TECHNICIAN CERTIFICATION FOR THE HVACR INDUSTRY \ MAY 2024 A2L TOOLS FOR NEW REGRIGERANTS UPDATED STUDY GUIDES TEACHING HVACR IN A CHANGING WORLD Training Technicians For The A2L Transition

Thanks to our dealers, Trane is unstoppable in more ways than one—earning honors as America’s Most Trusted HVAC brand 10 years in a row1. We build trust because we run together.

1Trane received the highest numerical score in the proprietary Lifestory Research 2015-2024 America’s Most Trusted® HVAC Brand studies. Study results are based on experiences and perceptions of people surveyed. Your experiences may vary. Visit www.lifestoryresearch.com. THAT’S RIGHT: 10 IN A ROW

WORD

TRAINING TECHNICIANS FOR THE A2L TRANSITION

A2L TOOLS BRING TECHNICIANS UP TO SPEED ON NEW REFRIGERANTS

UPDATED GAS HEATING, AC & HEAT PUMP STUDY GUIDES HELP TESTERS REACH NEXT LEVEL

TEACHING HVACR IN A CHANGING WORLD

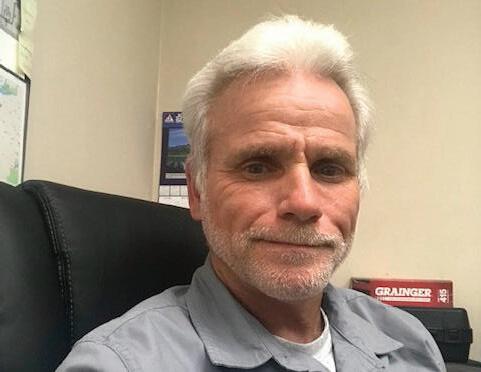

SPOTLIGHT ON NATE TECHNICIANS

Cover photo: 70415856 © David Spates | Dreamstime.com MAY 2024 NATEX.ORG 1 In This Issue MAY 2024 02 04 06 07 8 20 14 08 14 18 20 23

LETTER FROM THE NATE PRESIDENT YOU ASKED/WE ANSWERED NATE NEWS,

SEARCH PRODUCT NEWS

Promoting Continuous Education for HVACR Technicians

At NATE, we recognize that advancement and innovation within the HVACR industry hinge on the recruitment and retention of skilled technicians. That is why we are unwaveringly dedicated to fostering an inclusive and supportive environment that promotes continuous education. Our commitment extends to ensuring that all technicians have access to opportunities for learning, growth, and success throughout their careers. We work towards this goal by supporting technicians directly through our training and certification, as well as through our partnerships with contractors and educators who share our commitment to supporting technicians. Without the support of our community, our ability to assist technicians would not be the same.

In this issue, we highlight the essential collaboration between contractors and training providers in working alongside NATE to nurture and educate HVACR technicians. By emphasizing their invaluable contributions, we aim to underscore the importance of these partnerships in shaping the future of our industry.

One article features insightful interviews with educators who are preparing technicians for the A2L refrigerants transition. It explores their collaborative efforts with NATE in crafting their curriculum and the importance of providing technicians with comprehensive knowledge about these new refrigerants. The educators shed light on the importance of understanding A2L refrigerants in ensuring safety and compliance within the industry, how NATE supports their technician development, and their process of crafting their training programs to effectively impart this critical information.

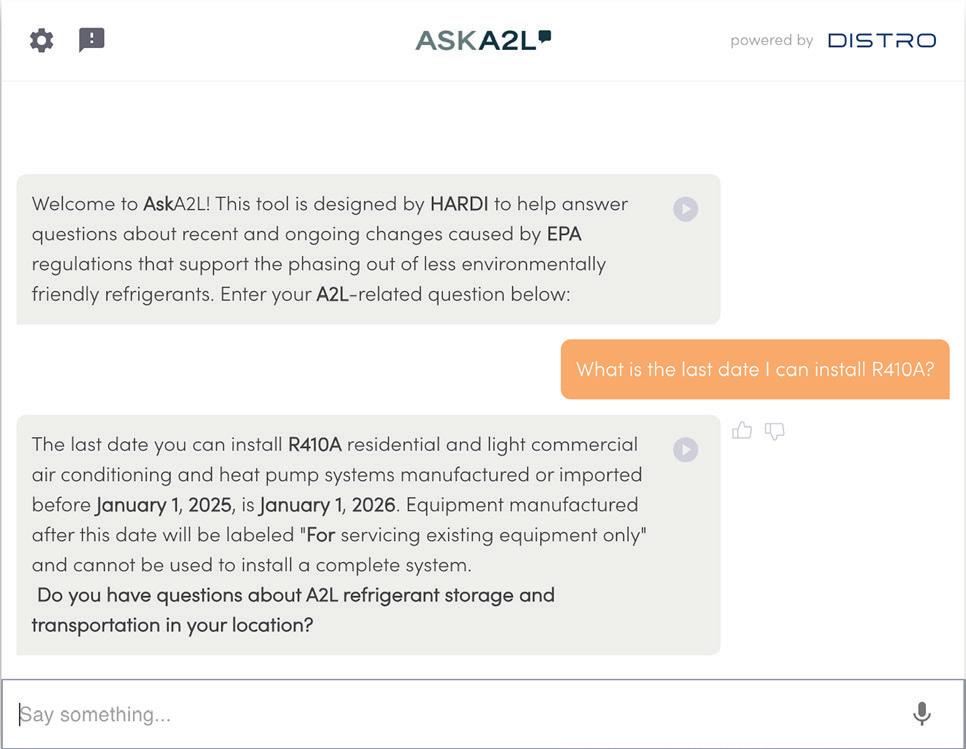

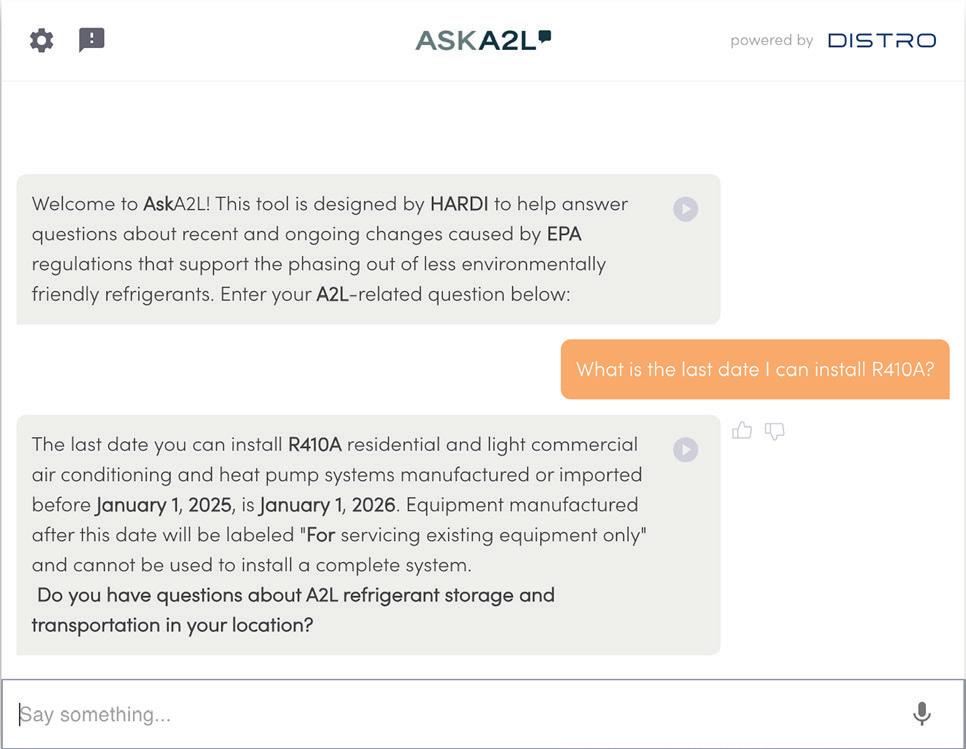

Ensuring technicians are ready for the transition to A2L refrigerants is crucial, and we take pride in the collaborative efforts of our industry partners to prepare them. You can find an article about HARDI’s partnership with Distro to develop a new online tool for technicians and contractors, AskA2L, an interactive chat that leverages artificial intelligence to produce accurate and real-time guidance on unique A2L questions.

Additionally, we are pleased to announce the introduction of updated NATE study guides. In the coming months, NATE will be rolling out an updated Gas Heating specialty exam and an AC & Heat Pump specialty exam. To support technicians in preparing for these new versions of the exams, we are releasing new editions of our study guides. These guides cover the latest material included in the exams, ensuring that technicians are equipped with the knowledge and skills necessary to excel. We are excited about these updates and confident that they will further elevate industry standards while empowering technicians to thrive in their careers.

Our whole team at NATE is continuously striving to improve the accessibility of technician training and certification. We deeply value and acknowledge the significant impact technicians have on our thriving HVACR community. We take immense pride in celebrating the accomplishments of technicians at every stage of their journey, recognizing the invaluable contributions they make to our vibrant HVACR community.

We invite you to join us in our mission to cultivate and honor the remarkable professionals who form the bedrock of our industry. Together, let us embrace the opportunities and challenges that lie ahead, empowering ourselves to drive innovation and excellence within the ever-evolving realm of HVACR. l

TRUSTEES

NATE OFFICES

2311 Wilson Blvd., #410 Arlington, VA 22201

P: 877/420-6283

F: 703/527-2316

THE NATE BOARD OF TRUSTEES

EXECUTIVE COMMITTEE

Chairman: Dave Kyle II

Trademasters, Lorton, Virginia

Vice-Chairman: Randy Roberts

Rheem, Atlanta, Georgia

Secretary/Treasurer: Jon Hirsch

Auer Steel, Milwaukee, Wisconsin

Parliamentarian: John Lanier

NATE President, COO of AHRI

Don Brenneman Portland, OR

Erica Leonor

GoodLeap, Roseville, California

Kevin Livingston

Mingledorff’s, Augusta, California

Ed McFarlane

Sila Services, King of Prussia, Pennsylvania

David Meyers

Carrier Enterprise, Indianapolis, Indiana

Terry Tanker

HVACR Business, North Ridgeville, Ohio

John Whinery

Lennox International, Plano, Texas

Rhonda Wight

Refrigeration Sales Corp., Valley View, Ohio

Steve Widhalm

Thermal Services, Omaha, Nebraska

Dean Wolffe

Johnstone Supply, Denver, Colorado

Luke Wrona

Cardinal Heating, Sun Prairie, Wisconsin

ADVISORY COUNCIL

Scott Boxer

Service Experts Heating & Air Conditioning, LLC, Lennox International, Plano, Texas

Kevin Dier

Johnstone Supply, Portland, Oregon

Laura DiFilippo

DiFilippo’s Service Co., Paoli, Pennsylvania

Don Frendberg

Phase 3 Insights, Naples, Florida

John Garvelink

Commercial Design Engineers Ltd., Colorado Springs, Colorado

Ray Isaac

Isaac Heating & Air Conditioning Inc., Rochester, New York

Wade Mayfield

Thermal Services Inc., Omaha, Nebraska

David McIlwaine

HVAC Distributors Inc., Mount Joy, Pennsylvania

Quan Nguyen

Lennox Residential, Richardson, Texas

Randy Tice

APR Supply Co., Lebanon, Pennsylvania

2 NATEX.ORG MAY 2024 PRESIDENT’S LETTER BY JOHN LANIER

ARE YOU READY FOR THE A2L TRANSITION?

