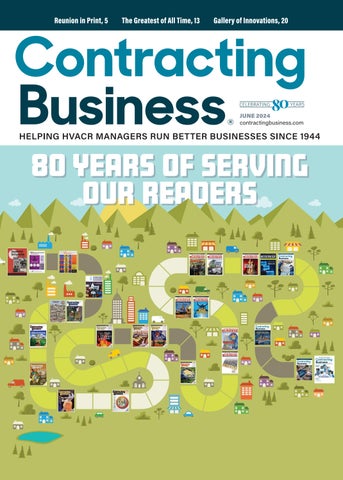

JUNE 2024 contractingbusiness.com HELPING HVACR MANAGERS RUN BETTER BUSINESSES SINCE 1944 Reunion in Print, 5 The Greatest of All Time, 13 Gallery of Innovations, 20 80 years of serving our readers

Innovative thermostats that raise the bar for connected features and value.

• Professional, contractor grade

• Residential, Commercial, and School models

• Easy to install, simple to program

• Can help reduce energy costs

• Reliable, feature rich, and better value

• Free Skyport Mobile App controls comfort from virtually anywhere

• Advanced geofencing, reporting, and alerts

Explorer Mini Explorer IAQ ColorTouch Smart. Simple. Trusted.

To find a distributor near you, visit venstar.com.

Commercial School Residential

P r o g r e s s i v e C a s u a t y I n s . C o C o v e r a g e p r o v i d e d a n d s e r v i c e d b y a f fi l a e d a n d t h r dp a r t y n s u r e r s As a small business owner, you can’t escape your to-do list. That’s why Progressive makes it easy to save with a commercial auto quote, so you can take on all your other to-dos. Get a quote in as little as 7 minutes at ProgressiveCommercial.com

Last Word | Dominick Guarino

ON THE COVER: For 80 years, we have been there, as HVACR service vehicles traveled the cities and towns of North America. We hope you’ve all had fun. Source: 54085865 © Deniscristo | Dreamstime.com, enhanced by Meg Fuschetti.

5 Reunion in Print

A recognition of the many people who have made this publication possible since 1944.

13 The Greatest HVAC Contractors of All Time

It’s not an overstatement. Read about just some of the contracting businesses who have brought comfort, safety and smart business practices to the HVAC industry over many decades of service.

20 Gallery of Innovations

From thousands of items, here are some HVACR product highlights of the past 80 years.

All OEM Systems ‘GO’

Select brand representatives provide updates on electrification, decarbonization and more.

31 Present, Propose, Close

Follow these fundamental steps to increase your closing rate and average sale ticket.

@contractingbiz

https://www.facebook.com/CBMag https://bit.ly/CBonLinkedin

Myths related to HFO and natural refrigerants can lead to uninformed decision making. Here are six myths that require clarification.

5

36 CB

Blissett

40

DEPARTMENTS 4

8

12

39

2 | CONTRACTING BUSINESS | JUNE 2024 FEATURES WHAT’S NEW? WHAT’S NEXT? 26

COLUMNISTS

First Word | Terry McIver

Influencers | David

& Joshua Crouch

What’s New Online

Products

From the Field

Ad Index

HVAC SALES

REFRIGERATION SERVICE TODAY 34 Unraveling the Myths and Facts about HFO and ‘Natural’ Refrigerants

JUNE 2024 | VOLUME 81, NUMBER 6 Connect with us: contractingbusiness.com 12

A ceiling fan with two settings: off and very very on.

Your customers have enough problems. But with a reliable, easy-to-use heating and cooling system from American Standard, they (and you) have one less thing to worry about.

Learn how to become an American Standard dealer

© 2 0 2 4 A m e r i c a n S t a n d a r d H e a t i n g a n d i r C o n d i t i o n i n g

contractingbusiness.com

New DIGITAL CONTENT

Popular Stories in Contracting Business

Issue Highlights

EMPIRE HVAC Thrives on Dependability

https://contractingbusiness.com/55018090

Trades Provide Fine Benefits

https://contractingbusiness.com/21283679

Are Your Sales Proposals Working?

https://contractingbusiness.com/21283264

News @ Press Time

Scholarship Winners

https://contractingbusiness.com/55054543

Samsung, Lennox Enter Joint Venture for Ductless https://contractingbusiness.com/55042888

Many from PHCC Visit D.C. https://contractingbusiness.com/55054669

Contracting Business Success

A Service Story to Use https://contractingbusiness.com/55040570

The 5-minute Meeting https://contractingbusiness.com/55038857

eNewsletter Update

Two Overlooked Supply Register Traits by David Richardson

Many in our industry overlook the importance of supply registers. https://contractingbusiness.com/55041328

To receive HVAC Intelligence and other newsletters, visit: bit.ly/CBnewslettersubscribe

VP/Market Leader—Buildings & Construction, Mike Hellman

Group Editorial Director

Buildings & Construction, Mike Eby

Editor-In-Chief, Terry McIver, tmciver@endeavorb2b.com

Art Director, Julie Whitty

Production Manager, Sam Schulenberg

Ad Services Manager, Deanna O’Byrne

CEO, Chris Ferrell

President, June Griffin

COO, Patrick Rains

CRO, Paul Andrews

Chief Digital Officer, Jacquie Niemiec

Chief Administrative and Legal Officer, Tracy Kane

EVP, Design & Engineering and Buildings, Lighting & Digital Infrastructure Group, Tracy Smith

Contracting Business (USPS Permit 010-480, ISSN 0279-4071 print, ISSN 2771-652X online) is published monthly by Endeavor Business Media, LLC, 201 N. Main St., 5th Floor, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI, and additional mailing offices. POSTMASTER: Send address changes to Contracting Business , PO Box 3257, Northbrook, IL 60065-3257.

SUBSCRIPTIONS: Publisher reserves the right to reject non-qualified subscriptions. Subscription prices: U.S. ($ 105.00); Canada/Mexico ($ 137.50); All other countries ($ 157.50). All subscriptions are payable in U.S. funds. Send subscription inquiries to Contracting Business , PO Box 3257, Northbrook, IL 60065-3257. Customer service can be reached tollfree at 877-382-9187 or at contractingbusiness@ omeda.com for magazine subscription assistance or questions.

Popular Online Galleries

HVACR & CB in the 1960s

https://contractingbusiness.com/5503885 HVACR & CB in the 1970s https://contractingbusiness.com/55019035

Printed in the USA. Copyright 2024 Endeavor Business Media, LLC. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopies, recordings, or any information storage or retrieval system without permission from the publisher. Endeavor Business Media, LLC does not assume and hereby disclaims any liability to any person or company for any loss or damage caused by errors or omissions in the material herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. The views and opinions in the articles herein are not to be taken as official expressions of the publishers, unless so stated. The publishers do not warrant either expressly or by implication, the factual accuracy of the articles herein, nor do they so warrant any views or opinions by the authors of said articles.

4 | CONTRACTING BUSINESS | JUNE 2024

HVAC INTELLIGENCE eNEWSLETTER

Visit the EGIA

Library

Good News! Digital Editions

Back 12

bit.ly/CBDigitalArchive

Resource

Searchable database can be found at mycontractoruniversity.com

Now Go

Years:

Reunion in Print

This is the 955th issue of the publication you know as Contracting Business. Our name has changed a few times since 1944, to signify our expanding HVACR industry coverage. We will resume our look at each decade of the magazine in the July issue, with HVACR in the 1980s.

For this official 80th Anniversary issue, I’d like to recognize those who have made this publication possible since 1944. In other pages you will find a feature presentation on the HVACR industry’s greatest contractors, and an abbreviated timeline of industry innovations over the years. Both subjects will be revisited from July and December.

June 1950. At first, our content was dominated by commercial refrigeration, but increasing content on residential and commercial HVAC was soon to come. In the coming months we will recognize leading commercial refrigeration contractors.

We remember D-Day, June 6, 1944.

I call this column a “reunion,” because I believe journalists for “the trades” feel connected to their predecessors. It’s nothing mystical, just a way of thinking. I truly wish I had met many of them. When I joined the staff in 2005, then editor-in-chief Mike Weil often spoke of the wit, wisdom and dedication of people like “Doc” Rusk and Jeff Forker, and some of the legendary contractors who helped take HVACR and CB to greater heights of excellence and awareness. But soon enough, I was speaking with and meeting some of the greats from the ’70s, ’80s and ’90s.

The first staff to produce The Refrigeration Industry in 1944 was editor T.T. Quinn and associate editor H.K. Smith, Jr. H.S. McCloud and Warren Farr were editorial advisors. They concentrated on wartime support and refrigeration systems used on the homefront, primarily in what would become “supermarket” settings. Irving B. Hexter was publisher/president.

The publication’s covers usually featured impressive photos of industrial refrigeration equipment or food processing and industrial settings.

