Energy prices keep rising and efficiency rules keep tightening — yet, the smart use of waste

if

Energy prices keep rising and efficiency rules keep tightening — yet, the smart use of waste

if

Here’s a compelling vision: smart, autonomous industrial facilities operating with minimal human oversight, driven by artificial intelligence and autonomous robots. Our author Ahlam Rais has collected success stories showing that the plant of the future is no longer a distant idea — it is taking shape today, with digital twins and augmented reality at its core. Robotics, perhaps the most visible aspect of this development, is already transforming the very nature of plant inspection and maintenance. Companies such as Evonik, Equinor, and BASF are deploying four-legged autonomous robots that can read gauges, perform acoustic measurements, and detect environmental hazards — all without human supervision.

AI is also proving it can manage complex operations: Yokogawa’s technology enabled a Japanese chemical plant to operate autonomously for 35 consecutive days. The Eneos Kawasaki Refinery’s successful use of AI-based autonomous operation for processing crude oil shows that AI can handle even the most complicated and large-scale tasks.

Digital twins allow a shift from previous reactive plant management methods towards truly predictive maintenance. Bentley’s digital twin implementation at China’s Shenyang Aluminium & Magnesium Engineering & Research Institute vividly illustrates how virtual models enable truly predictive maintenance.

This technological revolution brings tremendous opportunities but poses also significant challenges: Cybersecurity becomes paramount when plants operate autonomously. Workforce skills must evolve from operational to analytical. Investment priorities are shifting from hardware to software and data management capabilities. But the opportunities far outweigh the risks. For organizations ready to embrace this transformation, the rewards can be substantial: reduced operational costs, improved , enhanced efficiency, a lower environmental impact, and ultimately, a sustainable competintage in an increasingly demanding

Anke Geipel-Kern Senior Editor

BASF has successfully achieved mechanical completion of the steam cracker at the Zhanjiang Verbund site.

BASF and funds managed by global investmentfirmCarlyle,inpartnershipwithQatar Investment Authority, have entered into a binding agreement relating to the companies automotive OEM coatings, automotive refinish coatings, and surface treatment businesses. The enterprise value of the transaction amounts to 7.7 billion euros. Subject to customary regulatory approvals, the transaction is expected to close in Q2/2026. The business, together with the already closed divestiture of the decorative paints business, value the entire Coatings division at an enterprise value of 8.7 billion euros.BASFwillalsoreinvestinthecoatings business holding a 40 percent equity stake andwillreceivepre-taxcashproceedsofapprox 5.8billioneurosatclosingofthetransaction (wer)

BASF has reached two significant milestones at its Zhanjiang Verbund site: the successfulstart-upofthebutylacrylate(BA) plantandthemechanicalcompletionofthe steamcrackerandallintegratedpetrochemicalplants.Theseachievementsmarksteady progress toward the site’s full operational start-up by the end of 2025, reinforcing BASF’scommitmenttomeetingthegrowing demand for high-quality petrochemical products across the Asia Pacific region.

The butyl acrylate plant commenced operations on August 11, 2025, ahead of schedule and with an exemplary safety record. The first shipment was successfully delivered via tanker trucks on August 17, 2025, marking the plant's inaugural customer de-

ENERGY EFFICIENCY

livery With an annual capacity of approximately 400,000 metric tons, the plant furthersolidifiesBASF’sleadershipintheacrylics market, supplying essential materials to customers in the adhesives, industrial coatings, and architectural coatings industries. Moreover,BASFhasachievedmechanical completion of the steam cracker and all downstream petrochemical plants, includingethyleneoxide,oxoalcohols,syngas,and high-densitypolyethylene,attheZhanjiang Verbundsite,transitioningtheprojectfrom construction to operational readiness. This milestone ensures all systems are installed, connected, and tested, paving the way for commissioning and start-up activities scheduled for the end of 2025. (wer)

OQAlternativeEnergy(OQAE),asubsidiary of OQ, Oman’s global energy investment group, recently announced the launch of Oman’s first large-scale Superesco project. Through the Superesco model, OQAE will implement comprehensive energy efficiency upgrades at OQ Refineries & Petroleum Industries (OQRPI) facilities, including equipment replacement, system optimisation and operational improvements. The initiative will generate annual savings of 22.5 GWh and reduce CO₂ emissions by 9.4 kilotons,deliveringlong-termvaluethrough optimised operating costs and improved asset performance. In doing so, Superesco model supports Oman’s decarbonisation and sustainability objectives under Oman’s NetZero2050 Theprojectwillbecompleted within twelve months of implementation,

followed by a performance verification phase. Through such initiatives, OQAE continues to build a stronger foundation for Oman’s energy future, accelerating the nation’s transition toward a more sustainable and competitive low-carbon economy. (wer)

OQ Alternative Energy recently announced the launch of Oman’s first large-scale Superesco project.

124 MILLION DOLLAR INVESTMENT

facility

With an investment of 124.4 million dollars, Clariant has expanded its Daya BayfacilityinChina. The firm has also introduced new halogen-free Exolit OP flame retardants.

The new halogen-free flame retardants offer manufacturers an attractive alternative to traditional systems based on antimony trioxide (ATO), which has experienced dramatic price increases and supply chain volatility in recent years. As part of Clariant’s ambition toremovesubstancesofveryhighconcern(SVHC)from its portfolio, the company has also developed Exolit AP 422A,whichdeliversexceptionalfireprotectionforpolyisocyanurate(PIR)insulationpanelswhileofferingmanufacturers a melamine-free, SVHC-free solution that meets stringent fire safety standards. In polyurethane foam applications, this versatile halogen-free ammoniumpolyphosphateservesasaneffectivereplacementfor TCPP and TEP, providing robust flame retardancy without unwanted plasticizing effects. (wer)

IdemitsuKosanhasbeguncommercialoperationsofits newblackpelletplantinGiaLaiProvince(formerlyBinh Dinh Province), Vietnam. With an annual production capacityof120,000tons,theprojectisthecountry’sfirst commercialscaleBPproductionfacility BPproducedat this plant, branded as Idemitsu Green Energy Pellet (IGEP), which will be supplied as an alternative fuel to coal, primarilytosupportJapanesecoalcustomers’decarbonization goals.

Black Pellets are a biomass-based energy resource madefrommaterialssuchaswoodthatundergothermal processing While BP emit CO₂ during combustion, woods used as raw material absorb CO₂ through photosynthesis in the growth process, resulting in a net "carbon-neutral"status.IGEPisspecificallydesignedtomeet thedecarbonizationneedsofcustomerscurrentlyusing coal.

Since 2020, Idemitsu has operated a small-scale BP demonstrationplantinVietnam Duringthistime,trial batchesofIGEPhavebeensuppliedtoapproximately20 companies in Japan, where it has been evaluated as a viablealternativefueltocoal.IGEPisahigh-caloriefuel made from torrefied wood pellets. Compared to other biomassfuels,IGEPoffershandlingpropertiessimilarto coal, enabling a smoother transition without requiring majormodificationstoexistingfacilitiesofcoalcustomers. (wer)

Thehigh-performancediaphragm valve

Flexible,easy, compact, effective

•Easyand fast maintenance

•New diaphragmtechnologyfor high precision

•Flow- andweight-optimizeddesign

•Configuration varietyfor everyapplication

Performanceand precisioninyourplant with GEMÜ D40

Price shocks, supply chain risks, and trade conflicts: When the unimaginable becomes everyday reality, can companies react at all?

Do tried-and-tested strategies provide answers in uncertain times? And what exactly does VUCA stand for?

IWRITTEN BY

DominikStephan Editor PROCESS Worldwide

t’stheendoftheworldasweknowit,”proclaimedthe 1987 hit by alternative rock band R.E.M. Three years later, following the collapse of the Eastern Bloc, everything was indeed different. And today? With the tariffs introduced by U.S President Trump in 2025 and the suspension of arms deliveries to Ukraine, more certainties are collapsing Even a disintegration of NATO and the Western sphere of interest seems possible. This development poses a serious problem for an economy as closely linked to the world market as Germany’s — and it is life-threatening for the chemical industry Companies in many developed markets like e.g Germanycannotcompetewiththeenergyandrawmaterial costs of their international competitors, nor can they rely on robust sales markets. With the weakness of key

customer sectors, particularly the automotive industry, the demand for polymers, basic chemicals, paints, and coatings also weakens. Only the pharmaceutical industry proves crisis-resistant — no surprise, as people continue to get sick. “Without a strong chemical and pharmaceuticalindustry,therearenoresilientsupplychains, noleapsininnovationinvarioustechnologies,materials, andsubstances,andnosecuresupplyofessentialinputs for the entire industrial network,” emphasizes the German Chemical Industry Association VCI’s Chief Executive Wolfgang Große-Entrup “The Covid-19 pandemic has clearly demonstrated the importance of a strong industrial base.”