NATE Low-GWP

Refrigerant Certification

The Industry's Refrigerant Certification

Low-GWP refrigerants have different safety standards and can be more difficult for technicians to work with. NATE can help you ensure your technicians have the proven know-how to work safely and effectively on these more difficult refrigerants.

NATE is proud to offer a new refrigerant certification, designed to ensures technicians have the necessary skills and job knowledge to handle refrigerants of all types, with a strong emphasis on the safe handling and use of A2L refrigerants

Study Guide and Online Courses Available

www.NATEX.org/lowGWP

You Asked, We Answered

QUESTIONS ASKED BY NATE-CERTIFIED TECHNICIANS, ANSWERED BY THE NATE TEAM AND SHARED WITH YOU.

WHAT STEPS IS NATE TAKING TO SUPPORT CONTRACTORS AND TECHNICIANS IN PREPARATION FOR THE UPCOMING A2L REFRIGERANT REGULATION CHANGES?

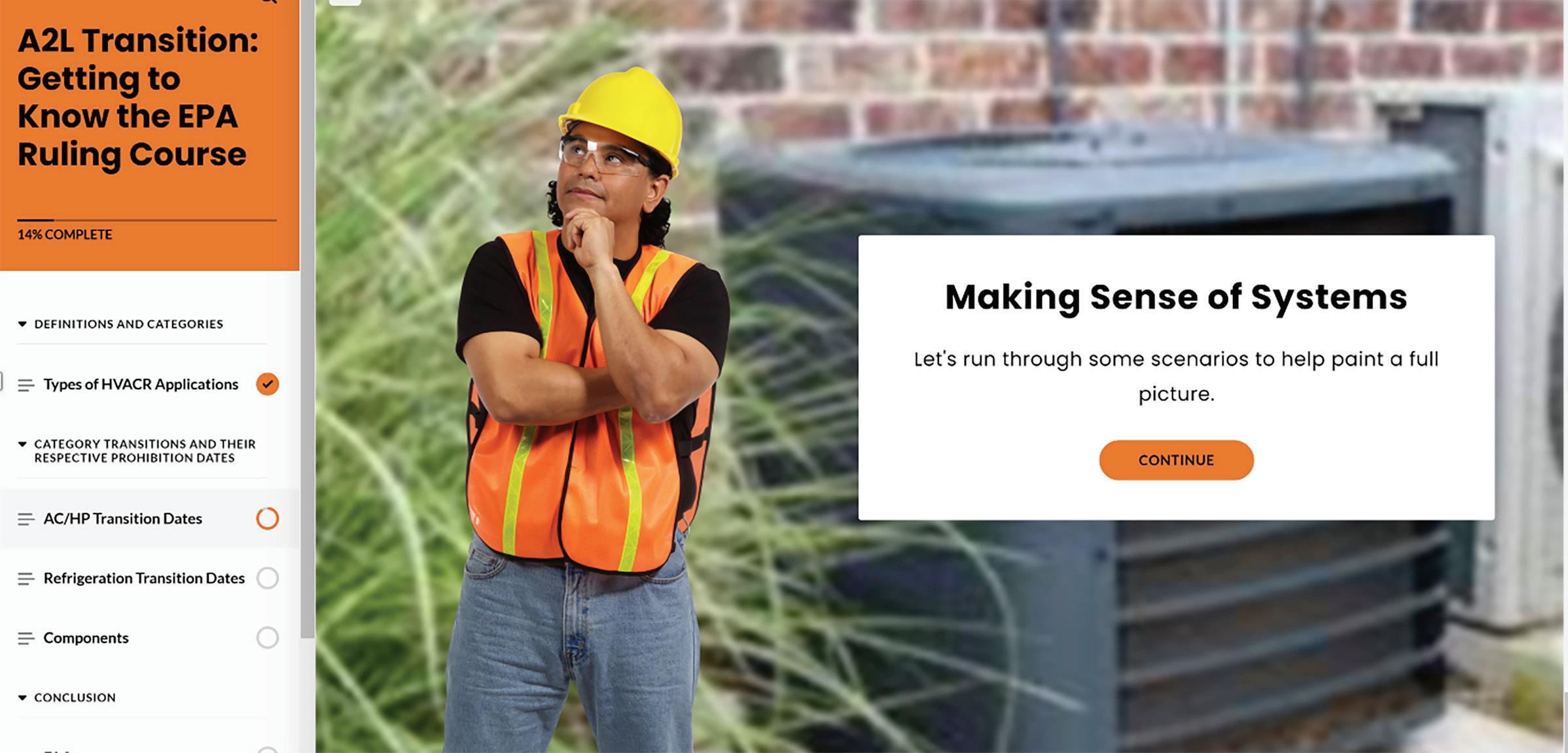

NATE is proud to offer a Low-GWP Refrigerants Certification exam, designed to ensure that technicians have the necessary knowledge and skills to handle these new refrigerants safely and effectively.

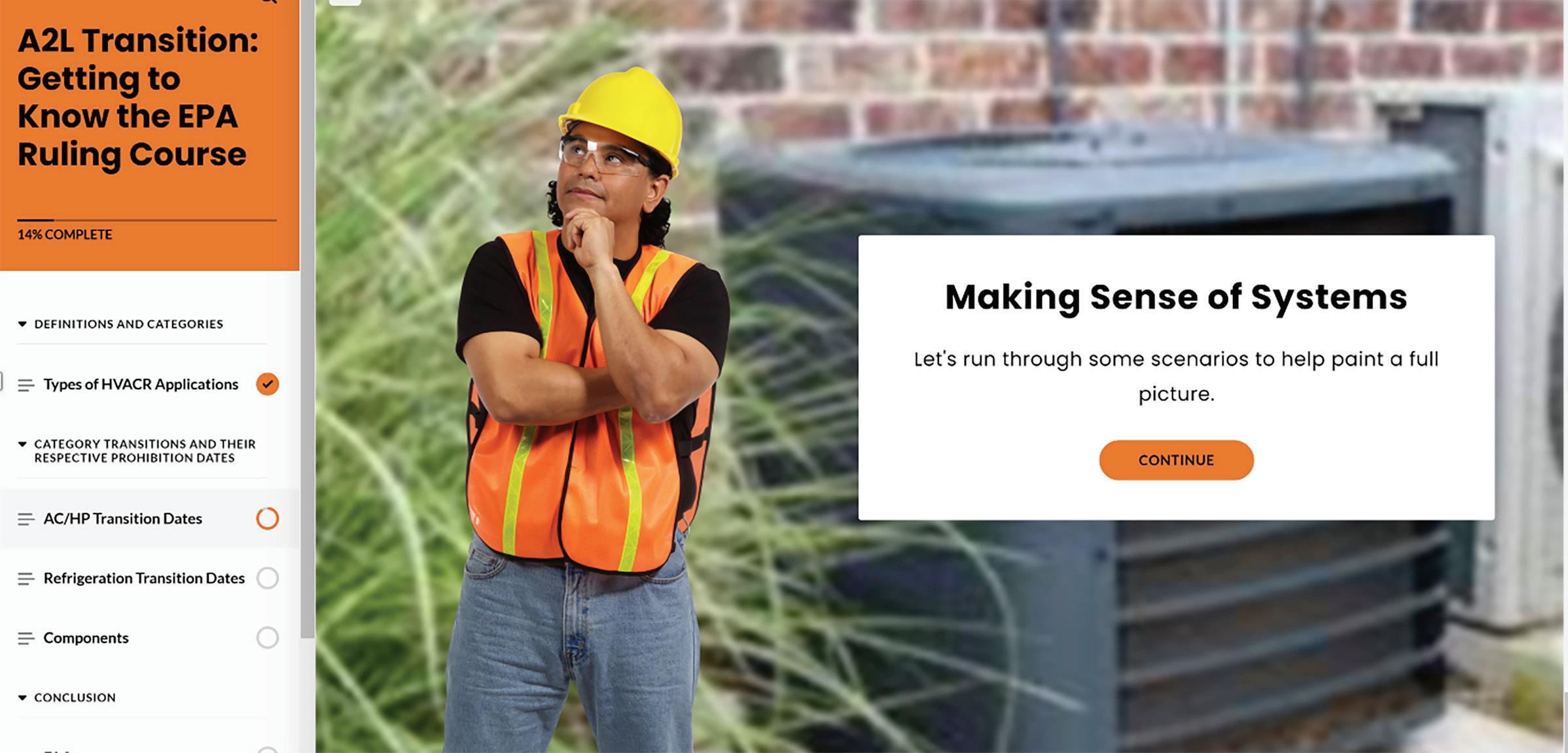

Additionally, we have several resources to help technicians prepare for the A2L refrigerants and their Low-GWP Refrigerants certification. NATE has partnered with Interplay Learning to create NATE Training Academy, an online platform designed to provide technicians with a way to train for NATE certification exams online at their own pace. The Low-GWP course is tailored to cover a spectrum of key topics, ranging from differentiating types of refrigerants based on GWP to installation and service best practices. NATE-certified technicians can earn continuing education hour (CEH) credit by completing the course.

We also offer a study guide to help technicians prepare for the exam. The paperback guide includes lots of graphics and practice questions at the end of each chapter. The guide is available for purchase in the NATE online store.

The comprehensive online courses are all available on-demand and can be taken at any time. You can find more information about NATE Training Academy’s Low-GWP Refrigerant exam, NATE Training Academy, and NATE study guides at www.NATEX. org/lowGWP. Together, let’s navigate these changes with confidence.

WHAT ARE THE DIFFERENT WAYS TECHNICIANS CAN BECOME NATE-CERTIFIED?

NATE now has two certification pathways for HVACR technicians, the Certified HVAC Professional (CHP-5) and the Traditional Pathway. By offering two different ways to earn NATE certification, technicians can

Have a question for NATE? Please email us at asknate@natex.org!

choose the pathway that aligns best with their individual preferences and learning styles.