“We have a special message to deliver to you and no special ax to grind. We are going to try to give you an interesting, timely and informative magazine that will bring you answers to some of your problems,” wrote Mr. Hexter in his welcoming editorial. He referred to

This 1994, 50th Anniversary issue cover is actually a fold-out, with the other half continuing the landscape of “Comfort City, USA,” by Robert M. Moyer. The 80th Anniversary issue cover is something of a homage to that 1994 cover.

the magazine’s leading circulation of 16,000. We still lead the industry, going to more than 38,000 print subscribers who request the publication.

By 1950, Jim McCallum, Jr. was lead editor, assisted by T.T. Quinn as managing editor. Joining McCallum at various times in the 1960s were Gordon Anderson, Warren Stevens, Earl Swaney, Scholer Banks and Henry Lefer. McCallum and Anderson were awarded multiple times for editorial excellence by the Merchandising, Trade & Export Press.

Sam Milnark served as editor in the early 1970s, with Joseph Hoffman, Jr. as publisher. Jeff Forker joined us in the 1970s, first as a managing director and later as editor and publisher. As publisher, Forker grew the publication’s sales base immensely. Others who joined in the mid- to late-1970s were Robert Mader, Bob Schwed, Dennis Orange and Don Carter.

James P. McDermott was publisher and editorial director through the 1980s. Editors progressed through different titles during this decade, including Bob Schwed, Joseph Miller, Jim Wheeler, Michael S. Weil, Dominick Guarino, Charles Reinhart, George Fodor, John Lawn, Lisa Murton and Reva Zaretsky. Notable publishers were Alex Carney and Joseph Fristik.

Bob Schwed, Joseph Miller, Jim Wheeler, Dominick Guarino, Mike Murphy and Michael S. Weil would eventually serve as editors-in-chief: Schwed in the early 1980s; Miller from the mid-1980s to March 1988; Wheeler from April 1988 to 1992; Guarino

JUNE 2024 | CONTRACTING BUSINESS | 5

FIRST WORD BY TERRY MCIVER, EDITOR-IN-CHIEF

Jim McCallum

Bob Schwed

Jeff Forker Thomas ‘Doc’ Rusk

Jim McDermott

Jim Wheeler

from September 1992 to 1998; Murphy from 1998 to November 2004, and Weil from December 2004 to September 2014. In their monthly commentaries, lead editors Wheeler, Guarino, Murphy and Weil were very adept at addressing industry issues related to business management, trade show attendance, government regulations, system performance standards, peer group networking and more. Wheeler received a Neil Award for Outstanding Journalism for a series of articles he wrote in 1990 about the then-upcoming phaseout of CFC refrigerants.

Following Mike Weil’s departure in late 2014 to join National Comfort Institute, Robert Mader served as editorial director, while also serving as editor-in-chief of Chicago-based CONTRACTOR, until his sudden death in February of 2021. Mike Eby, a veteran industry editor covering the electrical industry, succeeded Mader as editorial director of Contracting Business, CONTRACTOR and HPAC Engineering. He continues in that role today.

A Merry Band

Mike Weil and the editors who served under him make up my fondest CB memories. Mike hired me in 2005. Thank you, Mike! I came on board to work with Ron Rajecki, Valerie Stakes, Kate Kelly, Pete Grasso and our fantastic graphics designer Connie Conklin. By the way, other designers through the years were Lori Lipton; Carolyn Steinbicker; Jack Tetalman; Ashley Doles; Susan Lakin and Julie Whitty.

Gwen Hostnik, Marge Dietrich, Andrea Begany-Garsed and Steve Palmison were our fantastic administrative, marketing and Comfortech show support team.

We editors were close in age and had fun. Publisher Joe Fristik managed to put up with our occasional antics, probably because he knew we would get down to business when necessary. Joe joined Rheem in 2011, and passed away unexpectedly in March of 2015. As publisher, Joe was a master at developing and maintaining relationships with advertisers.

From Day 1 in 1944, this publication’s editors knew the value of contractor writers who had industry experience and could share it with others. One of the best from the 1960s was Art Bogen, who brought what were simple but novel ideas to the fore. Chief among them all was Thomas “Doc” Rusk, a successful HVAC contractor from Covington, KY, who believed in sharing and teaching. He was one of the first to share his accounting books during seminars to show other contractors the importance of profit and loss, overhead, inventory cycling, and so on. Rusk’s annual contractor seminars were sponsored by Honeywell.

In the more HVAC-focused decades, our best contributors have included the legendary Ron Smith, founder of Modern Air Conditioning; Tom McCart, a Smith employee and the first million-dollar HVAC salesman; Charlie Greer, a protege of McCart who wrote for us for 30 years; marketing expert Adams Hudson; consultant Vicki Laplant —“Sweetheart of the HVAC Rodeo”— who remains active as a consultant with her husband John. Charlie, John and Vicki are in our HVAC Hall of Fame, as is Matt Michel, who, like John and Vicki, was an ex-Lennox employeeturned-consultant who co-founded Service Roundtable. Tom Piscitelli shared articles on T.R.U.S.T. selling. Earlier, Tom was a Honeywell employee who helped organize Doc Rusk’s annual road shows. Earl King provided columns on commercial HVAC sales, and Dominick Guarino became our “Last Word” columnist

6 | CONTRACTING BUSINESS | JUNE 2024 FIRST WORD

Mike Weil

Dominick Guarino

Jim Norris Adams Hudson

Jon Pierce Pete Grasso

Kate Kelly Valerie Stakes Ron Rajecki Joe Fristik

Charlie Greer

Vicki and John Laplant

Mike Murphy

HVAC Comfortech

Contracting Business produced the HVAC Comfortech show from 1996 to 2016. Trade shows were nothing new, but HVAC Comfortech was something special. Jeff Forker, Dominick Guarino, Mike Weil, Bob Schwed and Ron Rajecki were all there for the first Ctech, September 4-7, 1996 in Cleveland, OH—the first and only industry-wide national residential product showcase and seminar.

What made HVAC Comfortech special was the magazine connection and seminars. Twenty first-year presenters included Matt Michel, Mike Weil, Tim Croppe, Rob Falke on air balancing business, Garry Upton, Larry Sinn, Mike Housh, Joel Williams, Mike Callahan, Don Kardux and

A show that set high standards for others to copy. Not the first industry event, but we made a difference during a fine 20-year run.

Bryce Johnson. Topics included comfort system selling, service agreements, selling IAQ, high-efficiency system sales, traits of successful contractors and technician training.

Comfortech parties were legendary, too. Emerson was among the very first brands to appreciate the value of this event, and

following his move to start National Comfort Institute with Rob “Doc” Falke, who provided us with regular columns related to home performance. Marc Sandofsky was a contributing editor on commercial refrigeration from 2000 to 2004.

had first dibs on the Opening Night Reception. Thank you, Karl Zellmer. And who can forget the various riverboat cruises whenever the show returned to Nashville?

Special twists through the years were the “Comfortech Idol” competition for mock-sales proposals and closing skills, hosted by the great Charlie Greer; and the “Comfortech Gives Back” day following the show, where volunteers would visit lowincome residents to spruce up their yards.

Matt Michel and Service Roundtable were especially supportive of the show, and brought the most contractors to the event for many consecutive years.

Watch for more reminiscing soon. —TM.

Our Quality Home Comfort Awards were another industry first that recognized excellence in HVAC home installations based on ACCA standards. Connie Conklin

ACCA Chairman Jim Norris was a special friend to whom we gave a forum as he worked to increase ACCA membership and promote the HVAC industry. Contractor commentators like Thomas “Doc” Rusk, “Skip” Snyder, Bryce Johnson, Buck St. Cyr, Jon Pierce, Robert Owens, Wallace Lee and Lee Rosenberg helped steady the ship with excellent commentaries on business development. Contractor advisors in the 1990s included John Owens, Vince DiFilippo, Alan Barnes, Steve Saunders, Larry Taylor, Ray Isaac, Lee Rosenberg, Barbara Keil, Andy Stack and at least a dozen more, and we continued to rely on contractor advisors into the 2000s under Murphy’s and Weil’s editorships.

Our “Contractor of the Year”, Design/Build Awards and Quality Home Comfort Awards all served to help revolutionize and uplift HVAC contracting by trumpeting the business and technical achievements of residential and commercial contractors.

Our “Woman of the Year” series brought more women into the conversation as business leaders. Groups such as Women in HVACR, which we provided with a space at HVAC Comfortech, have taken the baton and brought women’s achievements into the forefront of this industry. Watch our upcoming issues as I bring you more memorable highlights from this publication that you have been instrumental in supporting.

JUNE 2024 | CONTRACTING BUSINESS | 7

Earl King

Six of many contractors who provided commentaries in the 1970s and 1980s. St. Cyr, Lee, Owens, Ritchie, Edwards, Anderson.

