RAMPS | STEPS | HANDRAILS

Learn who we are, what we stand for, and our history.

View

Discover

Explore the full range of services we offer.

Understand

See

An overview of the industries and environments we support with our solutions.

Dive

A guide to the different finishes and textures available for our systems.

Tailor our products to fit your space.

Real-life

THE MODULAR ACCESS EXPERTS, FOR OVER 25 YEARS.

Easiaccess has grown to become the UK’s leading provider of modular access solutions and associated products, working closely with a broad spectrum of clients nationwide; providing our products and managing solutions for all public sectors, whether modular buildings or large-scale developments.

At Easiaccess we design, manufacture, supply, and install modular metal ramps, bespoke handrail systems, and complementary threshold solutions, delivering exceptional quality and functionality across the nation. Our ramps enhance accessibility in public and residential spaces, offering quick installation with minimal disruption. Their modular design ensures efficiency, making them ideal for tight deadlines while fully complying with accessibility standards.

At Easiaccess, we are committed to upholding the highest standards and conducting ourselves with unwavering professionalism. Our mission is clearly defined and embraced by every member of our team. We remain driven and focused on the core principles that fuel our company’s continued success.

We strive to shape a world where accessibility is standard, not a luxury. Through the continued growth of our business and the delivery of our reliable products, we aim to empower individuals and communities by removing barriers and improving lives.

Our values form the foundation of everything we do. Guiding our decisions, shaping our culture, and driving us toward continuous improvement. They influence how we work, how we serve our customers, and how we evolve as a business. By staying true to these principles, we strengthen our reputation, build trust, and position ourselves for long-term success.

Our goal is to be the most reliable company in the industry. We take pride in consistently delivering excellence, not just through our products and customer service, but also as a dedicated team committed to trust, quality, and teamwork.

At Easiaccess, we are committed to continuous improvement and advancement. This allows us to constantly enhance accessibility, empowering people to live with greater independence and freedom.

We remain committed to upholding the expertise and professionalism that have defined us for the past 25 years. Ensuring the UK becomes more accessible is a core mission for us.

Creating cost effective products is a top priority for us. We strive to ensure that everyone can afford and benefit from our products without compromising on quality.

In an ever-changing world, adaptability is essential. We remain committed to staying current with evolving trends and challenges, ensuring we’re always prepared for what lies ahead. The ability to adapt isn’t just important, it’s crucial.

By embracing diverse perspectives, backgrounds, and experiences, we foster a culture where everyone feels respected, included, and empowered to thrive. We believe every voice matters and every opinion deserves to be heard.

With over 25 years' experience providing access solutions, we are trusted to provide our systems across the whole of the UK. Our ever expanding portfolio includes collaborations with a diverse range of clients, from local authorities to nationwide construction companies.

Further case studies and detailed examples of our installations are available on our website.

At Easiaccess, we pride ourselves on guiding every project from concept to completion, keeping you informed and supported at every step. From the initial site survey and detailed plans, through installation and date confirmation, to the finished product, our team works closely with you to ensure a smooth, hassle-free experience. We focus on clear communication, expert advice, and meticulous attention to detail, ensuring not only a high-quality installation but also ongoing support and aftercare long after the project is complete.

Our surveyor visits the site to understand your project goals and access requirements. We assess gradients, obstacles, and site restrictions, while working closely with you to ensure your preferences are included. Health and safety and coordination with site managers or contractors are also considered to create a practical, compliant solution.

On the agreed date, our professional installation team arrives on site, fully briefed on health and safety protocols, site conditions, and any special requirements. Our fitters are highly experienced, working efficiently while minimising disruption, liaising with contractors where necessary, and ensuring the adaptation is installed to the highest standard.

Following the survey, we produce detailed 2D and 3D drawings which are accompanied by a quotation, enabling all stakeholders to clearly visualise the finished project. Any necessary permits or approvals are also highlighted at this stage to streamline the installation process. 1 4 2 3 5

Once the plans have been approved and all requirements agreed, a member of the Easiaccess team will confirm and arrange a convenient installation date. We take care to schedule work around site restrictions, operational hours, and contractor availability to ensure a smooth, coordinated delivery.

Upon completion, you receive a fully functional access solution that is safe, secure, and tailored to the project’s requirements. Every detail is checked for quality, usability, and compliance with relevant standards, providing confidence, peace of mind, and a long-lasting solution for the site.

As the leading accessibility adaptation company, we offer a comprehensive range of services tailored to meet diverse needs. From site surveys and installations, to the supply of high-quality equipment and various training plans, we support every stage of the process. Our team is committed to delivering safe, effective, and inclusive access solutions.

Surveying is the process of assessing a site to plan for and ensure the effective, safe, compliant installation of access equipment. Our team maps out physical features such as height differences, slopes, surfaces, and surrounding structures. This ensures the design fits the space, meets accessibility regulations, and provides safe, reliable access for all users in public and commercial environments.

Every installation begins with a thorough site survey. An Easiaccess surveyor visits the location to assess the access requirements for the intended users and the operational needs of the site.

During the survey, key factors are evaluated, including user requirements, gradient, ramp type, and potential obstacles. Our surveyors are trained in health and safety procedures, hold CSCS cards, and can wear high-visibility clothing, hard hats, and other required PPE. They will also complete site inductions and liaise with site managers or contractors as needed to ensure a safe and coordinated assessment. A site sketch is created to outline the proposed ramp placement and its interaction with the existing environment.

