PLATINUM SPONSOR

GOLD SPONSORS

LUKOIL BURCKHARDT COMPRESSION SAIFEE & JOME

OTHER MAJOR SPONSORS

AMS (DESTINI ARMADA)

HMS MARINE TRADER

XIN LONG SHIP REPAIR CO. LTD.

PLATINUM SPONSOR

GOLD SPONSORS

LUKOIL BURCKHARDT COMPRESSION SAIFEE & JOME

OTHER MAJOR SPONSORS

AMS (DESTINI ARMADA)

HMS MARINE TRADER

XIN LONG SHIP REPAIR CO. LTD.

Roy

Moloy Podder

Alok Pandey

Design and Production

Simple Reels Genesis Pte Ltd

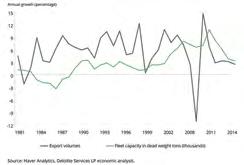

We are well into 2019, end of which will bring a major regulation into force. A regulation with such a high impact on shipping industry that hasn’t been since ships propulsion changed from Sails to Coal and then from Coal to Fuel Oil. The entire industry waits to witness the final outcome. No one is sure what to do – some are installing scrubbers while others have placed their bets on compliant fuels, yet others are planning innovative solutions like LPG Engines & Alternate Fuels. Batteries and Hydrogen Cells are also being tested, as technologies supporting these improve.

EU-MRV, IMO-DCS, Ship Recycling, Ballast Water Retrofits and headaches with existing Ballast Water Treatment Systems are few of the other challenges to companies in terms of extra investments required. This too in a climate where shipowners are struggling to make profits.

In all this certainty, job of a Marine Engineer becomes even more crucial as he has to keep up the running and maintenance of ships within tighter

budgets and yet ensure sufficient reliability and availability of ship for business.

This decade has also brought home the importance of innovation in marine industry, and how it helps in optimizing costs and improving efficiency. We have included articles on some of the innovations happening in industry. Its important to understand these technologies in order to benefit from them.

Amongst all this pressure, DMET-MERI Alumni, Singapore has taken time out to celebrate the quintessential Marine Engineer who is taking everything in his stride and keeps the propeller turning. This year’s reunion proves this.

Despite busy business schedules of members, Publishing Desk is proud to bring to you this year’s Reunion Magazine. This year’s drive was to improve production quality and content of this magazine. We hope you will all enjoy it. We look forward to your feedback and suggestions for the next year @ publishing@dmetsg.org ▄

For further information on sponsorship / advertisement contact us at publishing@dmetsg.org

Manoj Bole President

Vinay Gupta Vice President

Sanjiv Mishra Secretary

Sanjay Verma Asst Secretary

Balaji krishnamurthy Treasurer

Upendra Dubey Asst Treasurer

Kapil Berry Executive Member

Alok Pandey Executive Member

BG Singh Executive Member

Deependra Singh Executive Member

Kaushik Roy Executive Member

Moloy Podder Ordinary Member

Brijendra Singh Bisht Ordinary Member

by DMET Alumni Band 8.45

It’s time for another Reunion of DMET MERI Alumni Singapore and the first event of the year – the 10th Reunion – to be held on 4th May 2019.

At the onset we would like to thank Alumni for supporting us. Participation of all is key to the success of the association. We have grown in numbers albeit at a slower pace.

In 2018 there were several changes in the Organizing Committee and new faces have been inducted into the committee during the AGM held in August 2018.

The committee has been working with fervour and enthusiasm since inception. The association managed to organize the first ever Technical Meet in September 2018.

Technology has been an integral part of our lives and we as a team have used this to simplify the processes for organizing our events.

The Alumni Association in Singapore is now on Linkedin and this will not only strengthen our network but also help alumni worldwide to be abreast with events and connect with us.

It was decided to do our bit for charity as part of social responsibility and we have this year contributed to Sree Narayana Mission in Singapore, more details are inside this magazine.

More events are planned for this year and we look forward to your continued participation in each one of them.

Fellow alumni, we are once again delighted to have you here at the 10th Reunion for an evening full of bonhomie, excitement and fun.

(3) - Top three winners

Cheers!

Organizing committee ▄

endorse any companies, products or services that appear in this publication. All material is accepted on the understanding that it is copyright free. The magazine accepts no liability for any subsequent copyright issues. The magazine does not accept responsibility for and does not endorse views expressed by contributors.

The Destini Armada group of companies, which includes Destini Shipbuilding and Engineering, Vanguarde, the Techno Fibre Group and AMS, is able to o er manufacturing and construction services together with maintenance and through-life support for a wide variety of government and commercial vessels. Destini Armada has the capability to construct specialist vessels of up 100 meters in length as well as manufacture lifeboats and integrated davit systems for government agencies, shipping and o shore industries.

The Destini Armada group of companies, which includes Destini Shipbuilding and Engineering, Vanguarde, the Techno Fibre Group and AMS, is able to o er manufacturing and construction services together with maintenance and through-life support for a wide variety of government and commercial vessels. Destini Armada has the capability to construct specialist vessels of up to 100 meters in length as well as manufacture lifeboats and integrated davit systems for government agencies, shipping and o shore industries.

The Destini Armada group of companies, which includes Destini Shipbuilding and Engineering, Vanguarde, the Techno Fibre Group and AMS, is able to o er manufacturing and construction services together with maintenance and through-life support for a wide variety of government and commercial vessels. Destini Armada has the capability to construct specialist vessels of up to 100 meters in length as well as manufacture lifeboats and integrated davit systems for government agencies, shipping and o shore industries.

The Destini Armada group of companies, which includes Destini Shipbuilding and Engineering, Vanguarde, the Techno Fibre Group and AMS, is able to o er manufacturing and

AMS was established in Singapore to build and repair ships, tankers and other ocean-going vessels as well as manufacture and repair of marine engines. The company has three core business divisions which are; design, fabrication and servicing of heat exchangers, fabrication, installation and erection of piping and steelworks, calibration and automation for the marine, shipping and oil and gas industries.

42A Penjuru Road, #06-00, Singapore 609164

Tel: +65 6264 8222 | Fax: +65 6264 4948

Email: info@amsmarinegroup.com

Destini Shipbuilding & Engineering is a shipbuilding and ship repair company located in Port Klang, Selangor. The company has the capability to fabricate a wide range of vessels of up to 100 meters in length for the Government, maritime agencies as well as commercial marine companies.

No 10, Jalan Jurunilai U1/20, Hicom

Park, 40150

Alam, Selangor Darul Ehsan Malaysia.

Tel: +603 5567 0333 Fax: +603 5569 1233 info@destinigroup.com

Techno Fibre was established in 1993 in Singapore to serve the marine safety industry. As the years progressed, the group of four entities has evolved geographically to have a foothold in Australia and the UAE as one of the foremost names in the whole spectrum of lifeboats and marine safety industry.

42A Penjuru Road, #06-00, Singapore 609164

Tel: +65 6266 1412 | Fax: +65 6266 1435

Email: rajesh@techno bre.com

Singapore-based Vanguarde manufactures lifeboats, fast rescue boats, davit systems and a host of other safety and survival related equipment for the marine and oil and gas industries in South East Asia. The company prides itself of being able to build self-propelled hyperbaric lifeboats which are highly in demand as it meets the highest standards of marine safety and survival.

42A Penjuru Road, #06-00, Singapore 609164

Tel: +65 6887 5034 Fax: +65 6887 5043

Email: enquiry@vanguardelifeboat.com; shantanu@vanguardelifeboat.com

The Destini Fibre construction through-life commercial construct well for

As we look back, we can pride ourselves with the number of stalwarts that passed out of our institution spreading their wings to soar unfathomable heights across the globe. This has not been limited to Ship Management only, but teachers, technocrats, managers, industry leaders, authors, to name a few. The Alumni Council has reposed its faith in me to continue as the President of this esteemed organization, and hence, it’s my privilege to be able to write this message to you today.

am grateful that, last year, when I called out to my fellow aluminites to join the Alumni Council, many from the younger generation volunteered. After such an enthusiastic participation, this year’s event is brought to you by a new and younger team with fresher and better ideas. also thank the office bearers who have stepped down to pave way for the next generation to take the mantle. Their hard work has made this organization what it is today. This year’s Annual Reunion is the 10th reunion for Singapore Alumni and is a showcase for years of hard work since 2004 that has gone into raising the bar of the event management.

