SIs use knowledge of engineering, IT and business to automate manufacturing and processes from the plant floor to the enterprise level

INGRESS PROTECTION FOR HMI

EMERGENCY STOPS EXPLAINED

IS IT A PANEL OR A PC?

Streamline your machine processes with MOVI-C® Modular Automation System, offering seamless integration of hardware and software. This system simplifies engineering and reduces installation space and costs through plug-and-play connectivity. Configurable devices maintain all functions, from safety to robotics, within fewer variants. Designed for simplicity and userfriendliness, MOVI-C allows for effortless integration into any machine or system configuration, intuitive operation, and easy monitoring, making sophisticated automation accessible and manageable. Everything you need comes from one reliable source.

Visit us at BOOTH 8728

cover story

What is system integration?

SIs use knowledge of engineering, IT and business to automate manufacturing and processes from the plant oor to the enterprise level

Jose Rivera, Control System Integrators Association (CSIA)

machine input

How to achieve controlpanel adaptability

Optimize time to market, ef ciency and durability in electrical enclosures

Mike Bacidore, editor in chief

product roundup

Motion makes the di erence

Controllers, motors and drives enable actuation

Easily achieve high level, functional machine safety with the Yaskawa GA500.

Built-in, dual channel safe torque off (SIL3/PLe) provides the right solution to simplify machine safety integration – even when elevated levels of risk reduction are required.

Want to streamline your machine safety controls? Call Yaskawa at 1-800-927-5292.

FOR MORE INFORMATION: https://www.yaskawa.com/ga500

CEO

Endeavor Business Media, LLC

30 Burton Hills Blvd, Ste. 185, Nashville, TN 37215 800-547-7377

Chris Ferrell

President

June Griffin

COO

Patrick Rains

CRO

Paul Andrews

Chief Digital Officer

Jacquie Niemiec

Chief Administrative and Legal Officer

Tracy Kane

EVP Group Publisher

Tracy Smith

VP/Market Leader - Engineering Design & Automation Group

Keith Larson

editorial team

editor in chief

Mike Bacidore mbacidore@endeavorb2b.com

managing editor

Anna Townshend atownshend@endeavorb2b.com

digital editor

Madison Ratcliff mratcliff@endeavorb2b.com

contributing editor

Rick Rice

rcrice.us@gmail.com

contributing editor

Joey Stubbs

contributing editor

Tobey Strauch tobeylstrauch@gmail.com

contributing editor

Charles Palmer charles101143@gmail.com

columnist Jeremy Pollard jpollard@tsuonline.com

design/production

production manager

Rita Fitzgerald rfitzgerald@endeavorb2b.com ad services manager

Jennifer George

jgeorge@endeavorb2b.com

art director

Derek Chamberlain

subscriptions

Local: 847-559-7598 • Toll free: 877-382-9187 email: ControlDesign@omeda.com

sales team

Account Manager

Greg Zamin gzamin@endeavorb2b.com

704/256-5433 Fax: 704/256-5434

Account Manager

Jeff Mylin jmylin@endeavorb2b.com 847/516-5879 Fax: 630/625-1124

Account Manager

Kurt Belisle kbelisle@endeavorb2b.com

815/549-1034

Tobey

One control platform for all machine functions

TwinSAFE System-integrated with logic in all safety components

In machine safety, going for “good enough” is never the right choice. Ensuring the safety of your people, equipment and products is simply not optional. TwinSAFE from Beckhoff is the universal safety solution for everything from basic monitoring to complex motion in a fully integrated automation ecosystem.

Directly meshing with your PLC, motion control, measurement, IoT and vision technologies, TwinSAFE helps you implement more safety functionality in more places. This comprehensive platform streamlines machine design with programmable safety functionality to safeguard what you value most.

Integrated in all TwinSAFE components: the Safety Logic

Mike Bacidore editor in chief mbacidore@endeavorb2b.com

IN AUGUST, REGAL REXNORD hosted a group of individuals from the industrial press at its downtown Milwaukee headquarters to get to know the company and its diverse portfolio a little better.

With 250 global sites, 150 of them are manufacturing units, and more than 30,000 global associates—9,100 in United States; 8,400 in Mexico; 5,200 in Europe—sustainability is a priority for Regal Rexnord. “We’re committed to achieving carbon neutrality, scopes 1 and 2, by 2032, with a 12% reduction achieved in 2023,” pledged Scott Curley, senior vice president, sales and marketing, at Regal Rexnord.

Energy efficiency in motors and clutches is a big trend driving investment, but Curley also identified keeping up with regulations, as changes in fuel sources affect turbomachinery. Electrification has been at the forefront of many industries for over a decade. “We’ve been doing electric brakes for a long time,” noted Curley.

“Most of our businesses help to manage or control motion,” explained Kevin Zaba, president of the AMC division. “We’re technology-biased as a segment, and we have deep domain expertise.”

“When we first brought Regal and Rexnord together it was exciting, but, as we added the Altra products, we were able to enhance the overall set of offerings, but also from subsystems and powertrains that we’re able to build to meet the needs,” explained Zaba.

The organization’s biggest issue could also be its biggest opportunity.

Some motion-application customers have been late adopters of digitalization. “We’re seeing a lot more integration of the powertrain, integrating that data and those capabilities into a predictive-maintenance model,” said Curley.

Including the completed acquisition of Altra Industrial Motion in March 2023, 60 brands now fall under Regal Rexnord, whose automation and motion control (AMC) division includes conveying products, aerospace, seals and bearings, linear motion, precision motors, servo drives and controls and power management.

About two-thirds of its sales are in the Americas, with 68% directly to original equipment manufacturers (OEMs) and system integrators and the other 32% through distributors. Factory automation is the largest market segment with nearly a third of the business, while aerospace and food and beverage each comprise 20%.

Jerry Morton, president, industrial powertrain solutions (IPS), has been in the space for 37 years. “When I started, we had two brands,” he mentioned. “Today, we have 41. It’s been a tremendous transformation. We brought together the three formidable players in the powertrain space.”

The organization’s biggest issue could also be its biggest opportunity. “Many of our customers see different brands and think they’re all different companies,” said Morton. “Ultimately, we’re trying to get to supplying the entire powertrain.”

IPS products include gearing, couplings, bearings, mechanical drives, clutches and brakes, with 67% of its business in North America. “You see all of those in industrial powertrains,” noted Morton. Industry verticals for IPS with the most focus include heavy industry, mining, metals, agriculture, food and beverage, commercial HVAC, renewable energy and oil and gas.

One Regal Rexnord offering that could aid in bringing individually branded products under one unified umbrella is Perceptiv, its cloud-based asset-reliability platform for condition monitoring and predictive maintenance. It’s a single ecosystem for connectable equipment and brands, providing insights and recommendations based on machine-health data, explained Morton.

Jeremy Pollard jpollard@tsuonline.com

“HONEY, I’M HOME.” This was a normal thing to say in the 1950s and 1960s by Dad when he came home from work to let Mom and the family know that he had returned.

Today is different. My presence is known by simply approaching the house. My Ring camera goes off, my wife’s iPad tingles, and my phone lets Google Home know that I am on the premises—presence sensing at its best, and no words are even spoken.

Light curtains are used in robot cells to detect people who try and enter the cell at a time when they shouldn’t. I used light curtains to protect people who, for some strange reason, would traverse on a conveyor while a pallet wrapper was in operation, so that they didn’t get knocked out by the whirling arm.

The opposite is also true. If someone does not have my fob and tries to open the hatch, they will not be successful. Sensing has two sides—there and not there; presence and absence. It is important in a control narrative to determine which one needs to be sensed for the action at hand. Sometimes, it is both.

The cost of adding a sensor can be very insignificant to the cost of the machine and/or process.

We use various devices to sense things. People, product, air quality and pollutants, static location and movement are some of the myriad things that may need to be sensed.

Parts in place—photocell, proximity switch, limit switch—has been implemented for many years. With the advent of programmable logic controllers (PLCs) and programmable automation controllers (PACs) and control software, wiring in sensing hardware and using that information for control, feedback, alarming and trending has become commonplace.