Following the survey, detailed drawings are provided, showing the ramp’s location, style, and gradient, along with a quotation. This ensures all stakeholders can clearly visualise the final project. Our surveyors are available to provide expert guidance and answer any questions throughout the process.

During a survey, our team identifies any potential obstacles or restrictions, such as uneven surfaces, thresholds, steps, tight entrances, or limited access for equipment. We take detailed measurements, assess gradients, height differences, and surface types, and review health and safety considerations to design a solution that is fully compliant, safe, and user-friendly.

We provide a complimentary, no-obligation survey to assess the feasibility of an access solution and demonstrate how it would fit your site. Our team’s professional approach ensures the survey is carried out safely, efficiently, and in full coordination with your site requirements.

Contact our team today to schedule your survey and take the first step toward safe, accessible public access.

Once your quotation is approved, we’ll arrange a convenient installation date. At this stage, we review all site requirements identified during the survey, including access restrictions, working hours, and any permit considerations. This ensures that our installation team and any on-site personnel are fully informed and prepared, allowing the work to proceed smoothly and safely.

At Easiaccess, all installations are carried out by highly skilled professionals. Our installers hold valid CSCS cards and complete essential Health & Safety training, such as asbestos awareness, abrasive wheels, and ground scanning.

They are equipped to follow site protocols, wear required PPE such as high-visibility clothing and hard hats, and complete site inductions where necessary. Beyond technical expertise, our installers bring care and consideration to every project, ensuring the final installation is safe, compliant, and meets your expectations.

We combine advanced equipment, high-quality products, and experienced installers to complete ramps, step units, and handrails quickly and efficiently. Installation times vary depending on the project’s size and complexity, but our focus is always on minimising disruption to your site operations while maintaining the highest standards of quality.

Our support doesn’t end when the ramp is installed. We remain available to answer questions or address any concerns, and our products are backed by a warranty for added peace of mind. Should any issues arise, we are committed to resolving them promptly. Warranty durations vary depending on the product; for full details, visit our website or contact the Easiaccess team directly.

Our product and processes are the same as a full installation, with the only difference being that you either install the ramp yourself or hire the services of a subcontractor.

Our product is available from stock within 48 hours, except for special items which are subject to longer lead times. That, in conjunction with the modular nature of our products means that we can react very quickly and overall lead times are very short. Allowing fast turnarounds for self-installation.

For more information, contact our sales team on 0191 460 2777 or email at info@easiaccess.co.uk.

This element of the process is a crucial and final part of the process, we take great pride in ensuring that the goods are well packed, arrive safe, undamaged and on time for your planned installation.

Easiaccess always advise delivery to business premises ahead of an installation date, to give installers the opportunity to prepare for the installation and to avoid courier delays that may impact installation start times. Where site deliveries are unavoidable, Easiaccess will work closely with site staff to ensure that a nominated person is available to take receipt of the order and that the products arrive in a timely manner.

If you require our drawing services we will request a basic sketch of the required ramp, measurements of the site and some current site photos. The more information that is provided, the more accurate the end result will be.

Once in receipt of your information, we will produce and send a 2D & 3D visual, together with a quotation. Technical support is available through the process, from the start of your enquiry to the time that you are installing on site.

Modular solutions offer a range of benefits that traditional ramps and steps increasingly struggle to match. While there may still be occasional instances where a traditional approach is necessary, modular systems are rapidly becoming the preferred choice due to their costeffectiveness, efficiency, and versatility.

A major benefit to a modular solution is its re-usability. Once a product is no longer required, it can be easily removed from one location and used either in full or in part, in another. As such, a ‘recycling’ programme can help reduce financial outlay, maximising budget efficiency.

Our modular system is typically quicker to install when compared to other methods such as concrete. Minimal groundworks and integrated handrails allow for quicker installation times resulting in reduced labour costs.

Modular ramps are incredibly quick to install and can be used immediately upon completion.

The installation of a modular ramp is not restricted by weather conditions - it is not dependent on temperatures being above 5°C, unlike concrete.

High traction, self-draining platforms mean that water will drain quickly from platforms, ensuring enhanced slip resistance in all weather conditions. Especially when compared to traditional options such as timber and concrete.

Our modular solutions can easily be removed when no longer required and will not impact existing foundations or building facade.

Even after installation, our systems can be redesigned to suit a different need. This would not be possible with a concrete solution.

On medium to larger ramps, modular solutions are more cost effective as there is no requirement to build underneath the length of the ramp.

Metal modular ramps are durable, slip-resistant, low-maintenance, and fully adjustable. Unlike timber, which can rot, splinter, and requires ongoing upkeep, or concrete, which is permanent, inflexible, and slow to install, metal ramps can be installed quickly, modified or relocated, and provide a safe, cost-effective solution for any site.

We take our environmental responsibilities seriously, designing all products with longevity and sustainability in mind. To minimise our carbon footprint, we operate on 100% renewable energy with solar panels at our offices and warehouse, use mostly recyclable packaging, and closely monitor waste and recycling practices. Sustainability is central to everything we do, helping us contribute to a cleaner, more sustainable future.

As part of our commitment to sustainability, we have developed an innovative recycling scheme to extend the life cycle of our equipment. You can join our recycling programme, which offers a take-back service for products when they are no longer needed. We’ll store the item in our warehouse, restore and reconfigure it, and when it’s needed for future installations, you only pay the installation fee. This ensures our products are reused, reducing waste. At the end of its lifespan, we guarantee the product is fully recycled, minimising environmental impact and contributing to a circular economy.