New 1500 m3/h UV reactor for PureBallast 3

Alfa Laval PureBallast 3, the third generation of the leading ballast water treatment technology, is now even more optimized for large ballast water flows. A new 1500 m3/h reactor enables large-flow systems with less cost and complexity – and all the advantages that chemical-free UV treatment has over electrochlorination.

Discover the big difference at www.alfalaval.sg/pureballast

This year we decided to assign a name our magazine...a signature which is easy to connect to. After dabbling with various ideas, a very apt suggestion of naming it as “Engine Room” came up. The idea was liked by all for its simplicity and an easy connection every aluminite will feel with this name, since we have all spent most of our onboard working lives inside it. The idea clicked and when it was proposed to the Organizing Committee, it got almost instant approval. The idea of adding “The” in front of “Engine Room” creates a better impact for a magazine name. It is not any “Engine Room” but “THE ENGINE ROOM” which is part of our lives.

Recalling the good old days at DMET-MERI, the training structure itself developed a bond that has enabled us to stay connected, through thick and the thin of shipping industry and allowed us to compete globally. We are 340 plus strong today in Singapore and still counting. Our organization exists with a motive to unite alumni, magnify their impact globally, and position and retain them as a much sought-after brand in the global shipping industry. We request your suggestions and opinions on taking this organization to the next level.

Stay tuned as we roll out an exciting line-up of events that are planned for the current year. Starting with the Reunion, we intend to have the Technical Meet, and Family Day followed by the most awaited event – Diwali Movie. If you are interested in contributing in the organization of these events, please attend AGM planned later this year or contact members of Alumni Council to volunteer.

As we trot towards our goal, thoughts stay in our mind to incorporate and initiate philanthropic activities from our Alumni forum to help those who need it more than the others and give back to the society at large. To mark 10 th Annual Reunion it was decided by the Organizing Committee to participate in philanthropic activities in Singapore as a part of our social responsibility. Sree Narayana Mission, an old age home located in Yishun, was chosen as charity for this year. A lunch was organized for the inmates of the home on 13 th of April. A donation is also planned for Narayana Mission on 10th of May when they host a dinner to celebrate their 70 th Anniversary.

We use a WhatsApp number and transmit information and details through it from time to time. In order to receive messages, you need to save the number +65 8433 2312 in your address book. You can also send any suggestions you have at dmet@dmetsg.org. We have also increased the connectivity for our members through our dedicated Website, Emails, Facebook and LinkedIn pages where you can share your stories and memories. The WhatsApp broadcast number ( +65 8433 2312 ) is a great success and most of the Singapore Alumni are now connected on it. It is highly recommended to save this number on your contact list to receive regularly broadcasted updates. I am confident such connectivity will help strengthen our bond. Please send any suggestions you have to dmet@dmetsg.org

Thanks to all those who are able to attend this 10 th Reunion. look forward to connecting with you at one or more of our events this year. Do enjoy meeting your batch mates, and the grand shows planned for the day and tantalise your taste buds with delicious food that chefs have prepared specially for this occasion. We will not let you leave the hall before you rock the floor with some gyrating music brought in by our celebrity DJ that will reboot you for the productive and prosperous year ahead.

Have Fun.

Yours Sincerely,

Manoj Bole (Roll No. 3470) President (2019)

www.dmetalumnisg.com

Lloyd’s Register has developed a free evaluation tool in response to many enquiries from our clients to help them assess their possible routes to compliance with the global sulphur in fuel oil limit of 0.50% by 2020.

Visit lr.org/sulphur2020

It was nice to hear from Singapore Alumni and thanks for remembering your Alma Mater. It is always pleasure to learn that the alumni remains connected and is passionate about the welfare of institute. must acknowledge that it is a common trend with most of the prestigious institutes in the world to have a glorious and successful alma mater whose personal brilliance collectively lights up the academic space and proves an attraction for the aspiring youth to be part of the institute. In the coming years, it is critical that the alma mater remains more participative in the affairs of the institute and helps us to grow to a centre of excellence.

Your Alma Mater has a unique distinction of being probably one the very few institutes in post-independent era to be inaugurated directly by the Honourable Prime Minister; created for national interest and necessity. It has undergone several role changes with time, like for initial days we provided the qualified manpower who shored up the growing shipping and shipbuilding capacities of the nation till 1980s, after which we started providing manpower to foreign companies and all of a sudden Indians officers (especially engineers) found themselves at the crest of the demand curve for the quality man-power through out the world. After the business of ship management started to mature and mushroom throughout the world, these trained manpower from our institute found themselves at the important and top positions of the shipping management companies, many of which had been started by them.

This campus changed its name from Directorate of Marine Engineering and Training (DMET) to Marine Engineering and Research Institute(MERI) in 1996 and once again to Indian Maritime

University(Kolkata Campus) when the Indian Maritime University (IMU) Act was passed in 2008. Under the aegis of IMU we have started the Master’s Degree Program in both Marine Engineering and Marine Business Administration. We also have MS by Research for the Permanent faculty and slowly the young Alumni have started joining the Institute back as faculty. We have the most advanced Engine Simulator and have started major research initiative with the CIMAC, Wartsila and other universities in the world. We also have started modular post sea courses.

Our facilities have received a lot of upgradation viz., a huge auditorium capable of housing 1500 students, new CNC machine in our workshop, state of art Vibration Lab and large capacity new Academic Block. We have got a separate enclosure for a large two stroke marine diesel engine which we hope will be operationalised in near future. You would see a Green-field institute by next year. There is nothing more pleasurable than coming back to your institute and being a part of it; since it makes your life come full circle, “where it all began”.

As a retired senior defence officer, close with a few wise words of great maritime thinker Alfred Thyer Mahan “those who rule the waves rule the world” and as per one of the great strategist of 19th century Sir Julian Corbett “Command of the sea, therefore, means nothing but the control of maritime communications, whether for commercial or military purposes. The object of naval warfare is the control of communications, and not, as in land warfare, the conquest of territory”.

Best wishes for the DMET-MERI Singapore Alumni Reunion 2019. ▄

CV Subba Rao

Dear esteemed members of the DMET-MERI Alumni, Singapore,

Iam delighted to note that you have a strong fraternity of 350 members in such a strategic location, Singapore. Much as a cliché, a bonding of such nature creates a sense of wellbeing and happiness, and am sure all of you add to the growth of Singapore and its flourishing economy. would imagine that the underpinning culture of DMET-MERI saddles your inclusivity in a cosmopolitan atmosphere that you engage in.

I am a big believer in people and technology. Given the vagaries of our trade, I reckon that as a body, you have been able to leverage your education in the school well, when it gets transported to the shop floor.

We all understand that, just as for other faculties, marine engineering education is at the cusp of transformation that needs a reform, in letter and spirit. Too often and for too long, we have been driven by the logic of class room rote learning, without due consideration to the faculties of the human mind, which given an opportunity explores every thought and every action, in a manner many of us fail to fathom.

It is in Mark Twain’s language that one embarks onto a powerful domain of learning, as he rightly reflects, “I never let my schooling interfere with my education”.

am sure that you would know the steps being taken by Singapore in exploring the frontiers of education. wonder if your body could work with the local authorities in the education sector, and see if we could adopt such changes in our processes of admissions, curriculum and faculty.

Technology is changing at a rapid pace. am sure your body is closely following the changes in this area, and are able to see if it could be cuff linked into the domain in which you are operating.

