Wide range of SnowDogg® plows for trucks 1/2-ton and up

59" LED LIGHT BAR TRAFFIC ARROW

EXTRUDED ALUMINUM CONSTRUCTION WITH ADJUSTABLE ARROW POINTS

Featuring 72 LEDs. 8 directional and warning flash patterns, controlled by in-cab controller.

PICK-UP TRUCK CONTRACTOR TRUCK TOOL BOX SERIES

DIAMOND TREAD ALUMINUM CONSTRUCTION

Shut out weather and theft with locking, stainless steel compression latches. Available in Gloss Black, Matte Black, or Unpainted finish.

SALTDOGG® PRO-M SERIES POLY SPREADERS WITH IN-CAB MULTIPLEX CONTROLLER

Combines the power and reliability of SaltDogg PRO Series Spreaders with the advantages of modern CAN bus architecture.

SnowDogg® Illuminator ™ LP

Low Profile LED Plow Lights Part No. 16160900

LEARN MORE about the NEW SnowDogg® MXII

LOW PROFILE LED PLOW LIGHTS FULL RADIUS DESIGN WITH RIBBED STIFFENERS FOR ADDED STRENGTH

ALUMINUM FENDERS WIRELESS LED LIGHT BAR WITH REMOTE SNOWDOGG® ILLUMINATOR LP

PLUG AND PLAY COMPATIBILITY WITH ALL PAST & CURRENT SNOWDOGG® PLOWS

Patent pending integrated 5-pattern strobes powered by 4 Amber LEDs on each light.

Three different sizes for wheels 19.5" - 24.5". Enhances the truck's appearance while offering a durable, corrosion-resistant finish.

SAE J845 CLASS 1, CA13 & IP67 RATED Featuring 84 LEDs with 7 adjustable flash patterns. Magnetic mounts located on the bottom of each light for easy installation.

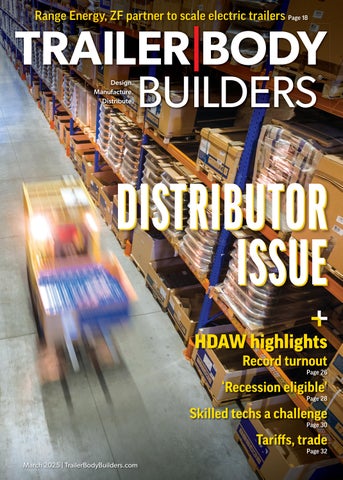

26 HDAW 2025 sets records in Grapevine gathering

Annual aftermarket industry meeting “brakes” new ground 28 Economy still ‘recession eligible’ in 2025

Beware of 'divots,' cautions MacKay market analyst 30 Fleet panel: Skilled techs, reliable parts a challenge

Maintenance pros share pain points that still pester shops

Tariffs, Trump, trade: aftermarket eyes borders MEMA government affairs rep outlines policy impacts 33 MEMA Aftermarket Suppliers names ledership

Tank trailer manufacturer adds attention-grabbing ‘glow heads’ to list of custom offerings

Range Energy and ZF partner to scale electric trailers

aims to take the lead on trailer electrification

‘Right to repair’ heating up in Congress—again

Wabash acquires startup TrailerHawk.ai, expanding TaaS security

Market Leader

Commercial Vehicle Group – Dyanna Hurley dhurley@endeavorb2b.com

Editorial Director – Kevin Jones kjones@endeavorb2b.com

Senior Editor – Jason McDaniel jmcdaniel@endeavorb2b.com

Associate Editor – Alex Keenan akeenan@endeavorb2b.com

Marketing/Advertising – Dan Elm delm@endeavorb2b.com

Art Director – Jennifer Dakas jdakas@endeavorb2b.com

Directories/Listings – Maria Singletary msingletary@endeavorb2b.com

Audience Development Manager – Laura Moulton lmoulton@endeavorb2b.com

Endeavor Business Media, LLC

CEO Chris Ferrell

COO Patrick Rains

CRO Paul Andrews

CDO Jacquie Niemiec

CALO Tracy Kane

CMO Amanda Landsaw

EVP/Transportation Kylie Hirko

TRAILER|BODY BUILDERS (USPS Permit 636660, ISSN 0041-0772 print, ISSN 2771-7542 online) Volume 66 Issue 5, is published monthly by Endeavor Business Media, LLC. 201 N Main St 5th Floor, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI, and additional mailing offices. POSTMASTER: Send address changes to Trailer/ Body Builders, PO Box 3257, Northbrook, IL 60065-3257. SUBSCRIPTIONS: Publisher reserves the right to reject nonqualified subscriptions. Subscription prices: U.S. ($79 per year); Canada/Mexico ($79 per year); All other countries ($157 per year). All subscriptions are payable in U.S. funds. Send subscription inquiries to Trailer/Body Builders, PO Box 3257, Northbrook, IL 60065-3257. Customer service can be reached toll-free at 877-382-9187 or at trailerbodybuilders@ omeda.com for magazine subscription assistance or questions. Printed in the USA. Copyright 2025 Endeavor Business Media, LLC. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopies, recordings, or any information storage or retrieval system without permission from the publisher. Endeavor Business Media, LLC does not assume and hereby disclaims any liability to any person or company for any loss or damage caused by errors or omissions in the material herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. The views and opinions in the articles herein are not to be taken as official expressions of the publishers, unless so stated. The publishers do not warrant either expressly or by implication, the factual accuracy of the articles herein, nor do they so warrant any views or opinions by the authors of said articles.

Corporate Office: Endeavor Business Media, LLC

30 Burton Hills Blvd, Ste. 185, Nashville, TN 37215 USA 800-547-7377

Isuzu to further partnership with Shyft Group Companies to collaborate in new Isuzu plant Trailer-BodyBuilders.com/55271177

Kwik Equipment marks 10 years Houston-area manufacturer eyes growth Trailer-BodyBuilders.com/55271176

Trailer backlogs grow for third consecutive month: ACT Research Trailer-BodyBuilders.com/ 55271180

Eaton to distribute new Bezares hydraulic dump pump Trailer-BodyBuilders.com/ 55271182

Read the digital edition online at

Aftermarket distributors report an easing in supplier problems, but...

Kevin Jones Editor

Uncertainty is better than knowing things are bad. That’s my story and I’m sticking to it.

Let me get this out of the way, right here up front: I am embarrassed by how many stories in the last couple of magazines have a “who knows?” element. Because, once upon a time when the world and TBB were young, the whole point for the two editors who came before me was to find someone who knew the answers.

Alas, I have not been particularly successful the first couple of months into the new year and new administration. Much optimism and fingers crossed but, to many folks, things are a little too fluid to get cocky. (Anyone with an answer, feel free to share your crystal ball.)

So, writing this as our team plans to cover TMC and Work Truck Week in coming days (I’m on a plane from NATDA’s first Trailer Tech event in Reno, a week after NATM’s annual gathering in Nashville), I promise we’ll be asking what trailer, body, and chassis OEMs are looking for from suppliers and distributors. (Look for details on the above in the next TBB mags.)

For now, let’s get some answers from the second edition Talk from the Top by Shannon O’Brien, commercial vehicle lead with MEMA Aftermarket Suppliers. (See Page 26 for complete HDAW coverage.)

Have the uncomfortable conversations. Not having the conversation doesn’t make the issue go away.

It’s an anonymous and candid survey for heavy-duty aftermarket distributor execs to get their feelings out about their supplier partners. O’Brien (who conducted the confidential interviews) explains that the purpose of constructive criticism is to help us improve. She also noted: “Please, don’t shoot the messenger!”

Broadly, distributor execs were not impressed with the market and the lack of a rebound. However, some good news: “Lead times are coming down and supplier performance is coming up…The supply base has seemed to get themselves together in this bit of a soft patch.” And, after a couple of years of supply

problems, “It’s a little bit more of a boring story going into ’25.”

Regarding innovation and technology, the distributor execs were virtually unanimous in encouraging suppliers to “Embrace it and go FASTER” and “You don’t want to be the one that’s trying to catch up.”

Not surprisingly, the distributors were not particularly impressed with “Made in America” pitches. For customers, by and large, “Where it’s made doesn’t matter. Quality and price do.” Similarly, they acknowledged North American suppliers can win on quality but said they need to be “much more nimble.” Said one exec: “Too many times we see U.S.-based manufacturers continue to have 8 week lead times… You are putting your domestic value proposition at risk.”