NATE’s goal with the CHP-5 is to offer technicians different pathways to NATE certification so they can choose the exam pathway that best fits their level of experience and learning style. With the CHP-5, technicians can earn their NATE certification through a series of five 30-question exams, each on a different subject domain: HVAC Fundamentals, Electrical and Controls, Comfort and Airflow, Installation, and Service. Technicians can take the exams in any order they choose and can take up to six months between each exam to study and prepare.

The NATE Traditional Pathway consists of the 50-question Core Exam and a 100-question Specialty exam. This pathway presents technicians with a choice of 13 specialty exams, with a focus on either installation or service-oriented specialties. These certification pathways reflect NATE’s commitment to providing comprehensive and accessible avenues for technicians to demonstrate their expertise in the HVACR field. For more information on how to become NATE-certified, email us at askNATE@natex.org .

CAN I OFFER NATE EXAMS AT MY OFFICE?

You can administer NATE exams at your office by becoming a NATE Testing Organization. As a Testing Organization, you can set your own exam times to best fit your company’s schedule. To register, you must complete a free NATE Testing Organization application. The application is available online at www.NATEX.org

To become a Testing Organization, you must employ at least five technicians, have an individual who can register and act as proctor for the exams, have the ability to conduct at least one test session per year, and have space, such as a training or meeting room, to conduct exams. For more information, reach out to us at askNATE@natex.org .

Mike Hellmann, Director Building Infrastructure mhellmann@endeavorb2b.com, 978-289-0098

Mike Eby, Senior Director of Content—Buildings meby@endeavorb2b.com, 913-209-9884

Steve Spaulding, Editor-in-Chief—CONTRACTOR sspaulding@endeavorb2b.com, 702-848-4703

Terry McIver, Director of Content—Contracting Business tmciver@endeavorb2b.com, 216-346-8978

Contributors: Michael Keating, Neal Lorenzi, Terry Persun, and Elaine Yetzer Simon

Joe Agron, Sales Manager jagron@endeavorb2b.com, 941-200-4778

Bill Boyadjis, Account Manager, Midwest bboyadjis@endeavorb2b.com, 973-722-2048

Brian Sack, Senior Manager, Business Development, East + Northeast bsack@endeavorb2b.com, 732-629-1949

Randy Jeter, Senior Manager, Business Development, South & West rjeter@endeavorb2b.com, 512-263-7280

David Sevin, Key Account Manager dsevin@endeavorb2b.com, 401-246-1903

Jay Thompson, Account Sales Manager jthompson@endeavorb2b.com, 913-707-0468

Steve Suarez, Media Account Executive ssuarez@endeavorb2b.com, 816-588-7372

Beverly Beckert, Endeavor Business Media Marketing Solutions bbeckert@endeavorb2b.com, 941-208-4308

Greg Araujo, Senior Production Operations Manager garaujo@endeavorb2b.com; 941-203-3722

Randy Schirz, Art Director, 773-259-7253

4 NATEX.ORG MAY 2024 QUESTIONS BY NATE STAFF AHRI IBC American Standard A/C 5 Daikin Comfort Technologies BC Fieldpiece Instruments Inc. 16 Hodes 11 NATE 3, 13 Trane Residential IFC Printed in the U.S.A. Copyright © 2024 by Endeavor Business Media

Some outlets are more convenient than others.

Your customers have enough problems. But with a reliable, easy-to-use heating and cooling system from American Standard, they (and you) have one less thing to worry about.

Learn how to become an American Standard dealer

© 2 0 2 4 A m e r i c a n S t a n d a r d H e a t i n g a n d i r C o n d i t i o n i n g

NATE News

NATE CERTIFICATIONS RECOGNIZED BY THE DEPARTMENT OF ENERGY

The U.S. Department of Energy (DOE) and Pacific Northwest National Laboratory (PNNL) have formally acknowledged the excellence of NATE’s Heat Pump Installation Specialty and Heat Service Specialty certifications, designating them as “Energy Skilled” in the categories of Heat Pump Installation and Heat Pump Comfort Advisor roles. This recognition is a result of NATE’s partnership with the DoE’s effort to upskill the HVACR workforce and Heat Pump training.

The DOE built this program to distinguish credential programs as leaders in preparing workers for meaningful and in-demand job opportunities. Recognition as Energy Skilled signifies that training programs and certifications align with clean energy transition goals. For more information about the DOE’s Energy Skilled recognition program, visit their website: bsesc.energy.gov/recognition.

MARK YOUR CALENDARS! ROUND 1 OF THE SERVICETITAN HVAC NATIONAL CHAMPIONSHIP CLOSES JUNE 15

Calling all HVACR technicians: The online quiz for Round 1 of the ServiceTitan HVAC National Championship is swiftly approaching its closing date on June 15. This crucial stage of the competition, featuring a 5-minute digital quiz with questions provided by NATE, offers technicians the chance to showcase their expertise and compete against the industry’s finest.

Technicians can enter the quiz as many times as they would like. The top apprentice and professional who score the highest each month will automatically qualify for Round 2. The technicians that have what it takes to make it through two qualifying rounds will receive an all-expense-paid trip to West Palm Beach, Florida, to compete for a share of over $100,000 in cash and prizes.

NATE encourages technicians to put their skills to the test and vie for the title of the 2024 Champion. Don’t miss out on this opportunity to compete against the industry’s finest. Mark your calendars and make sure to complete the Round 1 quiz before June 15 to stay in the running for the ultimate prize! Visit http://www.HVACNationals.com to enter the competition.

DAVID KYLE II – NEW CHAIRMAN OF NATE BOARD OF TRUSTEES

NATE is pleased to announce David Kyle II as the new Chairman of the Board of Trustees. Dave is the president and CEO of Trademasters Service Inc., a full-service HVACR contractor in Lorton, Virginia. He founded Trademasters over 30 years ago, and today the organization is an award-winning small business contractor with a nationwide presence. David Kyle II succeeds Quan Nguyen, who concluded his two-year term this past March.

Additionally, NATE welcomes several new members to the NATE Board of Trustees: Erica Leonor from GoodLeap LLC, Kevin Livingston from Mingledorff’s, and Dean Wolfe from Johnstone Supply Denver. Their expertise and passion for the industry are invaluable assets as we continue to lead the way in setting industry standards and fostering excellence. NATE is honored to have such accomplished individuals join our team, and we look forward to their contributions in shaping the future of HVACR.

Word Search

CORRECTION: On page 23 of the February issue, www.americanstandardair.com is the

6 NATEX.ORG MAY 2024 NATE NEWS BY NATE STAFF

American Standard. 1. Compressor 2. Evaporator 3. Training 4. Refrigerants 5. Safety 6. Equipment 7. Coil 8. Ductwork 9. Heat 10. Educator 11. Innovation 12. Partnership 13. Excellence 14. Unit 15. Regulation 16. Skills

URL for

Product News

AMERICAN STANDARD

The new American Standard Silver 15 SEER2 heat pump features the lower global warming potential R-454B refrigerant ahead of the Jan. 1, 2025, federal regulation deadline. American Standard’s units with the new A2L refrigerant include industry-leading refrigerant detection sensors that provide a patent-pending installation clip that lets them easily snap onto the side of the pan. When using this sensor, the unit can detect if there is a refrigerant leak.

Available in 1.5- to 5-tons, it has a fixed-speed ECM motor. It has a heating season performance factor (HSPF) of up to 8.5 HSPF2 if used as a heat pump.

American Standard Link can run and verify each mode of operation as well as verify that the overall system is functioning properly. This automatic verification provides two reports—a detailed Dealer Verification Report and a summarized Homeowner System Report, providing peace of mind to the customer.

americanstandardair.com

DAIKIN

Now re-engineered with R-32 lowGWP refrigerant, Daikin ENTRA wallmount systems provide an affordable, cost-saving solution for energy-efficient comfort control. Featuring streamlined, wall-mounted indoor units paired with compact, quiet outdoor units, Daikin ENTRA delivers excellent efficiencies, up to 18 SEER2 and 9 HSPF2. And pure, single-component R-32 is easy to top off, clean, and reuse on-site, or reclaim and recycle.

Simple to install, single-zone Daikin ENTRA provides an indoor comfort solution for primary living areas, rooms with poor air flow, renovations, basements, attics, garages and additions. Unobtrusively quiet, Daikin ENTRA runs as low as 25 dB(A) indoors and 46 dB(A) outdoors.

It’s feature-packed, including a titanium apatite photocatalytic air purifying filter; backlit wireless remote controller; Program Dry, Eco+, and Powerful Operation modes; auto fan speed control; hot start function; self-diagnostics with digital display; auto-restart after power failure; automatic defrosting; and anti-corrosion heat exchanger treatment. Available in 0.75 to 2 tons. daikin.com

TRANE

The 120V Modular Variable Speed Air Handler from Trane makes the conversion simple for customers who want to move away from a gas furnace and air conditioner to a high-efficiency, all-electric heat pump system. Industry-leading features include the patented Vortica™ II blower and variable-speed blower motor with Comfort-R™ humidity control; exclusive AirTite™ design ensures maximum efficiency and savings on your energy bills. In addition, it is designed with inputs directly from Trane dealers to ensure the air handlers are easy to maintain and repair. The unit’s blower motor housing sits on rails, making it easy to remove and replace. Available in 1.5- to 5-tons. It contains an ECM variable speed motor. trane.com

MAY 2024 NATEX.ORG 7

BY NATE STAFF PRODUCT NEWS

Training Technicians for the A2L Transition

NATE CERTIFICATION HELPS TECHNICIANS DEMONSTRATE THEIR KNOWLEDGE OF GREEN, SUSTAINABLE REFRIGERANTS.

When the American Innovation and Manufacturing Act (AIM Act) passed in 2020, it started the gradual phase-down in the production and consumption of listed hydrofluorocarbons (HFCs). The alternative refrigerants being used, including A2Ls, have additional safety concerns such as flammability.

NATE offers the Low-GWP (global warming potential) certification exam covering A2L refrigerants. Certification addresses these new safety concerns by ensuring techni-

8 NATEX.ORG MAY 2024

A2L TRANSITION BY MICHAEL KEATING

BY MICHAEL KEATING A2L TRANSITION

cians have the skills and job knowledge necessary to use these new refrigerants safely. NATE’s offering provides a strong emphasis on the safe handling and use of these new refrigerants.

To help technicians prepare for the LowGWP transition, NATE offers a variety of training resources. Technicians can take advantage of NATE’s paperback study guides and online training platform, NATE Training Academy. For technicians that are looking for in-person training opportunities, they can take courses with NATE’s Recognized Training Providers (RTP).