We all live in a bubble of generations; while on the surface we seem to pass the baton from one to the next, we often get caught in a web of uncertainty and hesitancy. We fall prey to the oft repeated logic of “the young are not doing as well as we did”, and we end up without a clear succession plan for the future of our industry.

Let us be aware of our responsibilities and the travails that such responsibilities bring forth to our doors.

On this happy occasion of the DMET-MERI 2019 Reunion, wish you all and your families all the best in all your endeavours. ▄

Safety, cost-effectiveness, and reliability is at the heart of what we do.

“We are extremely pleased with the services provided to us by CTS Offshore and Marine and have no hesitation in recommending their commendable work.”

Our in-situ asset integrity teams are on standby 24/7, 365 days a year to ensure that we are where you need us, when you need us.

Class of 1964

Introduction

The International Maritime Organization (IMO) is one of the United Nation’s divisions tasked with the responsibility of safety, security and minimizing marine and atmospheric pollution by shipping.

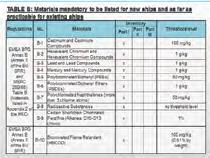

The IMO has been working to reduce harmful impact of shipping on the environment since the 1960s. Annex VI to the International Convention for the Prevention of Pollution from Ships (MARPOL Convention) was adopted in 1997, to address air pollution from shipping. Annex VI seeks to minimize air pollution from substances such as SOx, NOx, Ozone Depleting Substances (ODS); regulation of shipboard incineration discharge and control of emissions of Volatile Organic Compounds (VOC).

The IMO has set a global limit of 0.5% of sulfur content in marine fuels starting on 1st January 2020. The current sulfur limit is 3.5%. In more restricted Emission Control Areas (ECA) the sulfur content in marine fuels can only be 0.1%. IMO has confirmed that the date of 1st January 2020 is firm and there will be no postponement of this date. What option are available to Ship owners / operators to meet the requirements of this regulation.

Many in the Industry consider these latest requirements as a major disruption. am of the opposite view. consider these regulations as bringing in new opportunities – development of new grades of fuels by refiners and can maximize their profits. Use of alternate fuels will come into play and there will be corresponding development of technologies and fresh avenues for business. Use of scrubbers will become more common on ships which amount to reduction of costs in ship operation.

What are the possible options to meet the requirements of new regulation:

A. Us e of compliant fuel ( no more than 0.5% sulfur in the fuel ). This will mean use of distillate or low sulfur fuel blends availability of which the refiners have confirmed. Various refineries such Shell Exxon Indian Oil etc have confirmed that they will make the compliant fuels available around the 3 rd quarter of 2019. IMO has also advised that ISO will publish fresh standards for these

fuels sometime during the 3 rd quarter of 2019. However there are some issues that need to be kept in mind. Will these fuels ( BLENDED ) produced by different refineries be compatible with each other and will they be stable. Otherwise they may create operation problems such as generation of excessive sludge and choking purifiers and filters on board ships. Additionally these fuels will also be more expensive. Price spread between these fuels and high sulfur fuels ,as currently used is estimated to be a minimum of USD 200 per ton causing the operations cost to shoot up. There will other technical issues such as poor lubricity of these new fuels leading to fuel pump and fuel nozzle problems. Of course there are solutions to all problems but will require extra efforts and cost.

B. Us e alternate fuel such as LNG – LNG is environmentally friendly and and has no sulfur content but LNG retrofitting is very expensive and LNG bunkering is possible only in a few ports. At this time this is not a practical option. In the longer terms LNG may gain as a desirable option.

C. Ano ther option and a sensible one is to fit exhaust gas scrubbers By fitting scrubbers you can continue to use cheaper fuels and and use scrubbers to wash the exhaust gases to remove the harmful gases and resultant emissions are equivalent to using low sulfur fuels. Scrubbers are easy to operate help you save money on fuel costs and environmentally very effective. Ship owners will have to decide between using high Sulfur fuel along with an exhaust gas scrubber, or using distillates or other alternate fuels with very low Sulfur content. The cost and availability of alternative fuels such as LNG and the cost of retrofitting existing ships make this least viable and least likely choice for ship owners. Distillate fuels or low sulfur blends will be available. However, the possible poor quality of blends will give rise to associated problems in storage and use in the engines. The differential costs between high sulfur fuel oil and the lower sulfur blends or distillates will increase as 2020 approaches and likely stay increased for the near future. The lead time for refineries to prepare to make all the heavy fuel to distillates is also not sufficient to meet the 2020 regulations. This makes the use of heavy fuel oil with the use of a scrubber the most attractive and economical option.

And one fine day when disembark my last ship. As she goes away billowing from funnel. However old and rusted she was, however far farther she propels, it was only water all around, it was only humming machinery sound. The bollard where I sat and cried alone, the cabin where dreamt alone, also a few good fellas who saw it all. They who were there with me, when I drifted away.

Now that I am coming Home, now that I have done it all, I shall sign off one last time. Ship’s register will fade away. You shall be junked my dear ship. And one fine day when disembark my last ship, as she goes away my love, I tell ya, was a sailor once, a sailor shall always be.

Dash

By Anil Deswal Roll Number 4268 Class of 1995

From making me smile every day contrasting with having deep conversations..

love her, with all my heart even whenever we’re unfortunately far apart..

From laughing wildly at the most imbecile matters to sending one another endless pictures of us bawling our eyes out..

love her, her dynamic personality and pure soul..

From continuously barging into each other’s houses considering it to be our own to being equally as comfortable in school as we pass by corridors repeatedly informally communicating..

I love her, her smile, her eminently high yet lulling voice..

From trusting her with all my flaws, sharing my deepest secrets eagerly, to always being there for me when shut myself away...

love her, her limitless magnanimity, her tenderness, her warmth..

From just feeling so content with such a wonderful outgoing being to appreciating her efforts through a few words, I’ve found my tranquility, have any of you??

love my squirrel with all my heart

He’s my sweet little tart

He is striped but boy! He does not like to be wiped With a wet cloth and some soap

He has a cage with a bridge made of rope

His bed is made of a nest In which he loves to take rest

His eyes are like balls of cuteness wonder how he’d look toothless

I know will never forget my doll Even if he is really small

By Ashreya Shankar, 10 years old D/O Shankar Subramanian Roll Number 4262 Class of 1995 By Riddhi Garg (Mishtu) D/O Anubhav Garg, Roll Number 3913 Class of 1992

All of the marine scrubber manufacturers currently use the vertical in-line scrubber design. There are many disadvantages associated with the vertical scrubber design. Recently a horizontal design has been introduced with many advantages.

Scrubbers are an assorted group of air pollution control equipment which are used to remove certain gases or particulate matter from an exhaust gas stream.

They have been used widely in land-based applications. They are used for acid fume scrubbing, chemical fumes, paper and pulp industry, food processing industry, steel manufacturing industry, power plants, fertilizer and pharmaceutical industries.

Scrubbers are divided into the more common wet scrubbers which use a liquid to perform “scrubbing” or dry scrubbers which use a dry sorbent or dry spray absorbers.

Wet scrubbers work on the principle of a scrubbing liquid interacting with the exhaust stream to cause mass transfer of the gas into the liquid. This is dependent on the liquid to gas ratio (L/G ratio). The liquid quantity is often expressed in gallons per minute (gpm) of liquid and the gas volume is expressed as actual cubic feet per minute (acfm) of gas. This ratio is determined by the required concentration of the pollutant gas in the exhaust stream after scrubbing, solubility of the gas pollutants, the dwelling time of the gases in contact with the liquid, the temperature of the gases being scrubbed, the concentration of pollutants and particulate matter in the gas stream, and the mass transfer characteristics. Increasing L/G ratio usually increases the scrubbing efficiency of the equipment. However, this has to be weighed against the operational costs and an optimal L/G ratio can be reached in wet scrubbers.

