Wide range of SnowDogg® plows for trucks 1/2-ton and up

ALUMINUM ROLLBACK TRUCK TOOL BOX SERIES

DURABLE, LIGHTWEIGHT, ACCESSIBLE STORAGE FOR YOUR WORK TRUCK

Diamond tread aluminum construction with Gloss White, Gloss Black, and Matte Black finishes. Fleet models also available for boxes keyed alike.

INCREASED STORAGE FOR ROLLBACK WRECKERS

Keep chains, straps, and other gear protected from the elements. The bottomless box design uses perforated bed wells to prevent moisture buildup, while push-button locks on both sides enhance security.

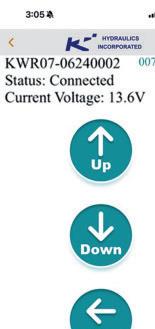

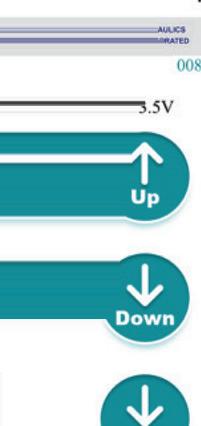

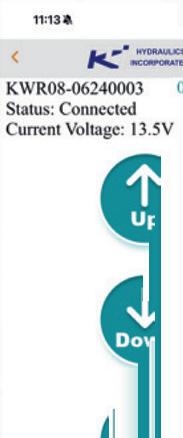

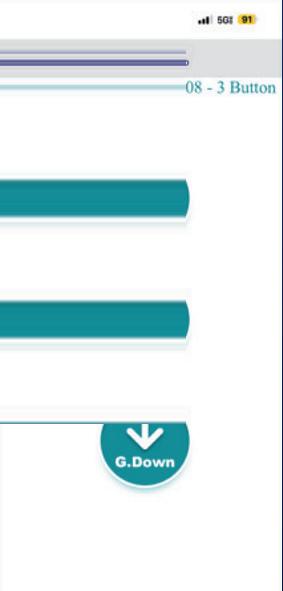

WITH IN-CAB MULTIPLEX CONTROLLER

Combines the power and reliability of SaltDogg PRO Series Spreaders with the advantages of modern CAN bus architecture.

SnowDogg® Illuminator ™ LP

Low Profile LED Plow Lights Part No. 16160900

LEARN MORE about the NEW SnowDogg® MXII

18 EV work trucks: Pros and cons Chevy Silverado EVs lead the charge for McKinstry eet electri cation program

20 Sand between your treads Ford F-250 Super Duty: A work truck that performs like a Tremor? 24 2025 Ram HD lineup makes it easy to tow the line in a work truck

Isuzu invests in $280 million S. Carolina facility

28 Betting on Beloit, USA Red, white, & blue grand opening for STE manufacturing facility

Truck Builders upgrades Houston specialty vehicle maker spotlights new space

Market Leader

Commercial Vehicle Group – Dyanna Hurley dhurley@endeavorb2b.com

Editorial Director – Kevin Jones kjones@endeavorb2b.com

Senior Editor – Jason McDaniel jmcdaniel@endeavorb2b.com

Associate Editor – Alex Keenan akeenan@endeavorb2b.com

Marketing/Advertising – Dan Elm delm@endeavorb2b.com

Art Director – Jennifer Dakas jdakas@endeavorb2b.com

Directories/Listings – Maria Singletary msingletary@endeavorb2b.com

Audience Development Manager – Laura Moulton lmoulton@endeavorb2b.com

Endeavor Business Media, LLC

CEO Chris Ferrell

COO Patrick Rains

CDO Jacquie Niemiec

CALO Tracy Kane

CMO Amanda Landsaw

EVP Transportation Group Chris Messer

VP of Content Strategy, Transportation Group Josh Fisher

TRAILER|BODY BUILDERS (USPS Permit 636660, ISSN 0041-0772 print, ISSN 2771-7542 online) Volume 67 Issue 1, is published monthly by Endeavor Business Media, LLC. 201 N Main St 5th Floor, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI, and additional mailing offices. POSTMASTER: Send address changes to Trailer/ Body Builders, PO Box 3257, Northbrook, IL 60065-3257. SUBSCRIPTIONS: Publisher reserves the right to reject nonqualified subscriptions. Subscription prices: U.S. ($79 per year); Canada/Mexico ($79 per year); All other countries ($157 per year). All subscriptions are payable in U.S. funds. Send subscription inquiries to Trailer/Body Builders, PO Box 3257, Northbrook, IL 60065-3257. Customer service can be reached toll-free at 877-382-9187 or at trailerbodybuilders@ omeda.com for magazine subscription assistance or questions. Printed in the USA. Copyright 2025 Endeavor Business Media, LLC. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopies, recordings, or any information storage or retrieval system without permission from the publisher. Endeavor Business Media, LLC does not assume and hereby disclaims any liability to any person or company for any loss or damage caused by errors or omissions in the material herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. The views and opinions in the articles herein are not to be taken as official expressions of the publishers, unless so stated. The publishers do not warrant either expressly or by implication, the factual accuracy of the articles herein, nor do they so warrant any views or opinions by the authors of said articles.

Visit Trailer-BodyBuilders.com for more information from stories in this issue, plus online exclusives on pertinent topics in the trailer manufacturing industry.

up

Stay up-to-date on industry news and events, new products launches, and more.

Trailer-BodyBuilders.com/subscribe

Upfitting for the winter season

Tips for getting gear ready for snow and ice Trailer-BodyBuilders.com/55322104

DTNA combines bus, chassis units

New division creates a ‘unified platform’ Trailer-BodyBuilders.com/55319718

Trailer orders climb, still lag long-term trend: Reports Trailer-BodyBuilders.com/ 55326909

Aurora Parts introduces consolidated billing program Trailer-BodyBuilders.com/ 55325945

Corporate Office: Endeavor Business Media, LLC, 30 Burton Hills Blvd, Ste. 185, Nashville, TN 37215 USA; 800-547-7377 Read the digital edition online at

In a regulatory pushback that should sound familiar to U.S. manufacturers, eight leading European truck-trailer builders have filed an appeal to the European Court of Justice against key provisions of Regulation (EU) 2024/1610. The regulation introduces binding CO2 reduction targets also for trailers—even though trailers themselves do not emit any CO2

The plaintiff companies (Fliegl Trailer, Kögel Trailer, Krone Trailer, Langendorf, Schmitz Cargobull, Schwarzmüller, System Trailers, and Wecon) account for more than 80% of annual trailer registrations in Germany and more than 70% across Europe.

While the companies noted that they fully support the EU’s climate goals, they warn against the consequences of a regulation detached from practical realities: Instead of reducing emissions, the regulation could lead to increased traffic volumes and overall emissions.

The group of eight companies had already filed an action for annulment before the General Court of the European Union, which dismissed the case on the grounds that there was “no individual concern.”

Since July 1st, 2024, the regulation mandates a 10% CO2 reduction for semi-trailers and 7.5% for other trailers—based on simulations using the EU’s own VECTO-Trailer tool, which forms the core of the Regulation. Failure to meet the targets may result in substantial annual penalties from 2030 onward: €4,250 per vehicle and per gram of CO2 emissions per ton-kilometer. Estimates suggest that these penalties alone could increase trailer prices by up to 40%, rendering them economically unviable for many manufacturers.

“A tool that simulates CO2 savings while in reality more trucks are on the road contradicts the climate goals. We need actual efficiency gains across the entire system, not simulated pseudo-solutions,” said Gero Schulze Isfort, spokesperson for the group. “In its current form, the regulation jeopardizes not only climate targets but also production sites, fair competition, and more than 70,000 jobs. We therefore see no alternative but to seek legal recourse.”

The eight plaintiffs are predominantly medium-sized enterprises. Unlike large corporations, they do not have unlimited financial or technological resources to cushion regulatory burdens in the short term, the group suggested. For them, the regulation poses an acute threat to their economic viability—with implications for thousands of jobs in the manufacturing and supplier industries.

The manufacturers particularly criticize the use of the VECTO-Trailer model. It positively rates theoretical

improvements to trailers—such as reduced height or lower weight—without considering real-world transport implications. In practice, these measures reduce loading volume, lead to more empty runs and increased traffic, ultimately resulting in higher CO2 emissions.

The manufacturers emphasize that modern trailers already contribute significantly to efficiency gains through lightweight construction, aerodynamics, reduced rolling resistance, and the use of steerable, lift, and e-axles. Instead of acknowledging real-world advances, the regulation focuses on isolated theoretical parameters that contradict practical logistics.

“Climate protection requires holistic thinking: Only if the entire transport chain becomes more efficient can we achieve genuine CO2 savings,” said Schulze Isfort.

To achieve these savings and avoid economic harm, the manufacturers call for:

• The abolition of the VECTO-Trailer simulation tool.

• A moratorium on penalties as long as the targets are technically unachievable.

• The crediting of zero-emission tractors in trailer CO2 targets (ZE Vehicle Correction Factor).