From public spaces to private projects, we provide adaptable access solutions designed to meet the needs of diverse environments. Our modular systems are flexible, durable, and fully compliant, making them suitable for a wide range of settings where safe and reliable access is essential.

Easiaccess is the UK’s leading manufacturer, supplier, and installer of modular metal ramps, rails, and steps. Our products are crafted from high-quality materials to ensure exceptional durability and longlasting performance. We are committed to delivering reliable, accessible solutions with a strong focus on quality at every stage.

The Easiaccess Modular Metal Ramp System sets the standard for quality, versatility, and affordability. Engineered for both performance and compliance with the latest accessibility regulations, this system offers a range of options designed to meet the specific needs of any environment.

Whether you require different colours, surfaces, or railings, our customisable features ensure the perfect solution for your project. Installation is quick and hassle-free, making it an ideal choice for both residential and commercial use. For a complete look at the customisation possibilities, visit our customisable options page (P56 - P57).

In addition to providing top-of-the-line ramps, we also offer comprehensive training programmes for organisations wishing to install and maintain our products, ensuring seamless integration and long-term performance.

The Metal Modular Ramp System is manufactured from galvanised steel and is simply bolted together. Installation is quick and easy, with the ramp available for immediate use.

Modular ramps come with a range of amazing features as standard; such as our galvanised platforms and handrails for long-lasting, complete protection against the elements. As well as trombone ends, to prevent snagging.

The modular nature of each ramp means they are designed to facilitate easy dismantling and speedy reconfiguration without the need for any cutting or customisation.

With recycling and reusability at the centre of our product design, considerable cost savings are achievable.

One of the key features that sets our ramps apart is their ability to be used all year-round, regardless of weather conditions. Whether in rain, wind, or snow, our ramps deliver consistent safety, reliability, and performance.

TROMBONE ENDS

Prevent clothing from snagging and to guide hands safely to the end of the ramp.

BALUSTRADE RAILS

Designed to prevent objects larger than a 100mm sphere from passing through, ensuring added safety.

Provide a clear visual cue of an upcoming change in level. An essential safety feature for people with visual impairments.

The Easiaccess connectors create a smooth, continuous top rail that allows your hands to glide along with ease.

UPSTAND

100mm high upstand contrasting visually with surface, while providing additional safety.

ADJUSTABLE LEGS

Legs adjust in 35mm increments with threaded feet, making it easy to set them at the perfect height.

Modular step units provide an excellent alternative to traditional methods, such as brick and flag steps, which are frequently installed with non-compliant handrails.

The Easiaccess modular metal ramp system is a class-leading product which is extremely cost effective. The range of options available provide flexibility, whilst ensuring compliance with the latest access regulations.

The system has been designed to be quick and easy to install. We are also able to offer a full training programme to organisations that wish to install our products.

Easiaccess modular step units provide a reliable solution for creating accessible entrances. From schools to public buildings, and healthcare facilities, they adapt seamlessly to a wide range of site conditions while ensuring safety and compliance.

The modular design allows units to be easily relocated or reconfigured if requirements change, providing long-term flexibility. Installation is quick and straightforward, and we offer expert guidance and optional training for organisations that wish to install the units in-house.

Built with durability and visual appeal in mind, the units combine strong construction, tested components, and corrosion-resistant finishes.

The result is a professional, long-lasting solution that gives confidence to specifiers, installers, and end users alike.

Easiaccess modular step units are more than just steps – they offer a dependable, future-proof way to create safe and accessible entrances wherever they are needed.

Our modular step units are designed for quick installation with minimal disruption. Components are prefabricated and delivered ready to assemble, ensuring projects can be completed quickly and efficiently. Reducing downtime while allowing safe, compliant access to be in place much sooner than with traditional construction methods.

A major benefit to a modular solution is its re-usability. Once a product is no longer required, it can be easily removed from one location and used either in full or in part, in another. As such, a ‘recycling’ programme can help reduce financial outlay, helping to stretch budgets much further.

Every environment is unique, which is why our step units are engineered with flexibility in mind. Height, gradient, and layout can all be tailored on-site to suit specific site conditions. This level of adjustability ensures a precise fit, compliance with regulations, and a safe, user-friendly solution for all access needs.

To meet the varied requirements of different sites, our step units can be complemented with a wide range of options. Handrails, colourcontrasting features, and bespoke finishes can all be incorporated to enhance usability, visibility, and aesthetics. These additions ensure safety and preference for each installation.

