We are delighted to proclaim that the Texas Coastal Bend stands as a proud testament to the resilience, innovation, and strength of American industry. From the bustling ports of Corpus Christi to the thriving refineries, steel mill, and energy facilities that dot the region, the Coastal Bend is a powerhouse of economic activity and opportunity, with more to come!

This region plays a vital role in fueling not only Texas, but the entire nation and many parts of the world. The Port of Corpus Christi—one of the largest in the country—moves millions of tons of goods each year, supporting global trade and securing America’s energy future. The petrochemical, oil refining, steel and other industries have made the Coastal Bend a hub for high-tech manufacturing and logistics, while new investments are paving the way for a very bright future.

Beyond the machinery and cargo ships are the right people—skilled, hardworking men and women who form the backbone of Coastal Bend industry. Welders, electricians, engineers, operators, technicians, and countless others bring knowledge, determination, and pride to their work each day. Their efforts drive growth, create jobs, and sustain families across the region. These powerful industries also contribute significantly to the financial stability and growth of the region and are very generous in their philanthropic involvement.

We salute the industries of the Texas Coastal Bend for their unwavering commitment to excellence, safety, and innovation. We honor the workers who have helped shape a legacy of progress and prosperity. As industry continues to evolve, the Coastal Bend stands ready to lead—powered by tradition, strengthened by community, and inspired by the promise of the future.

Dennis Wade Publisher

By Enbridge & Yara

The project’s design leverages the industry’s 100 years of continuous improvements in process safety as well as Yara’s century-long experience and approach — developing, operating and continuously enhancing ammonia facilities globally — which enabled safe operations at multiple facilities for over a decade.

As the emergence of Artificial Intelligence (AI) continues to rise to prominence in many arenas, industries both at home and abroad are continuing to look into the automated tools as the future of industry incorporates the advancements.

The rise of AI has been rapid in the last few years. According to the 2025 AI Index Report produced by Stanford University, AI investment in the United States boomed to $109.1 billion in 2024 - an increase of nearly 19% from the previous year. The report also said that used of AI in business has also accelerated, with 78% of businesses in 2024 reporting using AI in some form or fashion - up from 55% in 2023, according to the report.

And some local companies such as Cheniere have been looking

into using the tools as a way to maximize efficiency in transactions and more to keep pace with both others in the oil and gas industry as well as other industries.

Cheniere Supply Chain Center of Excellence lead Faraz Shahid said on an AI in Business Podcast this past January that the company was intrigued by the possibilities, and acknowledged that the future is now when it comes to carefully utilizing the available tools.

“…. What we are able to leverage AI around in terms of the biggest challenges we have (which) are probably around transactional efficiency,” Shahid said on the podcast. “…How do we, as an industry, become a lot more efficient and better at what we do versus some of the retail industries or other more technically-advanced industries that have leveraged some of these tools?”

Cheniere has one of the largest liquefaction platforms in the world, consisting of the Sabine Pass liquefaction facility, wholly-owned by its subsidiary Cheniere Energy Partners, L.P. and the Corpus Christi liquefaction facility, with a total combined production capacity of over 46 million tonnes per annum (“mtpa”) of LNG in operation and roughly an additional 13 mtpa of expected production capacity under construction or in commissioning.

The company is more than 80% of the way into its Corpus Christi Stage 3 project, and its board has given the go-ahead to Bechtel Engineering for the construction of two new Liquified Natural Gas (LNG) midscale liquefaction trains as part of its Stage III expansion, each of which are capable of producing up to 1.64 million metric tons of LNG per year according to officials. The trains will be build adjacent to the Corpus Christi Stage 3 Project, and in total consists of two midscale trains with an expected total liquefaction capacity of over 3 million tonnes per annum (“mtpa”) of liquefied natural gas (“LNG”) and other debottlenecking infrastructure.

Much of the oil and gas industry has data for days, Shahid said on the podcast, just as Cheniere does for its production and other factors. Much of it is unstructured data, however. And AI has started being used to help make sense of left and right and predictive models in the data, according to Shahid.

San Patricio County is rapidly becoming a regional benchmark for modern manufacturing.

Once known primarily for its agricultural output, the county has undergone a dramatic transformation over the past decade anchored by billions in industrial investment, world-class infrastructure, and a business-friendly climate.

Today, San Patricio County is the largest manufacturing hub in the Coastal Bend, and it’s showing no signs of slowing down.

Manufacturing now forms the backbone of San Patricio County’s economy, accounting for more than 10% of all local jobs. Over the last few years, the county has welcomed major investments from global industrial giants in steel production, petrochemicals, and advanced fabrication.

Adam Gawarecki, president and CEO of the San Patricio County Economic Development Corporation, said the arrivals of Steel Dynamics (2021) and ThyssenKrupp AG (2022) set the stage for more industries coming to the county.

“We weren’t very diverse until four years ago,” Gawarecki said. “But now we’ve become more responsible in how we develop, and we’re seeing a wider mix of industries come in.”

Steel Dynamics’ $2.1 billion flat roll steel mill is the largest of its kind in Texas. The project spans over 1,000 acres, creating a regional supply chain hub for raw materials and finished steel products.