Simultaneously, companies face significant uncertainty: raw material prices, energy supply, and political

framework conditions are changing faster than ever before Supply chains prove fragile, regulations become moreunpredictable,andmarketsmoredynamic.Energy transition, climate goals, environmental regulations, digitalization, and new technologies require a broader perspectiveinbusinessdecisions.Thisuncertaintyisnot justafeeling;thephenomenonhasaname:VUCA,short for Volatile, Uncertain, Complex, Ambiguous. Originally coined by the U.S. Army to describe future conflicts, the term gains new significance in times of multiple crises.

Chemicals and Petrochemicals: Basic chemical producers are struggling with high energy costs and price pressure from Asia. The path to sustainable alternatives demands significant investments amid uncertain market conditions.

Pharmaceuticals: The pharmaceutical industry, being the most crisis-resistant, demonstrates the importance of robust supply chains and strong innovation capacity. The lessons learned from the pandemic have intensified investments in resilient production structures.

Food & Beverage: The food industry faces fluctuating raw material prices and sustainability require-

“TheworldhasalwaysbeenVUCA—in additiontothewell-knowndemandsfor quality,performance,price,andjust-intimeavailability,flexibility,resilience, andservicearesuddenlyadded.”

Dr. Joachim von Heimburg, Innovation and Strategy Consultant

ments. Simultaneously, new markets for plant proteins and “functional food” are emerging, requiring innovative processing technologies.

Water & Wastewater: Climate change and stricter environmental regulations urge companies toward more efficient water cycles. Investments in water technologies are especially rising in regions facing increasing water scarcity

TheChallenge:Whentheworldchanges,appropriate strategies are needed to cope. But what if the change itselfisuncertain?Isstrategicactionevenpossibleinsuch

www.vogel-fachbuch.de/en

Wagner HeatTransferTechnique withOrganicFluids

3rd edition2019,1186pages ISBNhardcover 978-3-8343-3433-6 ISBNe-book 978-3-8343-6250-6

comprehensivestandardworkoffersnotonlyadetailed andwell-foundedpresentationofthebasicsofheattransfer technology, but also shows the latest state of the art in the use of organic fluids. It explains the latest regulations that are essential for the design, construction and operation of heattransferinstallations Furthermore,itcontainsmaterial data of organic heat transfer fluids. Price

anenvironment?TheVUCAworldreve raw material procurement: price fluctua force companies to react swiftly to mar changes.

Digitalization is also transforming production processes at a rapid pace. Leaders are tasked with navigating these changes proactively and developing agile corporate cultures.

“The world has always been VUCA,” explains innovation consultant Dr Joachim von Heimburg. Nowadays, however, new perspectives are coming into focus: “In addition to demands quality,performance,price,andjust-inavailability,flexibility,resilience,andservi also crucial.” Whether tried-and-tested strategies work when “basic chemicals suddenly lose their fundamentalrolebecausetheyarenolongeravailable,”asvon Heimburg puts it, remains an intriguing question. Chemicalcompaniesneedtounderstandtheactualvaluethattheirproductsandservicesaddfortheircustomers. “This means that supplier-customer relationships need a new foundation,” explains the innovation and strategyexpert.Providersandcustomersmustbetruthful with each other, von Heimburg elaborates No easy feat in a world marked by hard-fought price wars. But in VUCA times, being cheap is no longer enough:“Whenfactorsemergethatneitherthecustomer nor the supplier can foresee, flexibility, resilience, backups, and service become crucial,” von Heimburg asserts. Instead of the traditional just-in-time thinking, he advocates a just-in-case strategy that incorporates resilience.

VUCA has two faces: Instead of Volatile, Uncertain, Complex, and Ambiguous, one can also interpret it as Vision, Understanding, Agility, and Clarity — and perhaps find the right recipe for change.

The biggest misconception, according to business consultantDanielPanzer,founderofPanzerConsulting, is that companies cannot prepare for future uncertainties:“VUCAmanagementdoesn’tmakeeverythingeasy Itmeansactuallycreatingaplayingfieldwhereyoucan act.” The mantra reinforcing stability emphasizes that flexibilitymustaccompanyit.TheVCIalsostressesthat companies need a high degree of flexibility combined with keen situational awareness and responsiveness to withstand VUCA times. Digital processes and effective software tools might play a critical role in monitoring the supply chain, the association notes. “The key is to create freedom and possibilities in the first place,” DanielPanzerexplains.Theconsultantunequivocallywarns againstblindactionism:“Rushingofffasterinthewrong direction doesn’t help either.”

Concrete strategies often aim to make organizations moreagileandadaptable,expertsexplain Movingaway from hierarchical command structures toward small, decentralized teams does not mean that CEOs and central offices can rest, as central structures still need to maintain an overview, develop processes, and link different organizational units. At the same time, immediate decision-making autonomy is needed at the local

Artificial intelligence is becoming a game changer in the fields of healthcare, life sciences, and electronics — discover “How AI is Changing the Game” on www process-worldwide.com

espond swiftly to changes. Agility is the word that not only promises speed but alconciles the classical process-oriented industrial mindset with the project-orientedorganizationof,forexample,plant engineers. By implementing projects inmanageablesegments,agileproject management fosters flexibility and adaptability

Regular stand-up meetings allow for continuous communication to quickly identify problems and find solutions. Methods like Scrum and Kanbanencouragetaskandresource prioritization, continuous adaptation tonewrequirements,andfocusoncustomerfeedback.Thisdynamicapproach engthens collaboration and promotes oactiveactions,enablingcompaniestobetspond to unforeseen changes. Digitalization and technologies such as AI and IoT help optimize processes and adapt more flexibly to market demands. Companies investing here gain a competitive edge in the VUCA world.

Despite all the praise for agility and disruption, von Heimburgremindsusoftheneedforhonesty:Mostpeople want “as little change as possible, with minimal additional costs — in short: to do what they’ve always done.”Butthatmightbethewrongquestion:Therealityis not about minimizing costs but about “defining and delivering the value of the product or service to make it tangibleforthecustomer.”Thisinvolvesstrategicgoals and principles, which can sometimes be of an ethical nature. What can be done, and what am I willing to do? InPanzer’sview,despitetraditionallyhighCAPEXcosts in chemistry, operating expenses must also be considered. The VCI remains purposefully optimistic, emphasizes Große-Entrup: “Our industry can handle crises. Constant change is in the DNA of our companies. Historically,theyhaveoftenreinventedthemselvessuccessfully,” says the VCI Chief Executive Equally crucial in VUCA times, as Panzer emphasizes, is not to be afraid: “Engagingwithitisalreadywinning,”saystheconsultant. Adaptability will determine how well companies can compete (dst)

Recognize the need for action and become more agile immediately — this includes closely monitoring the situation and developing flexibility within the company.

Implement a digitalization strategy — companies should digitize their processes and ensure they use effective software tools to monitor the supply chain.

Bullack,Hans-Jürgen PipeElements

Calculationmodulesaccording totheEN13480-3:2002/2005

1.Edition,Kamprathinteraktiv ISBN978-3-8343-3123-6

Theuniversaltoolforcalculationandpipingdesign accordingtotheEN13480-3:2002/2005specification. Thetooloffers23modulesforthemostvitaldesign featuresandproofofpipingelements.

•Ratingofpipecomponentsunderinternal pressureload

•Ratingofpipecomponentsunderexternal pressureload

•Ratingofpipecomponentsunderalternating pressureload

Numerous four-legged robot dogs are inspecting different spaces across the industrial plant; facility personnel are wearing head-mounted displays, which helps them to get access to detailed information about an equipment or process in real time. Four technologies for the plant of the future!

Smart, innovative and autonomous — this is how one would describe the plant of the future. Although industrial plants have existed for over 150 years, only recently have these facilities significantly evolved.Withthehelpofvariousnewtechnologiessuch as Artificial Intelligence, Digital Twin, Augmented Reality and Robotics being incorporated across industrial plants, plant personnel can optimize their processes, enhance production based on real-time data, reduce downtime, slash costs and even carry out autonomous

plantinspections.Itwouldn’tbewrongtosaythatthese four contemporary technologies are slowly but steadily revolutionizing today’s industrial plants into the plants of the future.

Artificial Intelligence has become a buzzword in recent times. It simple terms, it can be defined as a smart technology that comprises of machines or systems that has

the ability to perform dedicated tasks that are usually carriedoutbyhumanintelligence.Acrosstheindustrial plants space, this technology has attracted eyeballs. A live industry example here: For the first time in the world, a chemical plant in Japan ran autonomously for 35 days in a row with the adoption of the AI technology Developed by the Japanese multinational electrical engineeringandsoftwarecompanyYokogawa,theAItechnologydemonstratedthatitcancontroloperationsthat have been beyond the capabilities of existing control methods (PID control/APC) and have up to now necessitated the manual operation of control valves based on thejudgementsofplantpersonnel,sharesapressrelease by Yokogawa. The AI solution is also able to take into account numerous factors such as quality, yield, energy saving, and sudden disturbances.

Another prominent example from the sector is the world’s first AI-based autonomous operation of a crude oil processing unit. The Eneos Kawasaki Refinery in Japan began continuous autonomous operation of an atmospheric distillation unit for processing crude oil in January 2024. The unit is operated autonomously with an AI system that is capable of automating large-scale and complex operations of oil refinery plants.

