The Atlas® PV series represents the absolute best value for the customer who demands a heavy-duty, professional grade 2-post lift at the lowest possible price. Thousands have been sold over two decades!

10,000 lb. Capacity

PV10PX - Overhead 2-Post

The Atlas® PV10PX lift is the perfect choice for use in either a large commercial service department or for the “pole barn” owner who wants the “biggest and baddest” lift in the country. The PV10PX is designed and engineered to safely lift (and work on) everything from a Smart Car ® to a one ton diesel dually.

•Overall Height: 143 1/8” (11’ 11 1/8”) or 147” (12’ 3”)

•Maximum Lift Height (With Adapters): 81 1/4”

•Drive Thru: 96 1/4” (8’ 1/4”) Symmetric or 90 1/4” (7’ 6 1/4”) Asymmetric

12,000 and 15,000 lb. Capacity Models Also Available

The Atlas Platinum® lifts are ALI Certified and catered toward those customers looking for “top-ofthe-line”. This line is our highest quality, most user friendly, and most rigorously tested equipment.

15,000 lb. Capacity

PVL15 - Overhead 2-Post

The Atlas® Platinum PVL15 is an ALI CERTIFIED, commercial grade, 15,000 lb. capacity overhead two-post lift designed to accommodate both long wheel base trucks and service trucks. Features a premium power unit certified by MET Laboratories Inc.

•Overall Height: 174 1/2” (14’ 6 1/2”)

•Maximum Lift Height (With Adapters): 87 1/2”

•Drive Thru: 107 1/2” (8’ 11 1/2”)

10,000 and 12,000 lb. Capacity Models Also Available

Everything from purchase decisions to long-term maintenance.

By Emily Markham, Editor, PTEN

If well taken care of, a vehicle lift will last around 10-15 years before a replacement is necessary. When purchasing a lift, careful thought and consideration should rule your decision-making process. Lifts are essential pieces of equipment that allow maintenance facilities and repair shops to run productively and efficiently.

In this guide, we cover the latest lift trends, how shops can use lifts to increase their productivity, the different types of lifts available, purchasing and maintenance considerations, and what it means to be ‘safe’ while operating a lift.

Safety should always be top of mind — especially when working with equipment like vehicle lifts that when operated improperly could have disastrous consequences. Apart from ensuring that all those who will be operating the lift have been fully trained and preventative safety measures such as an annual (at minimum) lift inspection by Automotive Lift Institute (ALI)-certified lift inspectors is performed, shops can also keep their employees safe by providing the appropriate lift adapters and accessories.

Accessories like adjustable creeper seats can help prevent neck and back strain and swing arm safety head guards work to lessen the impact of a blow to the head if a technician trips into the lift or stands up too suddenly. Having these additional tools can mean the difference between a fully staffed shop and technicians out on worker’s comp.

ALI recognizes seven lift types. In conjunction with these lift types, a lift can also be installed in multiple ways — mobile, inground, or surface-mounted — and vary in how it contacts a vehicle — frame-engaging, wheel-engaging, axleengaging, drive-on, and pad. With all these options, it can feel overwhelming when deciding what will work best for your shop or facility.

To help alleviate some of your decision fatigue, we’ve put together a chart of all the lift types covering which will work best in shops with limited space and the best uses for each lift.

Overall, make information and best practices a priority when it comes to your lift purchases and upkeep as well as your workers’ safety.

The

An introduction to the Vehicle Lift Guide, brought to you by Fleet Maintenance and PTEN magazines.

Lift trends veer toward technician productivity, safety

The latest developments coming from lift manufacturers are emphasizing getting more out of your most valuable resource: your techs.

Raise lift productivity through efficiency

A focus on improving the efficiency of your lifts will also enhance technician productivity, meaning more jobs your shop can take on.

Picking the right lift for your shop

A breakdown of the seven types of lifts to help you figure out what lift/s will fit best in your shop.

Lift purchasing and maintenance considerations

A Q&A with ALI, BendPak, and Challenger Lifts.

Three ways to improve lift safety

The three most important factors to improve lift safety in your shop.

The latest lifting equipment.

Investing in top-of-the-line shop equipment may seem capricious in this economy but can pay off by keeping techs productive and loyal. To read more, visit: FleetMaintenance.com/55088128

The guide covers cars, SUVs, EVs, and light trucks made from 2000 to 2024. To read more, visit: VehicleServicePros.com/55036016

In this video, Rotary Lift goes through the process of setting up the LT35A Lift Table. To watch the video, visit: VehicleServicePros.com/55270128

The Mobi-EVS4500 and EVS3000 models bring cordless convenience to heavyduty EV service. To read more, visit: FleetMaintenance.com/55133784

In this video, Challenger Lifts demonstrates the HD Mobile Column Lifts. To watch the video, visit: VehicleServicePros.com/55259701

The ALI Board of Directors will be headed by Doug Brown, with Gary Wainwright serving for another two years as Associate Class representative. To read more, visit: FleetMaintenance.com/55243032

The latest developments coming from lift manufacturers are emphasizing getting more out of your most valuable resource: your techs. By

John Hitch, Editor-in-Chief, Fleet Maintenance

Let’s face it. Lifts are usually the most expensive equipment in the shop and buying a new one is a big decision, particularly when the economy isn’t strong.