The companies remain committed to the Paris Climate Agreement and are convinced that climate protection can only be truly efficient if it is economically viable and technically feasible, according to the group’s statement.

The German Association of the Automotive Industry (VDA) shares the concerns regarding fleetwide unachievable CO2 targets. It also sees the majority of trailer manufacturers in Germany and Europe as threatened if Regulation (EU) 2014/1610 is implemented as it is, putting over 70,000 jobs at risk.

Designed for durability and uptime, East Aluminum Truck Dump Bodies are built for one purpose—to keep you working longer, hauling more and maximizing profit.

The Genesis® design features interlocking box-wall construction for unmatched strength, reducing deflection and cracking. Robotic vertical welds boost structural integrity and resist bowing and corrosion, while a double shoe hinge design adds dumping stability.

Whether you need a specific axle configuration or a custom body length, East builds to your exact specs. From light hauling to the most demanding truck applications, East aluminum dump bodies are built to outperform—and outlast—the competition.

Work Truck Solutions has completed the initial phase of a program aimed at making the commercial vehicle bailment pool process more efficient and transparent for the entire supply chain, the company recently reported.

The Bailment Pool Pilot involved one major OEM, three leading upfitters and a select group of dealerships, with the goal of improving visibility, transparency, and days-to-turn for commercial inventory.

OEMs utilize bailment pools to provide upfitters with access to their inventory of chassis and vans by flooring them at the upfitters’ locations to be ready to be modified.

Using the bailment pool approach, OEMs retain ownership of the vehicles, and upfitters may pay flooring fees to have the inventory immediately available for upfit orders. Once a dealership places the order for a specific vehicle configuration, the OEM reassigns ownership of that vehicle to the dealership, who then has an understood timeline to sell the vehicle before having to purchase it themselves.

Historically, there has been a lack of transparency into the availability, configuration, and status of OEM bailment pool vehicles available from upfitters at any given time.

• OEMs know what chassis have been assigned to which upfitters, but they do not have insight into what bodies or modifications will be or have been made to the chassis. OEMs do not have a means to track that information, nor the details of the final sale of the chassis.

• Upfitters typically share their inventory information with prospective dealership buyers via weekly spreadsheets, but this data quickly becomes outdated as vehicles are reassigned to another dealership who has ordered them from that pool.

• Dealerships do not have an efficient way to search upfitter pool inventory or view the status of their orders. This lack of transparency means they cannot market the inventory until they have the finished vehicles on their lot.

Due to the current nature of the process, it is possible for the entire transaction, from an OEM assigning a chassis to an upfitter to the finished commercial vehicle being sold to an end buyer, to take up to 12 months.

This lack of visibility into the bailment pool inventory was a key challenge that the Work Truck Solutions pilot was designed to address.

By providing all parties—dealers, upfitters and OEMs— access to current information about available pool inventory and orders in progress, the overall vehicle ordering and completion process can be streamlined.

This detailed information, built on the foundation of the VAST (Vehicle Acquisition Search Tool) network, reduces time from initial assignment to final sale.

“As a result of the pilot stage of the program, we’ve been able to identify key areas where we can enhance the commercial vehicle upfit and ordering process for our dealership partners, which will also provide value to both OEMs and upfitters” said Kathryn Schifferle, founder and chief vision officer at Work Truck Solutions. “By providing commercial vehicle dealers with better visibility of and access to pool inventory, we help reduce the overall days it takes to turn cab chassis and vans into the finished vehicle, which improves the overall customer experience.”

By integrating and standardizing data feeds from upfitters, dealerships are able to order and display on-order vehicles on their websites, which in turn enables customers to shop for and acquire vehicles while in production—expediting the overall process, noted Work Truck Solutions.

“As a leading truck body manufacturer and full service upfitter with 26 locations, we have been focused on building innovative trucks with an emphasis on safety and reliability for over 65 years,” Reading Truck Vice President of Sales and Business Development Eric McNally said. “We have always been dedicated to finding ways to better serve our dealership partners, so we were excited to participate in this bailment pool pilot to explore how to deliver more value in the overall process. Although still early, we have received excellent feedback from our dealer partners with several successfully selling trucks that were still in our shops being upfitted.”

The insights from the initial phase confirmed the value in expanding the program, and Work Truck Solutions will bring these benefits to a wider network of upfitters and dealerships, added Schifferle.

“We have the green light from all three domestic commercial OEMs to work with their pool holders and have started the outreach with specifics on how to leverage this new technology for their benefit,” she said. “We’re excited to continue working with our partners to drive innovation and efficiency throughout the commercial vehicle supply chain.”

Fleets and shops already know that having a strong digital system to track repairs and communicate between teams is a good way to increase overall fleet uptime.

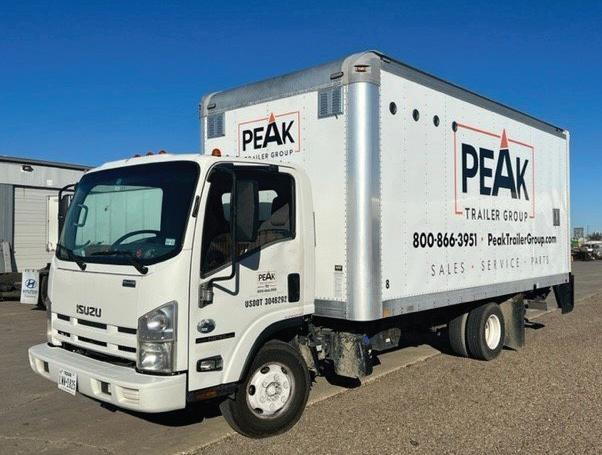

As an example, Peak Trailer Group has been using Decisiv SRM since May 2024 to handle an average of 300 repair orders per month, in the process reducing the time technicians spent waiting on parts by 6.5 hours on average. Additionally, since adopting the platform, the company has increased their shop efficiency compared to their expected repair time percentage from the low 70s to 95%, growing their gross profit margin to 70% per repair order.

“Higher average efficiency with Decisiv SRM is significant because it makes us far more profitable,” said Doug Fox, GM, Peak Trailer Group. “Now, our gross margin is considered best in class. From a process improvement standpoint as well, we have a lot more capacity so we can do more work with our existing staff.”

Peak Trailer Group is a multi-line Wabash dealer with two

shops, one in Dallas and one in San Antonio, Texas. While both locations handle service and repairs and feature wash and paint bays, there is some differentiation between the two locations. The Dallas facility typically focuses on repairs, body fabrication, and outfitting, while the San Antonio one leans into body work as well as routine maintenance and repairs.

Meanwhile, Decisiv SRM offers connected service management, proactive maintenance management, and asset service history, all of which Peak leveraged to increase their shop’s efficiency. More specifically, Peak used the platform to track and schedule PMs, communicate during service, and manage service and repair data through the Decisiv SRM Vision management dashboard.

“Even with two locations providing a different mix of services, the Decisiv SRM platform has been easy to implement and simple to use,” Fox commented. “In both of our shops, from the point when a trailer gets checked in until we’re ready to close out that ticket, we use Decisiv throughout the entire process.”

How Peak used Decisiv’s features Peak has found Decisiv SRM’s features to be helpful for the parts department, shop foremen, and senior management:

• The parts department uses Decisiv SRM to manage inventory, view how many trailers are waiting on parts, and make sure technicians aren’t waiting on repair parts

• Service advisors use the platform to see the number of estimates waiting for customer approval

• Shop foremen use Decisiv SRM to assign techs to jobs, while senior management can verify that the best person is assigned to each job based on their skillset

These features allowed Peak service advisors to create jobs and send parts requests and notes to foremen, who in turn could pass this information to technicians once they were assigned a particular job.

Plus, service advisors could send estimates and case details to customers for approval via email.

“All of the capabilities that Decisiv SRM enables make the customer experience much better,” Fox explained. “One of the biggest pain points they had was that it took too long to get a trailer out of the shop, and now we’re hearing that they can’t believe how fast that’s happening.”

Cummins has launched its Power to Build Community forum, which is designed to give vocational body builders access to expertise and assistance while integrating Cummins engines, hardware, and software on vehicles. The effort is being led by Obed Ruiz, GM of Vocational Business, and Reg Witt, technical support manager for North America, Cummins.

“We have partnered with our OEMs and are attending their seminars to guide as many people and companies as possible through the changes,” Ruiz said. “The Power to Build Community makes it possible to engage even more on a broad scale. Input through this resource can help fill any gaps while empowering

self-sufficiency among truck vehicle upfitters seeking the information they need.”

The forum allows bodybuilders to ask questions and provide feedback to Cummins experts, as well as access product specs, performance insights, and integration support. It is open to all truck vehicle upfitters, but Witt noted that smaller companies are likely to benefit the most from the accessible information.

“Some of the bigger bodybuilders are capable of keeping up with the technology,” Witt said. “It’s some of the smaller truck vehicle upfitters that have challenges trying to keep up with the technology such as multiplexing and Torque/Speed Control (TSC1).”