TheDigitalTwinisanothercutting-edgetechnologythat cantransformthewayinwhichindustrialplantsoperate. With the power to replicate the physical assets of a systemorproductionprocessintoavirtualsystem,theDigitalTwintechnologyassistsindustryplayerstooptimize plantprocesses,improveproductionbasedonreal-time dataaswellasenablesthemtomakeinformeddecisions aboutthelifecycleofplants.Recently,China’sShenyang Aluminum & Magnesium Engineering & Research Institute Co (Sami) appointed the American-based softwaredevelopmentcompanyBentleySystemstodevelop a plant-wide digital twin for Chalco’s Zhongrun aluminum facility in China. With the help of this technology, Sami was able to unify data from 52 subprojects across 13 disciplines, managing over 300 GB of data and 100,000documents,sharedPrathameshGawde,Senior Product Marketing Manager at Bentley Systems for an earlier feature.

He continues to state that this streamlined collaboration and improved design efficiency by 30 percent. 3D modeling time was reduced by over 15 percent, saving 3,000 work hours and nearly CNY 1 million in staffing costs, while digital asset management cut operational costs by CNY 6 million annually The digital twin also enabled real-time monitoring and predictive maintenance, reducing equipment failures by 40 percent and emissionsby5percent.IntegratedAIcapabilitieshelped minimize human intervention in high-risk zones and improved decision-making

The next big technology that will play a vital role in the plantofthefutureisAugmentedReality(AR).Thistechnology offers an interactive experience in which computer-generatedcontentissuperimposedonthereal-environment in real time. Accessible via head-mounted displays, smart glasses, head-up display and even hand-

held devices, AR solutions are embedded with cameras, sensors, software etc.

One of the major chemical companies Linde makes use of Augmented Reality for real-time field service maintenanceprocessesandincreasingoperationalsafety Withthehelpofthistechnology,plantpersonnelcan secureaccesstoremoteoff-siteexpertserviceswiththe assistance of mobile devices. BASF, another leading

ArtificialIntelligence,DigitalTwin, AugmentedRealityaswellasRobotics, thetechnologiesfortheautonomous plantsareallavailable.

chemicalproducer,utilizestheAugmentedRealitytechnology to train its plant operating teams.

Robotics has been a core part of many industries and going ahead will significantly contribute to the plant of thefuture.Themodernandadvancedrobotswillnolonger require constant human supervision but will rather work autonomously. Equipped with advanced sensors, cameras, actuators and AI systems, these robots are capableofperformingtasksandmakingdecisionsontheir own.Somecurrentdayindustrialfacilitieshavealready adopted four-legged autonomous robots to carry out boring, time-consuming and monotonous inspections of their large-scale chemical or petrochemical plants. For instance, the Germany-based global speciality chemicals company Evonik makes use of autonomous robots to make the data collection process at its facility easierforplantpersonnel.Next,themultinationalenergycompany,Equinoralsoutilizesautonomousrobotsfor its Northern Lights Carbon Capture and Storage (CCS) facility in Norway BASF is another prominent industry leader that has adopted autonomous robots at its Ludwigshafen site in Germany. In-charge of various inspectiontaskssuchasreadinggauges,undertakingacoustic measurements of pumps and compressors, and checkingtheenvironmentforhotspotsandgasleakagesusing its integrated thermal camera, the autonomous robots have made plant inspections convenient and easy.

WRITTEN BY AhlamRais Editor PROCESS Worldwide

These four technologies are just the starting solutions thatwillbeadoptedbyplantsofthefuture.Infact,with time, many new and breakthrough technologies will alsobeintroduced,exploredandevenbeevolvedtomake the process of industrial plant operations and maintenanceeasier,accessibleandmorecost-effective Fornow, guess we will just have to wait and watch! (agk)

These are challenging times: high energy costs, fierce competitive pressure, and experienced employees retiring. Nevertheless, plants in the chemical industry must continue to operate safely and profitably. The (partial) automation of plants is intended to contribute to this.

The potential benefits of autonomously operated plants could be numerous, including increased efficiency,improvedsafety,andreducedoperating expenses, experts believe Nevertheless, the procedure for implementation and the transition to a newly digitalizedplantenvironmentarestillresource-intensive A solid data foundation, which is derived from a diverse array of heterogeneous plant components, is necessary fortheend-to-enddigitalizationoftasks,data,processes, andworkflows.Thiswillenabletheautomaticexecution

ofspecificprocessesandtaskswithinaplantwithoutthe need for continuous human intervention.

For example, to achieve “real autonomy” in the process industries, it is necessary to comprehensively and in real-time capture all pertinent process variables, including temperature, pressure, flow rate, composition, andenergyconsumption.Therefore,sensorsneedtobe protectedfromfouling,ageing,drift,andfailure,oratthe veryleast,theyneedtogiveearlywarningswhendepositsstarttobuilduponthem.Insomesituations,thecon-

trolstrategieshavetoincludeadditionalsensingmodalities like vibration and acoustic measurements or still images and video footage.

Real-time capability, cybersecurity precautions, and standardizedinterfacesareadditionalfactorsthatneed to be considered. To facilitate the integration and synchronizationofdatafromDCS,MES,andERPsystems,a unified data model must be established.

Advanced Process Controls (APC, MPC) and AI/MLbased systems should only be implemented after these prerequisites have been established. They have the capacity to identify patterns and anomalies in process data, generate forecasts, automatically implement corrective actions, and adjust manipulated variables in real time Predictive algorithms identify maintenance requirements before the occurrence of an issue

Newautonomousapproachesareneeded,evenifnotall thequestionshavebeenanswered.Thisisthereasonthe autonomous plant is the primary focus of this year’s Namur(theGermanUser Association of Automation Technology in Process Industries) Annual General Meeting in late November Thesubjectis not entirely novel to Namur and its member companies.Severalyears ago, Working Group 4.2 identified the benefits of robot-assisted automation of inspection rounds and established the corresponding requirements. Data is collected by robotic assistants and analysed with AI and traditional analytical techniques. A further consequence is the systematic accumulationofavaluabledatacorpus,whichfacilitates the early detection of plant changes and the timely implementation of responses.

ppm range. Algorithms and artificial intelligence are employed to analyse data that is automatically transferredtoacloudplatform Ifmeasurementsdeviatefrom thepredeterminedstandardrange,amaintenancetechnician is notified.

Another thrilling field is the autonomous control and operation of plants The oil and gas industry is consideredtobethemostadvanced;autonomousoperationis notanovelconceptinthissector.In2017,Equinor(then Statoil) installed the first North Sea platform that could be remotely operated from Bergen, Norway, approximately 160 km away Gas and condensate were being produced at approximately 60,000 barrels per day at that time. At an Eneos Materials production site, Yokogawa also implemented an autonomous control AI on a distillation column several years ago

“Thepathtowardautonomous operationwillbeacatalystfor continuouslystrengthening competitiveness.”

Tobias Schlichtmann, BASF and Chairman of Namur

DuringtheNamurmeetinglastyear,Dr SabinePegel, Lead AI Operational Excellence Transformation at the materialchemicalscompanyCovestro,providedanoverview of the general process of implementation, the obstacles that had to be surmounted, and the potential benefits that the implementation of an autonomous plant with AI could bring In her company, she has already worked on the installation of the first autonomous batch plant. She presumes that AI has the potential to transporttheindustrytorealmsthathaveyettobeimagined, as it is capable of thinking in multiple dimensions. The data from the plant is now transmitted to the cloud, whereitisoptimizedbyanAIandretransmitted.Atthe time, Pegel’s final suggestion was, “We have everything weneed.Letpeoplego,andyou’llhavegreatmultipliers!”

WRITTEN BY Sabine Mühlenkamp

Freelance Editor PROCESS Worldwide

These self-sufficient artificial assistants are unquestionablynotasolutiontochallengesthatthehighcosts of energy and skills shortages pose. Nevertheless, the degree of automation can be leveraged to enhance specific energy consumption or mitigate risks for human personnel by enabling robots to enter confined spaces and hazardous areas. Additionally, robots are not susceptible to noise and heat. Above all, they liberate human time. Evonik has been testing a Boston Dynamics autonomous mobile robot for several years to inspect a pilotplant.Itemploysthermalimagingcameras,among other methods, to identify piping defects.

At its largest site in Germany, Shell Energy and ChemicalsalreadyimplementsEnergyRobotics'softwareplatform, two distinct robots, and a drone to facilitate 360-degreemonitoring Visualandthermalcameras,as wellasothersensors,areincludedintheunitstocapture imagesofanaloguepressuregaugesandthermometers in the plant. In the same way, they record and analyse valvepositionsandobjectssuchasfireextinguishersand capturethermalimagesofinsulationandmachineryto detect thermal anomalies.

Additionally,theyareabletodetectevenminutequantitiesofgasesthatescape,downtoconcentrationsinthe

Insummary,trustworthydataisnecessaryforasuccessfulentryintoatrulyautonomousplantera,whetherthat entailsplantcontroloradroneinspection.Theseinturn needtobeprovidedbysensorsthatfunctiondependably. For operators, the acceptance of these technologies depends upon the transparency and traceability of values. This year's Namur Annual General Meeting will offer practical examples and serve as a forum for discussion.