Analog sensing is also employed, as 4-20 mA signals for level, speed and the like are used in everyday solutions for automated processes and machines. Modern sensors have built-in networking capability to allow for the use of these devices anywhere on the machine and/or process.

Radio-frequency identification (RFID) technology is being implemented in the field. Imagine if your phone could connect you to a machine-control system simply by being in its presence. Well, if the machine can support Bluetooth, and the mobile app on your phone can talk to that machine, then it can. Your presence can be determined by your proximity to the machine. I have a new car whose key fob allows me to actually enter the car without unlocking it with the fob. It senses my proximity and marries my fob to the car so when I touch the door handle the doors unlock.

In a project in the 1980s I was using a proximity switch to gauge conveyor speed by counting teeth on the flywheel of the chain-driven system. I looked at the end of the tooth and then at the absence of the tooth. Knowing the distance of the tooth not being there and the time between the teeth being sensed, I determined the speed in lugs/min, which the customer needed for acceptance testing. Now, I would use a resolver or encoder, giving me the speed, which could be converted. A variable-frequency drive (VFD) would be employed instead of the hydraulic drive that was being used.

Sensing comes in many different packages with various connectivity options, such as Bluetooth, Wi-Fi, Ethernet and, of course, ac/dc direct connectivity.

The real question is why. Why do we need to sense anything? Safety comes to mind, as well as the process. When we implemented the light curtain for the wrapper it was for people and the machine.

Sensing is an integral part of any control narrative from a process and discrete point of view. Water treatment systems, making beer, a favorite of mine, an x-y machining table and drill platform all are different in function but similar in that they all need sensing of product, location and action, such as that valve needs to be closed.

The cost of adding a sensor can be very insignificant to the cost of the machine and/or process. The cost of fixing a busted system because you failed to sense that all stations are home on a dial-table application could be expensive.

Using our common sense will win the day.

JEREMY POLLARD, CET, has been writing about technology and software issues for many years. Pollard has been involved in control system programming and training for more than 25 years.

Rick Rice contributing editor rcrice.us@gmail.com

THROUGHOUT THE HISTORY of automation, the humanmachine interface (HMI) has evolved from simple lights on a board to sophisticated hardware with computers onboard and the possibility of combining the HMI and programmable logic controller (PLC) into the same physical package.

With sophistication comes the risk of exposure to the environment in which the HMI is installed. Just how do we keep the outside from getting inside?

An HMI does not necessarily imply a high-resolution screen with complex graphics. Industrial robots, for example, utilize a pendant with an array of buttons on it and a small display to interact with the user.

While this might work for an environment where dry goods are produced, it would not stand up to intentional water spray or pressurized materials. By comparison, an HMI with a rating of IP69K means that the device is completely dustproof and can withstand washdown at pressures up to 1,450 psi for periods of up to 15 minutes at a time and temperatures up to 176 °F.

The enclosure itself can be positively charged with air or an inert gas.

A commercial blender might use a pendant that is buttons and lights only. This, too, is an HMI. An operator station for a press might utilize palm buttons that light up to prompt the user to interact with the buttons. Again, this is an HMI.

Operator hardware is robust these days and current designs protect the components when used in a harsh environment. For example, 30-mm buttons can be purchased with a rubber boot that fits over the operating components that are outside of the enclosure. This reduces the risk of water or other contaminants from getting into the physical device and the components that are on the backside—inside the enclosure. The backside components can be totally encased to prevent contamination.

Aside from an all-mechanical device, HMIs do tend to be more fragile in nature. Essentially, they are computers with exposed screens that use a touch interface to interact with the user. Under normal operating conditions, the hardware might survive operation, but, as most of us know, conditions are rarely normal.

Hardware manufacturers go to great lengths to protect HMIs from the environment in which they operate. Again, much of this has improved with technology. For example, an HMI originating in the 1980s might have an IP54 rating. This means that it would be protected from limited dust ingress and water spray in any direction.

One approach that has gained traction lately is to use a tablet in place of a permanently mounted HMI. Tablets can be charged outside of the harsh environment and then brought into the area for use. Tablets, much like our smartphones, are designed to withstand environments that other devices could not.

There are some rules to follow.

For example, the application on the tablet can only control devices that are within eyesight of the operator. This means a means of locating the device must be made or the application on the device must be restricted to the immediate vicinity of the wireless access point (WAP) that the device connects with.

Another means of protecting the HMI is to mount it, as usual, in an enclosure and then add additional methods of protection. For example, if the HMI is used mostly as a visual tool, then a see-through cover could be added to the enclosure face to go over the HMI. If the operator needs to access the HMI directly, the cover can be unlatched and moved out of the way while in use and then latched back into place when done.

The enclosure itself can be positively charged with air or an inert gas to, effectively, push any foreign particles back out any small crevice that might be a point of entry otherwise.

Another approach that has merit is the use of a thin client. In these situations, the smarts of the HMI are located remotely, and only the display is mounted in the field. The screen itself can have ratings of IP66 or IP69K, making it an excellent choice for this application. Often, the membrane of the screen can be replaced in the field, and, if there is a failure, you are only replacing the touchscreen monitor and not the whole system.

With proper implementation, the HMI can last a very long time. Protecting these devices is very important to the

control system design. Manufacturers go to great efforts to provide us with a sufficient set of options to make sure that the device suits the need, and we don’t have to put an expensive piece of hardware in our design if we don’t really require it for our operating environment.

Happily, in most cases, these various degrees of construction are within a single product line, and an application design can easily be scaled up and down to meet the different physical device characteristics without reinventing our usual operator station design.

The HMI is an essential part of a control system design. The device provides direct interaction with the controller, as well as endless capabilities to provide troubleshooting for an operator or line technician.

With the high-resolution graphics, actual photos of the area of concern can be shown right on the screen with interactive popups to provide further details of the

various components that make up the control system. The approach at my place of work is to employ the HMI as a means of keeping people out of our control cabinets whenever possible.

To this end, we use graphical representations of most of our in-panel components and super-impose status lights right over the appropriate spot on the image. We then use soft buttons to pop up information that describes the device and what the various lights and patterns mean.

This approach keeps our control enclosures clean and reduces or eliminates the need to open the door to perform basic troubleshooting.

RICK RICE is a controls engineer at Crest Foods (www.crestfoods.com), a dry-foods manufacturing and packaging company in Ashton, Illinois.

Tobey Strauch contributing editor tobeylstrauch@gmail.com

IN ANY SAFETY configuration, one must consider how the machine is going to stop and in which instances. National Fire Protection Association (NFPA) 79 is an industrial machine safety regulation and defines stops in categories.

Category 0 is an uncontrolled stop by immediate removal of power to the machine actuators. This requires non-retentive relays. A reset to initial state is required.

Category 1 is a controlled stop with power to the machine actuators to achieve a stop and removed power when the stop is achieved.

Category 2 is a controlled stop with power left available to the machine actuators.

As a machine builder, it might be difficult to discern the differences as to when one might do a full stop, controlled stop, stop with power ready. What is a good reference to follow?

activated, the machine decelerates in a controlled manner to avoid damaging the workpiece or the cutting tool, and then power is cut off.

Automated guided vehicles (AGVs) used in warehouses and manufacturing plants rely on Category 1 stops to ensure safety. If an obstacle is detected in the vehicle’s path, the AGV will decelerate smoothly before stopping completely, reducing the risk of collisions and damage.

Would a stop due to fire be a Category 1 stop?

In packaging lines, Category 1 stops are used to prevent damage to both the machinery and the products being packaged. For example, if a jam is detected, the machine will decelerate before stopping, allowing operators to clear the jam safely.

High-speed printing presses use Category 1 stops to avoid damage to the printing plates and paper.

Emergency stops or conditions are the “darn it” buttons and require quick stops. This is a Category 1 type stop. Category 2 would be an instance when a stop requires power to remain on a circuit. Hydraulic oil may need to keep circulating for an auxiliary power unit (APU) response, even if a machine is stopped. E-stops are not Category 2 stops, but a machine stop can be Category 2.

Category 1, quick stops after short amount of time, are used for high inertia machines where an immediate stop would harm people or machine, and the safe way to stop is to allow a time to slow down before removing power.