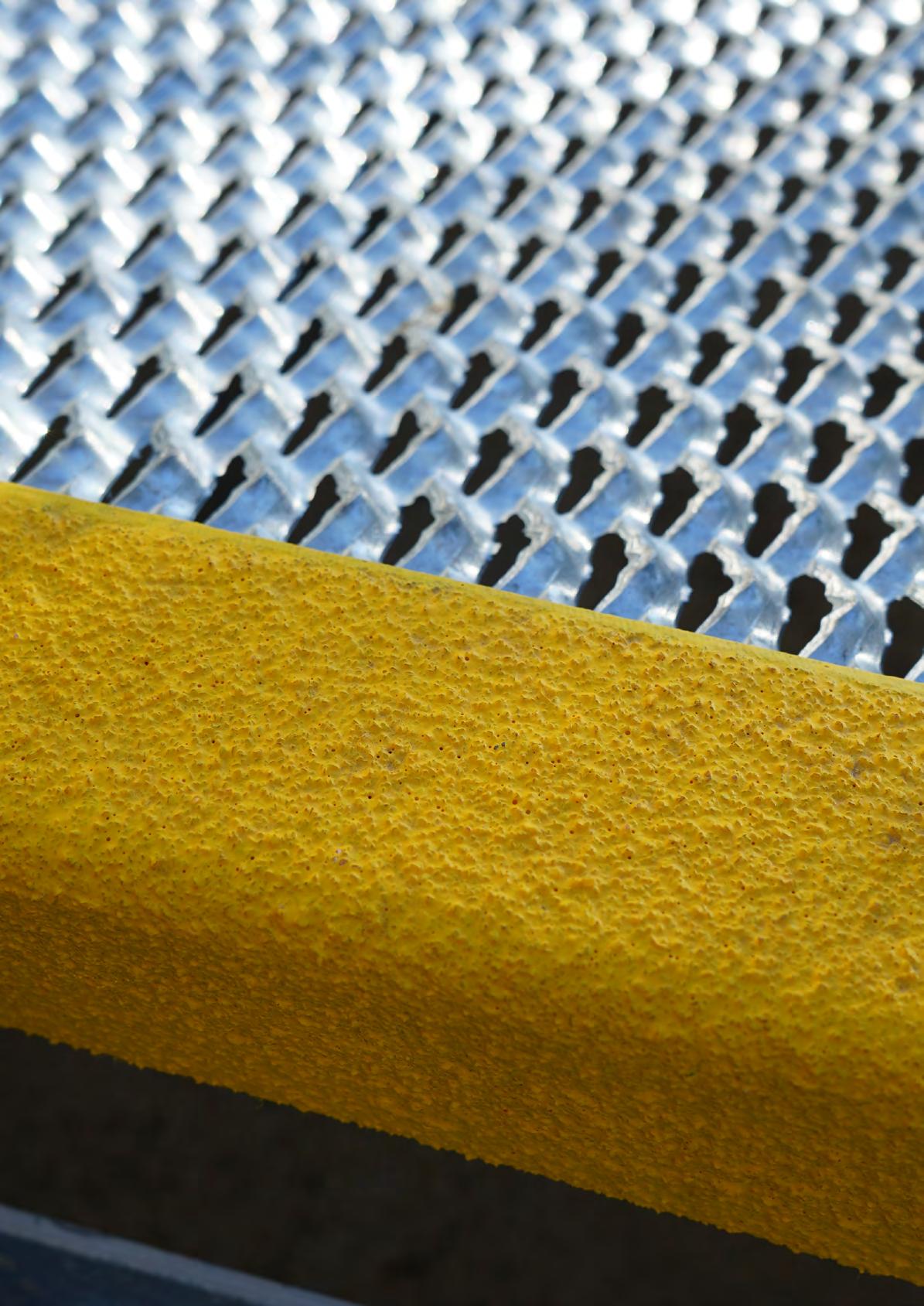

Whether positioned alongside existing steps or running down a walkway, Easirail avoids the traditional “industrial look” that other handrail systems provide, with oversized joints and a bare unpainted finish.

Using high quality materials and finishes, Easirail is designed to be fast to install, offering flexibility for a wide array of configurations. All rails and posts are galvanised and pre-coated for a corrosion resistant, durable finish.

The handrail is either selected from our pre-cut lengths or simply cut to size and attached using ultra strong rivets, providing a quick tamper-proof and secure method of installation.

Easirail is highly versatile, allowing for straight runs, gentle curves, and multiple intermediate platforms to accommodate complex site layouts. Its lightweight yet robust construction makes it easier to handle on site, reducing installation time and labour costs.

Each component is engineered to withstand harsh environments while maintaining a sleek, modern finish. The system’s clean lines and concealed fixings create a visually appealing finish that enhances the surrounding environment.

Optional accessories, such as midrails or underside skirting, can be incorporated to increase safety

and prevent debris accumulation without compromising aesthetics. Its modular design allows for easy future adjustments or extensions, providing long-term flexibility.

The materials used also require minimal maintenance, ensuring the handrail remains attractive and safe for years to come.

Our 42mm handrail tube is attached directly to the posts and brackets using 4.8mm domed rivets, providing a quick, strong and tamper resistant method of attachment. Additional rivets can be used to provide enhanced security, if required. All tubes are fully galvanised and powder coated providing a longlasting fine textured finish.

Our adjustable posts are either surface mounted by securing directly to the ground or permanently fixed into concrete. The high-grade stainless-steel thread provides up to 30mm vertical adjustment, making an installation easier when the ground is uneven.

OPEN TOP TO RECEIVE A CONNECTOR

ER-VP9T VERTICAL TERMINATION POST

900mm handrail post screwed/bolted directly to the floor

PIVOTING TOP PLATE

HEIGHT ADJUSTABLE EASY TO USE LOCK SYSTEM

ER-VP9/VP14/VP18 VERTICAL POST

900, 1400 or 1800mm post lengths to support a handrail

Our vertical posts and bracketry incorporate a marine grade stainless steel top plate bringing the following benefits:

• Resistant to corrosion and harsh environments even when they have been drilled or scratched.