According to Tobias Schlichtmann, Senior Vice PresidentStrategicProjectsatBASFandChairmanofNamur, the focus topic of this year is at the heart of current discussionsandconsiderations:“Wemustsimultaneously addressthechallengesofsustainabilityanddemographics while simultaneously enhancing the efficiency and flexibility of our chemical production.” To expedite the implementation process and, as a result, increase profitability, it is imperative to select appropriate technologies and milestones The journey to the autonomous plant will serve as a catalyst for the ongoing enhancement of competitiveness. (müh)

INTERVIEW: NEW INTERNATIONAL VENUES FOR MEORGA MSR-SPEZIALMESSEN

MEORGA goes international: With new exhibition venues in Vienna and Tarragona, exhibitors gain new opportunities to reach target audiences more efficiently and to expand their market presence in a targeted way. Bernd Weinig, Director Trade Fair Solutions & Partnerships at Vogel Communications Group, is driving this forward and offers insight into the further development.

“The application landscape for the use of instrumentation and control (I&C) and process automation is promising and diverse in both Vienna and Tarragona.” Bernd Weinig, Director Trade Fair Solutions & Partnerships at Vogel Communications Group, is looking forward to the two new venues.

Bernd,theMeorgaMSR-Spezialmessen—specialist trade fairs for I&C (instrumentation & control) and process automation—have been part of the Vogel Communications Group for almost two years now and complement the successful regional trade fair business. How did the integration into the Vogel familygo?

Bernd Weinig: The integration was collaborative and focused Itwasimportanttoustoretaintheexperienced Meorga team and its know-how. The previous management quite deliberately chose Vogel as the new shareholder because they saw in the group the ideal founda-

tions for the further development of the MSR-Spezialmessen—in particular thanks to strengths in specialist communication, event management and digital reach. Particular assets here are our specialist media PROCESS, PROCESS Worldwide, Schüttgut and elektrotechnik Automatisierung, which reach Meorga’s core target audiences. This enables us to place content in a targeted way through thematic content marketing and storytelling—to build a Meorga community continuously throughout the year Together with Vogel Event Solutions, we can now pool our capabilities across the group to best effect.

What sets the MSR-Spezialmessen apart, and how havetheydevelopedunderyourleadership?

The fairs stand for proximity, practical relevance and efficiency Trade visitors benefit from short journeys, directaccesstomanufacturers,hands-onsolutions,anda concise programme of talks delivering up-to-date technicalexpertise.Undermyleadership,wehavesharpened theprofile,addednewlocations,andintroduceddigital services such as lead tracking and cross-media reach—real added value for exhibitors and visitors.

And now the decision to take the step beyond Germany’sborders.Whatmotivatedthismove?

Good ideas know no bounds! The demand for regional specialist trade fairs offering practical solutions for efficient plant and process operations is not confined to Germany—especiallywhenitcomestodeliveringoperational advantages in process-engineering production and processing environments. Many exhibitors signalled interest in new markets. With Vogel as a strong partner, internationalisation was the next logical step

The two international venues next year are Vienna on15AprilandTarragonaon18November.Let’sfirst looktoourimmediateneighbour,beautifulAustria. WhyVienna,thecityofmusic?

Vienna is not only a culturally fascinating city, but also an important industrial location with a strong process industry The Vienna/Bratislava metropolitan region offers numerous dynamic and growing application sce-

narios for I&C technology and process automation, encompassing both industrial and commercial applications.Thecombinationoftechnologicalinnovationand internationalreachmakesthisregionparticularlyattractivefortheuseofI&Ctechnology.Bratislava’sproximity toViennaprovidesadditionaladvantagesthroughaccess to a broader market and international connections. Many of our exhibitors are already active in Austria In addition,withtheAustriaCenterViennawehavefoundan excellent venue that fits our trade fair concept perfectly. Vienna is the ideal starting point for our international expansion

ChemMed in Tarragona is considered the largest chemicals cluster in Southern Europe and the third-largest chemicals location in Europe—so it’s onlylogicaltobasetheMeorgaMSR-Spezialmessen here.Butperhapsyoucouldfurthersubstantiatethe “Spanish” decision and highlight the specific advantages.

‘firaReus’, our new international venue for the MSR-SpezialmessenintheprovinceofES-Tarragona,islocatedin an economically strong region with a high density of specialist audiences and decision-makers for I&C and process automation. The venue enjoys a prime location, just twenty minutes from the ChemMed cluster The application landscape for the use of I&C technology and processautomationinthegreaterTarragona/Barcelona/ Catalonia area is generally promising and diverse The new international venue in Spain is embedded in a dynamic innovation environment with strong, highly attractiveindustryclusters—ChemMed Cluster, Hydrogen Valley of Catalonia, Smart Port initiatives, Clúster de la Industria de la Automoció de Catalunya (CIAC), and more.

Will there be any changes to the trade fair concept compared with theGermanvenues?

The

Interested exhibitors will find further information on the benefits of the new international venues at www.meorga. de/neuestandorte.

Your expectations for the two new venues will be metwhen…

our exhibitors go home with qualified contacts and concrete leads—and say, ‘That was worth it.’ If we succeedindeliveringtheMeorgaexperienceinternationally as well, then we’ve achieved our goal.

Is further internationalisation of the MSR-Spezialmessenplanned?

We take a long-term view. If Vienna and Tarragona develop as we expect, we do not rule out additional locations. What matters to us is that every new trade fair meets the same standard of quality as our established formats in Germany.

“Manyofourlong-standing exhibitorsimmediately signalledtheirinterestin joiningusinternationally.”

Theprovenconceptremains:compact one-day events focused on trade visitors. We will adapt details such as language and the supporting programme to the local context—the Meorga experience will remain unchanged.

Bernd Weinig

Will there be specific focus topics in Vienna and Tarragona?

Yes. For the Vienna/Bratislava metropolitan region, the focus is on process automation in the chemicals, pharmaceuticals and food industries. In Tarragona, key themes include plant safety, digitalisation and sustainability—with a particular emphasis on I&C for explosion-protected areas, precise flow and level measurement, process analytics and integrated control systems. These technologies are essential for the highly automated production processes within the ChemMed cluster

Whathastheinitialresponsetothetwonewvenues been?

Theresponsehasbeenconsistentlypositive Manyofour long-standing exhibitors immediately signalled their interest in joining us internationally. I am confident we willalsoseestronginterestonsite—bothfrompotential exhibitors and from trade associations and industry partners.

To conclude: Which of the two trade fairs are you personally looking forwardtomore?

That’s like asking which child you prefer—impossibletoanswer!Viennaisthe perfectstartingpointformebecauseitis very familiar to us geographically and culturally. Tarragona, by contrast, is an exciting step into a new market with greatpotential.I’mlookingforwardtoboth—andtothe manyconversationswithexhibitorsandvisitorsonsite.

Bernd,thankyoufortheinterview!

18 March: Frankfurt am Main/Germany

15 April: Vienna/Austria

6 May: Bochum/Germany

17 June: Halle (Saale)/Germany

16 September: Ludwigshafen/Germany

18 November: Tarragona/Spain

Hydrogen is currently being discussed a lot in many places. It is also a hot topic in Bremerhaven, Germany, where this energy carrier is literally providing a tailwind on the path to climate-neutral mobility. At the Grauwallring industrial estate, Hy.City.Bremerhaven uses a wind turbine generator for the electrolysis of hydrogen directly on site.

The green hydrogen project was realized by GP Joule, the system provider for integrated energy solutions which acts as the general contractor. The production of green hydrogen is part of a regional hydrogen ecosystem and is considered a lighthouse whenswitchingfromfossilfuelstorenewablefuels.Automation technology from Phoenix Contact is used to ensure sector coupling with high availability and a secure remote connection. It makes economic sense for Germanytocontinuepursuinghydrogentechnology,so that it can maintain its standing as a global center of business.Sofar—atleastaccordingtoindustryexperts on a German television business programme broadcast in the summer of 2024 — the chances are good that the German SME sector will be able to play to its strengths andbecomeaglobaldriveroftheenergytransitionwith hydrogen.

But how is this possible? By industry and investors showing that it works — as it does in Bremerhaven, for example. Here, GP Joule has implemented a complete valuechainforgreenhydrogenforHy.City.Bremerhaven — from electrolysis as a key technology, through compressionandstorageinmobiletankers,rightthroughto deliverytotheservicestationandtherightfuelcellbusesforpublictransport.Onlythewindturbinegenerator, whichsuppliesenergytotheelectrolyzer,wasalreadyin place at the Grauwallring industrial estate, having been installed several years ago

Whatarethemainchallengescurrentlyfacedinthesupply of hydrogen? According to GP Joule, solutions must providetherighttypeofenergyintherequiredquantity, atthebestlocation,andattheexacttimeitisneeded.For hydrogen as an energy carrier, this means that, from a holistic point of view, it is not enough to focus your expertise on individual process steps; rather, the entire value chain and logistics must be included. This is precisely where the strength of the system provider from Germany lies, putting its own expertise in hydrogen mobilityintopracticeontheroad.GPJouledidjustthat in Bremerhaven, by creating the Hyrunner — a mobile

storage system for intelligent hydrogen transport from theelectrolysissitetotheservicestationortoindustrial customers.