Because standards don’t raise themselves, NTEA’s Member Verification Program (MVP) acknowledges the companies leading the industry to excellence. Fleet managers, truck dealers and OEMs know truck equipment manufacturers and distributors/upfitters with MVP status have successfully demonstrated an understanding of defined business principles and applicable government regulations.

New MVP members (since July 1, 2025)

• Allied Mobile Systems (Dunn, North Carolina)

• Knapheide Truck Equipment Center Denver (Longmont, Colorado)

• Auto Xtras Inc. (San Antonio, Texas)

• Cadet Mfg Inc. (Chouteau, Oklahoma)

• Champion Hoist & Equipment (Dunn, North Carolina)

• Knapheide Truck Equipment Center Birmingham (Birmingham, Alabama)

• Knapheide Truck Equipment Center Houston (Willis, Texas)

• Mike’s Truck Service & Sales Inc. (Gibsonia, Pennsylvania)

Current NTEA Distributor and Manufacturer members are encouraged to apply for MVP status at any time. There is no charge — NTEA underwrites the cost of MVP as part of an ongoing effort to enhance the core competencies of its members. Once qualified, companies receive MVP status for a three-year term. To renew, MVP members must again document compliance, ensuring their ongoing commitment to professionalism, industry knowledge and high performance.

Visit ntea.com/mvp to learn more and apply.

Registration and housing are now open for Work Truck Week 2026, which will be held March 10–13, 2026, at the Indiana Convention Center in Indianapolis.

Work Truck Week encompasses The Work Truck Show, Green Truck Summit, NTEA Annual Meeting, Work Truck Week Ride & Drive, educational program and more. Green Truck Summit is March 10, educational sessions run March 10–12, and Work Truck Show exhibits are open March 11–13. Work Truck Week is produced by NTEA – The Work Truck Association.

Equal parts industry gathering, product launchpad, information exchange, and business builder, Work Truck Week delivers opportunities to connect, explore and discover across the commercial vehicle market.

“Over the last 25 years, the industry has taken ownership of Work Truck Week and shaped it into the event it needs to be to drive business success for our exhibitors and attendees,” said Steve Carey, NTEA president & CEO. “There’s nowhere better to collaborate with colleagues from throughout the commercial vehicle ecosystem, evaluate the latest vehicles and equipment, learn about trends and technology, and prepare for the future.”

More than 500 companies fill the Work Truck Show exhibit hall and New Exhibitor Pavilion with the latest innovations in commercial vehicles, equipment, and technology.

This commercial vehicle trade show is a one-stop-shop to discover new products; optimize commercial vehicle

design and specification; find new business opportunities; meet with current and prospective customers; and consult with management, product, and engineering teams from multiple suppliers.

The main hall is open March 11–13, while the New Exhibitor Pavilion showcases first-time exhibitors March 11–12.

Experience commercial vehicles with the latest technology, fuel, sustainability offerings, and propulsion systems at Work Truck Week Ride & Drive, open to all attendees March 11–12.

Get event details, register, and book hotel rooms at worktruckweek.com. Early bird registration deadline is Feb. 13, 2026.

At Southside Trailer Service Inc., they value loyalty, honesty, integrity, and the kind of support that makes partnerships thrive.

Each year, their parts and sales staff present the Norman Stregiel Rep of the Year Award to the representative—or team—who best embodies these values, honoring the legacy of Norman, who inspired so many with his character and commitment before his passing in 2010.

For 2025, they recognized not just one individual, but for the first time ever, an entire team. Shur-Co’s Spencer Andree (sales engineer), Ron Knuele (territory sales representative), and Hailey Woodhams (customer service representative) have stood out for their loyalty, integrity, honesty, and exceptional support.

In just a single year of working together, their partnership with Shur-Co has already delivered impressive growth in product and systems sales. But more than the numbers, what truly matters is the teamwork—how consistently the Shur-Co reps have worked side-by-side with Southside to serve their customers.

“The Rep of the Year award is meaningful because it comes directly from our parts and sales team,” said President and

Owner Skip Coder. “Spencer, Ron, and Hailey have shown what genuine partnership looks like.”

Southside presented the award during our 36th Annual Customer and Supplier Appreciation Days this summer— a perfect moment to celebrate collaboration, commitment, and the people who make this industry work.

Southside Trailer Service looks forward to continuing this momentum and showing what strong partnerships can achieve for the customers the company and its suppliers serve together.

High Bar Brands (HBB), parent company of Panelite, has launched two new stainless steel sub-brands—Elite and Select— designed to deliver greater choice, flexibility, and value to the heavy-duty aftermarket.

The new Elite line features premium 304 stainless steel, renowned for its corrosion resistance and longlasting durability, while the Select line introduces a cost-effective 430 stainless steel option to meet the demands of cost-sensitive markets.

According to company leaders, the launch reflects direct customer input.

“More than a year ago, we began surveying our customers to better understand their needs,” said Steve Hansen, HBB vice president of marketing and communications. “Based on that feedback, we expanded our offering to cover both 304 and 430 stainless steel options. With two distinct product lines, we can ensure we’re meeting the needs of every customer.”

Mat Tondat, project engineer, added, “A northern customer is going to

prioritize corrosion resistance because they need products that withstand harsh winters, but that isn’t as critical in areas where road salt isn’t used.

“Elite and Select ensure we have the right options for every market.”

The dual-line strategy is part of a broader HBB commitment to become the supplier of choice across all markets.

“It’s a deliberate, strategic move,” said Christopher ‘CT’ Thorpe, HBB president and CEO. “By offering both materials, we support dual-sourcing needs—including OEMs—without leaving the door open to competitors.”

For distributors, the new lines simplify sourcing while reinforcing HBB’s ‘onestop shop’ value proposition.

“Previously, many distributors had

to dual-source stainless steel products since we only offered 304,” Hansen said. “Now, with both 430 and 304 available directly from HBB, they can consolidate their purchasing while maintaining the quality and service they’ve come to expect.

“End-users also benefit from greater choice without compromising on performance.”

Jim Richards, vice president of operations at HBB, highlighted the broader market impact.

“This launch covers the bulk of aftermarket needs, giving distributors a clearer sales story and end-users confidence they’re getting the right product at the right price,” Richards said.

The rollout will be phased, with full line availability expected by year-end and a major promotional push at the aftermarket’s biggest event, Heavy Duty Aftermarket Week, in January.

“Elite and Select are only the beginning, with more launches ahead to keep broadening the ways we support the aftermarket,” Richards said.

Liberty Trailers’ full line of trailers is now eligible for retail financing through Synchrony, one of the nation’s premier consumer financial services providers.

This new eligibility enables Liberty Trailers dealers to offer flexible financing options to customers, making it easier than ever to purchase the trailers they need—while helping dealers close more sales and increase profitability.

“At Liberty Trailers, we’re committed to supporting our dealers and their customers with real, practical solutions,” stated Johnathan Bradley, chief commercial officer, Liberty Trailers. “The availability of Synchrony financing for our trailers means customers can buy with confidence, and dealers can sell with greater ease and flexibility.”

With Liberty Trailers now qualifying for Synchrony’s Secured Installment Loan

Program, participating dealers gain access to tools designed to simplify the sales process, including:

• Loan structures that cover Liberty Trailers and accessories in one convenient payment

• Promotion options to help customers fit purchases into their budgets

• Prequalification and digital application tools for faster approvals

• Electronic contract signing through DocuSign

• 7-day-a-week dealer support and 24/7 access to Synchrony’s Business Center

From October 1 through December 31, 2025, dealers offering Synchrony financing on Liberty Trailers can earn cash incentives on funded loans:

• $100 for loans between $5,000–$9,999

• $200 for loans between $10,000–$19,999

• $300 for loans between $20,000–$25,000

These incentives are in addition to Synchrony’s standard dealer rebates, giving Liberty dealers even more reason to take advantage of the program.

Dealers can enroll quickly and start offering financing right away by visiting SYFENROLL.COM or calling 1-866-2094457 and entering campaign code: SSI. For more information or to view the current rates and incentive flyer, dealers can visit the Synchrony Business Center. TBB

Inside McKinstry’s electrification strategy: Chevy Silverado EVs lead the charge

By Jade Brasher

Having an electric fleet vehicle is becoming less of a rarity and more of a natural evolution for two types of fleets: those with sustainability goals and those that want to save money on fuel and maintenance.

McKinstry, a national construction and energy services firm with locations in nearly all four corners of the U.S., belongs in the former category. The nationwide company has a fleet of approximately 860 vehicles. Of those 860 vehicles, 114 are electric: a few Rivian R1Ts, Chevrolet Blazer EVs, and Chevrolet Equinox EVs. However, the majority of the EV fleet—100 to be exact—are Silverado EVs.

The goal is to eventually have a 100% EV fleet.

McKinstry is “on the leading edge of technology,” Ryan Winchester, McKinstry’s fleet manager, said. “EVs are obviously right there in that space. We’re not doing this because it’s a popular or unpopular thing to do. We’re doing it because we want to reduce our carbon footprint here at McKinstry, because we like to do things that are good for our environment and good for the places that we work—our communities.”