The distributors’ opinions were mixed on supplier service levels, with responses ranging from “ton of improvement” and “it’s become a non issue” to “My biggest concern is that they are patting themselves on the back and not thinking about their production capabilities during a pre-buy with peak demand.”

Ultimately, the aftermarket is still a relationship business—but a lot of distributors aren’t “feeling the love” from their suppliers:

• The worst are those that are not transparent with issues. Issues don’t get better with age.

• They tell you they have a plan to get their back-orders down, and then they don’t meet it. And it’s the same month after month.

• Have the uncomfortable conversations. Not having the conversation doesn’t make the issue go away.

• We get left in the dark and get some story about an issue getting better next month, and then it doesn’t. When you get that over and over again, even from senior people, you start to wonder if they care?

• Treat your aftermarket distributor as a customer and not just a means to get your product to market end users.

• Don’t look to us to grow your business and at the same time spend zero time with us.

• They have so much dedication to pleasing the OEM, at the end of the day they forget about who is bringing the profitable business to them. TBB

Wisconsin Manufacturers & Commerce has inducted Don Wahlin, founder of Stoughton Trailers, into Wisconsin Manufacturers & Commerce’s Wisconsin Manufacturing Hall of Fame.

Wahlin, a Wisconsin native, purchased the remaining assets of a small, bankrupt business is 1961 and founded Stoughton Trailers. Over the course of the next four decades, Wahlin’s leadership and business acumen built the company into one of North America’s largest trailer manufacturers. Eventually, Stoughton grew to become the largest manufacturer in its home county.

In addition to his industry leadership, Wahlin served as a pilot in the Air National Guard for 23 years and raised eight children with his wife, Carol. Together, they also founded The Wahlin Foundation to invest in local communities. The Foundation has contributed to various projects such as the Stoughton Youth Center, the VFW Memorial Park, the Evansville Aquatic Center, the Stoughton Hospital, the Stoughton Library and more.

Don was an obvious addition to the Hall of Fame. He is a champion of industry, leadership and philanthropy and a great servant to our country and his family.

Kurt R. Bauer, WMC president and CEO

“I am deeply honored and humbled to be inducted into the Wisconsin Manufacturing Hall of Fame,” stated Wahlin. “None of this would have been possible without

the hard work and dedication of our talented team of employees and the support and continued leadership of my family. It’s a true privilege to join these Wisconsin icons as an inductee.”

Wahlin is the 80th inductee, joining a list of Wisconsin industry titans including the last year’s inductee, Ashley Furniture’s Ron Wanek and historical inductees such as Jerome Case, Patrick Cudahy, Kurtis Froedtert, Henry Harnischfeger, Samuel Curtis Johnson, John Kimberly, Walter Hohler, Oscar Mayer, George Mead, Frederick Miller, Charles Nash, Gustave Pabst, F.J. Sensenbrenner, Arthur O. Smith and Reuben Trane.

“Don was an obvious addition to the Hall of Fame,” said WMC President and CEO Kurt R. Bauer. “He is a champion of industry, leadership and philanthropy and a great servant

to our country and his family. His legacy will undoubtedly endure for generations to come.”

The induction ceremony was held Feb. 21 at the Pfister Hotel in Milwaukee as part of the annual Wisconsin Manufacturer of the Year (MOTY) awards.

WMC’s predecessor organization, Wisconsin Manufacturers’ Association, started the then-called Industrial Hall of Fame in the 1950s “to honor those individuals who made significant contributions to the state’s industrial history.”

The Wisconsin Manufacturing Hall of Fame distinguishes and honors the legacy of the leaders who have built Wisconsin. Wisconsin has a rich heritage of manufacturers who have impacted its economy and expertly lead companies, all while investing in their communities through philanthropy and civic engagement.

Tank trailer manufacturer Tremcar recently welcomed Mid America Trailers as an authorized distributor in Owensboro, Kentucky. Their collaboration marks a significant expansion in Tremcar’s distribution network, enhancing its ability to serve customers across the Midwest region, the company reported.

Mid America brings decades of experience in the tanker industry, making them a valuable addition to the Tremcar family. With a history rooted in transportation and a deep understanding of customer needs, they are poised to deliver exceptional service and industry expertise.

“Tremcar isn’t just a manufacturer; they’re a collaborator,” Willie Stroup, Mid America founder, said in a news release. “Their engineers sit at the table with us, ensuring our needs are met with tailored solutions.”

Mid America’s journey began in the mid-1980s with the transportation of jet engines, eventually evolving into a robust business in the tank industry. Stroup, an industry veteran, leveraged his experience to create a brand known for reliability and customer-centric service. Over the years, they have gained a wealth of knowledge about what works in tanker operations, making them a valuable partner.

The company maintains strong family ties within the industry, sharing resources and insights with associated businesses, including First Class Services in Kentucky and Farmers Oil Company in Kansas and Oklahoma. This network enables Mid America to provide highly personalized customer service.

Mid America decided to partner with Tremcar due to the manufacturer’s dedication to quality and innovation, the companies said. The distributor also values Tremcar’s

custom-engineering approach, exceptional service, and equipment dependability—particularly in its leasing division, American Tank Leasing—all of which were key factors in its decision to represent Tremcar’s products.

“Tremcar’s craftsmanship stands out in the industry,” Stroup said. “Their tankers are built to last, ensuring our customers receive the highest-quality products available.”

SmithCo Mfg. Inc. has reached an agreement with TransWorld Equipment Corp. to sell SmithCo’s premium line of side dump trailers in seven northeast U.S. states. TransWorld Equipment is headquartered in Little Silver, New Jersey.

“We are pleased to announce that Transworld Equipment has officially joined the esteemed SmithCo family as a dealer for the Northeast region,” Transworld Equipment Corp. President Al Terrone said. “We recognize SmithCo’s commitment to quality, expertise, and support, which has established them as a leader in the side dump industry. Our partnership will enable us to expand their product offerings into New Jersey, Delaware, Maryland, Connecticut, Rhode Island, Eastern Pennsylvania, and Southeast New York. This collaboration ensures that our current and future clients will have access to the most reliable and efficient equipment for their operations.”

TransWorld Equipment has provided intermodal equipment, including new and used container chassis, trailers, dump equipment, ISO tanks and containers for over 25 years.

“The safety and efficiency of using SmithCo Side Dump Trailers is relatively unknown in certain parts of the country,” said Todd Karolczak, SmithCo’s director of sales and marketing. “With TransWorld’s experience in transportation, they will help us educate many more haulers in the region.”

To meet growing demand for their new line of non-demountable truck bodies, Victory Truck Body Inc., formerly Demountable Concepts, is building an additional 65,000-sq.-ft. facility in Glassboro, New Jersey, the site of their current facility. This addition more than doubles the company’s total manufacturing space to 115,000 sq. ft.

fabrication techniques utilized at the current facility, which is staffed by nearly 100 employees, including an in-house engineering team. This will ensure efficiency and top-tier craftsmanship across the Victory product line, including dry freight van, curtain-side, flatbed, and refrigerated truck bodies, according to the company.

The state-of-the-art facility will house a multi-truck sized downdraft paint booth and overhead cranes to complement human and robotic welding capabilities, CNC laser cutting, and precision

This new space also lets Victory expand production of products and services established during the Demountable Concepts years, including Swap Body and Warehouse on Wheels

delivery truck solutions for straight trucks. MyGlassTruck will continue to manufacture and supply glass carts and dollies, bolt-on glass racks, glass trucks, trailers, parts and accessories. And DCI Fleet Service will take on the additional role of in-house service department for Victory Truck Bodies while continuing to perform fleet repairs for customers throughout the Delaware Valley market.

“We often experienced delays in receiving upfitted truck bodies for our Swap Body straight truck systems and had to find ways to bridge the gaps to meet critical deadlines,” Rustin Cassway, CEO of Victory Truck Bodies, said. “This and our 35-plus years of niche bodybuilding led us to bring the truck body portion of our operation in-house to better control production.

“It wasn’t long before customers and newcomers started requesting that we build bodies for their non-demountable trucks as well. Having additional bodybuilders, like Victory, to supply the MidAtlantic and eventually national market will help companies delivering goods by straight truck to procure the vehicles they need in a timely manner.”

