Daniela

Kamila Bouskova

Kamila Hanelova

Kasper Vrijbloed Lori Goodwin

Roel van Leeuwen

Volker Müller

Wilbert Stapelvoort

Willem Schreurs

Esmée Booms

Daniela

Kamila Bouskova

Kamila Hanelova

Kasper Vrijbloed Lori Goodwin

Roel van Leeuwen

Volker Müller

Wilbert Stapelvoort

Willem Schreurs

Esmée Booms

intense. Fortunately, we’ve recently been able to add a number of great large projects to our portfolio

course, there are the usual teething problems, but overall, it feels like a very good and comfortable working environment. Compliments to the project team for working day and night to get it all done on time! Meanwhile, the setup of the building on Edisonstraat is also progressing steadily.

Business-wise, things are in full swing and we’re operating in a highly turbulent environment. Naturally, everyone thinks of developments in the US, China, Russia, Ukraine and so on. And even before all those developments, the economic situation in Europe was already far from ideal. The silver lining might be that European governments have once again come to realize the importance of a healthy business climate.

As you may know, we managed to achieve another good year, partly thanks to favorable steel price developments. However, we’ve been noticing for a while that the market has become more challenging and we need to work hard to secure new business. Competition has become quicker and much more

A few weeks ago, we also participated in the LogiMAT trade fair in Stuttgart. It was encouraging to see that the event was busier than last year. Many of our contacts visited our stand, which gives us some hope for the future. It also became clear that the trend toward robotization will definitely continue.

There are also several internal developments underway. Projects like 3D, modularization and the investments in the US are essential for the long term. In addition, we’re also implementing some organizational changes to make our company more future-proof. It’s important that we keep moving forward.

I’d already like to wish you all a wonderful holiday season!

Kind regards,

Hans Jacobs

The logistics world is constantly evolving. To stay aligned with the changing market and customer needs, we have revised our current vision and mission.

Through various brainstorming sessions, we explored NEDCON’s DNA, our unique strengths compared to competitors and how we can remain relevant in the market. This has resulted in a new vision, mission and pay-off.

Vision

We are living in a fast-changing world in which robotization and scarcity of human capacity are big themes and the economy, environment and customer demands are constantly changing. It is NEDCON’s goal to enable organizations to meet these challenges with smart and safe storage solutions.

Context vision

Currently, we see several important market trends:

Automation & robotics

Flexibility & scalability

Sustainability

Local warehouses

Mission

To design and realize smart, safe storage solutions, to enable customers to increase their logistic efficiency.

Context mission

We have researched the biggest challenges our customers and end-users face. These include:

Improving efficiency

Fast delivery & reliability

Flexibility & scalability

Minimum space required

Speed of the picking process

Sustainability

Pay-off

smart. safe. storage solutions.

Context Safe

Safety is deeply embedded in our DNA and is one of our key differentiators. While it may seem self-evident to us, this is not the case for all competitors.

The first sentence of our Health & Safety policy perfectly reflects our approach to health and safety:

„Health&SafetyofallemployeesisforNEDCON an objective as important as turnover, profit, quality, productivity and other dominant objectives.

„

Context Smart

The core value ‘Smart’ has multiple layers, which is why we have broken it down:

The interpretation of these core values may differ per department. Our managers actively work on integrating the SMART philosophy within their teams and linking it to concrete objectives, allowing us to measure and improve progress.

We are proud to introduce our new pay-off and will implement it sustainably by gradually adapting our materials to align with our new branding.

Making time for your hobbies is a vital part of a healthy work life balance & offers a break from the daily grind of work, driving the kids EVERYWHERE and other endless stressors that tend to pile up. Hobbies provide you with an opportunity to express yourself, relax and grow, resulting in increased happiness and satisfaction. Unfortunately, for many of us (myself included) it’s all too easy to flop on the couch after a long day at work and binge-watch Dexter or The Office. While this may be relaxing it provides no growth or self-improvement leaving you feeling unfulfilled.

Let me preface this by saying I’m a big nerd with a lot of interests and limited time. I enjoy traveling, biking and kayaking with my wife, swimming and lifting with my daughter and playing board games and building LEGO with my son. These are both mentally and physically fulfilling, but half are seasonal and all require another person. So, I’m going to focus on one that I thoroughly enjoy but is the hardest to find time for and that’s writing and performing standup comedy.

Writing on my phone

I’ve been performing amateur standup on and off for several years, but I write on a regular basis. Even if it’s just a rough idea or something funny that just happened I’ll whip out my phone and write it down. Then when I find the time and courage, I’ll reach out to a local comedy club to join their open mic night. In fact, Dennis encouraged me to get back on stage and perform last fall. Of course he didn’t come to the show, but I still appreciated the encouragement.

Five minutes

Once I have a date set it forces me to take those snippets and expand on them until I have about five minutes of material. Five minutes may not sound like much, but if you’re not getting laughs, it’s an eternity. Reading through my notes is one of my favorite parts of the process. It lets me reflect on moments I might have forgotten and, occasionally, leaves me wondering what I was thinking when I wrote that in the first place. Unfortunately, the latter happens more than I’d like, but at least it still makes me laugh. Case in point: a note I scribbled while in Amsterdam „I’m so old, the only drugs I took in Amsterdam were Tylenol.“

Rehearsing

At this point I’m about a week out from the date due to procrastination and I’ve written and revised it so many times none of it seems funny to me anymore. I write out a 1-2 word note card as prompts for the jokes. Then I rehearse it in my head over and over again timing it out and including pauses for laughter… PLEASE LET THERE BE LAUGHTER.

Awaiting my turn

I even practice in the bathroom, quietly mumbling my set in front of the mirror. My wife has never commented on my extended bathroom breaks or my mumbling, but the next day, I noticed some constipation medication on the counter with a Post-it note that simply said: Love you. Finally, the big day has arrived. I’m equal parts excited and anxious with a touch of constipation. I think my wife knows me better than I know myself at this point. I

sit with friends anxiously awaiting my turn to get on stage while listening to other amateurs and rating them in my head. I laugh at everything, even the stuff that’s not very funny in the hopes that they’ll grant me the same kindness.

Into the bright lights

I nervously glance at my note card 500 times as if something might magically change. Then, my name is finally called. My heart skips as I rush up on stage, thank the host and while staring into the bright lights forget everything. Luckily, this brief paralysis is something I’ve come to expect. I fiddle with the mic for a second, glance at my note card on the stool and launch into my first joke. It lands. Solid laugh. The adrenaline kicks in.

The next four minutes are a blur of laughter and bright lights. I exit stage left with a smile, an adrenaline high and a sense of accomplishment.

In August 2023, just before successfully handing over our latest big project completed with TGW Austria in Poland, we received the next big order from TGW. This project involves supplying an automated Beamtype Miniload racking for a leading European fashion-specialist’s new logistics center, with a total order sum of almost 12 million euros.

The contact with TGW was still warm as we worked together with the same contact persons as we did for the project in Poland. This made the collaboration effective right from the start.