“Thetwoelectrolysiscontainersatthebaseofthewind turbinegeneratoroperateatfullload,eachwithanelectrical output of one megawatt. From this, electrolysis produces up to 900 kilograms of hydrogen per day, which fills one of the tankers in around six hours,” explains Marian Hieke, Head of Engineering at GP Joule.

The tank and storage system operates at 380 bar pressure. Compressors are used to compress the hydrogen obtainedfromelectrolysis,whichisataninitialpressure of30bar Itisfirsttransferredtoabufferstorageunitand from there converted to the desired tank pressure.

Asmobilestorageandtransporttanks,hydrogentrailers playacentralroleintheprocesschain.Thevehiclescontainalargeamountofcontrolandinterfaceintelligence, which is housed in a robust stainless steel control cabinet. The production and use of hydrogen raises various questions about explosion protection (Ex). To avoid the risk assessment leading to a situation where the entire automation system consists of expensive Ex components, a functional modular system is recommended. This covers both Ex and non-Ex areas economically.

In the Bremerhaven project, Phoenix Contact only equips those processes that actually require Ex protection with Ex I/O modules from the Axioline product family. For example, input cards are used in the Hyrunner for the valves of the hydrogen lines. They can be used to wire the signals directly to the correspondinglycertifiedI/Omodules. So, there is no need for separate Ex impeding devices, which saves valuable space and reduces costs. Outside of the Ex-zone, the standardI/OportfoliofromtheAxioline modular system is sufficient — and there are no functional limitations due to the consistent overall system

maximum security against cyberattacks.

from a digitalization perspective PLC next Control is alsousedasthehighestcontrolinstanceatthelocation of the electrolyzers. The so-called location controller collects all operating data of the process chain, from electrolysis through to the tank trailers, and forwards it wirelesslytoacentralevaluationunitviatheTCMguard router and an antenna.

When it comes to the technical equipment of data logistics — referred to as Hysite — availability is extremely important. Failsafe performance is technically ensured by two Quint4PS power supplies in conjunction with a redundancy module from the Quint-Oring product family. The solution is supported by five battery modules, which together withaQuint4-UPSformanuninterruptible power supply.

Automationtechnologyfrom PhoenixContactisusedto ensuresectorcouplingwith highavailabilityandasecure remoteconnection.

A large amount of data is generated during the various processes, which can be stored in a cloud and used in a variety of ways. Data is transmitted to the cloud via an industrial cellular router from the TC Router 3002T-4G series installed in the control cabinet. The TC Mguard RS4000 router provides the necessary IT/OT security With this equipment, the roadworthy storage system is able to communicate independently and securely with thecloud,enablingtime-efficientrefuelingincoordinationwiththeupstreamelectrolysisandstorageprocesses “Forexample,wecandeterminefillvolumes,control valves, and track the current location of the trailer via GPS,”explainsMarianHieke.“ThefunctionsaresupplementedbyasystemintegratedintothePLCnextControl forthecalibration-lawcompliantbillingofthesupplied hydrogen.”

AlthoughtheHyrunnerisdesignedtosupplyBremerhaven’s hydrogen-based public transport system autonomously, it fits seamlessly into the entire process chain

WRITTEN BY ThorstenSienk Specialist Editor for Sustainability and Technology in Corporate Communications Phoenix Contact

Inthisway,short-termpowerfailures can be bridged or the entire system can be shut down in a controlledmannerintheeventofamalfunction,withoutit reaching a critical state due to the high reactivity of hydrogen. The two control units also create a high-availability redundancy pair via the applicative system redundancy (ASR) concept from Phoenix Contact The availability solution is rounded out by the network, which connects the individual submodules of the locationtoeachotherand,duetoitsringstructure,isfailsafe against individual faults

The production of renewable hydrogen from wind powerrepresentsthebeginningofhydrogen-ledmobilityin Bremerhaven. Since considerable amounts of (waste) heat and oxygen are generated during electrolysis, the visionary entrepreneurial consortium behind Hy.City Bremerhavenisalreadythinkingabouthowtouseboth economically.Accordingtotheprojectteam,alocaldistrictheatingnetworkissuitableforutilizingthe340kW of (waste) heat, especially as there are sufficient commercial and industrial consumers in the immediate vicinity The further processing of oxygen is also on the agenda. (agk)

HEAT RECOVERY

Energy prices keep rising and environmental regulations are getting stricter. Yet, the smart use of waste heat could help to cut costs and emissions. Especially, if they are able to bundle several heat sources, raising them with one heat pump.

The industry runs on heat: It is the driving force behind reactions, distillation, drying, and sterilizationprocesses.Thetypicallow-temperatureof waste heat streams, however, carries only little useful energy Thus,italsoofferslimitedutility Andeveryconversion step further reduces the usable energy level.

Therefore, waste heat often remains unused and is released as excess heat into the surrounding air or throughwastewater Insomecases,thisheatevenhasto befurthercooleddownbeforeitcanbesafelydischarged into the environment. Sites lose money and emit more carbon dioxide than necessary

Industrialheatpumpscouldhelptoreshapethispicture: GIG Karasek’s VarioVAP technology for example turns previously unused waste heat into useful energy It can handle multiple streams - even those so far considered as uneconomic. For the developers of this new innovation,thisapproachsetsnewbenchmarksforsustainable and cost-effective energy recovery An innovative plate falling-film evaporator sits at the core of this process, which handles several waste-heat sources at the same time. Instead of handling each source separately, the system collects large and small streams with different properties in a single centralised unit, transforming energy that previously went unused, into valuable fresh steam.

VarioVAPcanbeoperatedeitherasastandaloneheat-exchanger solution or as an integrated process with a mechanicalvapourrecompression(MVR),forminganopen heat-pump loop Meanwhile, conventional concepts oftenrequireoneheatpumpforeachheatsource.VarioVAP stands out by combining numerous sources into one central unit and using them in an integrated way.

Thus,forthefirsttime,theVarioVAPsystemprovides the basis for efficient and economical use of multiple waste-heat sources in one single centralized solution, setting new standards in industrial energy efficiency:

It makes both large and small waste-heat streams viable when bundled

Centralization lifts overall efficiency and improves project economics.

Surplus heat can be used to generate steam instead of being sunk in cooling water

Advanced controls balance variable sources in real time. The system modulates duty, and avoids cross-contamination.Loadsharingsupportsstablesteamproduction under fluctuating conditions

With VarioVAP, “Zero Waste Heat” moves from a mere aspirationtoaplan,asthesystemcanupgradeevenlowgradewasteheatintoavaluableresource,closingenergy loopsandreducingcoolingdemand Technologycreates new options for sustainable and profitable energy integration. The flexible design fits single plants and entire industrial parks, as its greatest potential lies in large thermal separation processes.

VarioVAPcanutilizewasteheatfromawidevarietyof processes such as distillation, evaporation, or drying, Thus,especiallyenergy-intensivesectorslikechemicals, beverages and food, pulp and paper, and metallurgy, could benefit most. Industrial parks offer a prime use case as operators can bundle heat streams from several

Heating plate of the plate falling-film evaporator – part of the heart of the VarioVAP system.

WRITTEN BY

LuisPereira

Process Engineer

GIG Karasek

PROCESSTIP

Find out more about a showcase project:

CO2-free steam generation with one of the world's largest industrial heat pump systems at BASF Ludwigshafen www.process-worldwide. com!

companies. They can feed the recovered energy back into production or into district heating networks.

Operators profit from:

Shared utilization: Firms from different sectors can benefit together from a common centralized waste-heat recovery

Economics: Operators cut energy costs and may earn revenue from heat or steam exports.

Flexibility: The system scales as more companies join or as new sources connect.

Sustainability: Waste-heat use reduces the site’s carbon footprint and supports an organization's Zero Waste Heat goals.

Commercial frameworks for a joint heat utilization can include metered deliveries to the individual users, as well as a fair-share allocation of energy A common infrastructure reduces duplication and improves load factors across sites.

The design of the VarioVAP system emphasizes safety and reliability as well as an efficient heat utilization. As the novel system setup merges various heat sources in

onecompactunit,eachheatstreamcanflowthroughits own fully welded lamella bundle.

Thus,vaporsandcondensatesstaysecurelyseparated, which assures product purity The sealed, gasket-free design ensures safe handling of explosive vapours and allows simultaneous heat recovery from both ex and non-ex heat sources

Heat sources with different compositions, temperatures, and pressures enter the plate falling-film evaporator via separate lines.

Each source remains separated by passing through completely separate lamella bundles. Explosive vapours remain segregated.

In the evaporator, waste heat generates fresh steam.

The system collects condensate separately and returns it as reflux if desired.

As an option, mechanical vapour compressors raise the steam to a higher energy level. Users deploy it in internal or external processes.

The vertical layout of the evaporator columns further minimizes footprint and eases brownfield integration.

Core technology:

Unique plate falling-film evaporator serving as an innovative heat exchanger.

