THE TOP 40

We rank this year’s industry leaders in electrical design. Read more on pg. 16 IN THIS

How to Get Along with an Electrical Inspector pg. 8

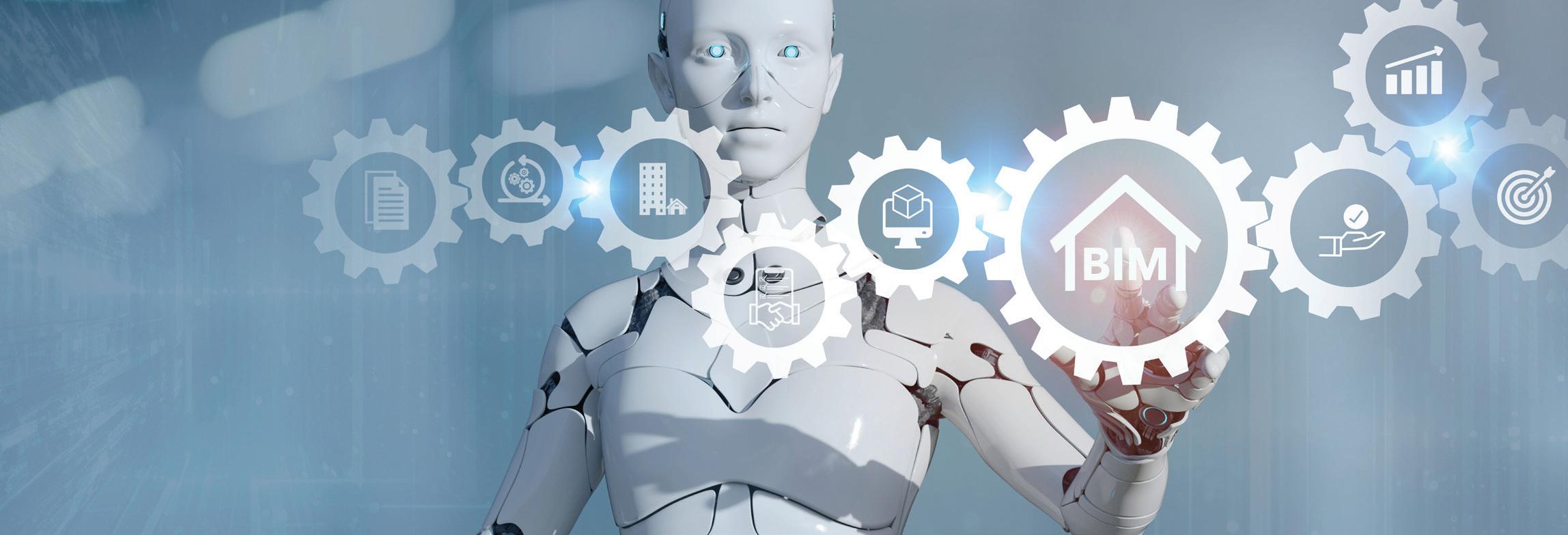

Installing EV Infrastructure in the Home pg. 12 Is AI the Future of BIM? pg. 48

NEC Requirements for Solar pg. 57 Understanding Snap Switches and the Code pg. 62

Our families. Our neighbors. Our future.

Buying American-made steel conduit can help make an impact that is felt far and wide. American-made steel conduit means jobs for you and your neighbors. American-made steel conduit means completely American-made from coil to conduit. American-made steel conduit means higher standards and a lower carbon footprint than imported materials. American-made steel conduit means a bright future of Building Better Together.

*Does not include Kwik products

Source: American Steel Tube Institute https://steeltubeinstitute.org/wp-content/uploads/2021/11/SteelConduit_Sustainability-Fact-Sheet_111621.pd f

Learn more at atkore.com

Dominant electrical design practices run up revenue again for this year’s Top 40 Electrical Design Firms, but temper their outlook amid uncertainty.

For electrical design firms, another challenge is keeping up with all of the new AI tools and their capabilities. The selection grows every day — not only from BIM vendors, but also from IT companies. Here’s how — and what it will take to achieve that and other business benefits.

ECMWEB.COM

With its exclusive online content, ecmweb.com is a valuable source of industry insight for electrical professionals. Here’s a sample of what you can find on our site right now:

THE 5 HIGHEST-PAYING STATES FOR ELECTRICIANS: 2023

Gallery See which states topped the charts in terms of compensation. ecmweb.com/55038733

EC&M ON AIR — UNDERSTANDING 2024 LABOR PRODUCTIVITY TRENDS IN THE CONSTRUCTION INDUSTRY

Podcast Ellen Parson and Tyler

Paré dissect findings from FMI’s 2023 Labor Productivity Study. ecmweb.com/55042823

AVOIDING UNCOMMON MISTAKES ON JOB SITES

Safety Mark Lamendola discusses how to keep workers safe by avoiding unlikely scenarios. ecmweb.com/55020229

Editorial

Group Editorial Director - Buildings & Construction: Michael Eby, meby@endeavorb2b.com

Editor-in-Chief: Ellen Parson, eparson@endeavorb2b.com

Managing Editor: Ellie Coggins, ecoggins@endeavorb2b.com

Editor: Michael Morris, mmorris@endeavorb2b.com

Art Director: David Eckhart, deckhart@endeavorb2b.com

Consultants and Contributors

NEC Consultant: Mike Holt, mike@mikeholt.com

NEC Consultant: Russ LeBlanc, russ@russleblanc.net

Sales and Marketing

VP/Market Leader - Buildings & Construction: Mike Hellmann, mhellmann@endeavorb2b.com

Regional/Territory Account Manager: David Sevin, dsevin@endeavorb2b.com

Regional/Territory Account Manager: Jay Thompson, jthompson@endeavorb2b.com

Media Account Executive – Classifieds/Inside Sales: Steve Suarez, ssuarez@endeavorb2b.com

Production and Circulation

Production Manager: Josh Troutman, jtroutman@endeavorb2b.com

Ad Services Manager: Deanna O’Byrne, dobyrne@endeavorb2b.com

User Marketing Manager: James Marinaccio, jmarinaccio@endeavorb2b.com

Classified Ad Coordinator: Terry Gann, tgann@endeavorb2b.com

Endeavor Business Media, LLC

CEO: Chris Ferrell President: June Griffin COO: Patrick Rains

CRO: Paul Andrews

Chief Digital Officer: Jacquie Niemiec

Chief Administrative and Legal Officer: Tracy Kane EVP, Group Publisher – Buildings/Lighting/Digital Infrastructure: Tracy Smith

Electrical Construction & Maintenance (USPS Permit 499-790 , ISSN 1082-295X print, ISSN 2771-6384 online) is published monthly by Endeavor Business Media, LLC. 201 N. Main St 5th Floor, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI, and additional mailing offices. POSTMASTER: Send address changes to Electrical Construction & Maintenance, PO Box 3257, Northbrook, IL 60065-3257. SUBSCRIPTIONS: Publisher reserves the right to reject non-qualified subscriptions. Subscription prices: U.S. ($68.75 year); Canada/Mexico ($ 112.50); All other countries ($162.50). All subscriptions are payable in U.S. funds. Send subscription inquiries to Electrical Construction & Maintenance, PO Box 3257, Northbrook, IL 60065-3257. Customer service can be reached toll-free at 877-382-9187 or at electricalconstmaint@omeda.com for magazine subscription assistance or questions.

Printed in the USA. Copyright 2024 Endeavor Business Media, LLC. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopies, recordings, or any information storage or retrieval system without permission from the publisher. Endeavor Business Media, LLC does not assume and hereby disclaims any liability to any person or company for any loss or damage caused by errors or omissions in the material herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. The views and opinions in the articles herein are not to be taken as official expressions of the publishers, unless so stated. The publishers do not warrant either expressly or by implication, the factual accuracy of the articles herein, nor do they so warrant any views or opinions by the authors of said articles.

Reprints: Contact reprints@endeavorb2b.com to purchase custom reprints or e-prints of articles appearing in this publication.

Photocopies: Authorization to photocopy articles for internal corporate, personal, or instructional use may be obtained from the Copyright Clearance Center (CCC) at (978) 750-8400. Obtain further information at www.copyright.com.

Archives and Microform: This magazine is available for research and retrieval of selected archived articles from leading electronic databases and online search services, including Factiva, LexisNexis, and ProQuest.

Privacy Policy: Your privacy is a priority to us. For a detailed policy statement about privacy and information dissemination practices related to Endeavor Business Media products, please visit our website at www.endeavorbusinessmedia.com.

Please Note: The designations “National Electrical Code,” “NE Code,” and “NEC” refer to the National Electrical Code , which is a registered trademark of the National Fire Protection Association.

Corporate Office: Endeavor

Inside the Ever-Evolving World of Electrical Design

By Ellen Parson, Editor-in-Chief

Every June, we present the results of our annual Top 40 Electrical Design Firms survey, which, for the most part, asks the same set of questions each year in an effort to establish historical trends in certain areas, including business climate, backlog, revenue performance, hot and cold markets, recruiting/hiring trends, and technology. Based on total revenue related to electrical design work performed in 2023, the 2024 Top 40 Electrical Design Firms special report is featured in this issue starting on page 16.