Tom McCart Rob ‘Doc’ Falke Matt Michel

Heat Pumps

Watertown, MA, April 22, 2024— Bosch Home Comfort sources report today the brand is continuing its commitment to high-quality green living with the addition of its latest HVAC solutions: Bosch CL and RL Series Water Source Heat Pumps (WSHP). The new CL and RL Series heat pumps feature a low global warming potential (GWP) refrigerant in accordance with the forthcoming AIM Act, which will go in effect in January 2025.

Driven by industry-leading heat pump technology, the release of Bosch Home Comfort’s CL and RL Series WSHP reinforces the company’s reputation as a leading manufacturer of highly efficient, electric solution heat pumps across residential and commercial markets.

Adaptability Joins Serviceability

The single-stage unit Bosch CL Series was designed to fit most commercial replacement projects given its compact cabinet design and its quiet operations to eliminate unwanted noise. The CL Series has a swinging electrical box, a slide out blower on the vertical units, and designated compartments for high and low voltage components.

Together, these features not only improve safety conditions for technicians and installers, but also streamline routine services and repairs by offering greater accessibility to the unit’s compressor, air coils and other internal components.

The CL Series is available in vertical or horizontal units with sizes ranging from 1/2 to 6 tons.

RL Series a One-Stop-Shop for Retrofits, New Construction

The Bosch RL Series builds off the company’s legacy of unrivaled HVAC technologies in a smaller design that’s easier to service and ideal for any home HVAC upgrade or new construction project. Similar to the commercial model, the Bosch RL Series is equipped with a swinging and divided electrical box for faster and safer maintenance, as well as a slide out blower on the vertical units. Additionally, each RL Series is made with Permanent Split Capacitor Motors (PSC), which use the latest stator technology at a lower cost and a Unit Protection Module (UPM) that interfaces directly with homeowners’ thermostats to provide time delays and protect the unit against freezing of the water coil and evaporated coil.

The Bosch RL Series is available in vertical and horizontal sizes and has a one-year parts limited warranty and a five-year compressor limited warranty.

CL/RL additional features for residential or commercial applications:

• Meets or exceeds ASHRAE’s 90.1 efficiency standard

• Low GWP compliant with R454B refrigerant

• Quiet operation

• Water coil and air coil freeze protection

Brownout protection

• Copper or Cupro-nickel water coil

• Standard filter drier

• Connection between refrigerant gauges and temperature probes

For more information about Bosch Home Comfort and its product portfolio, or to join the Home Comfort PRO HVAC technician and installer benefits program, visit https://www. bosch-homecomfort.com/us/en/residential/home/.

Louvers & Dampers

Grandview, MO —Ruskin announced the BTD830 bubble tight isolation damper, the company’s newest addition to its bubble tight product series. The BTD830 is a rectangular bubble tight damper ideal for applications where extremely low leakage is required. The rectangular design offers more free area, lower pressure drops, better airflow compared to round or oval dampers, and is a lower-cost alternative to other bubble tight dampers.

Typical applications include biotech labs, food processing operations, industrial process systems, laboratories and nuclear power plants, along with medical, military and pharmaceutical facilities. The BTD830 is bubble tight according to the AMCA 500-D standard with a maximum velocity of 4,000 FPM, a static pressure of 10.0” w.g. (2.5 kPa) and a temperature range of -40°F to 250°F (-40°C to 121°C). Damper sizes range from

8 | CONTRACTING BUSINESS | JUNE 2024

EDITOR’S NOTEBOOK: PRODUCTS | COMPILED BY TERRY MCIVER

BTD830 direct-mount

BTD830 electric

Bosch CL and RL

6-in. x 6-in. (15.2cm x 15.2cm) to 36-in. x 16-in. (91.4cm x 40.6cm). The flanged dampers can be mounted for horizontal or vertical airflow, and standard or custom mounting hole configurations are available. There are many standard features and Ruskin can supply and mount actuators and limit switches as needed. www.ruskin.com

Link compatibility as of May 20 th , 2024. The addition of a Link Relay Panel allows Trane Link Communicating Systems to pair with noncommunicating 24V variable speed indoor units and provides customers with more flexibility and a lower-cost alternative to a communicating air handler or furnace, while still getting

the comfort and energy efficiency of variable-speed technology. Panel will be compatible with the following systems:

• TEM8 Air Handler

• S9V2 Furnace

S9V2-VS Furnace

• L8V1 Low NOx Furnace

• POVO Modular Air Handler.

SCHOFIELD, WI— Greenheck’s line of FEMA 361 tornado louvers has expanded with the addition of model AFL-601, the first wind-driven rain FEMA louver to be listed for AMCA 550 HighVelocity Wind-Driven Rain. Constructed of extruded aluminum with a 6-inch frame depth, the unit’s dual module design incorporates front chevron blades with rear vertical rainresistant blades for superior weather resistance.

In addition to AMCA 550, the AFL-601 is listed for AMCA 540 (Test Method for Louvers Impacted by Wind Borne Debris), Certified for AMCA 500-L Wind-Driven Rain, Water Penetration, and Airflow Performance, and boasts 43.6% free area (4 ft. x 4 ft.)—the highest in its class. AFL-601 is a UL Classified Wind-Storm Rated Assembly passing the stringent ICC 500 test standards for both structural and debris impact criteria in accordance with FEMA Guidelines P-320 and P-361. Model AFL-601 is ideal for FEMA tornado safe rooms, storm shelters, and applications in the Hurricane-Prone Region or any location where maximum protection against wind-driven rain is necessary. Louver model AFL-601 is patent pending.

Controls

Trane Technologies’ residential HVAC brands (Trane Residential and American Standard Heating & Air Conditioning) expanded Trane and American Standard

Innovative Products.

Proven Performance.

If you only think of Greenheck as a fan company, think again. We engineer and manufacture the industry’s most comprehensive line of air movement, control, conditioning, and distribution products for commercial, industrial, and institutional buildings. Our energy-efficient products keep occupants comfortable, productive, and safe while supporting sustainability. Let us help with your next project.

MY REP

FIND

2406CB_Greenheck.indd 1 4/23/24 11:07 AM JUNE 2024 | CONTRACTING BUSINESS | 9

Sources report the initial launch is focused on the XV17 lineup, however, compatibility will expand to Trane’s full Link communicating variable speed outdoor lineup later this year.

With the addition of the Link Relay Panel, certain 24V variable speed indoor products will be able to pair with the XV17 lineup, including the ability to add Trane Link functionality and connectivity to 90% furnaces

Trane

Trane Link is a next-generation communicating platform that wirelessly communicates with the Trane Diagnostics mobile app, helping to ensure installation accuracy and faster

Data Center Cooling Innovations

by Jim Magallanes

Today’s fast-paced world of data centers have forced the cooling industry to evolve. Two key trends are influencing the landscape. One being the surge of high-density equipment supporting Artificial Intelligence (AI) platforms in large data centers. Secondly, the emergence of edge computing deployments outside data center environments. These trends are changing the demands on cooling infrastructure, and inspiring the development of novel solutions.

The Rise of High-Density AI Equipment: The Challenge of Advanced Cooling

With the rise of AI technologies, data centers are experiencing a boom in high-density equipment tailored to support AI platforms. Traditionally, heat loads per rack range from 10 to 12 kW, but with AI equipment, this figure skyrockets to 50 kW and beyond. To cope with these high heat loads, data centers are moving away from traditional air-cooled systems. Liquid cooling, renowned for its superior heat dissipation, is essential to handle the thermal demands of AI equipment. As a result, various liquid cooling methods have emerged:

• Server rack door cooling

• Immersion cooling

• Direct-to-chip cooling

Liquid Cooling: Efficiency Takes a Leap

Liquid cooling is significantly different from traditional air-cooled systems. Liquid cooling offers unmatched efficiency in removing heat from racks. Server rack door cooling employs chilled liquid heat exchangers to absorb heat at the back of the rack, while immersion cooling submerges IT equipment into a bath of mineral oil. Direct-to-chip cooling brings the cooling liquid to the central processing unit’s (CPU) cold plate, focusing the cooling directly at the heat source.

Despite its effectiveness, adopting liquid cooling solutions requires substantial infrastructure investments, differing significantly from traditional air-cooled setups. Additionally, these are newer technologies so reliability is unproven, and then there’s the challenge of mitigating the risk of bringing liquid into the data center,

commissioning during the installation process of Variable Speed systems. Plus, the Trane Diagnostics mobile app accesses Trane Link’s built-in system sensors for simple configuration and diagnostics that technicians can perform with a hand-held device.

Trane Link systems are also built to be “plug and play.” Once the technician has connected the outdoor unit, indoor unit, system controller and smart thermostat, they simply need to turn on the system. The equipment will communicate and configure the system automatically to default settings. Learn more at trane.com/residential

10 | CONTRACTING BUSINESS | JUNE 2024

EDITOR’S NOTEBOOK: PRODUCTS

DENSO Edge-Cool the 2024 AHR Expo. DENSO

which can be scary to some operators. While widespread deployment of highdensity AI equipment (50+ kW heat loads per rack) is anticipated, its not predicted to be prevalent in most data centers in the near future.