McKinstry’s electrification journey began several years ago. It received its first few electric vehicles, Rivian R1Ts, all the way back in 2017.

But the Rivian pickups, while great for supervisors, weren’t suitable as work trucks for McKinstry’s construction needs, according to Winchester. When GM announced an electric version of the Silverado, the fleet ordered 100 trucks immediately.

To be a McKinstry work truck, a vehicle needs space to handle extra upfits, extra weight, and ample storage. The Silverado EV, as a full-size pickup, allows just that, Winchester said. Further, the fact that it’s an EV allows for even more storage space with the vehicle’s front trunk.

Silverado EV performance

Winchester thinks that in some ways, the Silverado EVs’ performance is superior to that of an ICE pickup.

“They’re quieter, they’re more comfortable, and they’re smoother,” Winchester said. “The EV Silverados with the ... [EV

battery] weight there—they’re just a better riding vehicle. Longdistance driving ... is more comfortable than an ICE vehicle.”

He also appreciates the absence of typical vehicle engine noise found in ICE trucks.

“You can drive down the road and have a regular conversation,” Winchester said. “You don’t have to raise your voice at all. You don’t even have to have the radio up loud in them.”

However, there are some important factors to consider when comparing an EV with an ICE vehicle—especially in a work truck application. One of the most important being the vehicle’s weight-to-range ratio.

Though McKinstry needed a full-size electric pickup for its upfits and equipment, loading the vehicle with extra weight sacrifices battery range. One of McKinstry’s Silverado EVs lost 20 miles of range after being equipped with 520 extra pounds of upfits, Winchester said.

While a similar effect happens with an ICE pickup’s fuel mileage after adding upfits, the EV driver’s experience is going to be vastly different considering public chargers aren’t as prevalent as gas stations.

Thankfully for Winchester and his drivers, the Silverado

EV automatically calculates its own weight via sensors and adjusts the vehicle’s range accordingly. Not only does the Silverado EV sense weight, it also takes driver behaviors into consideration.

“If you’re hot-rodding everywhere you go around town in it, it starts to calculate how heavy you are on the accelerator, and the computer starts to decrease its range so that it’ll tell you that it’s time to charge it sooner,” Winchester explained.

While other EV fleets have found charging to be the biggest EV-associated headache, McKinstry’s charging challenges have been minimal, according to Winchester. The company uses all methods of charging that are available to it to ensure its fleet is charged and ready; this includes charging at drivers’ homes, campus charging at McKinstry facilities, and public charging.

Perhaps one of the biggest reasons why charging hasn’t been much of a headache for McKinstry is because the company completes its own charger installations on its campuses. Winchester said that the only problem installation teams have run into so far is power constraints.

“Depending on how many chargers you put into a building, you start to get limited on the power usage because you only have so much power coming in,” Winchester said.

As for home charging, McKinstry uses its fleet management providers to facilitate that.

While McKinstry facilitated and initiated the buildout of their charging infrastructure in-house, Winchester said GM is ready and able to help when they need additional electrification expertise.

One way GM assists McKinstry is by analyzing telematics and charging data to help the company decide how best to implement EVs within the fleet.

“They’re going over all the data using telematics and helping

To be a McKinstry work truck, a vehicle needs space to handle upfits, extra weight, and ample storage, and the Silverado EV, as a full-size pickup, allows just that.

us with ... plans of rollout for the next line of EVs that we’ll be getting,” Winchester said.

According to Winchester, it works like this: General Motors Envolve—the team dedicated to working specifically with commercial customers on all things fleet—looks at McKinstry’s fleet usage to determine the routes best suited for electrification. GM alerts McKinstry of routes under 200 miles, where electrification with at-home charging will be no problem. Then for other routes, perhaps routes that travel more than 400 miles a day, GM shows McKinstry how electrification would be possible with adequate charging infrastructure.

“Right now, it wouldn’t make sense to deploy 50 EVs into Montana because the infrastructure is not there,” Winchester said. “In that way, [GM Envolve has] really started to become more involved as we get into the next wave of EVs.”

As with charging, overall implementation of the Silverado EV into the McKinstry fleet wasn’t much of a daunting task. Getting drivers on board didn’t pose a problem as McKinstry first distributed the EVs to drivers on a volunteer basis, Winchester said. This also gave Winchester and fleet leaders time to iron out the wrinkles of running EVs in a primarily ICE fleet with drivers who wanted to be in them.

There were some fluke incidents, such as the time a driver shifted the Silverado EV to drive when it was still charging. This triggered a safety redundancy, forcing a tow. But “outside of that, for the most part, there hasn’t really been too many issues,” Winchester said. “It’s been pretty easy.”

Along with the Silverado EVs’ ease of implementation in the fleet, Winchester said the fleet is also saving money on fuel.

“I had a guy [who spent] roughly $1,200 a month in gas,” he said. “He’s now down to $600 in charging.”

When spread across an entire fleet, that’s a significant saving. Another advantage of EVs that McKinstry found is decreased maintenance needs, requiring only regular tire rotations and pivot point lubrication, Winchester said. Additional maintenance includes occasional OEM updates, which are conducted over the air. Drivers can activate these updates at the push of a button when they return home at the end of the day.

Overall, Winchester and McKinstry are pleased with the Silverado EVs’ performance in the fleet. Winchester’s advice to other fleet leaders is to just do it.

“Once you do it and you realize, ‘Oh, this isn’t really that big of a deal,’ then it makes it easier to keep going forward,” Winchester said.

But he cautions fleets to grow “responsibly,” implementing small batches of EVs at a time to ensure they’re working properly, that drivers are acclimating to them, and that they make sense for the application and operation.

By Jade Brasher

It looks like a work truck. No chrome, no fancy wheels, no leather-wrapped accents. Yet, it’s what’s on the inside that really counts for the Ford F-250 Super Duty XL 6.7L Power Stroke Turbo Diesel.

When a member of the Ford team first told me about the F-250 XL Power Stroke, he said this particular truck was just as capable as a Super Duty equipped with the brand’s Tremor Off-Road package, designed for the road less traveled. Naturally, I had to test that theory.

Before testing the truck’s off-road capabilities, I used it as my daily driver for the week. Navigating a vehicle this size through the one-way streets in my neighborhood isn’t exactly a walk in the park, but the F-250 handled it with ease.

The engine is also quiet compared to the older diesels you’ll hear puttering around town. The Power Stroke turbo diesel won’t wake up the neighbors

when work starts before the sun, and the person taking your order in the drivethru won’t ask you to cut the engine so they can hear you properly. All in all, my daily driving experience with the F-250 Super Duty XL wasn’t half bad.

Then the weekend came, and it was time to test the truck’s 4x4 capabilities at Silver Lake Sand Dunes. The dunes are in West Michigan, about a four-hour drive from my Metro Detroit home.

While it wasn’t equipped with the finer things like power-adjustable or heated/ventilated seats, I wasn’t aching during that long drive—and that means a lot coming from someone with herniated discs.

One thing that was surprising about the Ford F-250 Super Duty XL, however, was that it didn’t have a regular power outlet, which was noticed on the way back because my occupant needed to charge their laptop. Designed as a work truck (even equipped with a stowable

work surface), one would think having a 115V AC outlet would be a no-brainer. Go figure.

While driving, I noticed how well the truck handled: first through the tight streets of my neighborhood, then along the crowded Interstate highways, and then through the winding state routes. Though it appears to be a Plain Jane work truck, its suspension is tuned perfectly. It also handled well because— unlike your typical off-road truck with beefy tires—its smaller wheels keep the truck nimble and feeling lighter.

I have plenty of off-road experience, but I’ll admit I was nervous to take this truck out on the dunes. Surrounded by

Jeep Wranglers and dune buggies, the sheer size of the F-250 Super Duty made it seem totally out of place. To make matters worse, Silver Lake Sand Dunes consist mostly of “scramble” areas, which basically means there are NO RULES.

Friends who’d been there before had already shared horror stories about nearly being hit, both when they were inside and outside their vehicles. Other friends shared their stories of a broken window and damaged bumper. As far as I’m concerned, Silver Lake Sand Dunes is Michigan’s Wild West.

But my worries subsided once I got the truck out on the dunes. The weekend crowd had mostly gone home by Sunday afternoon when we got there, leaving plenty of room in the park for my test drive.

The first hill I tried to tackle was a no-go—but that’s likely because of me. The F-250 scaled the first half well, but just before reaching the top, I saw the flag of a buggy coming up the other side and opted to slow down and let it pass.

By the time it passed, the truck had sunk too low into the sand, and the only way out was to reverse downhill. Taking another angle, I got it up the hill the second time.

That first hill wasn’t much to write home about, though it was steep. Really, it was the hills that the buggies were gliding over that had my interest.

I had never driven over sand dunes, but I discovered that in a vehicle of this size, navigating dunes requires a perfect dance between speed and control. Speed is required to scale the steep hills without sinking too far into the sand. Yet once you get over the hill, control is required to master all the bumps going down. I’ll admit that there were moments when the hills and dips were closer together than I anticipated, and I crossed them with too much speed. In those moments, I just thanked God for seat belts.