NATE RTPs are organizations with established training courses that have worked with NATE to ensure their curriculum covers the Knowledge Areas of Technician Expertise (KATE) for the Low-GWP Refrigerant Certification Exam. Manufacturers, wholesalers and distributors, contractors, trade associations, and educational organizations from across the HVACR industry participate in NATE’s RTP program. By taking courses with training providers with NATE-recognized course content, technicians can ensure they are not only prepared to pass the Low-GWP Refrigerant Certification Exam but also ready to meet the evolving demands of the HVACR industry.

One supporter of NATE and its Low-GWP refrigerant certification program is Don Gillis, senior technical trainer, The Chemours Company, a NATE RTP. Gillis’ firm has begun taking orders from North American customers for its Opteon XL41 (R-454B) hydrofluoroolefin (HFO) refrigerant. The product is an R-410A replacement in new air conditioning and heat pump applications. It offers zero ozone depletion potential (ODP) and an approximate 78 percent reduction in GWP when compared to R-410A (AR4 GWP).

Gillis explains that NATE certification can help technicians as they prepare for the A2L refrigerant transition. “I love the NATE program, and all Chemours’ courses meet requirements as preparation to take NATE certification exams. NATE is a great resource for A2L training—and it is training I’ve taken. The courses are up to date with the latest information to help technicians make a smooth transition into A2L refrigerants.”

For the past several years, Gillis says that Chemours has been implementing a robust strategy to increase awareness of the importance of A2L training. His company has also helped support HVACR technicians gain access to resources they need to receive that A2L training. “Our instructional support runs the gamut, including everything from us hosting training webinars to cast a wide net as well as going onsite to train large or small groups of technicians.”

“I LOVE THE NATE PROGRAM, AND ALL CHEMOURS’ COURSES MEET REQUIREMENTS AS PREPARATION TO TAKE NATE CERTIFICATION EXAMS.”

– Don Gillis, senior technical trainer, The Chemours Company

“NATE is very important to the industry, and NATE’s Low-GWP Refrigerants Certification Exam provides validation that a technician is proficient when it comes to explaining, designing, and working with Low-GWP refrigerants,” says Benjamin S. Middleton, national sales training manager at Daikin Comfort Technologies North America, Inc.

Middleton says Daikin offers training for HVACR technicians and others in preparation for the A2L refrigerant transition. Additionally, as a NATE RTP, Daikin has had its technician courses recognized by NATE. “We have live training options, virtual reality (VR) training, and prerecorded content geared towards technicians and Comfort Advisors.” Students in the Daikin A2L training initiative include business owners, sales professionals, installers, and service technicians.

The Daikin executive says it is crucial for HVACR technicians to learn about A2L refrigerants. “From a service and installation standpoint, there is not much difference between A1s and A2Ls. However, there are differences when it comes to storage and transportation, and you need to make sure that your tools are compliant.” (Tool compliance is directed by the tool manufacturer and not through regulation.)

Popular refrigerants that possess a much higher GWP, such as R-410A, R-22, and R-407C, are classified as A1 refrigerants, which mean they are identified as having “no flame propagation.” A2L refrigerants are slightly more flammable.

NATE certification on A2L Low-GWP refrigerants can provide benefits for technicians and end-users alike says Lenny Diaddario, manager, contractor services at Copeland, a global provider of sustainable climate solutions, including Low-GWP refrigerant options. The company offers products in compression, controls, software, and monitoring for heating, cooling, and refrigeration.

MAY 2024 NATEX.ORG 9

“TECHNICIANS ARE AT THE FRONT LINES OF THE REFRIGERANT TRANSITION, SO MANY CONTRACTING COMPANIES WILL SEND THEIR TEAMS FOR TRAINING.”

– Lenny Diaddario, manager, contractor services, Copeland

Diaddario identifies two key benefits to certification:

1) It gives technicians the confidence, knowledge, and training they need to stay competitive and offer their A2L expertise.

2) It provides end-users with peace of mind knowing they have access to a qualified service network needed to make the transition to new refrigerant and system technologies.

Diaddario says Copeland offers a wealth of instruction on the refrigerant transition: “Our Educational Services team is conducting in-person and online A2L training seminars as part of its ‘Fit for the Future’ training initiative. Its objectives are to prepare service technicians with the fundamentals needed to safely install, service, and recover A2L refrigerants.”

The audience for Copeland training is broad, Diaddario explains: “Technicians are at the front lines of the refrigerant transition, so many contracting companies will send their teams for training. We also have retail end-user and original equipment manufacturer (OEM) customers enroll so they can familiarize themselves with the nuances of working with A2Ls.”

IT’S ALL ABOUT TRAINING

There’s no shortage of training at Carrier, says Jim Price, technical training center manager, Carrier: “A2L competency is a critical component of a successful installation; therefore, we offer A2L- and R-454B-specific online training through our learning management system (LMS), My Learning Center. Additional R-454B training is integrated into our hands-on training offered at the My Learning Center Technical Training Center in Indianapolis, Indiana.”

The change process for refrigerants has been on-going, according to Price. “The new requirements for refrigerant transition,” he says, “are almost entirely rooted in proper refrigerant

practices that have been in place for several decades.” Price’s take on certification?

“NATE-certified technicians are often more familiar with industry regulations, best practices and, in turn, can provide homeowners peace of mind.”

Price says a variety of students take Carrier’s A2L refrigerants classes: “The industry transition impacts everyone in the field. Our students range from upcoming technicians to longtime HVACR tradesmen and women, to distributors looking to get a better understanding of what’s coming down the pipeline. We highly encourage everyone in our channel to participate in training in advance of 2025.”

Price notes that the Carrier training keeps learners aware of changes in the industry: “Our online courses are designed for students that need baseline knowledge of regulation and refrigerant standards; however, most students are technicians that are interested in ‘getting ahead of the curve.’” He adds, “Our students don’t want to be surprised by what they encounter in the field.”

Multiple training tools are in place, Price explains: “At Carrier, we have developed a variety of easily accessible resources to keep our technicians informed of the latest developments and regulations regarding A2L. From social media series to newsletters and e-communications, we are diligent about consistent communication as the industry shift nears. Our information sources help inform A2L training curriculums as we gather feedback and identify recurring questions not currently addressed in training.”

The HVACR industry needs to prepare technicians for changes coming to equipment and servicing, says Chris Rich, district service coordinator-GA at Dealers Supply Co. The firm is a wholesale distributor of heating, ventilating, and air conditioning equipment, supplies, and accessories. He notes, “I see in my classes that about half of the contractors are totally unaware of the changes brought on by the A2L refrigerant transition.”

“THE NEW REQUIREMENTS FOR REFRIGERANT TRANSITION ARE ALMOST ENTIRELY ROOTED IN PROPER REFRIGERANT PRACTICES THAT HAVE BEEN IN PLACE FOR SEVERAL DECADES.”

– Jim Price, technical training center manager, Carrier

10 NATEX.ORG MAY 2024

A2L TRANSITION BY MICHAEL KEATING

BY MICHAEL

Rich says he offers a comprehensive overview in his Dealers Supply classes. “I will start with an overview of the M-M1 (Minimum efficiency standard to M1 minimum efficiency standard) changes and then an overview of how and why we are changing to the new A2L refrigerants. Then, we cover myths and facts on the A2L refrigerants and proper install and service procedures. In addition, we discuss changes in equipment and tools. In the classes we cover safety thoroughly on working with the A2L refrigerants.” A wide cross-section of professionals attends Dealers Supply A2L classes. “The majority are contractors that are our customers. We are also educating our sales staff and warehouse counter sales teams,” Rich explains.

“IT’S A DIFFERENT WORLD TRYING TO TEACH SOME YOUNGSTERS. SOME OF THE FOLKS COMING OUT OF HIGH SCHOOL DON’T KNOW HOW TO READ A TAPE MEASURE. IT’S A LEARNING CURVE. WE MAY HAVE TO ADJUST OUR TEACHING APPROACH TO ADAPT.”

– Greg Creel, training analyst, Alabama Power’s HVAC Training Center

Regarding the transition, Rich observes that information on the safety concerns are being spread incorrectly. “I see that most professionals,” he says, “think that the new A2L refrigerants have a propane base and are highly flammable. We are having to correct all these misconceptions as much as actually teach the facts.”

A2L refrigerant training for technicians is especially important for today’s workforce, Rich believes. “This is due to the fact that the newer generation of service technicians is lacking in practical experience and skills. These skills include soldering, brazing, and torch use around these refrigerants. Proper instruction, therefore, becomes critical. It becomes very important to have training on using brazing equipment around a flammable refrigerant.”

On the subject of training the newer generation, Greg Creel, a training analyst at Alabama Power’s HVAC Training Center in Jasper, Alabama, offers this thought: “It’s a different world trying to teach some youngsters. Some of the folks coming out of high school don’t know how to read a tape measure. It’s a learning curve. We may have to adjust our teaching approach to adapt.”

The HVAC Training Center does a one-day review covering all aspects of Low GWP Refrigerant Safety-A2L Refrigerants. Creel says there is a mix of older and younger technicians who take the center’s review session. The center conducts a variety of classes, including NATE Review and Testing and sessions on the EPA Section 608 Review and Testing.

“We train at the highest level for our dealer base, to ensure the end-user is getting an informed technician (with current information) on their site to resolve their HVACR issues,” says Bruce O. Davis, technical support advisor at Koch Air, one of the oldest Carrier distribu-

tors in North America. The company provides residential and commercial HVACR equipment as well as parts and supplies from 11 locations across the Midwest.

Davis’ team currently conducts R-454B (Puron Advance, an A2L refrigerant) training to the Koch Air dealer base.

“We want to make sure all service personnel are fully up to date with our industry standards,” Davis explains.

MAY 2024 NATEX.ORG 11

KEATING A2L TRANSITION 2405CB_Nate_Hodes_MKPL.indd 1 3/27/24 10:38 AM

“ABSOLUTELY SPEND THE TIME AND MONEY NOW FOR TRAINING. SMARTER, SAFER WORKERS PAY FOR THEMSELVES IN LESS DOWNTIME AND HIGHER SAFETY LEVELS FOR ALL INVOLVED IN YOUR BUSINESS. IT JUST MAKES BUSINESS SENSE!”

– Greg Guse, director of engineering for Ritchie Engineering Co.

Davis believes all distributors and manufacturers are doing their part in getting the information out on the A2L refrigerant transition. He adds that the dealer base “has an obligation to the end-users (home owners) to make sure they have a well-trained staff that will be able to work confidently and safely with this new refrigerant in our industry.”

MORE MANUFACTURERS WEIGH IN

Greg Guse, director of engineering for Ritchie Engineering Co., has been involved in training in several ways. His firm is a worldwide supplier of U.S.-designed and manufactured tools and equipment with its Yellow Jacket brand.

for themselves in less downtime and higher safety levels for all involved in your business. It just makes business sense!”