Edge Computing: Redefining the Data Center

Alongside the surge in AI equipment, edge computing deployments are a popular solution to support anything from Internet of Things (IoT) devices to self-driving cars. Unlike centralized data centers, edge computing places IT equipment closer to end-users, often in unconventional spaces such as storage rooms, coat closets, or on the manufacturing floor. Edge computing brings computation and data storage closer to the source of data, this improves latency, response times, saves bandwidth, and helps meet regional data regulations. Micro Data Centers (mDC), which includes rackmount cooling, offers a flexible solution for edge computing installations. Edge computing heat loads mostly range from 2 kW to 10 kW. While rackmount air conditioners come in both air cooled and liquid cooled form factors that can easily maintain acceptable temperatures inside the server rack no matter where the mDC is located, air cooled solutions tend to be more popular because of their low cost installation.

The mDC solutions can be portable and offer remote monitoring capabilities, enabling proactive maintenance and troubleshooting, which is critical since most installations are located in remote locations without IT or Facilities support. As edge computing gains traction, rackmount cooling serves as a bridge between traditional data center cooling and the evolving needs of decentralized computing environments.

Embracing the Future of Data Center Cooling

High-density AI equipment and edge computing deployments are propelling the evolution of cooling solutions. From liquid cooling innovations capable of handling unprecedented heat loads to the versatile rackmount cooling found

in mDC solutions that facilitates edge computing installations, the industry is witnessing a shift towards efficiency and flexibility.

As data center operators navigate these transformative trends, the key lies in embracing innovative cooling solutions that strike the optimal balance between performance,

cost-effectiveness, and scalability. By staying ahead of the curve and investing in adaptive infrastructure, data centers can not only meet today’s demands but also future-proof their operations for the evolving challenges of tomorrow’s digital landscape.

Jim Magallanes is president of TechniCool Innovations, Inc. www.DENSOedgecool.com

805.566.0064 No Tools No Plastic No Problem! griplocksystems.com 60% FASTER than traditional hangers Griplock’s SMACNA TRI verified grippers require no tools to adjust, contain no plastic components, and will dramatically decrease installation time, reducing labor costs and saving you money! 2406CB_GriplockSystems.indd 1 4/26/24 1:52 PM JUNE 2024 | CONTRACTING BUSINESS | 11

If It’s Orlando in October, It’s Service World Expo!

Irving, TX—Service World Expo, a leading event for residential service professionals, including HVAC, plumbing, electrical, smart home, remodeling contractors, is excited to be convening contractors from across the U.S. and Canada for the eighth year, October 14-18, 2024, at the Disney Coronado Springs Resort®, 1000 W. Buena Vista Drive, Lake Buena Vista, FL.

Attendees can partake in a highly engaging, comprehensive agenda of industry-leading keynote speakers, breakout sessions, and business training sessions with real-world applications. New pre-conference workshops will also be available involving topics such as AI, leadership, field service management, marketing, and financing led by contractors and other industry experts. Meanwhile, hundreds of exhibitors will present the most current services and solutions to help add value to home service businesses nationwide. The numerous networking opportunities, success planning strategies, and growth mindset insights are not to be missed.

“At this year’s dynamic expo, home service contractors will hear more content than ever before on how to improve their business. The vast, majority of educational sessions are presented by contractors that have been in the trenches, including many

Innovative Tools for Temperature and Humidity

sessions focused on implementation,” said Tom Peregrino, president, Service Nation. “Our keynote presenters will bring high quality content with a lot of takeaways while our exhibitors provide great products, services, and resources to help you build your business as well.”

Contractors will have the unique opportunity to hear from keynote speakers like entrepreneur Daymond John, CEO and Founder of FUBU, and industry legend Matt Michel, Founder of Service Nation, Inc., among others. Attendees can also check out the podcast stage with leading industry influencers and enjoy evening networking events.

Registration for Service World Expo 2024 is open. Contractors receive one complimentary afternoon admission ticket to one of the four Walt Disney World® parks, redeemable October 14-18 (theme park reservation required) for each conference registration purchased before April 30, 2024. Registrations for the event can be made at serviceworldexpo.com. Additional updates and information on the show can be found through the Service World Expo Facebook and Instagram pages.

For more information, visit serviceworldexpo.com.

PHCC Visits DC Legislators

FALLS CHURCH, VA—The Plumbing-Heating-Cooling Contractors-National Association (PHCC) welcomed PHCC members, chapter executives, and corporate partners to Washington, D.C., May 21-22, to meet with lawmakers and educate them on energy, economic, and workforce policies that are important to the industry and consumers. More than 60 were in attendance. Read more about the agenda at bit.ly/phccdc24 .

Facilities Expo Expands to Reno, NV

Reno, NV—The Facilities Expo will be held in Reno, NV, August 21-22, 2024, at the Grand Sierra Resort and Casino. This addition stems from growing demand in the Reno market and positive feedback from existing exhibitors. For exhibiting information, visit www.fern.facilitiesexpo.com. For information on attending, visit https://www.facilitiesexpo.com.

M e t e r - S e n s o r f o r Te m p e r a t u r e & H u m i d i t y c a n b e u s e d w i t h o r w i t h o u t Wr i s t R e p o r t e r 2310CB_EverygreenTelemetry.indd 1 9/15/23 11:29 AM 12 | CONTRACTING BUSINESS | JUNE 2024 FROM THE FIELD COMPILED BY TERRY MCIVER, EDITOR-IN-CHIEF

The PHCC contingent for the 2024 legislative day. PHCC

Our 80th Anniversary Issue would be incomplete without acknowledging many of the true greats of the residential and commercial HVAC industry.

With apologies to so many excellent HVACR and refrigeration service companies that we could not picture in print, we share a look at many of “The Greats” of HVAC. A more inclusive collection of photos will appear online. Numbers do not indicate rank. I focused on our “Contractor of the Year” winners, and added others that are leaders in their cities and states. More will appear online.

Many of you, listed and not listed, have blazed new trails, maintained high standards, fought against lowballing fly-bynighters and are doing all you can for customers, community and employees. You also support ACCA, PHCC, RSES, EGIA MCAA and MSCA on a national level and within your local chapters.

Some we could not describe in detail: Aaron York’s Quality Air, Indianapolis, IN; AC by J, Scottsdale, AZ; Batchelor’s Service, Mobile, AL; Benson’s Heating & Air Conditioning, Tallahassee, FL; Beutler Air Conditioning & Plumbing, Sacramento, CA;Blind & Sons, Barberton, OH; Brandt Engineering Co., Dallas, TX; Climate Engineering, Corp., St. Louis, MO; Coastal Mechanical

Still Number One

The “Citizen Kane” of HVAC, Ron Smith still gets the top spot of every list of HVAC business leaders and innovators, as the founder of the modern service agreement. He started Modern Air Conditioning, Ft. Myers, FL in 1965 on $500, with no customers and no employees. He built Modern up to be one of the premier and most recognized and respected firms in the U.S. with $15 million in annual revenues (that translates to about $45 million in annual revenues in today’s HVAC industry) before selling it in 1986. Later he purchased, grew, and then sold three similar air conditioning and heating companies in Louisiana and Florida. In 1985 Ron founded Service America, based in Atlanta, GA, the first national HVAC franchiser. In 1997 he joined Service Experts in Brentwood, TN, an HVAC consolidator and public company as Chief Operating Officer and served in that position until after the company was sold to Lennox Industries. Add to that his books, company visits and trade show presentations, as proof of total commitment to helping others succeed. Ron Smith died in December 2023.

One of our best covers, for Ron Rajecki’s profile of “Leader of the Pack” Randy Seaman, who built Seaman’s AC&R on quality, integrity, honesty and fairness.

Services, Melbourne, FL; Flame Heating, Cooling, Plumbing & Electrical, Warren MI. Since 1949. Geisel Heating, Air Conditioning, Plumbing, Elyria, OH; General Heating Engineering Co., Inc., Manassas VA; Gowan, Inc./ Houston, TX, now an EMCOR Company; H.J. Ziegler, Ashtabula, OH; Jon Le Heating & Cooling, Cincinnati, OH; Hobaica Services, Phoenix, AZ; Jon Wayne Service Co., San Antonio, TX; Mechanical Systems, Inc., Salem, NH; Mediterranean Heating & Air Conditioning, Canoga Park, CA.

