By Commercial UAV News Staff

Throughout Europe, countries are expanding and refining their Energy & Utilities systems. They are also streamlining their inspection operations and finding ways to make their systems more efficient, sustainable, and environmentally responsible. Many are incorporating drone technology to do this work.

That’s no surprise because the value of using drones in energy, utilities, and inspection work has been proven time and again the world over. “Drones enhance the productivity and range of inspection crews by order of magnitude, boosting coverage, volume, and quality of data capture,” a Commercial UAV News article on the use of drones for inspections explained. “Since flying a drone repeatedly is less expensive than flying a helicopter or sending out ground crews equipped with traditional equipment, it is also easier, quicker, and more efficient to detect an asset’s faults.”

European companies and government agencies are enjoying the many benefits of uncrewed systems. Looking ahead, advances in artificial intelligence, drone-in-a-box, detect-and-avoid systems, coupled with changes in regulations governing drone flights, will enable operators across the continent to improve value, efficiency, and safety further.

This report will show how Energy & Utilities companies and public entities in Europe are tapping into drone technology for their operations and finding new and innovative ways to deploy uncrewed systems to increase profits, enhance safety, and serve the public good.

The current market for inspection drones in Europe is strong and poised to get stronger. A recent market survey study stated that the “Global Inspection Drones Market size is expected to grow from USD 12.3 Billion in 2023 to USD 47.88 Billion by 2032, at a CAGR of 16.3% during the forecast period (2024-2032).” Also, the firm Astute Analytica reported that “the Europe autonomous BVLOS drone market was valued at US$ 3,447.0 million in 2023 and is projected to surpass around US$ 14,828.8 million by 2032, growing at a CAGR of 17.6% during the forecast period of 2024–2032.”

A growing recognition of the enhanced safety and efficiency of drone-based inspections is driving this expansion, but changes in the regulatory environment across the continent are also having an impact. As Astute Analytica stated, “On the regulatory side, the European Commission’s Drone Strategy 2.0 and the ECC’s decisions regarding communication technologies demonstrate a strategic shift towards BVLOS operations. The U-space Regulatory Package, emphasizing network connectivity for BVLOS flights, further underscores its importance.”

A number of new projects and initiatives highlight the growing adoption of drones in inspection work in Europe. For example, in 2024, the UK Civil Aviation Authority selected six projects for trials to help integrate drones into the UK airspace. A plan to inspect offshore windfarms by Airspection and a NATS project to conduct BVLOS inspections over the North Sea were among the chosen initiatives.

Further, recent announcements by private companies to launch or expand drone-based inspection services point to greater adoption of the technology. These announcements include:

• Germany’s Solevi reported that it will begin performing rooftop solar inspections. For this work, the company is using a field inspection system “equipped with a gimbal, a full-frame camera with an electroluminescence (EL) lens, and a Matrice multicopter-type drone made by China-based DJI.” The company plans to “automate further and expand geographically.”

• Madrid, Spain-based Telefónica Tech has developed a drone solution for predictive maintenance of electricity grids. According to the company, their drones “are equipped with cameras and sensors that transmit the information collected via 5G to be processed with Artificial Intelligence.” Telefónica Tech say this “makes it possible to detect corrosion in grid insulators, perform predictive maintenance by detecting excessive hot spots, prevent fires caused by trees falling on towers, as well as identify insulating gas leaks, bird nests and weeds that could cause power outages.”

• The European Union funds the SUNRISE Project, which “aims to ensure greater availability, reliability, and continuity of critical infrastructures, to the benefit of all European citizens.” Beginning in October 2022, the SUNRISE Project has engaged 41 organizations from 15 countries to develop “a suite of new technologies and solutions to safeguard critical infrastructures during pandemics and other major risks.” Recently, the initiative has been piloting a tool for remote physical infrastructure inspection involving critical infrastructure operators in Spain, Slovenia, and Italy working with transport, water, and electricity operators.