ZM Trucks is establishing its first North American manufacturing plant in Fontana, California. This also marks the relocation of the company’s regional headquarters to the Fontana facility. The newly constructed facility spans 9.67 acres with a 210,000-sq.ft. factory floor and is located about 49 miles from downtown Los Angeles.

“Our new Fontana facility reflects ZO Motors’ commitment to the U.S. market and sustainable innovation,” said Joost de Vries, CEO of ZO Motors. “This expansion allows us to deliver zero-emission solutions that lower total cost of ownership and drive long-term value for our customers.”

The manufacturing plant will serve as the cornerstone of ZO Motors’ U.S. operations through its subsidiary, ZM Trucks, supporting the production of a portfolio of zero-emission products. Initially, this will include electric commercial trucks, terminal tractors, and airport ground service equipment under the ZM Trucks brand. The facility is expected to begin production in the first half of 2025.

The new regional headquarters and manufacturing facility in Fontana are expected to create significant job opportunities throughout the region while also reinforcing ZO Motors’ mission to lead the transition to cleaner, more sustainable transportation solutions in the industry.

Doran recently introduced a new system that helps tank truckers avoid mispulls.

The company’s SmartLink solution with Platform Scienece ensures drivers connect to the correct trailer, eliminating delays, cost overruns, and potential safety issues, Doran reported. Using RF technology, the system compares the trailer’s ID with the one provided in the driver’s workflow on the Platform Science system. If the two match, the truck and trailer icons are illuminated with a green checkmark. If there is no trailer connected or if the wrong trailer is connected, the trailer icon is illuminated with a red X, alerting the driver to a mismatch.

“Trailer SmartLink empowers fleets to operate smarter, safer, and more efficiently,” Lee Demis, Doran VP of business development, said in a news release. “The ‘digital handshake’ technology gives drivers a clear visual indication that they have the correct trailer or not, providing more accountability and safety across a broad range of industries.”

displays them through the Platform Science tablet, via the Doran TPMS mobile app and remotely through the Doran TPMS portal for convenience and clarity. Continuously monitoring and reporting tire pressure and temperatures helps fleets reduce tire-related operating expenses, increase equipment uptime, and improve vehicle safety.

This unique add-on module enhances safety and accountability and eliminates the delays and extra costs associated with mispulls.

In addition to providing trailer identification and tracking, the SmartLink system continuously monitors all connected tires for pressure and temperature and

Rizon, Daimler Truck’s newest brand of all-electric vehicles, recently announced its first official handover in Canada, an 18,850-lb. GVW e18L fitted with a dump body to Villamar Construction in Victoria, British Columbia. The unit will be integrated into Villamar’s operations and used on custom home-building projects.

There will be an additional 18 units delivered to customers across British Columbia and Quebec in the coming weeks upfitted with various bodies, such as dry boxes, service bodies, and landscape dumps.

Customers include municipalities, rental and leasing providers, and freight and logistics companies.

“This handover marks a significant step for Daimler Truck in bringing zero-emission commercial vehicles to Canadian businesses,” Andreas Deuschle, the global head of Rizon Truck, said. “Commercial EVs are no longer a future concept; they’re here, hitting the road and serving in communities across Canada. We congratulate Villamar Construction on leading the charge and look forward to seeing Rizon trucks drive the growth of zero-emission transportation nationwide.”

Rizon’s current network of dealers in Canada includes nine locations across British Columbia, Ontario, and Quebec with plans to expand to other locations in the near future.

Data captured and displayed includes real-time notifications for cautionary and critical low-pressure alerts, FastLeak rapid deflation events, and high tire-temperature conditions, with the option to add a high-pressure warning. These insights also provide driver managers and fleet maintenance teams with real-time visibility on problem tires through email alert notifications, daily summary reporting, and current tire status by vehicle.

Rizon Truck launched in Canada in 2024 to meet the demand for zero-emission vehicles as the government aims for net-zero emissions by 2050. The Canadian government has established an incentive program to encourage fleets to electrify. These vehicles will qualify for the Canadian government’s Incentives for Medium- and Heavy-Duty-Zero-Vehicles program, which has been in effect since 2022. A Rizon truck will qualify for approximately $75,000 at the point of sale under this program.

Crosspoint Power & Refrigeration, a Carrier Transicold dealership, is donating the installation of a X4 7500 trailer refrigeration unit to Gleaners Food Bank of Indiana. The company installed the unit on a 35-ft. trailer that entered into service last month.

“Crosspoint Power & Refrigeration has regularly serviced our Carrier Transicold refrigeration units and allows us to distribute more than 55 million meals a year, including nearly 5 million meals through our mobile pantries,” said Joe Slater, chief operations officer at Gleaners Food Bank of Indiana. “Almost 80% of the food we distribute is fresh produce, lean protein, dairy, or other perishables. Reliable temperature control and dependable transportation are essential in the movement to end hunger.”

Gleaners Food Bank of Indiana partners with more than 300 pantries, shelters, senior centers and other organizations to

relieve hunger in 21 counties across central Indiana. Its fleet of trailers and box trucks also provides mobile pantry services for families and individuals who fall outside the reach of its network. The Carrier Transicold dealer’s newest facility is located across the street from Gleaners’ food bank and on-site pantry in Indianapolis.

“Our support for Gleaners Food Bank of Indiana goes beyond installing and servicing their refrigeration units. We’re literally neighbors. We see the lines at the pantry,” said Shawn Aitken, vice president and general manager, Carrier division, at Crosspoint Power & Refrigeration.

The X4 7500 is the second Carrier Transicold refrigeration unit Crosspoint Power & Refrigeration has provided to Gleaners Food Bank of Indiana. In 2023, the dealer donated an X4 7300 unit for a 35-ft. trailer.

Carrier is a supporter of Feeding America, a network of more than 200

hunger-relief organizations across the United States, including Gleaners Food Bank of Indiana. Carrier provided $200,000 in grants to food banks affiliated with Feeding America near Carrier facilities across nine U.S. states for use throughout 2024—$20,000 of which was directed to Gleaners Food Bank of Indiana.

The Precision Metalforming Association Educational Foundation (PMAEF), in partnership with 15 districts of the Precision Metalforming Association (PMA), is now accepting scholarship applications from high school students and others pursuing careers in

the metalforming industry. The deadline to apply for a PMAEF spring scholarship is March 16, 2025.

“Manufacturing offers outstanding career opportunities, yet companies in our industry continue to cite attracting, training and retaining workers as a top challenge,”

said PMA President David Klotz. “One of the ways that the PMA Educational Foundation is addressing this challenge is through our scholarship program, which helps deserving individuals obtain the essential skills needed for careers in the industry. PMA is pleased that PMAEF and our local districts are leading the way in building the workforce of tomorrow.”

Scholarship applicants must be a high school senior and/or formally enrolled in a post-secondary metalforming/ manufacturing/technology/engineering program; trades job training/apprenticeship; or a machining, CNC, tool and die, welding or stamping certificate program with 20 or more contact hours.

The 15 PMA districts participating in the PMAEF scholarship program include: California, Chicago, Cleveland, East Michigan, Lone Star, Indiana, MidAtlantic, Ohio Valley, New England, Southeast, Southern New England, Tennessee, Twin Cities, West Michigan and Wisconsin districts.

During the fall 2024 scholarship campaign, PMAEF and PMA districts provided $50,000 in scholarships to 27 talented individuals from 13 PMA districts, bringing the total awarded to nearly $200,000 since the program’s inception in 2020.

“Every year, our districts’ support of the PMAEF scholarship program continues to grow,” said Randy Kish, PMA member engagement manager. “Their support allowed a record number of aspiring industry professionals to receive scholarships this past fall and we look forward to building upon this further in 2025. PMA districts are proud to help educate the next generation of metalformers.”

Those interested in learning more about the program are encouraged to visit the website, www.pma.org.

Fontaine Modification has acquired ProBilt Services, an upfitter located three miles from Peterbilt’s Denton, Texas, truck manufacturing facility. With the acquisition, Fontaine is expanding the modification and upfit services it offers for Peterbilt trucks and others.

The Denton acquisition gives Fontaine its third modification center in Texas, joining locations in Garland and Laredo. It follows Fontaine’s 2019 acquisition of the other ProBilt Services operation located near the Kenworth plant in Chillicothe, Ohio. Fontaine now has 11 modification centers nationwide.