Due to the construction of the stainless steel top plate, it ensures the handrails are exceptionally strong, durable, and long-lasting.

All vertical posts that utilise the top plates are embossed with our company logo – so you know you are getting a genuine product. The connectors are embossed with the product code for easy identification.

• Widened profile to better support the handrails and “cupped” to provide increased rigidity.

Multiple rivet hole positions and a short plate allowing for an easy, flexible installation.

Utilises screw thread to provide height adjustability.

• A wide range of horizontal adjustment is achieved by utilising a central pivot point.

EFFECTIVE CORROSION RESISTANCE

MULTIPLE RIVET HOLES FOR EASE OF ATTACHMENT

ADJUSTABLE FOR FLEXIBILITY

We offer a range of slip-resistant surfaces, each with unique features and benefits, available across our full platform range. All options are designed to withstand high weight capacities and frequent use, making them ideal for both everyday access and high-footfall environments.

Surfaces can be customised with highlighted edges or colours to suit different settings. Metal surfaces are often chosen for domestic applications, while GRP and Easitread are typically preferred for non-domestic use. Our team can advise on the best option for your specific requirements.

MOST POPULAR, HIGH QUALITY AND COST EFFECTIVE

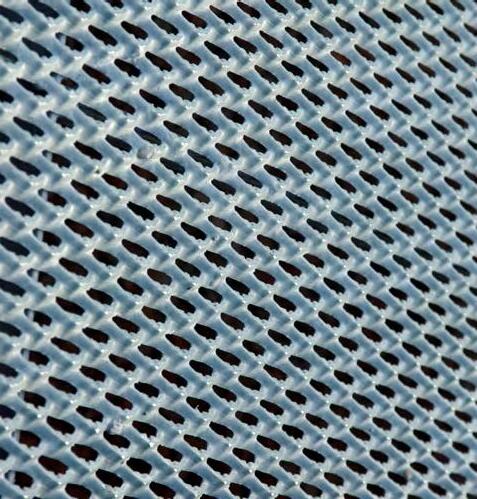

Our expanded metal surface is a high quality, cost effective option, produced from mild steel. The multi-directional slip resistant surface has been tested and certified to BS7976 Part 2 (Pendulum Test) and has been identified as having a low slip potential rating (>35 PTV) across a range of gradients, in both wet and dry conditions. The properties/design of the surface provides natural drainage allowing users to maintain a secure footing in all weather conditions. Due to the mesh profile, grip is provided in all directions and is designed to create a comfortable yet sturdy surface underfoot, that is suitable for most types of footwear.

• Readily available from stock.

• Self-draining and comfortable underfoot. Can be removed and reused on numerous occasions.

• Available in widths of 900mm, 1000mm, 1200mm and 1500mm, other sizes can be created by bolting multiple sections together. Hatch sections can be provided to maintain access to inspection chambers.

• Can be sprayed to include a “highlighted edge” for use by people with visual impairments. Multi-directional low slip potential surface.

• Easy to clean and maintain.

Expanded metal is produced by an expanding machine, which turns solid metal sheets (in our case steel) into an expanded metal mesh. The expanding machine is fitted with a knife which determines the pattern for the mesh. As the metal is fed through the expanding machine, it is cut and stretched simultaneously using a pressured slitting and stretching process. The slits created by the knife allow the metal to be stretched, which produces uniform holes. This mesh is then welded onto the steel frame to create our platforms that make up the ramps. These platform sections are then hot dip galvanised, a process that involves dipping into a bath of molten zinc. This provides an extremely effective barrier to all weathering and totally prevents rusting.

Expanded metal platforms and sections can be cleaned with water, a mild detergent and a hard brush where required. In most cases debris below the ramp can simply be brushed away.

Weed killer should also be used, where required, to suppress plant growth; this can be sprayed through the surface of the ramp without any adverse effect.

For our high traffic and safety surfaces we would recommend a high-powered hose to remove any contaminants and other debris.

Easitread is porous, hard-wearing, and weatherproof. It provides a soft yet durable walkway with excellent drainage properties, while also absorbing impact, making it ideal for use in child friendly environments, like nurseries, schools, and leisure centres.

Produced in black as standard, (colour options are available at an additional charge), it is also possible to incorporate highlighted sections or even signage/branding – please contact a member of the team to discuss these options.

To create the Easitread platform, rubber granules are screeded on to a metal platform frame at a thickness of 15mm, using a polyurethane binder. We do not use low grade EPDM & colour coated rubber granules, but opt for the highest quality granules available in the UK.

Their unique chemistry, raw materials and advanced manufacturing processes, ensure consistent, vibrant coloured granules that deliver unrivalled UV resistance and long-lasting elasticity. This ensures that the surface will remain supple to the touch, even after extremes of UV ageing, helping it withstand many years of wear and tear.

Available in a range of colours and can be incorporated with highlighted sections/edges or branding/signage.

• Highly durable, UV stable and with long-lasting elasticity.

• Effectively absorbs impact from falls and trips - perfect for schools. Self-draining and comfortable underfoot.

• Non-toxic and non-allergenic.

• Short lead times. Pet friendly.

Occasional brushing with a mild detergent solution may be desirable to restore appearance and remove any deposits such as mud. For our high traffic and safety surfaces we would recommend a highpowered hose to remove any contaminants and other debris.