There are many types of wet scrubbers. The most common ones are the spray towers, cyclonic scrubbers, tray towers/chambers, venturi and packed bed scrubbers.

They are characterized by the scrubbing liquid goes through spray nozzles and comes out as droplets. Using the increased surface area from multiple small droplets, there is more efficient scrubbing of the exhaust gas. The droplets must have uniform spray distribution and adequate size. If the header pressure is reduced, the droplet size can increase thereby reducing the effectiveness of scrubbing. Particulate removal happens due to impaction of the particulate matter on the droplets. They usually have lower power consumption, lower fouling and lower operating costs.

Cyclonic scrubbers

The exhaust gas stream enters the cyclonic spray tower at a tangent to the wall. The gas inlet is narrowed which furthers increases the velocity of the gas. The gas flows in a cyclonic manner within the cyclonic scrubbers. The scrubbing liquid is usually sprayed from nozzles in a central pipe. The liquid droplets are subject to the centrifugal force as a result of the spinning motion of the gas stream. This causes them to be moved to the scrubber walls. The droplets fall to the bottom of the scrubber along with the particulate matter. The cost of a cyclonic scrubber is more than a spray tower/chamber and the operating costs are also higher.

Tray towers/chambers

Tray tower/chamber scrubbers consist of a tower or chamber with perforated trays. The exhaust gas mixes with the liquid over the tray with increased gas liquid contact compared with the spray tower/ chamber designs. The trays used are called impingement trays. There is liquid flow over these trays which can remove certain gases and particulate matter. Due to the low velocity of the liquid, the L/G ratio can be small for these. Baffles can be placed before the impingement trays with settling out of the particulate matter before it goes through the perforation of the impingement tray. The cost of a tray chamber is higher than a spray chamber and operating costs are also more.

Venturi scrubbers use the velocity change and energy of the exhaust gas stream to convert the scrubbing liquid into small droplets and maximize the interaction between the exhaust gas and the liquid.

A venturi has a converging part, throat and a diverging part. The exhaust gas stream enters the converging part. As the diameter decreases in the throat, the velocity of the exhaust gas increases. This increased gas velocity is able to convert the liquid into small droplets enabling improved mixing of the gas and liquid and scrubbing. Venturis can remove both particulate matter and gases. Venturis are among the best in the wet scrubbers at removing particulate matter. However, venturi scrubbers are more expensive, consume more energy, have higher pressure drops and have higher operational costs.

Packed bed scrubbers

Packed chamber/tower scrubbers contain a bed of packing material. The packing material provides a larger surface area for gas-liquid contact. The scrubbing liquid is used to wet the packing material and form a thin film. The exhaust gas interacts with the liquid all over the surface area of the packing material. Packing materials are available in an assortment of shapes, weights, pressure drop, surface areas, corrosion resistance and cost. Packed bed scrubbers can provide ideal gas removal/scrubbing with optimized L/G ratio.

Many scrubber systems have one or more of these different components to achieve the total scrubbing requirements needed from the system.

Modes

Open Loop

The scrubber can be used in the open loop mode where the scrubbing liquid is sea water. The sea water’s natural alkalinity is used to “scrub” the SOx from the exhaust gases. The wash water is then treated and discharged back into the ocean after treatment.

Closed Loop

The scrubber can be operated in the closed loop mode when the alkalinity of the sea water is not adequate or where there are regulations for no discharge of the used sea water. In closed loop, sea water with an alkaline substance such as sodium hydroxide (caustic soda) is used for scrubbing. The wash water is recirculated and a small quantity keeps getting bled off. This is treated by the wash water treatment equipment and then discharged into the sea. Any loss of water from this operation is replaced by additional water. If water cannot be discharged, then it can be stored in a holding tank.

Hybrid Operation

The scrubber can be used in both closed and open loop modes. The closed loop mode can be used while in port and during maneuvering. A switch to the open loop mode can be made in open seas.

Counter Current Flow

The scrubbing liquid and the exhaust gas flow in opposite directions in a tower. The countercurrent flow is best suited for conditions where the peak of the SOx concentration may not be predictable and where there can be large variation in the SOx concentration.

Co Current Flow

The exhaust gas and liquid stream move in the same direction. These are not as effective as the counter current scrubbers. Co current scrubbers maybe used when space is limited and if high efficiency scrubbing is not needed.

Cross Current Flow

The exhaust gas and the scrubbing liquid flow at right angles to each other. The liquid usually flows vertically down and the exhaust gas flows horizontally. This type of scrubber can be used where space is a premium and where lower pressure drop is desired. The operating

costs are also lower in this scrubber when compared with the countercurrent scrubber. This scrubber is suited for applications where the maximum SOx concentrations are known and predictable.

The exhaust gas volume coming from the main engine depends on the MCR (maximum continuous rating). Other factors that will need to be considered in the estimation of the exhaust gas volume are whether the auxiliary engine is to be connected, if there is a boiler exhaust that has be connected, the time the ship is in the ECA (emission control area) and out of the ECA regions. The exhaust gas coming from the main engine usually comes out at around 250 ° C.

The mechanism of SO 2 absorption in seawater is impacted by several factors such as the sea water temperature, partial pressure of SO 2 seawater salinity, seawater alkalinity, interfacial contacting area between the exhaust gas and the seawater and residence time. The absorption capacity of the sea water declines with reducing salinity and alkalinity.

The temperature of the exhaust gas where it meets the sea water for majority of the scrubbing needs to be lowered so that the efficiency of the sea water scrubbing can be maximized. Scrubbing also necessitates a large contact area between the exhaust gas and the seawater.

The advantages of Horizontal scrubber include lower weight, significant ease of installation, lower immobilization time for installation, stability, ease of access for service and maintenance, lower weight to carry for all future voyages and hence lower fuel use and overall lower power consumption.

Manholes can be placed in the scrubber. These can be opened and the inside of the scrubber can be examined as needed. Given the height of the horizontal scrubber, there is easy access to view the inside of the scrubber.

The Guidelines permit two basic Schemes to be used for approval, Scheme A or Scheme B.

Scheme A is based on initial emission performance unit certification together with a continuous parameter check of operating parameters and daily exhaust emission monitoring.

Scheme B is based on continuous exhaust emission monitoring together with a daily parameter check of operating parameters. A majority of ship owners and operators have chosen Scheme B certification.

Approximately 2000 scrubbers are on order with various manufacturers world wide. Many owners are looking favorably at fitting the scrubbers mainly considering economic advantages. Capital costs are recovered within one year to one and half year and after that savings on fuel costs are for the owners / operators.

In recent developments even the charterers are offering higher day rates for ships fitted with scrubbers and in some cases even offering to finance the scrubbers and retrofitting.

PLEASE CONSIDER CAREFULLY THE COSTS AND SAVINGS AND MAKE A WELL CONSIDERED DECISION. ▄

Additive manufacturing (AM), also referred to as 3D printing, is a common name for technologies where an object is manufactured layer by layer. Additive manufacturing enables the building of three-dimensional, solid objects from digital models, and thus the realization of complex parts. This is in contrast with many traditional manufacturing methods, where the final parts are machined out from a pre-made form.

AM is expected to revolutionize the way products are designed, manufactured and distributed. Together with digitalization it is viewed as another potential game changer in the maritime, offshore, oil & gas industries. The use of AM results in new designs for more efficient components, it could also allow spare parts to be produced locally around the world. This would equate to less lead time, less cost, less logistics, and less need to keep stocks of spare parts. This would shorten the time required for repairs and contribute to more efficient ship operations. AM could also be used for maintenance and repair, simply adding layers of material to worn components, thus negating the need to replace them.

However, one of the most serious hurdles to the broad adoption of additive manufacturing of materials is the qualification of additively manufactured parts. For shipowners, while the potential to save costs and time is promising, the risks associated with AM parts and their quality assurance – which includes answering the question whether a given part is “fake” or not – could increase.