Removing power from the machine in a hard stop, would require a timed slow down and then removal of power. This is discerned by the application. Things to consider are time to stop, damage in not waiting for a controlled stop, risks between controlled stop and depowered stop regarding people.

In automated assembly lines, a Category 1 stop is crucial for safely halting operations. For instance, if a sensor detects an obstruction or a malfunction, the system initiates a controlled deceleration of the conveyor belts and robotic arms before cutting off power.

Computer numerical control (CNC) machines, which are used for precise cutting, milling and drilling, often employ Category 1 stops. When an emergency stop is

When an emergency stop is triggered, the press decelerates in a controlled manner before stopping, ensuring that the print quality is maintained and the equipment is protected.

Cold mills hold high tension with dangerous metal sheets. When a Category 1 stop is made the tension can be decreased on a set ramp to allow safe maneuvering of metal sheeting on a roll. This saves the material and the people. A hard depowered stop would leave tension on the sheet and risk a break and possible equipment damage.

Would a stop due to fire be a Category 1 stop? No. That is a Category 0 stop. Why? Fire hazard. Get out now.

Category 2 stops are like pushing the stop button in manual mode but keeping the power on because the drive should be ready for a “jog” function.

In conclusion, there are three types of category stops for machine builders: categories 0, 1 and 2. The most extreme is a hard-stop Category 0. The least extreme is a soft stop, which is Category 2, and Category 2 may not be an emergency stop .

Tobey Strauch is an independent principal industrial controls engineer.

Charles Palmer contributing editor

TECHNOLOGY HAS TRANSFORMED all types of sensors leading to massive improvements in manufacturing enterprises through better quality control and many others.

Having started my instrumentation career in heavy industry in the 1960s, when pneumatics was very much the core competency, and having moved on through the 4-20 mA analog era, finally ending up in the world of digitalization, I have been extremely blessed to have been able to witness these incredible changes in the process industries.

I once travelled 300 miles by car to tend to a faulty control valve, for a company who had no instrument staff. All I did was re-attach a positioner feedback arm to the valve stem, allowing the boiler feedwater to flow once more. The time taken to rectify this was less than 10 minutes and the company’s engineering manager was in total disbelief when my solution solved the problem.

the signal latched on. This series of electrodes provided the 4/6/8/10/12/14/16/18/20-mA output to the turbine speed con troller. It proved fully functional and highly efficient.

The second major sensor-related problem was the auto mated cane tippler system. Small cane-filled rail cars were hydraulically pushed into a 270° rotating tippler mecha nism. All position sensors used in the operation to position the car, lock it in place, rotate it and then unlock and eject on the rail system were of the simple mechanical type.

I was faced with an aging factory in dire need of automation.

In 1979, I was offered the position of instrument engineer at a sugar mill.

I was faced with an aging factory in dire need of automation, and, in the first 13 years I spent there, I systematically installed the latest, at the time, high-tech analog measurement and control instrumentation in the entire factory.

One of the major challenges was the measurement and control of the multi-stage steam-turbine-driven roller sugar-cane crushers. The shredded cane was fed into chutes, the levels in which were required to control the speed of these turbines. The existing solution was not successful in that the measurement of the conductivity of the shredded cane across the chute to determine its respective height in the chute was not reliable and caused much under- and over-feeding. The solution I arrived at was a system of a solid reference strip, vertically mounted on Perspex, electrode on the one side of the 84-inch-wide chute, with a series of nine button probes, also mounted on Perspex fitted to the other side of the chute.

This worked to a degree but suffered due to the signals across the chute being interrupted by air pockets in the cane mass. The ultimate solution was to incorporate positive feedback to the system of logic gates so that, once detected,

These devices suffered many failures due to the ruggedness of the application, in which fulllength sticks of cane, protruding out of the car, came into contact with these switches, thereby damaging them. I found a sim ple solution, in that I installed a highly rated series of magnetic switches, extremely rugged and virtually bullet-proof. Connecting cable was permanently connected, thus the ingress of moisture was prevented. End of problem.

Then there was the not-so-user-friendly system of moni toring the many boiler drum level gauge glasses, whose installation was mandatory under safety regulations. Because these were installed on the boiler drum and four or more floors above the ground, it was not possible to read them continuously. The interim solution was to drop two long lines down to ground level and mount a second gauge glass within normal visionary contact. The problem here was that, with many boilers, not all of these indicators were in direct line of sight of the boiler control room. This meant that the operator still had to leave the control room to verify any suspected problem. The simple answer, by 21st Century standards, was to install cameras facing each of the drummounted indicators and provide a desktop computer, where the screen was split into four segments, showing each of the four boilers. It was very much appreciated in the 1970s.

Charles Palmer is a process control specialist and lecturer at Charles Palmer Consulting (CPC). Contact him at charles101143@gmail.com.

Optimize time to market, efficiency and durability in electrical enclosures

by Mike Bacidore, editor in chief

MICHAEL BLASS IS design team manager at Concept Systems, a CSIAcertified system integrator headquartered in Albany, Oregon. Mike Moreau is senior electrician at Innovative Automation, a system integrator in Barrie, Canada, which developed the RoboTape platform. Moreau holds Construction Maintenance 309A RSE and Industrial Electrician 442A electrical licenses.

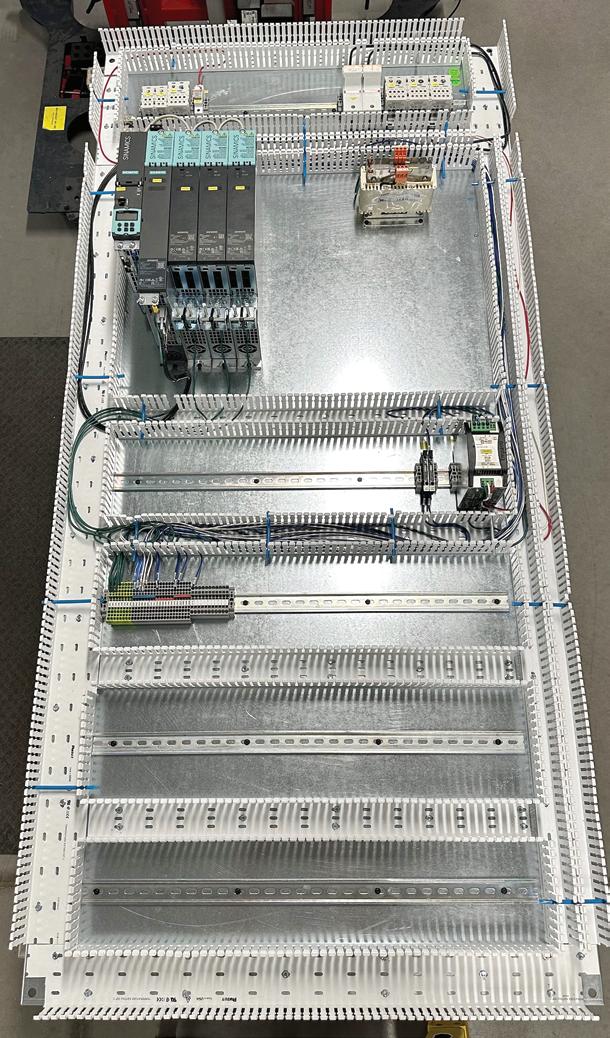

Figure 1: In Canada, Innovative Automation follows the CSA equivalent of the NFPA 79 which is a combination of CSA C22.2 No. 301 (Industrial Electrical Machinery) and CSA C22.2 No. 286 (Industrial Control Panels and Assemblies), as well as the Canadian Electrical Code.

(SOURCE: INNOVATIVE AUTOMATION)

Is NFPA 79 still the go-to standard? What does it tell us about installing electrical equipment properly?

Mike Moreau , senior electrician, Innovative Automation : In Canada, we follow the CSA equivalent of the NFPA 79 which is a combination of CSA C22.2 No. 301 (Industrial Electrical Machinery) and CSA C22.2 No. 286 (Industrial Control Panels and Assemblies), as well as the Canadian Electrical Code (Figure 1). These codes and standards lay out the minimum safety precautions and rules we must follow to build safe equipment that will not harm or cause injury. We then have a reputable inspection agency, such as the Electrical Safety Authority (ESA) come in and inspect this equipment before supplying it to our customers.