Trane and American Standard both provide training for HVACR technicians in preparation for the A2L refrigerant transition, says Eric Weiss, technical trainer, Trane Technologies Residential Solutions. “Our dealers and technicians have access to our one-hour eLearning course, or they can attend live training that is delivered by the local factory tech representatives. We have approximately 220 across the U.S. and Canada.”

The transition to A2L refrigerants provides the opportunity to discuss safe handling refrigerant practices in general. Weiss offers one safe practice example: “Technicians should always cut out refrigerant components rather than unbraze; this practice applies to all refrigerants—not just A2Ls.”

Weiss offers this advice to HVACR contractors and others in the building comfort industry that are considering investing in A2L refrigerant training for their technicians: “Realize that whatever training they attended is likely to change a little over the next few years. Continue to attend training, review updates in the manufacturers’ literature, and be ready to manage these small changes.” l

FOR MORE INFORMATION

To learn more about NATE’s A2L certification, Low-GWP Refrigerants study guide, and online NATE Training Academy courses, visit: www.NATEX.org/LowGWP

For more information about some of NATE’s Recognized Training Provider A2L training programs, check out the sites below:

• For locations near you: https://natex.org/locate-a-training-organization

• The Chemours Company: https://www.opteon.com/en/; https://www.opteon.com/en/support/training

• Daikin Comfort Technologies North America: www.HVACLEarningCampus.com

• Carrier: MLCtraining.com

“Ritchie works with their reps to help train wherever we can,” says Guse. “Personally, I have been on several podcasts discussing our tools and helping people understand the hazards of A2Ls and A3s (higher flammability) as well as how to approach a safe system.” Guse has also been a presenter for two years at the HVAC Excellence training program, where he helps train the instructors and educate them on the changes coming with A2Ls and A3 refrigerants.

Guse offers the following advice to HVACR contractors who are considering investing in A2L refrigerant transition training for their technicians: “Absolutely spend the time and money now for training. Smarter, safer workers pay

• In addition, the Air Conditioning Contractors of America (ACCA) offers A2L refrigerant safety training. The course is designed for individuals who are already certified as EPA Section 608 Universal Technicians, or have a good understanding of the refrigeration cycle, refrigerant applications/blends, recovery equipment/procedures, and cylinder safety. Based on the ASHRAE Standards 15 (2019), 15.2 (2022), and 34 (2019) and UL Safety Standards 60335-2-40 (2019), and 60335-2-89 (2019), it’s available in English and Spanish; the training is free for ACCA members and offered as a value to nonmembers. Visit https://www.acca.org/education/a2ltraining

12 NATEX.ORG MAY 2024

A2L TRANSITION BY MICHAEL KEATING

Michael Keating is a contributor to the NATE Magazine.

CHP-5 CERTIFICATION

NEW: NATE TRAINING ACADEMY NATE has teamed up with Interplay Learning to create a new online platform with on-demand interactive courses that prepare technicians for the CHP-5 exams. Technicians can now earn their NATE Certification with five thirty-question exams designed to mirror the ways they learn and grow in the field. Online exam options available. www.NATEX.org

A2L Tools Bring Technicians Up to Speed on New Refrigerants

AN ARRAY OF SUPPORT TOOLS ENABLES HVACR INDUSTRY STAKEHOLDERS TO LEARN MORE ABOUT THE TRANSITION TO A2L REFRIGERANTS AND THEIR IMPLEMENTATION.

The American Innovation & Manufacturing (AIM) act of 2020 requires an 85 percent reduction in the use of hydrofluorocarbon (HFC) refrigerants over the next 15 years. This phasedown has paved the way for the use of A2L refrigerants as a substitute in many applications. A2L refrigerants offer lower toxicity and flammability compared to other products, making them a safer refrigerant option. These refrigerants also provide a lower global warming potential (GWP) than HFCs, an important part of the phasedown plan.

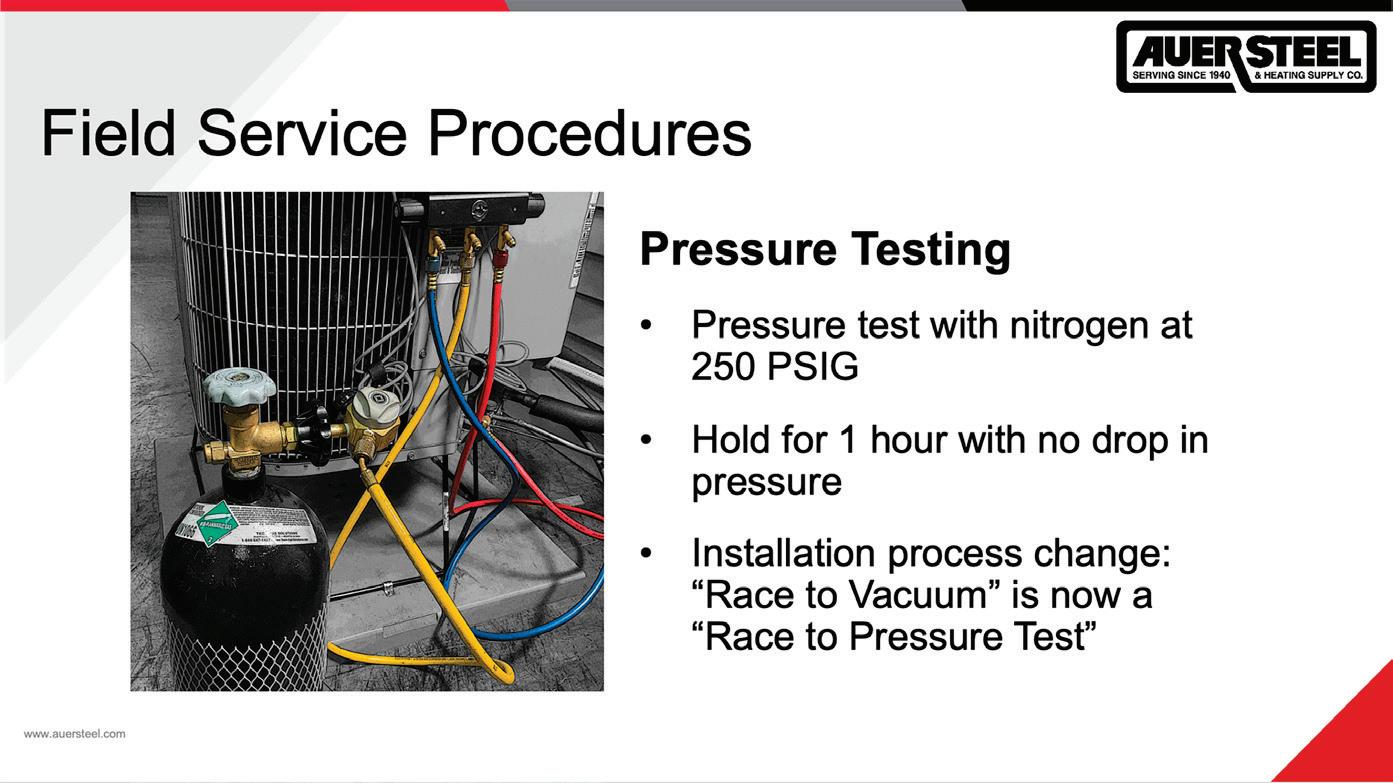

The HVACR industry has gone through transitions before, but the transition to A2L refrigerants has introduced more complexity than past transitions, such as different rules for the same product depending on how

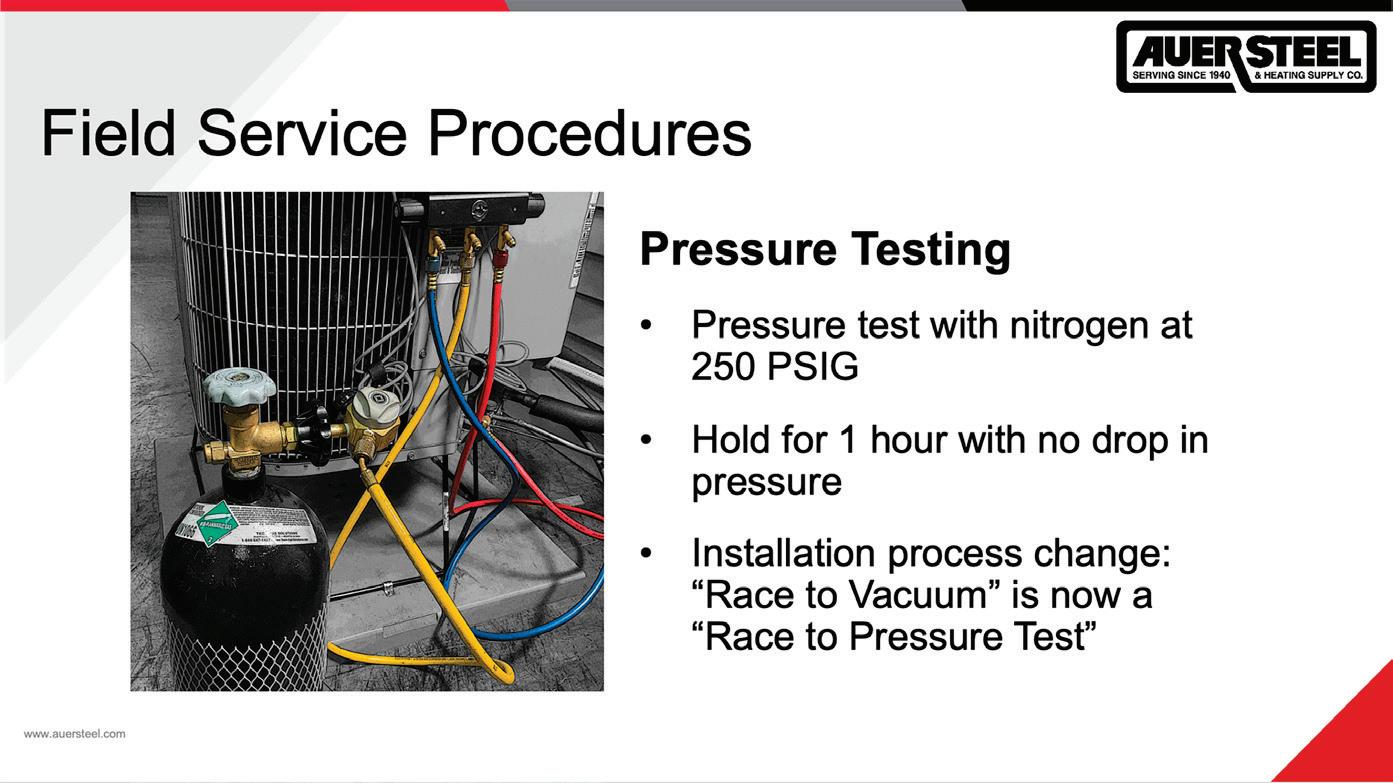

it is used. What this means to technicians is that they will require new tools to work with the A2L refrigerants. According to Mike Breen, senior manager of technical support, training, and warranty at Auer Steel & Heating Supply Company, “We are taking a proactive approach to technical support, training, and even warranty concerns.”