DiFilippo’s Service

After migrating from a small town in Italy, Domenic and Rose DiFilippo settled down in Wayne, PA and raised three children. Vince’s older brother began working in the HVAC industry and then established his own company. Vince started to help his brother with service and installations on the weekends and developed a passion for the trade. Vince bought the company in 1989 when he was 27 years old. He was an ACCA National Residential Contractor of the Year, and NCI Contractor of the Year. Laura DiFilippo has served on the Board of Directors of PA ACCA for over 20 years, serving as their first female President for 5 years. She served as ACCA National Board of Director for 13 years and was elected their chairman in 2012. She was the 2013 Contracting Business HVAC Woman of the Year.

JUNE 2024 | CONTRACTING BUSINESS | 13 THE GREATS | BY TERRY MCIVER

1. Elliott-Lewis Corp. had undergone several transitions, each of which would meet the changing economy and build on its reputation for service. Story by Dennis Sadowski.

2. Steve Andrade and A.O. Reed had just about locked up San Diego building HVAC service and new HVAC construction to the tune of $105 million in 2006. Among the team at that time were Special Projects Manager Ed Blum and Jaimi Lomas, Service Division General Manager. Story and a cool title (“California Beaming”) by Ron Rajecki.

3. Many roads lead to HVAC success. Hugh E. Joyce started James River in 1967 as a Trane Authorized Dealer. His son Hugh A. Joyce purchased the business from his dad in 1995. Hugh was the sales and marketing expert and he surrounded himself with the technical professionals who support NATE certification. Quality control and high standards are religion at James River. Story by Kate Kelly.

4. Automatic Controls Service, Inc.: In the face of adversity and change, the father-daughter team of Clifford and Terri Hardt doubled sales twice from 1985 to 1990. Others pictured: Ron Smith, Larry Hayward; Sandy Kiley; Heb Huelsmann. Story by Lisa Murton.

5. In 2001 Tom Casey, Jr. was assuming a leading role at what was then Climate Engineering, later Climate Partners, a residential leader founded by Tom Casey, Sr. “If it’s not exceptional it’s not acceptable,” was their motto. Tom Jr. and family relocated to Florida in the 2010s, where he started Griffin Service. Story by Ron Rajecki.

6. Larry Taylor joined Airrite as a partner in 1990, and later purchased the business. He restructured the company and rescued it from bankruptcy through training, service management and IAQ. He was previously at TDIndustries. Always active in ACCA, Taylor is in the CB HVAC Hall of Fame. There’s nobody nicer. Story by Valerie Stakes.

7. Barry Burnett founded B & B Heating & Air Conditioning, Inc. in Redmond, WA in 1977. By 1991, B&B Heating & Air attained annual sales of more than $15,000,000. Burnett’s vision

7 5 14 | CONTRACTING BUSINESS | JUNE 2024 THE GREATS 1

2 Mike Muckley, Mike Muckley Photography 3

Dennis Sadowski

4

Connie Blackwood

6

Scott Goldsmith/copyright

1989

8

Larry Taylor(left near vehicle) and the AIRRITE team. Reid Horn/SABA

was wide in scope, and he always followed a five-year plan. Later he would start Business Development Resources with Bruce Wiseman and Kiim Archer. Barry passed away in 2018, but his legacy lives on in BDR. Story by Mike Weil.

8. Two words described Shambaugh & Son: opportunity and drive. In 1990 it was a more than $90 million mechanical and electrical systems business. They did $30 million in process piping and refrigeration in 1988. Story by Dominick Guarino.

9. CB HVAC Hall of Fame member Mitch Cropp, second from left in the cover photo, founded Cropp-Metcalfe in 1979. Five trucks grew to 125 by 2008, with 200 employees in four locations. Mitch is considered the best example of grabbing hold of the money to be made in service agreements when the concept was still strange to many. Story by Pete Grasso.

10. Leon Lee founded Lee Refrigeration Service Co. in 1944. His son Wallace took over in 1960 and by 1966 new HVAC construction reached $400,000. 1983 sales exceeded $12 million. Wallace (left in photo) was a leading voice of wisdom throughout his career. Story by John Lawn.

11. 1991 Commercial Contractor of the Year MacDonald-Miller Industries, Inc. had the conviction required to provide customers and employees with the very best. Story by Mike Weil.

12. R.H. “Buck” St. Cyr was a true pioneer. He guided residential contractor Hallmark , which he and two others bought in 1967 into commercial contracting and later became a Linc commercial franchisee. He was ACCA’s 1986 president. Story by Joseph Miller.

13. Total Comfort. Founded by I. Ahron Katz, a combination of marketing savvy and superb customer service had guided this contractor down the road to success. It rebounded from nearfailure in 1994 to a position of leadership. Gary Katz led the overhaul, which included a new name, from A-abc Appliance and Heating to Total Comfort. Still owned by Gary and Laura Katz. Story by Valerie Stakes.

14. All Makes Heating & Air Conditioning provided the latest high-tech products and services and an unwavering commitment to personalized customer satisfaction. Story by Valerie Stakes and Ron Rajecki.

JUNE 2024 | CONTRACTING BUSINESS | 15

Don Wilson

10

Peter Grimaldi Pat Lang

9 11

13 14

Kevin Spangler, Image Makers Photography

Scott Wyberg Photography

12

Lori Adams

15. One of the nicest professionals and a visionary leader, Dick Starr was a sales engineer with a Cleveland controls company and then a mechanical contractor. He acquired Enterprise Heating & Air Conditioning in 1977, sold its residential business, and proceeded to grow its commercial controls “enterprise” as Enterprise HVAC Service & Controls. Starr was also a very active member of MSCA, was LEED accredited and community-minded. Story by Ron Rajecki.

16. Chuck and Mike Gardner would not settle for anything less than the best for their customers. Chuck started Mediterranean in 1961. Story by Bob Schwed.

17. Drew Barbosa’s childhood hobby grew into a rewarding career and successful Dallas plumbing, heating and cooling business. Drew was just a boy when he began learning about HVAC and plumbing. That developed into formal HVAC training and in 1979, Drew and his wife Janet started the Barbosa Plumbing & AC business out of their garage. Their first building was established in 1984. Drew’s and Janet’s children are also part of the residential and commercial business.

18. You could have called Jackie Rainwater, “Mr. Customer Service”. Rainwater is a 2002 CB HVAC Hall of Famer. At

Shumate Heating & AC, he brought energy upgrades to existing HVAC equipment with high-efficiency units. Jackie combined his philosophy on customer service with the sale of maintenance agreements and came up with a formula that spelled success. He provided training for more than 60,000 contractors across the USA. Story by Joseph Miller and Mike Weil.

19. Dewey Jenkins acquired Morris Heating & Cooling in 1990. Sales hit $19.4 million in 2007. The Wrench Group recognized greatness and purchased Morris-Jenkins in October 2021. They’re a fine team, with excellent TV commercials. Story by Terry McIver.

20. Gillette Air Conditioning was “Holding Down the Fort” in San Antonio and celebrating 50 years at the time of this recognition for excellence in commercial HVAC contracting. Vince Gillette, Sr. said “never break a promise”, and honesty took the company to the top. Sons Vince Jr., Tom and Ed were heirs to Vince Sr.’s tradition of excellence. Story by Terry McIver.

21. Steve Saunders is front and center, pictured with the other employee-owners of Tempo Mechanical. For Tempo anything less than complete customer satisfaction was, and still is, unacceptable. Story by Valerie Stakes.

16 | CONTRACTING BUSINESS | JUNE 2024 THE GREATS

Terry McIver

Chuck Heaton Photography

15 18 20

Tim Ryan

17 22

Drew Barbosa

21 16 19

Shelly Katz/SABA

22. 2001 Commercial Contractor of the Year Southland Industries relied on technical expertise, enthusiastic employees and a firm set of core values to reach the mountain top, and in 2024, they’re not coming down. Story written by Bob Schwed.

23. Steve Miles and Jerry Kelly paid attention to the things that matter at Jerry Kelly Co., and constant business education from trade shows has helped them remain St. Louis regional leaders. The Lewis and Clark memorial inspired the cover photo. Story by Terry McIver (his first profile for CB).

24. A steadfast determination to provide employee and customer satisfaction was the driving force behind the success of Hill York . Story by Bob Schwed.

25. Ann and Josh Kahn, the greatest mother-son team ever, still lead Kahn Mechanical. Meeting and speaking with them, you could sense their heart for customers and community. High-profile clients still include comfort cooling for DFW airport terminals. Story by Terry McIver

26. Barbara Keil learned every aspect of running a home service business at Keil Heating & AC. In 1994, she and husband Milton Baum purchased the company. Training, money-back guarantees,

marketing and concern for employee well-being were their standards. Now in its 116th year. Story by Valerie Stakes.

27. Goettl, Inc. was founded by Gust and Adam Goettl in Phoenix, AZ in 1939. During WWII they turned to manufacturing to help the US war effort. Ken Goodrich helped his father as a youngster and purchased the Goettl business in 2013. Ken is a sought-after trade show presenter, because he tells it like it is and is always willing to help contractors succeed.