Regardless of the inexperienced driver behind the wheel, the increased weight from the diesel engine, and its

long wheelbase, the Ford F-250 XL handled the sand as if it were designed for it.

While I do not expect drivers of this work truck to venture onto sand dunes, it was refreshing to know that my friends at Ford don’t mince words when touting their vehicles’ capabilities.

After this experience, I believe this F-250 Super Duty XL can go anywhere the job requires—from the suburbs to the sand dunes.

By Jade Brasher

LAUGHLIN, Nevada—The best way to gauge a pickup’s capabilities is by testing them. Ram recently treated members of the media to a ride-and-drive event here, testing its new HD lineup of the Ram 2500 and 3500 equipped with a new powertrain: the 6.7L Cummins Turbo Diesel paired with a TorqueFlite HD 8-speed transmission.

The event allowed the media to drive a Ram 2500 and 3500 hauling another pickup, an excavator, a fifth-wheel camper, and a tractor up the Davis Dam grade, testing the HD lineup’s ability according to the SAE J2807 industry standards.

New with the 2025 Ram HD line

Building a product suited for commercial applications means building a product with commercial-grade capabilities. These products were designed for that “5% customer,” Matt Huber, SVP of Ram brand product, explained. These customers “need the capability to get the job done,” and that’s where the new powertrain comes in. The 6.7L high-output turbo diesel engine is capable of 430 hp and 1,075 lb.-ft. of torque. That torque rating—a best-in-class rating for base diesel torque, according to the OEM—is standard across the lineup. And that was designed with intention.

“Of our heavy-duty pickup trucks we sell, 70% of them are the 2500 class,” Huber said. “And of those, 80% of people get diesel, and they’ve been asking for

that 1,075 lb.-ft. option. ... So, this year, we not only gave them the option, but we made it standard.”

Also back for 2025 across the whole lineup, including chassis cabs, is a column shifter.

“We got feedback from customers that they wanted a consistent shifter throughout the lineup so that when they buy fleets of trucks, they’re all the same,” Huber said. “But then also, when you have someone doing a vocation like driving a snowplow truck, and they’re driving it for up to 15 hours a day, they want a shifter that can have muscle memory so they can shift from Drive to Reverse back to Drive when they’re going back and forth plowing snow.”

The trucks also feature technology and comfort updates that are carried over from the brand’s light-duty lineup.

Choosing to host a towing event at the Davis Dam grade helped determine a benchmark for what to expect from the Ram HD. The 11-mile stretch of road is the exact testing ground that determines the industry standard for tow ratings.

More specifically, the Davis Dam grade determines “tow-vehicle gross combination weight rating and trailer weight rating” for passenger cars and pickup trucks up to 14,000 lbs. GVWR.

Not only does the SAE require this particular stretch of road be used, but it also requires specific weather conditions. For an SAE-validated test, temperatures at the bottom of the grade in Bullhead City must be 100 degrees Fahrenheit. The vehicle’s AC must also be on full blast.

Once these conditions are met, a truck coupled with a trailer must drive up the

grade—a climb of more than 2,950 ft. over 11 miles—maintaining 40 mph until the peak of the grade at Union Pass, Ram Professional’s Dave Sowers told me.

While the conditions of the event were a bit different than required for SAE testing standards—sunny and in the 60s—I tried to make up for it as best as I could by running the trucks a little harder than the test requires.

I drove three different trucks up the grade: two Ram 3500 Heavy Duty trucks, one Limited dually hauling a farm tractor (the heaviest load at 19,000 lbs.) and one Laramie dually hauling a fifth-wheel camper at 13,500 lbs.; and one Ram 2500 HD Laramie hauling an excavator weighing 13,000 lbs.

No truck showed signs of struggle throughout any run up the 11-mile stretch. The noise of the engine revs were louder for those larger tows—especially the tractor—but to me, that was the most noticeable difference between each haul.

It took me a few miles to get comfortable driving the large loads up the steep grades, and it was in these moments— especially for the first two trucks—that I took my time ascending the climb; however, I consistently drove the trucks above the testing requirements at a relatively consistent 55 mph.

The trucks performed well, and what really highlighted the capability of the Ram HD lineup was that once you get the truck up to speed, you hardly remember you’re towing heavy equipment. And even getting up to speed is something the Ram HD makes seem easy.

The new 8-speed TorqueFlite transmission is an upgrade from the lineup’s previous 6-speed transmission. While

the addition of the two gears provides a more fuel-efficient gear ratio, it also provided a smooth shift when hauling thousands of pounds of equipment.

The coordinators of the event loaded the trucks up with about 60% of their max capacity, and I knew that no manufacturer would invite media out in test conditions where its trucks couldn’t perform. No, what impressed me the most was the sheer ease of trailering.

With the Ram 3500, there were moments I forgot I was towing 19,000 lbs. and 22,000 lbs. behind me, and that’s saying a lot, for someone with little towing and trailering experience.

Sowers, who was my passenger with each drive, told me that Ram placed a lot of focus on visibility with the Ram HD’s technology, and I can personally attest to that. While I did rely on the trucks’ side mirrors, the rear-view mirror of the 3500 Laramie doubled as a split camera monitor, displaying two camera views of the side of the fifth-wheel camper it was hauling.

This took a minute to get used to, as I am accustomed to relying on my side mirrors. But once I realized it was easier to glance up at the rear-view mirror monitor instead of glancing between the side mirrors, I was hooked. I really missed having that option on my next run up the grade in a truck that didn’t have that feature.

For Ram, successfully scaling the Davis Dam grade to the SAE’s standards is only half the story, Doug Killian, Ram chief vehicle synthesis manager for the truck segment, said at the event.

Instead, the engineers sought to make a truck that could scale the grade while making it a comfortable drive.

“Can I have a conversation? Can I change the radio? How do I feel when I’m passing somebody on a downhill because maybe they’re white-knuckling?” Killian challenged. “It’s about that subjective point.”

When I ask myself those questions looking back on the trip, I can confidently say ‘yes’ to all of the above.

By Jade Brasher

PIEDMONT, South Carolina—Isuzu hosted a celebratory groundbreaking ceremony with the state governor, both its global and North American CEOs, and several high-ranking executives and state officials from the U.S. and Japan. The ceremony marks the beginning of construction on a new Isuzu Trucks production facility—a $280 million investment requiring more than 700 employees once completed.

While a 1,000,000-sq.-ft. facility already rests on the 200-plus-acre lot, Isuzu will spend the next 14-18 months modifying the building and several surrounding acres to accommodate production lines for the N-Series Gas, N-Series Electric, and F-Series Diesel trucks as well as clearing land for assembled truck storage. The company seeks a production capacity of 50,000 trucks per year by 2030.

“This Greenville plant will be essential to advancing strategy here in the U.S.,” Masanori Katayama, chairman and CEO of Isuzu Motors, said. “North America is also our second-largest truck

market after Japan.”

“Together we will create jobs, drive innovation, and contribute to the future of mobility and this community,” Noboro Murakami, Isuzu North America chairman and CEO, said at the event.

Isuzu’s groundbreaking ceremony

Local and state officials, including South Carolina Governor Henry McMaster, attended the ceremony, which included remarks from McMaster and the Japanese ambassador to the United States, a cherry tree planting, and gifts of bonsai trees to all the guests.

This isn’t the first such event held in South Carolina. Multiple manufacturing companies have already made the state their home. McMaster said it’s South Carolina’s benefits

that make it a hotbed for manufacturing.

“We believe in the ‘Three Es’: economic growth, education, and environmental protection and conservation,” McMaster said to the crowd.

What brings businesses, namely manufacturing businesses, to South Carolina, is its tax system and its port access, allowing shipments all over the world, according to McMaster. It also has “one of the best technical college systems in the world,” he said, with 16 area universities and colleges that funnel a skilled workforce into the area.

“We are pushing and thriving,” McMaster said. “And we will keep going because we want to attract the kind of businesses like Isuzu. It is a fine company.”

Isuzu didn’t immediately choose South Carolina as the location to build this eventual state-of-the-art facility (which is set to be Isuzu’s most technologically advanced facility in the world).

In fact, the state worked with Isuzu for a little more than a year before the decision was finalized, McMaster told Trailer/Body Builders. However, Isuzu

North America CEO Murakami said that choosing South Carolina for its production base was an easy decision.

The state “stood out as an ideal location” for Isuzu because of its existing manufacturing, “a globally renowned approach, and a growing, innovative economy,” he said.

“We are proud to make the Upstate [region of South Carolina] our new home,” Isuzu Motors CEO Katayama said. “We are especially grateful for the kindness and energy of this community. We are committed to working alongside you, not only a company that builds trucks, but also as a neighbor and partner that contributes to the life and future of this vision.”

Why is Isuzu opening a new truck manufacturing plant?

Isuzu currently produces its N-Series Gas, N-Series EV, and F-Series Diesel trucks stateside in Charlotte, Michigan, in partnership with The Shyft Group. While Shaun Skinner, president of Isuzu Commercial Truck of America emphasized how well the partnership with Shyft has worked over the years, Isuzu has simply outgrown Shyft’s production capacity, currently storing parts in different areas across the town. Additionally, this new facility will be completely owned and run by Isuzu, granting the company flexibility and complete control in its production.