“Lift sales tend to be somewhat recession-sensitive, as replacements often get deferred during tough times,” noted Pete Liebetreu, Hunter VP of marketing. “That’s too bad, because the proper lift can add a ton of productivity to the shop.”

In the past few years, the economy—and lift sales— have been “steady,” Liebetreu said, but who knows what the future will bring, and should that affect your purchasing decisions?

Like lifts, the economy is always going up and down, so it’s best not to let external factors determine how you improve the inside of your shop. And whether the economy is good or bad, the “proper lift,” as Liebetreu said, has

the potential to raise your productivity and profits, as well as employee safety and satisfaction.

Steve Perlstein, president of Mohawk Lifts, concurred.

“Speed and efficiency all lead to employee productivity and getting more vehicles in and out of your shop faster can increase the bottom line—and make a higher percentage of the fleet available for use vs. waiting to be repaired,” Perlstein said.

But what is the “proper lift”? That means something different to each shop, but basically, it’s best to think of it as whatever lift allows your technicians to safely perform more jobs per day, and more types of jobs as well.

The right lift also helps you maximize the potential of your technicians. And while the basic designs of lifts don’t change very often, the sector is always moving forward with continuous improvement tweaks and addons. So, let’s take a look at some of the recent trends making lifts more efficient and the employees who use them more productive.

As mentioned, lifts are a substantial investment, but techs are truly a shop’s most valuable asset. And they’ll increase in value over the coming years, as stronger demand expects to continue through the rest of the decade. In 2024, TechForce Foundation had reduced its 2024-2028 demand projections for auto, diesel, collision, and aviation techs by 20%. But this January, they called that back and upped demand by the same amount to 971,000 needed.

These numbers always go up and down, but you can stay consistent by using versatile, high-performing lifts and adding accessories and adapters that allow your techs to do the most work in the safest way.

“Lift options make the jobs go faster, keep your employees safe, and ergonomically don’t risk a sick day because the tech hurt his knees bending down six times per day,” Perlstein noted.

He also suggested support equipment like tire dollies.

“If you own a 30,000-lb. lift and don’t have a tire dolly to remove these heavy tires, then expect a call from your injured tech as he threw out his back trying to remove a 22.5” tire,” he said.

The BendPak MaxJax Reclining Creeper Seat, for example, has a backrest that can be positioned from 0 to 70 degrees, allowing techs to roll under a lifted vehicle and work for an extended period of time at the most comfortable position — and without straining their neck and back.

Muscle strains are one thing, but working around lifts also presents immediate injuries, as they are often positioned at different heights, sometimes with the swing arms sticking out.

“Is there a tech who hasn’t accidentally banged their head on the bottom of a swing arm?” Perlstein asked rhetorically. To solve that issue, he recommended Swing Arm Safety Head Guards, foam covers that soften the blow if you were to trip over an air hose and fall headfirst into the lift.

There’s also some additions that can save time and have maintenance benefits.

Weight gauges, what Perlstein called “essentially a scale on the lift,” can save an extra step for fleets that have to weigh their trucks more often, but also help a repair shop sell more parts that will help customers. Perlstein noted if a customer complains about premature wear and you notice the truck has budget brake pads on a heavier truck, you can “proactively sell up to better ply tires, better brake pads, or load levelers instead of shock absorbers.”

All lifts are designed to be safe, but the industry is always trending toward more safety. For example, at the end of 2023,

Rotary Lift unveiled its All-Vehicle lift arms found on the company’s SPOA10 two-post asymmetric lift. These allow technicians to correctly spot and lift nearly any vehicle make and model under 10,000 lbs.

Rotary said the AV arms, which can be retrofitted, offer the shortest amount of retraction while still maintaining a wide pickup range, with 20% more reach than 3-stage arms with thread adapters and 30% larger arm sweep than conventional 2-stage arms with flip-up adapters. Because the adapter height matches the outer arm height, this also reduces the likelihood the arm could contact and damage a vehicle’s underbody.

Jason Matthews, director of product management for Rotary, said it’s “the only automotive two-post lift [shops will] ever need.

“A lot of people talk about the importance of future-proofing automotive service shops to prepare for the surge in EVs,” Matthews added. “This is all that and then some. It’s helping shops prepare to service more vehicles, optimize operations, and increase profits.”

That versatility will be needed as shops start to service more electric vehicles, which have pre-defined lifting to prevent causing damaging to the battery. R.W. “Bob” O’Gorman, president of the Automotive Lift Institute, agreed there is an uptick in specialized adapters designed to support specific EVs.

“And there is a plethora of activity associated with both existing and new models being updated with a wider stance or lower bolsters or adapters designed to accommodate lifting points at the outer edges of the vehicle frame without interfering with the highvoltage battery,” he said. “We are even seeing some light lift models redesigned to accommodate heavier capacities associated with market needs to support the addition of those heavy battery packs.”

On its AP Series two-post lifts, BendPak has replaced the half-moon gears that lock swing arm restraints in place with the patent-pending Automatic Swing Arm Restraint System (ASARS). This system uses a complete circle of forged steel teeth to secure the swing arms in place.