28. Lee Rosenberg has served the industry as an owner, mentor, ACCA executive and all-around ambassador for smart business practices. “Know your numbers COLD” is his best advice. Lee is in the CB HVAC Hall of Fame. The first family business was Metro-Tech. The next was Rosenberg Indoor Comfort Lee, wife Betsy and son Michael Rosenberg are in it together. Rosenberg Plumbing & Air is now part of Hometown Services.

29. Isaac Heating & AC. This “low-key” company rode a wave of professionalism to the top of the HVAC industry. For years, Jim Isaac was a beacon of light to companies seeking guidance. Son Ray, front, took over and was himself a source of help for others. Now owned by TruArc partners.

Story by Ron Rajecki.

JUNE 2024 | CONTRACTING BUSINESS | 17

Terry McIver

Corbis/Sba Stuart Goley, Island Studio 28 25 29 23

Terry McIver

26 27 24

Tom Sobolik

30. Ken Haines started his first HVAC business at age 19. In 2003, he purchased Coolray, a $6 million dollar residential service and replacement business based in Atlanta. By 2015, he had taken Coolray ’s revenue to over $60 million.

satisfaction. The firm managed the HVAC Design/Build plan for Seattle Seahawks stadium. Story by Valerie Stakes.

34. New England Mechanical’s leaders knew that the future of commercial contracting was in building energy and indoor environmental services. 60% of its new construction was D/B. Now part of EMCOR Services. Story by Mike Weil.

In 2016, Haines and Coolray merged with two other amazing contractors – Paul Kelly of Parker & Sons, and Alan O’Neill of Abacus Plumbing to form The Wrench Group. Today, The Wrench Group is comprised of 28 companies across 15 states, with approximately 7,300 employees and more than 400,000 service agreements.

Ken Haines and his teams applied a new approach to consolidating, primarily to leave most of the existing operations just the way they are, familiar and trusted by loyal customers in each respective region.

31. Murphy Co. was a $183 million company that still had a family feel. From two men doing plumbing to 200 employees 100 years later. Another St. Louis leader. Story by Ron Rajecki.

32. Bob Owens of Owen’s Services campaigned to get independent contractors access to technical chiller information. They formed Chiller Systems Group, a network for the independents. Bob and son John were editorial advisors. Son Jim Owens, an avid cyclist, lost a heroic battle to cancer. John continues to support cancer research. Story by Mike Weil.

33. Since 1960, the McKinstry name has resonated excellence. This 2002 article described how it had built its Design/Build reputation for cutting edge design and tenacious customer

35. McGee Swepston purchased Ramey Manufacturing Company in the 1910s, and soon after, Butler Furnace. The name Atlas-Butler was chosen in 1934. Son Dwight was a leading source of information for the magazine, and his son Mark became a worthy successor. Still based in Columbus, O-H-I-O. Story by Terry McIver.

36. Schaafsma Heating & Cooling has survived for more than 100 years because its leaders were open to change They adopted a “retail mentality,” added new services and procedures, and basically started running the business like a business. Story by Terry McIver. More companies will appear online.

Ed. note: I credited the CB editors who wrote a “Contractor of the Year” profile, for three reasons: they proved to be total professionals; they were excellent writers; and those that I knew personally, I still consider to be a friend. I worked with Mike Weil, Ron Rajecki, Valerie Stakes, Kate Kelly and Pete Grasso. Others, such as Jim McCallum, Jim Wheeler, Mike Murphy, Dominick Guarino, Bob Schwed, John Lawn, Dennis Sadowski and Lisa Murton were before my time. Dominick continues to write our “Last Word” column. If you still have stacks of past issues, reread their articles to see what I mean. —TM

18 | CONTRACTING BUSINESS | JUNE 2024 THE GREATS

Peter Yates, SABA

Jim Shively, Larry Phillips Photography Terry McIver

Greg Wanbaugh

31 30 32 33 34 35 36

Peter Newcomb

Electrification. Decarbonization. Efficiency. Geothermal Heat Pump Solutions from limateMaster® Discover the Difference climatemaster.com

From thousands of items, here are some HVACR product highlights over the past 80 years.

1. 1851: Physician and scientist John Gorrie is issued a patent for an ice making machine, for use with patients experiencing high fevers. Despite Dr. Gorrie’s efforts, the invention is not developed due to lack of funding and support.

2. 1883: Warren Johnson patents the “electric telethermoscope,” a building temperature-control device, and travels from his Whitewater, Wis., home to Milwaukee in search of manufacturing financing.

3. 1885: Warren Johnson partners with Milwaukee businessman and financier William Plankinton to form the Johnson Electric Service Company. Within two years, his quickly growing Johnson Electric Service Company brings evenly regulated temperatures to buildings around the world.

4. 1886: The Workshop for Precision Mechanics and Electrical Bosch was founded. Pictured: Robert Bosch and associates.

5. 1913: the Trane Company was incorporated by father-son duo James and Reuben Trane. The company expanded, innovated technologies, and even assisted national programs, such as the WWII Allied Airforce and U.S. space program. In 1984, American Standard, another legacy HVAC brand, established in 1875, acquired Trane. The resulting innovations furthered the heating and cooling industries with the first variable speed hermetic compressor and the first two-stage gas furnace in the 1980s-1990s. Today, both brands, now owned by Trane Technologies, are leaders in home automation and diagnostics with Link Technology Compatibility

across the brands’ variable speed systems.

6. 1921: The Copeland brand traces its history to inventor Edmund Copeland, who founded a company in Detroit, Mich., to transform the refrigeration industry with his unique inventions.

7. 1922: Willis Carrier invents the centrifugal chiller, the innovation famous for introducing the general public to air conditioning.

1925: The Rheem Company is founded. This is one of Rheem’s first product badges.

1928: Midgley, Henne and McNary develop chlorofluorcarbon (CFC) refrigerants.

20 | CONTRACTING BUSINESS | JUNE 2024 GALLERY OF INNOVATION | BY TERRY MCIVER 8 9 Smithsonian 7 Copeland 6 Trane 5 Bosch Home Comfort 4 2 Johnson Controls 3 1

1930: Lester U. Larkin creates a new refrigeration method and apparatus for cooling units using tinned copper plates and tubes.

8. 1945: It was only our second year, and Copeland had already been a leading compressor manufacturer for 25 years

9. 1961: Among the box makers that were starting to advertise by the 1960s was Chrysler, for its Airtemp gas furnace.

10. 1960s: Honeywell T651 light duty thermostat for commercial heating and cooling.

11. 1961: The Mueller Climatrol Electric Humidifier, with no-clog needle valves and floats that will not leak or

disintegrate. A division of Worthington.

12. 1961: Larkin marketed a comprehensive line of heat exchangers, cooling towers, AC units and coils.

13. 1961: General Electric advertised its Weathertron gas, oil and electric furnaces as being made under a rigid quality control system.

14. 1967: Dunham-Bush achieved a technological breakthrough and was the first company to develop and use screw compressor technology for air conditioning and refrigeration.

15. 1970: During the energyconscious ‘70s, Trane’s many innovations included the air-cooled CenTraVac chiller, for use in water-deprived regions. A three-stage was introduced in 1982. In 1983 Trane increased its presence

by purchasing General Electric’s residential HVAC division. In 1984, Trane became a division of American Standard.

1971: Ruskin introduced the IBD2 (interlocking blade design) fire damper, which became the industry standard.

16. 1973: Rheem formed two divisions--the Air Conditioning Division producing heating and cooling products and the Water Heater Division producing water heaters .Photo: a lowprofile, single zone system for commercial and industrial applications.

17. 1975: Amprobe “Work Mates” were used to read the

“vital signs” of heating, cooling, refrigeration or freezer equipment.

18. 1975: Copeland introduced a new line of highefficiency compressors for heat pumps, at 24,000 to 62,500 Btus.

19. 1975: Robinair charging and testing units featured double “O” ring protection and a tough Teflon seat.

20. 1975: This Honeywell wiring panel was for an economizer system that brought cooler outside air into the house while exhausting inside air.

JUNE 2024 | CONTRACTING BUSINESS | 21 Chrysler 14 GE 13 Trane 15 Mueller 11 10 Larkin 12 Honeywell 20 Rheem 16 Amprobe 17 Copeland 18 Robinair 19

21. 1975: Larkin first introduced its Humi-Temp line in the 1930s. By 1975 121 models were available for low/medium temps.

22. 1977: This microcomputer-based system could control up to 120 electrical loads subject to peak demand limiting.

23. 1977: The Penn Division of Johnson Controls made a complete line of operating and safety controls for solar, gas and electric heating.

24. 1977: Ralph and Bob Liebert were marketing computer room air conditioning. Expanding technology and what was described as, “a growing

energy crisis” were providing new opportunities.

25. 1977: Sporlan type F, C and G valves covered refrigeration loads from onequarter ton to eight tons.