Building a new facility here in South Carolina “allows us to have everything in one area and will allow us to grow our volume ... [and] do it in a way that’s more effective,” Skinner said to a group of trade media invited to the event.

And while the timing might look like this move from Isuzu is a response to tariffs, or even nearshoring, Skinner said that’s not exactly the case.

“The timing of the announcement came right about the same time you heard a lot of the talk with the tariffs and everything,” Skinner told TBB. “So the timing of it is coincidental, but in fact, it does allow us to be better prepared for a lot of that.”

The local area is already home to multiple manufacturing facilities, and

Murakami said that fact helped influence the decision to build here. BMW came to the state in 1992, building its largest manufacturing facility to date in the same county. Michelin, Bosch, and 3M also have facilities in the area. These existing businesses help the area offer an “excellent business climate, a strong automotive production base, a skilled workforce,” access to the Port of

Upfitting Summit, held in October in Sandusky, Ohio, once again allowed TEMs and upfitters to check out the spec updates on the newest trucks. From the top, an Isuzu NRR EV battery/frame layout draws attention; a Western Star gets a once-over for mounting measurements; Ford, as usual, showed off a roomful of chassis cabs, vans, and pickups. See www. trailer-bodybuilders.com for additional coverage.

Photos: Kevin Jones | TBB

Charleston, and more, he said.

Benton Blount, chairman of the Greenville County Council, said he believes this facility is one of the biggest investments into the area since BMW and brings with it not only an “economic investment, but real quality jobs that pay a good wage for our citizens.”

Isuzu plans to begin producing vehicles at the facility in 2027. TBB

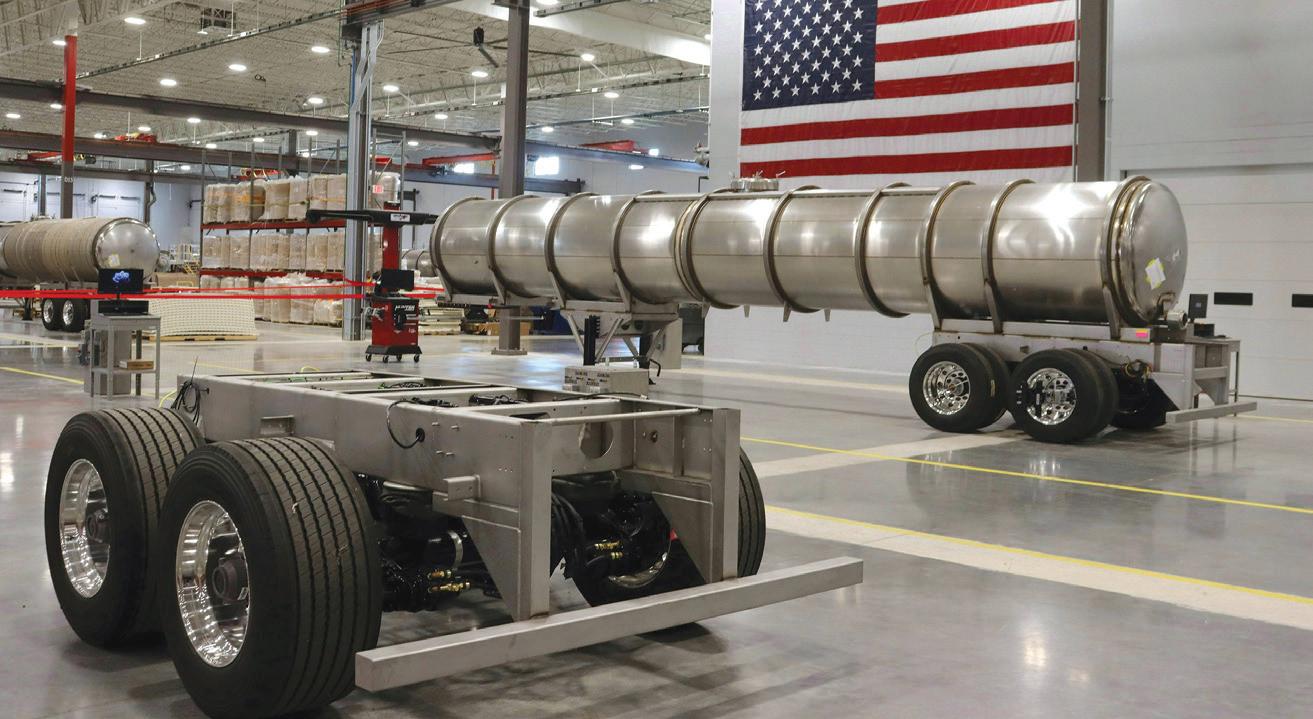

BELOIT, Wisconsin— e power of American ingenuity was on full display Sept. 23 at STE’s new tank trailer manufacturing facility in Southern Wisconsin—and some of the country’s most powerful people were paying attention.

STE’s official grand opening and ribbon-cutting ceremony featured prolific businesswoman Diane Hendricks, chairman of Hendricks Holding—STE’s parent company—her son, Brent Fox, Hendricks

president and CEO; her daughter, Konya Hendricks Schuh, Diane’s co-star in the new A&E show “Betting on Beloit;” U.S. Sen. Ron Johnson, a Republican from Wisconsin, along with other national,

By Jason McDaniel

Transport

state, and local dignitaries—and even President Trump.

“A very special congratulations to Diane Hendricks and the entire Hendricks Holding team on the grand opening of your new Stainless Tank and Equipment facility, which will employ 200 American workers in the great state of Wisconsin,” Trump said in a recorded video message shown during a tour-concluding luncheon. “For over 50 years, your company has manufactured high-quality, stainless-steel tank trailers stamped with those beautiful words ‘Made in America.’ Companies like theirs not only create American jobs, but restore American communities, build up our industrial base, and make our entire nation very proud.”

The occasion drew more than 200 people, including suppliers, dealers, and fleet customers, to Beloit to celebrate the opening of STE’s highly automated 400,000-sq.-ft. plant purpose-built for tanker production. They gathered expectantly outside the modern building—with its sleek lines and pristine

façade—to witness Diane, Fox, and Johnson snip the ceremonial red ribbon while flanked by a trio of tank trucks. Then they filed inside for an eight-stop tour of the greenfield factory, temporarily idled to safely showcase its technologically advanced systems.

STE President Chris Sipe deemed the event one of the most important in STE’s 59-year history, second only to the Hendricks family’s 2006 purchase of the company to save 60 local jobs.

“This facility offers several major benefits, the first being jobs. Over the next five years, we’ll add over 250 top wage-earning jobs,” Sipe predicted in his opening remarks. “The second is the advancement in the safety and quality of our products. We say internally we have an unmistakable commitment to precision. The state-of-the-art technology being deployed in this facility gives us the ability to build the safest, strongest, and highest-quality tank trailers available anywhere.

“This facility also represents the largest investment in the tank trailer manufacturing industry in history. I personally want to thank the Hendricks family for their investment and unwavering dedication to the tank trailer industry.”

The opening ceremony also included comments from Derek Nilsen, STE director of sales and marketing, who coordinated the massive event, and Ryan

Streblow, president and CEO of National Tank Truck Carriers, who thanked STE and Hendricks Holding for its visible and valued commitment to a vital industry.

“For the tank truck industry, this facility means progress,” Streblow declared. “Tank trailers are the backbone of how essential goods, chemicals, food products, and fuel are safely and reliably moved across our nation every day. With this advanced facility, STE is taking design, safety, and efficiency to a whole new level. The technologies integrated here are set to deliver higher-quality trailers with greater durability, improved safety features, and sustainable production methods that reduce waste and emissions.

“Simply put, this new facility sets a new benchmark for the industry, reaffirming STE’s position in building the future of bulk transportation.”

Trump wasn’t the only official to express his excitement on this historic occasion.

U.S. Reps. Derrick Van Orden and Tony Wied, both Republican members of the House Committee on Agriculture, and Devin LeMahieu, the majority leader of the Wisconsin Senate, also spoke during the luncheon. They joined Diane, Fox, Streblow, and Samuel Popa, American Aluminum Extrusion owner and president, for a visit guided by Sipe.

Johnson, who spent 30 years in manufacturing before entering politics, expressed his appreciation for the Hendricks family’s steadfast devotion to boosting the local and state economies.

“This is a first-class manufacturing facility,” Johnson told TBB. “Because of that, the specifications on these tanks are tighter than any competitor can maintain, which means safer products on the road. That’s a great thing right there. But also, because of what they’ve done with the technology, they can compete with Mexican labor. And my guess is, with the combination of being able to compete on the labor, and the quality of its products— with those tighter specifications—this business is probably going to take off.”

Van Orden, also a military veteran and actor, thanked Hendricks Holding and STE for celebrating “people who work with their hands” and keeping America’s food supply moving.