TheAutomotive Lift Institute has reported increased demand of its Check360 Certified Lift Inspection as the CV repair sector has worked to make sure these innovations are up to spec in terms of productivity and safety. The inspection launched in 2021 can only be performed by ALI-certified lift inspectors, and ensures a lift meets all the ANSI/ALI ALOIM requirements. The comprehensive check verifies the lift’s structure and components, along with training logs, operating instructions, and safety manuals are all in working order.

These premium annual inspections ensure customers get what they paid for, explained ALI President R.W. “Bob” O’Gorman.

“ASARS can withstand an industryleading 2,000 lbs. of side force, making it less likely to give way if the vehicle shifts,” explained Tyler Rex, BendPak senior director of marketing.

This style lift also uses lowprofile, triple-telescoping, nested swing arms for better under-vehicle clearance, and they offer longer reach and shorter retraction to land at more OEM-recommended vehicle lift-points.

“This not only saves technicians time and hassle when positioning vehicles on the lifts, it also enhances safety since improper spotting is a leading cause of lift accidents,” Rex said.

Rex also noted BendPak is developing the Octa-Flex Series two-post lift, which has eight fully adjustable, telescoping swing arms.

“Often in the past and even today, inspection services from unqualified providers don’t include documentation summarizing the findings,” O’Gorman said. “Those who are unqualified also often overlook OEM-defined inspection points while others apply misleading lift inspection labels. As a result, even customers who hired ALI-certified lift inspectors were not always confident they had received thorough lift inspections.”

“This groundbreaking design enables technicians to use a two-post lift in entirely new ways,” he explained. “For example, when performing caboff repairs, a single Octa-Flex lift can simultaneously hold/lift and lower both the cab and chassis. Its auxiliary arms also enable Octa-Flex to remove and hold heavy components like EV battery packs, drivetrains, and wheel assemblies without additional equipment or a second tech.”

BendPak is currently finalizing the Octa-Flex based on customer feedback.

Hunter, meanwhile, made some changes to its RX14 and RX16 scissor alignment racks. The OE lengthened the RX14KL by 13” and RX16KL by 17”, allowing them both to accommodate up to 195” two-wheel wheelbases.

“With last-mile delivery vehicles and longer wheelbase trucks growing every day, we added additional length to simplify alignment operations,” Liebetreu said. “While almost all these long vehicles fit on Hunter’s previous-generation runways, adding length simplifies alignment compensation, and therefore speeds services. Essentially, we added length to make alignments easier and faster.”

Liebetreu added that scissor racks are more space-efficient than four-post lifts and better suited to ADAS service. Shops can also flush-mount them for more efficiency.

Hunter added flexibility to shops aligning both light- and heavy-duty vehicles with the L494HD Four-Post Lift. He noted the lift was specifically designed for heavy-duty trucks, with long-haul models adopting aero packages that decrease their ground clearance.

“HD trucks are as low as cars these days,” Liebetreu said. “Crawling under a truck for alignment and general service should be a thing of the past if you wish to keep your staff—and keep them healthy.”

A focus on improving the efficiency of your lifts will also enhance technician productivity, meaning more jobs your shop can take on. By

Dan Quigley, Director of Sales and Marketing, Mohawk Lifts

In today’s fast-paced vehicle service industry, maintenance shops are facing mounting pressure to boost throughput and service more vehicles daily. This challenge is felt in both private garages focused on profitability and fleet maintenance facilities supporting large vehicle fleets. Garage managers often face the task of doing more with less, driven by the lack of available technicians. This shortage drives the need for greater efficiency, pushing shops to streamline workflows and make the most of their available staff and resources.

Vehicle lifts are essential tools that provide under-vehicle access for inspections and repairs, making them indispensable for many jobs. However, the potential of lifts to drive efficiency is frequently underestimated, especially when taking into consideration the wide range of lift options and accessories

available. Many shops overlook how the right lift options can increase workflow and boost productivity. Lift manufacturers offer various options and accessories that save time and make tasks faster for technicians. The right lift with the right options can make technicians’ jobs easier, faster, and safer.

When tasked with making a process faster, people often focus on the total time it takes to complete a job. In vehicle repair, technicians are often judged by how they perform against standard repair time (SRT) for a total job. Breaking jobs even further down into specific tasks can help identify where time is being lost and where improvements can be made. Efficiency in a maintenance shop is often achieved through the accumulation of incremental time savings across various tasks.

Take two-post swing arm lifts for example. These are the most popular lifts on the market and are known for versatility and efficiency, but they can still be improved upon. Positioning the swing arms can take from two to 10 minutes depending on the vehicle. This can be reduced by using the drive-on ramp option that some lift manufacturers offer. This accessory doesn’t require techs to position the arms, yet still leaves the tires hanging free for tire, brake, and front-end

work. If each cycle saves an average of four minutes, and a shop handles five jobs per day, that equates to 20 minutes saved daily. Over a week, this adds up to 100 minutes of additional productive repair time. Over a year, that adds up to over 85 hours.

How many additional jobs could your team complete with essentially two full work weeks of productivity each year?

Another example is the Backsaver, a simple but effective tool that allows technicians to hang tires from lift swing arms instead of constantly bending down to lift them off the ground. By minimizing the physical strain on technicians and minimizing movements, the Backsaver streamlines repair jobs by reducing the need for technicians to repeatedly lift tires, helping to mitigate the risk of back injury. Just as the drive-on accessory adds productivity, the Backsaver prevents lost labor time due to musculoskeletal issues (which may also cost employers in the form of workman’s compensation).