In order to meet the needs of their customers, Auer Steel has been developing training classes, tech tips, and videos to ensure they have the tools readily available for their customers’ technicians. The goal is to get them familiar with the process of working with A2L refrigerants as early as possible, so that when they are in the field, they’re ready to do so.

North American Technician Excellence (NATE) is taking proactive steps to support technicians and

14 NATEX.ORG MAY 2024 A2L TOOLS BY TERRY PERSUN

Training sessions are the perfect place to hear directly from customers, allowing for future training materials to focus on the most prevalent challenges.

training providers as they prepare for the A2L transition. To facilitate learning, NATE has introduced a comprehensive study guide, filled with engaging graphics and clear language, which has become a staple in technician resource libraries for many contractors and training providers.

In addition, NATE has launched an interactive, ondemand online course hosted on the NATE Training Academy platform. This course, created in partnership with Interplay Learning, covers a broad spectrum of essential topics, including safety, transportation and handling, and mastering installation and service best practices. NATE-certified technicians can also earn continuing education credit upon completing the course. What’s more, NATE offers a specialized Low-GWP Refrigerants Certification exam, allowing technicians to showcase their proficiency in handling these advanced refrigerants safely and confidently.

In a similar vein, the Heating Air-conditioning & Refrigeration Distributors International (HARDI) wanted to ensure that its members and other industry professionals had pertinent information whenever and wherever they needed it for selling, storing,

and managing new equipment and refrigerants. HARDI partnered with Distro to create AskA2L, an interactive chat feature that takes the thousands of pages of regulations, safety standards, and industry information on A2Ls and makes it easy for industry professionals to get the answers they are seeking.

According to HARDI CEO Talbot Gee, “We’ve realized that AskA2L is valuable to more than just HVACR distributors and have made it available to the wider industry to quickly access information that is accurate and specific to their location and needs.”

CONSISTENCY COUNTS

There can be a lot of misconceptions about the latest A2L refrigerant changes, which is why the most important part of any messaging is to be consistent. This means that staff at the counter, outside salespeople, technical support staff, and training professionals all need to be on the same page, providing the most accurate information available. According to Auer Steel’s Breen, “We have a library of tech tips available to our dealers so that they have the right answers to common questions.”

The company continually updates its materials, including detailed step-by-step processes that dealers can view on their smart devices or print later. Technicians also have access to videos any time so they can review information when they need it most. Watching an actual process being demonstrated by a professional can be the perfect tool.

Auer Steel also has an extensive learning library on its website, with videos ranging from a few minutes to a full day’s worth of recordings. Dealers and their

MAY 2024 NATEX.ORG 15 BY TERRY PERSUN A2L TOOLS

Auer Steel offers a series of relevant Field Service Procedures that can be viewed at any time on a smart device or printed out.

AskA2L uses an AI-generated Q&A format to help technicians get a quick answer concerning an immediate problem they might be having.

technical staff receive continuing education credits for completing a test after viewing the videos.

The HARDI interactive chat is built on a database that continually learns as data is updated from trusted source documents. To maintain accuracy and consistency, the database relies on source documents from the EPA; Air-Conditioning, Heating, and Refrigeration Institute’s (AHRI’s) Safe Refrigerant Transition Task Force; and industry documents. “An important part of the information includes location-based information enabling users to ask about the building code status at a particular location to understand where A2Ls are legal to install,” Gee explains.

“Staying up-to-date on the latest safety and regulatory requirements associated with working with A2L refrigerants takes work,” Breen says. To ensure that the company’s trainers are well-versed, they also attend webinars and training classes on policies and regulations. Whenever they find the least discrepancy in messaging, the team investigates to pinpoint the issue. Getting the best and most recent information to customers is essential, and

the company will recreate tips and videos to be sure everything is on-target and consistent.

Auer Steel adds elements of this new training content to all its classes, spreading the word even during gas furnace classes. The company’s digital library for tech tips is available at any time. Dealers can train their teams on their own time. Opportunities include safety courses, NATE-accredited curriculum, and a broad number of A2L training courses. As a NATE Recognized Training Provider, many of Auer Steel’s training courses have been reviewed by NATE and cover essential content found in NATE’s certification exams and Low-GWP Refrigerants certification exam.

As for HARDI, its AskA2L is only considered one part of preparing for the transition to A2Ls. For distributors, HARDI has created training tools to develop a baseline understanding of the transition so that AskA2L serves as a tool for the trained professionals to add to their knowledge base.

HARDI’s Government Affairs and Talent Development teams have partnered to create A2L coursework to help HARDI members provide educational support to their employees. Gee explains, “We’ve developed courses complete with knowledge verification testing for compliance with EPA rules and the storage and transportation of A2L products and containers. These courses are updated if and when there are updates to the EPA’s final published rule and are just as essential for associates who are brand new to the industry as they are for the continued education of seasoned HVACR professionals. The coursework is structured as a reference guide, so learners don’t have to rely on memory and can consult the content at any time.”

CUSTOMERS AS PARTNERS

Feedback is a necessary part of providing the right training tools for dealers and other customers. At Auer Steel, listening to feedback, hearing what challenges customers run into, and reacting to all inputs has helped them to maintain a good working relationship between all parties.

Manufacturing partners and vendors have also recognized the company’s efforts and proactive approach. Carrier Corp. recognized Auer Steel for the largest reduction in warranty projects year over year, indicating that training was a major factor in that accomplishment.

Many of the new required processes related to dealing with the new A2L refrigerants have only been recommended processes to HVACR technicians in

16 NATEX.ORG MAY 2024

2405CB_Nate_Fieldpiece.indd 1 4/2/24 2:50 PM A2L TOOLS BY TERRY PERSUN

“STAYING UP-TO-DATE ON THE LATEST SAFETY AND REGULATORY REQUIREMENTS ASSOCIATED WITH WORKING WITH A2L REFRIGERANTS TAKES WORK.”

– Mike Breen, senior manager of technical support, training, and warranty at Auer Steel & Heating Supply Company

the past. Making these processes a requirement will improve the efficiency and effectiveness of the technicians in the field. These tools and processes will cut down on call-backs and warranty calls because technicians will not leave the product to the customer until the system has been fully leak checked.

“Many of our customers won’t see the new A2L refrigerant for quite some time, but we want technicians to start implementing some of these changes with the existing processes,” Breen notes. By starting to work with these new methods now, companies will be well-prepared when the new refrigerant is all that they’re working with. Doing installations and service calls correctly will also save time and money throughout the entire job.

When HARDI created AskA2L, it had to consider the audience, as well. While excitement around AI applications has been high lately, so too has the skepticism about the accuracy of the tools. This is why HARDI partnered with

Distro to create the software. Distro has worked with AI products specifically for the HVACR industry as a core part of its business. This means that its AI model already knows how to “speak” the language of HVACR, avoiding the challenges another AI company might encounter.

The hope is that distributors in the network will be able to use the tool to empower their contractors and technicians to make quick, informed decisions in order to ensure they comply with safety standards and federal regulations when in the field. This will inevitably lead to better partnerships between supplier manufacturers, wholesalers, and contractors. It is HARDI’s belief that since customers are often confused about the latest requirements during this transition, the most educated contractors and distributors will grow the fastest in the next few years.

CONCLUSION

Having consistent, ongoing updates and changes to training tools is critical. Having an array of tools to choose from to answer immediate questions, provide hands-on type videos, or a quick tips sheet all provide ways to stay current with the new rules while maintaining a healthy understanding of what’s required so that the customer is best served. Using multiple tools can increase the capabilities of technicians, providing the confidence needed to do their job well. l

Terry Persun is a contributor to the NATE Magazine.

MAY 2024 NATEX.ORG 17

BY TERRY PERSUN A2L TOOLS HARDI coursework is structured so that learners

consult

any time.

can

content at

Updated Gas Heating, AC & Heat Pump Study Guides Help Testers Reach Next Level

REVISED STUDY GUIDES ENCOMPASS NOT ONLY CURRENT INDUSTRY STANDARDS BUT ALSO EMERGING TRENDS, PREPARING TECHNICIANS FOR BOTH PRESENT AND FUTURE CHALLENGES.

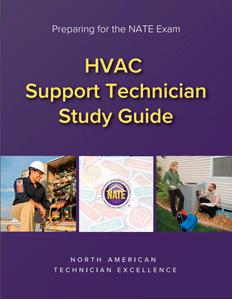

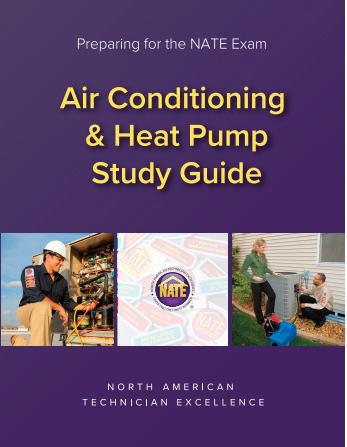

When NATE first developed its own study guides several years ago, the goal was to utilize the expertise of its Technical Committee to help technicians and others in the industry adequately prepare for its certification exams.

At the time, Jose De La Portilla, senior manager education and training, Rheem Manufacturing, and a member of NATE’s Technical Committee, explained the process as going back to the fundamentals.

“As a technical committee,” De La Portilla says, “we discussed it and

“IN ORDER TO CERTIFY THE BEST TECHNICIANS IN THE INDUSTRY. IT IS IMPORTANT TO OUR ORGANIZATION TO UNDERSTAND AND RECOGNIZE HOW INDUSTRY TRENDS, EVOLVING BEST PRACTICES, AND NEW TECHNICAL KNOWLEDGE ARE AFFECTING OUR TECHNICIANS’ WORK.”

— Gurminder Sidhu, NATE director of business operations

thought, ‘You know what? We really need to create our own study guides that are a little bit more concentrated on the core concepts of the exams. They help the individuals focus on the topics they really need to focus on when it comes time to testing and certification. The study guides whittle down that massive pile of data to a more comprehensible, more digestible set of knowledge skills that they will need to understand to take the exams.”

The NATE Board of Directors approved the study guides’ project in the fall of 2018, and the team started development in the beginning of 2019, according to Gurminder Sidhu, NATE director of business operations.

