2 The Progression of Extended Warehouse Management

1.2.1 SAP EWM with Non-SAP S/4HANA (SAP EWM

5.0 to SAP EWM 9.5)

1.2.2 Embedded EWM and Decentralized EWM

1.2.3 Cloud-Based SAP EWM

1.3 System Environment and Deployment Options

1.3.1 On-Premise

1.3.2 Cloud Deployment

1.3.3 SAP NetWeaver Deployments

1.3.4 Non-SAP ERP Systems with Decentralized EWM

1.4 Data Transfers between SAP ERP or SAP S/4HANA and SAP EWM

1.5 Integration with Other SAP Modules and Business Process

1.6 Industry Adoption of Extended Warehouse Management Solutions

1.7 Significant SAP Notes on Deployment Options and Other Functionalities

1.8 Summary

2 Production Planning

2.1 Overview of Production Integration

2.2 Delivery-Based Production Integration

2.2.1 Overview

2.2.2 Staging for Manufacturing Orders

2.2.3 Consumption for Manufacturing Orders

2.2.4 Goods Receipt for Manufacturing Orders

2.3 Advanced Production Integration

2.3.1 Staging for Manufacturing Orders

2.3.2 Consumption for Manufacturing Orders

2.3.3 Goods Receipt for Manufacturing Orders

2.3.4 Clear Production Supply Area Bin for Manufacturing Orders

2.3.5 Create Part Replenishment Process

2.4 SAP Manufacturing Execution Integration

2.4.1 SAP Manufacturing Execution Triggered Staging to Production

2.4.2 Integrating SAP EWM to SAP Manufacturing Execution and SAP Manufacturing Integration and Intelligence to Receive Goods from Production