“Without your work … agriculture would stop, because it doesn’t matter how much milk you produce in a barn, if you can’t get it in a trailer, you’re not going to have cheese, and I truly love cheese,” he quipped. “So, without our transportation industry, and our ag industry, America would stop. And any country that is dependent on another nation for its food is in an inherently bad place.”

Wied, who previously owned a chain of convenience stores, marveled at the

facility’s engineering and manufacturing excellence, and Hendricks Holding’s passion for advancing American interests.

“It’s so important that we have family businesses here in our country,” he said. “It’s important for our economy, and for our national security, and this is an incredible example of a family business that continues to prosper. And then you look at proudly ‘Made in America’ displayed everywhere within this factory. That is so amazing and so critical.”

Streblow—who was joined by NTTC Chairman David Price, United Petroleum Transports executive vice chairman—agreed, crediting STE for advancing tanker safety during a stop in STE’s service center. “This is one of the most critical components any OEM can bring forth to our industry—repairs being done here, and staying out of a court of law,” he said. “With the risk of liability our carriers go through when having to do repairs or spec a piece of equipment, they get scrutinized very quickly. And we’ve seen that in some of these frivolous nuclear verdicts.

“Having a facility of this nature step up, along with other OEMs, to take on repairs with pride, instead of pawning them off on the side, not only elevates STE, but … our carriers and our industry.”

Attendees walked the expansive factory floor during an eight-station exhibition of the facility, which began production in January and is expected to gradually

Tour guests learned at Station 8 that STE’s 400,000-sq.-ft. manufacturing facility changes out the air in the building every 12 minutes to ensure employee comfort and equipment quality.

ramp up operations over the next few years.

The first stop spotlighted STE’s ring-making machine and a hydroforming press that shapes tanker end caps with 1,500 tons of pressure, increasing throughput and accuracy. Previously, one person made about eight heads per day, Sipe shared.

Now, robot-aided lines turn out caps in 6 minutes. “This facility was designed to take what I call the old ‘arts-andcrafts’ or ‘iron-hammer’ method and add automation and precision to it,” Sipe explained.

The second displayed STE’s up-front barrel processing capabilities. Using advanced automation, STE takes stainless-steel coils primarily sourced domestically and flattens, straightens, cuts, and rounds them into “cans” that

are welded and polished in a fraction of the traditional time before moving into the final stages of construction. STE currently boasts the capacity to turn out 2,400 tankers—at an average length of 44 ft.—per year on two shifts, Sipe said.

Stations 3 and 4 demonstrated the precision of STE’s bending and welding robot cells in decelerated and shadow modes. Station 3 also featured two manual press brakes—a small one for small parts, and a larger bending backup; and Station 4 included a 6,250-gallon milk tanker and a hydrostatic system connected to a 60,000-gallon in-floor tank filled with filtered water for leak testing.

The fifth tour stop sent guests outside to view the facility’s vast trailer staging area; towering U.S. flagpole—which, at 132 ft., is the second tallest in Wisconsin (Acuity’s flag in Sheboygan waves 400 ft. in the air)—and a 9,500-gallon, fouraxle food-grade trailer belonging to one of the country’s largest dairy haulers. STE’s concrete lot boasts enough space for 192 new trailers and 60 service trailers, Sipe said. Then they headed back inside for Stage 6, a look at the company’s 13-bay maintenance and repair shop that services all tanker makes. “The advantage of taking your trailer to an OEM is that we always fix it correctly,” Sipe maintained.

“Why? It’s a huge liability for us. We’re considered an expert in a court of law, so we always fix things correctly.”

The circuit ended with examinations of STE’s loading and unloading, and frame-welding machines in Station 7; and the finishing space in Station 8, where workers affix fenders, lights, reflective tape, and more. Sipe proudly highlighted the facility’s in-house welding school. The ASME-accredited builder partners with Blackhawk Technical College to train and develop technicians, driving value for customers and setting standards that are “second to none.”

“I love what I do, and I know Brent supports and feels the same way,” Diane concluded. “You see it in the communities we live in, the businesses around here, and the opportunities that drive us to buy new real estate and invest in companies—and we’ve got a great company here.” TBB

By Jason McDaniel

National Tank Truck Carriers continued to celebrate its 80th anniversary at Tank Truck Week 2025 by tackling the issues of today, exploring the solutions of tomorrow, and reconnecting with members from yesterday.

“This year’s Tank Truck Week embraces yesterday, today, and tomorrow—and part of that is welcoming members who’ve come back,” said Ryan Streblow, NTTC president and CEO. “We’ve had an amazing year with fleets and carriers coming on board. So we have a great group already, and commitments from a variety of carriers that aren’t members now but have heard about the progress we’ve been making over the past three to five years.

“We’re a recognized name on Capitol Hill, we’re fully embedded in the regulatory environment, and we’re laser-focused on improving the tank truck industry’s image—and that’s really starting to resonate.”

Tank Truck Week 2025 ran Oct. 5-8 in Kansas City, Missouri.

Among the news of interest to Trailer-Body Builders readers, Drōv Technologies’ AirBoxOne smart-trailer system is now available to any manufacturer’s tanker through a new aftermarket agreement with Kraft Tank that allows operators to upgrade equipment with intelligent technology that reduces downtime, optimizes fuel efficiency, and enhances safety.

“This partnership marks an exciting new chapter in aftermarket innovation for the tank trailer sector,” Drōv CEO Lisa Mullen said. “By combining Drōv’s advanced sensor-driven solutions with Kraft’s unmatched installation and servicing capabilities, we’re enabling fleets to unlock unprecedented operational insights and reliability.”

TankAi platform powered by Drōv’s AirBoxOne, a cloud-enabled control box with multiple wireless connections that unites smart components, including trailer cameras, weight sensors, and automatic tire-pressure regulators. But as Drōv’s preferred partner, Kraft now will be able to install, repair, and maintain AirBoxOne-enabled ecosystems in any fleet’s newly purchased, used, or leased tank trailers.

“Kraft can bring these fleets in and monitor their trailer systems,” Bob Davis, Drōv vice president of business enterprise, told TBB. “They have the facilities and the capabilities to diagnose various issues. And it might not be an AirBoxOne issue. It could be an ABS sensor. Well, they understand that, and they can fix it before any major problems occur.”

Drōv first introduced its solution to tank fleets at Tank Truck Week 2021. Four years later, the Oklahoma City-based company is still adding and testing innovative new features such as dry bulk pressure sensors and multi-axle tire monitoring.

“We’ve had great feedback from fleets who’ve already equipped the AirBoxOne, and we have a lot of people asking for it—so they can truly monitor the entire trailer,” said Jeremy Capra, Kraft parts director.

EnTrans International, the parent company of Heil Trailer, Polar Tank, and other tanker brands, remains the exclusive provider of the factory-integrated

“There is nobody else out there who can deliver that ability to this level.”

Drōv’s technology unlocks real-time trailer health monitoring and comprehensive data collection. The partnership with Kraft leverages the tank trailer equipment and service provider’s nationwide network and expertise to expand distribution, professional retrofitting, and ongoing system care, ensuring seamless integration and long-term support for customers.

By Jason McDaniel

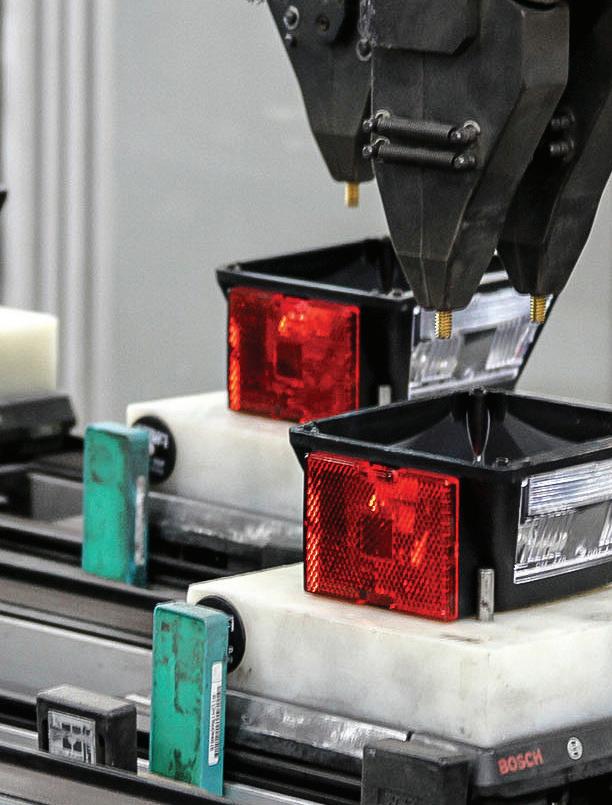

GRANDVIEW, Missouri— Peterson Manufacturing turned 80 years old in 2025.

To mark the oak anniversary, the vertically integrated supplier of commercial vehicle lighting and wiring harnesses modernized its signature stop-sign logo to elevate brand awareness, redesigned its website to enhance functionality, refreshed its LED and incandescent print catalogs, and rolled out new products, including the “firstof-its-kind” repairable J560 connector.