In short, the right tools reduce downtime and improve workflow in busy maintenance shops.

Efficiency improvements often come from optimizing lift setups. Some shops use options to streamline workflows for the types of jobs they handle most frequently. For example, because an estimated 60-70 percent of vehicles on the road today are front-wheel drive, transmission repair specialists can benefit from using a two-post lift with wheelengaging adapters on the rear arms and traditional lift pads on the front arms.

This option streamlines vehicle setup while still allowing full access to transmission and drivetrain components. Using wheel-engaging adapters

saves time by eliminating the need to manually adjust lift swing arms under the vehicle, making setup faster and easier for technicians. Over time, those saved minutes add up.

While reducing task times is vital, preventing equipment downtime is even more crucial. An out-of-service

lift will disrupt even the most efficient operation. When selecting a lift, it’s essential to consider the equipment’s reliability. Downtime can lead to significant revenue loss, especially if repairs are delayed due to the unavailability of an operating lift.

Many vehicle lifts utilize components such as plastic slide blocks, overhead cables, and plastic pulleys that require frequent maintenance and

replacement. Lift maintenance needs are costly and time-consuming, rendering the lift unusable during repairs. Selecting lifts with durable components and robust construction will reduce both the frequency of maintenance and the likelihood of unexpected breakdowns, saving time and money.

It’s important to remember that you get what you pay for. Higher-quality lifts may cost more upfront, but when you factor in long-term ownership costs and the high cost of downtime, they can be a much smarter investment. Some lifts offer a 25-year warranty while others offer only a one- or two-year warranty. Comparing warranties, maintenance needs, and overall reliability is essential. Every hour a lift is down costs the shop money, both in lost productivity and missed revenue opportunities. A lift that requires fewer repairs and lasts longer will save money and reduce

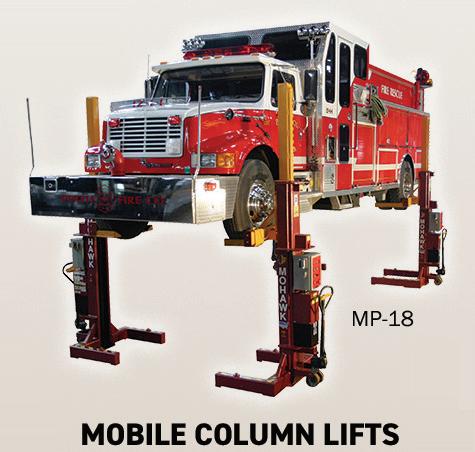

a drive-on platform lift with tracks or a set of mobile column lifts. Mobile column lifts require positioning a column at each tire, powering them on, and raising the lift. On average, setting up and raising a vehicle with four mobile columns takes about five to 10 minutes. In contrast, a large drive-on lift (such as a fourpost, parallelogram, or vertical rise lift) only requires driving the vehicle into the bay and raising it, which typically takes around two minutes. As mentioned previously, a few minutes per job escalates to dozens of hours per year. Additionally, compared to mobile lifts, drive-ons can be equipped with a wheels-free rolling jack for tire and brake work, further enhancing versatility.

When considering mobile column lifts, it’s essential to review lift specifications to ensure they align with your shop’s needs and goal of improving efficiency. For example, some hydraulic

types in various configurations. While this added capability allows garages to service a wider range of vehicles, it may sacrifice some efficiency due to the time required to set up and lift. Because mobile columns lift vehicles from the wheels, this can limit the types of tasks that technicians can conduct. However, most manufacturers offer versatile options to address these limitations such as a front-to-rear frame-engaging adapter or a side-to-side auto frame adapter, which allows tires to hang free if needed. Also, with the right adapter, mobile columns can lift low-riding forklifts, offering significant flexibility for diverse vehicle types and configurations. As a well-informed shopper, take the time to verify the capacity of these options, as some models can barely lift more than an F-350, while others are rated for up to 26,000 lbs.

Lifts, regardless of type, are a longterm investment and play a crucial role in ensuring both safety and efficiency in your garage operations. Taking the time to research your options thoroughly will help you choose the right lift to meet your specific needs. By prioritizing features such as durability, reliability, and compatibility with your workflow, you can maximize productivity and reduce downtime. Remember, a great price on the wrong piece of equipment is still the wrong piece of equipment. Do your research and you will be a happy lift operator.

DANIEL QUIGLEY is the director of sales and marketing at Mohawk Lifts, LLC, a premier lift manufacturer based in Amsterdam, NY, and the second oldest member of the Automotive Lift Institute (ALI). For over 40 years, Mohawk Lifts has proudly designed and manufactured its products in the USA with unmatched versatility, safety, and reliability.

FINDING A LIFT TO SUIT YOUR SHOP’S NEEDS isn’t always easy. With today’s modern vehicles—electric vehicles in particular—shop owners have more considerations to keep in mind – different lift points, heavier vehicles, and so on. That’s why we’ve put together this breakdown of lift types to help point you in the right direction of the lift or lifts that will make the most sense in your shop. Also, although the Automotive Lift Institute (ALI) recognizes seven different types of lifts, regardless of the lift type you may be considering, keep in mind that in North America, the International Building Code requires all lifts to be ALI-certified.