Michael Blass , design team manager, Concept Systems : NFPA 79 is certainly one of the key standards to consider, but it’s important to recognize that not all control panels require industrial machinery-level compliance. In cases where NFPA 79 is applicable, it plays a vital role in ensuring that human-machine interactions and electrical safety hardware adhere to a standardized methodology. This consistency is crucial, as it allows both operations and maintenance personnel to easily understand and operate the system.

However, the need for NFPA 79 compliance should be evaluated based on the specific requirements of each project, as other standards may be more relevant depending on the application.

How does proper routing ensure cable protection outside the enclosure, and why are bundling and labeling important?

Michael Blass , design team manager, Concept Systems: One of the biggest threats to system reliability is the integrity of the

Figure 2: Important parts of cable configuration in and out of the cabinet are accurate bundling and clear labeling.

(SOURCE: CONCEPT SYSTEMS)

interconnect hardware. Sharp edges, burrs and even minor vibrations in machinery can lead to the premature failure of cable and wire insulation. This is why proper routing and effective strain relief techniques are critical—they help protect the cables from these potential hazards. Equally important is accurate bundling and clear labeling (Figure 2). Proper labeling ensures that if a cable or wire causes issues, it can be quickly identified at both ends, making troubleshooting faster and more efficient. Additionally, it aids in aligning the physical wiring with the design documentation, reducing the risk of errors during maintenance or modifications.

Mike Moreau , senior electrician, Innovative Automation : Cable/ wire routing is important for different applications, equipment location and inspection bodies who will be certifying the equipment and cable ratings, as well as separation to reduce the chance of noise and electromagnetic interference (EMI). Depending on all these factors, we do separate wires and cable of different voltages, such as 480-600 V, threephase power distribution and low-voltage communications, such as Ethernet, Profinet and EtherCAT, and we will fully separate any ac wiring from 24 Vdc wiring and communication cables in cable tray (Figure 3).

Can you explain the different types of termination devices and the best applications for each?

Mike Moreau , senior electrician, Innovative Automation : In regard to panel and enclosure

wiring there are two main types of terminations we use, spring clamp and screw type. Spring-type connections can be a variation of push-in, where you simply push the wire into the terminal and it locks in place, versus having to compress the spring with a terminal driver to open the mechanism and then insert the wire. Spring-type connections are great for applications exposed to vibration where the spring keeps a constant pressure on the wire. Screw-type terminals use a set screw to compress and apply force to the wire to hold it in place; often screw-type terminals can be used for larger-gauge wires for higher current applications.

Michael Blass , design team manager, Concept Systems : There are several categories of termination methods for panel wiring, but they generally fall into two main types: screw clamp and spring cage.

While there are various versions within each category, these two styles are the foundation of most termination methods.

Screw termination, which has the longest history, involves securing the wire by torquing it to a specific pressure to prevent it from loosening over time. This method requires the use of calibrated torque drivers, adding both cost and time—not just in the initial procurement, but also in the ongoing maintenance of the tools. While screw clamps have been reliable for decades, they can be less efficient and more labor-intensive.

In contrast, spring cage technology is becoming increasingly popular due to its ease of use and resilience in high-vibration environments. Unlike screw clamps, spring cage terminals do not require specific torque, making them more straightforward to install. A version of this technology, known as push-in terminals, further

simplifies the process. With pushin terminals, no special tools are needed—wires of a certain minimum size can be directly inserted into the spring cage, and removal is as simple as pressing a button. The only caveat is that push-in terminals require the use of wire end ferrules. However, this is often not an issue since many customers already mandate the use of ferrules for all terminations.

Overall, the choice between screw clamp and spring cage methods depends on the specific application requirements, including factors like vibration levels, ease of maintenance and the need for specialized tools.

Considering the increasing complexity of machinery and the critical role of control panels, how can you effectively balance the demand for faster time-to-market with the need for robust, longlasting control panels?

Michael Blass , design team manager, Concept Systems : In today’s fast-paced, just-intime manufacturing environment, we achieve success by leveraging standard designs that incorporate built-in flexibility. One key approach is the inclusion of 20% spare I/O points and additional space in control panels, along with slightly oversized variablespeed motor controllers. This strategy reduces the level of detail required during the design phase and enables the early procurement of long-leadtime components.

The provision of spare I/O points and additional space offers signifi-

cant advantages, such as the ability to accommodate future expansions, updates and adaptations to evolving regulations. By planning for these contingencies upfront, we ensure that the control panels remain robust and adaptable over time.

Similarly, slightly oversizing variable-frequency drives (VFDs) and servo drives, within reason, provides crucial benefits. It allows for motor sizing to be finalized later in the design cycle, offering flexibility during development. Additionally, these oversized components are better equipped to handle the demands of aging motors that may operate continuously at the higher end of their ampacity range, reducing the risk of premature failure and extending the overall lifespan of the control panel.

By balancing the need for speed with thoughtful design considerations, we can deliver control panels that meet the demands of rapid time-to-market while maintaining the durability and reliability required for long-term performance.

Mike Moreau , senior electrician, Innovative Automation : Multiple strategies can be used to decrease the assembly time and provide robust solutions in a timely manner. Some of these strategies may include using spring-type terminals that offer quick assembly time but provide a durable connection compared to screw-type terminals that take longer to tighten down, as well as require preventive maintenance to make sure connections don’t come loose over time.

Another strategy we use is to move toward more devices that communicate with the programmable

Figure 4: Moving toward devices that communicate with the programmable logic controller (PLC) and other components through varying communication protocols such as Ethernet IP, EtherCAT and Profinet helps to reduce time to market. (SOURCE: INNOVATIVE AUTOMATION)

logic controller (PLC) and other components through varying communication protocols such as Ethernet IP, EtherCAT and Profinet among others (Figure 4). This helps reduce the time-to-market by not having electricians hardwire signals between both devices in the electrical control panel and devices outside the control panel. This also offers a larger range of control and enables troubleshooting to be able to pass more information back and forth over a communication protocol, rather than multiple wires between devices.

What are the most effective methods for standardizing panel design and components while maintaining flexibility to accommodate diverse machine requirements?

Mike Moreau , senior electrician, Innovative Automation : One cost-effective method we like to do is to use field-mounted communication-based I/O systems— remote I/O. These systems communicate using protocols such as Ethernet IP, EtherCAT or Profinet, for example, and are flexible with using discrete or analog I/O systems. The other benefit to these devices is you reduce the number of hardwired signals back to the main PLC and can reduce control panel size. Another advantage to using remote I/O is the large variation of hardware configurations.

Michael Blass , design team manager, Concept Systems : Incorporating flexibility into control panel design is essential for minimizing budget and schedule

impacts, particularly when dealing with one-off turnkey machinery. However, the diverse requirements of each application can make this a complex task. To address this, standardizing hardware and panel layouts across systems can significantly reduce overall design time, allowing for greater focus on creating adaptable solutions (Figure 5). This approach not only streamlines the

(SOURCE: CONCEPT SYSTEMS)

gearbox applications, DOL starters do not allow for speed adjustments, making any necessary changes costly in terms of both hardware and labor.

While VFDs may initially cost up to three times more than DOL starters, they provide a safeguard against late-stage speed adjustments, thereby protecting the project timeline and budget. Additionally, using the same motor and VFD sizes across various

VFDs offer motor speed adjustability, which is crucial since the exact speed required for a system’s cycle time is often estimated early on.

design process but also mitigates the impact of changes during both the design cycle and system commissioning. The foundation of this flexibility lies in building spare capacity wherever possible.

For instance, even when a functional safety level of Category 2, Performance Level C, is required, opting for the slight increase in labor and hardware costs to achieve a Category 3, Performance Level D system often proves advantageous. This proactive approach allows for potential hazards that could elevate the required safety level to be addressed later in the design or commissioning process, without disrupting budgets or schedules.

Another effective strategy is substituting VFDs for full-voltage direct-online (DOL) starters. This decision has multiple benefits. First, VFDs offer motor speed adjustability, which is crucial since the exact speed required for a system’s cycle time is often estimated early on. In fixed motor and

applications simplifies parts selection and spares management.