Now it’s asking a group of third-party providers to help spread the word.

“You guys are the storytellers—and you do it well,” Missy Pinksaw, Peterson marketing director, told reporters gathered for a media open house Oct. 9 at the company’s 44-acre headquarters. “I really do believe this is the final piece of the puzzle for us. You highlight innovations, and you tell your readers—who are our customers—what matters.”

The event, which coincided with NTTC’s Tank Truck Week, included presentations on Peterson’s American-made history and unique manufacturing capabilities; a tour of the family-owned company’s highly automated lighting and harness facilities, and its Mission Plastics North and Vector Tool and Engineering operations; and an exclusive look at the Armacosts’ compelling collection of classic cars.

Several members of Peterson’s experienced executive team, including Vice President of Sales and Marketing Al Anderson, Senior Manufacturing Manager Jake Chambers, Product Manager Bill Cook, Director of OEM Sales Jay Davenport, Senior Manager of Fleet Sales Dan Miller, and VP of

Operations Jim Rash, set the stage for attendees, providing industry insights, behind-the-scenes production details, and a sneak peek of innovative new offerings still to come.

“We’re proud of our heritage and what you’re going to see,” Anderson said.

The Peterson difference Wilbur Peterson founded Peterson Manufacturing in 1945 in nearby Kansas City. The company’s first customer was Western Auto, whose iconic sign still sits atop the original downtown building, about 18 miles north of Grandview. The first product was a bike pump, an example of which was displayed in Peterson’s main conference room.

Local businessman Don Armacost Sr. purchased Peterson in 1956, beginning the Armacosts’ 69-year stewardship. Now his sons, Don Armacost Jr. and David Armacost, lead the company, Don Jr. as chairman and David as president and CEO. Today, the quarter-billion-dollar, multi-faceted corporation supplies premium side and rear safety lighting and wiring solutions globally across a range of commercial vehicle markets, including heavy-duty and tank trailers; light- and medium-duty trailers and straight trucks; intermodal chassis trailers; and work and utility trucks.

Peterson’s vast product portfolio includes 2,500 unique lighting SKUs and 6,200 wiring harness SKUs.

“The wiring harnesses are very unique,” Anderson said. “Every trailer manufacturer and every fleet has its own unique way of lighting things up—and we must accommodate all of those things.”

Vertical integration across the lighting and wiring supply chain is the key to Peterson’s lasting success, Anderson

added. Vector makes plastic injection molds, tools, and fixtures, and designs and builds much of Peterson’s automation; and Mission produces the plastic parts that go into Peterson’s products. The group also makes its circuit boards, tests devices for FMVSS 108 compliance in its certified metrology lab, and checks reliability in its environmental lab. Integration and process innovation also lower production costs—and keep Peterson’s pricing competitive.

“We have not had any adjustments in our price sheets since Jan. 1, 2023,” Anderson noted. “In the face of inflation, and all the uncertainty, we’ve held the line [for almost three years]. Now, we are going to have a price adjustment … on Jan. 1, 2026, but about 97% [of our prices] are going to stay the same or go down— and some will go down dramatically.

“That’s a testament to our factory, and the innovation engineering puts together.”

Trademark innovations include Peterson’s Defender and PetersonPatriot lighting systems, and the PetersonPulse smart trailer system. The company also

released a 506K LED Heated Snow Plow Light Kit and launched the repairable J560 seven-way connector in the last three months.

Defender and PetersonPatriot, Defender’s “little brother,” both feature LED diodes and corrosion-resistant construction that protects electrical systems from deicing road chemicals. The highly customizable Defender boasts “billions of miles” with “virtually zero” corrosion issues, Anderson said.

PetersonPulse, which debuted in 2018, is Peterson’s still-evolving CAN bus-based intelligent trailer controller that monitors vital systems in real time, delivers alerts to drivers and fleet managers via Bluetooth and telematics-enabled communications, and unlocks unique capabilities like pinpoint lightout detection.

Manufacturing innovations include longer-lasting fiberglass circuit boards, surface-mounted LEDs with optimized heat dissipation, and molded terminals that provide an elite moisture seal.

Peterson’s Grandview campus includes four factories that total 675,000 sq. ft. of production space, all connected by enclosed walkways, or “tunnels” as they’re called internally, that keep employees out of the elements yearround. Along with one other Mission location in Nashville, Arkansas, Peterson’s manufacturing capabilities leverage proprietary automation—much of it built in-house—that boost scale and volume to “reduce labor costs considerably,” Rash said.

The tour, led by Chambers, started in the harness facility, then took guests through the Vector and Mission facilities before ending in the lighting plant. “We pride ourselves on having a single factory that can do everything right here,” Anderson said.

The wiring harness operation includes its own engineering and customer service teams, and most manufacturing runs are in small, customized batches, Chambers said. The first stop highlighted the injection molding machines that mold around Peterson’s myriad pigtails and harness extensions—including amp-style connectors—allowing it to offer the industry’s only 10-year corrosion warranty. All Defender harnesses are seal-tested in a fresh-water station using pressurized air.

Chambers also pointed out Peterson’s unique harness manufacturing

techniques, including pulse injection molding and ultrasonic welding.

Vector, where Chambers spent the first 16 years of his Peterson career, serves internal and external customers, who make up about 50% of its business. Chambers spotlighted the operation’s horizontal and vertical mills, and fiveaxis lathe; and explained how Vector utilizes electrical-discharge machining to erode and shape electrically conductive materials with high precision—an “invaluable process in the mold-building industry,” Chambers maintained.

“East Trailers asked us to make a smaller mold to run through their rails,” he said. “Any other manufacturer would have needed six to 12 weeks to do that. We had the molds ready in two weeks.”

Mission runs three shifts, while the other three facilities each run two shifts. Injection molding requires careful setup of time, temperature, and materials; every parts recipe is recorded in hardcopy form and stored.

Before heading to the lighting facility, attendees stopped in the metrology lab, where Peterson performs first-part inspections and ensures lights conform to regulations—typically up to 25% brighter than required by FMVSS 108—in a blacked-out, 100-ft.-long photometric tunnel.

The final stop showcased Peterson’s robot-assisted flexibility, which allows it to manufacture lights in high- and low-volume runs as needed; circuit-board production, which takes place in a temperature-controlled, static electricity-proof room; and environmental lab, in which Peterson monitors durability using a Tenney environmental tester, vibration tester, and run-time test board—where some parts have been running for more than 20 years.

“Our engineering team is constantly looking at different ways to do things— and not necessarily cheaper,” Anderson concluded. “We don’t do cheaper. We innovate. As Don Jr. says, we’re the best at what we do.

“It’s about making things more reliable and durable, and, at the same time, using more cost-effective technology.” TBB

ATA’s Spear urges trucking industry to ‘do more with less’ to overcome unprecedented challenges

By John Hitch

SAN DIEGO—It’s hard to ever call the picturesque San Diego Bay gloomy, even on an overcast October day, but the morning economic update on Oct. 27 from Bob Costello, chief economist and SVP for the American Trucking Associations, at the trucking group’s Management Conference and Exhibition, could dampen even the sunniest of dispositions. This day, Costello was the groundhog popping up to tell the crowd there would be six (or more) months of freight recession.

He attributed it to the tariffs President Donald Trump is using as a “blunt tool” to beat back years of global trade inequity. In this trade war, like in any war, “there’s going to be casualties—and it’s going to hurt, especially around U.S. manufacturing,” Costello remarked.

None of this is particularly revelatory to anyone who’s been staying abreast of the latest forecasts from trucking economists. The question is how will the industry’s fleet leaders and other stakeholders, such as truck and trailer manufacturers, respond?

Based on conversation throughout the ATA convention, many in the industry are just waiting for some daylight to break through, something to illuminate the uncertainty. Fittingly, that afternoon as the clouds burned off over the bay and convention center, ATA President and CEO Chris Spear took to the stage for his annual address to members.

Referencing Costello’s earlier report,

Spear, too, began with some hard truths.

“We are in a market situation where demand remains low…and capacity is far too high,” Spear began to the packed crowd at the San Diego Convention Center. “And while cyclical freight is not uncommon, this is the third straight year the industry is feeling the pain of a freight recession.”

The downturn is exacerbated by the chaotic political climate, where election results swing the policy pendulum wildly from one extreme to the other, not only for the economy but the regulatory environment as well.

Just last year, fleets had to prepare for federal and state emissions rules that would force them to rapidly scale zero-emission vehicle adoption. This year, under President Donald Trump, the EPA is attempting to undo more than a decade of environmental regulations.

And, next year, things could change even more—or stay the same. No one here at MCE really knows for sure. It’s left companies making, operating, and supporting the trucking industry anxious.

“With more than three decades in government relations, I have never witnessed anything close to what we’re navigating right now,” Spear noted.

ATA, though, prefers the anti-regulatory stance of the current administration, with Spear assuring its members the government is here to help trucking.

“President Trump and the Republicanled Congress have wasted zero time moving several ATA priority issues,” he asserted.

Chief among these is the attack on emissions regulations. Trump has undercut California Air Resource Board’s major