• Wheel-engaging, but can be configured for wheels-free service

• More shop space is needed for this option

• Versatile option for light, medium, or heavy duty vehicles

• Highly versatile — shops can perform almost any repair/ maintenance on almost any vehicle

• Ideal for shops with limited space

• Ideal for tire, wheel, and brake service, as well as collision work

• Works well in shops with low ceilings

• Can be moved as needed

• Most often used in heavy duty facilities

• Used in sets of two, four, six, or more

• Works well in shops with low ceilings

• Can be frame- or bodyengaging or equipped as a drive-on style

• Works well for servicing heavy duty vehicles like multiple axle trucks, buses, fire and rescue vehicles, etc.

• Offers full access underneath light and medium duty vehicles

• Smaller floor space footprint

• Typically frameengaging but can become wheel-engaging with certain adapters

• Works best for medium to heavy duty, off-highway equipment

• More shop space is needed for this option

A Q&A with ALI President R.W. “Bob” O’Gorman, BendPak’s Director of New Product Development Sean Price, and Challenger Lift’s Sales National Manager for North America Trevor Coleman.

By Emily Markham, Editor, PTEN

Q: What are some reasons a shop may need a new lift?

Trevor Coleman: Lift repairs are over one-third of the cost of a new lift; buying new and having a new warranty would make more sense. Another reason is if your needs have changed, like the types of vehicles you repair. Maybe you have started to repair EV or HD. You should own lifts that service 90 percent or more of vehicles that come in your shop, allowing you to maximize your profit.

Sean Price: You may want to take advantage of the latest lift technology, like better arm restraints, greater arm extension and retraction to reach more OEM lifting points, or other advances that help boost technician productivity and safety.

Bob O’Gorman: Putting aside any business reasons associated with the decision to replace a car lift, and instead with a focus purely on employee and customer safety, it is important to understand that an annual lift

inspection performed by an ALI-certified lift inspector can identify if a lift is no longer fit for service.

In addition to the mandated annual inspection, technicians and other employees must be empowered to take action if a lift is showing signs of malfunctioning. This boils down to an operator immediately stopping use of the lift and the employer scheduling an inspection to determine if maintenance or replacement is required.

Q: What additional equipment is needed to accompany lifts?

SP: Lift adapters! Having the right adapters lets you use a single two-post lift to service a wide range of vehicles. Screw pad lift assemblies, stacking adapters, slotted pinch-weld pucks or pads, cradle adapters, and more are

all designed to help you reach more OEM-recommended lifting points for secure lifting.

Also consider rolling jacks for four-post lifts or a crossbeam adapter for mobile column lifts expands their versatility to let you do wheelsfree work.

And lift tables save your back by using portable lifting tables to lift and lower heavy components like EV battery packs, engines, and other powertrain components.

Q: What training/safety precautions are necessary for technicians operating a lift?

TC: Technicians should receive handson training by their employer based on the type of lift they will be utilizing. They should also be given a copy of [ALI’s] Lifting it Right Guide and the daily maintenance schedule for their equipment. This will allow them to do a visual inspection daily to ensure their lift is operating properly.

They should also utilize the ALI training program. This program teaches the basics of lifting and comes with a short test the technician has to answer to pass. It is not lift-specific but covers the basics of lifting and the different types of lifts.

Q: What is the importance of having an ALI-certified lift?

SP: The significance is that you are trusting that lift with your life every time you walk under it to work. The only way to guarantee your lift meets industry safety and performance standards is to buy an ALI-certified lift. ALI is the only organization in North America with an accredited program to independently test and certify that a lift model meets safety and performance requirements and that the manufacturer meets quality control mandates. Sadly,

ALI-certifi ed lifts have been tested by experts from nationally recognized testing labs to verify material strength and performance of every component on the lift.

– R.W. "Bob" O'Gorman, president, Automotive Lift Institute

some people seem to think all lifts are pretty much built the same. But ALI-certified lifts have been tested by experts from nationally recognized testing labs to verify the material strength and performance of every component on the lift, as well as to confirm it operates as designed and can lift its rated capacity without failure. Uncertified lifts are untested, unproven lifts.

In addition to safety, the other significant point is a practical one. There are plenty of uncertified lifts out there for sale. But if you install any of them in a commercial setting, you’re violating the International Building Code. So, if protecting your life isn’t reason enough to choose ALI-certified, how about protecting your livelihood? A lift that gets tagged out by an OSHA or building inspector for not being ALI-certified isn’t helping you make a living.

Q: What upkeep is needed for lifts?

TC: The manufacturer’s maintenance schedules should be followed. Most will call out daily, weekly, and monthly maintenance schedules — typically located in the installation manual. Most will call out:

• Visual inspections for broken or missing parts

• Making sure lifts are lubricated where needed

• Check for leaking hydraulics

• Check the torque of anchors

• Check to ensure that locks are functioning properly

• Check for frayed or damaged cables

Q: How often should a shop have their lift/s inspected? Who can perform these inspections?