The second impact is on installation labor costs. As Ethernet communications become more prevalent in machinery, the extensive labor hours traditionally required for I/O wiring of DOL starters are significantly reduced. Ethernet connections streamline the process, reducing complexity and saving time.

Finally, modern VFDs often include functional safety-rated safe-torque-off (STO) control. This feature enhances motor safety control without the need for additional contactors and safety wiring, minimizing hardware within the panel and leaving extra space for potential design changes or future system expansion.

By standardizing key components while incorporating these flexible strategies, control panel designs can accommodate diverse machine requirements without sacrificing efficiency, safety or long-term adaptability.

WHAT IS A system integrator (SI)? Most people have an overall understanding about their role providing solutions by bringing components together into a working system. While there are system integrators in many fields, this article restricts the term SIs to those working in industrial automation.

The CSIA (Control System Integrators Association) provides the following definition: “System integrators design and implement sophisticated control systems for manufacturing, process and other industrial facilities. Using their knowledge of engineering, information technology and business, system integrators integrate plant equipment to automate manufacturing and processes from the plant floor to the enterprise level. Automation helps manufacturers and processors reduce cost, increase production, use less energy and lower environmental impact.”

SIs represent a diverse community providing a broad spectrum of solutions over many industries. Some suggest that there isn’t a “typical SI.” To better understand these solution providers, it is necessary to dive into further detail.

SIs specialize along the following categories:

• industry verticals/applications

• technology

• scope of supply (types of services provided)

• geographical presence

• company setup.

When asked to select their top-served end markets, up to three, SIs selected food and beverage (50%), water and wastewater (29%) and OEM/industrial equipment (23%) (Figure 1).

Most significant served end markets (Select up to 3)

Packaging

Chemicals and petrochemicals

Consumer goods / Household products

Automotive

Other (please specify) Building

The digital world returns to CSIA Exchange in Dallas

Digital tools have become important assets in the system integrator’s arsenal. A variety of products and services are changing the way controls automation is utilized in equipment. At the CSIA Exchange in Dallas, which marked the 30th anniversary of the Control System Integrators Association (CSIA) meeting and conference, Tim Ogden, director, solution provider program, GE Digital, led a diverse group of panelists representing the process/ discrete manufacturing industries, industrial automation and manufacturing execution and operations.

All three panelists— Brian Romano, director of technology development at Arthur G. Russell (AGR), an original equipment manufacturer (OEM) that builds equipment; Renato Leal, founder/CEO, GreyLogix Brasil; and Sam Hoff, president and CEO of system integrator Patti Engineering—were part of a similar panel at the previous year’s CSIA Exchange in New Orleans.

At Patti Engineering, digital twins and virtual commissioning have become esteemed components in the toolkit. “We’re doing a lot of work using the Siemens product,” said Hoff. “We do a lot of upgrades.” In fact, Patti Engineering shut down a line and upgraded a system the weekend following CSIA Exchange in Dallas. The upgraded system needed to be up and running on Monday after the weekend upgrade.

Patti Engineering’s use of simulation shortens the time to production start. “You have to build a model,” explained Hoff. “The whole idea is to be able to simulate the code and simulate the system beforehand. Maybe you’re building a new line for General Motors (GM); those parts are very expensive for GM to build. There are certifications on drives that are being done digitally now. It does cost a little more upfront, but you’ll save time in the field.”

Hoff also explained the difference between a simulation and a digital twin. “You have to feed that real-world data back to make it a digital twin,” he said. “Now you

can feed historical data back to the digital twin. In the old days of delivering a system, you handed them a manual and said, ‘Call me when it breaks.’ That’s not a good way of doing business. We have monthly calls with customers and do service calls. Through analyzing data, you can use the twin for what-if scenarios.”

AGR’s Romano has been in automation more than 43 years. “We start off at the proof-ofconcept level,” he explained. “I specialize in connecting the factory floor to the business system. We were doing Industry 4.0 before it was a thing.” Romano identified four steps:

• expose the date

• collect the data

• analyze the data

• apply the learning.

“My mandate when first coming onboard was to put together a data system that would differentiate us as an OEM that would do things others wouldn’t do,” explained Romano, whose vision was to build that system into the equipment, so the customer could just plug into it.

“We also wanted to offer customers a way to bring the old machines into the digital thread,” he recalled. “Some tools we use go back to legacy stuff, like unplugging a photo eye. How can I go to Industry 4.0 if I can’t bring the full legacy suite into the realm?”

Once Arthur G. Russell got its customers onboard, it took a step back and gave remote support.

“There’s a lack of technical help out there because of the silver tsunami and COVID,” said Romano. “I put together a skills matrix. I have a spreadsheet for every employee in my department. Some are specific to us, but some are not. By being able to look at the skills matrix, I can assign the right person to the right job. Plus, I can do pairing to train new employees with skills.”

GreyLogix now has an office in Florida, giving the organization three different touchpoints with customers, said Leal. “We

try to make things simpler,” he noted. “We invested in an online virtual tour, so people can go into our facilities and see what we do. We created a platform where you can navigate through the system.”

When GreyLogix calls on customers, it brings a ready-made opportunity for a user to enter the Industry 4.0 world. “We have a YoT box,” explained Leal. “IoT solutions are a fast-track way for customers to get to Industry 4.0. When we go to the customer, we try to remove the barriers to saying no. When the customer sees the information from his own machine or process, it’s the kind of solution you can charge as a service, so you have recurring revenue.”

Once the customer sees the information via the YoT box and likes the information, Leal said he hasn’t had a customer that returned the contract.

“We believed in this idea,” he explained. “It’s the kind of venture that doesn’t pay off from the get-go. We spent some hours and money on that. We started investing in that. During the development, we realized we needed a lot of IoT capabilities. Now our IoT team is a mixture of IT and OT guys. We have more than 100 of these boxes installed. It’s a process.”

The first two markets are widely distributed geographically providing many SIs with the opportunity to participate. There are other industries that tend to be more geographically concentrated, like automotive and oil and gas, thus limiting their appeal.

Delivering solutions requires a solid understanding of the needs of the clients. It starts with the selection of the industry vertical and includes the industry drivers, regulations, applications and processes. In addition, most manufacturing and process companies have their own standards and preferences that SIs must follow.

• Those serving oil and gas, chemicals and petrochemicals understand that they work in explosive and poisonous environments where their processes are to operate continuously for long periods of time, ideally until the next scheduled shutdown. This has big implications for the selection, installation and operation of equipment.

• Those serving the life-science industries understand that their clients deliver products that are consumed—ingested or injected— by individuals. Food and Drug Administration (FDA) regulations play a key role in ensuring product safety. Their requirements around validation are of paramount importance for this industry. SIs serving this industry need to master FDA validation standards.

Another way SIs may specialize is through their targeted applications. This approach is not completely divorced from the industry verticals. The SIs that specialize in the automa-

Process Refining, chemical

Discrete Automotive, Packaging

DCS (distributed control system)

PLC (programmable logic controller), PC (personal computer) based control

Batch Brewing, Life Sciences Either

tion of machines understand they tend to go into certain industries.

The selection of the industries and/or applications to serve has implications for the automation technology to deploy. From the perspective of the control system, industries can be grouped into process, discrete and batch. Over time the border lines between these categories have blurred as the systems have become more flexible (Table 1).

SIs servicing brownfield installations need to master the existing control system, no matter how old they are. While the approach to SI project management may be replicable, there is a learning curve when it comes to the specifics of the various control system platforms. SIs need to invest in the technical competence of their staff through continuous education. Practically, this means that SIs select a finite number of platforms and vendors that they focus on.

Technology goes beyond the control system, and it includes systems like supervisory control and data acquisition (SCADA) systems, manufacturing execution systems (MES), emergency shutdown (ESD) systems and alarm monitoring systems. Underneath the control system are the field devices— actuators like valves and motors—and instrumentation. Depending on the

industry and application, other technologies such as robotics can come into play. The palette is very broad.

Services provided by system integrators

Many SIs engage with clients after the project has been specified. The services on a typical project include the configuration of the control system to perform the desired tasks, the integration to other systems or applications, procurement of the automation equipment, construction of the control panel, installation, commissioning and startup.