To address this, in 2018 DNV-GL released the first approval of manufacturer (AoM) scheme for additive manufacturing producers wishing to supply products that comply with the DNV-GL rules and

standards, following the publication of the first guideline for the use of AM in the maritime and oil & gas industries in 2017. The guideline - DNVGL-CG-0197 – offers a step by step process. Beginning with a complete review of any requested 3D prototype model that is to be printed. DNV-GL looks at the design, functionality, materials – every parameter that will impact upon the final product. Then there is then a technology assessment, manufacturing procedure qualification, data transfer and then the printing and post processing. DNV-GL is also physically present for the printing of the prototype, with a full understanding of the printer capability, to ensure that it can be emulated anywhere around the world.

To examine the potential of additive manufacturing, DNV-GL is carrying out several joint industry feasibility and pilot study projects on 3D-printed products in the maritime and offshore industries, in collaboration with our industry partners. DNV-GL established a new Global Additive Manufacturing Technology Centre in Singapore that is supported by the Singapore Economic Development Board (EDB). The center serves as an incubator and testbed focusing on DNV-GL’s global competence and service delivery for assurance and advisory services in additive manufacturing for the maritime, offshore and oil and gas industries. Most recently, in April 2019 DNV-GL has been appointed as the lead researcher of the first phase of a new Singapore-based joint industry program by the Maritime and Port Authority of Singapore (MPA), to study the feasibility of additive manufacturing (AM), or 3D printing, in the maritime industry. In this joint industry program (JIP) initiated DNV-GL teamed up with ten member companies of the Singapore Ship Association (SSA) to examine how spare parts produced by 3D printers can help the capital-intensive industry to cut costs and downtimes. ▄

The FIVA (Fuel Injection-Valve actuator) Valve is essential to the running of the new generation electronic engines as it controls the fuel injection and the exhaust valve actuation. FIVA valve carries out the injection profiles specified by the control system with absolute precision. This enables fuel consumption to be reduced and ultra-low emissions to be achieved - even in extreme conditions.

This is the reason why the FIVA Valve is considered an essential wear part which need to be reconditioned and calibrated at set intervals to meet performance standards. As an alternative to buying new expensive FIVA Valves, facilities are being set up for reconditioning FIVA units to their original design and quality, but at a much lower cost. In future, full exchange program of FIVA is also being planned to relieve the ship managers and ship owners from the burden of replacing FIVA valves at higher costs.

Injection Control Unit (ICU) – widely used on Wartsila RTFlex engines - is a type of electronic control unit that controls a series of actuators on an internal combustion engine to ensure optimal engine performance. It does this by reading values from a multitude of sensors within the engine bay, interpreting the data using multidimensional performance parameters and adjusting the engine actuators. Before ICUs, air-fuel mixture, ignition timing, and idle speed were mechanically set and dynamically controlled by mechanical and pneumatic means.

Complete test rig for the ICU, FIVA and the HPS (hydraulic power system) is being set up in Singapore to provide full testing facility to the ship owners and ship managers to have the ICU/ FIVA/ HPS fully tested as per original specification. ▄

www.recreatemarine.com Email: recreatemarine@recreatemarine.com

Services offered

• Hull, structural, piping, engine and mechanical repairs

• In-situ machining of crank shafts (main and auxiliary engines)

• Cold metal stitching of damaged A-frames of marine engines

• Hydraulic works

• Main propulsion system service and troubleshooting

• Voyage repair services

• Marine Consultancy services:

o Sale & purchase inspections of all types of ships including oil/ chemical/ gas tankers/dry vessels

o Dry docking services

o Pre-vetting inspection/ TMSA audits preparation

Contact: +65-97265084

Change is inevitable; it remains the only constant (Smith, 2004). In today’s fast-paced world of technological advancement, transformation is happening in every aspect of our lives. To cope up with this speed of change is quite a challenging task for the global industry leaders. The amount of pressure, internal & external, is immense to meet organizational growth, justify shareholders’ investment by achieving high ROI and the last but not least is to survive in this highly volatile market, especially after the global economic meltdown of 2008 and falling oil prices thereafter.

There is a greater need from organisations to develop strategies to keep up with tomorrow, even if it includes changing the organisation culture. Although many might fight to hang on to the way things “used to be done,” others embrace the revolving door of change. Change is not the problem – but resistance to change can be a huge problem. In the 1920s, H.P. Lovecraft said “The oldest and strongest emotion of mankind is fear, and the oldest and strongest kind of fear is fear of the unknown.” This quote, said over 96 years ago, still holds true today when it comes to organizational culture change. Basic understanding and how to interpret the resistance is still challenging even though the concept is quite popular (Bareil, 2013).

It is unrealistic not to have any resistance to change, but the mitigations measure like effective management, understanding of individual interpretation, clear communication of the idea behind the idea of change has emerged as the essential skill for the change manager. The change situation will worsen if purpose of change is not communicated well to the individuals (I Palmer, R Dunford, G Akin, 2009, P162-64). With the help of this paper, writer has tried to explain how to identify different types of resistances, reasons behind these resistances and most importantly how to manage this resistance (Manuela, Clara, 2003).

Resistance to change is defined as “refusal to accept new ideas or changes” by the Longman dictionary of contemporary English (as cited in Bareil C, 2013). It’s a behavioural response of the change recipient or stake holders towards a change initiative which may emerge before, during or after change implementation. (Bareil, 2013). It is a main obstacle in the change management process. The basic assumptions, deep routed beliefs, individual attitude or perception and the present culture - these are the main reasons which cause resistance to change. These causes may delay the change process, increase the cost associated with the change process and at times can become the main cause of failure for these changes.

Human nature is to maintain status quo and this itself can act as restraint for basic idea of change. This is often taken negatively by any change leader as a direct objection towards the change. It’s all about the feeling towards the change. Feeling can be comfortable in form of enthusiasm or elated, but there can be a negative feeling in the form of anxiety, apprehension, fear. All these negative apprehensions, anxiety are self-made, just like an “psychological contract”, which we make ourselves and then start believing that things around us should be according to that belief.

Studies in the behavioural aspects define the resistance as “intentional acts of defiance or omission” (Ashforth and Mael, 1998, as cited in Piderit 2000). The behaviour response is the output in the form of act or deed of the individual about the change (I Palmer, R Dunford, G Akin, 2009, P50). According to Bareil, 2013, “the behavioural response can also be interpreted as a resource that represents the feedback of discomfort about the change initiative”. In the contrary the compliant behaviour of individual is interpreted as evidence of reduced resistance (Sagie, Elizur, Greenbaum,1995, as cited in Piderit 2000). It’s a natural

human behaviour to oppose any action or idea or plan which requires any additional amount of work/effort to be put without knowing the benefit or result. If a person is happy and content, he doesn’t want to go out of comfort zone unless he himself needs it or does it selflessly for someone else.

All changes are situational or need of time, but it always has one thing in the vision and that is betterment/profitability/survival of the organisation where the change is being planned. If a change process is not properly disseminated, discussed and explained by the change manager it can lead to distorted perceptions from all individuals/ departments to the extent of implicit assumptions. This sometimes leads to a negative impact of the change on one’s sphere of interest, often described as parochial self-interest by Kotter & Schlesinger (2008).

Other reasons like monetary involvement, motivation factor, past experience may also influence change. Market condition, timing of the year, unclear understanding of the need for change or the strategic intentions among the employees will surely reduce the creativity in change process, and hence will be the part of resistance. Basically when the expectations of the organisation and the employees are incompatible it gives rise to resistance. (Burnes, 2015)

Another important source of resistance is the change process itself. Maybe the idea and philosophy behind the change is very good but if the planning of execution is not done properly, then resistance develops. So it very important for the change managers to study the proposal of change in the full context of that particular organisation.

It is unrealistic to consider ways which can totally eliminate the resistance from any change process. Managing resistance tactfully is an important skill for the success of the change process.