One of the most impactful technological developments of 2023 that affected not only society as a whole but also the electrical design industry in particular was the emergence and normalization of generative artificial intelligence (AI) tools bursting onto the scene in the form of chatbots. One of those (ChatGPT) gained 1 million users within five days of launching in November 2022, and many others also went viral quickly after their debuts. How does this relate to the electrical engineering profession specifically and to the electrical industry in general? There are many predictions from experts that attempt to scratch the surface regarding how AI will transform our world going forward. “I believe AI is going to change the world more than anything in the history of humanity. More than electricity,” said AI expert Kai-Fu Lee, Chairman & CEO of Sinovation Ventures, in an interview with 60 Minutes and CBS News in 2019.

Whether that turns out to be true or not, the idea is intriguing. How do Top 40 firms plan to harness the power of AI in the short and long term? Although we’ve asked questions about respondents using augmented reality (AR) and virtual reality VR) tools in electrical applications for years, this is the first time we’ve asked specifically about AI. Whereas AR and VR enhance real-world objects on a virtual platform to create immersive environments, AI enables computer applications to mimic human-like intelligence and resolve problems, make predictions, and provide solutions. We asked respondents this year: How long will it take for AI to become a viable component of electrical design work? According to this year’s results, 43% of Top 40 firms say they’re already using it.

Just for fun, I decided to ask ChatGPT the same question with the exact same wording — it will be interesting to watch and see how accurate the following prose proves to be when we look back a few years from now in future Top 40 analysis reports. After typing the question into the prompt, the machine spit out the following synopsis in less than 5 seconds: AI is already making strides in electrical design, but its full integration into the field will depend on several factors. These include the development of AI algorithms tailored specifically for electrical design tasks, advancements in computational power to handle complex simulations and optimizations, and the acceptance and adoption of AI tools by engineers and companies.

Given the current rate of progress, it’s reasonable to expect AI to become a viable component of electrical design work within the next 5 to 10 years. However, this timeline could vary depending on the pace of technological innovation and the specific subfields within electrical design. As AI technologies continue to mature and demonstrate their capabilities in tasks such as circuit design, optimization, and fault detection, engineers will increasingly rely on these tools to streamline their workflows, improve efficiency, and uncover new design possibilities. Additionally, the integration of AI into design software platforms will likely accelerate its adoption within the industry. Ultimately, while AI will undoubtedly transform the practice of electrical design, human expertise and creativity will remain essential in guiding the design process, interpreting results, and ensuring that designs meet the required standards and specifications.

Turn to the Top 40 cover story for more commentary and analysis on this year’s survey results, including specific ways in which these leading electrical design firms are using AI. Predictably, their top answer was “optimizing processing and improving efficiencies;” however, the second most popular response (marketing and promotions) did surprise me a bit. Digging into this concept a little deeper, don’t miss Freelance Writer Tim Kridel’s feature article on page 48, which contemplates the future of building information modeling (BIM). Although combining AI with BIM can obviously make design engineers more productive, this piece takes an in-depth look at what it will actually take to get there as well as evaluates the other business benefits and pitfalls that could come along with the AI evolution.

Dressed to Impress, Now Slimming in Black

Upgrade your home’s outdoor aesthetic with modern, low-profile weatherproof covers from Intermatic. Now available in Black, our popular expandable covers offer a slim alternative to traditional in-use weatherproof cover options.

The unique design of the WP6000, WP6200, WP7000, and WP7200 Series includes an expandable front window that can be collapsed to save space when not in use. This improves aesthetics while delivering dependable, code-compliant protection for a range of outdoor applications. Additional colors available:

Learn more today at Intermatic.com/low-profile-in-use-cover

How to Get Along with an Electrical Inspector

Best practices for enhancing the working relationship between electrical contractors and inspectors

By Joseph Wages, Jr., IAEIIstarted my career sweeping floors in the basement of a university building hoping to be seen as worthy to become an electrical apprentice. In those days, there were no mandatory apprenticeship training programs. To become an apprentice — and then be placed into an electrical apprenticeship program — was an expense to the contractor that may or may not produce a licensed employee. A strong work ethic, reliability, and a willingness to learn were necessary to even be considered for this type of position. During this time as an apprentice — and eventually a licensed electrician — I heard several stories about those evil, despicable electrical inspectors. I never dreamed I would become one later in my career. This article presents some ways you as an electrical professional can enhance your working relationship with the electrical inspector.

BRIBES, KICKBACKS, AND MAFIA PAYOFFS

Who remembers the movie back in the ’80s called “Back to School”? Rodney Dangerfield played a successful older businessman who decided to enroll in college with his son. During one scene in the movie, his character, Thorton Melon, decides to inform the business professor he was wrong about how to get things built. Dr. Barbay (the professor) responded, “Maybe bribes, kickbacks, and mafia payoffs are how you do business, but they are not part of the legitimate business world!”

Some people believe that to appease the electrical inspector, you need to take them to lunch, send them presents

Learning how to foster a healthy and, most importantly, professional working relationship with your local electrical inspector is essential.

during the holiday season, take them on expensive hunting or fishing excursions, etc. Do not go down this path. Bribes and kickbacks have no place in the legitimate electrical installation and inspection world.

Some of these offerings may be innocent with no favors expected. Even at

that, the public seeing this type of relationship can get the gossip mill running. Plus, other electrical professionals begin jumping to conclusions that there may be something inappropriate going on between a certain electrical contractor and the local or state inspector. Putting a bottle of the inspector’s favorite alcoholic

beverage or an envelope full of money in the inspection vehicle when the inspector is conducting the inspection is a good way to be arrested and/or cause the inspector to lose their job. You may be laughing, but this has happened — and the inspector immediately called the police and his supervisors to the scene. A few dollars in bribes can cost a person their integrity and jeopardize working as an inspector in other jurisdictions.

Many states and municipalities have strict guidelines on these types of activities that could result in disciplinary actions, including termination. Contrary to what you learned as an apprentice or during your time as an electrician, bribes or kickbacks cannot exist in the electrical installation/inspection relationship.

KNOW WHAT TO DO, AND DO

WHAT YOU ARE SUPPOSED TO DO

A surefire way to build and maintain a good working relationship with an

Inspector Intel articles are provided by the Independent Alliance of the Electrical Industry (IAEI), www.iaei.org, a membershipdriven, non-profit association headquartered in Richardson, Texas, that promotes electrical safety throughout the industry by providing education, certification of inspectors, advocacy, partnerships, and expert leadership in electrical codes and standards.

electrical inspector is simple. Know how to do your job, and understand/follow the local and state Code requirements as

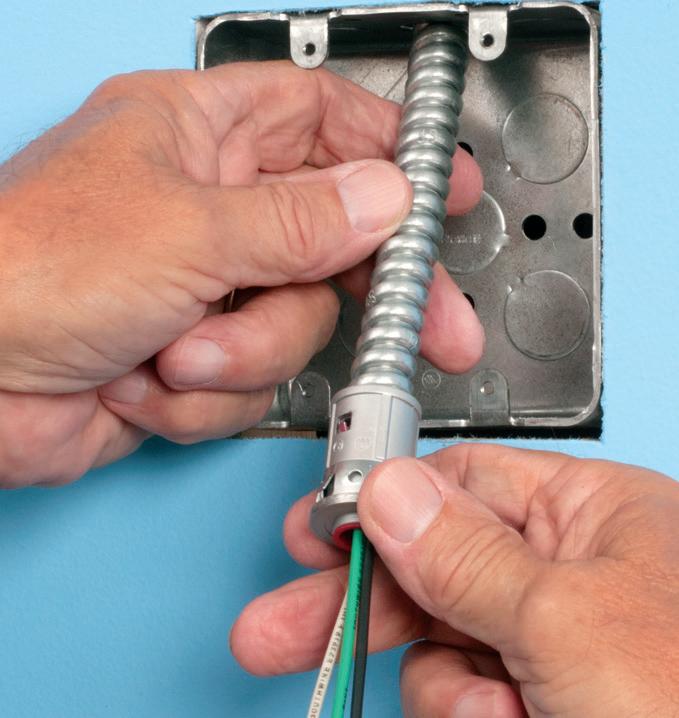

New Universal Stud-mount Brackets

Maximize your jobsite flexibility, save time and labor!

Easily mount any RACO 4” or 4-11/16” box to metal studs or our new open center bracket and add a mud ring. Just snap the Universal Stud-mount Bracket to the stud for hands-free installation.

The rigid design eliminates the need for far-side support. Install vertical or horizontal. Even gang multiple brackets together. These cost-effective brackets save time and effort.

Available as a flat bracket, raised mud rings, and adjustable mud rings.

they pertain to your electrical work. In the end, this is what the inspector expects — a Code-compliant installation that follows state and local electrical requirements done in a workmanlike manner.

As an installer, this means listening to those who are willing to share the secrets of the electrical trade with you, going to your apprenticeship classes and learning all there is to know about the electrical industry, and testing for and receiving your electrical license upon completion of your apprenticeship training.