There are many other services provided:

• operator (client) training

• solution design, functional specification

• electrical design and construction

• mechanical design and construction

• functional safety design

• cost estimation

• risk assessment

• engineering staffing services

• remote monitoring of critical assets / processes

• data management services.

Some SIs engage early with their clients, allowing them to design the solution. At this stage, the client may only have a vague idea of what

is needed. Other SIs provide services that keep them engaged after project delivery. This may include the upkeep of a virtual twin of the plant or machine or operator training to help them leverage procured process or machine data.

Historically, end users favored SIs that were geographically close to their sites. There was little expectation that the selected SI would be able to cover multiple plants spread over a wide territory. While this may still represent the prevalent mode, some industries, such as automotive and life sciences, have pushed SIs to develop regional and, in some cases, global presences to support their plants.

Certain geographies favor certain industries—Houston for oil and gas, refining, chemical and petrochemical. This will be reflected in the local SIs. On the other hand, other industries like food and beverage and water and wastewater geographically are widely spread, partially explaining the larger participation in these segments by SIs.

The SI company may take different forms. If the focus is on the way industrial system integration is delivered, then the following options, which are neither exhaustive nor mutually exclusive, emerge:

• independent system integrator

• machine builder

• IT SI/consulting

• Engineering, procurement and construction (EPC)

• automation equipment vendor

• end user (Figure 2).

Independent system integrator: It is estimated that there are around 3,000 SIs in North America. This number includes many independent contractors that operate by themselves or with a small support staff. On the other extreme are SI companies that started as independent contractors and have grown to be large, multimillion-dollar companies, some of them with an international presence.

According to the Spring 2023 CSIA-JP Morgan survey, 52% of the represented SI companies had annual revenues below $10 million and 19% had annual revenues under $2 million. There are a few large independent system integration companies that have grown successfully past the $200 million mark. For these companies, system integration represents

a key part of their deliverables; some offer additional services, often electrical construction.

Machine builder: In this category, the deliverable includes the mechanical design and construction. The machines in this category tend to be highly tailored and sometimes unique—production of one. Frequently there is a group or division in charge of the deployment of the automation. In certain parts of the world with long machine-building traditions, such as Germany, Italy and Austria, the automation and the mechanical parts are viewed as integral. Some machine builders opt to work with an external SI company for the automation portion.

IT SI/consulting: The trend toward digital transformation/smart manufacturing/Industry 4.0—pick

your term—has driven the need for solutions that reach from the corporate level down to the factory floor. IT SIs are companies that often provide solutions around consulting and deployment of enterprise resource planning (ERP) software. For the newer solutions, these IT SIs have either acquired industrial automation Sis, in this context sometimes referred to as operational technology (OT) SIs, or partnered with independent ones. Engineering, procurement and construction (EPC): These are large service providers that often deliver civil, mechanical and electrical design and construction of large industrial plants or installations. Some of

To gain the expertise to augment their existing internal capabilities, some automation equipment vendors chose to acquire SIs.

these companies have a division that handles the automation required in the larger projects of the EPC and/or procures external projects. Some EPCs don’t have an internal SI division, and they work with third-party SIs.

Automation equipment vendor: The trend toward solutions forced many automation equipment vendors to adapt their strategies and deliver the full solution. To gain the

expertise to augment their existing internal capabilities, some automation equipment vendors chose to acquire SIs. This direct approach is reserved for large, strategic accounts. The rest the automation equipment vendors tend to work together with their network of SI partners.

End user: It used to be common for larger manufacturing and process end users to have their own internal sys-

• Unmanaged 10/100/1000 Mbps Ethernet switches

• Single mode and multimode fiber optic switches and media converters

• Diagnostic switches for network troubleshooting

• PoE switches, mid-span splitters and injectors

• Wired and wireless IP routers for secure remote access

• Custom configurations and outdoorrated options available

tem integration groups within their engineering departments. As competition forced these companies to focus on their core capabilities, many chose to eliminate their SI groups. In some cases, the employees of the SI groups saw the opportunity to set up their own SIs companies. While some end users still retain their SI capabilities, the trend over the past decades continues to be to outsource the work.

The Control System Integrators Association was established in 1994 with the mission to help system integrators build successful businesses and advance the impact system integrators have in industry. Through Best Practices and Benchmarking manual and its optional certification program, it provides an objective framework to help SIs set up and improve their companies. Since its founding CSIA has witnessed significant changes in the SI landscape. Through its annual conference, webinars, podcasts and community of peers it helps SIs stay engaged and up to date.

The term SI is frequently used but often in need of additional explanation. SIs represent a key entity for the delivery of industrial automation solutions. They are key for their manufacturing and process clients; they are also key for their automation equipment providing partners. CSIA helps SIs build better companies for the benefit of their clients and partners.

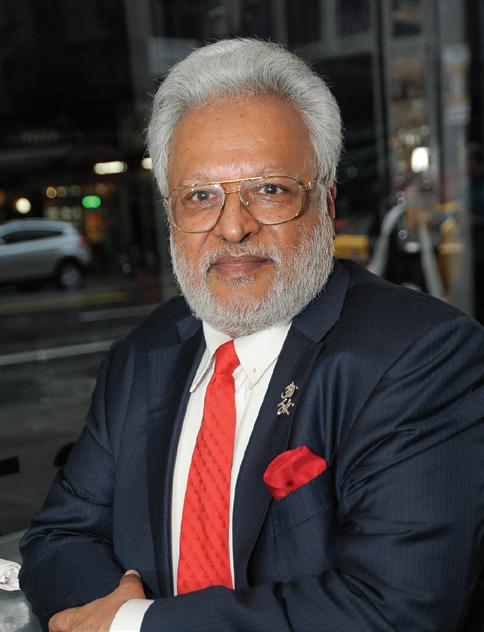

CEO of the Control System Integrators Association since March 2015, Jose M. Rivera works to help independent system integrators build better companies through the adoption of the association’s

best practices guidelines. His global career in the automation industry, including Emerson Electric, Schneider Electric and Siemens, has spanned six countries, most often with regional or

global leadership roles. Rivera holds an MBA from Kellogg School of Management at Northwestern University, and Lic (MS) and BS degrees in electrical engineering from the University of Costa Rica.

Co o ling capacity rang e: 1,000 to 21,000 BTU/ hr

C onta ct us for a brochure or more informa tion on a ll the other options a nd specs.

“SHALLI” KUMAR, founder and chairman, EZAutomation

IN 2025, AVG Automation, parent company of EZAutomation, a midwestern U.S. manufacturer and factory-direct purveyor of industrial automation systems and components, will celebrate 50 years since its founding in 1975. The automation technology landscape has changed dramatically since that time, but many of the underlying industry needs remain unchanged.

Q: Innovation has always been a strong suit with EZAutomation and AVG Advanced Technologies. As founder and chairman, how have you been able to maintain a continued run of technology and products that transform the industrial automation space over the course of decades?

A: Innovation is in my blood, in my DNA. It is food for my soul. I don’t think I can live without it. I deal with it every day.

In 1984, General Motors had decided to buy 100 press lines for the stamping plant. In early 1985, I thought of a resolver with built-in electronics using a flexible potting compound. There was nothing like that on the market. I called the chief engineer of General Motors and told him about my idea. Within the next three days, he gave me an order for $10 million worth of resolvers with no physical sample and no prototype ever built. Sometimes innovation at the right time has great rewards. Sometimes necessity is the mother of invention.

In summer of 2004, we got a notice from our marketing partner with mutual exclusivity that they were going to terminate our contract for stocking and selling our EZTouch product line. We designed and put in stock 10 new product lines including the EZPLC, the EZTouchPLC and EZMarquee. Our survival was at stake.

Q: You’re calling the EZTouch Series 5 HMI your “China killer.” How has the touchscreen interface been redesigned to make it less expen-

sive than those sourced from China, while still delivering the functionality and support that your customers have come to expect?