Location

This newly built project site is located on an industrial park nearby Cheb in the Czech Republic, just 15 kilometers away from the eastern German border. But even more important, the site is only 300 km from our production facility in Pardubice, which is very beneficial for a system consisting of 90% self-produced parts.

Scope, specs and numbers

Racking type:

Length:

Height: Depth

Capacity:

Crane type:

Load h andling device:

Toprail:

Supplied options

AUT-ML3 (Beamtype Miniload)

The new distribution facility stretches over a length of 700 meters and counts a total footprint of approximately 120,000 m2. It has been divided into 7 intermediate building sections, containing multiple types of storage and distribution systems. Our scope has been concentrated in the last 2 building sections, 6 and 7.

37 bays / 137 load units / 110 meter

30 levels / 30 load units / 18 meter

46 crane aisles / 276 load units / 237 meter

1.083.396 load units

TGW Mustang E+ with top drive and top buffers

Twister X V3

Flat steel bar 90 x 30 mm (supplied and installed by TGW)

Integrated conveyor platforms incl. portal construction and handrailing

Overhead netting protection

Safety mesh fencing front / rear including doors (h=2200 mm)

Safety mesh fencing along 4 racking sides (h=2200 mm)

Vertical safety netting along 4 racking sides (2200 mm – 18000 mm)

Special dilatation joint beams

Platform cantilever construction

Total weight

Total length of uprights

Total length of diagonals

Total length of beams

length of shelves

From an Engineering point of view, a project with a Beamtype Miniload system seems to be quite standard and modular in the first place and actually for a large part it is. But it are the project specific challenges which really show how important the added value of experienced project engineering is.

Starting with integrating the system into the new building, which in several areas caused a lot of challenges in designing the top drive and top buffer bracing, which we normally guide straight forward down to the ground. In this project, at certain locations this area was blocked by a building column, so the situation asked for a special design.

As well as the TGW conveyor lanes which had to be integrated at the front side of the system over a 4 meter high platform. The combination tight TGW specifications, safety precautions and the integration of fire safety systems such as sprinkler and smoke detection, caused some inspiring cases for engineering. These resulted in the integration of some huge project specific portals over the complete front area of the system. This process was well led by Ahmad Hassan as project lead engineer.

On top of that, the involvement of different stakeholders with various nationalities in such a large project demands extensive communication and coordination. Ensuring that all parties are aligned and confident in the designed solution is essential.

On top of that, the involvement of different stakeholders with various nationalities in such a large project demands extensive communication and coordination. Ensuring that all parties are aligned and confident in the designed solution is essential.

Since the beginning of the project we started intensively discussing the project installation timeline, site circumstances and site infrastructure together with TGW. In some cases, this seemed to be a bit early in the whole process. However, it eventually gave us the advantage of leading discussions about the

installation timeline, as we were well prepared and able to inform logistic integrator Fortna in time.

Our installation was led on site by our Czech colleague Ladislav Takac. In combination with Czech subcontractor Jasopa from Pardubice, on a Czech building site, you can imagine this has been given allot of benefits. After a challenging starting period in Q4 2024, when we were installing the heavy portal constructions and integrated mezzanines, we eventually managed to stay on track and even catch up a week delay in the start of Hall 7, caused by unfinished roof lighting work.

In March, a group of Czech colleagues visited Cheb to get a close-up look at the installation of the project. During a guided tour of the project site, they gained detailed insights into the installation of our racking systems.

The demand for sustainable solutions is growing. Our customers, suppliers and society increasingly expect environmentally friendly alternatives. At NEDCON, we are responding to this demand by offering greentec steel: a type of steel with the same quality as regular steel but with significantly lower CO₂ emissions.

The combination of various techniques makes it possible to reduce CO₂ emissions for steel products. With these technologies, we provide our customers with an environmentally friendly alternative to conventional steel.

A 5% reduction in Austria’s total CO₂ emissions

In the future, we aim to reduce both our own CO₂ emissions and those within our supply chain. Greentec steel plays a crucial role in this effort.

As of today

Greentec steel is a process optimization that uses green electricity and cleaner alternatives to coal, resulting in a CO₂ reduction of approximately 10%.

From 2027 onwards

Greentec steel will have an even greater impact through the implementation of two Electric Arc Furnaces (EAF). This technology will drastically reduce CO₂ emissions from steel production, and in the future, it will even be possible to produce carbon-neutral steel using EAF. voestalpine can reduce CO₂ emissions by up to 30%, which corresponds to 5% of Austria’s total CO₂ emissions. For NEDCON, this could lead to a significant reduction in emissions within our supply chain.

In the meantime

Our goal is to minimize CO₂ emissions wherever possible to protect the environment. We aim to accelerate this process by selling three greentec steel projects in the coming year and ensuring that greentec steel is mentioned in every quotation process.

The European Union has introduced regulations requiring companies to report their CO₂ emissions. The EU aims to become carbon neutral, with various interim targets to be achieved between now and 2050. For NEDCON and voestalpine, greentec steel is crucial in meeting these targets. CO₂ reporting and reduction are also becoming increasingly relevant for large intermediaries and end customers, as they must report their own CO₂ emissions and those of their supply chain once they meet certain criteria.

The conventional steel production process in a nutshell

The standard steel production process follows the traditional Blast Furnace (BF) and Basic Oxygen Furnace (BOF) route. In the blast furnace, coke (purified coal), various iron products and coal are heated. The result is molten metal, which is then mixed with scrap in the BOF to produce steel. Scrap is added to reduce CO₂ emissions and lower material consumption. voestalpine plants use up to 30% scrap per ton of steel produced, while the industry average ranges between 13-21%.

Scrap plays a key role in reducing emissions in the steel industry. By using scrap, the demand for new raw materials decreases, reducing the need for mining and processing.

The greentec steel production process in a nutshell

The greentec steel process begins by heating iron ore with natural gas or, in the future, hydrogen to obtain a purified form of iron ore. This purified ore is then compressed for easier transportation.

In the blast furnace, this compressed purified iron ore is further heated with gases from the blast furnace, hydrogen, natural gas and/or coke (compressed purified coal). The result is molten metal, which is mixed in the converter with up to 30% scrap. The converter runs on locally generated green energy, further reducing CO₂ emissions.

Each of these steps contributes to a reduction in CO₂ emissions per ton of steel. To put this into perspective: the emission reduction achieved with this process is nearly three times the amount of CO₂ NEDCON emits per ton of steel produced.

The impact of a more sustainable production process

This CO₂-saving process reduces emissions by approximately 10% compared to voestalpine’s standard steel process. In 2019, voestalpine analyzed its CO₂ emissions per kilogram of steel compared to the European and global averages. The study showed that voestalpine already had lower emissions than both averages: about 10% lower than the European average and 15% lower than the global average.

With the implementation of greentec steel, this difference will grow even further. The CO₂ emissions will be approximately 20% lower than the average European steel and 25% lower than global steel. In the future, emission reductions in the standard greentec steel process will be further enhanced by the use of the Electric Arc Furnace (EAF). This will enable steel production using (green) electricity and (green) hydrogen or natural gas, along with high scrap content, significantly reducing emissions.