“This acquisition strengthens our position in the heavy-truck industry, provides new opportunities for growth and expands our ability to support our customers,” said Jamil Young, Fontaine Modification president. “We look forward to continuing to build on ProBilt’s reputation for quality and reliability.”

The Denton site includes a 30,000sq.-ft. facility that boasts parking for 250 trucks. It is configured for post-production truck upfits and modifications, including body modification and drivetrain changes, primarily to heavy-duty Peterbilt truck models. The Denton team also installs clean fuel technology, including options for battery electric, hybrid, and alternative-fuel vehicles.

Fontaine acquired ProBilt from its founders, Toney Fitzgerald and Fred Toothman. While Fitzgerald has elected to retire, the rest of the ProBilt

team will continue with Fontaine, led by Toothman as Denton operations manager.

“I’m excited to be a part of the evolution of the ProBilt legacy and am dedicated to a seamless and successful transition,” said Toothman.

“After 14-plus years, it was time to take

ProBilt to the next level,” Fitzgerald said. “It made total sense for ProBilt to be a Fontaine location. As I embark on retirement after over 50 years in the heavy truck business, I will cherish all the relationships, experiences, and memories I have been fortunate to have.”

The North American robotics market demonstrated minor overall growth in 2024, reflecting resilience and adaptability as automation strengthened its role across industries. According to new data from the Association for Advancing Automation (A3), North American companies ordered 31,311 robots valued at $1.963 billion, representing slight increases of 0.5% in units and 0.1% in revenue over 2023. These gains mark stabilization after years of volatility and record-breaking growth, the report noted.

2024 saw a notable shift as non-automotive industries captured a larger market share. Food and consumer goods emerged as the year’s fastest-growing sector, with robot orders surging by 65%. This underscores the sector’s growing reliance on automation to meet consumer expectations, streamline supply chains, and address labor shortages.

Life sciences, pharmaceutical, and biomedical industries also posted strong results, with 46% growth in orders. These gains highlight automation’s critical role in advancing healthcare innovation and improving operational efficiencies.

A strong finish to the year

In Q4 2024, North American companies ordered 8,277 robots valued at $506 million, reflecting 8% growth in both units and revenue compared to Q4 2023. Food and consumer goods led the quarter with 77% year-over-year growth.

While growth was robust in many areas, challenges remained. Semiconductor and electronics orders fell by 37% annually, reflecting supply chain and demand pressures. Metals and automotive components saw declines of 4% and 15%, respectively.

“In 2024, the North American robotics market saw mixed results following a challenging 2023,” said Alex Shikany, executive vice president at A3. “While sectors such as automotive components are still navigating recovery, we have seen encouraging signs of resilience across various industries. As we look to 2025, the mood among our members is optimistic, reflecting a robust belief in the enduring value of robotics and automation technologies. These tools are essential for enhancing efficiency and competitiveness on a global scale.”

Maxon introduces the DMD 3.0, a next-gen liftgate designed for high-demand transport environments. Equipped with new dock impact bumpers, it delivers enhanced durability and efficient dock loading. We’ve kept all the features that made its predecessor a standout: lightweight aluminum columns, improved operator ergonomics, our Edge Guard roll-off barrier and the MAX GRIP® platform surface treatment. Plus, with three different capacities and 12V and 24V options — including a hybrid model — the DMD 3.0 is perfectly suited for the growing number of electric vehicles in the market.

By Kevin Jones

Range Energy is partnering with ZF to help drive the development and adoption of the Range eTrailer System within the North American commercial trucking industry. e collaboration will see ZF’s AxTrax 2 e-axle integrated into Range’s eTrailer System to address critical fleet demands, such as greater e ciency, emissions reductions, and range extension, with the goal of advancing the widespread scalability of hybrid and zero-emissions trucking.

“We believe electrified trailers are a viable solution to help lower emissions for food delivery or transportation of goods, improve fuel economy for combustion engines in the powertrain, extend the range of BEV and electric trucks, reduce exhaust, noise and brake particle pollution, and further improve total cost of ownership,” said John Hawkins, senior vice president, Commercial Vehicle Solutions, ZF. “Collaborating with Range not only

expands the electric mobility applications of our products, it gives us the opportunity to work with an emerging leader offering a smart solution to emissions in a hard-to-abate sector.”

In addition to supplying its electric axle to Range, ZF will also seek to accelerate Range’s relationships with ecosystem partners, such as component suppliers and integrations with

trailer and tractor original equipment manufacturers. Range’s eTrailer System includes a modular battery pack, the ZF AxTrax 2 e-axle, and a smart kingpin, which is equipped with Range’s patented control algorithms.

Indeed, trailers are emerging as a critical technology area for further supply chain carbon emission reductions to meet transition timelines in Europe and the U.S., as ZF and several European trailer manufacturers explained at

IAA Transportation 2024 in Hannover, Germany, last fall.

Under the new brand name TrailTrax, ZF’s electric trailer concept integrates its in-house developed 210 kW AxTrax 2 e-Axle, trailer EBS, and battery system box into a trailer. Leading trailer manufacturers, including Kässbohrer and Krone, have tested the system as well.

So why isn’t ZF bringing their entire package to North America? Simply because the markets are different and, given Range’s head start on this side of the Atlantic, the partnership is “a winwin,” Jason Paauwe, ZF North American lead for trailer sales, explained to Trailer-Body Builders.

“To get this solution into the hands of the fleets the quickest was in both our interests,” Paauwe said. “They really have a unique concept here for the North American market. And trucks and trailers were a little different here versus in Europe.”

Range’s eTrailer System is delivering projected savings of up to $20,000 per trailer per year in early tests, and up to 70% reduction in emissions, all while using existing equipment and infrastructure, the company said.

“Time is of the essence to get solutions into the hands of commercial fleet owners and operators to ensure smooth and consistent operations as their fleets evolve to address emissions reduction targets,” said Ali Javidan, Range CEO and founder. “With ZF, we aim to rapidly advance our platform with tried and tested components, further proving that electric-powered trailers can play a critical role in reducing the environmental impact of commercial trucking.”

AxTrax 2 is an axle-based, fully integrated system, featuring a compact design to help maximize the available space for batteries and enhance manufacturers’ design flexibility for future vehicle concepts, the company noted. It is designed to be fully synchronized with key vehicle functions, including braking, ADAS and automated driving systems to help enhance vehicle safety and efficiency. It also enables advanced digital and telematics systems via CAN

bus to communicate and share e-axle system information.

And it’s not unusual for global giant ZF to take on the role of a Tier Two supplier, Paauwe continued, pointing to the relationship the company has had with Hendrickson for the MAXX22T air disc brake as evidence.

Range and ZF began their discussion at ACT Expo in 2023, where ZF first showcased the AxTrax 2.

“Range was looking for a trusted partner, someone at the forefront of electrification, and a reliable supplier who could help usher in that trailer electrification technology,” Paauwe said. “We’ve definitely had some of those direct discus -

and emissions and the impacts on commercial vehicle electrification “will be interesting to see,” Paauwe noted.

“There is a real business case here. The most exciting is the opportunity to continue to use an ICE-engine truck or tractor to pull an e-trailer,” he said. “Again, this just helps the calculation— the stepping stone—for TCO make a little more sense in the short term for fleets and end users to still accomplish their sustainability and ESG goals.”

Initial customer deliveries of Range’s eTrailer System are expected to begin this year, and the company currently has pre-production units deployed in customer pilots across North America.

sions with OEMs before, but we were trying to decide on what makes the most realistic sense; who has all the pieces to pull this together? So we’re looking to accelerate Range’s relationships with the ecosystem partners, and this collaboration would be the way to go to get the solutions into the hands of the fleets and the end users the quickest.”

Range and ZF have identified several use cases where trailer electrification makes sense in North America as opposed to Europe, but Trump administration policy changes regarding EVs

“We want to get there first and be quick but, at the same time and since this is such a new endeavor for both companies, we want to make sure the service and support is there from the grassroots level,” Paauwe said. TBB

Editor’s note: Look for additional coverage of the Range platform in TBB’s reporting from the American Trucking Association Technoology and Maintenance Council’s 2025 Annual Meeting and Transportation Technology Exhibition on the web and in next month’s magazine.

In 1953 we invented the truck/trailer roll-up door and started an industry!