To begin with, NATE offered the following guides:

• Ready to Work: launched in 2016; the Spanish version was launched in 2019

• HVAC Support Tech: launched in 2016; the Spanish version was launched in 2019

• Core: launched November 2019

• Gas Heating: launched November 2019

• Air Conditioning and Heat Pumps: launched January 2020

• Certified HVAC Professional: launched August 2020

18 NATEX.ORG MAY 2024 EXAM PREPARATION BY ELAINE YETZER SIMON

That first generation of study guides has served its purpose, and now NATE is ready to update and improve them, especially since NATE undertakes a regular process of reviewing and validating the exams, according to Anthony Spagnoli, NATE’s director, testing and education.

“In order to certify the best technicians in the industry,” Sidhu says, “it is important to our organization to understand and recognize how industry trends, evolving best practices, and new technical knowledge are affecting our technicians’ work. There has simply been a lot of innovation in the last several years, and it is important to us that our exams reflect these changes in our industry.”

In terms of the Gas Heating and AC & Heat Pump specialty exams, the key updates focus on:

• Microchannel coils

• Mechanical press fittings

• Inverter-driven compressors

• Cold climate heat pumps

• Heat pumps as substitutes for fossil fuel heating

• Smart diagnostic tools

“Additionally, NATE worked with the Pacific Northwest Laboratory to update the Heat Pump specialty exam Knowledge Areas of Technician Expertise (KATE) to include the Department of Education’s industrial decarbonization goals,” Sidhu says. “The updated exam now includes the Department of Energy’s new guidance on smart diagnostic tools, decarbonization, and coal climate heat pumps.”

Spagnoli adds that NATE ensures its study guides accurately reflect the knowledge and skills required for technicians to succeed on the updated exams because they are mapped to the job task analysis (JTA), which is validated with an industry-wide survey for the frequency and criticality of each domain area.

That JTA also is where the NATE Technical Committee members play a critical role in the development of the study guides.

“Their input was around the JTA; the study guide was updated by NATE staff using the updates to the JTA as guidance,” Spagnoli says.

ENDURING RESOURCES

The updated study guides still include a number of elements that made the original guides successful.

“When we first created our NATE study guides, it was important to us to include lots of graphics, easyto-digest language, and practice questions to help technicians check their knowledge and progression,” Sidhu says. “We have received a lot of positive feedback from technicians and contractors about our guides, so it was important to us to make sure these elements are still key features in our new edition.”

In addition, NATE took the time and planned to make sure these updated guides are invaluable resources for technicians and truly contain information they need in their day-to-day work.

Sidhu explains, “We made sure the updated content encompasses not only current industry standards but also emerging trends, preparing technicians for both present and future challenges. We envision NATE study guides as enduring resources. They are intended to be shared among technicians within a team and passed on to friends.”

In fact, Sidhu says NATE has learned that many contractors find its study guides so valuable that they purchase multiple copies to stock their technician training libraries.

“By stocking their technician training libraries with multiple copies of our study guides, contractors not only ensure that technicians have the tools they need for exam prep

but also demonstrate their trust in the reliability and effectiveness of our guides in boosting their teams’ knowledge and expertise,” she says.

NATE Technical Committee member Charles R. White, vice president, regulatory affairs for the Plumbing-Heating-Cooling Contractors, points out that just like the HVACR products of today, NATE is an ever-evolving certification program.

“For consumers to have confidence in their service technicians, those technicians must be trained and assessed on the most current technology in the market,” he says. “The subject-matter experts who volunteer their efforts for this represent hundreds of years of experience in the HVACR industry. These experts want to share their knowledge of the best practices that will result in the highest performing installation and operation of not only legacy equipment but also today’s sophisticated energy-saving HVACR equipment.”

Sidhu offers the following advice to technicians who are planning to take the updated Gas Heating or AC & Heat Pump specialty exams using the new study guides:

“Technicians should keep in mind that NATE certification exams are tailored to assess their practical expertise in HVACR systems, acquired through real-world experience. While study guides are valuable resources, they’re just one part of the equation. Continuous learning and hands-on training in the field are essential for technicians to be fully equipped for NATE exams. These exams aren’t just about what’s in the books; they’re about applying that knowledge effectively in the field. So, while study guides are fantastic tools, they should be complemented by ongoing field experience and training to ensure technicians are truly prepared.” l Elaine Yetzer Simon is a contributor to the NATE Magazine.

MAY 2024 NATEX.ORG 19 BY ELAINE YETZER SIMON EXAM PREPARATION

TEACHING HVACR IN A CHANGING WORLD

ELLEN LOGUE LEVERAGES NATE STUDY GUIDES TO PREPARE STUDENTS FOR NATE CERTIFICATION.

Ellen Logue has come a long way since her father introduced her to the HVACR field when she was 12 years old. She found that she liked the field and has since pursued a career in teaching HVACR to students in central Florida.

Logue is training director/program coordinator for the Air Conditioning Contractors Association of Central Florida (ACCA/CF), where she teaches the third-year class students. She taught the HVACR program for Orange Technical College-West Campus, Winter Garden, Florida, for nine years, as well as the second-year class for ACCA/CF for nine years.

The ACCA/CF program is a threeyear apprenticeship program. In the first year, apprentices learn about specialty tools, refrigerant cycle, psychometrics, and the major components that make up a system. In the second year, apprentices learn about ducts, building envelope, and different types of units such as straight cool, heat pump, and gas and electric heat. In the third year, apprentices focus mainly on electrical components, reading schematics, rewiring equipment, zoning configurations, and electrical testing by using their meters.

20 NATEX.ORG MAY 2024

EDUCATION BY NEAL LORENZI

The program at Orange Technical College-West Campus is a two-year program. However, a student can complete the first year and have enough lab time and certifications to work in the field as a helper. In their first year, students learn the tools, refrigerant cycle, basic electricity, maintenance, brazing, and individual components within an air conditioning system. These students are not working in the field but learning about the trade to make it their career path.

What is Logue’s teaching approach and how does it set her apart from other teachers? “One thing that students have commented on is how I interact with them,” she notes. “I like to use open-ended questions and make the lessons more of a debate. This tends to keep students engaged longer.”

Logue has used several methods to incorporate new content. “We play quiz games, hold competitions between groups, watch videos, use hands-on materials, and ‘break’ parts to see what’s inside of them. With 10 to 30 students in a class,” she says, “I use multiple methods at the same time to ensure that everyone understands the material. Students then practice the skills on their own.”

This will be Logue’s first time prepping students for NATE certifications. She plans to use the NATE study manuals for the Core and Heat Pump certification. “I plan to use a PowerPoint that ACCA/CF has used,” she says. “However, as with any exam, I will tell students to pay attention to what the question is asking. If you don’t know the answer right away, skip it and go back to it. Take a deep breath before you read the question. With the exams being timed, students sometimes feel like they have to rush to finish before they run out of time. That is when mistakes are made.”

“NATE CERTIFICATION ALLOWS TECHNICIANS TO FEEL CONFIDENT AND ACCOMPLISHED IN THEIR CAREERS. IN ORDER TO KEEP THEIR NATE CERTIFICATION ACTIVE, THEY MUST TAKE CONTINUING EDUCATION CLASSES.

TAKING THESE CLASSES IS OPTIONAL, BUT THE HVACR INDUSTRY IS ALWAYS CHANGING AND COMING OUT WITH NEW TECHNOLOGY.

TECHNICIANS NEED TO TAKE TRAINING CLASSES TO KEEP UP IN THE INDUSTRY.”

IN THE BEGINNING

Logue says that her father was the reason she entered the HVACR industry. “My father owned his own HVACR business when I was growing up. One summer weekend, while I was bored at home, he took me to a new residential construction project. It was hot and he was running duct work. At 12 years old, I was able to climb through attics quite easily compared to him. He handed me one end of the duct and said, ‘Go that way and don’t fall.’ I enjoyed the work so much that I continued to work with him every chance I could.”

When Logue attended high school, she decided to join the dual-enrollment HVACR program, which allows students to take a technical class for half the day while taking high school classes the other half. Thanks to this dual-enrollment program, she was able to embark on a career in the HVACR field.

Logue’s mentor, Gary MacLeod, encouraged her to be an instructor. “I had held small training classes for the technicians that I worked with,” she says. “This sounded like a new adventure and a way for me to give back to the industry. I enjoy teaching potential technicians. When the light

bulb goes on, and all of a sudden they get what they are doing, it makes the teaching so rewarding.”

MacLeod was the HVACR instructor at Orange Technical College-West Campus when it was called Westside Vo-Tech Center and was Logue’s instructor when she was a student there. “Gary is the person who got me employed with a local contractor when I finished the program. Over the past 15 years, he has called to check on me periodically to see how I am doing in the field.”

CERTIFICATION HAS VALUE

Logue believes that NATE certification is valuable for HVACR technicians, both for students seeking a new career and experienced technicians. “NATE certification allows technicians to feel confident and accomplished in their careers. In order to keep their NATE certification active, they must take continuing education classes. Taking these classes is optional, but the HVACR industry is always changing and coming out with new technology. Technicians need to take training classes to keep up in the industry.”

Other benefits of NATE certification are pay increases and improve -

MAY 2024 NATEX.ORG 21 BY NEAL LORENZI EDUCATION

ments to technicians’ knowledge of the trade. “When training classes are held, the course can be an approved NATE education class. This means that the class not only provides new information to the technicians but also counts towards the renewal of their NATE certification.”

Another major benefit that technicians gain from obtaining NATE certification is self-confidence, Logue adds. “This is extremely important for beginning technicians. When one of my students passed his NATE exam for the Core and Air-toAir Heat Pump Service Technician certification, he was so proud of himself, and it added confidence to his performance as a technician. When the student went back to his employer and told him that he had passed, the employer raised his hourly rate of pay.”

One of the proudest moments of Logue’s career as an instructor was watching a student grow from high school student to an adult. The student graduated from the HVACR program and was the only applicant of 70 to be chosen to work for Lennox. “This student was top of the program and won an award for Outstanding Post-Secondary Student of the Year. Since then, he has moved on to another company as a lead technician and is training new hires.”

EMERGING TRENDS

Logue is aware of emerging trends and advances in the HVACR field and plans to incorporate this information into her class curriculum to ensure that students are well-prepared for the future. One trend is in the area of refrigerant changes. In January 2025, a new refrigerant will be used in residential and light commercial HVACR equipment. This new refrigerant has a lower Global Warming Potential (GWP) and is classified as A2L. Logue has attended several

“MY ADVICE TO ANY TECHNICIAN WHO IS CONSIDERING NATE CERTIFICATION IS TO PURCHASE THE NATE STUDY GUIDES. EVEN IF A TECHNICIAN JUST NEEDS TO RECERTIFY, IT IS A GOOD REFRESHER. THE STUDY GUIDES ARE A GREAT RESOURCE TO HAVE.”

training classes and requested to purchase the new equipment. She plans to install the equipment in her lab for students to see and train on. ACCA/CF also has scheduled training sessions for contractors.