Kotter and Schlesinger (as cited in Palmer, R Dunford, G Akin, 2009, P172) propose managing resistance by communicating and educating the people, to apprise them of the reason for change, involving them in the change process, encouraging participation, providing technical and emotional support to address anxiety and uncertainty, manipulation by offering key role to certain individuals thereby getting support when the change is absolutely necessary for the existence of organization.

In the traditional approach coercive methods, explicit and implicit coercion, are often used to persuade the change resistors when the resources are limited, and the survival of the organization is at stake. The concept of managing resistance has undergone significant transformation over years - from traditional suggestions of coercive methods, minimising and eliminating resistance to the modern theories of analysing, simplifying and utilizing the resistance to change. (Bareil, 2013). As per some modern theories, the resistance can be a resource rather than a threat (Ford et al, 2009) to the change process which can help to bring sometimes a commitment from the change recipient.

Scott and Jaffe,1989, (as cited in Palmer, R Dunford, G Akin, 2009, P173) suggested that individual goes through four psychological stages, denial, resistance, exploration and commitment as they respond to the organizational change. In the denial stage, individuals don’t tend to give enough importance or sort of ignore the requirement of the changes having the perception that the change is short lived and things will come back to the status quo. As the change progresses, fear, uncertainty and anxiety of future creeps in and thus causes resistance to the change. In the exploration stage, when the individual realizes that the change is here to stay, one starts to evaluate his own position, visualise the upcoming changed scenario and will try to modulate oneself to fit for the change. Once the individual realizes the benefits of change, they will enter in a commitment stage and focus on the change process. Going through all these four stages will bring about the positive approach and remove the negative thoughts for the change resistance. ▄

Over 5 billion people on the face of the Earth (70%) lack access to safe surgical and medical care. As a result more than 17 million people die each year. This statement alone explains why Mercy Ships exists.

By Kapil Berry Roll number 3381 Class of 1987Welcome to Mercy Ships, a compassionate response to a world where many have lost hope.

Adream that began in a young man’s heart has become reality — a big, white, state-of-the-art hospital ship that delivers hope and healing to people around the globe living in dire circumstances.

When Don Stephens, President & Founder of Mercy Ships found out that 95 of 100 largest cities of the world were port cities, and 50% of the world’s population lives within 160 kms of the coasts, the idea of delivering healthcare very efficiently to large numbers of people around the world was born. The birth of his profoundly disabled son also inspired him to move forward with his vision of a floating hospital. A visit with Mother Teresa in Calcutta, India, further deepened his commitment to serving the world’s neediest people.

It took years for this idea to reach fruition, but in 1978 Don’s goal became reality when he and fellow fundraisers paid USD1 million for the “Victoria”, a former cruise liner, and work began to convert her to a hospital ship. The nine-deck vessel was transformed into the hospital ship over a four-year period. In 1982, the vessel, refitted with three operating theatres, a dental clinic, X-Ray machine, a laboratory and a 40-bed ward, sailed as the “MV Anastasis” – the first Mercy Ship. The ship’s 350-member crew included Mercy Ships founders Don and Deyon Stephens, who lived on board the ship with their four young children for ten years.

Since then, four ships, including the current vessel, the Africa Mercy, have served in 150 ports throughout developing nations, bringing hope, relief and healing to the most vulnerable people.

Mercy Ships purchased the Norwegian coastal ferry “Polarlys” in 1994 and transformed it into the “Caribbean Mercy”, a hospital ship serving Central American and Caribbean ports.

In 1983, the Canadian ferry “Petite Forte” was donated to Mercy Ships to provide relief operations in the Caribbean. Initially christened the “Good Samaritan”, the ship was re-christened the “Island Mercy” in 1994.

Since 2000 Mercy Ships has the 16,500-ton flagship “Africa Mercy”, which measures almost 500 feet long.

“Global Mercy”, the world’s first purpose-built hospital ship, currently under construction, will grant the poorest of the poor access to highquality health care.

“Atlantic Mercy” will be delivered in 2019 with hospital area of abt. 7,000 m2 contains six operating rooms, an intensive care unit, clinical laboratory, diagnostic radiology, hospital supply and pharmacy services. The vessel is even equipped with a school and kindergarten for the staff’s children.

Mercy Ships now is a global charity that has operated hospital ships in developing nations, bringing hope and healing to the forgotten poor by mobilising people and resources worldwide, serving all people without regard for race, gender or religion.

In many developing countries in Africa, even basic medical care is a luxury. People are plagued by preventable disease, untreated illnesses and neglected injuries. Nearly 50 percent of the people have no access to a hospital or doctor. Children, teens, adults and the elderly suffer and die every day from curable or treatable causes. A staggering 6.6 million children under the age of five died in year 2012 alone, from treatable diseases – more than 18,000 children per day.

Mercy Ships has provided $1 billion worth of services, including nearly Hundred Thousand surgeries in more than 70 countries, directly benefiting nearly 2.7 million patients – no mean task for any organisation.

In order to do the good work to fulfil their mission, they depend on:

Volunteering Mercy Ships are all manned by volunteers. For example, the volunteer crew of the Africa Mercy is made up of more than 400 volunteers from more than 45 nations. Volunteers with Mercy Ships are responsible for paying all costs associated with their service, including crew fees, travel expenses, passports, immunizations, insurance and personal expenses. Volunteers are also need for their shore operations.

Mercy Ships offers short-term (two weeks to two years) and longterm (minimum two years) volunteer opportunities. There is a need for volunteers for both medical and non-medical jobs. Due to the nature of the ship, positions for surgeons, dentists, and nurses are often readily available, but jobs such as deckhands, carpenters, seamen, teachers, cooks, engineers, machinists, welders, plumbers, videographers, photographers, writers, electricians and agriculturalists are also available. Volunteer crew often serve as blood donors, since there is a high demand for donated blood due to limited space to maintain a blood bank on board.

Because of this commitment, Mercy Ships is able to use direct contributions from its supporters to bring hope and healing to the poorest of the poor.

Volunteering with Mercy Ships will not only change the lives of those you serve, it will change you. There are many ways to support Mercy Ships in our global medical mission to help the poor. It takes all kinds, with all skills. There is a need for both medical and non-medical volunteers. There are volunteer positions in a variety of areas including: housekeeping, galley, deck crew, doctors, engineers and nurses and everything in between.

You may find a role for yourself at https://www.mercyships.org.uk/ serve-onboard/volunteer/

Donations are required to keep their operations running. Donations can be sent by post, in person, direct debit, credit card etc. The donations can be made at following link https://www.mercyships.org.uk/ donate/

Fund Raising

Several fund-raising events are organized around the world to generate revenue.

Wills and Bequests

By remembering Mercy Ships in your Will, you can help save and transform the lives of future generations. Your bequest can help children and adults to see, walk or smile for the first time. You could even transform the lives of whole communities through one of our many development projects. Imagine funding a health clinic, safe water supply or a livestock or agricultural program for an entire village. For more info, use following link:

https://www.mercyships.org.uk/get-involved/give-in-your-will/

Corporate Social Responsibility and Philanthropy

If your company is considering partnering with Mercy Ships, Mercy Ships would love to hear from you. They will work closely with you to create a partnership that suits you and synchronises with your company’s Corporate Social Responsibilities.

Your support will enable them to continue our work in sub-Saharan Africa, providing free surgeries to people who otherwise couldn’t afford or access the care they desperately need. Your support will have a direct impact, transforming hundreds of lives.

Use following link for more info for Corporate donations: https://www.mercyships.org.uk/get-involved/philanthropy/

Spread the Message

Not many in shipping industry know about this amazing charity which should be close to any seafarer’s heart. So, spread the message, make people aware of the amazing work this organization is doing, and how every seafarer can and should contribute to it.

See their amazing at work at: https://www.youtube.com/ watch?v=vWL4MujgWRw ▄

ADITYA, being a catamaran, has high margin of stability. There are submerged bilge pumps installed in all water-tight compartments (ten of them) which will automatically start pumping out water when there is an ingress.