Tank trailer manufacturer adds attention-grabbing ‘glow heads’ to list of custom o erings

By Jason McDaniel

KENT, Ohio—Safety innovation is a guiding light for MAC LTT. e tank trailer manufacturer introduced its Total Area Lighting Kit (TALK) system more than 10 years ago. MAC LTT also was the first manufacturer to put a ring of lights around the back of a tanker, and, more recently, it rolled out fuel-saving molded aero skirts and life-saving side underride guards for tank trailers.

Now Jim Maiorana, MAC LTT president, is out to redefine highway visibility.

His company, which holds 35 patents—most of which are based on his designs—debuted its illuminated “glow heads” last year at National Tank Truck Carriers’ Tank Truck Week in Charlotte, North Carolina. The patentpending technology features a giant Lexan lens with hidden lighting that transforms the entire rear end of a MAC LTT trailer into an attention-grabbing stop/tail/turn light.

“For us, it’s all about safety—the safety of the driver, and for the tank going down the highway,” Maiorana said.

“When the tank is more visible, everyone is better off.”

MAC LTT’s glow-head tank was impossible to miss at Tank Truck Week, where Maiorana said reactions were overwhelmingly positive. The system’s turn signals light up half the rear end, the left side when turning left, and the right when turning right. The manufacturer also can embed logos behind the lens. “Essentially, we add an extension to the barrel to create a void behind

the Lexan lens, which also is used for draining the top vapor rails, and then there is a series of lights behind the lens that work together as a stop/turn/tail system reflected through the lens,” Maiorana explained.

The system went on sale last year. Only 12 glow head-equipped units were on the road as of January, but Maiorana is hoping to increase adoption going forward. MAC LTT now offers the glow head with its TALK system, which goes on 30% of the trailers the manufacturer sells, with plenty of repeat buyers, he added.

“The glow head is adaptable to numerous tanks,” Maiorana said. “We can put it on chemical tanks, milk tankers, and 406s.”

TALK safety technology includes a set of self-illuminated arms—each one features red LED light strips on the sides, white LEDs on the bottom, and an amber strobe on the end—that swing out to create a protected work zone; a fully illuminated interlock bar for safer hose connections; a lighted hose guard for barrel protection; and a ladder with lights that are embedded inside special extrusions for clearer climbing.

The system also is available with a unique electron-beam warning system.

“That’s what we’re all about—building custom trailers for end users that fit their needs and make their fleets stand out from the rest of the pack,” Maiorana said.

“That’s our specialty.” TBB

GRAPEVINE, Texas—

Heavy Duty A ermarket Week (HDAW), an annual gathering of heavy duty a ermarket professionals, concluded its 2025 event with “record-breaking success,” organizers report.

Over four days at the Gaylord Texan Resort & Convention Center in last

January, HDAW’25 brought together more than 2,900 executives and managers from various industry sectors, providing an array of opportunities for distributors, suppliers, service providers and thought leaders.

This year, the industry was proud to honor Dominic Grote, president and CEO of Grote Industries, as the 2025 Heavy Duty Aftermarket Hall of Fame inductee, Vander Haag’s Inc. as the Distributor of the Year and Toni Nastali,

The sold-out HDAW’25 show floor—with extended hours this year upon request— spanned 143,000+ square feet and hosted 330+ exhibitors.

owner of Spring-Align, as the inaugural Women in Leadership Award recipient. Themed “Brake New Ground,” HDAW’25 embraced the industry’s forward-thinking perspective in a rapidly advancing environment.

The sold-out show floor—with extended hours this year upon request— spanned 143,000+ sq. ft. and hosted 330+ exhibitors. This growth included 40 first-time exhibitors, showcasing the industry’s expansion and commitment to innovation.

“The continuing success of HDAW, marked by another year of record-breaking growth, showcases the commitment of these heavy duty aftermarket professionals,” Michael Keller, vice president of category management and sourcing at FleetPride and HDAW’25 distributor co-chair, said. “It’s exciting to see the innovation and collaboration displayed in the sessions, on the show floor and in the networking events at HDAW’25.” Programs and sessions HDAW’25 featured included the One-on-One Business Meetings program, hosting nearly 2,000 sessions with distributors and suppliers

over the course of the show. This popular program continues to expand each year and to foster an environment for distributors and suppliers to connect for deal-making opportunities.

“HDAW’s One-on-One Business Meetings program is a truly unique opportunity for heavy duty aftermarket professionals to come together and make connections and deals in real time,” Jean Gregoire, president of Marmon Heavy Duty Brakes Group and HDAW’25 supplier co-chair, said. “There’s no other place or time of year when so many of the industry’s best operators can collaborate to solidify meaningful partnerships and prepare for the full year ahead.”

Attendees actively participated in many of the diverse networking programs available:

• The Leaders of Tomorrow (LOT) program provided a platform for emerging professionals to connect and collaborate, fostering the industry’s next generation of leaders.

• The HDAWomen Reception created a dynamic space for professionals to support women in the heavy-duty aftermarket industry and build meaningful connections, share insights and discuss how to inspire confidence in younger generations.

• The Wednesday Night Heavy Hitter Reception at Globe Life Field, home of the Texas Rangers, brought together industry professionals in a celebratory atmosphere.

The education program also highlighted critical developments that continue to shape the industry as well as actionable steps to secure its overall health and viability. Attendees walked away with the most recent updates on topics including AI and its practical application, recruitment and retention.

The all-new Innovation Intersection offered resources to learn more about heavy duty training and certification. The newly-expanded Student Program welcomed its largest cohort yet with 27 students from 5 different universities.

Additionally, retired U.S. Air Force Colonel and fighter pilot Kim “KC” Campbell took the stage for a keynote

address, speaking about how adversity can either hold us back or drive us forward toward growth and transformation—if we learn to harness it

effectively. Planning for HDAW’26 is already underway, with the event scheduled to take place January 19-22, 2026, once again here in Grapevine.

Dominic Grote, president and CEO of Grote Industries, has been inducted into the prestigious Heavy Duty Aftermarket Hall of Fame. Grote also serves as chairman of the MEMA Aftermarket Suppliers board of directors, and a member of the executive committee of the MEMA board of directors. The honor was awarded during the opening ceremonies of HDAW’25. The Heavy Duty Aftermarket Hall of Fame recognizes exceptional leaders whose achievements and dedication have significantly advanced the heavy-duty aftermarket industry. Grote’s exemplary leadership and commitment to innovation at Grote Industries have left an indelible mark on the industry, earning him this distinguished accolade. “Dominic’s induction into the Hall of Fame is a well-earned recognition of his transformative contributions to the aftermarket,” said Bill Long, president and CEO of MEMA. “His visionary leadership, not only at Grote Industries but also as Chairman of the MEMA Aftermarket Suppliers Board of Directors, has propelled our industry forward. We are honored to celebrate this milestone with him.” As president and CEO of Grote Industries, a leading manufacturer of vehicle lighting and safety systems, Grote has driven growth and innovation while setting the standard for excellence in the heavy-duty sector, according to the award announcement. His leadership on the MEMA Aftermarket Suppliers Board of Directors underscores his dedication to fostering collaboration, advancing key industry priorities, and supporting the success of vehicle suppliers across the aftermarket community. MEMA congratulates Grote on this achievement and thanks him for his ongoing efforts to elevate the vehicle supplier industry. His induction into the Heavy Duty Aftermarket Hall of Fame is a testament to his enduring impact and exceptional legacy.

By Alex Keenan

At MEMA’s Heavy Duty Aftermarket Dialogue on Jan. 20, MacKay & Company’s chief economist, Dr. Robert F. Dieli, strolled on to the stage to Darth Vader’s signature anthem “The Imperial March” blaring over the Gaylord Texan auditorium speakers. It quickly became apparent why: the economy may still be pulling toward the dark side.

While experts have predicted a positive economic turnaround this year, Dieli’s models forecasted that the economy is in what the chief economist calls a “divot” and still “recession eligible.”

As he pointed to his chart, he said “every divot that the model has produced since 1970 has had one, if not two, recessions in it.”

Dieli based his analysis on two main metrics: Truckable Economic Activity (TEA) and the Enhanced Aggregate Spread (EAS).

TEA works as a report on the main economic segments that support the trucking industry, while EAS considers treasury note yields, the federal funds rate, inflation rate, and short-term unemployment.

“We have found that when TEA is tracking at 5% or better, what we hear from you or the rest of the trade press is that conditions are good,” Dieli noted in his presentation. “You’ll notice that we are below 5% and have been below 5% for quite a while.”