A: We went to work to reduce our cost of manufacturing further by more efficient design, investing in more automated manufacturing lines and are proud to introduce EZ5. EZ5 has a newer microprocessor. Its memory is a bit smaller. The number of screens are limited to 64. For most customers, 64 is sufficient, but it retains all the other exceptionally innovative features of HMI— online edit, visibility tags, remote monitoring and control over smartphones, real-time datalogging, email and text alerts, on-screen recipe edit, C Level scripting to save PLC code, and screen life of 50,000 hours at 40 °C.

Q: The EZTouch miniPLC combines HMI and PLC functions and features in a small form factor. Given the punch it packs, the term “mini” might even be misleading. Can you talk about the amount of innovative technology per cubic inch that OEMs will find in this component?

A: Perhaps it should be called “mega in a mini size.” The reason we called it mini is because this product has its 4-inch screen size with 27 I/O points and it’s only 5 inch by 4 inch, and it is only 1.5 inch deep. That’s the reason we thought of calling it a mini. The website also has a very nice 360° rotational view of the product to view what it looks like overall. Using EZTouchPLC is a prime example of made-in-America innovation costing less than made-in-China. Inspiration for this product, as usual, came from talking to our customers. They needed a very compact and thin HMI with PLC integrated in it, 27 I/O, that is 12 dc inputs, eight dc outputs, 4 of 5-A one form C relays, two analog in, one analog out, 250 kHz encoder input. All I/O is wired through plug-in terminal blocks with LED indicators.

These dc outputs are shortcircuit-proof. We even put in numbers on all relay contact outputs, so the customers do not have to put external numbers costing at least $20 plus labor for each number across the contact. Our customers save at least $200 for each PLC. Besides a very low cost of EZTouch miniPLC at $399 for a 4-inch 27 I/O model. Coming back to the PLC, it’s a high-end PLC with lots of function blocks with a unique drag-and-drop feature in its PLC programming.

Q: What benefits come with products that are made in America, and how will those benefits carry on into the decades ahead, in light of the changing technological, financial and political climates?

A: If China attacks Taiwan, there will be complete embargo on Chinese goods. There are significant advantages of design in made-inAmerica products. When you are closer to your customers and are in the field in their facilities, you design better products such as EZTouch with patented HMI online edit, saving thousands of dollars in changing screen design on the fly with zero downtime. No other HMI can do it. This is American innovation on full display; both EZ5 and miniTouch PLC have it.

HMI design, so they do not want the user to have access to the screen designs using our programming software. Yet they still want to be able to upgrade their HMI screen design from time to time.

With the OEM utility, all the OEM has to do is to email an executable file to the user and without any software just connect the programming port to the laptop with the email in it that the executable file is sent over email. EZ5 on any TouchPLC will do the rest.

There’s another feature that came out of a close customer contact. This is mini 5’s mini Wi-Fi capability, both EZ5 and mini have the option of inserting a tiny Wi-Fi module to the RS-232 port. You can program, monitor, edit your EZ file or mini from 50 feet away and sitting on a proper workbench instead of climbing on obstacles like conveyors or suiting up to go near the HMI in an environmentally controlled area.

I’ll close by telling you another story. You all know about 24 Vdc fans and solenoid. You know their wattage and dc nomimal current. Let’s say it’s a 6-Watt fan with 250 mA nominal current. It should be no sweat for dc outputs rated at 500 mA,right?

You build your machine but constantly see your PLC dc outputs burning out. You tried to contact your automation supplier’s tech support, but no luck. Frustrated, you just decide to add external 5-A solid-state relays, costing $30 in just relay cost, plus labor.

Another innovative feature we have is the visibility tag. That is, we lay objects on top of each other and make them visible only when needed. This is a great space saver on the panels. Another is C Level scripting that cuts down PLC logic; real time data logging came out of a personal customer visit at an OEM’s facility. This customer makes compressors, and some customers of theirs do not maintain the compressor properly and claim warranty.

So this OEM wanted to have real-time data-logging, so that, sitting in New Jersey, the OEM can show a customer that their maintenance did not pay attention to a number of alarms resulting in the motor burning up.

Another feature that came from a customer visit was OEM utility. Many OEMs want to protect their intellectual property in the

You have four outputs that are giving you trouble, so spend another $200 in cost plus lose precious panel space. On top of all this, you want the PLC outputs to be shortcircuit-proof. You do not want to have to install fuses and increase the downtime of the machine if something burns out. But the 5-A SSR unfortunately is not shortcircuit-proof. The problem here is a locked rotor current of the fan motor, which is 600 mA, and the inrush current of the fan motor is almost 1 A. This is a real-life story. EZautomation came up with a current module with eight outputs, each one capable of handling 1-A locked rotor current and 4-Amp inrush current, fully shortcircuit-proof in a 2-by-2-by-1-inch EZ PLC I/O module. This was done from notice to production in three months.

For more information, visit osi.ezautomation.net.

Controllers, motors and drives enable actuation

M.G.M Electric IEC motors and brake motors

M.G.M. Electric IEC standard and brake motors are manufactured in Italy and are rated for general-purpose and inverter duty. IEC motors provide the same power output as NEMA motors but have a smaller footprint and feature a lightweight aluminum construction.

IEC standard motors offer outputs rated up to 5 hp at 1,800 rpm and up to 1 hp at 3,600 rpm. M.G.M. brake motors are available with outputs rated up to 5 hp at 1,800 rpm and feature brakes that are direct three-phase ac coils (no dc rectifier required). Replacement brakes are also available. M.G.M. IEC and brake motors start at $144, and all motors come with an 18-month warranty.

AutomationDirect / www.automationdirect.com

KEB’s DL4 servo motors are designed to deliver high torque and precision in a compact design. They are designed for demanding industrial applications and offer options for cooling, protection and feedback systems. Available in multiple sizes with torque ratings ranging from 11 to 520 Nm, DL4 servo motors are designed to deliver performance for a range of large-power machinery.

KEB America / www.kebamerica.com

Beckhoff AA3100 series is designed as a drop-in replacement for hydraulic or pneumatic actuators. To simplify replacement, the AA3100 devices leverage an ISO 15552 flange size and bolting points on both sides, as well as an external thread mount on the shaft end of the spindle to mount ball heads, clamping hooks or other common adapters. There

are two variants each for the first products in the series, the AA3123 and AA3133 electric cylinders. The AA3123 has 5,300 N peak force, 1,300 N continuous force and 0.28 m/s maximum speed, as well as 2,650 N peak force, 650 N continuous force and 0.56 m/s maximum speed. The AA3133 has 12,500 N peak force, 2,800 N continuous force and 0.12 m/s maximum speed, as well as 6,000 N peak force, 1,400 N continuous force and 0.24 m/s maximum speed.

Beckhoff / www.beckhoff.com

The Festo CMMT-ST multi-protocol dc servo drives are configurable for EtherNet/IP, EtherCAT, Profinet and Modbus TCP. OEMs can use the Festo Automation Suite configuration tool to log onto the drive and select a protocol from a dropdown menu. A single drive for multiple protocols lowers inventory overhead and learning curve. The CMMT-ST and ac version CMMT-AS are available globally with fast shipping times.

Festo / www.festo.com

Yaskawa’s GA800 variable speed drive is designed to control traditional and emerging motor technologies. The GA800 handles applications ranging from simple fans and pumps to test dynamometers requiring precise regulation. The GA800 provides network communications, embedded functional safety and tools featuring mobile device connectivity. GA800 frame 12 standard drives include 480 V, 700 to 1000 HP.

Yaskawa / www.yaskawa.com

The PKP stepper motor series by Oriental Motor offers two phase options: two-phase for high torque and low vibration, or five-phase for high accuracy and low vibration. Available in motor frame sizes ranging from 20 mm to 85 mm, the PKP series features an enhanced magnetic and structural design. Additionally, the torque in the high-speed range can be increased by using high-current motors. Reducing the running current supplied to PKP motors maintains the same torque as conventional products while decreasing power consumption. By replacing a standard PK series motor with a PKP Series motor, equivalent torque can be achieved, while reducing the motor size.

MiSuMi / www.misumiusa.com

Control Techniques’ Commander S100 series ac drives, ranging from 0.18 to 4 kW (0.25 to 5 hp), are designed to offer versatile performance for various applications. Available in single-phase and three-phase options, these drives support Linear V to F, Square V to F, and Resistance Compensation modes. The integration of NFC technology and the Marshal app are designed to simplify drive commissioning, cloning and diagnostics, enabling seamless configuration and realtime monitoring.