2.5 Summary

3 Quality Management

3.1 Overview of Quality Management in SAP EWM

3.2 Inspection Product/Batch for Inbound Deliveries

3.2.1 Inspection after Goods Receipts from External Procurement (With Inspection Rule)

3.2.2 Pre-Sampling in Production or Inspection after Goods Receipt from Production

3.3 Warehouse Stock Inspections

3.3.1 Stock Inspections (With Inspection Rules)

3.3.2 Recurring Inspections (With Inspection Rules)

3.3.3 Customer Return Inspections Using Advanced Returns Management

3.4 Important SAP Notes for Quality Management in SAP EWM

3.5 Summary

4 Transportation Management

4.1 Overview of Transportation Management Systems

4.2 Shipping and Receiving in Inbound and Outbound Processes

4.3 Freight Order Integration

4.3.1 Inbound Process

4.3.2 Outbound Process

4.4 Advanced Shipping and Receiving

4.4.1 Inbound Process

4.4.2 Outbound Process

4.5 Shipment Integration

4.5.1 Transportation Planning in an ERP System

4.5.2 Transportation Planning in SAP EWM

4.6 Summary

5 Dock Appointment

Scheduling

5.1 Overview of Dock Appointment Scheduling

5.2 Dock Appointment Planning

5.2.1 Inbound Process in SAP Dock Appointment Scheduling

5.2.2 Dock Appointment Planning in SAP EWM

5.3 Summary

6 Warehouse Automation Systems

6.1 Overview of Warehouse Automation Systems

6.2 Material Flow Systems

6.2.1 Inbound Process

6.2.2 Outbound Process

6.3 SAP Warehouse Robotics

6.4 Automated Storage and Retrieval Systems

6.4.1 Integration with a Material Flow System

6.4.2 Integration with Automated Guided Vehicles

6.5 Automated Guided Vehicles

6.6 Summary

7 Yard Logistics

7.1 Overview of Yard Logistics

7.2 Using SAP Yard Logistics

7.2.1 Inbound Process

7.2.2 Outbound Process

7.3 Summary

8 Environmental Health and

Safety

8.1 Overview of Environmental Health Safety

8.2 Goods Receipt and Goods Issue

Process Using SAP EHS Management

8.2.1 Inbound Process

8.2.2 Outbound Process

8.3 Summary

9 Plant Maintenance

9.1 Overview of Plant Maintenance

9.2 Using Plant Maintenance Orders

9.2.1 Outbound Process

9.2.2 Inbound Process

9.3 Summary

10 SAP Advanced Track and Trace for Pharmaceuticals

10.1 Overview of SAP Advanced Track and Trace for Pharmaceuticals

10.2 Using SAP Advanced Track and Trace for Pharmaceuticals with SAP EWM and SAP S/4HANA

10.2.1 Inbound Process

10.2.2 Outbound Process

10.3 Summary

The Authors

Index Service Pages

Legal Notes

Preface

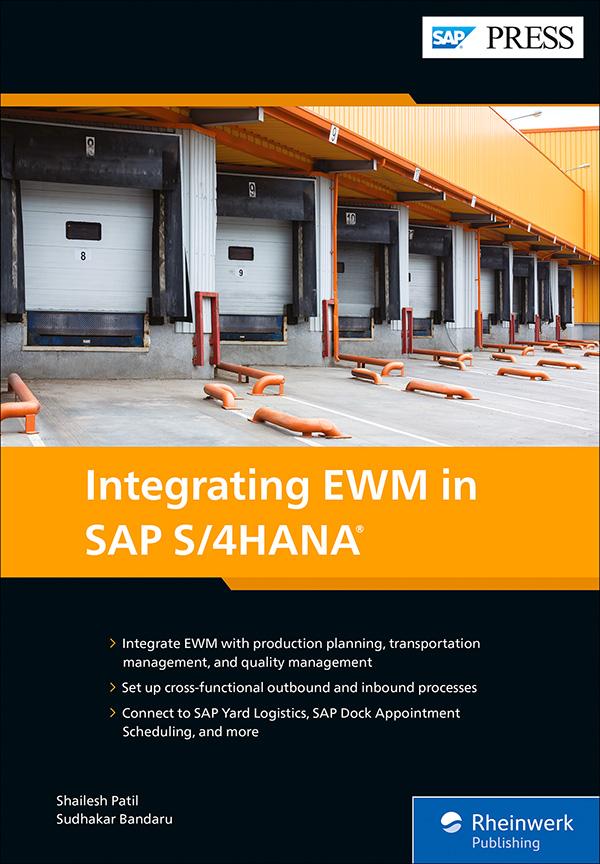

In today’s fast-paced and ever-changing business environment, organizations are constantly looking for innovative ways to optimize their supply chain processes and improve the efficiency of their warehouses. Real-time warehouse operations are closely intertwined with other business functions such as transportation management, production processes, quality control, yard management, advanced track and trace, and plant maintenance. These core business processes are often implemented using SAP software.

For modern warehouse management, what are known as extended warehouse management (EWM) solutions are required. Within the realm of SAP, SAP Extended Warehouse Management (SAP EWM) is a specialized solution that caters to the unique requirements of managing warehouse space. However, integrating your core business processes in SAP with the warehouse management system (WMS) can be challenging. This scenario is where the integration of SAP EWM in SAP S/4HANA is a top-notch solution designed to address the evolving challenges faced by many organizations.

The integration of SAP EWM in SAP S/4HANA represents a transformative shift in warehouse management practices. By leveraging cutting-edge technologies and advanced

functionalities, this integration streamlines operations, improves inventory accuracy, and delivers exceptional customer service. It sets the stage for exploring the immense potential of SAP EWM integration and its significant impact on modern supply chain management.

Through the insights and knowledge shared by industry professionals, this preface delves into the key drivers behind the adoption of SAP EWM in SAP S/4HANA. We’ll elucidate the fundamental concepts involved in this integration and provide an overview of the associated benefits and best practices. By showcasing real-world case studies and success stories, we hope this book will inspire and equip business leaders, SAP consultants, SAP architects, and supply chain practitioners with actionable insights to embark on their SAP EWM integration journeys.

To provide a clear understanding into business processes, configuration, master data, and process demos, we’ve set up a dedicated SAP EWM system, along with other modules like SAP Transportation Management (SAP TM), SAP Yard Logistics, and SAP Advanced Track and Trace for Pharmaceuticals. This practical setup is designed to help you grasp the concepts more effectively.

Objective of This Book

The main goal of this book is to provide a thorough exploration of integrating SAP EWM with an SAP S/4HANA system and other SAP modules. These modules include warehouse automation, production planning, and quality management as well as SAP TM; SAP Environment, Health,

and Safety Management (SAP EHS Management); yard management; and plant maintenance. We hope to deliver a detailed and knowledgeable account of the complexities and functionalities involved in combining SAP EWM with the advanced capabilities of the SAP S/4HANA platform.

Through clear and understandable writing, the main objectives of this book include providing valuable insights and deep knowledge to help you navigate the complex world of SAP EWM integration in SAP S/4HANA with confidence and expertise.

The central idea of this book revolves around fostering a deeper understanding of the interaction between SAP EWM and SAP S/4HANA, revealing the potential benefits that arise from their integration. By using eloquent language and a rigorous analytical approach, the book hopes to demystify the intricacies of SAP EWM integration, helping you grasp the subject with a higher level of understanding.

Target Audience

The target audience of Integrating SAP EWM in SAP S/4HANA primarily consists of organizations, warehousing professionals, and EWM consultants who require a comprehensive warehouse management functionality integrated directly into their SAP S/4HANA enterprise resource planning (ERP) system. This solution is well suited for companies of various sizes and industries that possess complex warehousing operations and need to optimize their logistics processes.