The factors that most impact TEA include U.S. consumption, investment, exports, imports, and government spending, with exports and imports growing in market share influence (up to almost 22%) in the last few years.

Meanwhile, the EAS, Dieli said, has functioned as a solid predictor for recessions, with every drop, or “divot,” in this report usually coming with 1-2

recessions since 1970, or as far back as MacKay has used this metric. And he said we are currently in a divot, thus making a recession possible.

By combining both TEA and EAS rates, this can provide a more holistic picture of where the trucking industry is headed going into 2025. But according to Dieli, the industry isn’t out of the woods yet.

Part of what’s putting the TEA in a questionable position for Dieli is how key segments of the indicator are underperforming, with the expectation that segments performing above 5% are doing well, and those beneath are not.

According to MacKay, only the government and import indicators are doing generally well, but those elements only comprise 18% of TEA overall. Why each sector is struggling or succeeding is based on various elements which Dieli summarized by sector:

• Consumption is struggling with a softening labor market, slow income growth and the effects of inflation on spending

• Investment is hurting from high interest rates, weak profit growth and regulatory uncertainty

• Government spending is expected to do better due to the Department of Government Efficiency, policies in Project 2025, the debt ceiling and state and local revenue growth

• Exports are fighting the high U.S. dollar, which is hurting our competitiveness in the export market, weak foreign demand and ocean shipping issues

• Imports could struggle due to potential tariffs and ocean shipping issues

Tariffs, in particular, were a large part of the economic conversation at HDAD, largely because how they are implemented can be varied and there’s no way to predict when and how they’ll go into effect. Yet if they’re implemented, Dieli was very frank about their impacts on the industry.

“It was already mentioned by several panelists earlier that they would feel no problem at passing the cost on to the consumer, this will show up on producer price index, but eventually the super pricing index,” he warned.

Other economic monitors

But Dieli didn’t just base his analysis on the TEA and EAS.

Additionally, he delved into other trucking industry monitors, such as truck transportation employment, fuel costs, truck transportation services, and Class 8 truck sales. For employment, Dieli noted that general employment has been decreasing roughly since 2022, with a particularly steep dip due to Yellow Freight going out of business.

“Going on almost three years, the employment situation has been flat,” Dieli explained. “And typically, when you’re not hiring, it’s because you’re not moving freight.”

Similarly, the U.S. decline in retail diesel prices reflects how the trucking industry hasn’t been moving as much freight, and thus buying less fuel. Similarly, he noted how truck transportation services and Class 8 retail sales have also been flat or declining.

“As you can see, those numbers represent the distance between the peak in sales and the next business cycle,” Dieli noted. “These elements have been forecasting the recessions that the model

HDAD’s presentations included insights into how the aftermarket can better support fleets. HDAD Jan 2025 | 2025 MacKay & Company

told us we were liable to have during that period.”

Finally, one of the largest indicatorsDieli considered was federal interest rates. It’s possible to gauge the advent of a recession based on when the Fed cuts interest rates, the economist suggested.

“We’re four months past the last cut,” he noted. “The average of those numbers

is seven months. I’m thinking that if we’re going to have a cycle, it’ll be in the first half of the year, there’s this cycle model that is going to prevail.”

Taking all of these factors into account, Dieli’s final conclusion for the trucking economy was a simple one, and one that the industry is used to: “2025 will be a challenging year.”

Comprised of E-Track, F-Fitting, and our revolutionary, patent-pending multi-purpose anchor point securement options, K-Track delivers unparalleled flexibility, enabling users to secure cargo more easily, quickly, and efficiently.

By Alex Keenan

At MEMA’s Heavy Duty Aftermarket Dialogue, fleet maintenance professionals who spoke during the event’s Fleet Perspective panel were not shy about sharing their top two pain points: finding both qualified technicians and quality replacement parts.

These included Nick Forte, VP of maintenance for Stevens Transport; Joe Phillips, VP of fleet maintenance and equipment for Eagle Transport; and Amanda Schuier, strategic maintenance director for Jetco Delivery and TMC General Chair.

The three fleet executives represented maintenance departments both small and large, with vehicles suited to

various industries, including general freight (Jetco Delivery), petroleum and chemical delivery (Eagle Transport), and temperature-controlled delivery

Cummins completed its acquistion of Meritor in 2022 and changed the business unit’s name to Cummins-Meritor. This summer Cummins-Meritor will become Cummins Drivetrain and Braking Systems. The Meritor and Euclid aftermarket brands will remain the same.

“We gave up simplicity for specificity, especially for the aftermarket,” explained Alan Rabadi, Cummins aftermarket leader in a statement to the media at Heavy Duty Aftermarket Week 2025.

“The reason we were insistent on having ‘braking’ in the name is so people knew we remain committed to the aftermarket braking and related componentry.”

Meritor was founded in 1997 and gained a solid footing in the industry for its brakes, axles, and countless other components. The aftermarket leader explained that part of the reason for the name change was to help make the 10,000 Meritor employees who have been there since truly feel a part of the rebranded company. “How do you feel a part of Cummins if [it] isn’t standing out in your name?” Rabadi asked.

The company also provided an update on their air disc brake production and distribution, which has reached 60% penetration in the market, according to Brittany Soika, director of product management. This will include expanding Cummins’ air disc brake

(Stevens Transport). Yet regardless of their size, purchasing plan, or fleet age, their concerns were largely the same. And the effects of not having

remanufacturing capacity and solutions alongside expanding their work with hydraulic brakes. However, Cummins will also continue to engage with the drum brake market as well, Soika added.

Finally, Cummins also unveiled their partnership with Nexus Automotive International in the form of an agreement on terms and principles to create a global framework for the company.

“What that really means is when we focus on global aftermarket revenue growth, we’re looking at expanding not just North America, but in Europe, Latin America, Asia Pacific, Middle East, Africa,” said Terry Livingston, global business development leader for Cummins. “We believe that the platform and the distribution model [Nexus] has will allow us to tap into that revenue growth.”

Alongside the name change, product announcements, and global partnership announcement, the company also made a $50,000 donation to the Wyakin Foundation. The donation was a result of Cummins’ 2024 Shoes for Soldiers program, which ran from November 12 through December 31, 2024, and involved Cummins donating a portion of new and remanufactured Meritor brake shoe sales to the foundation. The partnership between Cummins and Wyakin originated from the former Meritor Inc.’s work with the organization to support military veterans through various initiatives.

the personnel or parts to maintain their fleets ripple throughout their businesses.

For instance, Phillips noted that his company would not be participating in prebuy before MY 2027 vehicles because he worried that his technicians would not be ready to efficiently service the more advanced trucks in-house. And part of his fears came from a similar experience a few years ago when the industry first integrated selective catalytic reduction technology.

“The last time we did a prebuy, I felt like it really put us behind the eight ball as far as technology,” Phillips explained.

Of course, one way to mitigate this fear would be to ensure technicians had the proper industry training to help them prepare. But here, too, the maintenance executives at HDAD feel that they’re fighting an uphill battle to find qualified, well-educated technicians they can train. In particular, Forte said that he felt technicians from vocational

schools were coming into his shop unprepared for the work environment.

“They’re very book-driven and not hands-on, and whenever a technician comes in, you’ve gotta stick them in the shop and show them what a brake [system] is,” Forte stated. “They’ve done it on a computer or iPad, but they really have no hands-on experiences.”

And this kind of retraining can be difficult, Schuier said, because of their need for qualified help.

“My top two [challenges] probably are technician staffing and labor, and then the cost, and the continual [way that] I never feel like I’m getting a win for my boss,” she said.

Additionally, Forte said that while he wasn’t struggling with the same parts shortages as he did during COVID, that doesn’t mean fleets are out of the woods yet. Instead, what “keeps him up at night” was the need for parts that lasted.

“I can go out and buy all the parts I like… but I’m not getting the quality that I used to,” he said.

He said that this was true regardless of whether he was purchasing genuine parts or those from the aftermarket, particularly for parts such as disc brakes, calipers, batteries, radar, harnesses and connection packs. Philips concurred, adding that finding quality air dryers, air system components and anything with electronics was difficult.

“It doesn’t matter if it’s genuine or aftermarket,” Forte explained. “It comes back to the point of who’s building the market.”

And worse, when delays did happen for parts or there were quality issues, the fleets all stated that their interactions with suppliers and distributors to handle the issue were often soured by poor communication.