GLASS REINFORCED PLASTICTOUGH AND DURABLE

Our GRP surface is 6mm thick, extremely tough, durable and designed with enhanced slip resistance. Making it practical for use in high footfall environments such as hospitals, museums, and airport installations. Available in grey and black as standard, the edges can be highlighted to signal the start/end of a ramp or platform as required.

The standard surface grade is 24 (known as ‘Pedestrian Grade’) indicating that for every cm2 there are approximately 24 pieces of aluminium oxide, itself much harder wearing compared to common quartz finishes. Other surface grades available are 40 (‘Barefoot Grade’) and 16 (‘Industrial Grade’).

The GRP sheets are manufactured from glass fibre, high grade isophthalic polyester resins, UV stabilisers, flame retardants, colour pigments and aluminium oxide granules. This coating provides a higher level of resistance to impact, abrasion, and solvents - making it ideal for public access ramp installations.

The GRP surface is fixed to a specially designed galvanised steel frame using a single part polyurethane sealant and rivets, providing an extremely strong solution. These platforms can be supplied readymade, or can be delivered separately as a sheet and frame, whereby they can be installed on-site.

Long lasting and durable. Highly effective anti-slip surface.

• Suitable for all environments.

• Little or no maintenance requirement - easily cleanable. Reduced weight compared with rubber crumb/metal. Rapid and easy installation - choice of fasteners/adhesives .

• Refined, extra-hard aluminium oxide granules providing superior performance and wear characteristics. Choice of grades and colours . Pet friendly.

Occasional brushing with a mild detergent solution may be desirable to restore appearance and remove any deposits such as mud. For our high traffic and safety surfaces we would recommend a high-powered hose to remove any contaminants and other debris.

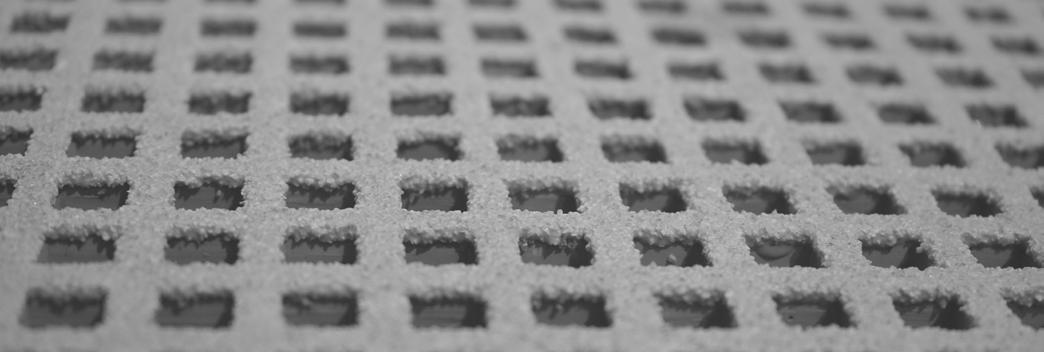

Glass-Reinforced-Plastic Open Mini-Mesh panels (Waffle) are renowned for their exceptional durability, load-bearing capacity, and resistance to harsh environments.

They are specifically designed for pedestrian walkways in diverse settings, including domestic, industrial, and commercial applications. Common uses encompass ramps, platforms, and gantries.

This is manufactured in a similar way to GRP, with the addition of quartz granules for enhanced slip resistance. The reduced mesh openings meet ballproof safety standards, prevent debris build-up, and allow smoother movement for wheelchairs, trolleys, and other wheeled equipment.

Cleaning:

Routine cleaning can typically be achieved by brushing away debris.

For more stubborn dirt, a solution of mild detergent and water applied with a stiff brush may be necessary.

• Weed growth can be controlled by applying a suitable weed killer directly to the mesh surface. This will not adversely affect the material properties of the GRP Mini Mesh.

• High-pressure water washing can be used to assist with cleaning, ensuring a safe distance is maintained.

Winter Conditions:

• Ice and snow can be removed by sweeping.

• The use of de-icing salts or chemicals will not adversely affect the material properties of GRP Mini Mesh.

Lightweight and Robust: offering a balance of strength and ease of handling.

• Abrasive Anti-Slip Surface: enhancing safety by providing superior slip resistance.

• Reduced Hole Size: compared to standard sized Open-Mesh GRP grating, Mini-Mesh features smaller apertures, facilitating smooth and unimpeded pedestrian movement and minimising the risk of trips and entrapment caused by some footwear.

Improved Accessibility: provides a smoother surface for wheeled traffic, including wheelchairs, scooters, and other wheeled equipment.

• Enhanced Debris Containment: prevents the passage of debris while ensuring effective liquid drainage and ventilation.

GRP Mini-Mesh panels offer a practical and safe solution for pedestrian walkways where durability, safety, and ease of maintenance are paramount.

We can provide a hazard warning surface such as Corduroy, Tactile or Blister effect paving – this is compatible with all our surfaces mentioned above. Hazard warning paving systems offer significant advantages over traditional yellow nosing as they provide a hard-wearing surface that warns people using the ramp, who maybe visually impaired, that there is an upcoming “hazard” such as a ramp flight or some steps. They provide fast and easy installation and provide full compliance with building regulations and the Equality Act 2010.

Crucially, these hazard warning systems also hold a low slip potential rating and are also not subject to freeze/thaw or spalling.

Colours as standard are Buff and Charcoal Grey. Typical paver size is 400x400mm.