BOG: Every lift should be inspected by a qualified lift inspector at least annually, more often if recommended by the lift manufacturer. In 2021, we introduced the Check360 Certified Lift Inspection. This is a comprehensive lift inspection process that meets all the requirements outlined in ANSI/ALI ALOIM: 2020, including a comprehensive examination of the lift structure, electrical and mechanical components, as well as a review of training logs, operating instructions and safety materials. Only ALI-certified lift inspectors can perform Check360 lift inspections. At the conclusion of a Check360 lift inspection, the lift inspector will provide a thorough report of the results, including any concerns and recommendations. Those lifts that pass inspection will receive an exclusive Check360 Certified Lift Inspection label.

Q: How does servicing EVs affect the lift a shop might buy?

SP: Lifting electric vehicles presents unique challenges because EVs tend to be heavier and have harder-to-reach lift points than traditional vehicles. Most EVs are designed with their high-voltage batteries under the vehicle. The battery packs are large – taking up most of the undercarriage – and heavy. As a result, the OEM-recommended lifting points are often on the far edges of the vehicle frame. To safely lift an EV, you’ll need a vehicle lift with sufficient rated capacity and the capability to engage with the lifting points.

The three most important factors to ensure lift safety in your shop. By

Todd Michalski, VP of Sales and Marketing, Gray Manufacturing

Quality technicians are the lifeblood of any professional shop. In my experience, shops do a great job of educating technicians in several aspects of their everyday work. However, one area where qualified training is lacking is how to properly lift and secure a vehicle.

Every time a vehicle is lifted off the ground, shop management trusts that the technician has followed all proper procedures for safety and security. If the technician is not appropriately trained and does not follow the correct procedures, the results can be catastrophic. To ensure a safe lifting environment, a shop must buy the correct lift for the job, maintain said lift through certified inspections, and have a formal lift training program.

In purchasing a lift, the most important consideration is safety. To start, shops should make sure the lift is of the proper capacity and can access the manufacturer’s recommended lifting points for the types of vehicles they are servicing. Different types of lifts reach these lifting points through different methods; they may be drive-on, two-post, or wheel-engaging mobile columns. With the variety of lift options available, shops may want to

consult a trusted professional to help determine the best lift for their shop’s specific needs.

Additionally, shops should confirm the lift is Automotive Lift Institute (ALI)-certified before purchase. ALIcertified lifts have been third-party tested to meet all safety standards.

Proper maintenance and inspection of any lift is a key to continued safe lifting. All lifts should be maintained strictly adhering to the respective manufacturer’s guidelines and inspected annually to ensure a safe shop. The American National Safety Standard requires a lift owner to utilize a qualified lift inspector to inspect all lifts a minimum of once a year. A proper lift inspection will include an examination of all lift components along with making sure all decals and safety materials are present. Detailed records should be kept on inspection findings to ensure existing issues are addressed in a timely

fashion and can be prevented in the future. The Automotive Lift Institute has developed a certified lift inspection program to provide users with certification of the lift inspection.

The last component of safe lifting is technician training. Most technicians probably know the basics of lifting and securing vehicles, but it is easy to fall into bad habits. Formalizing a lift training program in a shop can help provide peace of mind in knowing the technicians are following proper lifting procedures. Each shop should tailor a program around their specific shop needs.

To help shops create their lifting programs, ALI offers the Lifting it Right program. This program explains the correct way to lift vehicles safely and provides a certification of completion to help with training records in compliance with national safety training requirements.

Overall, anytime a technician walks under a vehicle on a lift, they trust the vehicle has been correctly lifted and secured. If not, the results could be disastrous. So make sure your lifts have been properly certified and maintained, and all technicians have been formally trained on their proper use.

¶ Visual inspection relating to damage

¶ Cracked welds

¶ Retention pin holes oblong-shaped

¶ Correct retention pins

¶ Readable decals and placards

¶ Compromised

¶ Visual inspection relating to damage

¶ Excessive wear

¶ Missing components

¶ Leaks

¶ Complete functional test

¶ Readable decals and placards

¶ Visual inspection relating to damage

¶ Leaking fluids

¶ Non-OEM conforming, tampered with or missing components

¶ Readable decals and placards

Scan the qr code to view the entire product line at grayusa.com

¶ Visual inspection relating to damage

¶ Cracked welds

¶ Excessive wear

¶ Missing components

¶ Complete functional test

¶ Readable decals and placards

¶ Compromised

The Kangaroo Jack , No. WS-24-LPJ, from ARI-Hetra, is designed with precision and durability in mind. This hydraulic jack is equipped with a versatile, adjustable lifting bracket ensuring it meets a wide range of industrial needs. It can lift 12,000 lbs at the lift bracket, and it can lift 22,000 lbs on top of the piston. The lift is compact and portable, allowing the user to move and operate it in any workspace.

For more information, visit VehicleServicePros.com/55250138

The 1/2-Ton Two-Stage Telescopic Jack Stand , No. 371-03321, from Ascot Supply, uses foot pedals for handsfree operation. An overload valve prevents the jack from being used beyond its rated capacity, while a speed-limiting valve guarantees an automatic safe speed descent of no greater than 1” per second. Hydraulic double pumps ensure that the jack can quickly lift its load in no more than 35 pumps, and the jack’s piston rod and pump core are chromeplated for a longer service life. The jack also includes a 59” tiedown chain and 4” steel swivel casters for easy transportation around the shop.