Many believe that once they graduate from the apprenticeship program and get their license, they never need to open that Code book again. If that is what you believe, I have news for you: Learning never stops in this trade or any other profession. Continuing education in this trade is a requirement to produce Code-compliant electrical installations. The technological advances taking place today require all electrical professionals

Try RACO universal stud-mount brackets for yourself! Scan to request a sample.

INSPECTOR INTEL

to stay engaged in the learning process. How many folks attending an apprenticeship training program in the 1960s received electrical training on renewable energy systems? Today, these seasoned professionals are being looked upon to install or inspect these systems in a Code-compliant manner. To achieve this level of expertise, the electrical professional must attend electrical continuing education events. A training event can help fill in the gaps that might exist with your electrical training needs.

Other ways to ensure a good relationship with an inspector is to have quick access to the edition of the NEC — or other standards being enforced in the area where you’re performing work — and know those requirements. If you have a disagreement or misunderstanding with an inspector, open the standards

being enforced, and seek clarification. Have the plans for the electrical project available to discuss the installation.

As an inspector, I appreciated the installers who wanted to meet with me before the start of the project and discuss any local ordinances or other requirements that might be in place that would affect their work. Examples might be local ordinances concerning burial depths that exceed what the NEC specifies for the installation — or an ordinance that does not allow a branch circuit less than 20A to be installed in a dwelling unit. It is always less frustrating and expensive to find out about these ordinances before beginning the electrical project. Electrical professionals must always remember that the NEC is a minimal standard. Being barely above illegal is one way to think of it.

Get your permits before beginning the project and have the electrical work ready for inspection when the electrical inspector arrives. Many municipalities have a lot of construction taking place. Your project is not the only one in the municipality they must inspect. Not being ready causes extra trips to the job site for the inspector. In some cases, this can result in re-inspection fees being assessed to the electrical contractor.

Above all else, make sure you have inspected the work before the inspector inspects the work. You are the first set of eyes on the project. Check your work! Make sure you have torqued the terminations that require torquing. Look for any missing receptacles or switch covers. Is the panel schedule in place? Are all the locknuts tightened on your connectors? Did you put all the screws in the panel cover when you placed it on the cabinet? Have you checked the polarity on all the receptacles in the structure to make sure they are wired correctly? Did you test your GFCI devices to make sure they function as intended? All of these above-mentioned items (and numerous others) help ensure the integrity and safety of the electrical installation.

NOW YOU KNOW

Most electrical professionals strive to do the best work possible. They take pride in their chosen career and are deeply concerned about electrical safety. Electrical inspectors share that same passion for safe electrical installations. They are like an umpire at a baseball game, calling balls and strikes batter after batter. They know the strike zone and are consistently using it to determine a ball from a strike.

At the end of the day, everyone wants to go home knowing they had a small part in keeping families electrically safe. As the installer, your job is to know the electrical installation requirements and to abide by them. This will ensure a good relationship with the electrical inspector. Doing so will keep you from striking out on your next electrical inspection.

Joseph Wages, Jr. is the Director of Education with IAEI. He can be reached at jwages@iaei.org.

NO BURN-THROUGH

CHAMPION DUCT® SOLVES

UTILITIES CHALLENGES

No burn-through eliminates elbow repairs

Lower material and installation costs

DOWNLOAD FIBERGLASS VS

GRC

COMPARISON

Fault resistance makes repairing cables easy

Durable and corrosion-resistant for project longevity

EV Installations on the Home Front — Part 4 of 4 Preparing for the future of home energy

By Dan Carnovale, Eaton

The energy transition continues to advance, and with it comes rising demand for electric vehicle (EV) infrastructure in single-family homes.

Throughout this article series, we’ve explored a multitude of important considerations for electrical professionals when it comes to installing EV infrastructure. First, we looked at the need to ensure energy capacity meets charging needs. Next, we examined safety as a paramount concern. Most recently, we looked at different charging configurations and the role they play in optimizing customers’ experiences with their EV purchases.

In this final installment, we’ll look at a topic that should be on every electrical professional’s mind: installing EV infrastructure amid the transformation of home energy systems.

INNOVATION ON THE HORIZON

Residential energy systems are undergoing major changes as EVs proliferate. The energy transition has given homeowners new opportunities to reduce their carbon footprints through electrification — from adding more electric appliances to achieving whole-home electrification.

Many homeowners are also embracing alternative approaches to powering the home — from the integration of more renewable energy (e.g., solar) and battery energy storage to full-scale residential and community microgrids. Managing this new electrical ecosystem requires special knowledge and consideration.

Each innovation presents an opportunity for contractors to design electrical systems that help homeowners become smarter and more efficient, sustainable users of energy. Therefore, when approaching EV charging installation

projects, contractors should think about installation not simply as a solitary addition to a home but also as part of the broader transformation of home energy systems that will provide benefits for years to come.

EMERGING TRENDS

To understand the role of EV charging in the transformation of home energy systems, contractors need to become familiar with the innovations supporting this transformation and their impact on electrical loads in the home.

One such innovation is the growth of smart home energy management solutions, which encompass smart appliances and thermostats as well as components like smart wiring devices, circuit breakers, and load centers. These solutions, when integrated with smart home ecosystems and managed

via integrated mobile apps, give homeowners greater control over their home energy usage and enable them to make smarter energy decisions. Many homeowners will want to include and manage home EV charging within this ecosystem, making it important for contractors to understand the technologies (both hardware and software) and standards that may impact it.

Another innovation is the integration of renewable energy and residential microgrids. More homeowners than ever are seeking to generate their own power through the deployment of solar and battery energy storage to offset energy costs and increase resiliency. Some are even implementing dedicated microgrids, which can help power the home when grid power is unavailable — an attractive solution in outage-prone regions.

In addition to their benefits during outages, microgrids can reduce energy costs by helping to effectively manage loads, which is especially critical for

larger loads like EVs. It can also help homeowners take advantage of utility incentives for initiatives such as peak shaving and demand response.

Microgrids can reduce energy costs by helping to effectively manage loads, which is especially critical for larger loads like EVs.

One more innovation on the horizon is the opportunity to use the stored energy in EVs as a source of power rather than a load, providing energy back to different elements of the home.

Some examples include:

• Vehicle-to-home (V2H): Leverages the vehicle’s battery to power essential needs in the home, especially when the grid is down.

• Vehicle-to-grid (V2G): Puts EVs to work by returning energy stored in batteries to the grid, especially during peak load times when the utility can use extra capacity.

• Vehicle-to-vehicle (V2V): Enables flexibility to recharge anywhere by plugging into another EV.

• Vehicle-to-everything (V2X): Uses stored power in vehicles to provide energy during an emergency or wherever the grid is remote or doesn’t exist.

Contractors should take steps to learn more about these approaches as more homeowners may seek to implement them in the years to come. They should consider enabling technologies, such as smart circuit breakers, that can help prepare homes for the transition to help future-proof investments.

CHANGING LANDSCAPE FOR ELECTRIC UTILITIES

The landscape for electric utilities is evolving amid the transformation of home energy systems. EVs represent a significant power draw for the grid, and many electric utilities are taking creative approaches to manage this power draw in a way that ensures adequate power availability for charging and other needs. This can include the addition of programs like frequency regulation and demand response as well as new rate structures that might benefit both the electric utility and their customers.

Contractors should become familiar with the local electric utility’s special programs and rates as well as incentives available at the state and federal level that can help homeowners uncover opportunities to save costs and more effectively use energy when charging their EV. With more installations will

come more knowledge, so contractors should make a checklist of rates and incentives to educate customers proactively and help maximize their investment and cost savings.

FUTURE-PROOFING INVESTMENTS

While the adoption of technologies such as smart home energy management and renewables may be nascent, many homeowners will want to implement them shortly. This is why contractors must help future-proof customer investments, ask questions about their energy goals, and install solutions that will make it easier for them to integrate new solutions as their needs evolve. For example, installing a smart circuit breaker in the load center can enable the future ability to integrate smart home energy management technologies. The advancing energy transition is causing important and welcome changes

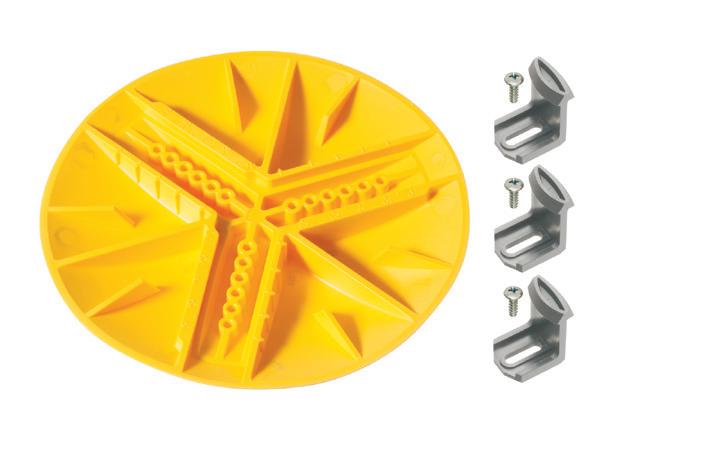

New Grand Slam home run junction box

Hit efficiency out of the park!