The typical target audience for embedded Extended Warehouse Management in SAP S/4HANA (embedded EWM) includes the following organizations:

Manufacturing companies

Organizations engaged in production and assembly processes often have extensive warehousing requirements. Embedded EWM enables these companies to efficiently manage inventory, track material movements, and optimize warehouse operations.

Distribution and logistics companies

Businesses specializing in distribution, warehousing, and transportation can benefit from embedded EWM. This approach enables end-to-end visibility into the supply chain, streamlines order fulfillment processes, and supports transportation management.

Retail and e-commerce companies

Both brick-and-mortar stores and online retailers require effective inventory management and order fulfillment capabilities. Embedded EWM helps optimize stock levels, improve picking and packing processes, and facilitate efficient order processing.

Third-party logistics (3PL) providers

Companies offering outsourced logistics services often handle multiple clients and complex supply chain requirements. Embedded EWM allows 3PL providers to manage diverse customer inventories, handle crossdocking scenarios, and support value-added services.

Wholesale and distribution centers

Wholesalers and distributors deal with large volumes of inventory and require accurate tracking, efficient storage,

and streamlined order processing. Embedded EWM offers functionalities such as wave picking, putaway strategies, and advanced slotting optimization.

High-tech and electronics companies

Industries dealing with technologically advanced products, such as electronics and high-tech manufacturing, often have complex supply chains. Embedded EWM provides real-time visibility into inventory, supports kitting and assembly processes, and facilitates reverse logistics.

Pharmaceutical companies

Pharmaceutical companies working with pharmaceutical serialization generally require track and trace solutions to meet regulatory requirements.

Structure of This Book

This book’s ten chapters cover the scope of embedded EWM in SAP S/4HANA 2021. Each chapter primarily focuses on various business processes and scenarios, along with the necessary configuration and master data requirements. Additionally, each chapter provides in-depth process demonstrations for relevant business processes. The introductory section of this book provides an overview of SAP EWM and explores the benefits of warehouse management, including different deployment options and a comprehensive range of features. The chapters in the book encompass a wide range of topics, including production planning, quality management, transportation management,

dock appointment scheduling, warehouse automation systems, yard logistics, environmental health and safety, plant maintenance, and advanced track and trace.

The chapters are as follows:

Chapter 1

The main goal of this introductory chapter is to provide a thorough understanding of SAP EWM, which serves as SAP’s warehouse management solution for numerous industries. This chapter explores the various features and advantages offered by SAP EWM, the evolution of SAP EWM, the system environment, and deployment options provided by SAP for implementing SAP EWM as a warehouse management solution. Additionally, we’ll cover data transfer techniques and industry adoption of SAP EWM.

Chapter 2

The purpose of this chapter is to provide guidance on various methods to achieve production integration and how these methods integrate embedded EWM. This chapter primarily focuses on providing a detailed explanation of production integration methods, including delivery-based production integration and advanced production integration. Additionally, this chapter delves into manufacturing execution integration, specifically addressing SAP Manufacturing Execution-triggered staging for production and goods receipt from production using SAP Manufacturing Execution and SAP Manufacturing Integration and Intelligence (SAP MII). Moreover, this chapter presents a thorough discussion of the configuration and master data requirements

necessary to enable end-to-end testing of your business scenarios. Finally, we’ll provide a step-by-step demonstration of the process to enhance your understanding.

Chapter 3

The objective of this chapter is to serve as a comprehensive guide on the several quality management processes and their seamless integration with SAP EWM. In this chapter, we’ll cover business processes such as the inbound delivery inspection for external vendors and for production, as well as various stock inspection methods including stock inspections and recurring inspections. Additionally, we’ll delve into customer returns inspection using the advanced returns management process. To accomplish these tasks, this chapter will go into detail for the business processes associated with each method. This description will be followed by a thorough discussion of the configuration and master data requirements necessary to facilitate end-to-end testing of your business scenarios. Finally, this chapter will provide a step-by-step demonstration of the process to enhance your understanding.

Chapter 4

The purpose of this chapter is to enhance your understanding of SAP TM and its integration with embedded EWM. This chapter discusses different business processes for shipping and receiving, including inbound and outbound processes such as the integration of freight orders with SAP TM and SAP EWM, advanced shipping and receiving processes, and the integration of shipments with transportation planning in SAP ERP and SAP EWM.

Chapter 5

The goal of this chapter is to serve as a comprehensive guide to various dock management procedures and their smooth integration with embedded EWM. This chapter focuses on detailed business processes, such as dock appointment planning in SAP Dock Appointment Scheduling. We’ll cover dock appointment planning in SAP EWM to meet the needs of inbound and outbound processes, with or without the yard management functionality.