With the greentec steel 600 edition, the CO₂ savings from multiple coils are combined into a single coil. This results in more than a 75% reduction in CO₂ emissions compared to European and global steel.

The first greentec steel project sold was a collaboration with sports and apparel giant Nike. In partnership with Dürkopp, a Hanging Garments system and flooring were supplied, incorporating over 450 tons of the greentec steel Edition 600. Nike deliberately chose greentec steel as part of its commitment to sustainable business practices.

The building and surrounding campus in Corby, United Kingdom, adhere to the highest sustainability standards and offer ample space for nature and various sports facilities. Additionally, Nike aims for zero CO₂ emissions during construction, which is independently verified. This project demonstrates that the market is willing to invest in more sustainable initiatives, even when they come with higher costs.

To ensure that the greentec steel ordered by our customers is actually used in their projects, we offer full tracking of greentec steel within our production. This is achieved through our ERP system, which makes our coil numbers, batch numbers and final product numbers traceable.

Certificates

To confirm that the emission reductions have indeed taken place, customers receive a certificate from our greentec steel supplier, verified by a third party. Additionally, NEDCON provides a certificate to confirm the tracking of the material.

Currently, greentec steel can only be used for products from our in-house production. voestalpine has made 1 million tons of greentec steel available, with 200,000 tons annually for the Edition 600.

Because Nike requires that the steel is traceable within NEDCON’s production processes, a new process has been introduced. This process is designed to ensure that greentec steel moves through the organization as efficiently and transparently as possible.

Based on the experiences from the Nike project, this process is being further optimized. So far, its implementation has been successful due to strong collaboration between the project team, the delivery team and sales. Additionally, agreements have been made regarding scrap management and minimum order quantities.

Goals have been set to increase the sales and inclusion of greentec steel in quotations. To achieve these objectives and strengthen greentec steel’s presence both internally and externally, training sessions, instructions and informational documents are being developed. These will not only provide explanations about greentec steel itself but also about the associated processes.

Furthermore, efforts are underway to standardize emission data per project in quotations with greentec steel. This initiative aims to drive more greentec steel sales in the future, support compliance with reporting obligations and add extra value for our customers.

Some careers start at an early age and that certainly applies to our two newest additions to the NEDCON family: Ayaan and Naomi. Both are already set for their future role as Supervisors!

Welcome Ayaan!

On January 18, 2025, Ayaan was born. The son of our colleague Emir Hodzic and mother Adna. Welcome Naomi!

On February 4, 2025, Naomi was born. The daughter of our colleague Josue Valenzuela and mother Sandra.

Imagine having a laptop that you can easily customize. When you need more memory, you don’t have to buy a completely new laptop, you simply replace the RAM module. This principle is called Modular Design and it is applied in many fields, from electronics to architecture and product development.

In Modular Design, a product or system consists of individual modules, each serving a specific function. These modules work together but can also be replaced or upgraded

independently. This approach enhances flexibility, cost savings and efficiency. A great example is a prefabricated house built from standard components, allowing quick and cost-effective modifications or expansions.

In the software world, this principle works similarly. Programs are divided into separate code blocks that can be developed and tested independently. This simplifies debugging and ensures that updates can be implemented seamlessly. Companies benefit

by accelerating product development and adaptation without needing to rebuild everything from scratch.

Another well-known example is LEGO. The individual bricks can be repeatedly combined into different structures. This perfectly illustrates how Modular Design works: reusability and adaptability are key.

Thanks to this design principle, companies can work more efficiently, offer customers more customization options and make products more sustainable. Therefore, Modular Design is a powerful concept applied across various industries, from automotive and software to construction and product development.

NEDCON has incorporated this principle into its strategy. We already have many structured systems, making it an exciting challenge to start with a one-day training session last year with the NEM managers from different disciplines. Consultant Frank Rood guided us through this process in a “Foundation” training, introducing us to the fundamentals, building blocks and benefits of Modular Design. The NEM/Board unanimously agreed that we should further implement this methodology.

Major advantages of a modular architecture:

Reduces the time needed to find information

Reduces the time required for design

Shortens the cross-control process

Speeds up the process of implementing changes

Reduces production time (including setup time)

Lowers development costs

Minimizes design errors

Increases productivity

Enhances efficiency in the procurement process

Optimizes assembly efficiency

Following this, we formed a team consisting of Key Account and Reseller-related colleagues. Representatives from sales, product development and digitalization joined forces to build a modular architecture for the NR1 (manual pallet racking). This was accomplished in the following steps:

First, a business strategy was formulated from voestalpine, followed by a strategy tailored to NEDCON. It was important for NEDCON to integrate the vision of Modular Design within its organization, making it part of the current business strategy.

The next step involved three actions. The first was analyzing and defining the market segments served. Can the entire market be divided into segments where customers within each segment share similar characteristics?

Next, we determined the values that each customer segment prioritizes. This resulted in a matrix with customer segments on one axis and customer values on the other. For example, for a customer from the Logistics Service Providers segment, Operational Availability is crucial and, therefore, receives a high score. The Market Segmentation-Customer Values matrix is sales-driven and assists in both customer and product development.

To serve customers effectively, it was essential to clarify which types of products we could offer. Therefore, we categorized our product types into a matrix.

Standard or non-standard components.

Predefined product, parametrically defined product (CTO), or a product requiring new design (ETO).

SSR (Smart Standard Range – CTO fixed), SFP (Standard For Production – CTO parametric), or a NEDCON-known product requiring special configuration or a fully project-specific solution (ETO non-standard).

Standard available product description (STD-SAP) or custom product registration (NONSTD-SAP).

Categorization of products.

The further left above a product appears in area 5, the faster and more digitalized its processing within NEDCON.

Step

Sales input is crucial as it defines customer requirements, which lead to functions and specifications, ultimately forming the basis for module and interface definitions.

Step 3.2

This step involves data analysis to identify market opportunities and assess which systems are promising for NEDCON based on market growth potential and stability.

Step 3.3

R&D assesses system-level technical feasibility,

determines strategic focus areas and assigns development capacity.

Combining all previous data provides a clear market potential overview, strengths, and weaknesses, allowing the formulation of a robust sales strategy.

Based on sales strategy and system requirements, functions and specifications are identified, leading to the definition of modules. For the NR1 Manual, the initial approach is as follows:

Architecture NR1-Manual

The table shows that NEDCON beams have 49,152,000,000 possible variants, indicating the extensive customization we offer.

Defined modules are stored in a database, making them easily accessible for users, similar to how we currently use NC-Viewer.

A core value of Modular Design is utilizing standardized parts. To facilitate their use, a configurator is developed, ensuring optimal customization while using as many standard components as possible. Our CSA application for pallet and shelving racks is a great example, as are all SAP product configurators.

A future development in CREO would allow higher automation levels, assembling multiple modules into a unit, such as a pallet rack bay. By patterning this unit, we can rapidly create entire systems.