26. 1979: Sun Dial was a Square D Company, owned by Schneider Electric. This was their HS Series heat pump. Daffodils at no cost.

27. In 1979, “Mr. Dave Lennox” showed off the new model in the “Landmark” series, HS11, with patented Lennox two-speed compressor.

28. 1981: Imperial bending tools included single and triple head designs, with easy

90-degree starts, fixed hook, calibrated head and deep groove forming shoes.

29. 1981: Johnson Controls got mileage from its “That’s nice, Johnson!” campaign for increasingly innovative controls.

31. The Bryant Plus 90 was called, “the most incredibly quiet, efficient and reliable furnace ever.” It was meant to compete directly with “pulse-fired gas furnaces with their vibration and noise problems.”

In 1982, the Lennox PULSE furnace was quite the innovation. Its combustion assembly was unique and very efficient, up to 97% AFUE.

30. 1982: Daikin develops the first VRV system. (Variable Refrigerant Volume) . In 1990 Daikin develops the first inverter VRV system. Many additional VRV advancements follow, to today.

32. 1984: The Honeywell T8100 Chronotherm could be installed in 10 minutes or less. Programming took about 30 seconds.

33. 1985: Coleman was on its own and seeking to follow up four product lines released in 1984 with many more in 1985.

34. Daikin residential was around long before the 2000s. This multi-zone heat pump provided individual

22 | CONTRACTING BUSINESS | JUNE 2024 GALLERY OF INNOVATION Daikin Penn 21 JCI 29

25 23 Bryant 31 Lennox 27 22 30 Sun Dial 26 Liebert 24 Imperial 28

Sporlan Valve Co.

controls for different room temperatures. Multiple wallor floor-mounted indoor units could be controlled with a single outdoor unit.

35. 1987: Today you know Addison HVAC, but did you know they marketed Weather King? This was the 900+ replacement condensing unit. It was compatible with almost any coil.

36. 1987: After purchasing Janitrol, Goodman had lots of units to sell through. This ad was a homage to the unit’s various suppliers.

37. 1987: The ‘convertible’ YORK Sunline 2000 series was designed with one cabinet size regardless of tonnage or unit type. One roof curb could fit all models.

In 1989, Ruskin launched dynamic curtain fire dampers and patented true-round combination fire and smoke dampers, revolutionizing the safety and ease of damper installation.

38. 1995: Relax, it’s Rheem’s 90 Plus gas furnace, “the best we’ve ever made,” said the copy. Prior to release, it was refined based on the findings of 200 prototypes installed across the US and Canada.

1995: R-410A refrigerant comes into the picture as the eventual replacement for R22.

1995: Initially designed in response to the original Montreal Protocol, the TU expansion valve features a hermetically sealed construction. This will be useful with A2L refrigerants in 2024. It can handle A2L refrigerants without leakage,

1996: Heatcraft introduces the original Beacon Controller, a complete factory mounted refrigeration control system utilizing integrated microcomputer-based

electronic control. Beacon II followed in 2001.

39. 1996: A Rheem 36-ton rooftop unit.

40. By 1998, 10,000 Johnson Controls Metasys building controls had been installed around the world.

1999: Tridium launches the Niagara Framework building management platform.

JUNE 2024 | CONTRACTING BUSINESS | 23 YORK 37 Coleman 33 Rheem 39 Addison 35

38 34 Honeywell 32 Johnson Controls 40 Goodman 36

Rheem

41. 2002: National Refrigerants’ advertisement reports they have CFCs to last into the next century.

42. 2002: Friedrich dual-zone ductless system, up to 10.5 SEER.

43. 2002: Emerson releases Comfort Alert for home diagnostics.

44. 2002: Grasslin Controls Multi-Voltage Defrost Timer.

45. 2003: Trane XL19i released, with SEER ratings of up to 19.5.

46. 2003: Sanyo’s gas heaterair conditioner was designed to maintain a consistent performance level regardless of outside ambient temperature.

47. 2003: Goodman’s 14 SEER high efficiency split system air conditioner featured copper tube, aluminum finned coil construction and brass section.

2003: R22 production and import phase out begins. R410A becomes the preferred HVAC refrigerant, until EPA final rule of 2021, which will bring A2L refrigerants into the picture.

48. 2003: The 2003 version of Carrier’s WeatherMaker used Carrier’s environmentally friendly refrigerant Puron and operated on low capacity 80 percent of the time.

49. In 2005, the Honeywell VisionPRO 8000 was offered for commercial applications.

50. 2005: The American Standard Freedom 90 furnace and Allegience 18 air conditioner. Clever ad copy advised contractors to not sell them if they were against making money.

51. 2005: Daikin Industries Ltd. held a grand event in November to officially announce Daikin’s new US-based headquarters in Carrolton, TX. Daikin’s Variable Refrigerant Volume inverter technology offered advanced home zoning capabilities.

2006: The 13 SEER minimum efficiency standard goes into effect in January 2006.

2006: With 13 SEER in place, Emerson ships final products that support 10 SEER systems in November; begins 13 SEER communications program.

2006: Daikin releases Altherma air-to-water heat pump.

2008: Ingersoll-Rand acquires Trane. Will spin it off in 2020.

24 | CONTRACTING BUSINESS | JUNE 2024 GALLERY OF INNOVATION 50 American Standard Trane 45

49 47

Honeywell

46 48 44 National Refrigerants 41 42 43 Emerson 51

Sanyo

Terry McIver

52. 2008: Indoor Air Quality becomes more of a major category. American Standard offered the AccuClean. Others were Trane CleanEffects, and those by Carrier, Bryant, Goodman, etc.

53. 2008: Rotobrush system is an effective method of Indoor Air Quality improvement.

54. 2011: Carrier introduced the Infinity® heat pump with Greenspeed™ intelligence, using a variable speed scroll compressor.

2011: Ritchie Engineering releases Yellow Jacket SMAN3 digital manifold.

2012: Daikin Industries announces acquisition of Goodman Global Group, Inc. for $3.7 billion.

55. 2013: Danfoss acquires full owner ship of the Danfoss Turbocor compressor, the first, oil-free, magnetic-bearing compressor for HVAC.

2015/2018: Heatcraft introduces the Quick Response Controller.

2018: Ingersoll-Rand and Mitsubishi Electric Corp. enter joint venture to market, sell and distribute ductless VRF systems. US EPA issues final rule to cap and phase down HFC refrigerants. This paves the way for adoption of A2L refrigerants.

2022: Mitsubishi Electric Trane HVAC wins Global Innovation Award for its SLZKF four-way ceiling cassette.

56. 2016: Bosch Inverter Ducted Split (IDS 1.0) technology line hits the market.

57. 2018: Emerson E2 commercial refrigeration monitor.

2018: Daikin releases Daikin FIT and VRV LIFE.

2019/2021: Honeywell partners with Parker Sporlan and Trane Technologies in field tests for Solstice® N41 (R-466A) nonflammable refrigerant.

2022: Emerson sells Climate Technologies business to Blackstone for $14 billion. Copeland retakes center stage for HVAC products.

58. 2022: Daikin launches ATMOSPHERA R32 ductless mini-split system.

2023: Bosch Thermotechnology rebrands as Bosch Home Comfort Group.

59. 2023: Rheem’s Endeavor Line Prestige® Series iM heat pump (RP18AZ) has patented, industry-first features

and inverter-driven and variable-speed compressor technology, for super-efficient operation and precise temperature control.

60. 2023: Rheem® expands Renaissance™ line from 3 to 25 tons, engineered to streamline replacement jobs with exclusive industry-common footprints that eliminate new curb adapters, saving material and labor costs.

61. 2023: Chemours releases Opteon XL40, XL41 and XL20 (R454-A/B/C) as replacement refrigerants for R410A.

62. 2024: Johnson Controls re-engineers the YORK® CYK Water-to-Water Compound Centrifugal heat pump for superior operational savings and stringent sustainability standards; 3 to 5 times greater efficiency than conventional fossil fuel burning systems.

55

Danfoss

JUNE 2024 | CONTRACTING BUSINESS | 25 52 53 Carrier 54 Rheem 59 Bosch Home Comfort 56 60 57 58 YORK 62 61

All OEM Systems ‘GO’

For our Anniversary edition, we’ve expanded our ‘What’s New? What’s Next?’ special multi-part feature to include multiple industry-leading brands. They’re doing what must be done to help ensure contractor readiness for 2025.

What is the status of electrification, decarbonization and refrigerant selection among some of the leading HVAC brands? We contacted five commentators for their respective brand updates. - ed.

COMMENTARY by Chemours

Responses by Thom Hermens, Business Development, Marketing and Strategy Executive, The Chemours Company.

Contracting Business: How does Chemours feel about the status of industry preparedness for the release of A2L refrigerantfriendly HVAC systems?