Each heat source (typically exhaust steam) is routed via a separate line into the fully welded plate evaporator, where it is “recycled” into sustainable fresh steam.

Operating modes:

Standalone: Functions as an independent heat-exchanger solution.

Integrated: Can be combined with a Mechanical Vapour Recompression (MVR) system to elevate steam to a higher energy level.

System requirements:

Minimum size: Total heat-source capacity should be ≥ 1 MW for economic operation.

Scalability: Additional evaporator units can be added in parallel once capacity is reached

Typical applications:

Industrial plants ideal for processes involving distillation, evaporation, or drying

Industrial parks enables joint utilisation of waste-heat streams from multiple operators for reuse or district heating

Versus conventional designs, the system has three key advantages:

Fewer components: One unit, one circulation pump, and fewer instruments and valves.

Lower capital expenditure: A compact design and economies of scale reduce capital cost per kilogram of steel.

Easy maintenance: Fewer spare parts and faster service.

VarioVAPcanbeintegratedintoexistingprocesseswithouttheneedforacompletesiteshutdown,allowingthe overarching process to continue. Installation often involves routing a feed line and tying into existing equipment.

No modifications to production plants required

No decentralized heat pumps at individual sources

Process continuity during installation.

Moderate temperature lifts typically deliver the best efficiency Intelligent process control solutions help to maintainstableoperationwhenthetemperaturesofthe individual heat sources drift. In addition, rules for the prioritizing of the heat-sources optimize steam output and economics.

Anotherkeyaspectofthisparticular process is that typically the operating costofMVRpertonneofsteamfallsas the throughput rises. Compressing larger volumes is more efficient than compressingsmallvolumes,thedevelopers explain. Bundling multiple heat sources in one system further helps to improve efficiency and overall economics.

Visualisation of a typical VarioVAP waste heat recovery system with plate falling-film evaporator and compressors.

tenance windows and supports hygienic duties significantly.

VarioVAP offers a future-proof solution for industrial waste-heat recovery It turns many large as well as very small waste-heat streams into a valuable resource. The approachiswellsuitedforlargeplants and entire industrial parks. By bundling diverse sources, it minimizes energy losses and supports a Zero Waste Heat vision.

VarioVAPcanalsobeused withoutacompressor, servingpurelyasahighly efficientheatexchanger.

The benefits are clear: Waste-heat recovery lowers the primary energy demand and cuts carbon emissions. It also reduces the need for fresh steam and cooling water. That saves valuable resources and reduces operating costs.

Asearlierexplained,theVarioVAPunitcanalsoberun independently, without a compressor Equipped with a highly efficient heat exchanger, this configuration is idealforapplicationsthatrequiremediumheatingrather than steam generation.

Instead of installing three separate heat exchangers, VarioVAP aggregates three sources in one unit. That savesspaceandcostandsimplifiestheplantlayout,the developers state.

While VarioVAP primarily uses vapour to raise steam it can also utilize liquid heat sources, such as wastewater, if an additional step: A flash tank is used to convert the liquid into vapour

For a sound business case, the combined capacity of allheatsourcesshouldreachatleastonemegawatt.The number of usable sources depends on the evaporator size.Oncethemaximumsizeisreached,theprocesscan bescaledupbyaddingasecondoreventhirdevaporator in parallel.

The system continues to operate reliably even at partialload:Ifoneheatsourcefails,theremainingstreams continuetosupplyenergyfortheprocess.Maintenance teamscanaccesskeycomponentsfromtheserviceside. A true clean-in-place capability helps to shorten main-

VarioVAP combines sustainability, efficiency, and cost-effectiveness, setting new standards for an energy-efficient industry (dst)

VarioVAPHeatPump–AdvantagesonAGlance

Environment and Sustainability

Economic Viability

Technical Efficiency

Safety

Simple Integration

Maintenance and Reliability

Source: GIG Karasek

Fully electrically operated

Reduced need for fossil fuels

Reduced demand for steam and cooling water

Lowered CO2 emissions

Costs per tonne go down as production increases

Lower invest and operating costs

Smaller heat sources can be combined and re-used

Steam and condensate are separated

Availability of a variety of different stainless-steel materials for different media

Separation of hazardous zones

One water circulating pump only

Should one heat source fail, the remaining ones can continue to operate with reduced load

Only limited changes at existing intallation

Columns and reboilers must not be revamped

Simple and quick installation or retrofit

Reduced demand of spare parts

Lower maintenance expenditures

Every producer knows the challenge: Homogenizinglargebatchesof40,60,oreven100cubicmeters of powder or granulate involves a dilemma. Conventional silo mixers handle large volumes but strugglewithhighmixingquality Additionally,theydemand high drive power Precision mixers, on the other hand,areusuallylimitedtosmallervolumesandconsume enormous amounts of energy for large batches The result:uneconomicalcompromisesinmixingqualityor operating costs.

TheGyratonsilomixerbyamixonunifieslargevolumes, precision, and energy efficiency The secret lies in its unique mixing principle: The vertically arranged helix mixingtoolperformsacontrolledprecessionmovement centeredabovethemixingchamber Thisensuresevery point is systematically reached.

The mixing tool tapers from top to bottom, requiring significantlylessdrivepowerthanconventionalflat-bottomsingle-shaftmixers.Idealforprocesseswheretime doesn’t matter all the time.

Thesuspendedbearinginthegearboxeliminatesproduct-contactingsealsinthefloorplate,enhancingmaintenance and product safety The result: homogeneous mixing even in slow processes of 30 to 90 minutes —

The Gyraton from amixon combines large batch volumes of up to 100 cubic meters with precise and gentle homogenization at minimal energy consumption.

withoutqualityloss,butwithsignificantlyreducedenergy consumption and minimal mechanical stress on the particles.

Gentle Mixing: Extremely low rotation speeds of up to one revolution per minute protect even the most sensitive particles. Tea leaves, pharmaceutical agents, or food ingredients retain their original structure and properties.

Handling Large Volumes: Batch sizes from 3 to 100 cubic meters are homogenized with ease — where conventional precision mixers hit their economic limits.

Guaranteed Precision Mixing: Despite the gentle operation, the Gyraton achieves ideal mixing quality — even with a component ratio of up to 1:100,000

Minimal Energy Consumption: Whereas conventional precision mixers require 20–30kW per ton of mix, the Gyraton operates with up to ten times lower drive power. An invaluable advantage, especially in regions with limited power supply or rising energy costs.

TheGyratonmixerisparticularlyinterestingforpowdery raw materials used at the beginning of long process routes. Its versatility is evident in the wide range of possible applications. Whether sensitive pharmaceutical agents,high-qualityfoodingredients,orabrasiveindustrialmaterials—thegentlemixingprocessadaptstothe specific needs of each industry

Pharmaceuticals: Homogenization of large batches of excipients, granulates, or powder blends while maintaining particle integrity

Food Industry: From tea blends of various origins to gelatin compounds or spice mixes — always with gentle treatment of high-quality raw materials.

Chemical Industry: Basic homogenization of ores, abrasive materials, or specialty chemicals with minimal wear and reduced dust production.

Sponsored by

Is the Gyraton suitable for your products? Test your ownproductsinthetrialapparatusandminimizeinvestmentdecisionrisks.Experiencehowprecision,product protection, and energy efficiency unite with large volumes.

“Weoftenhearthatonlylimiteddrivepower isavailable.Itisbeneficialtobeableto operateverylargemixerswithsmalldrives.”

Markus Mettenborg, Head of the Technical Center at amixon

WalterWagner HeatTransfer Technique withOrganic Fluids

3rd edition,2019

ISBNhardcover: 978-3-8343-3433-6

This comprehensive standard work not only offers a detailed and well-founded presentation of the basics of heat transfer technology, but also shows the latest state of the art in the use of organic fluids. In addition, the book explains the latest regulations that are essential for the design, construction and operation of heat transfer installations and contains property dataoforganicheattransferfluids

Price permanently reduced

ISBNe-book: 978-3-8343-6250-6 9.00EUR 149.00EUR

8

StefanWürz HeatTransferFluids–Propertiesand Comparisons

1st version,2021

ISBN:978-3-8343-2471-9

249.00EUR

Theprogramprovidespropertyvaluesofheattransferfluids for quick and easy calculation as well as comparisons All properties are calculated exclusively using precise approximationfunctions,whichcanbeconvenientlyintegratedinto yourowncalculations.Inadditiontocurrentfluids,theprogram also includes fluids that are no longer available to facilitate thesearchforsuitablesuccessorproductswithcomparable qualities.

StefanWürz WaterandSteam PropertiesAccordingto IAPWS

1st version,2022

ISBN:978-3-8343-2472-6

99.80EUR

The program provides water and steam properties for the mostcommonindustrialapplicationsupto1000baror2000°C The calculations are based on the equations of the International Association for the Properties of Water and Steam (IAPWS). Pressure and temperature are used as a basis, but the properties can also be calculated on the saturation line andinthewetsteamarea.Allcalculationmodulescaneasily be integratedinto your ownworkbooks.