“If you let us down, just tell us,” Schuier emphasized. “We’re gonna find out [eventually]. We need to know so we can block and tackle.”

By Jeremy Wolfe

Historic tariffs and major trade agreements are poised to disrupt commercial vehicle manufacturing in the U.S.

Ana Meuwissen, SVP of government affairs for the Motor & Equipment Manufacturers Association, outlined the rising key issues and officials at MEMA’s Heavy-Duty Aftermarket Dialogue conference. The topmost issues that Meuwissen outlined were trade and tariffs, as Trump’s possible tariff scenarios and their effects are a major concern for MEMA’s membership.

“This is the number one issue that we in the MEMA Government Affairs Office have been hearing about from member companies across the whole span of the industry,” Meuwissen said.

The latest trade agreement between North American countries also faces major revisions in mid-2026, and MEMA is hard at work in facilitating negotiations with industry stakeholders.

Congress is the nation’s main tariff authority, but the president has some power to enact tariffs. The exact limits of the president’s tariff authority are unclear, but Trump nevertheless has

of 1930; Section 338 of the Tariff Act of 1930; and the International Emergency Economic Power Act of 1977, to name a few. Some of the tariff statutes require fixed maximum severities, such as a 15% limit or 150-day duration.

“Trump actually threatened to impose tariffs on Mexico in 2019 under IEEPA,” Meuwissen said. “But this threat was subsequently removed after bilateral negotiations between the two countries.”

Trump’s treasury secretary, Scott Bessent, shared his attitude toward tariffs during his Senate hearing. When testifying before the Senate, Bessent outlined tariffs as a methodology for three potential outcomes:

• A means to fix unfair trade practices,

• A revenue raiser for the United States, and

• As a negotiating tactic for other non-tariff issues

“I think that gives us some insight into the thinking of the president’s senior advisors coming in,” Meuwissen said.

The United States-Mexico-Canada Agreement is another of MEMA’s top priorities. The trade deal has major influ-

Honestly, we don’t know how the reviews can be managed. We’ve never done one like this before; there’s no prototype for this type of review.

Ana Meuwissen, SVP of government affairs, MEMA

been vocal in his desire to impose historic tariffs on U.S. trade partners, with a number of key initiatives announced, paused, and modified in the weeks after this presentation in late January.

The president’s tariff authority could come from several laws: Section 232 of the Trade Expansion Act of 1962; Section 122, 201, and 301 of the Trade Act of 1974; Section 338 of the Tariff Act

States,” Meuwissen said. “We basically had a complete rewrite of our chapter of the agreement, with brand-new rules and requirements being put in that impact the sector every day.”

The agreement entered force on July 2020 and has a 16-year timeline. Different vehicle classes covered by the agreement have multi-year phase-in periods. Passenger car and light-duty vehicles had a three-year phase-in period, which ended in 2023. The phase-in period for commercial vehicles is seven years and concludes in 2027.

Another change for the agreement is a review mechanism. Review for USMCA is scheduled for July 2026, where the three countries will discuss how the agreement is working and make changes. But the U.S. has never experienced a trade agreement review process like this, so the outcome of the review is uncertain.

“Honestly, we don’t know how the reviews can be managed,” Meuwissen said. “We’ve never done one like this before; there’s no prototype for this type of review.”

ence on the U.S. economy broadly and the automotive industry specifically.

USMCA is a renegotiation of the North American Free Trade Agreement under Trump’s first term. The renegotiation brought significant changes for the automotive and commercial vehicle sectors.

“This is the most stringent automotive and commercial vehicle agreement that we have on the books in the United

Some terms that the countries might renegotiate include restricting Chinese investment in Mexico, stricter regional value content requirements, and increased duty rates to compel compliance.

MEMA has a USMCA working group, started in 2024, and is meeting with officials to facilitate negotiations.

“We want to make sure that there are not dramatic additional changes to the agreement while the industry is still working through that phase-in period,” Meuwissen said.

The Heavy Duty Manufacturers Representatives Council of MEMA Aftermarket Suppliers announced its new chair and welcomed two new members to its executive committee. Mike Mowchan, president of ShermanPearson Company, will serve as the 2025 council chair, and Ryan Eichhorn, principal at NorthPro Representatives, and Ryan Stronk, president of Western States Marketing, joined the executive committee.

“We are thrilled to welcome Mike Mowchan as the new chair of the Heavy Duty Manufacturers Representatives Council and to have Ryan Eichhorn and Ryan Stronk join the executive committee,” said Danielle Kaspar, HDMRC lead. “Mike’s leadership and deep industry knowledge, combined with the fresh perspectives and expertise that

Ryan and Ryan bring, will support the council’s mission to be a forum for discussing issues and trends and sharing best practices among industry peers.”

The full HDMRC executive committee is comprised of:

• Chair: Mike Mowchan, president, ShermanPearson Company

• Past Chair: Stephen Joyce, president, Joyce Sales LLC

• Ex Officio: John Adami, principal, Northwest Heavy Duty, Inc.

• Adam Crisp, division president, Grant Brothers Sales

• Ryan Eichhorn, principal, NorthPro Representatives

• Wayne McKitrick, senior vice president, NA Williams – Commercial Vehicle Division

• Will Nees, Sales Representative, Cree and Cree, Inc.

• Ryan Stronk, President, Western States Marketing

The Heavy Duty Manufacturers Representatives Council is part of the executive councils and forums offered by MEMA Aftermarket Suppliers. It lets participants discuss shared issues in the industry. Members participate to stay up to date on issues and trends and to better themselves as representatives in the markets they serve.

MEMA Aftermarket Suppliers announced three new board members to its 2025 advisory board:

• Cal Ganda, aftermarket lead, Continental ContiTech

• John Hanighen, president & CEO, Cloyes

• Emily Poladian, president, Bridgestone Mobility Solutions

The MEMA Aftermarket Suppliers advisory board reflects the supplier industry and its various tiers.

“We are thrilled to welcome Cal Ganda, John Hanighen and Emily Poladian to the MEMA Aftermarket Suppliers advisory board,” said Dominic Grote, president & CEO of Grote Industries and Chairman of the MEMA Aftermarket Suppliers advisory board. “The diverse perspectives they bring from

their respective organizations will strengthen our ability to set strategic priorities that support the success of aftermarket suppliers.”

Board members who have reached their term limits and will exit the board are Rob Phillips, president and CEO, Phillips Industries, and Scott Miller, vice president of remanufacturing, LKQ Corporation.

“I welcome Cal Ganda, John Hanighen, and Emily Poladian to the board, where

their leadership and deep industry expertise will be invaluable as we work to address the challenges and opportunities facing our members and the aftermarket industry at large,” said Paul McCarthy, president of MEMA Aftermarket Suppliers.

2025 MEMA Aftermarket Suppliers advisory board officers include:

• Chairman: Dominic Grote, president and CEO, Grote Industries

• 1st Vice Chairman: Eric Steinbecher, president, Automotive Aftermarket – Americas, Schaeffler Group USA

• 2nd Vice Chairman: Kevin Olsen, president and CEO, Dorman Products Inc.

• Immediate Past Chairman: Eric Sills, president and CEO, Standard Motor Products Inc. TBB

By Alex Keenan

The Automotive Service Association, Society of Collision Repair Specialists, and the Alliance for Automotive Innovation proposed the Safety as First Emphasis (SAFE) Repair Act to congressional leaders on Feb. 18 as an alternative to the Right to Equitable and Professional Auto Industry Repair (REPAIR) Act. But other organizations with commercial vehicle aftermarket ties suggest ‘not so fast.’

In a letter to Congress, the three organizations argued that the REPAIR Act was not suitable for four key reasons:

• Because automotive right-to-repair is already established in the U.S.

• Because automakers already provide information, tools, and data for diagnosing and repairing vehicles to independent shops, and that the associations work with the industry to get answers to technical issues

• That the REPAIR Act does not provide enough protection for consumer choice in making sure that repair data is used to fix vehicle safety systems and structures

• And that there is a 2014 national memorandum of understanding for automakers, aftermarket distributors, and manufacturer associations that guarantees access to repair and diagnostic information for repair shops

“While these existing frameworks have created a thriving and competitive repair marketplace, we understand the desire for a federal legislative solution that addresses evolving consumer expectations and technological advancements,” the letter to Congress stated. “That’s why our three organizations have come together to propose a new path forward—one that builds on existing protections while introducing additional measures to prioritize consumer safety and choice.”