“A2L means that the equipment has some flammability to it but is on the lower side for the toxicity level,” Logue explains. “There is a misconception I have seen with some of my students and apprentices regarding A2L because of the flammability issue. They hear the flammable part and think they might ‘blow up,’ as they say. From the classes I have attended, the flammability issue is not that extreme. Yes, the refrigerant can catch a flame but it’s mildly flammable. There are very specific conditions that need to occur to make it ignite.”

Every day, Logue sees more technicians using tablets when writing up service tickets instead of the old paper methods. Technology use has increased over the years, and it has improved work productivity. “For the new Orange Technical College – West Campus building scheduled to open this summer, I plan to implement a

way for students to use this technology to write up their lab assignments.”

However, new technology such as cell phones represents a double-edged sword, Logue says, noting that some students want to watch movies and text their buddies instead of getting in the lab and practicing the skills needed to be a technician. “This is not true for all of my students, but the problem exists. I have had many awesome students complete the program who are now supervisors in the field for their employer. I hope that with HVACR’s growing popularity among young people, we can solve the problem posed by the shortage of technicians.”

What advice would Logue offer to aspiring HVACR technicians who are thinking about pursuing NATE certification and seeking training opportunities? “My advice to any technician who is considering NATE certification is to purchase the NATE study guides. Even if a technician just needs to recertify, it is a good refresher. The study guides are a great resource to have.” l

Neal Lorenzi is a contributor to the NATE Magazine.

22 NATEX.ORG MAY 2024

EDUCATION BY NEAL LORENZI

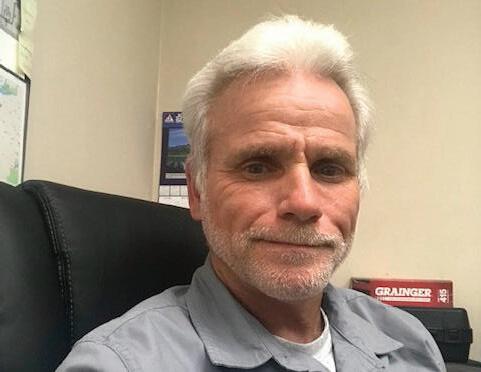

Spotlight On NATE Technicians

There are many traits that describe great leaders. A great leader is ambitious, has vision, and is resourceful. Great leaders are well-educated and know that in order to be successful in a career, the learning process never ends. In the HVACR industry, technicians continue the education process by gaining NATE certifications. The NATE Magazine would like to put the spotlight on the following NATE-certified technicians who are leaders in the HVACR industry.

COREY JENKINS

1. TITLE/EMPLOYER: I am employed with Auburn University, Auburn, Alabama, as a senior HVACR equipment mechanic.

2. HOW MANY YEARS HAVE YOU BEEN WORKING IN THE HVACR INDUSTRY OVERALL? I started working in the HVACR industry 13 years ago, part-time as a senior in high school.

3. WHAT DO YOU DO (AS A TECHNICIAN) ON A DAILY BASIS? I maintain and repair building systems for student residences and dining halls (mechanical systems, chilled and heating water systems, domestic hot water systems, pneumatic systems, etc.).

I also maintain and repair all forms of commercial kitchen equipment. This includes ovens, dish machines, mixers, slicers and grinders, and low-temperature and medium-temperature refrigeration systems.

4. WHAT LED YOU TO A CAREER IN HVACR? Years ago, my parents hired a technician to service their HVACR system. He was very knowledgeable and was nice enough to show me a few things while he worked. He told me about the high demand for technicians and suggested that I look into a career in HVACR. I worked with a small HVACR company while in high school and college and decided to get my associate degree in HVACR.

After college, I was fortunate enough to start working with that same man who had given me the advice years ago. He was a great teacher, and his father’s company introduced me to all kinds of equipment. From residential units to industrial-sized units, we serviced just about anything. I am grateful for the knowledge I gained during the five years I worked with that company. In 2018, I started working at Auburn University, where I am still learning more and more every day.

5. WHAT NATE CERTIFICATIONS DO YOU CURRENTLY HAVE? WHEN DID YOU GET THOSE CERTIFICATIONS? I have NATE certifications in Air to Air Heat Pump Service, Air to Air Heat Pump Installation, Air Conditioning Service, and Air Conditioning Installation. I gained those in 2022.

6. WHAT VALUE DO YOU FEEL THAT THE NATE CERTIFICATIONS HAVE ON YOUR CAREER IN HVACR? NATE has brought great value to my career. It has allowed me to move up to a higher position. Also, being NATE-certified shows my employer that I am serious about being the best technician possible.

7. HOW DO NATE’S LATEST OFFERINGS (CHP5, LIVE ONLINE PROCTORING, STUDY GUIDES) SPEAK TO NATE’S ABILITY TO ADAPT TO THE INDUSTRY’S CHANGING NEEDS? I have not yet used these programs. I chose the

MAY 2024 NATEX.ORG 23 BY NEAL LORENZI SUPERIOR SERVICE TECHNICIANS

traditional pathway. But I think this shows that NATE is definitely able to adapt to the needs of technicians. It shows that NATE is serious about helping technicians get trained by offering many different ways to become certified.

8. WHAT ADVICE WOULD YOU GIVE A NEWCOMER LOOKING TO BE SUCCESSFUL IN THE HVACR INDUSTRY? My advice to new technicians is to focus on the fundamentals of HVACR. Also, understand that every piece of equipment has a sequence of operation. These two pieces of information are critical to solving any problem. Becoming NATE-certified can help in both of these areas.

LOREN MASON

1. TITLE/EMPLOYER: Service field supervisor at Benson’s Heating and Air Conditioning, Tallahassee, Florida. We cover part of the Florida Panhandle-Central and part of South Georgia.

2. HOW MANY YEARS HAVE YOU BEEN WORKING IN THE HVACR INDUSTRY OVERALL? 21 years

3. WHAT DO YOU DO (AS A TECHNICIAN) ON A DAILY BASIS? I manage field operations for the service department. Sometimes that has me going into the field to address mechanical issues with technicians or meeting with customers to alleviate their concerns. I am National Air Duct Cleaners Association (NADCA)-certified and work with Watt Master Controls. I also hold certification on Liebert Thermal and Power Systems. I’ve serviced everything from small residential units to large chillers.

4. WHAT LED YOU TO A CAREER IN HVACR? I worked in the aviation industry overhauling aircraft engines when 9/11 happened, and the company decided to relocate to another town. Because of family issues, I was not able to relocate. The opportunity arose to get into HVACR and I took it. I’ve been with Benson’s Heating and Air Conditioning ever since. I joined the company in April 2003, starting out in service as a tech running residential and commercial. I then managed residential change-outs with some light commercial along with indoor air quality.

5. WHAT NATE CERTIFICATIONS DO YOU CURRENTLY HAVE? WHEN DID YOU GET THOSE CERTIFICATIONS? I have the Air Conditioning and Heat Pump certification, which I obtained three years ago.

6. WHAT VALUE DO YOU FEEL THAT NATE CERTIFICATIONS HAVE ON YOUR CAREER IN HVACR? HOW HAVE NATE CERTIFICATIONS BENEFITED YOU AND YOUR COMPANY OVER THE YEARS? NATE certification gives me more knowledge into the industry, going more in-depth on equipment operations. I think it shows a level of learning that technicians, and for that matter, the company are willing to invest into having more knowledge to provide the customer with better service in the long run—along with mitigating call backs.

7. HOW DO NATE’S LATEST OFFERINGS (CHP-5, LIVE ONLINE PROCTORING, STUDY GUIDES) SPEAK TO NATE’S ABILITY TO ADAPT TO THE INDUSTRY’S CHANGING NEEDS? I have not yet used these programs. I chose the traditional pathway. But it shows that NATE can change with keeping information updated for the certifications. This, in the long run, helps ensure that work is done properly in the field.

8. WHAT ADVICE WOULD YOU GIVE A NEWCOMER LOOKING TO BE SUCCESSFUL IN THE HVACR INDUSTRY? Keep on learning! This industry constantly changes, especially with government mandates. You must be able to adapt quickly. You will constantly be changing to fit customers’ needs. This industry can be very challenging but very rewarding. You will have to put in your time—from crawling through attics to going under houses to putting in those late nights on-call and working the weekends. But in the end, you are helping the customer with their issues and…sometimes feeling like a super hero when done! Just keep your ego in check! l

24 NATEX.ORG MAY 2024

SUPERIOR SERVICE TECHNICIANS BY NEAL LORENZI

Sustainability and Innovation Advancing

AHRI ifi an indifipfinfiablfi fififiouficfi

in thfi global communityfi hffilfiffiffifi

fifi fiffiffiffilffififififfi ffiffivffifififfififfiffififil

susfififfiffifififfilffififfiffi ffiffiffifififfi ffiffiffiffiffiffiffiffiffi

fiffifi fiffifiulfififififfi ffifififilffififfiffiffi

Only AHRI offffffffff

• A ffifififififfihffiffisffivffi HVACR ffiquffifififfiffifi fiffififfififififfiffiffi ffiffifififfififfifififfififfi fififififififi fififfififfifi fiffi fifififfi fihfiffi 100 ffiffififis fif ffiffififfiffiuffififfi

• Bffisfi-ffiffi-ffilfiss fiffifilffififfiffis fifi sufififififi fi fi

• Exfiffififi filfififil ffiffifiusfififfi fifivfiffififfiffi

• Ovffifi 150 sfififfififififis fiffifi fiffiffihffiffiffifil fi s

Intfifinational manufactufififififi fipficifififififi

fifigulatofififi and building ownfififi fifily on AHRI to do bfittfifi bufiinfififi.

Whatfiafififiyoufiwaitingfifofi?

Lfitfiufififihowfiyoufihow.

Lfiafinfimofififiatfiwww.ahfiinfit.ofig AHRIconnffct AHRI @AHRIConnffct AHRIcommunicationff 5538ND

For more info visit daikinfit.com 2024 compared to traditional, non-inverter systems 5x quieter Up to AVAILABLE FOR AIR CONDITIONER, HEAT PUMP, AND DUAL FUEL APPLICATIONS! 1.5-5 Ton Up to 17.5 SEER2 | Up to 8.5 HSPF2 | Up to 97% AFUE

INFORMATION Before purchasing this appliance, read important information about its estimated annual energy consumption, yearly operating cost, or energy efficiency rating that is available from your retailer. Inflation Reduction Act COLD CLIMATE * Select DZ6VS heat pump models meet the ENERGY STAR® cold climate requirements. Please refer to product engineering manuals for additional information or visit www.energystar.gov.

ADDITIONAL