Thom Hermens: Overall, Chemours feels the industry has experienced the consistent progress necessary to ensure a smooth transition into A2L technology. Most of the major boxes for preparedness have been checked. These include: the finalization of Federal regulations, the defining of industry standards, and updates to model building and fire codes. In addition, refrigerant manufacturers have production strategies in place to ensure an ample and reliable supply of A2Ls, OEMs are starting to launch their A2L products, and A2L training programs are going strong across multiple industry channels. Lastly, distributors have access to A2L service cylinders—however, as they begin to implement their A2L refrigerant management strategy, it’s important that distributors get local fire marshal approval to ensure they are compliant with NFPA-1 (2024 ed.) maximum allowable quantities for storage of A2Ls.

CB: Where do you feel contactor awareness of A2L refrigerants and the continued phasedown of HFC refrigerants falls?

TH: For about the past 3-4 years, the HVACR industry has pursued a robust strategy to heighten awareness of HFC phasedowns under the AIM Act, as well as the impact phasedowns could have on the industry as well contractors’ businesses. Efforts grew in intensity each time an additional reduction in the phasedown schedule approached to create a further sense of urgency as we encouraged contractors to prepare. The same holds true as technology transition compliance dates approach. The industry has made strong efforts to reach a wide based of contractors through various communications ranging from articles in trade publications and outreach to associations to social media campaigns, webinars, seminars at major tradeshows, and more.

Most of the major boxes for preparedness have been checked. These include: the finalization of Federal regulations, the defining of industry standards, and updates to model building and fire codes.

Similar efforts to generate both awareness of and education on A2L refrigerants paralleled HFC phasedown communications. While these efforts are also robust in their strategy, we are seeing the nature of change come into play. That is, we’ve started with the early adopters who are more open to investing the time and resources to increase their awareness and education and are steadily picking up other contractors doing the same because they realize now the transition to A2Ls is not only happening but represents a strong business strategy they will need to embrace.

CB: What is the level of contractor eagerness in taking the necessary steps to prepare for the A2L transition?

TH: I’d say one of the strongest indicators of contractors’ eagerness to prepare comes from the incredibly high demand for A2L training resources. Chemours’ senior technical trainer is averaging close to 40 weeks annually traveling across the country to present training classes and seminars. And he’s just one of our team members—we have high demand for training webinars, see strong traffic tapping into training resources on our website and social media channels, and so forth. This demand for training shows that contractors understand the need to know how to properly and safely work with A2Ls.

Contractors still need clarity in talking to their customers about A2Ls—and actually need to have those conversations. This is going to be a massive necessity for HVAC and commercial refrigeration businesses as the transition continues. When a contractor engages with a customer, they tend to talk about the topics with which they are comfortable. Right now, that comfortable topic is, naturally, the existing A1 systems they have been working with. However, by not talking about A2L equipment—including the safety of A2Ls, their environmental advantages over HFCs, their performance attributes, and so forth—contractors will quickly find themselves losing out to competitors who are talking about A2Ls. Put another way, a contactor only talking about A1s will, by default, find themselves in a “repair only business model.” They will be repairing existing systems for a fraction of the income and, possibly, lose business to companies talking about A2Ls and A1s, which find themselves in a repair and replacement business model.

Contractors need to get comfortable with both working with A2Ls and talking about these refrigerants with commercial customers and homeowners.

WHAT’S NEW? WHAT’S NEXT? | COMPILED BY TERRY MCIVER

26 | CONTRACTING BUSINESS | JUNE 2024

Exclusive to Contracting Business

CB: Does Chemours wish to comment on preparedness in terms of, specifically, storage facilities and vehicles for transport of A2Ls?

TH: We would advise contractors to reference the 2024 IFC to ensure compliance with A2L storage guidelines. In terms of transport, 440 lbs. is the total weight of all hazardous materials and their packaging that can be transported in a service van as a Material of Trade.

CB: What proactive steps has Chemours taken to help any and all groups in need of A2L information and/or training?

TH: For the past several years, Chemours has been implementing a robust strategy to increase awareness of the importance of A2L training and support HVAC technicians in having access to the resources they need to receive that training. Our training support is diverse, offering both virtual and in-person options in multiple languages and formats. We host regular webinars, train onsite both large groups and small teams of technicians, as well as keep updated training resources easily accessible on opteon.com.

COMMENTARY

by Daikin

Responses by Doug Widenmann, Senior Vice President, Marketing.

Contracting Business: Please share Daikin’s progress to date related electrification manufacturing goals and why those products will be signficicant technological developments.

Doug Widenmann: Daikin is a responsible company that believes in being a good corporate steward and improving society. We support this responsibility through the development of advanced technologies based on Daikin’s core strengths of inverter, heat pump and refrigerant management. In 2018 Daikin Comfort Technologies North America, Inc. (DNA) launched Daikin FIT, a compact, efficient, and quiet, communicating horizontal discharge ducted unitary system. These systems have been very successful for Daikin and our contractors appreciate the ease of installation and application flexibility

not to mention the comfort and efficiency they offer.

The significance of Daikin FIT is multifaceted. The units are compact, highly efficient and use significantly less refrigerant than traditional cube-style units, such as Daikin’s DZ18TC non-inverter cube style heat pump with efficiencies up to 19 SEER. This combination of small footprint which supports long term affordability concerns, superior efficiency and the dramatic reduction in refrigerant required to deliver a high-performance system are critical to meet goals as we experience a phase down in HFC refrigerants and future DOE minimum efficiency requirements.

CB: Decarbonization is of course related to electrification, but can something be provided about how you are progressing in meeting decarbonization goals?

DW: From a global perspective, from Daikin Industries, Ltd. in Osaka, Japan, air conditioners have become vital to people’s lives around the world, and yet they emit large amounts of CO2 through energy consumption during use and from the impacts of their refrigerants. As the only manufacturer in the world to produce both air conditioners and refrigerants, Daikin recognizes it has a major social responsibility.

As the only manufacturer in the world to produce both air conditioners and refrigerants, Daikin recognizes it has a major social responsibility.

Daikin formulated Environmental Vision 2050 in an effort to achieve net zero greenhouse gas emissions (carbon neutrality) by 2050. Under the Fusion 25 Strategic Management Plan, which targets fiscal 2025, Daikin has positioned “Challenge to achieve carbon neutrality” as one of its growth strategies. The target for this strategy aims to lower net greenhouse gas emissions by 30% or more in 2025 and by 50% or more in 2030, with 2019 as the base year. Using innovative initiatives reflected in this management strategy, we will develop a roadmap to net zero greenhouse gases and aim to balance business growth with these goals.

Daikin has a “Simple. Powerful. Sustainable.” approach to decarbonization that revolves around the core technologies—low-global warming potential (GWP) refrigerants, inverter compressors and heat pumps—developed to create comfortable, efficient, and sustainable spaces to live and work.

From a United States and Canadian perspective, Daikin is promoting decarbonization through advancements in fully communicating equipment with inverter heat pump technology. Daikin continues to expand its Daikin FIT heat pump product offerings which we believe provide the best solution to address the need for efficient products, alternatives to traditional fossil fuel heating systems and reduced refrigerant volume, compared to cube style R-410A systems of like capacity, which is key.

Daikin has chosen R-32 refrigerant. We believe R-32 is the best choice to realize decarbonization goals for several reasons. First, it is a proven commodity. R-32 is the global low GWP refrigerant standard with over 230 million installations worldwide. It is a simple refrigerant because it is not a blend like other A2L alternatives or even R-410A. As a pure, single-component refrigerant, R-32 can be topped off and recharged in the field, in both liquid and gas phases, without changes in composition. It is easy to clean and reuse on-site and is easy to reclaim off-site with a simple cleaning process, particularly as compared to blends with HFOs that are typically reclaimed by being distilled to their pure compounds and then remixed. It is more efficient and has more capacity than other A2L alternatives like R-454B. R-32 is readily available and is not a proprietary refrigerant.

Daikin’s Manufacturing Operations Team has a goal to achieve net zero CO2 emissions by 2030, including our Quietflex operations. Net zero emissions efforts include reductions on liquified petroleum gas (LPG), fluorinated greenhouse gases (F-gas), natural gas, electricity and diesel. Our different pillars for this strategy are based on 1) Development of stringent internal rules and standards, 2) Supporting social recognition of carbon neutrality, and 3) Technological development. Daikin has plans in place and has committed the capital investment needed to develop and

JUNE 2024 | CONTRACTING BUSINESS | 27

implement new technologies as we also adopt current solutions.

Finally, DNA is investing in refrigerant recovery. For more than a year now, through our company owned distribution channels, we have been actively recovering refrigerant from our contractors. We have established a simple program for contractors to participate in and have established aggressive targets for our sales teams to make it easy and desirable for our contractors to get paid for used refrigerant that can be recycled and reused.

CB: Please share an update on the status of Daikin’s A2L refrigerant product development related to making products available to contractors by fall/end of 2024.