• Another German company, Energy Robotics, made news recently for its AI software platform for autonomous inspection robots. A DroneDJ article explained that the company’s system can be controlled remotely “thanks to Beyond Visual Line of Sight (BVLOS) approvals in the EU,” enabling it to “conduct automated flights, eliminating the need for inspectors to be present on-site.” Energy Robotics claims that its system “can complete what would normally be eight hours of manual inspections in just 30 minutes.”

In recent months, Commercial UAV News has published a series of articles looking closely at the commercial drone industry in several European countries. The series highlighted some of the companies, products, and services that are driving drone sector growth in Europe—and having a significant impact around the world. Below is a sampling of how European countries are leveraging uncrewed technology to improve inspections and other operations in the Energy & Utilities sector.

Destined to operate under harsh arctic conditions in the Barents Sea for the next 30 years, proper inspection of Equinor’s Johan Castberg, a floating production, storage, and offloading (FPSO) unit, requires several revisits and many inspection hours. To document the coating condition and as-built structure welded to the underside of the FPSO, IKM Testing, a Norwegian service provider to the energy industry, inspected the newly built vessel using the Scout 137 Drone System from ScoutDI.

As a developer of drone-based systems for fully digitalized inspections of industrial confined spaces based in Norway, ScoutDI designed the Scout 137 with a tethered system. This system provides valuable flexibility for organizing the job while eliminating the stress of limited flight time and battery management related to non-tethered solutions. To make inspections even easier, the drone also features a virtual anti-collision bubble that ensures it always remains at a safe distance from any obstacles.

Featuring a 37,000 square ft. cargo tank deck area and a height of 65 to 100 ft., a responsible and meticulous inspection is vital to ensure there aren’t any potential falling objects or issues that can harm the integrity of tanks and pumps. Conducted from the cargo tank floor of Johan Castberg, IKM Testing’s inspection crew completed the job efficiently after a total of 22 hours.

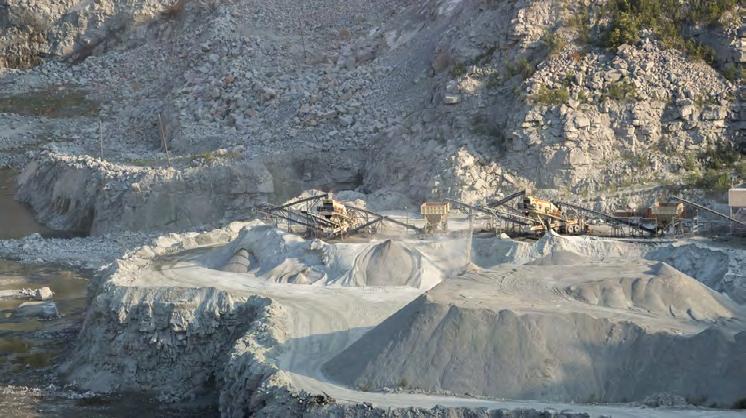

As one of Italy’s leading lime producers with 11 plants across the country, UNICALCE manages its quarries with a focus on sustainability. To check the condition and plan possible maintenance of a 190-meter high and 4-meter wide furnace, the company partnered with WACO, an inspection company focused on confined or difficult-to-access spaces.

The inspection aimed to identify the causes behind the rock detachments in the base chamber of the quarry to assess the possible need for structural repairs, without interrupting operations for too long. On top of that, UNICALCE also wanted a detailed maintenance inspection of the furnace to assess its overall condition and plan preventive interventions, as well as an accurately scaled point cloud to determine the exact morphology of the furnace and make informed long-term maintenance decisions.

To achieve all mission objectives effectively, WACO chose Flyability’s Elios drone due to its protective cage, capacity to fly in difficult places, versatility, and speed of execution without putting people’s safety at risk. In less than 2 hours, WACO completed four flights and was able to provide UNICALCE with all the required data, helping the company’s decision-making process and enabling it to plan timely interventions needed to ensure safety in the quarry furnace.

Penstocks are pressure vessels in the form of a channel or pipe that carry water down from a water reservoir directly into the turbines in a power station. Penstocks are widely used to produce clean energy in the hydropower industry. Penstocks require regular inspections to ensure the good condition of the inner surface and prevent potential damages that occur over the years due to continuous friction with high-pressure water.