The goal is to design customer systems using configurators, maximizing standardization benefits. In some cases, new designs (ETO) may still be necessary. Currently, ETO is required to sell a

system, but the long-term goal is to refine market requirements so that we have the right LEGO bricks in our toolbox to provide a CTO solution.

With the modular architecture of NR1-Manual established, the focus shifts to maintaining defined modules. The Sales Gate serves as a central hub within RD&P’s P&T unit, where product managers assist with commercial challenges, determining whether a CTO solution is viable or if ETO is necessary. If an ETO solution proves useful, it can be integrated into our LEGO toolbox as a standard module.

This step centralizes product knowledge within NEDCON, improving efficiency and service. Product Managers are available daily from 9:00-10:00, both in-person and online, and at other times when available.

This overview outlines how Modular Design is taking shape at NEDCON. If you’re interested or have questions, feel free to visit Product & Technology. We are happy to assist!

At Rusta’s existing distribution center in Norrköping, we are currently working on the installation of a new Adapto system. Rusta is a Swedish retailer specialized in home and leisure products, offering a wide range of items through both physical stores and online platforms. The company operates over 200 stores across Sweden, Norway, Finland and Germany. The warehouse in Norrköping plays a key role in distributing products to these locations.

This project, executed by NEDCON on behalf of Vanderlande, introduces advanced automation to Rusta’s distribution network.

Adapto system

In week 6, we started constructing the Adapto system, which consists of 22 aisles, each nearly 44 meters long and approximately 11 meters high. Part of the existing pallet racking is being replaced with the Adapto system, allowing for more efficient and compact storage. This system will optimize storage and order processing within the distribution center without disrupting ongoing operations.

One of the biggest challenges in this project is carrying out construction activities alongside Rusta’s daily logistics operations. This requires careful planning and coordination to minimize disruptions. Safety and efficiency are top priorities to ensure that both construction and daily activities continue smoothly. To separate NEDCON’s activities from Rusta’s ongoing operations, Rusta has installed a soundproof partition around the entire assembly area.

By implementing the Adapto system, Rusta is making a significant leap toward further automation in its distribution processes. The system increases storage capacity and optimizes order fulfillment, ensuring a more efficient and scalable logistics operation.

At Kappahl’s newly built distribution center in Gothenburg, a new Adapto system is also being installed. Kappahl is a Swedish fashion retailer designing and selling clothing for women, men and children. The company operates over 330 stores across Sweden, Norway, Finland, Poland and the United Kingdom and offers online sales in more than 20 countries across Europe and Asia.

This project is also executed by NEDCON on behalf of Vanderlande.

In week 7, we started constructing an Adapto system consisting of 27 aisles, each measuring 52 meters in length and 11.5 meters in height. This system enables efficient storage and flexible order processing, allowing Kappahl to operate faster and more accurately within its distribution network.

In addition to the Adapto system, construction of a High-Density Storage (HDS) multilevel shuttle system will commence in week 24. This system features 6 aisles, each over 72 meters long and

nearly 12 meters high. The HDS solution provides high storage density and fast product access, further optimizing Kappahl’s logistics processes.

With the successful implementation of the Adapto and HDS systems, Kappahl is taking a major step forward in automated warehousing, enhancing efficiency and sustainability across its supply chain. Due to the expertise of NEDCON and Vanderlande, a system is being developed that not only increases current storage capacity but also remains flexible and scalable for future expansions.

Where were you born?

I was born in Dayton, Ohio. I enjoyed my time in Dayton but was excited when I moved away.

What is your family situation like?

I am married to my wife Angela and we have 7 children and 7 grandchildren. All of our children are adults and have moved out.

What is your best trait?

I am very outgoing and easy to talk to.

What is your worst trait?

If you ask my wife and kids they would say I am very direct and regimented.

What is your favorite food?

I really like fried chicken at home.

What kind of music do you like to listen to?

Anything that doesn’t put me to sleep. I do not really have any specific favorite song, as long as they get me motivated to work out.

What are your hobbies?

I like to spend time with family, play golf when I have time, workout and ride my Harley.

What can we wake you up at night for? I really like my sleep, so only for emergencies!

Who would you like to eat a biscuit with?

I would like to sit down with Denzel Washington.

Do you have a motto or slogan you would like to share with your colleagues?

If you stay ready, you don’t have to get ready.

What dream do you most want to see come true? To retire and play golf full time.

What do you like to do on weekends?

Relax with my family, lift weights, play golf and ride my motorcycle.

What news from the past six months has impressed you the most?

How NEDCON continues to be like no other company I have worked for in the past. The family environment is impressive to say the least. The first time I really felt the family feeling was when the team and I were in Pardubice. We shared great memories while sitting on the terrace.

What is your favorite vacation destination or activity?

My favorite destination is Germany. I was stationed in Germany and love the culture. But Florida is a close second because of the beaches.

What achievement of yourself are you most proud of?

I’m most proud of my time playing college football and my service in the military.

Can you tell something about how you came to work at NEDCON?

I had recently moved to Shelbyville and was looking for a job, not in the automotive field. Two weeks after moving, this position at NEDCON was posted. I was very impressed upon doing my research of the company and applied.

What employer did you work for before NEDCON and what position did you have there?

I was a Plant Manager at Delaco Kassle, which is a tier one supplier to Ford Automotive.

A question asked by

What is your biggest challenge at NEDCON? Making sure the team gains as much knowledge as they can from more experienced colleagues.

What other role within NEDCON would you like to spend a week doing?

I would like to shadow one of the Installation Managers for a week. It would be interesting to see how our product comes together at the site.

What will NEDCON look like in 5 years? What is the biggest change you predict?

I think the growth will continue to increase and that would include the growth of the US market.

My first months were very exciting. It involved a lot of work on the infrastructure of the US facility along with hiring of the colleagues. NEDCON is different from other companies I have worked for. NEDCON truly cares about all colleagues and their continued success.

How were your first months here when you became a Plant Manger? Do you think NEDCON is different compared to other US companies? And I would like to ask him the following...

Where do you see NEDCON USA in the next two years?