Furtherinformationandpurchaseat www.vogel-fachbuch.de/en

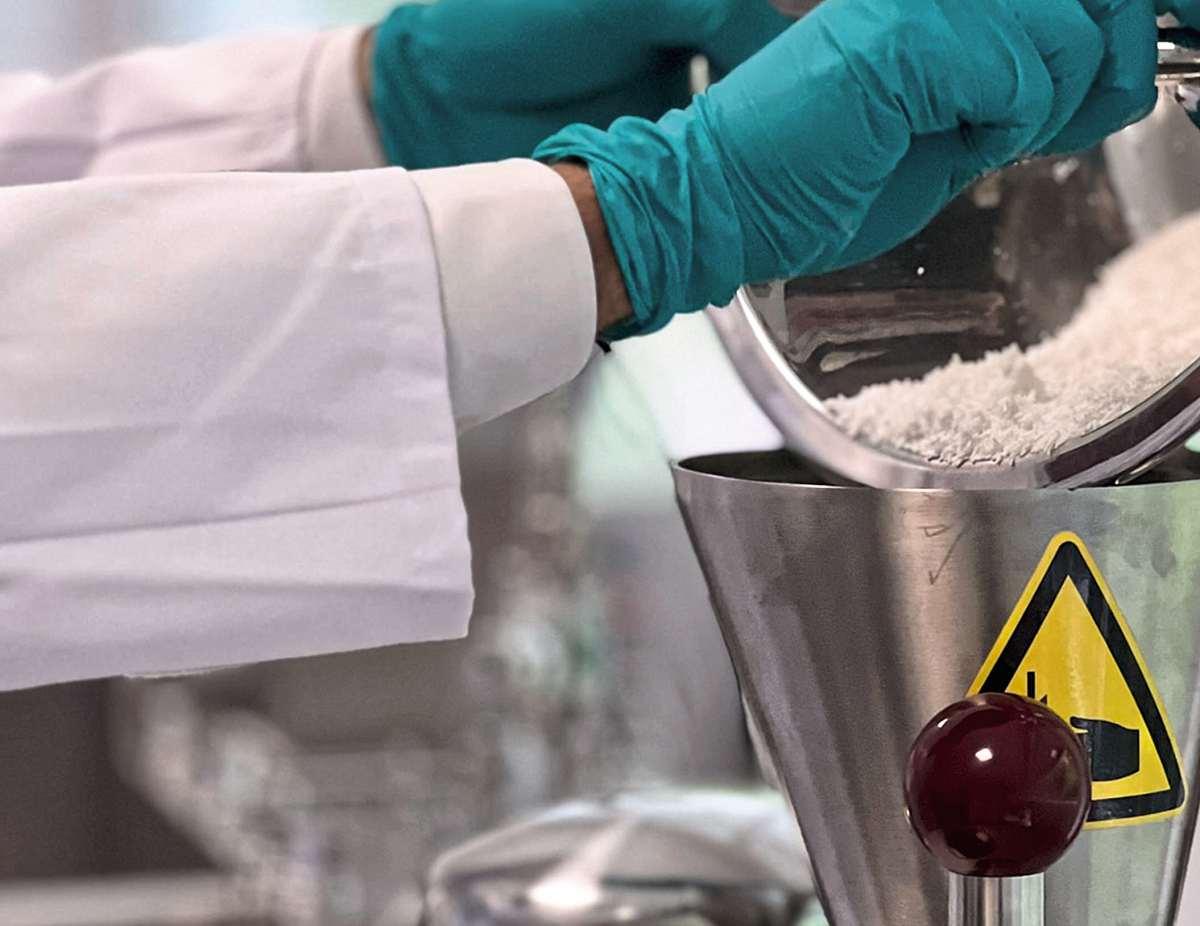

The production of high-quality pellets for pharmaceutical products or nutraceuticals begins in the laboratory At the summit, it was demonstrated how the Diosna laboratory mixer works perfectly in conjunction with the Gabler Spheronizer

Demographic changes, new drugs and processes are ensuring solid growth in the pharmaceutical, and nutraceutical, dietary supplement industries. Since 2023, Coperion has brought together all solutions for their manufacture under one roof. At a summit this summer visitors were given an insight on Coperion’s Health & Nutrition (H&N) solutions.

Coperion offers a wide range of technologies and systems for the production of medicines, active ingredients and dietary supplements, whether tablets,inhalantsorgummynutraceuticals.Theserange from material handling, dosing, depositing and mixing to granulation, extrusion, film coating and the production of rubber-coated tablets. While the H&N segment previously focused primarily just on dry processes, it now also has expertise in handling liquids and viscous products. Coperion thus offers the entire process chain, right through to upstream solutions.

“At our first Industry Summit, we wanted to demonstrate the growth of our portfolio in recent years,” said

Sharon Nowak, Global Business Development Manager, H&N. “It wasn’t just about presenting our products; we alsowantedtobringourcompaniestogether,explainour technologies and discuss market trends.” Around 80 participants accepted the invitation in mid-June this year Topics ranged from handling emulsions and containment requirements to extrusion and pelletising

ThesummittookplacetheGermanfacilityoftheCoperion technology brand Diosna. As well as machines for dough production, the brand of Diosna primarily man-

ufactures solutions for the production of pharmaceutical products. “Today, more than 60 percent of active ingredients are in tablet form. One challenge is to bind the APIs correctly; otherwise, there will be problems duringsubsequentprocessing,”saidMichaelBenjamin ofDiosnaduringthefactorytour Thisprovidedinsight into the production of moist or dry granulates, which form the basis of tablets, effervescent granulates and pellets.

The multi-process step method (high-shear granulator and fluidised bed processor) and the single-pot methodfromDiosnaareidealforthispurpose TheSingle Pot VAC 800 can perform virtually all steps—mixing, adding liquid, wet granulation and drying—in a single machine “The advantages are the smaller footprint and the ability to implement changes in the process more quickly. Users also find it easier to meet containment requirements up to OEB levels 4 and 5,” says Benjamin, speaking from experience. Another alternative for automated batch production is a combination ofahigh-sheargranulatorandafluidisedbedprocessor This requires a larger setup and longer process times. Thiscombinationisusuallysupplementedwithatablet press.Pneumaticmaterialhandling,dosingandfeeding

To maximise the efficiency of R&D, the Diosna P1-6 mixer offers a multifunctional, space-saving solution. Together with Gabler, they demonstrated how the mixer interacts with an extruder and a spheronizer. A special feature of the P1-6 is its cylindrical-conical mixer geometry, which ensures perfect particle size homogeneity and optimal API distribution during mixing. The P1-6 laboratory mixer guarantees consistent product quality. Coperion showcased the Gabler Engineering Spheronizer R250, which is available in models ranging from laboratory-scale to automatic production lines with a capacity of 100 kg per batch and a GMP design for the pharmaceutical industry. Customers can choose between pellet sizes ranging from 0.4 to 5 mm and process batches from 0.15 to 6 kg. The rounding time varies between one and five minutes. Gabler also offers various options, such as Atex-compliant machine designs, to meet individual requirements in the pelletising process. PROCESSINFO

“Ourportfoliohasgrown enormouslyinrecentyears. Wewereabletopresentthe entirerangeatthesummit.”

Sharon Nowak, Coperion

options are utilized by the technology brand Coperion K-Tron.

Emulsions,includingbothoil-in-waterandwater-in-oil types, are commonly found in pharmaceutical formulations. Stability, texture and preservation of the active ingredients are crucial. Consistent quality depends significantly on the mixing process. “Shear rate, mixing speedandequipmentdesignareimportantparameters for emulsification and stable pharmaceutical products,” explained Corinne Delpy from VMI, the experts for mixingandkneadingsolutionsintheCoperionGroup “Controlling these parameters is essential for producing a smooth, easy-to-process, high-quality end product that meets strict industry standards. The main parameters are the propeller shape and speed. “If the speed is too high,itdestroystheemulsion;ifitistoolow,themixing isineffective,”saysDelpy Thespeedoftherotorensures greater fractionation of the fat particles. The higher the tangential velocity, the smaller the droplet size and the better the distribution The higher the viscosity of the

The Coperion K-Tron K3 pharmaceutical dosing device series has a modular design offering significantly reduced space requirements thanks to a new, smaller D4 platform scale. The patented, highly accurate Smart Force Transducer (SFT) weighing technology has a high sampling rate to ensure maximum accuracy. The ‘Quick Change’ design allows the dosing unit (including the horizontal agitator and screws) to be quickly disconnected from the dosing drive, enabling speedy and easy product changes. All that is required is to loosen two clamps, remove the used dosing unit and replace it with a cleaned one.