For more information, visit VehicleServicePros.com/55038297

The Atlas Commercial-Grade Two-Post Baseplate Lift is designed for lifting heavy vehicles in low-ceiling garages. It features a single-point lock release and 9’4” columns with a middle-welded support gusset for added strength. It’s ideal for lifting 1-ton dually trucks or smart cars in shops with limited ceiling height. The lift has a 10,000-lb capacity.

For more information, visit VehicleServicePros.com/55137706

The CEAS 2,640-lb Lifting Table, Electric/Hydraulic w/ Adapters is designed to remove/replace battery packs for electric vehicles and engine, transmission, drive axle, fuel tank, suspension, and subframes of traditional vehicles. Reserved holes on the working table allow for positioning and fixing components with specialized fixtures. The lift also features a dual-speed system with fast, precise lifting. Additional features include an electrically controlled mechanical locking button, hand-held button control with a stop function, and an extendable table for greater versatility. Lifting adapters are included. For more information, visit VehicleServicePros.com/55089602

The BedLock System , No. BL-450A/B from BedLock Safety Products is engineered to prevent the unexpected movement of the raised dump bed, increasing user safety. With its robust design and locking mechanism, the BL-450A/B keeps the dump bed in place. Crafted from highstrength materials, this product is built to withstand the rigors of daily use. The BL-450A/B features a dual-chain system that provides redundant safety measures. Even if one chain were to fail, the second would continue to hold the bed in place. It’s built for heavyweight, with the ability to bear a maximum load of 50,000 lbs per pair.

For more information, visit

The ATD Tools 1/2-Ton Hydraulic Telescope Transmission Jack 7429, features an extrawide base for stability. It has a capacity of 1,000 lbs and rises to a maximum height of 74.8”. Its adjustable saddle tilts in both directions and when expanded it has an area of 13.58” by 13.78”. The transmission jack also features a chrome-plated ram for smooth operation and a welded hydraulic pump for durability. It meets or exceeds ASME/PASE 2019 standards.

For more information, visit VehicleServicePros.com/53059126

The Tuxedo Distributors iDEAL EV/ Hybrid Lift Table , No. LT-EV2500AH-X incorporates multi-adjustable and directional EV-insulated platforms for controlled lifting and lowering tasks to safely remove, replace, or service heavy vehicle components for EV or hybrid vehicles, such as EV batteries, motors, powertrains, or similar heavy components. The table also features air-hydraulic power and fully operational hand controls for lifting, locking, and lowering. The table can hold up to 2,500 lbs.

For more information, visit

The Scissor Lifting Table, No. SLT-2500, from Mohawk Lifts , is a heavy duty lift capable of lifting up to 2,500 lbs. The lift is engineered to accommodate transmissions or differential repairs and auto EV battery service. The lift provides easy 360-degree access to any component and includes heavy duty ratchet tie-downs to secure the load. It uses an air/hydraulic foot pump with a metered valve for safe lowering and includes four locking swivel casters for easy manueverability. It is made in the USA.

For more information, visit

The Harbor Freight Daytona 3-Ton Super Duty Floor Jack in Metallic Purple is a low-profile floor jack featuring Rapid

pump system with integral magnetic filtration to maximize pump life. For more information, visit

The Gray Manufacturing Wireless Mobile Column Lifts , Nos. WPLS-135, WPLS-185, and WPLS-185W, feature a wireless communication system and touchscreen controls and can provide up to 69” of lift. No. WPLS-135 is a 13,500lb capacity, 24V mobile column that can be operated in sets, allowing a capacity of 25,500 to 108,000 lbs. No. WPLS-185 is an 18,500-lb capacity, 24V unit, that can be used in sets for a capacity range of 37,000 to 148,000 lbs. No. WPLS185W shares those specs and includes a wide adjustable carriage for oversized tire engagement.

For more information, visit VehicleServicePros.com/55057018

The BendPak AP Series Two-Post Lifts feature rated lifting capacities ranging from 10,000 lbs to 20,000 lbs. Each AP Series lift uses BendPak’s Automatic Swing Arm Restraint System, safety lock system, and swing arm design. The AP Series uses high-strength steel and a multi-face lift column for stronger lifts with longer lifespans. The series includes extended height, short-rise, symmetric, and asymmetric options that can meet the needs of most Class 1 through 5 applications. The 10AP, 10APX, 10APX-168, 10APX-181, 12APX, 12APX-192, 12AP-SRT, 16AP, and 20AP lifts are ALI certified. For more information, visit VehicleServicePros.com/55267992

The 3-Ton Steel Jack Stand from OTC Tools is built with a durable, formed, and welded high-quality steel base for long-lasting stability and safety, making them a reliable choice for any garage or workshop. The self-locking ratchet handle ensures secure height adjustments and cannot be released under load. With multiple locking positions, these stands provide a versatile fit for most vehicles and serve as a complement to OTC’s 2-ton and 3-ton capacity service jacks.

For more information, visit VehicleServicePros.com/55265403

The AFF 2-Ton Lightning Lift Super Duty Long Chassis Floor Jack , No. 202LCJ, features single piston, one-pump-to-load technology. The jack has a minimum height of 2.9” and a maximum height of 23.6”. Once on a load, this jack maintains a quick pumping efficiency of about a 3” lift per stroke, says the company. Other notable features include heavy gauge steel, UV powder coated frames, ballbearing rear mounted swivel casters, foam pad on handle, cushioned saddle, built-in bypass system, and industrial-quality seals and O-rings. The extra-long chassis reaches all lift points under the vehicle.