First

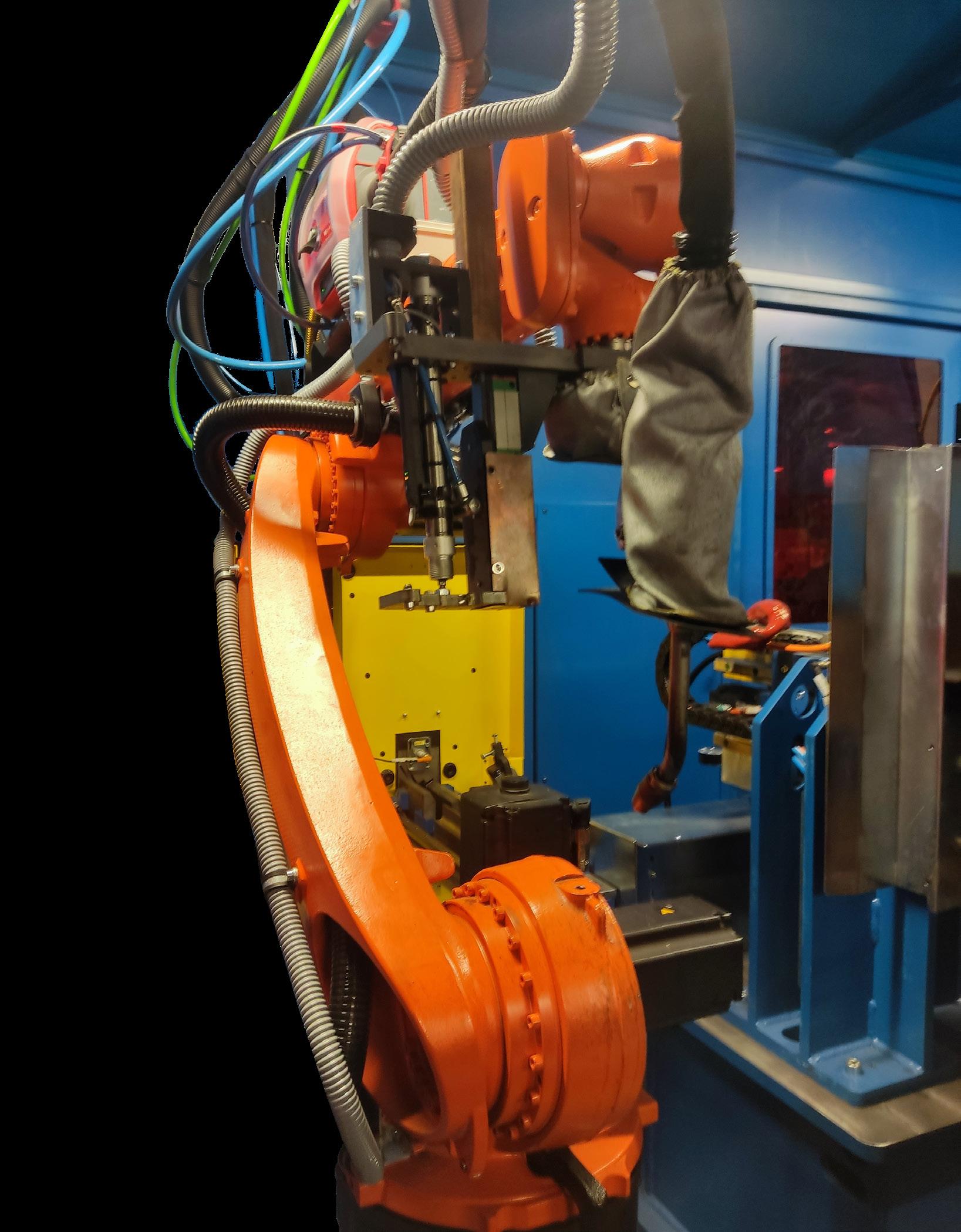

Almost exactly 6 years after the launch of the welding line WM 21-10 for CC and NC beams, we are launching the new welding line WM 21-11. The preparation of the investment began in autumn 2022 by comparing possible scenarios for the development of the welding department in Pardubice. At that time, we were faced with the decision of whether to carry out a major upgrade of the three old semi-automatic lines commissioned already in the Netherlands or to invest in a new line.

In Pardubice, we weld approximately 850,000 beams annually, 50% of which are CC/NC profiles welded on the WM 21-10 line. Smaller batches of these CC/NC profiles and all other miniload, sigma and tube profiles were distributed among the remaining three semi-automatic lines and the robotic welding line for cantilevered beams.

As usual, we faced many constraints in preparing the investment. The main one was of course the budget and the return on investment. From a production point of view, it was desirable to acquire a line that would simplify and speed up conversions to small orders, which were covered by the line 21-02. But at the same time, we wanted to acquire technology that would be ready to support the emerging market for mobile ASRS systems. Whether from a capacity or technical perspective.

After weighing up all the pros and cons, a decision was made on how the line would look and what would happen to the other machines in the welding department. The new line 21-11 is robotic and continues a trend in the department that started in November 2014. That‘s when the 21-09 robotic welding line for cantilevered beams was commissioned. The decision to acquire a new robotic line also considered the aspect of attractiveness. That is, the acquisition of such a line should help us to better attract potential candidates for work in this field.

In addition to the purchase of a new line, we have decided to overhaul one of the semiautomatic lines (21-01). As long as it is beneficial, line 21-08, which is technically optimized for efficient welding of ML-front beams, will remain in operation. The third line, line 21-02, which acts as a conversion line, was dismantled in October 2024. This created the physical space to install the new line.

The 21-11 welding line is based on the experience we gained while working on the 21-10 line. In particular, the way the connectors are inserted and the distribution of the gap between the profile and the connectors on both sides. Each profile is automatically measured before the cycle starts and profiles outside the length tolerance are not welded. This virtually eliminates run-in scrap, which is unavoidable with every length conversion on old semi-automatic lines. Even gap distribution at both ends allows for visually and qualitatively better joints.

Setting up and rebuilding a line is of course a completely different job compared to a semiautomatic. With a robotic line, the need for mechanical adjustments to the profile clamping or welding nozzle position is minimised. All this is done by program selection and, if necessary, by correcting the path of the robots. This flexibility simplifies the changeover and allows easier and finer corrections when profiles are shaped differently.

Thanks to our relatively open concept, we have a line that is ready to weld virtually all our profile families (CC, NC, sigma, front beam, backstop, tube). The length range of the profiles is 1,000 - 6,000 mm. We also expect the line to be able to achieve a higher production rate than the current semi-automatic machines and thus we will strive for maximum utilization.

However, the line’s high versatility also comes with certain limitations. In our case, these certainly include the ergonomics of inserting profiles and removing welded beams. Given the large length span, the considerable variation in profile shapes and the space constraints, there is no affordable automation to replace these activities, similar to the 21-10 line. Given

the budget, the line is not even equipped with automatic weld control. Handling and visual inspection must therefore be carried out by operators in a similar way to the old lines. From the point of view of the operator‘s workload, it would be preferable to solve the handling at the outlet.

Nevertheless, we can say that in the field of occupational safety and working environment, the line is a great asset. Compared to semiautomatic lines, welding takes place inside a closed cell. Less welding gases and smoke escape into the surrounding area. At the same time, unwanted radiation can be almost perfectly shielded, protecting not only the operator but also other employees who are in the vicinity of the workplace.

The basis of the line is a profile length measuring system, a rotary welding table, a stop mechanism for connectors, four KUKA welding robots with automatic nozzle cleaning stations and, of course, an operator interface that allows the selection of a program for a given product with the possibility of corrections. The list of all the variants and combinations that had to be programmed was really long.

As with line 21-10, the connector insertion is performed by two robots which, in addition to welding the back weld, remove connectors from 2 x 50 pcs capacity bins. This means that there is less logistical downtime associated with the preparation of the connectors and the operator has more time for other activities.