Experience the most labor savings and flexibility of any home run box on the market! The Grand Slam Box is the quickest and easiest way to terminate commercial home runs. Built-in STAB-iT® connectors are field-proven 3X faster than other MC connectors. Part of RACO’s ProReady™ solutions, driving jobsite productivity and efficiency!

• Upgraded STAB-iT® II connectors accept larger MC cable sizes

• Optional cable management and 2 multi-function clips

• Pre-installed ground bar

to both transportation and residential energy. Electrical professionals have an essential opportunity to become trusted advisors as they help customers assess EV deployments and consider future steps in their electrification journey. By understanding innovations on the horizon and the role EVs play as part of the broader ecosystem, electrical contractors can help prepare homeowners to become active participants in a more sustainable future.

Dan Carnovale is the director of the Eaton Experience Centers in Pittsburgh and Houston. He is a registered Professional Engineer in the states of Pennsylvania, California, and Alaska, a Certified Energy Manager (CEM), and a Senior Member of IEEE. He can be reached at danieljcarnovale@eaton. com. To learn more about the Eaton Experience Centers, visit Eaton.com/ Experience.

Order it today! Learn more about the Grand Slam Box

Arlington’s steel SliderBar™ offers the easy, NEAT way to mount single or two-gang boxes between wood or metal studs with non-standard stud cavities.

No more cutting, nailing and fitting extra 2x4s to fill the space! SliderBar saves about 20 minutes per box. Designed for studs spaced 12” to 18” apart, SL18 allows positioning of one or more boxes anywhere in the stud cavity.

• Bending guides on bracket assure proper positioning on studs

• Interlocking tab stop prevents accidental disassembly

• Pre-punched pilot holes on BOTH sides of S for easy attachment of one or two boxes

Dominant electrical design practices run up revenue again for this year’s Top 40 Electrical Design Firms, but temper their outlook amid uncertainty.

Ayear of friction — a recovering and fairly robust economy running up against inflation and interest rate worries — made 2023 a conundrum of sorts. Was something beginning or ending? That was the question in the construction sector, where projects

that were in the pipeline ramped up, but growing concerns about the cost of money, labor availability, and recession loomed. A year of transition, possibly. To what, though, is the question.

Engineering and design firms, whose work often foretells upturns or downturns in construction, might provide some of the answers. And one vital

component of that industry — electrical design — is offering some mixed, though largely upbeat, signals.

Fresh insights come from companies that make up EC&M’s 2024 Top 40, an annual ranking of design engineering firms based on revenues derived from providing electrical design services in North America. In another broad

The McLaren Health Greater Lansing Replacement Hospital, in Lansing, Mich. utilized the Central Utilities Plant (CUP), which was created using the most efficient, longest life, cost-efficient design possible. The CUP is arranged and located to provide efficient, unobtrusive service to the hospital mission. It’s positioned to allow easy maintenance and the ability to provide upgrades and change-outs without interrupting hospital operations.

Top 40 Electrical Design Firms

Notes:

List based on proprietary survey. To get on the list to receive the survey for next year, please contact Editor-in-Chief Ellen Parson at eparson@endeavorb2b.com or call (816) 560-6448.

NL - Not listed. This company did not appear in last year’s electrical design services revenue listing.

NA - Not available.

LISTED BOX EXTENDERS

Arlington’s variety of cULus Listed Box Extenders extend set back electrical boxes up to 1-1/2”.

Made of heavy-duty, 105°C continuous use 94V0 rated, flame retardant plastic, they level and support wiring devices, while protecting wires against damage and stripping.

Choose the one that’s right for you!

BE1, BE2, BE3, BE4...Single-, two-, three- and four-gang, and BE1R for round or octagonal boxes...

Box Extenders

device support in oversized or mis-cut wall openings, available in single-, two-, three- and four-gang, (patented BE1X, BE2X, BE3X, BE4X.)

Our new heavy duty, COMMERCIAL-GRADE steel support plate! As shipped, the single gang BE1XLS works with maxi cover plates, but it’s Convenient. Saves time. Great for poorly cut drywall.

For all standard devices, switches and GFCIs, our box extenders comply with NEC Article 314.20 for set back boxes.

The 2023 Business Climate (N=37)

Revenue Expectations in 2023 (N=36)

Fig. 1. The number of firms characterizing the current business climate as “strong” skyrocketed last year, increasing from 57% in 2022 to 91% in 2023. This year, that number tempered a bit to nearly 80%.

realized versus expected performance (see 2024 Rankings Table on page 18).

While more than three-quarters of firms rated the 2023 business climate as “strong” (Fig. 1), that was a clear falloff from last year, when 91% of firms said 2022 was strong. Defectors from the “strong” camp went to the “fair”

Fig. 2. Last year, optimistic forecasts bounced back — with 66% of respondents expecting to exceed expectations compared to 43% in 2022. This year, that number fell somewhere in the middle at 58%. survey of business conditions and sentiment, this year’s group hit a solid new, non-inflation adjusted high in collective prior-year (2023) revenues — $4.447 billion. That’s 13% higher than the $3.918 billion last year’s Top 40 secured in 2022, which was a 22% gain over the revenue reported for 2021. Still, this year’s group weighed in with comparatively muted assessments of the year as well as their

Fig. 3. The numbers here remained steady for the last few years when it comes to change in backlog. The number of firms reporting an increase in 2023 was 81% compared to 83% in 2022 and 86% in 2021.

group, which comprised 22%. None rated it “weak.” Also telling, the share saying they met or exceeded revenue expectations for the prior year declined from 66% to 58% (Fig. 2). Coming off a sparkling 2022 that saw Top 40 combined revenues vault to $3.918 billion, it may be no surprise that more firms had cooler takes on the previous past.

In a tight spot? Arlington’s new SNAP-TITE® Transition Fitting offers the time-saving solution for installing additional conduit or cable in an already congested panel. It allows installers to work around tightly spaced, installed fittings in a panel, box or enclosure – where installing and tightening additional locknut fittings would be next to impossible.

Convenient, Time-Saving 2450ST snaps into a 1/2" knockout and connects 1/2" trade size threaded fittings or pipe.

Arlington’s new duplex diecast couplings save time and easy transitions from 3/4" EMT to 3/8" trade size flexible metal cables – perfect for running MC cable above a drop ceiling and connecting EMT to feed a box or switch. combination couplings install easily on AC, MCI-A, HCF steel and aluminum cable, flexible metal conduit (steel and aluminum, regular and reduced wall), MCI cable and continuous corrugated aluminum. And offer independent securing of different size cables. • Tested, LISTED to exceed UL ground fault requirements Compatible with 3/4" EMT

SADDLE GRIP® styles

The Swissport Lounge is located within Billy Bishop Airport’s domestic lounge in Toronto. At 3,620 square feet, the refurbished space has at least 110 seats throughout the lounge and restaurant. The existing perimeter of the lounge space had already been built when Billy Bishop had two extensions added in 2017. However, Stantec renovated the space to handle the new programming. This includes interior glass partitions separating the domestic lounge from the Swissport Lounge, new flooring, new interior partitions, exposed ceilings, as well as updated plumbing, HVAC, and electrical to accommodate kitchen, bar, and food service areas.

By What Percentage Did Your Backlog Change?

More than a 10% decrease

6% to 9% decrease

5% or less decrease Stayed the same

5% or less increase

6% to 9% increase

10% to 14% increase

More than a 15% increase

Fig. 4. Two-thirds of firms reported an increase in backlog of 6% or more in 2023.

Sentiment overall, though, is hardly gloomy. Most firms (81%) said their backlog increased in 2023 (Fig. 3 on page 20), evidence that their pace of banking projects that have some chance of weathering any short-term

downturn isn’t slowing. Two-thirds of firms said it increased upward of 6% (Fig. 4).

Fig. 5. The number of firms forecasting an increase in backlog for the current year decreased slightly — from 82% in last year’s survey to nearly 74% this year.

Looking ahead to the expected final tally for 2024, more than 70% say they expect their backlog to grow (Fig. 5), and 26% see it unchanged. That is a fair dropoff from the 82% of last year’s Top 40 who predicted a backlog increase in 2023. Most see a 5% to 9% increase (Fig. 6 on page 24), but nearly 20% say it could rise 10% to 14%.

Extra-duty one-piece design

Pre-installed strut clip for faster installation on strut Stainless steel screw

Arlington’s corrosion-resistant QUICKLATCH™ pipe hangers cost the same as a steel pipe hanger with a bolt and nut – but better. They’re faster and easier to install. And SAVE 25 seconds* per installation!

• UV rated for outdoor use

• Listed for environmental air handling spaces

• For thin walls, rigid conduit, PVC conduit or copper

By What Percentage Do You Expect Your Backlog to Change?

(N=31)

More than a 15% increase

Fig. 6. Nearly half of respondents expect an increase in backlog of 5% to 9% in 2024.

On revenue, the outlook is mostly sunny. A plurality of firms (one in three) expect a revenue boost of 10% or more this year (Fig. 7).

Firms elaborating on their survey responses were largely satisfied with how 2023 turned out. More importantly, they’re confident about their prospects coming off a year that delivered either solid growth or evidence that long-term demand for their services is solidly intact.