Galco / www.galco.com

adaptability. Enhanced by MoviSuite software, Movi-C is designed to simplify setup and operation.

SEW-Eurodrive / www.seweurodrive.com

Fuji Electric Frenic-Mega series is designed to offer high-performance features and functions, allowing one product family to cover a broader range of applications. Offering expanded power ratings and flexible configurations that support 1/2 hp up to 1,000 hp, the Frenic-Mega is designed for industrial applications where standardizing on one product across a facility can lead to increased productivity.

Fuji Electric / www.fujielectric.com

The Omron CK5M EtherCAT modular multi-axis PMAC controller is designed to remove constraints and barriers and maximize a machine’s capabilities, helping to obtain the best performance. The CK5M EtherCAT modular multi-axis controller has motion control capability with its compact design, multivendor connectivity and flexible development capability.

Omron Automation Americas / automation.omron.com

The Movi-C Modular Automation System from SEW-Eurodrive integrates drive components, control electronics and software into a singlesource product. This system supports applications from conveyors to robotics, offering scalable control technologies and customizable MoviKit modules for

The 24 Vdc geared motor from RS Pro is designed to deliver durable, high-power performance in a variety of industrial applications. It features an iron core, spur gear and 6-mm straight shaft, delivers 9 rpm and 600 mN/m torque and measures 110.10 x 38 x 38 mm. It is also RoHScompliant, equipped with a three-year warranty and backed by the RS Pro seal of approval based on a testing, inspection and auditing process aligned with demanding international standards.

RS / us.rs-online.com

ABB’s CIP Safety FSCS-21 function module is compatible with its ACS380 (machinery), ACS580 (general purpose) and ACS880 (industrial) series of drives. Certified by TUV, this plug-in safety module is designed to enable seamless integration of ABB drives into a CIP Safety network with any CIP Safety PLC. The module features two built-in safety functions: Safety Torque Off (STO) and Safe Stop 1, time controlled (SS1-t), which meet machinery safety requirements up to SIL3/Ple. These safety functions require no special parameterization, software or safety password. Simply define the safety network number and EtherNet/IP communication settings and start running your application. Additional features include support for DLR ring networks and predefined safety and non-safety add-on instructions for advanced PLC integration. ABB / www.abb.com

ABB’s synchronous reluctance motor (SynRM) technology is a magnet-free design reaching IE6 hyper-efficiency, an anticipated efficiency level ABB defines as achieving a 20% reduction in energy losses against comparable IE5 motors. Magnet-free SynRM motors are part of a wide-ranging technology portfolio that also includes permanent magnet (PM) and magnet-assisted SynRM (PMaSynRM) motors covering a wide range of application needs. ABB’s magnet-free SynRM motors are an element in ABB’s premium portfolio of high-performance motors.

ABB Motion / www.abb.com

ABB Baldor-Reliance SP4 motor line

The cast-iron totally enclosed fan cooled (TEFC) severe duty motor marks the second phase of ABB’s SP4 technology launch. This model is designed for applications in hazardous environments with certifications for Division 2 and Class I Groups A, B, C, D, as well as Class II Groups F, and G,

making it suitable for areas with explosive gases and combustible dust. The model also features an IP55 rating. The SP4 product line builds on the simplicity of ABB’s ac induction motors. These motors are compatible with pumps, fans, compressors and conveyors and are designed for all industries. The cast-iron motors cover a power range of 25 to 300 hp, and the rolled steel models are available in ¼ to 20 hp.

ABB Baldor-Reliance / go.abb/motion

Curtiss-Wright’s Exlar Tritex EVA electric valve actuator has achieved CSA Class 1, Division 2 (C1D2) Hazardous Location certification. The Tritex EVA is designed to meet the Methane Emissions Reduction Program (MERP) and Quad-O zero-emissions regulations in the oil-and-gas industry. The Tritex EVA is designed to be environmentally friendly and efficient with a compact system integrating a servo drive, motor and roller screw actuator to achieve extreme life, speed and accuracy. Combining the actuation system with Modbus RTU communications enables producers to have remote operation and monitoring. The electric Tritex EVA has been under field test throughout 2023. Curtiss-Wright / www.curtisswright.com

IDEC’s ez-Wheel Assist Wheel Drive (AWD) EW1A series provides electrical motion assistance for industrial manual material-handling equipment. The EW1A system ‘s main drive unit is available with 150 mm or 160 mm resilient polyurethane wheels, and the ability to support a vertical working load up to 400 kg, and to transfer loads up to 1,000 kg. A suspension bracket provides an adapt-

able way to add the main drive unit to upgrade any equipment. All models can accept internal batteries, which are recharged with a specific cable and charger. However, for greater capacity designers can alternately choose to use an external battery pack by means of an adapter cable. Batteries operate at a nominal 24 Vdc, with capacities ranging from 3 Ah to 15 Ah, depending on the model. The wheels operate at about 0 to 5 km/hr (0 to 3 mph) in both directions and are available with adjustable braking modes and an option parking brake. The wheels are rated for indoor use, in nonfreezing temperatures and up to 40 °C.

IDEC / www.idec.com

The ECF series of brushless DC flat slotted motors, with diameters as small as 20 mm, are designed for robotic applications where space is limited and performance demands are high. Their compact, flat form factor and high-power density ensure higher load capacity without speed loss, while smooth output torque enhances efficiency. Extensive customization options are designed to make the ECF series versatile and able to meet a diverse range of needs.

Portescap / www.portescap.com

The smarty7, fully programmable, four-channel controller has selectable inputs for all common types of loadcells and is integrated into drive systems to provide accurate load and tension control. The basic model dw2501210, designed and built in the USA, includes drive. web Ethernet for interface to drives and plug-and-play interface to savvyPanel touch screens. Diameter compensated winder controls and web splice logic can be added. Multiple controllers, drives and touchscreens can be networked peer-to-peer over Ethernet for a complete system in one homogeneous technology.

Bardac / www.bardac.com

Parvalux by maxon has designed and manufactured a series of modular components that are mixed and matched so that users get a paired system from one manufacturer. In a threestep selection process, designers can purchase a motor that is built to order using the company’s online configurator. Designers need to focus on voltage, speed and torque in every case. Users of the online configurator can fine-tune their selections using a range of accessories including brakes, encoders, shaft extension kits and controllers. Parvalux offers a line of motors that includes permanent magnet dc motors, brushless dc motors and single-phase or three-phase ac motors, all of which are available with inline or right-angle gearboxes. The company’s line of ac/dc motors are available in series-wound or shunt-would versions. Accessories, such as encoders and brakes can be selected.

Parvalux / www.parvalux

Altivar Solar variable speed drive is compatible with a wide range of pumps and solar arrays. The Altivar Solar ATV320 drive is designed to be robust, simple to commission and easy to integrate for pumping applications. The drive embeds solar-specific functions to address application requirements and improve pump performance. Key features for the Altivar 320 Solar include intelligent algorithm to detect solar panel parameters; dual supply to change over alternatively from solar to grid and vice versa; Ethernet/IP option module to allow Altivar Solar drives to be integrated into scalable automation systems; safe pump operation with built-in protections like dry pump protection, pump overload, tank-full detection, over-voltage and under-voltage fault protection; low operating voltage range, allowing for extended pumping hours, early in the morning and late in the evening; and anti-jam function to enable auto pump cleaning through forward and reverse movement.

Schneider Electric / www.se.com

A CONTROL DESIGN reader writes: I’ve seen basic standard stacklight colors on machines for years, but now it seems there are a variety of other colors for various conditions. Are there any downsides to adding colors or flashing patterns? Do they confuse operators? And what about “smart” stacklights with advanced communication technology? Is it overkill, or are we missing an opportunity by not including them on our machines?

The evolution of stacklight colors and patterns offers a range of perspectives. To begin, it’s essential to understand the standards relevant to your industry. NFPA 79, Section 10.3.3 and the OMAC PackML guidelines are widely recognized in machine automation and control. However, many industries have their own formal and informal standards, so thorough research and alignment with your specific application are critical.