The grid cost is calculated by taking the cost of power from electricity bill of the shore charging facility. Since the power is utilized for jetty and office lighting, the amount of power consumed is taken from the energy meter in the boat. This is about 61% of the total consumption. A total of 13,030 units was consumed in the boat jetty of which 7,969 units was used by the boat (61%). At 11 US Cents, this comes to total energy cost of US$889 for the whole year.

Daily Propulsion Energy

In the first year, for 347 days of operation, the average consumption comes to 71.4 kWh. Once it is adjusted for 22 trips, the average consumption comes to 72.8 kWh per day. The low consumption are days with calm conditions whereas higher are days with adverse weather – current, wind, and waves.

Daily Solar Production

The daily solar power generation is tracked in the automatic log. It varies from extremely low value to maximum of 66 kWh.

By Sandith Thandasherry(Published in IEEE, 11/2018)

Story of ADITYA - first solar boat

Environment viability it wins hands down, but economic superiority is proven below with respect to a diesel ferry.

A typical ferry boat operating across the backwater in VaikomThavanakkadavu sector, a distance of 2.8 km, with ticket price of only 6 US Cents for the journey, generates about 71 US $ daily in revenue. However just energy cost of 100 ltrs of diesel was higher than this fig .The direct cost of energy and maintenance is 94US$/day along overhead and crew cost approx. 43$/day. Hence the opex is US$137/ day. This means US$137-US$71 = US$66 shortfall considering only opex.

It is not easy to find a solution, since existing ferry boats are heavy and with high drag, hence these cannot be retrofitted with solar-electric propulsion. Three things were needed to make solar ferry work. Firstly, the weight of the boat needed to be around 17 tonnes compared to 35 tonnes for typical diesel ferries. Secondly, along with weight reduction, the underwater shape was needed to be optimised to reduce the drag significantly so that just 20 kW motor power is needed to run at 6 knots with 75 people onboard. Thirdly, the power train, consisting of lithium

ADITYA is a catamaran ferry boat with GRP hull and aluminium superstructure build under IR class The vessel particulars are as follows:

Length overall 20.0 m

Breadth 7.0 m

Breadth, demi hull 1.5 m

Depth 1.6 m

Draft 0.8 m

Complement 75 passengers + 3 Crew

Maximum speed 7.5 knots (14 km/hr)

Solar panel Main System - 18 kW (poly-crystalline)

Auxiliary System - 2kW (poly-crystalline)

Batteries Main System - 2 x 25kWh (lithium-ionphosphate)

Auxiliary System - 2 x 5 kWh (lead-acid)

Motors AC induction 2 x 20kW (asynchornous)

Shore charging 2 x 6kW (32A three phase connection)

The battery system meets very high standards of safety, which is essential for public transportation.. The battery meets IP56 ingress protection and the ventilation system is designed for lifecycle at operating temperatures higher than 30 degrees by monitoring charge and air cooling by PLC.

The average daily solar production in the propulsion array (18 kW) is 42.8 kWh for the whole year. This include the three months of monsoon (Jun-Aug) where the average drops to 38 kWh. For an 18 kW system, the energy produced is lower than expected, around 60 kWh. This is because by the mid part of the lunch break on most days, the battery is full and in the second part of the break there is no space to store the energy from the sun at its peak power. This can be solved with a larger battery bank, say 80 kWh. There were few days with practically not much sun which mostly occurred during monsoon.

Daily Battery State of Charge (SOC) and the Grid

The battery size for ADITYA is designed for average sunny day. Hence in most days there is no need to charge the battery from shore during daytime. The real SOC is slightly more than the observed SOC.

Real SOC = (Observed SOC x 45 + 5) / 50

The lithium batteries are designed to go to SOC of 20%. If one sees the state of charge in the one year period, the average is 58%. This means that the battery will last longer, over seven years.

Economics CAPEX

This is the initial cost of owning the boat. The cost of ADITYA was US$278,600. A diesel ferry with similar capacity (75 persons) is about US$214,300.

In the total cost of operating the boat, there are three broad cost groups: (i) Energy; (ii) Maintenance, and (iii) Crew and overheads.

Energy Cost

For a solar ferry the energy cost is the cost of grid used to charge battery. The total energy consumption is 7,969 units and energy cost was US$889. This energy cost is expected to increase at 5% every year with increase in grid cost.

The fuel consumption is approx. 100ltrs/day. Daily cost US$86 that makes in a year total cost of US$30,000, where the diesel prices are volatile.

Maintenance Cost

There are three kind of maintenance activities. On an average the maintenance cost is about 3% for lube oil and 7% for filters and engine overhaul of fuel cost. The total is about US$8 per day. In the first year this was US$30,000.

The second type is the cost of replacing the battery cells. The propulsion battery has a warranty of five years. However based on the battery discharge level, the replacement cycle for the battery would be seven years. The replacement cost of the cells is expected to be US$35,700 at the current price

The third type is cost of replacing or repairing damaged parts, equipment and cost of maintaining the boat in good condition. It is assumed that this is similar in both boats and hence not considered.

Crew and Overheads

Both type of boats needs similar manpower so not considered for Comparison.

Finance Cost

The difference in Diesel and Solar Ferry’s intial cost is US$64,300.This Financing attracts interest which will be possible to pay in a period of 3 yrs, an amount of US$110,000. After which the solar ferry will give a huge saving every year.

TCO

Summarising the calculation, we can see that in its life cycle of twenty years, the TCO comparison is shown on Chart 1.

Conclusion

From the above calculations one can easily conclude that ADITYA solar ferry is far more economical than a diesel ferry. It is for this reason SWTD has ordered three more solar ferries for public transport. They have already announced plans to phase out all their diesel boats to solar in the next five years. ▄

The Union budget 2019 presented by the interim finance minister

Mr Piyush Goyal, the government proposed a number of tax sops to lure home buyers and also announced relief to real estate developers by extending a tax rebate on the development of affordable housing till the next fiscal. These measures are expected to boost the real estate sector across the country.

As always the Union Budget continues to grapple the nation’s attention, and almost everyone wants to know how it will impact them as well as other the real estate industry stakeholders the most important one being the homebuyers and the real estate developers. Here is a list of the key changes that the real estate sector can be excited about in Interim Budget -2019.

The levy of tax on notional rent, on unsold inventories has been increased from one year to two years, from the end of the year in which the project is completed. A recent reports mentions that currently there are about 6-7 lakh unsold units lying with real estate developers in top major cities due to poor demand. This proposal is expected to bring much-needed relief to such developers.

There is also a relief offered in the form of exemption of tax levied on income tax on notional rent on the second self-occupied house.

“Currently, income tax on notional rent is payable if one has more than one self-occupied house. Considering the difficulty of the middle class having to maintain families at two locations on account of their job, children’s education, care of parents etc. am proposing to exempt levy of income tax on notional rent on a second self-occupied house,” said Mr Piyush Goyal during his budget speech.

And if you are thinking what will happen if one owns 3 houses, if a person has three houses In that case only the third house will attract a rent tax considering that he/she lives in one house and two other are self-occupied properties. This will benefit most the consumers who would like to own multiple house and hence boost property sales.

The TDS threshold for deduction of tax on rent is proposed to be increased from INR 1,80,000 to INR 2,40,000 for providing relief to small taxpayers.

The budget offers breathing room for people who are planning to save on paying tax on the profit they get from selling off property. Those who get a neat profit of up to INR 2 crore from selling property can invest that money in not one but two properties to avoid paying capital gains tax (CGT). This is applicable only in some conditions and benefit taxpayers who have capital gains of up to INR 2 crores and under Section 54 of the Income Tax Act, the rollover benefit can be availed once in a lifetime.availed once in the lifetime This will incentivise and lure many individuals to purchase more than one house, thus boosting the real estate sales.