Additionally, high-potent APIs (HPAPIs) are being used more frequently. These are active ingredients that areeffectiveeveninverylowdoses “We’retalkingabout 10 µg per cubic metre, or OEL 6, although these limits are not uniformly defined. I like the approach of an ItaliancustomerwhoprocessesproductsaboveOEB3inan isolatorassoonasenergyisintroducedintotheprocess, forexamplethroughaclassifieroramill.Thisincreases theneedtoimprovesafety,”saysBrown.Nevertheless,it isdifficulttohandletheseHPAPIswithouttherightpartner with experience in safety concepts. Valve technologies, strict isolation and vacuum systems are generally available. However, Brown, speaking from experience, says that “in my opinion, flexible containment systems are the only way to handle HPAPIs safely”

These systems are also attractive from a cost perspective, as the following figures show: The cost of a sample projectwas€30,000insteadof€300,000;setuptooksix weeks instead of a year; and cleaning and validation timesweredrasticallyreduced Single-usecontainment systems are already being used in the manufacture of hormones, biopharmaceuticals, and immunoconjugates.

product,thelowerthethroughputandthemorehomogenizationtimeincreases.“Therefore,therightchoiceof homogeniser(rotor/stator),especiallyintermsofgeometry and gap size, as well as the right scale-up, are immensely important for obtaining stable emulsions," warns Delpy.

Mike Brown, one of the guest speakers, from Onfab providedinsightintothefuturehandlingofhighlyeffective andtoxicmolecules.Onfabofferscost-efficient,flexible containment systems that protect users from exposure to highly hazardous substances. The protection level rangesfrom30ng/m³to1ng/m³.Containmentsystems are in increasingly high demand as more products are reclassified and new active ingredients are discovered.

The VMI Trilab is a series of vacuum mixing homogenisers for laboratory and pilot plants, with working volumes of 5, 10, 30 and 50 litres. It combines internal and external counter-rotating coaxial agitators with an efficient rotor-stator highshear mixer with bottom drive. Trilab systems are vacuum-compatible, can be jacketed for heating or cooling, and have a stirred melt tank. Like the Multilab, the Trilab is controlled via a PLC with a colour touchscreen HMI interface.

Prof JamesScicolone,PhD,ResearchProfessoratC-SOPS (Center for Structured Organic Particulate System) at Rutgers, The State University of New Jersey, whose institute has been working on continuous production since 2006,highlightedanewaspectoftheuseofblendersin continuous direct press production lines. The Covid-19 pandemichasalsoshownthatsupplychainsarebecoming increasingly vulnerable, and that pharmaceutical production must become faster Although batch processesarestilldominant,continuousproductionisgaining ground.

So, what does this mean for blenders? “In batch processes, raw materials are added in large quantities and thoroughlymixed.Incontrast,incontinuousprocesses, thecomponentsareaddedinsmallamounts.Thisraises the question of whether special mixing reactions are necessary at all,” says Scicolone, who is therefore eager toseeifmixingcanbeconvertedintocontinuousdirect compaction, which would eliminate one process step Thiswouldspeeduptheentireproductionprocess.Studies on residence time distribution using spectroscopic markersathisinstitutehaveshownthatblendingmainly takes place at the feed point of the tablet press rather than in the blender.

What’s more: Scicolone shared that results show that direct feeding achieves a level of homogeneity comparable to that in traditional manufacturing processes. This provides a cost-effective alternative that not only simplifies production but also accelerates product development.

Dr JosipMatić,ScientificAreaLeaderforModellingand Prediction at RCPE, reported on the use of modelling toolsinhotmeltextrusion.Thesearenowusednotonly in the food and polymer industries, but also for a wide range of pharmaceutical formulations. These range from oral to implantable dosage forms and filament-based 3D printing In his opinion, using digital

tools opens up new perspectives for formulation and process development.

This is because designing, setting up and scaling extrusionprocessesremainschallenging Thisisduetothe varyingtemperaturesofthemeltalongthescrewduring the process. This causes changes in viscosity, for example. Complex interactions between material properties, process configurations and product performance are added to this “Of course, you have to consider whether the active ingredient survives the process undamaged and which additives can be used Finding the optimal configuration is a major challenge here,” says Matić. RCPM has therefore developed a range of digital modelling tools to accelerate the screening of formulations. “Thesefacilitateprocessdevelopmentfromthelaboratorytotheproductionline.Wearenowverysatisfiedwith therealisticmodellingandcanidentifytheoptimalprocess window more quickly. Incidentally, this is not only interesting for process development, but also very practical for scaling up,” Matić concludes.

Dr JohannesTrappfromLosanPharma,aCDMO,provided insight into modern contract manufacturing and plantdevelopmentinGermany.Thefocuswasonpellets, which offer users a wide range of advantages. These include a potentially high active ingredient load, ease of administration, and the option of packaging in stick packs.Trappdemonstratedhowthesearemanufactured using the layout of a high-volume production line

Thisexpandstherangeofapplicationsforsuchpellets. Modified-release formulations can help to reduce side effectsand/orincreasetheefficacyofadrug.“Thanksto ourcomprehensiveexpertiseinfluidbedcoating,wecan apply different coatings to each pellet,” explains Trapp “We can offer pellets with targeted release using pH-dependent coatings, or prolonged release using pH-independent swelling coatings.” Matrix formulations combiningpelletswithimmediateandprolongedreleaseare also possible, and these can be filled into a capsule or

PROCESSINFO

The Servoform mini despositing machine from Coperion’s technology brand Baker Perkins can produce a wide range of starch-free confectionery and neutracutical products, including jellies, hard candies, lollipops, toffee, and high-quality medicinal or functional products. The output capacity is 50 kg/hour. The resulting product is always smooth and consistent in size and shape, with high piece weight accuracy. A low reject rate, fast product changes and continuous processing ensure a quick return on investment using this depositor.

stickpack.Thisoffersenormousadvantagesforpatients, for example, reducing a medication that must be taken three times a day to one dose per day, or ensuring overnight intake.

The Coperion H&N Industry Summit showcased practical applications of modern technologies, such as single-usecontainment,digitalmodelling,andcontinuous processes, which are streamlining the production of pharmaceuticals and supplements, making it safer, moreefficient,andmoreflexible.Integratingthesetechnologies is essential to meet increasing demands for quality, safety and speed. (müh)

PROCESSINFO

Kemutec's H&N solution, the KEK cone mill, can process a wide range of materials and is often used in the food, pharmaceutical and chemical industries. The mills are ideal for intermediate comminution in wet and dry granulation, carefully grinding the material at high speed. They also feature variable speed control for maximum process flexibility.

The Perfima Edge wedge wire screen drum achieves full functionality of tablets and pellets with lower coating levels. This can reduce the footprint of the products. The design ensures gentle handling and high process air volumes, allowing high spray rates and short process times.

When deciding on a particular coating technology, it is essential to consider the quality and economic efficiency of the process, along with space requirements. Factors such as processing timeandcoatinguniformityofthefinalproductarealso crucial considerations. A study by Ima and BASF evaluates the Perfima Edge coating technology in terms of efficiencyinapelletcoatingprocesstoachievefullfunctionality

PerfimaEdge:PropertiesoftheWedgeWire ScreenDrum

ImaActive’swedgewirescreendrumiscompatiblewith the standard Perfima equipment, enabling the Perfima

Edge to provide side-vented pan coating for small particlessuchaspelletsortablets.Thedrum’swedgewirehas a rounded, smooth shape, ensuring gentle handling of theproductandenhancingflowability Thisdesignofthe drum also allows high process air volumes, resulting in high spray rates and economical short process times, similar to conventional perforated drum coaters. Compared to the fluid bed technology, Perfima Edge comes with a reduced footprint, requires less space for equipment installation, and provides easy access to the spraygunsduringoperation.Thedrumcoatingprocess is easier to control, simplifying upscaling procedures. Fromtheproduct’sperspective,bothtechnologies,fluid bed and Perfima Edge, provide coated pellets of equal quality and performance.

Source: Ima

Sugar spheres (20-25 mesh, IPS) consisting of sucrose andmicrocrystallinecellulosewereusedassubstrate.As tracer,riboflavin(BASF)embeddedinafilmofPVA-PEG graft copolymer (Kollicoat IR, BASF) was applied up to a weight gain of 4.84%.

The functional coat was based on 50% Kollicoat Smartseal30D(BASF),apolymerdeliveringtaste-maskingfunctionalityduetoitspH-dependentsolubility Additional components of the formulation were:

1% FD&C Blue No. 1 (BASF) as coloring agent and tracer,

acetyl tributyl citrate (ATBC, Jungbunzlauer) as plasticizer (7.6% formulation, 15% polymer-based),

buthylene hydroxy toluene (BHT, Sigma-Aldrich) as antioxidant (1.3% formulation, 2.5% polymer-based),

39% talc (Merck) as anti-tacking agent.

The coating was conducted with an aqueous coating formulation (15% solid matter content), consisting of 10% riboflavin, 5% Kollicoat IR, and 85% water

In this study, the Perfima Edge, Ima’s side-vented pan coater (SVP), equipped with a wedge wire screen drum specificallydesignedforcoatingofsmallsubstrateslike pellets,wasused.Allexperimentswerecarriedoutusing pilot-scale equipment. The drum incorporates small wedgewiresinsteadoftheconventionalperforatedwall to enable airflow passage during the coating process. Theequipmentmaintainedtheoriginaldrumshape,geometry, and spray system of the standard tablet coating machinery. To handle substrates of various shapes and sizes, specially designed mixing baffles were welded to both the center and side walls of the drum. The coating trialswereperformedfollowingtheparametersoutlined in the table.