UNDERLYING STRENGTH

HED (No. 32), Royal Oak, Mich. saw its revenue decline more than 30%,

but Michael Cooper, managing principal/president, doesn’t see that as cause for alarm. Coming off a strong 2022 when revenue rose some 90% as pandemic-stalled business restarted, the company had to readjust to a normalizing business environment and work through an internal restructuring prioritizing cultivation of market sector design expertise.

“Last year presented some economic uncertainty and more severe labor shortages, but we remain optimistic about growing our electrical engineering practice,” Cooper says. “(The reorganization)

positions us for future growth, higher operational efficiency, and a stronger value proposition.”

Citing growing prospects for a taming of inflation and falling interest rates, supply chains untangling, and recession talk fading as the economy seems to strengthen, Cooper sees a solid 2024 unfolding for the company. Specific market sectors do bear watching as they’re sensitive to macroeconomic forces and investment decisions, he says, but “we see significant opportunities and are extremely optimistic.”

Overall economic conditions and continued recession talk are the top current threats to company growth for Kunal Shah, president/CEO of PBS Engineers, Inc. (No. 34), Glendora, Calif. Total company revenue grew 40% in 2023 while electrical grew 10%, and 2024 is shaping up as a flattish year for revenues due to stubborn inflation, supply chain, and interest rate pressures on the client base.

The bigger story for PBS on the electrical side is that it made substantial progress in cementing ties with customers by expanding the scope of its design services. By cultivating and marketing growing expertise in the progressive design-build model, Shah says, the company found a way to work more closely and collaboratively with clients

Overall Design Services Revenue Forecast for 2024

More than 10% decrease

Fig. 7. One in three Top 40 firms expect an

improvement. However, 34% expect either a decline or for conditions to remain flat.

FAN/FIXTURE PAN BOX

Arlington’s convenient fan/fixture pan box works with 1/2", and single or double 5/8" drywall –on furring strips or hat channel.

• Easy mounting in new work

•Fan bracket installation screws ship captive until ready for use

•Secure joist-mount installation

•14.4 cu. in. UL/CSA Listed

Product info aifittings.com/catalog/fan-fixture-boxes/fan-fixturemounting-boxes-for-drywall-with-furring-strips-or-hat-channel/FB412

This convenient combo box has power and low voltage openings in the same box for a

The box adjusts to fit wall thicknesses from 1/4" to 1-1/2". Mounting wing screws hold it securely in place. • 2-Hour Fire Rating

• Low voltage side has a combo 1/2" and 3/4" KO for raceway

• Includes NM cable connector (power side)

Super-secure installation! Our lowest cost, L-shaped fan/fixture box mounts to single or double joists with a captive center screw. No loose parts! screws ship captive, ready to install box and bracket. For 1/2" or 5/8" drywall Fast, easy installation

• Locator posts assure proper positioning of fan/fixture bracket • 2-hour Fire Rating

The Washington Metropolitan Area Transit Authority (WMATA) completed a project to refurbish the Yellow Line tunnel between the L’Enfant and Pentagon stations. In this photo, modern equipment for critical electrical and communication infrastructure is being installed. Burns Engineering developed the Relocation of Railway System Design Plan and Systems Integration Plan, which included equipment placement for temporary and permanent installation, detailed specifications for phasing, and detailed performance criteria to ensure each subsystem functioned as a fully operating system.

in markets such as utilities, aviation, and transportation — where complex project delivery processes can benefit from enhanced cooperation, sharing and early involvement from all parties. The key has been identifying project “pain points,” such as costly change-orders, which can be mitigated through better communication and deeper involvement by the design team.

“We’ve worked in this capacity before, but not at the volume we are now,” Shah says. “We’re focused more on the entire life cycle of a project — from pre-construction, construction design, and through to closeout. Partnerships that bring in expertise from both the design and construction perspective bring value, and last year we really started to see the fruits of those relationships.”

Close, long-standing ties with customers in the highly active utility sector (its primary market) worked to the benefit of Mesa Associates, Inc. (No. 6), Madison, Ala. in 2023. The firm saw electrical design revenue advance a modest 5%, much of it coming from 10 primary clients who generate about 80% of revenues, says General Manager Reggie Headrick. Demand was on the lighter side as interest rates kept a lid on some projects, but all signs point to sustained growth as utilities look to invest more in infrastructure upgrades that will demand specialized competence and expertise on the design services side.

“The renewables space got more of Mesa’s attention beginning in the middle of last year,” Headrick says. “Utilities are focused on decarbonization, and that will probably keep their spending at a

historically high level. We’ll reap more of the benefits this year.”

MARKET TRENDS STEADY

That anticipated revolution in the power generation and T&D world kept the sector near the top of the list of hot 2023 market sectors for the Top 40 (Table 1 on page 28). It ranked third, with 30% naming it one of their three most active market sectors, behind health care (46%) and education/institution (32%). Rounding out the top five were government (24%) and data centers, government and water/wastewater (22% each). The top hot market sectors in the 2023 survey were health care, power/T&D, education, renewables, manufacturing, and data centers.

Sectors ranked particularly sluggish this year were private office,

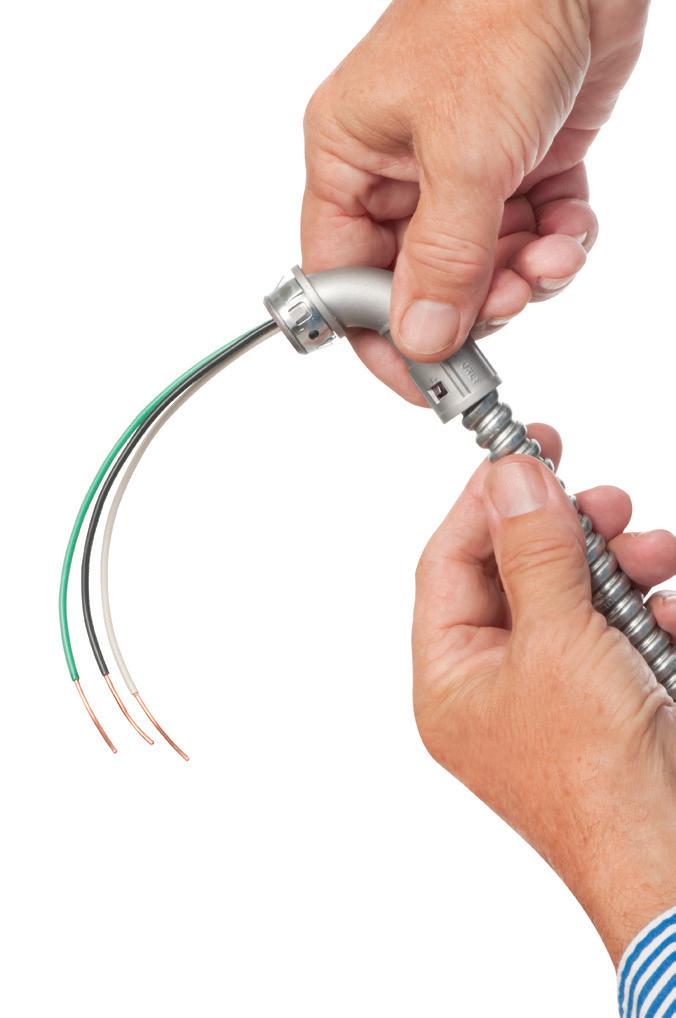

Fully assembled, SNAP2IT® fittings handle the widest variety of MC cable AND THE NEW MC-PCS cables.

Compared to fittings with a locknut and screw, you can’t beat these snap in connectors for time-savings!

LISTED SNAP2IT ® CONNECTORS FOR NEW MC-PCS CABLE ...lighting & low voltage circuits in the same cable

• Fits widest range and variety of MC cable 14/2 to 3/3

AC, MC, HCF, MC continuous corrugated aluminum cable and MCI-A cables (steel and aluminum)...including the new MC-PCS cable that combines power and low voltage in the same MC cable

ANY Snap2It Connectors LISTED for MC cable are also LISTED for MC-PCS cable! These products offer the greatest time-savings.

• Fast, secure snap-on installation

• Easy to remove, reusable connector From cable Loosen screw on top. Remove connector from cable. From box Slip screwdriver under notch in Snap-Tite® Remove connector.

RMF Engineering, Inc. provided electrical engineering design services for Sharing Hope SC’s new 50,850-square-foot headquarters facility in West Ashley, S.C. Modern luminaires and power systems adorn this sleek new building, welcoming visitors and employees to Sharing Hope.

Hottest Market Segments

Health Care

Power (Utilities/T&D)

Government

Manufacturing (tie) 5. Data Centers (tie) 5. Water/Wastewater (tie)

Table 1. Again this year, “health care” retained its No. 1 spot as the hottest market, but “education” surpassed “power,” moving into the second spot.

Coolest Market Segments

Table 2. As for the coolest markets, private office had the greatest number of responses, followed by hospitality, residential, retail, housing, and manufacturing.

hospitality, retail, residential, housing, and manufacturing (Table 2). Neither private office, residential, or housing were in last year’s top five. Last year’s ranking was retail, hospitality, manufacturing, food & beverage, aviation, and sports/recreation.