All hazard warning tiles can be incorporated across our full range of walkway surfaces - for more information please contact us to speak to a member of our team.

• Rapid installation – reduced labour costs and disruption

Ready to use within 2 hours

• Tiles are lightweight and easy to cut, no hot works permits required

Very durable, harder wearing than concrete

Will not crack/spall like concrete

• High slip resistance

• Can be installed even in damp weather conditions

UV tested – no colour fade

• Freeze/Thaw tested

• Quality assured – manufactured to BS EN ISO 9001-2008

The Hazard Warning is extremely durable therefore requiring little to no maintenance in most external environments. Occasional brushing with a mild detergent solution may be desirable to restore appearance and remove any deposits such as mud. For our high traffic and safety surfaces we would recommend a high-powered hose to remove any contaminants and other debris.

We provide a wide variety of customisation options to ensure our products meet your specific requirements. Whether you’re looking for functional adjustments or aesthetic enhancements, our tailored solutions are designed to fit your exact needs, delivering the perfect result for every project.

Our product development specialists can create tailored access solutions that fit your exact requirements. Adapting our existing solutions to suit different spaces, styles and specifications.

Balustrade handrails reduce open spaces to under 100mm and are required when heights exceed 380mm. In nursery schools or similar, balustrade is often preferred for the safety of small children. Midrails are an optional extra and are a useful addition to assist selfpropelling wheelchair users.

Handrails must contrast with the surface of the ramp, with highlighted edges/nosings incorporated to signify level changes and step edges, particularly useful for those who are visually impaired. We offer black as standard (RAL 9005) but can provide other colours subject to a lead time and surcharge.

Hatch sections provide built-in access to drains, manholes, or service points located beneath a ramp or platform. They are seamlessly integrated into the modular design, allowing maintenance to be carried out without dismantling the system. This option keeps ramps fully functional while ensuring essential services remain accessible.

Sometimes specified for ramps constructed at height or when heavy duty use is expected, cross bracing is utilised to reinforce the ramp structure, incorporating intersecting diagonal and horizontal supports.

Boxing in underneath ramps is regularly requested to prevent rubbish and debris collecting and stop pedestrians or wildlife getting under the equipment. The method can vary between using mesh or more substantial boarding as determined by the client.

Midrails provide an extra horizontal rail positioned between the top handrail and the platform, enhancing safety and stability. They are particularly beneficial for wheelchair users, helping them self-propel along the ramp. Midrails also create a more enclosed feel to ramps and steps, offering reassurance for users of all ages.

Highlighted edges is a safety feature to help those with impaired vision identify the start and end of a ramp or level change.

We take great pride in showcasing our installations, as every project reflects our commitment to quality and craftsmanship. In our detailed descriptions, you’ll find insights into how each job comes together, including the challenges we encounter and the innovative solutions we apply to meet deadlines and time frames.

Every job is unique, with distinct requirements such as environmental considerations or bespoke product designs, ensuring that we tailor our approach to suit the specific needs of each project.

The customer for this project was a company that supplies and installs modular buildings that are used to provide merchandise stores for professional sports clubs. They were contracted to install a new temporary merchandise store for Newcastle United Football Club. This was designed to be used for a total of 12 weeks while the permanent kit store within St James’ Park was being refurbished ready for the beginning of the new football season.

Within this project we were asked to survey a working construction site, once the modular buildings had been installed in the proposed location, and to discuss all available options with the client, about the surface of the ramp given its use by the public. The tight timescales of the project, meant we had to undertake a survey as soon as the building works commenced.

Easiaccess were able to survey this on the 6th May and the equipment was all installed on the 13th Mayan overall turnaround time of 1 week from survey to installation.

The ramp needed to be suitable and fit for purpose, following on from our site survey we determined that the ramp needed to have the following specification:

• Balustrade handrails - This is required within non-domestic settings at heights of over 380mm.

• Ramp dimensions - 5.8m in total length and included the main platform of 2700x2500mm.

• Gradient - 1 : 15 gradient as per surveyors recommendation.

• Continuous handrails - We used our standard connectors which allow continuous handrails meaning we could ensure compliance.

• 1100mm high handrails - To all level walkway areas.

The install was completed within 12 hours, our installers were able to liaise with the office staff and keep them up to date with progress and the project management team were able keep the client up to date with the install.

It was proposed that the ramp be removed once no longer needed (12 weeks) and then moved to another location where our client can reinstall the ramp/steps. This was a notable project to work on, in light of our employees’ interest in Newcastle United.

The client was very happy with the installation, and we were pleased to support both them and Newcastle United Football Club in opening the new merchandise store.

The requirement for this unique project, was the supply and installation of a temporary metal modular walkway and ramp system, that would effectively be used as a raised gantry to allow access from the St Michael’s Street entrance to the park across an area of the park known as Bell Meadow. This area had been cordoned off from the general public for an 18 month period due to extensive flooding, which had caused significant damage to the tarmac path that runs through Bell Meadow, making access impossible for anyone who wished to access this area of the park.

Whilst the design and manufacture of our equipment is an important factor when it comes to safety and functionality, the survey, specification and installation of the equipment is equally important.

We have amassed a wealth of experience surveying and installing access solutions in all kinds of environments, and are highly skilled in ensuring the solution specified will be fit for purpose, compliant and future-proof.