The installation of line 21-11 began at our Pardubice plant in January 2025 and although we were initially very optimistic, the following weeks showed us that achieving the required quality and quantity targets would not be nearly as easy. The existing MDM system that we use to collect and evaluate measurements has provided invaluable support. With this online system, we were able to collect and evaluate weldment parameters very quickly and communicate defects towards the supplier. At the same time, we were able to monitor trends in key areas. In particular, length stability, weld height, face overlap of connectors and connector deflections, which seemed to be a difficult problem to solve at a certain stage of the implementation.

The handover of the line by the end of March 2025, the end of the fiscal year, was a common interest of both parties, but unfortunately it could not be achieved. It was only in the second half of March that we found out what was causing the

unstable connector deflections and, due to other technical difficulties, it was not possible to carry out the final testing (Site Acceptance Test) on the expected date. It is now mid-April. We are gradually eliminating the shortcomings and I believe that by the time you read this, the new line will be working without major problems.

Finally, we note that there will be one more welding line installation at NEDCON this year. This time it will be the first welding line in a US plant.

submissions, we selected three recipes that we believed could be contenders for the title of the ultimate burger.

Here are the three burgers competing for the title of ‘The Ultimate Hamburger’:

The Wagyu burger with cheese and caramelized onions, submitted by our colleague Alle Diks.

The MOINK burger, submitted by our colleague Roland Hulshof.

A more traditional smashburger, submitted by our very own The Great NEDCON Grill Off-team.

We prepared all three burgers and presented them to a jury existing out of 5 colleagues with one question: Which one is the ultimate hamburger?

And believe it or not, the jury reached an unanimous verdict:

Each burger has its own unique flavor. Choosing a winner was simply impossible because they were all incredibly delicious. So, just go ahead and make them yourself and decide which one you like best!

Tip from the pitmasters:

Going to make a burger for the first time? Try to follow the recipe as closely as possible. Sometimes, the combination of ingredients or the cooking method creates a whole different flavor experience. But feel free to experiment and adjust. It’s all about what you like and what ingredients make the ultimate hamburger for you!

Enjoy your meal!

Esmée and Wilbert

Course:

Cuisine:

Preparation time:

Servings:

Main course

Barbecue, originally Japanese

35 minutes

2 people

Step 1: Slice the onions into rings and sauté them until translucent. Reduce the heat, add a splash of balsamic vinegar and half a tablespoon of honey. Let simmer for 10 minutes, stirring occasionally.

Step 2: Finely chop the iceberg lettuce and place it in a bowl.

Step 3: Mix 6 tablespoons of mayonnaise with 1 tablespoon of whole-grain mustard in a bowl.

Step 4: Let the pickle slices drain on a paper towel.

Step 5: Cut 4 slices of Swiss cheese, slightly smaller than the burgers.

Ingredients

•

•

•

• 3 white

• Pickle

Additional equipment

• Iceberg lettuce

• Balsamic vinegar

• Honey

• Mayonnaise

• Mustard

Step 6: Remove the Wagyu burgers from the fridge and heat the BBQ to 200°C (direct heat). Place the cast iron grill grate over the coals.

Step 7: Once the BBQ and grill grate are up to temperature, slice the buns in half and grill them briefly. This creates a crispy inside and prevents them from becoming soggy.

Step 8: Grill the burgers for about four minutes per side with the BBQ lid open. Optionally, rotate them a quarter turn halfway through for a nice grill pattern.

9: When the burgers have developed a good color and reached an internal temperature of around 50°C, move them to the indirect heat zone of the BBQ.

Step 10: Place the cheese on the burgers and close the BBQ lid. Once the cheese has melted nicely, remove the burgers from the grill.

Step 11: Start building the burger. Spread a generous amount of mustard-mayo on the bottom bun and add a handful of chopped iceberg lettuce.

Step 12: Place the grilled burger with melted cheese on the bun, add a spoonful of caramelized onions, and top it with pickle slices.

Step 13: Finally, spread some mustard-mayo on the top bun and place it on the burger. Time to eat!

Course:

Cuisine:

Preparation time:

Servings:

Step 1: Start by making the coleslaw, as it tastes best when the dressing has time to soak into the cabbage and carrots.

Step 2: In a small bowl, mix the mayonnaise, crème fraîche, apple cider vinegar, mustard, honey, mustard powder and parsley to create the dressing.

Step 3: Finely slice or grate the red cabbage, white cabbage, and carrots into thin, long strips. Place them in a large bowl for easy mixing. Add the dressing to the vegetables and mix well. Set the coleslaw aside in the fridge.

• 4 hamburger buns

• 500 grams ground beef

• 16 slices smoked bacon

• 40 grams grated Parmesan cheese

• 2 teaspoons garlic powder

• 1 egg

• 75 milliliters milk

• 50 grams breadcrumbs

• 2 tablespoons Italian herbs

• 1 tablespoon freshly ground black pepper

• 1 teaspoon salt

• 5 tablespoons Piggy Mix

• 5 tablespoons BBQ sauce

Tip: Roland Hulshof makes the Piggy Mix and BBQ sauce himself. Want the recipe? He’s happy to share!

• 200 grams fresh red cabbage

• 200 grams fresh white cabbage

• 2 carrots

• 2 tablespoons mayonnaise

• 2 tablespoons crème fraîche

• BBQ with a lid

• Smoking wood (hickory)

Step 4: Now it‘s time to fire up the BBQ. Set it up for indirect heat and bring the temperature to around 120°C.

Step 5: In a large mixing bowl, combine the ground beef, egg, milk, Parmesan cheese, garlic powder, Italian herbs, pepper, salt and breadcrumbs. Mix well and form four equal-sized burger patties.

Step 6: Sprinkle half of the rub over the burgers, flip them and coat the other side with the remaining rub. Ensure the burgers are fully covered. Wrap each burger with four slices of bacon.

• 2 tablespoons apple cider vinegar

• 1 tablespoon mustard

• 1 tablespoon honey

• 1 teaspoon mustard powder

• 1 tablespoon dried parsley

• Basting brush

• Cocktail sticks (optional)

Step 7: Once the BBQ is up to temperature, add the smoking wood and place the MOINK burgers on the grill. Close the lid and let them cook for 45 minutes. After this time, baste the burgers all over with BBQ sauce, close the lid again and cook for another 15 minutes until the sauce has caramelized.

Step 8: While the burgers are finishing, slice open the hamburger buns and toast them on the indirect heat zone of the BBQ for a few minutes. If toasting directly over the hot coals, 30 seconds should be enough.

Step 9: Remove the burgers and buns from the BBQ and grab your coleslaw. Place a generous scoop of coleslaw on the bottom halves of the buns, then add the MOINK burgers and top them with the upper halves of the buns. Serve with extra coleslaw and enjoy!

Course:

Cuisine:

Preparation time:

Servings:

Main course

Barbecue, American 30 minutes 2 people

• 2 hamburger buns

• 400 grams ground beef

• 4 slices cheddar cheese

• 1 onion

• 1.5 tablespoons mayonnaise

• 1 tablespoon ketchup

Step 1: Fire up the BBQ and set it up for direct heat at around 230°C. Place a griddle or plancha on the BBQ.