According to the associations, the SAFE Repair Act addresses these issues by preserving data access parity between shops and dealers and grants consumers more protection. More specifically, the proposed act affirms that:

• Independents have the same ability to perform diagnostic and repair services as dealers

• Consumers have the right to decide where and how they want vehicles repaired

• Consumers can have their vehicle repaired in accordance with OEM procedures to restore vehicle safety systems and structure

• Consumers are provided with a choice of parts between OEM and non-OEM parts for repairs

• Consumers who choose non-OEM parts have the same recall and safety protections as those who choose OEM parts

• Consumers who purchase used vehicles are made aware of prior alterations or repairs

• There will be safety inspection and post-collision inspection programs to ensure repairs are properly completed

In response to the letter, the Auto Care Association President and CEO Bill Hanvey and MEMA Aftermarket Suppliers President Paul McCarthy said the views in the proposal represent “a small fraction of the repair market.” The two men also stated that while they appreciated the associations’ agreement that federal legislation is needed to protect consumer choice in vehicle repair, they found the new proposal to be more of a hindrance than a help.

“That said, this latest proposal appears to be a tactic to delay and defeat pro-consumer right to repair legislation at every level,” McCarthy and Hanvey said in a release. “The bipartisan Right to Equitable and Professional Auto Industry Repair Act (REPAIR Act) is a straightforward approach to ensure safe and secure access to vehicle repair and maintenance data.”

The REPAIR Act was not considered for a vote in the previous Congress.

Historically, the independent aftermarket has performed over 80% of out-of-warranty vehicle repairs (Source: Auto Care Association/MEMA Aftermarket Suppliers Joint Forecast Model) and these repairs are generally 36% less expensive than dealerships. Car owners appreciate independent repair shops for their “trustworthiness, reasonable prices, knowledgeable mechanics, and good reputation.” Today, independent repair shops and alternative manufacturers are increasingly being crowded out as OEMs collect terabytes of data from vehicles wirelessly and unilaterally decide to whom they give access to this data and under what terms and conditions, all without input from vehicle owners, according to comments filed by AAI in a regulatory rulemaking. An independent survey conducted last year demonstrated that 63% of repair shops report having difficulties making routine repairs on a daily or weekly basis due to data restrictions, ACA reported. Moreover, 51% of shops report sending up to five cars per month to the dealer because of these restrictions. On Feb. 11, U.S. District Court Judge Denise Casper dismissed AAI’s four-year effort to block the implementation of Massachusetts’ right to repair law. TBB

By Jeremy Wolfe

Wabash has acquired TrailerHawk.ai, a cargo security and access management startup, to integrate into its Trailers-asa-Service offering.

Hawkeye’s solutions aimed to provide secure, transparent, and efficient freight movement. The company offered smart asset access management with verified asset chain of custody. Brett Suma, TrailerHawk’s founder and CEO, will join Wabash to develop the company’s solutions further, according to the OEM.

“His tech will now help improve the way we acquire [trailers], do those damage audits, create those cases, and supercharge our on-demand capacity offering,” Cory O’Brien, Wabash’s VP of digital enablement, said during Wabash’s acquisition announcement webinar. “We’re going to continue to develop these platforms and merge them together to create an enhanced offering that addresses the cargo security element.”

Inspiration from scooter sharing Suma founded TrailerHawk around April 2024. The idea of TrailerHawk came when Suma first tried using Lime scooters with his son. Lime’s shared electric mobility platform includes inspection and verification processes to monitor asset damage and location.

“It essentially requires you to do an inspection to make sure that the scooter is in working order,” Suma said. “You know the health of it because it tells you the battery percentage, and it unlocks itself for you when you’re in communication with it. Then you can use the scooter, and it’s geofenced to disallow you to go to certain locations. When you’re done with it, you do your disposition inspection, you take a picture, you leave it, and [Lime] charges you.”

The robust system helps Lime operate a profitable business loaning equipment that only costs around $1,000. The same idea could translate to trailers—a much more valuable asset.

“I thought, ‘This technology doesn’t exist in a trailer that costs upwards of $40,000 that can have hundreds of thousands of dollars of cargo in it,’” Suma said.

Cargo theft is a significant and growing industry issue. A commonly cited statistic from the FBI suggests that cargo theft costs $15 billion to $30 billion annually— that statistic originated in 2006 and is likely now much higher.

Wabash said the acquisition will strengthen its TaaS by enhancing its customers’ freight security, visibility, and operational efficiency. The company’s TaaS provides a nationwide trailer subscription model with maintenance support and data

insights, allowing customers access to trailers on demand without the usual significant capital investment.

“We’re really proud of our legacy of manufacturing, but we realized going forward that, if we’re going to seamlessly serve our customers in this space, we’re going to have to get good at merging physical and digital technologies,” Mike Pettit, chief growth officer at Wabash, said.

With on-demand trailer offerings, Wabash also needed a technology that would allow them to efficiently and securely control the acquisition/disposition processes: trailer access, inspection technology, damage attribution, and more.

investment.

Jeremy Wolfe | Trailer|Body Builders

As part of the acquisition, Suma will join Wabash Marketplace to lead the ongoing development and scaling of the TaaS and TrailerHawk.ai solutions.

Suma previously served as CEO of Loadsmith, a 3PL startup focused on autonomous trucks acquired by FreightVana in December. Wabash’s TaaS was vocally supported by Suma in 2024 as a tool for Loadsmith.

“Having experienced Wabash’s TaaS platform as a customer, I’ve seen its ability to transform logistics operations,” Suma said. “By helping logistics providers streamline operations and protect assets, we’re creating solutions that deliver immediate and long-term benefits.” TBB

Hyva has launched their Beta Rear Loader, which is available in 11, 13, and 16-yard configurations for the U.S. and Canadian markets.

Hyva USA, celebrating their 20th anniversary in the U.S., continues to be a key supplier to both major chassis OEMs and body manufacturers.

“We’re very excited to launch the Beta Rear Loader as it delivers a level of performance and value that fleet owners are looking for,” said Chris Zuniga, Hyva’s head of sales for its North American recycling business. “With our acquisition of

Usimeca in 2021, we absorbed over 50 years of experience in the design of rear loaders that continue to perform in some of the toughest environments on the planet. That DNA melded very well with our European engineering processes to create the Beta.”

The Hyva Beta represents a quality-built solution to address the continued issue of finding and retaining CDL drivers in the waste collection market segment, according to the manufacturer. The 11-yard Beta can be mounted on a non-CDL chassis, and its lower weight does not require FET.

By Jenna Hume

Workhorse Group has announced that NorthStar Courier, a FedEx Ground contract service provider based in Minneapolis, Minnesota, will become the first customer to operate their new W56 208” extended wheelbase EV step van. This addition complements the company’s existing W56 178” wheelbase truck, expanding its zero-emission delivery capabilities for the industry.

The W56 extended wheelbase version offers nearly 1,200 cu.-ft. of cargo capacity. Real-world results demonstrate the work-ready performance of the W56, proving the vehicle’s ability to tackle the toughest delivery and service routes.

NorthStar Courier’s purchase is supported by Minnesota state grants. Minnesota continues to make strides

in commercial EV adoption, and these grants, offered by the Minnesota Pollution Control Agency, provide funding for medium-duty commercial trucks, including the W56, to replace older fossil fuel-powered vehicles with all-electric models.

“We are thrilled that NorthStar Courier has chosen to expand its fleet by adding a W56 extended wheelbase EV step van,” Kelly Kiger, vice president of sales at Workhorse,said. “NorthStar Courier’s continued trust in our vehicles and in Ziegler as its dealer underscores the reliability and efficiency of the W56 and the excellent service and support network that we offer through dealers like Ziegler. We are proud to support NorthStar Courier’s efforts in electrification and help it achieve lower

Additionally, the Beta features a flatfloor design, a heavy-duty floor-mounted ejector cylinder, a large 2-yard hopper, and a tailgate that can accommodate a bin lifter, winch, and container kick bar.

The 8- and 10-yard low-profile bodies for the cab-over market would be available soon, Zuniga added. Parts will be distributed from Hyva’s Chicago-area warehouse through its network of dealers throughout the country. Local dealers will also provide service backed up by trained factory technicians.

Zuniga, an industry veteran, is leading the sales effort as well as working to establish more dealers throughout the country.