Chapter 6

This chapter explores a variety of warehouse automation components that can be easily integrated with SAP EWM. We’ll examine various automation system components, such as the material flow system, the warehouse robotics system, the automated storage and retrieval system, and automated guided vehicles (AGVs). This chapter specifically focuses on inbound and outbound business processes using the material flow system, on the integration options for SAP Warehouse Robotics, on the integration options for automated storage and retrieval systems, and on AGVs in detail.

Chapter 7

This chapter provides an overview of yard logistics, including its functionality and integration options with SAP Yard Logistics. Furthermore, this chapter offers a detailed explanation of inbound and outbound processes utilizing SAP Yard Logistics. To achieve this goal, the chapter will present a comprehensive overview of the associated business processes for each method. Subsequently, we will discuss the configuration and master data

requirements needed to facilitate end-to-end testing of the business scenarios. Finally, this chapter will provide a step-by-step demonstration of the process to enhance your understanding.

Chapter 8

This chapter provides an overview of SAP EHS Management and its key functionalities, benefits, and integration options with SAP EWM. Furthermore, we’ll provide a detailed explanation of inbound and outbound processes utilizing SAP EHS Management.

Chapter 9

In this chapter, we’ll delve into the integration of plant maintenance with SAP EWM. This overview of plant maintenance will cover its key functionalities, benefits, and integration options with SAP EWM. Furthermore, this chapter offers a detailed explanation of inbound and outbound processes utilizing plant maintenance.

Chapter 10

The main objective of this chapter is to present extensive information about SAP Advanced Track and Trace for Pharmaceuticals, an advanced system used for tracing serial numbers for pharmaceutical products. This chapter includes an overview of SAP Advanced Track and Trace for Pharmaceuticals and its integration with SAP EWM, as well as the deployment options provided by SAP for integrating SAP Advanced Track and Trace for Pharmaceuticals with SAP EWM. Furthermore, this chapter provides a detailed explanation of inbound and outbound processes utilizing SAP Advanced Track and Trace for Pharmaceuticals.

We anticipate that this book will facilitate the EWM community in enhancing their comprehension of the integration of diverse SAP modules, which together can serve as a comprehensive solution. Furthermore, this book aims to furnish you with the necessary resources to proficiently execute all-encompassing embedded EWM implementations.

References

For more information on SAP EWM, visit the following websites:

http://help.sap.com/ewm

https://blogs.sap.com

https://help.sap.com/attp

https://help.sap.com/docs/SAP_YARD_LOGISTICS

https://help.sap.com/docs/SAP_TRANSPORTATION_MANA GEMENT

Acknowledgments

We would like to express our heartfelt gratitude to the entire team at SAP PRESS, with special mention of Rachel Gibson, the esteemed editor of this book. Her unwavering support and dedication have been indispensable throughout this endeavor. Furthermore, we wish to sincerely appreciate Emily Nicholls for her discerning eye in recognizing the potential of this book concept and for her invaluable

assistance in transforming a mere concept into the tangible and remarkable book in your hands.

We would like to extend our thanks to our friends, colleagues, and family members for their support and encouragement, without which we could never have completed this book. A special “thank you” goes to our friend and Basis architect, HK Laxman, for setting up the Basis system, ensuring sufficient space, and backing up the server for this SAP EWM instance. We are also grateful to Rameshwar Verma for his creative contribution in crafting few of the diagrams and valuable help and Yugandhar Karturi for supporting critical Basis activities.

We also want to express our gratitude to Sarang Pathak, Sarvesh Gudapati, Sydulu Koleti, and Naveen Babu Garikapati for their support throughout our journey writing this world-class manuscript.

— Shailesh Patil and Sudhakar Bandaru

A special thanks to my wife, Dipti; my daughters, Advika and Anayra; and my father, Mr. Abhimanyu Patil. Without your support and sacrifice of your own personal time, I could never have imagined starting this journey and completing this book. I also want to express my gratitude to my mentors, Kavita and Shyam, for their contributions in shaping my career. Finally, I dedicate this book to my late mother, Mrs. Jijabai Patil, for her blessings and lifelong support.

— Shailesh Patil

I would like to extend heartfelt appreciation to my beloved wife, Naga Bhawani Bandaru, and our precious daughter,

Twisha. I dedicate this book to my wife for accepting my prolonged absences while writing this book. Furthermore, I would like to express my deepest gratitude to my respected benefactors Siva Prakash Karuparti, Madhukar Sanmane, Srinivas Thodupunuri, Rakesh Kumar, Sathish Kumar Murugesan, and Abdul Ghani, whose invaluable guidance and contributions have played a pivotal role in shaping my career.

— Sudhakar Bandaru