Our installation teams are fully qualified, highly trained and DBS cleared. We have amassed a wealth of experience surveying and installing access solutions in all kinds of environments, and are highly skilled in ensuring the solution specified will be fit for purpose, compliant and future-proof. Our installation teams are fully qualified, highly trained and DBS cleared ensuring a safe, efficient.

The install was completed after 40 hours on site, our installers were able to liaise with the local authority staff who were able to meet our team on site to discuss any extra requirements and keep the project running smoothly. We liaised regularly with the public and local stakeholders at the park entrance, providing updates and ensuring safe access during installation.

The installation presented several challenges, the significantly damaged path, which was extensively flooded, proved difficult to work with – due to flood water, damaged tarmac, extensive debris from the flooding and the path was not a perfectly straight footpath, it was strewn with small angles and slight deviations along the route.

We are proud to have delivered this project and happy to have played our part in the reopening of the Bell Meadow section of Verulamium Park. As mentioned, the project was not without its challenges but the end result makes it all worthwhile and Easiaccess are incredibly proud of the finished installation.

The project required the supply and installation of a semi-permanent metal modular access ramp to a two-storey modular classroom building, providing both ramped and stepped access for students to safely enter and exit the new classrooms. The school contacted Easiaccess directly, having been satisfied with a previous ramp installation at the site.

During the survey, it was determined that, given the nature of the site and the number of students using the ramp, it would be beneficial to provide stepped access opposite the ramp for those who preferred not to use it. The school also requested that the ramp be enclosed beneath to prevent access and limit debris build-up whilst requiring work to be carried out during half-term, ensuring no students were on-site and only a limited number of staff were present.

• Balustrade handrails - 1100mm high on all walkways and intermediate platforms, ensuring compliance with Building Regulations (Approved Document M).

• Ramp dimensions - 7.8m long with a 1.5m × 1.5m intermediate platform, 1:15 gradient as recommended by surveyors.

• Continuous handrails - Standard connectors maintain uninterrupted handrails for full compliance.

• Plans & drawings - 2D plan and 3D elevation provided.

• Threshold extension plate - Smooth transition from ramp to existing platform.

• Highlighted edges - 55mm yellow strips provide visual contrast for users with visual impairments.

• Underside Skirting - Treated timber boards installed to prevent access beneath the ramp.

The install was completed after 16 hours on site, our installers were able to liaise with the estates manager of the school to ensure we could gain access to site and ensure smooth deliveries of any products/equipment.

The installation was relatively straightforward, we were removing an existing timber ramp and replacing it with our modular system.

Overall, the ramp we provided created safe access to and from the classroom unit. With this classroom being used by upwards of 100 students per day, we needed to provide the most suitable, safe and compliant ramp as possible.

All our products have been developed from the ground up, to be fully compliant with the latest accessibility regulations, whilst being tested for strength, corrosion resistance and safety against recognised standards.

This gives us the ability to offer our market leading warranty period, providing clients with the confidence they are receiving a high quality, tried and tested system.

Our walkway surfaces provide multi-directional slip resistance and have been tested and certified against BS7976 Part 2 (Pendulum Test), scoring a low slip potential rating (>35 PTV) across a range of gradients, in both wet and dry conditions.

Tested against the requirements of BS4592, our standard surface satisfies the requirements of the 3kNm loading conditions. We can provide 'heavier duty' surface options when required.

Our handrails have been tested against and satisfy the load deflection requirements of BS6180:2011, with an acceptable level of deflection against pre-defined loads.

Our system is predominantly manufactured from mild steel, and is galvanised to EN ISO 1461 standards, offering superior corrosion resistance as verified via the destructive “Salt Spray Test” (ASTM B117).

Our electrostatic powder coated handrails, with a highly durable, fine textured, non-reflective surface, satisfies the ‘not cold to the touch’ criteria. Cross hatch testing to EN ISO 2409 provides quality assurance.

The Equality Act 2010 has major implications for sectors like construction, infrastructure, and public services, requiring 'reasonable adjustments' to be made to ensure accessible environments.

Approved documents are an extension of building regulations, offering detailed guidance on satisfying the requirements of BS 8300, designed to provide recommendations on inclusive and accessible design of buildings the spaces within them.

Covers recommendations that seek to ensure everyone can access and use buildings and their facilities safely and comfortably.

Addresses the safety of building users by providing protection from falls, collisions, and impacts in and around the building.

Our team is dedicated to delivering safe, accessible, and fully compliant solutions that meet the needs of all users and our system has been designed from the ground up with compliance in mind.

Unobstructed landing lengths of at least 1200mm and flight widths of at least 1500mm.

• Intermediate landings at least 1500mm long and clear of door swings or obstructions.

• Individual flights not longer than 10m, for gradients not steeper than 1:20, 5m for gradients not steeper than 1:15, and 2m for gradients of 1:12.

Kerbs on any open side at least 100mm high, which contrasts visually with the walkway surface

Slip resistant surface, especially when wet.

Highlighted edges to level changes and step nosings to aid visually impaired users.

• Continuous handrail on each side of a flight and landings.

• Tactile hazard warning surface considerations when circumstances require.

Handrails terminated in a way to prevent snagging of clothes whilst projecting 300mm past end of the ramp.

1100mm high balustrade handrails to all landings, and 900-1000mm to all ramps and steps, when height is over 380mm from ground level.

• Balustrade handrails to ensure no passing point of more than 100mm.

• Step options can be added, for use by ambulant users.

32 - 50mm outer diameter of main handrail.