In order to boost the affordable housing sector in India, an additional tax benefit for affordable housing developers was also proposed by the government in its interim budget. “For making more homes available under affordable housing, the benefits under Section 80-IBA of the Income Tax Act is being extended for one more year to the housing projects approved till March 31, 2020,” said Goyal during his budget speech.This essentially means that projects under Section 80-IBA will offer 100 per cent deduction of profits to an assesse engaged in developing affordable housing projects.

While there have been many big positive announcements for real estate industry in this Interim budget what has been a big miss is the much expected GST relief on the purchase of property. The industry players were keenly looking forward to this announcement from this budget as the experts were expecting that the GST relief would have helped boost the subdued sentiments in the real estate industry and would have helped to push up the real estate sales. ▄

world first autonomous projects. However, this project, a world first for the deployment of autonomous navigational technology to an oceangoing vessel for commercial operations, pushes the boundaries of autonomous technology and moves the industry towards deployment of autonomous navigation systems onboard vessels for enhanced performance and critically, safety.

Increasing interest in maritime autonomy and remote access/control technologies is a specific example of larger technological changes we are currently seeing in the maritime industry. Essential to the successful and safe adoption of these technologies is that robust use cases are established, for example to improve navigational safety, supply chain efficiency or operational costs of marine assets. Autonomous systems will also provide opportunities for skilled seafarers to focus on what they do best, and the safe and sustainable integration of autonomous systems relies on the appropriate engagement with seafaring professionals.

The case for autonomous ships keeps getting stronger as evidence of its commercial viability increases especially from the safety dimension, with the sensors on board to provide greater situational awareness. It will also help to meet future requirements for CO 2 emissions.

By Brijesh TewariLloyd’s Register

Roll Number 3275

Class of 1986

While autonomous shipping is a hot topic today, most of us believe that it is a thing of the future and we don’t have to do anything with it.

Well, you will be pleasantly surprised to know that our own DMET Singapore alumni Chinmoy Ghosh is deep into it and was recently featured in Channel News Asia. Please see Picture 1.

A Memorandum of Understanding (MoU) has been signed between ST Engineering Electronics Ltd. (STEE), a leading Information Communications Technologies (ICT) provider and co-creator of Smart City Solutions, and Mitsui & Co., Ltd (Mitsui), the second largest trading house in Japan to collaborate on the ‘Development of Ocean-going Autonomous Navigation System on a Marine Asset’. The MoU forms the foundation of the MPA-funded ‘World’s Largest Ocean-Going Autonomous Vessel Programme’.

Chinmoy Ghose represents the ship-owner Mitsui.

Lloyd’s Register’s involvement in this project builds on the capability and experience already gained from previous industry-leading and

Autonomous vessels may account for up to 17% of global shipping by 2040 according to a recent World Maritime University study but some sectors are likely to embrace it sooner than others.

Short sea shipping where vessels move back and forth on the same route, road ferry types, are candidates for early adoption, but deep-sea going vessels too are coming into the picture.

For that international regulations and standards must be in place. The International Maritime Organization is taking steps but more needs to be done as standardization is needed to allow autonomous ships to cross international waters.

LR has developed framework for autonomous shipping as per Figure

1 which allows for increasingly complex systems to be integrated on board ships.

LR has also published a Code for Unmanned Ships which creates a whole-platform certification process. The salient features of the code are as follows:

• A ddresses when vessels are manned as well as unmanned

• Go al-based approach to assess risks for providing assurance to platform

• Consider s more than just autonomous/robotic system of an asset

• Provides certification process for unmanned assets

• Applic able to all UMS operated on or below the surface

• If occ asionally manned all relevant conventions must also be complied with

• T he code covers following elements – Structures, Stability, Control Systems, Electrical Systems, Navigation Systems, Propulsion and Manoeuvring, Fire, Auxiliary Systems

We can look forward to the day when the Master and Chief Engineer will be navigating the vessel from the comfort of their office ashore, but am sure most of us will miss the days when we used to be at sea in our own world as king in our own kingdom with no interference from ashore!! ▄

Most shipping companies have a training department or have tied up with a training institute to fulfil training requirements as per their training matrix (a mandatory requirement of TMSA).

But we hardly come across competency management solutions being implemented by shipping companies or their crewing arms. Although class societies have laid out standards for competency management systems for shipping companies and had also implemented their sea skills program in some shipping companies. Currently very few, if any, shipping companies seem inclined to invest in a separate department for competency management solutions.

The root cause of this apathy is ignorance, regarding the usefulness of such a department besides of course commercial considerations such as a very dynamic and unpredictable crewing job market and manning functions, where additional barriers are never welcome.

To understand the need, first we need to have clarity regarding the term “competence” vis a vis “training”.

Training is about enabling acquisition of skill and not simply knowledge. However, a trained person need not necessarily be a competent person. Competence is the ability to demonstrate use of knowledge, skills and attitude to achieve results which are the objectives of a job.

Under class room conditions, or a training environment which enables practice of techniques, a person may have acquired the necessary skills, but he may fail to demonstrate same at the actual workplace where these skills need to be applied. This can be due to several factors which affects his ability to produce results required of a job.

So, it is obvious that a trained person need not necessarily be a competent person!

Training can be a combination of theory and practice, taught courses, on job training etc. However, competency has several aspects, of which training may be only one. Other aspects can be skills, pre-existing knowledge, experience, aptitude, attitude, understanding of job objectives, surrounding environment, wide array of human factors etc.

So, qualifications accrued from training does not necessarily guarantee competence. Inherent aptitude, experience, intuition etc. all singly or in combination can ensure achievement of objectives of a job.

Now the question arises, how does one ensure competence? To be able to answer this question, one must first ascertain the expectations or objectives of a job role or function. Surely, this will require a review of job descriptions, responsibilities and roles as also minimum standards such as industry best practices and required training/certification.

For high risk jobs like in maritime industry, higher competency is required due to the degree of complexity and expertise, besides of course the degree of risk.

Once the core needs of the job have been identified in terms of experience, certifications, qualifications, skills etc., one can easily develop a matrix which would still be a basic or elementary matrix, in which minimum requirements have been identified.

Now comes the real challenge of aligning people against proposed roles and evaluating or assessing their existing competencies to carry out such alignment. This would give a scientific way of gaining an insight into strengths and weaknesses of employees including prospective ones. Further, this would streamline efforts to plug the identified weaknesses and make such efforts more organised.

Such efforts can be in the form of more training in theory or practice or both followed by re-evaluating competencies through evaluations, assessments, performance reviews etc. This can be followed by planned learning, training and development programs. The best part is competence evaluations or assessments against well laid out standards also gives an opportunity to improve quality of training or learning programs since they provide us with a measure of training effectiveness!

Many argue that in the context of seafarer’s training and certification, assessments of seafarers form the basis upon which they are granted a COC (certificate of competency) for particular roles and responsibilities, thus licensing them to operate and maintain a vessel and its equipment. Then why duplicate the exercise at the recruitment stage of different companies?

But we are all aware that accidents on and involving ships have often resulted in loss of life or limb and damage to marine environment. Analysis of these accidents and incidents have proved conclusively that major percentage of such accidents can be attributed to human error Operational mistakes and errors by ship’s crew have negatively affected all stakeholders in maritime industry, besides of course taking toll on human life and limb and marine environment. This clearly points to the fact that seafarers’ competence levels have been far from that required to operate ships safely and efficiently. Assessment methods used prior issuing COC’s are hence not reliable. And that further points to inadequacy of STCW standards that are used by administrations and training institutes to certify, train and re-train! In a fast changing regulatory regime and engineering developments, standards like STCW, are bound to get obsolete by the time they are released, leave alone implemented!

So, what’s the way out? The maritime training institutes are powerless to improve STCW. IMO works at its own pace in formulating and releasing these standards. And administrations are bound by these standards to assess and issue COC’s which eventually end up being just qualifications with no guarantee of competence! Scenario seems quite hopeless, doesn’t it?