Both rankings amply reflect where money is going due to demographic shifts and societal responses to emerging challenges and changing norms. And more than a few sectors are ones that have a pronounced electrical component, such as data centers, power, renewables, residential, and office.

Core States Group (No. 40), Duluth, Ga. saw two sectors emerge with more force. Health care raised its profile because project demand is growing as the population ages, and more residential projects — notably multi-family/ mixed use — that address housing shortages, came the company’s way.

“The company’s acquisition of an architectural practice brought in more housing, and our work in health care, which has pretty consistent demand,

HOLE COVER KITS

ENSURES COMPLIANCE WITH OSHA

Arlington’s non-metallic hole cover kits offer the fastest way to cover a hole – and ensure compliance with OSHA safety standards on a multi-story building site. Available in three sizes, our hole cover kits come with retaining clips that adjust to fit a range of hole sizes.

• Reference scale for precise sizing to hole diameter

• Complies with OSHA Standard 1910.28 (b) (3) (i) (A)

• Rated for 250 lb load HC1742 fits 1-3/4" to 4-1/4" opening, HC1762 1-3/4" to 6-1/4” hole HC3792

clips set for 1-3/4" hole set for 6" hole

ROOF TOPPER® supports raise conduit/raceway 4" or more off the roof surface, allowing contractors to comply with the 2017 NEC® for temperature adjustment for circular conduit.

The heavy-duty base, made of 100% recycled material, sits on the roof deck. There’s no need to mount ROOF TOPPER to the surface with mechanical fasteners.

Offered in a variety of sizes and configurations, ROOF TOPPER supports up to 2000 lbs, and stands up to extreme rooftop conditions protecting and elevating conduit or raceway above the roof deck.

H

O’Brien is providing the electrical, IT, and security design for the renovation and expansion of this world-class performing arts center in downtown Calgary, Canada. The project team is designing for LEED-silver certification. The first phase involves the development of two new purpose-built venues and amenities across Stephen Street to the north while the second phase involves revitalizing the existing five venues, lobbies, and offices to create an accessible civic Arts Centre, which is consolidated with Stephen Street and upgraded with new support structure and technology.

would probably be good to bolt on in a similar way because it doesn’t swing with the economy as much,” says John Ferguson, senior director of engineering.

Looking ahead, Chris Sacco, director of electrical engineering, sees opportunity in food & beverage, which is resurfacing as a market with new site concepts, and within the office space, where ground-up and renovation projects are incorporating smart management concepts that demand heavy electrical know-how.

The office market has fallen off the radar of Henderson Engineers (No. 11), Lenexa, Kan. It, along with hospitality and residential, were slow in 2023. Since those turned down, the company has slowly migrated to sectors with more promise, steadily building up staff expertise to handle expected demand, says Jason Wollum, chief growth officer. Data

centers, aviation, and sports/recreation fit that bill and topped the list of active markets. They’ll likely get more competition for a spot on future hot lists from a host of sectors, he says, from ones due for a comeback like retail, grocery, and office to those that align with trends in science and technology, such as laboratories, mission critical, and connected infrastructure.

“In building our staff for growing areas of the market, important areas of expertise will be in controls, integrated automation, and medium-voltage system design,” Wollum says, adding that building a company presence in areas that are “hotbeds” for innovation is on the radar.

New York-based Jaros, Baum & Bolles (No. 30) saw strong demand in aviation, health care, and residential, while education/institution, hospitality, and retail gained little traction. Oncereliable office projects remain mired in

a slump, but those less reliant on private funding have filled some of the gap, says John Koch, a firm partner. An exception is high-end residential, where the company has seized opportunity from a boom in lavish, well-funded projects in Florida especially. Besides that ultra specialty, other rising markets have helped the firm diversify.

“Over the past 10 to 12 years, we’ve diversified, and growth in sectors like institutional, infrastructure, energy storage, and grid utility have picked up,” Koch says. “The electrification push keeps going, too, and that’s presenting some opportunities in projects we haven’t seen in the past.”

RATING AN INFRASTRUCTURE BOOST

Design firms are likely to see a fair number of novel market opportunities

FLOOR BOX

FLBC8500 Single gang box FLBC8500

(3) FLBC8500 boxes

Cover/frame kits

in USA Plastic Cover/frame Kit

Single gang

FLBC8510BR Brown

FLBC8510BL Black

FLBC8510GY Gray

FLBC8510CA Caramel

FLBC8510LA Lt Almond

Two-gang

FLBC8520BR Brown

FLBC8520BL Black

FLBC8520GY Gray

FLBC8520CA Caramel

FLBC8520LA Lt Almond

Three-gang

FLBC8530BR Brown

FLBC8530BL Black

FLBC8530GY Gray

FLBC8530CA Caramel

FLBC8530LA Lt Almond

a two-gang box. Add another for three-gang!

Build a two- or three-gang concrete floor box by simply locking single gang boxes together!

Then buy the UL LISTED single, two- or three-gang cover/frame kit, with devices included, in PLASTIC, FIVE COLORS – or in economical diecast zinc with a brass or nickel finish. Fast, easy installation.

Cover installs with hinge on either side.

Cover/frame Kit

Two-gang FLBC8520MB

Three-gang FLBC8530MB

Three-gang FLBC8530NL

Impact Infrastructure Investment and Jobs Act Will Have on Business (N=34)

Projected Revenue Increase Directly from Federal Infrastructure Projects (N=31)

Fig. 8. Approximately 70% of Top 40 firms expect infrastructure legislation to have a “minor” or “moderate” positive impact on their business. This is similar to the past two surveys in which 71% in 2023 and 70% in 2022 answered as such.

emerge in coming years. A key contributor might be growth in infrastructure spending, some of which might call for a substantial electrical element. But few Top 40 firms see any big dollars flowing their way soon, specifically from federal infrastructure investment.

All but about 10% of firms saw, at best, only moderate positive impact from the 2021 Infrastructure Investment and Jobs Act (Fig. 8) now starting

Fig. 9. Like last year (56%), a little over half of survey respondents (55%) anticipated no more than a 5% revenue increase in new project revenue tied to federal infrastructure funds.

to roll out. Fewer this year than last, in fact, expect to realize a significant current year positive impact. And fewer see anything close to a double-digit boost to their top line in 2024. Half see just a 0% to 5% impact, up from 35% of last year’s Top 40 (Fig. 9). More than half last year predicted a 6% to 19% boost, but that fell to 19% this year. As for sectors likely to get a boost from the Act this year, electric vehicle (EV) charging infrastructure, renewables (solar and wind), and electric grid updates led the way again (Table 3).

In its primary electrical design role of providing a broad array of services

to small utilities, chiefly in the Midwest, Toth and Associates, Inc. (No. 27), Springfield, Mo., is poised to benefit from more electrical infrastructure spending, public or private. President Adam Toth, P.E. says he’s waiting to see if infrastructure upgrade grants sought on behalf of some clients will materialize.

“Smaller utilities that haven’t done much in the last 60 years now have to update to newer equipment,” he says. “A lot of it needs to be replaced.”

Ultimately, Toth sees the impact of infrastructure spending on the firm to be more indirect. Designing systems for utilities to furnish power to lithium miners that will be needed for EV expansion, for instance, might be one route. A below-the-radar benefit might be conducting studies to gauge the feasibility of utilizing rural utility power lines for fiber cable needed to develop more rural broadband — one target of the federal infrastructure plan.

Though he doesn’t see much direct infrastructure spending impact now, HED’s Cooper views the federal government’s growing role in the economy, more broadly, as a potential new vein of growth. Its decision to dive deeper into select sectors to spur growth elevates government as a market target. Its present strong private market orientation likely forecloses a windfall from most current infrastructure spending, Cooper says, but the prospect of expanded long-term federal investments in housing, health care, research, and mission critical offers “long-term opportunity with significant upside.”

Table 3. Top 40 firms identified several sectors they felt would produce the biggest increase in new project activity in 2024 from federal infrastructure dollars. Taking the top spot again this year, electric vehicle charging infrastructure was followed by renewables, and electric grid updates.

MC CABLE FITTINGS

Save time and money! Arlington’s low cost MC cable fittings, for dry locations only, are super-convenient and cost-effective. End stop bushings vary the size of the opening so ONE trade size fits several cable sizes!

Changing end stop bushings is fast and easy. No need to remove the strap. Insert the bushing that works the best with the cables you’re installing.

Reduce inventory –

Costs much less than steel and malleable iron fittings Built-in end stop

8412 1" .780 1.120 .660 1.000 6/3, 6/4, 4-3, 4-4, 2-3, 2-4, 1-3 8413 1-1/4" 1.000 1.460 .870 1.370 2-3, 2-4, 1-3, 1-4, 1/0-3, 1/0-4, 2/0-3, 2/0-4, 3/0-3

8414 1-1/2" 1.360 1.770 1.250 1.590 2/0-4, 3/0-3, 3/0-4, 4/0-3, 4/0-4, 250-3, 250-4 8415 2" 1.700 2.200 1.550 2.050 250-4, 300-4, 350-3, 350-4, 500-3 8416 2-1/2" 2.100 2.700 1.950 2.400 500-3, 500-4, 600-3, 600-4, 750-3 8417 3" 2.500 3.300 2.350 3.000 600-4, 750-3, 750-4 8418 3-1/2" 3.300 3.600 3.031 3.500 750-3, 750-4, 1000-4

* Examples of 3- and 4-conductor cables accommodated.