Step 2: Slice the hamburger buns open and spread butter on the cut sides. Divide the ground beef into four equal portions and roll them into balls. Cut a square piece of parchment paper, making sure it‘s larger than your burger buns.

Step 3: In a small bowl, mix the mayonnaise, ketchup, mustard and your favorite hot sauce. Grate the pickles and stir them into the sauce.

Step 4: Peel the onion and slice it into very thin rings. A mandoline makes this easier, but a sharp knife works as well.

Step 5: Once the BBQ and griddle are hot, place the hamburger buns cut-side down on the griddle and toast them for about a minute until golden brown and crispy. Remove the buns and set them aside.

Step 6: Place the beef balls onto the griddle. Add a small pile of thinly sliced onions on top of each beef ball.

• 2 teaspoons yellow mustard

• 0.5 teaspoon hot sauce (choose your favorite)

• 2 pickles

• Freshly ground black pepper

• Sea salt

• Mandoline (optional)

• Burger smasher or large spatula

• Sharp spatula

Step 7: Take the parchment paper and place it over one of the beef balls with onions. Use a burger smasher or large spatula to press the beef into a thin patty. Repeat for the other balls. Season the patties with freshly ground black pepper and sea salt.

Step 8: Cook the smashburgers for about a minute. Use a sharp spatula to scrape them loose and flip them over.

Top each patty with a slice of cheddar cheese and cook for another minute. Then, remove the burgers from the BBQ.

Step 10: Spread the burger sauce on the bottom halves of the toasted buns. Stack two patties on each bun.

Step 11: Spread sauce on the top halves of the buns and place them on the burgers. Your smashburgers are ready to serve!

A new exhibition stand, live demonstrations, stroopwafels and the NEDCONNECT game

LogiMAT in Stuttgart. The event took place from Tuesday, March 11, till Thursday, March 13. Throughout all three days, our NEDCON team welcomed visitors to our brand-new booth. We had engaging conversations, demonstrated our CSA tool multiple times, attracted many visitors with our stroopwafel baker and were pleased with the success of the NEDCONNECT game.

Live demonstrations of the CSA tool

We gave live demonstrations of our CSA tool. With this tool, we can quickly and easily configure a customized 3D representation of a warehouse based on our standard product range. The tool automatically designs the safest and most optimal configuration. This allowed us to demonstrate how we can quickly support our customers with their storage challenges.

Fresh Dutch stroopwafels at our booth

This year, we had some additional help: the irresistible aroma of freshly baked stroopwafels filled the halls of the LogiMAT in Stuttgart. Just

Scan the QR code to see our stroopwafel baker in action.

to our booth. Our master stroopwafel baker worked overtime to treat visitors to a warm stroopwafel, while our team demonstrated how NEDCON can optimize their distribution center.

Also new this year was the NEDCONNECT game. Visitors who scheduled a one-on-one meeting with one of our experts before the LogiMAT had the chance to participate. After their meeting, they got to pick a box from our racking. Each box contained a prize. The prizes were products we purchased from our customers, including Amazon, REWE, Lidl, Nike and Tommy Hilfiger.

Scan the QR code to watch theLogiMAT2025aftermovie.

It’s the weekend after the official relocation of our NEDCON headquarters in Doetinchem, March 24, 2025. I have been living and working in Doetinchem for about 26 years and now that this wonderful occasion presents itself, I’d like to take the opportunity to share something about Doetinchem. More specifically: three events that took place in Doetinchem during the week of March 17–23, 2025. A week in which I experienced, on three occasions, how visibility and openness are sometimes taken for granted and sometimes deliberately avoided.

It felt somewhat sad to say goodbye to our old office after 26 years and to know that it was no longer „ours.“ Fortunately, we already knew in advance that the new location was more than suitable. And the beautiful spring weather, with a clear blue sky, made the transition even smoother.

For those unfamiliar with our new building, I‘ll try to describe it briefly: it is both spacious and compact. It is open yet calm. Open, transparent and cozy. It seems that the architect of this building has managed to successfully merge several apparent contradictions. Hopefully, the future will bring us many good things. In any case, it won’t be due to the conditions in our new office! Throughout the entire workweek, I never once had the urge to take the exit to our old office in the morning. If that’s not a good sign, I don’t know what is!

Coincidence or not, but on Saturday I helped with another move, ironically,

from the building right across our new office. About 100 pallets of clothing and store items needed to be relocated. The building, which is set to be demolished, housed the clothing bank. The clothing bank helps people who lack the means to properly clothe themselves or their children. I believe many residents of Doetinchem are relatively unaware of the clothing bank‘s existence or would be surprised by the scale of the assistance it provides. This is mainly because the help is provided as discreetly and anonymously as possible.

And last Sunday morning, still blessed with beautiful weather, I attended a short film screening in the center of Doetinchem. Exactly eighty years ago, also in beautiful spring weather, between March 19 and 23, 1945, just before the liberation, the city center was bombed three times by the Allies. Around 170 people lost their lives and the historic city center was reduced to rubble. Doetinchem was, of course, not the only city bombed during World War II, but it was among the most heavily affected cities in the Netherlands.

Why am I telling this? Mainly because, until a few years ago, I had never

heard of these bombings. Eighty years later, they remain shrouded in mystery. For a long time, this history was suppressed—even by the residents of Doetinchem themselves. It’s complicated to see yourself as a victim of the liberators. Much is also unknown about the 170 Jews who lived in Doetinchem before the war. 125 of them never returned. These victims had no voice. The screening aimed, 80 years later, to give the more than 300 victims a place in the history books.

For readers who have not yet had the chance to visit our beautiful office and the city of Doetinchem, I hope I’ve provided some broader insight. So, if you ever visit us, you’ll see that we carry out our work with pride and quite literally in full transparency. There is little room left for modesty. You also now know that, in Doetinchem, we are working hard to find a place for the discomfort of victimhood. But we have yet to break all the taboos. So, if you do visit our office, you are more than welcome—but please, leave your poverty at home.

As our facility continues to expand and evolve, we are making significant strides to enhance our operations at the Shelbyville Plant.

A new centralized location for quality

Initially, the Quality Department was located in a small, prefabricated office in the far corner of the facility. However, as our operations grow and we expect even more expansion in the near future, we recognized the need for a more functional and centralized space. We’ve made the decision to move the entire department to a new, centrally located area within the facility. This move will improve efficiency, allow better collaboration across teams and streamline our processes as we continue to scale. In addition to a new location, we are also adding new personnel to the Quality team to help manage the expected increase in responsibilities and allow us to continue to meet production demands.

In addition to the move, we’re preparing for a significant milestone in our production capabilities: the launch of welding. As we approach the start of welding operations, scheduled for the beginning of the 3rd quarter, we are outfitting our Quality Department with new tools and devices to ensure we meet the highest quality standards during the welding process.