One of the most adopted solutions for inspecting these hillside-built structures, including hard-toreach interior locations, is professional climber teams. However, this is a slow, time-consuming, and risky process, including descending through the penstock cavity and working in a confined space, in total darkness, with teams of 2 or 3 people. That’s why Spain-based Hovering Solutions, a designer and manufacturer of autonomous aerial robots for underground and GNSS-denied environments, developed a new generation of flying robots that fly autonomously through the interior of vertical or inclined pipes such as the penstocks.

According to the company, using these drones reduces the time needed for a regular inspection from days to only a few hours, decreases the costs by 50%, requires only 1 person to do the job, and removes most of the risks it involves.

Airpelago, a Sweden-based software company and service provider with BVLOS authorization, is using drones to perform low-, medium-, and high-voltage power line inspections worldwide. The company offers a complete flight solution, Airpelago Power, that turns drones into “autonomous bees” to conduct large inspection projects with 100% autonomous flights.

France’s power distribution network is one of the largest in Europe, spanning over 800,000 miles, and requires regular inspections to ensure reliable electricity delivery. By replacing helicopters with automated drones, Airpelago claims to save over 4,000 tons of carbon dioxide annually and detect up to five times more defects, leading to a higher-quality grid and proactive maintenance.

In 2022, Airpelago worked with a potential client in France, near Valence, south of Lyon, to demonstrate its technology throughout approximately 100 km of power lines in diverse terrains, ranging from flat farmlands to steep hillsides. By taking 6 high-quality images of each pole from different angles, Airpelago produced produce deliverables that not only met the client’s requirements but also surpassed initial expectations by completing the job in only two days.

Committed to protecting the environment and the climate, E.ON, Sweden’s largest DSO, always seeks climate-friendly solutions to minimize adverse environmental impacts. On the lookout for a green and efficient power line inspection solution that could be applied at scale, the company knew it had to get rid of helicopters and for the next big contender, drones.

After over two years of thorough full-scale inspections on 1200 miles of overhead line around Stockholm and Sundsvall, E.ON finally decided to initiate drone inspections of the company’s 15,000-mile-long high-voltage network. With the help of Airpelago, a drone service provider, E.ON successfully inspected approximately 6,300 miles, reducing carbon emissions by 35 tons for 2023. When fully implemented, E.ON expects emissions to be reduced by 100 tons annually.

“The experiments have also taught us that by using drones, we get the opportunity to thermograph larger parts of the electricity grid and, via temperature differences, find any hot passages that risk leading to a malfunction,” commented Martin Höhler, CEO of E.ON Energy Distribution. “At the same time, we have laser scanned the network to provide precise data on, for example, where the poles are, which laid the foundation for the drones to take care of themselves when the legislation allows.”

As the examples presented in this report show, European countries have embraced drones for inspection work and are enjoying the many benefits of uncrewed technology. The adoption of drone technology has been many years in the making. According to a recent report, the European Union (EU) “has invested almost €980 million in the development or use of drones for innovative applications” since 2003, and “it has funded 320 projects relating drones under its research and innovation programmes.”

The work continues as the continent’s Energy & Utilities sector is well on its way to fully integrating uncrewed technology. This integration will be spurred largely by the region’s commitment to clean energy development and overall sustainability.

A report by the International Energy Agency (IEA) stated that the “European Union (EU) is one of the leading regions for clean energy deployment and policy momentum has intensified in many countries, and at EU level, due to the global energy crisis that followed Russia’s invasion of Ukraine and its subsequent cut in gas deliveries.” The study explained that the EU’s “investment in renewables generation totaled almost USD 110 billion” in 2023. Moreover, the EU has “set a target to reduce net greenhouse gas emissions by at least 55% by 2030, relative to 1990 levels, and to reach climate neutrality by mid-century.”

Drones, with their ability to operate safely, efficiently, and quietly in a variety of environments while making little to no impact on the natural environment, are sure to be a central tool in helping the EU reach its targets.