GROUNDING BUSHINGS

for THREADED and UNTHREADED RIGID and IMC

UNTHREADED conduit

Get convenience and time-savings with Arlington’s 550 series SPLIT grounding bushings. The split allows the addition of a bushing AFTER conductors are installed in threaded or unthreaded Rigid/IMC conduit. Great for tight spaces!

• In 1/2" to 4" trade sizes – Ships Assembled

• Compatible with EMT, 2-1/2" to 4" trade sizes, and threaded electrical fittings

1 Loosen side screws. Allow bushing to pivot around installed cables

2 Tighten set screw to seat bushing on conduit

Is Your Firm Having Difficulty Filling Open Job Positions?

Fig. 10. Not surprisingly, the number of survey respondents experiencing staffing issues remained high at 86% but slightly less than previous years (92% in 2022 and 94% in 2023).

Should infrastructure spending get on a sustained roll, electrical designers are almost certain to benefit. That, along with the trend to widespread electrification of the economy, expansion of electrical grid modernization, and sustained economic growth lifting all boats will give them a commanding role in how things get built.

STAFFING WORRIES REDUX

To do that, they’ll need top-flight design talent in sufficient numbers to take on the work they need to thrive. But finding and keeping that asset has been and remains a challenge, as survey results through the years attest. Though down from 94% last year, 86% of firms said they’re having a hard time filling open positions (Fig. 10). That figure has consistently been in the 80% to 90% range, dipping to around 70% only during the pandemic. What’s the most challenging position to fill these days? Project engineer, the essential role that continues to top the list by a good margin (Fig. 11).

Tough or not, firms continue to staff up. Most (86%) said they added employees (Fig. 12), though that was down from 92% last year. For 2024, all but a few say their head count will grow (Fig. 13).

Staffing is, by far, the biggest worry for companies looking to excel and grow

Most Difficult Positions to Fill

Supervising Engineer

Project Engineer

Design

Project

Fig. 11. For the fourth year in a row, “project engineer” topped the list as “most difficult job title to fill” for Top 40 firms followed by “supervising engineer.”

Employee

Trends in 2023 (N=36)

Projected Employee Trends in 2024 (N=36)

Fig. 12. The number of Top 40 adding head count in 2023 (86%) decreased slightly from the previous year (92%). Laid Off 3%

in a demanding market bursting with potential. From a list of plausible barriers to growth, difficulty finding and keeping “quality” staff was again the single factor most chose to the exclusion of others (Table 4 on page 36). Only economic conditions and the prospect of recession came close.

Toth and Associates’ growth and near-exclusive focus on the small utility market necessitates but complicates the hunt for design talent. Preferred experienced talent is in shorter supply, but the firm’s location in a more rural setting makes attracting a greener pool harder. Additionally, the company is

Fig. 13. After a never-before-seen 100% of firms indicated they planned to add head count last year, that number dropped slightly with this year’s survey to 92%.

firm on in-office presence, ruling out recruits who may desire more remote arrangements.

“Finding experienced people here is hard, and they don’t teach in college a lot of what we do here, but if you’re growing like we are you have to find talent,” Toth says. “We can train young engineers, but they can be difficult to hire.”

There’s some concern at Mesa Associates about the future availability and quality of design talent. The company continues to hire, Headrick says, but worries that bidding wars for experience carries the risk of increasing the cost of design services.

Arlington’s STEEL FLOOR BOX KITS give installers a low cost, convenient way to install a receptacle in a new or existing floor.

Listed Single Gang Steel Floor Boxes deliver easy, flush-to-the-floor installation.

• Brass covers hide miscut flooring; gaskets prevent water intrusion; flip lids protect the box when it’s not in use.

• Single gang brass and nickel-plated Brass Covers fit our boxes and other manufacturers’ single gang boxes. Covers also sold separately.

the climate in mind, Mason and Hanger incorporated numerous sustainable design features for the multi-building U.S. Depart ment of State compound in Rabat, Morocco. These include lights that automatically dim to take advantage of daylight, reduced water use plumbing fixtures, rain gardens, and indigenous/adapted plant species for reduced irrigation demand. This shot shows one of the conference rooms, featuring lighting, telecom, and AV systems.

The talent crunch, he says, “is getting more pronounced, with not near as many going into the field.” The company outsources some of its recruiting in a bid to find experienced engineers who can fit into the minority-owned firm’s culture, which can be a competitive advantage. Entry-level talent is sought, but there’s always the challenge of training given the “steep learning curve” that exists, he says.

Like many others, Core States Group confronts that problem with heavy reliance on an intern pipeline. Promising students are regularly brought in and immersed in the types of projects and subject matter they’d encounter. The approach has largely worked, says John Ferguson, senior director of engineering, because a fair number bridges some of the experience gap and land on the company’s payroll.

“Coming out of college, the theory is there but not so much the practical knowledge,” he says, adding that an approach that accelerates its uptake among raw talent can be more appealing than seeking more costly senior talent in the current labor market.

TRAINING PRESSURES MOUNT

To take that route — and also address the hardening demand for staying current on

Factors Having the Most Negative Impact on the Growth of Your Business

5

(SEE ABOVE)

• Easy snap-in cable installation Save time over 90° 2-screw MC Connectors at same cost per connector

• Handles widest range & variety of cables: 14/2 to 10/2 AC, MC, HCF, MC continuous corrugated aluminum cable, MCI-A cables (steel & aluminum), AC90 and ACG90

• Fast, secure installation...No pullout

• Easy to remove from box...reusable

Core States Energy, a division of Core States Group, has successfully completed 100-plus design-build projects for Electrify America, a leading EV charging network operator, at various retail locations across California. These projects have included partnerships with leading brands, such as Target, Bank of America, Macerich, and Westfield. Most of the sites are equipped with four to six state-of-theart DC fast charging (DCFC) stations with speeds of up to 350kW. For this 2023 project in Kettleman City, Calif., the company designed and constructed ten 350kW EV charging stations and designed/oversaw installation of the solar system located on the canopy.

Areas in Which Employees Need the Most Training

Table 5. Again this year, Top 40 firms report the need for training in various areas, but especially related to power system analysis, electrical design software, and the NEC.

critical areas of knowledge — design firms must be ever more focused on training. Imparting knowledge to younger recruits and keeping all staffers up to date on fast-moving change in electrical design demands dedication to education.

Rankings of areas where firms say they need the most training support may partly reflect emerging market priorities for firms. Growth in transmission and distribution projects, for instance, necessitates power systems analysis training,

again listed by more firms than any other as a training area where the most support is needed (Table 5).

Also commonly mentioned were electrical design software, important as technology applications advance,

Snap 2it® connectorS

the cable into the connector and rotate the connector clockwise.

YEARS

Available in 3/8" trade size, both connectors install into a 1/2" knockout, and are Listed for steel and aluminum AC, HCF, MCI and MCI-A cable.

The tinted 40STS has more room inside for easier cable insertion.

for use with AC90 and ACG90 cable.

• Tested to UL 514B and Listed to meet UL ground fault requirements

• Removable Unscrew the connector counterclockwise to remove it from the cable. Remove the connector from the box using a flat blade screw driver. Release the snap tangs from the inside of the box while pulling the connector out of the knockout.

• Packed in heavy-duty, 200-piece boxes

CATALOG NUMBER CABLE RANGES STEEL Snap2It® connectors

38STSC AC, HCF, MCI, MC!-A 14/2 w ground, 14/3, 14/2 12/2 w ground, 12/3, 12/2 • 10/2 w ground, 10/3, 10/2 .405” Dia. Minimum to .605” Dia. Maximum

40STSC AC, HCF, MCI, MC!-A Tinted 12/2 w ground, 12/3, 12/2 • 10/2 w ground, 10/3, 10/2 .480” Dia. Minimum to .605” Dia. Maximum

Illumination Insider

This e-newsletter tracks the research, development, design, installation and operation of all types of lighting and control products.

This twice-a-month product is geared toward professionals working in the industrial, commercial, retail, residential, institutional, health care, government, and utility market sectors.

Subscribe Today

See all of our EC&M e-newsletters at www.ecmweb.com

How Long Will It Take for Augmented Reality to Become a Viable Component of Design Work?

Already using it

One year

Two years

Three years

Four years

Five years or more

When it comes to augmented reality (AR) adoption, Top 40 firms seem to be consistent. Last year, 49% of Top 40 firms said they were already using AR compared to 42% this year.

How Long Will It Take for Virtual Reality to Become a Viable Component of Design

Work?

Already using it

One year

Two years

Three years

Four years

Five years or more

Fig. 15. Virtual reality adoption stayed about the same as the past two year’s of survey results — rising slightly from 50% in 2023 to 52% this year among firms saying that they’re already using the technology.

and building management/automation systems, reflective of more smart building projects.