We are also preparing for our upcoming surveillance audit of ISO 9001, which is scheduled for completion in June. This audit is a critical part of maintaining our high standards for quality management and continuous improvement across our operations.

In addition, we’re excited to continue our partnership with RFC as we work together to launch our own internal calibration program. This program will enhance our ability to maintain precise and accurate operations, further ensuring that our products meet or exceed customer expectations.

NG1 extension

We’re thrilled to share some exciting updates from our US office regarding the NG1 project in McCordsville, Indiana.

The NG1 extension began in February 2025 and has quickly evolved into a major undertaking. This project involves multiple phases of expansion, with a total of 87 aisles planned once completed. This project will stand as the largest KNAPP project ever finished by NEDCON in the United States.

NG1 Extension (Phase 2) – The first extension of 6 aisles kicked off early in the year, bringing the total to 60 aisles.

NG1 Extension (Phase 3) – After the summer of 2025, we should begin another major extension, expanding the facility by an additional 27 aisles. This will bring the total number of aisles to 87.

We just finished a 9 aisle extension at the end of February 2025, bringing the project total to 30 aisles. We are also excited to share that Skechers is in the process of constructing a new building across the street from their current facility. Our team is optimistic about the opportunity to contribute to this new development and hopefully further our partnership with KNAPP.

My name is Adéla Vatterová and I joined NEDCON in September 2018 as a receptionist. I went on maternity leave in 2020, during which time I worked with the HR department in the area of internal communication. I held this position for a few months after I returned to the company. However, in the first half of 2024 I became part of the security department where I still work today on a part-time basis.

No time to waste!

It‘s a weekday, 6:00 a.m., and my alarm is ringing. I get up after the first ring, as there is no time to waste. I have exactly one hour to get my older son off to school and our twins (also boys) off to kindergarten. Within 10 minutes, my husband is up and my children are rushing around. At 7:05 (no later) we leave the apartment and set off on a tour of the sprawling city of Pardubice. I drop our twins off at the kindergarten, where we do the obligatory morning homework with parents and then I have to drive just 12 km to work. If it goes well, I can do it in 30 minutes.

My working day starts with a cup of tea

Between 7:45 and 8:00, I arrive at work. I say hello to my colleagues, turn on my computer and prepare my morning cup of green tea. Without it, my workday cannot begin. My supervisor and I discuss what needs to be done today. Only then do I settle into my seat and start working. First, I check the new incoming mail and answer emails.

Between 8:30 and 9:00 I walk around the hall to count waste containers and decide which ones need to be reported for collection. At 9:00 it‘s time to train new employees in H&S. The training is in the form of videos with additional information from me and takes approximately one hour and ten minutes. I then enter the training data into the internal OKBase system. I spend the remaining time until lunchtime on administrative activities including creating screen content and creating requisitions in SAP, which means working closely with the purchasing department and then with the accounts department.

Hunger is the best sauce

It‘s 11:40, time to go to the cafeteria for the lunch I ordered in advance. As a mother of three kids, I enjoy any meal I don‘t have to prepare myself. I spend the next 30 minutes not only eating, but also in the lovely company of my colleagues. I finish with a coffee with my colleague and friend Kamča. We discuss some important girl stuff and then it‘s time to get back to work.

At 12:30 p.m., after a morning of passing each other, I finally meet with Miloš Dobrý, the H&S specialist and my supervisor. We plan the Safety Day. The rest of my working time is then devoted to planning periodic trainings of various kinds, visualizations on the hall (waste, clothing) and minor H&S measures. The work in the H&S department is varied and diverse, and I enjoy it.

It‘s approaching 2 pm and my work day is coming to the end. I get in my car and drive home. But I still have to wait for a well-deserved rest. At home I check my son‘s schoolwork. At 2:30 I walk to the kindergarten to pick up the twins, sometimes we bring a friend of theirs (my part-time job is also good for other mothers). In the afternoon everyone has their own sports activities. The kids go to floorball practice, I go to an aquafit class and my husband plays hockey. Since my home is filled with sporty men I am forced to do sports and our days are mostly devoted to activities of this kind: cycling, rollerblading, hiking, swimming, skiing and skating in the winter. Our kids have a floorball tournament once a month. I am rewarded for my efforts by my husband who offers me a motorbike trip in warm weather to see the beauty of Bohemia.

It‘s 6:00 p.m. and all the members of our large family are sitting down to dinner. The kids are watching the evening story or I am reading it to them. Following that, the five-year-old twins are getting ready for bed. The longed-for moment of a busy day is approaching: peace. By 8:30 p.m., all three kids are asleep and I have time to rest and relax with a book, which I usually fall asleep to. That‘s a sign that it‘s time to go to bed and recharge for the next busy day.

HUGO BOSS is currently expanding its distribution center in Filderstadt-Bonlanden, near Stuttgart, Germany. This ambitious project involves an investment of over €100 million euros and aims to significantly increase shipping and storage capacity.

During the initial construction of the distribution center, HUGO BOSS collaborated with KNAPP and NEDCON to implement an innovative shuttle storage system with 400,000 storage locations. NEDCON has now installed three OSR systems for KNAPP, adding another 340,000 storage locations.

The expansion of the distribution center is part of HUGO BOSS‘s broader strategy to make its supply chain future-proof and enhance overall company performance. The expansion is expected to be completed in 2026 and will contribute to further optimizing the company‘s logistics processes.

At NEDCON, we highly value the development of our employees. In line with this vision, we have created in-house training programs for CREO and Windchill, specifically tailored to the needs of our organization. These training sessions are designed to provide optimal support for our employees in their daily work. Recently, we completed and published the final lessons, marking the conclusion of the development and writing process.

The development of the CREO and Windchill training programs began with an analysis of various roles within NEDCON and the corresponding 3D design skills required. Based on this analysis, we designed a series of training sessions that combine both theoretical knowledge and practical skills.

The training courses are divided into several programs:

Creo View

Creo Basic

Creo Advanced

Creo Drawings

Windchill Basic

Windchill Advanced

Each training is carefully aligned with different roles within NEDCON. For example, our engineers benefit from Advanced CREO training sessions that help them model components and manage files within Windchill.

The training content has been developed by our colleagues Robin Stammes, Thijs Esselink, Annemijn Tijhuis and Rinus IJzereef. All lessons are individually available in our LMS, making them easy to find and revisit.

The training courses are offered both in-person and through the LMS. Many colleagues work on their training at different times throughout the week. The in-person sessions provide an opportunity to exchange knowledge and experiences, as well as to ask questions directly to our trainers.

Our trainers Robin, Thijs, Ersin, Rens and Annemijn play a crucial role in the success of these training programs. They are not only experts in their respective fields but have also undergone specialized training to enhance their own teaching skills.

By offering training programs that are precisely tailored to the needs of our organization, we ensure that our employees acquire the knowledge and skills they need to work effectively. Our trainers and course developers have played a key role in the creation of these training programs. Their dedication has been invaluable, and we sincerely appreciate their efforts.