For more information, visit VehicleServicePros.com/53063043

The Hunter Engineering RX14KL and RX16KL Scissor Alignment Lifts can accommodate up to a 195” two-wheel wheelbase, offering longer variations of Hunter’s RX14 and RX16 Scissor Alignment Lifts. The new models offer adjustable turnplate pockets that provide an 88” to 168” four-wheel alignment service range. When aligning a shorter vehicle, the turnplates can be moved back into the pocket within seconds. Additionally, a flush-mount arrangement simplifies floor-level rolling compensation and ADAS calibrations. The surfacemount RX14 and flush-mount RX16 series provide 14,000 and 16,000 lbs respective capacity and both include two 9,000-lb capacity jacks. Both models offer low drive-on height and are also PowerSlide and InflationStation capable.

For more information, visit

VehicleServicePros.com/53076321

The SUNEX Tools 2-Ton Off-Road Jack , No. 6602RJ, features a 28.4” lift height and a dual piston mechanism for rapid lifting. It has a fulllength wraparound steel skid plate for stability even on soft surfaces, and heavy duty wheels on solid steel axles allow for easy navigation on rough terrain. It has a locking height adapter and stainless steel hardware for durability and corrosion resistance.

For more information, visit VehicleServicePros.com/55127670

The Autel Alignment Scissor Lift is a flush/surface-mounted hydraulic vehicle lift compatible with passenger cars and light trucks and is available in 12,000- and 14,000-lb capacity versions with jacking beams similar to the company’s Bay Max Lifts but without the floor lift table. The Alignment Scissor Lift includes front and rear opening runways, flip-down wheel stops, and low-angle approach ramps for easier access. Made in North America and ALI certified, the lift comes standard with built-in runway air tire inflation kits at each wheel, shatterproof undercarriage LED with automatic shut off, and an enclosed console power control unit.

For more information, visit

The Ford 3.5L and 3.7L EcoBoost Engine Out Lift Plate Hoist Tool , No. STC50133, from Steck Manufacturing , is specifically designed for both turbo and nonturbo Ford EcoBoost engines, making it compatible with the Ford Transit, F-150, Navigator, Flex, and more. The lift plate mounts directly to the left and right cylinder heads to allow for secure engine removal without removing the subframe and eliminating the risk of broken chassis bolts. It’s made in the USA from thick steel with full-length welds and is rated for over 2,500 lbs.

For more information, visit VehicleServicePros.com/55263180

The Thexton Lift Alignment Tool , No. 962, is designed to streamline the positioning of lift arms to vehicle lift points. With the capability to position both front and rear arms, the alignment tool minimizes the need for constant up and down movements, reducing strain on the user. Crafted with a lightweight yet robust design, this tool aims to ensure ease of handling without compromising durability. Equipped with two flush-mounted laser guides, it provides precise visualization of the outer edge of the lifting point. The laser guide features a twist-on/ off mechanism and replaceable batteries. Designed to accommodate most lift pads up to 6.75”, the tool also comes with a magnetic hook for storage on the lift.

For more information, visit VehicleServicePros.com/55019223

The OEMTOOLS 2-1/2 Ton Aluminum/ Steel Hybrid Floor Jack , No. 24869, features an aluminum construction and steel frame that provides the benefit of strength within a lightweight chassis, weighing only 58.2 lbs. With a 3-1/2” minimum and 19-1/4” maximum height, this floor jack is ideal for sports cars as well as SUVs and pick-up trucks. Nylon casters protect sealed floors and dealer showrooms. The 4.3” saddle with a jack support pad and foam handle cover prevents damage to the vehicle. The jack has undergone rigorous safety testing, as outlined by the ASME PASE-2014 Safety Standard for Portable Automotive Service Equipment.

For more information, visit VehicleServicePros.com/55021570

The Rotary Lift Two-Post Asymmetric Lift with All-Vehicle Lift Arms , No. SPOA10-AV, is designed to accommodate all vehicle types under 10,000 lbs with its all-vehicle (AV) lift arms. The arms provide technicians the ability to lift and service almost all roadgoing vehicles on a singular lift, including battery electric, exotic low profile, truck frame, and unibody cars and SUVs. Additional features include a 3-3/8” minimum adapter height, as well as 20 percent more reach than 30-stage arms with thread-up adapters, and 30 percent larger arm sweep than conventional two-stage arms with flip-up adapters, according to the company. The lift comes standard with adjustable round, truck, and stackable adapter extensions.

For more information, visit VehicleServicePros.com/53078181

The 1-1/2 Ton Hydraulic Transmission Jack , No. FTJ150, from Snap-on , uses articulating saddle arms that can quickly adjust without additional adaptors, creating a secure fit for nearly any configuration of FWD, RWD, and 4WD transfer cases. The jack’s front legs offer a wider opening for increased access to the transmission during the removal and installation process, while its low saddle height of 8-1/2” can be used to remove most transmissions. Its maximum height of 36-1/2” can be used for any cases where extended reach is necessary.

For more information, visit

VehicleServicePros.com/55054522