The latter is a top priority at HED because the firm is growing that facet of its electrical design practice. Many new hires often come with fairly robust technology skills that bring staff up a notch in that area, Cooper says, but building management systems design demand a “specialized and scare set of skills needed to respond,” that only robust training can address. Training is a focus, generally, he adds, because a shortage of experienced

talent has led HED to hire more recent graduates and invest more in their professional development.

Being an employee-owned company that offers more than a paycheck gives Henderson Engineers an advantage in hiring more scarce talent, Wollum says. In hiring mode and concerned about the electrical talent pipeline, the company has forged ties to feeder universities with the aim of “making sure the curriculum they have is preparing students to work in the industry.” It’s also working closely with STEM-related programs to help

up to 100 lbs.

Pre-set for 1/2" ceiling – depth adjustment screw positions the box flush with the ceiling after it’s in place

Complies with 2020 NEC, 314.20 for set back boxes • (4) screws attach box securely to joist in new work

2-Hour Fire Rating

Arlington’s heavy-duty, plated steel fan/ fixture box has an adjustable bracket that mounts securely between joists spaced 16" to 24" o.c.

Flush ceiling installations

FBRS415 is designed for ceilings up to 1-1/4" thick. For 1/2" ceilings, use the pre-bent positioning tab. For other ceiling thicknesses, bend along the appropriate score line.

• 15.6 cu. inch box ships with captive screws, mud cover, installed NM cable connector

The Engineering Enterprise provided electrical engineering design services for the Monterey Regional Airport’s new 10,000-squarefoot Aircraft Rescue and Fire Fighting Facility in Monterey, Calif. Engineers collaborated with the Monterey Airport, the Monterey Fire Department, and MARJANG Architecture to design this critical facility that includes four apparatus bays, apparatus bay support areas, living quarters with dorm rooms, kitchen/dining/day room, watch room, exercise room and offices. They also worked closely with contractor partners Mills Construction and Collins Electric on this design-build project.

mint younger talent that might find its way to the field and, possibly, Henderson, motivated to make their mark in a growing and consequential profession.

“Across multiple market sectors, many new projects we work on today are just cool,” Wollum observes. “People who get into the field can live their design dream working on projects they have a passion for.”

AI JOINS TECH MIX

Against a backdrop of staffing concerns, the practice of electrical design continues to change, utilizing more technology that could ease those worries by making designers more efficient and productive. Among them are augmented reality (AR) and virtual reality (VR) aids, and new on the scene is artificial intelligence (AI).

AR and VR are making slow, steady inroads into electrical design. More than 40% of Top 40 firms are using AR (Fig. 14 on page 40) and around half are using VR (Fig. 15 on page 40) in that capacity. Among possible broad applications for each, collaboration with clients and other project delivery partners are cited by most (Fig. 16 and Fig. 17 on page 44).

Ways Firms Plan to Incorporate AR into Their Business

with

Collaboration with other trades/ electrical contractor/general contractor

Fig. 16. As has been the case for the past many years, Top 40 firms already using this technology frequently indicated they plan to use AR for “collaboration with their own clients.”

Those now using AR in electrical work say its applications include supplementing 3-D modeling, helping design equipment layout, aiding conduit routing, and assisting virtual construction/product troubleshooting. VR applications span equipment room walk-throughs, design option evaluations, deeper understanding of

complex systems and site investigations to document as-built conditions.

Echoing other firms, JB&B’s Koch characterizes AR/VR as still being in their “infancy” as design tools. They show promise, he says, and are being leveraged where possible to make the firm’s essential product — construction documents — more useful, especially in

Arlington’s mounting brackets are the best way to install Class 2 wiring. They seat wall plates flush with the mounting surface and install fast!

Our new single gang, zinc mounting bracket, LV1M, for existing construction, offers extra rigidity so it won’t bend as easily as plastic. Plus, it has threaded holes for easy, fast device installation – and LABOR SAVINGS.

Arlington’s recessed STEEL combination power/low voltage TV BOX™ is the best way to mount an LED or Hi-Def TV flush against a wall.

TV BOX provides power and/or low voltage in one or more of the openings. Plugs and connectors stay inside the box, without extending past the wall.

Designed for use in new or retrofit commercial construction where metal raceway is used, we have a STEEL TV BOX for almost any application!

• Steel box; non-metallic paintable white trim plate

• Easy, secure installation

• Optional covers

Toth and Associates provided electrical engineering for Umatilla Electric Cooperative’s Juniper Canyon West Substation in Hermiston, Ore. The substation is designed to support 200MW of 115kV transmission and up to 112MW of 12.47kV distribution load.

larger projects. But the technology “has to ramp up over time, and the ability to scale it is key.” Likewise, PBS’s Shah says AR/VR and other technologies for electrical design will evolve, with “every iteration focused on how to better harness the tools,” and be like “going from AutoCAD to Revit.”

With AI, design firms say they have a potentially powerful and versatile tool that can aid all elements of their business. While a majority say using it in an electrical design capacity is a ways off, more than 40% say they’re doing so now (Fig. 18 on page 46), primarily to aid process optimization/efficiency improvement; marketing and promotion tasks; and human resources/recruitment functions (Fig. 19 on page 46).

Citing statistics showing more than 40% of AEC firms are using artificial intelligence (AI) in some fashion, Mesa’s Headrick says the firm has gotten on board, forming a team to explore its possible applications. So far, there’s been progress on using it for project management, enabling “lessons learned to be better shared and used by project managers to for process and procedure control.” AI may also be leveraged to help utility clients make better sense of

Key Areas Firms Plan to Incorporate VR into Their Business

Fig. 17. Mirroring last year’s responses, Top 40 firms that are already using this technology overwhelmingly indicated they plan to use VR for “collaboration with their own clients.”

their data and use it “to predict the end of asset useful life and important predictors of failure.”

At Core States, AI could become an important element of the technology tool bag the company uses to put a microscope on projects and processes.

“We have a formal design, efficiency, and analytics team whose job it is to analyze design and delivery models,

and some in that group are interested in AI,” says Sacco. “The team is interested in determining ahead of time where we can improve and how to deliver our product quicker and more completely. AI could help improve the efficiency of that effort.”

In some respects, AI’s sudden emergence in 2023 helps clarify the road ahead for the electrical design field. Relying as

Arlington’s new one-piece RETROFIT SNAP2IT® fittings are easy to use in an OLD WORK installation, and handle the widest variety of cables! They’re ideal for adding additional circuits to a load center. And you get the same labor-savings in a retrofit installation!

Easy snap-in installation - NO TOOLS. Install connector into the knockout in an existing box, pulling cable/conduit through the knockout. Slip the fitting onto the cable, then snap the assembly into the box. That’s it... a secure installation with no pullout

Widest total cable ranges 14/2 to 10/3

Widest variety of cables AC, MC, HCF, MC continuous corrugated aluminum cable, MCI-A cables (steel and aluminum), AC90,

Designed for devices, Arlington’s economical single and two-gang Vapor Boxes offer easy nail-on installation in new construction.

These cost-saving boxes don’t include gaskets, but when caulked around the NM cable during installation, they meet the requirements of NEMA 0S-4 And help meet International Energy Conservation Codes (IECC), and other codes where required.

• Nails ship captive –Plugs and NM cable connectors supplied 2-hour Fire Rating

it does on inputs of correct, proven and reliable data, designs that can be readily improved and refined in that regard will become the gold standard. Billed as possibly transformative for the broad economy, AI could be revolutionary for an industry poised for a critical role in a new, emerging construction economy and a more electrified world.

“The AEC industry is due for major change in delivery methods, from conception through construction, commissioning, and maintenance,” says Wollum. “There is an opportunity for us to leverage change, embrace technology in the form of AI and other generative and automated design concepts. It’s a very exciting time of change in the industry.”

Tom Zind is a freelance writer based in Lee’s Summit, Mo. He can be reached at tomzind@att.net.

How Long Will it Take for AI to Become a Viable Component of Design Work?

Already using it

One year

Two years

Three years

Four years

Five years or more

Fig. 18. Whereas AR and VR enhance real-world objects on a virtual platform to create immersive environments, artificial intelligence (AI) enables computer applications to mimic human-like intelligence and resolve problems, make predictions, and provide solutions. When asked when they expected AI to become a viable component of electrical design work — the first year we have asked this question — 43% of respondents indicated they were already using it.

How Is Your Firm Using Artificial Intelligence?

Generate, analyze, and optimize electrical designs/BIM (e.g., conduit groupings, raceway sizing, routing, etc.)

Human resources/employee recruitment

Marketing/promotions

Diagnostics and troubleshooting

Optimize processes/improve efficiency

Gather intelligence data on electrical equipment (e.g., fault detection/diagnosis)

Improve profitability/cost estimating

Labor management

Predictive maintenance

Energy management

Autonomous systems/robots/drones

Finance/accounting

Creating multiple outcome scenarios/solutions for clients on the same project

Other

Fig. 19. How do Top 40 firms plan to harness the power of AI going forward? The first time asking this question, the greatest number of Top 40 survey respondents noted plans to use AI to optimize processes/improve efficiency and for marketing/promotions.

CABLE SUPPORT

Arlington’s economical CUS6 galvanized steel Cable Support holds cable secure and centered on a metal or wood stud.