Other high-profile developments in San Patricio County have been Cheniere’s $23 billion liquid natural gas plant and a $7 billion ExxonMobil/ SABIC steam cracker facility. The county has seen $37 billion in capital investment in the last decade.

There’s a logical reason San Patricio County is a popular choice. Its location along the Gulf Coast gives the county unmatched access to Port Corpus Christi – one of the largest ports in the nation – as well as the Port of Aransas, both accessible via the La Quinta Channel.

This infrastructure allows industries to move raw materials and finished goods by sea, rail, and highway with maximum efficiency.

The county is also part of a deregulated electricity market and boasts a modern, industrialgrade power grid supported by AEP Texas and the San Patricio Electric Cooperative. These utilities ensure reliable and cost-effective power, which are essential for heavy manufacturing.

Covering nine cities and over 443,000 acres, San Patricio County still has room to accommodate more industrial expansion. Approximately 85% of the land is undeveloped, providing a long runway for future projects.

“We’ve got a new industrial master plan that’s

about to come out,” Gawarecki said. “It’s based on land owned by Exxon and others. We want industrial development in the right places, and we’ve mapped those out.”

The county also offers some of the lowest costs of land, labor, and taxes in the region, making it a top-tier destination for global manufacturers.

“In the last year and a half, we’ve generated 180 total leads,” Gawarecki said. “And right now I feel like we’ve got nine good projects going.”

The labor force is robust with over 29,000 workers in the county and more than 260,000 across the greater Coastal Bend region. A skilled workforce, combined with technical education programs and proximity to institutions like Del Mar College and Texas A&M University-Corpus Christi, ensures that manufacturers have access to qualified talent.

San Patricio County is also showing promise in green energy manufacturing and renewables. Wind power, in particular, plays a growing role. The Papalote Creek Wind Farm operates 196 turbines that can power over 114,000 homes, while saving hundreds of thousands of tons in carbon dioxide emissions annually.

Supporting the manufacturing surge is a booming construction sector – the county’s leading private employer. Construction activity ranges from new industrial sites to infrastructure improvements that support port and rail logistics.

San Patricio County is also home to several companies in support industries such as mechanical services, trucking, pipeline construction, and maintenance operations. This cluster effect reinforces the county’s value as a comprehensive industrial ecosystem.

Though no longer the county’s economic engine, agriculture remains part of the broader landscape. San Patricio County continues to produce cotton, grain sorghum, and cattle, contributing roughly $300 million annually to the local economy.

Legacy operations like cotton gins, grain elevators, and tractor dealerships remain part of the rural business community, even as the county tilts toward industrial development.

One challenge facing both industrial and residential growth is water. Regional drought conditions and limited reservoir levels have slowed expansion plans in some areas.

Efforts to address water availability through pipeline expansion, desalination research, and shared resource planning are underway to ensure that San Patricio County remains viable for According to Gawarecki, with competitive infrastructure, ample land, and strong leadership, San Patricio is laying the foundation for even more long-term, sustainable growth.

n Coy Slavik, Editor

From PREVIOUS PAGE

“What we’ve started to see is the acceptance to the use of generative and predictive AI to structure that data but also work with that unstructured data to have better databases and embedded models where that knowledge base can be used for generative as well as predictive AI,” he said.

And regardless of how it gets used, Shahid said Cheniere was taking great care to look into the viability of AI to help in their transactional efficiency and other aspects of industry in which in could be used.

“I think there’s more of a (space) for predictive AI right now, because using that data there are more of those lowhanging fruits that are accessible. But we’re also seeing the use of Chatbots and generative AI - which we’re looking into with great curiosity, because there is a future in that space,” Shahid said on the podcast. “Whether it’s in the sourcing space, contracting space, inventory management space, those digital tools - whether they’re in the predictive modeling or Chatbot/generative AI - are definitely there.”

However, Shahid said in January that the use of AI is not all-powerful or onesize-fits all, and it is not as simple as a plug and play. He acknowledged during the podcast that one of the first questions springing to mind is ‘how many human jobs will be replaced?” But according to Shahid, the transition is not so linear.

He said there are so many factors which go into AI decisions - not least of all how it affects the workforce and the nature of jobs in the future. And it’s a future, he said, that is coming fast.

“…. It becomes harder to quantify, because the nature of the workforce going forward will need to change,” he said on the podcast. “Eventually there are going to be more jobs, but the nature of the jobs is going to be different…. It’s not a simple case of ‘by introducing this AI, I will get rid of three head counts’.”

n Landan Kuhlmann, Writer

When Stephanie Hajducek began This One’s For The Gals to introduce school-age girls to potential careers in industry, she said it started as a simple field trip. Now, she said, it has turned into a mission that evolves along with the industries in feeds into.

Hajducek is the founder of Sinton-based nonprofit organization This One’s For the Gals. The organization’s mission is working to help girls learn about potential career

pathways in industry lines of work such as construction, energy, manufacturing and maritime. And what began as a hope, has now turned into reality.

According to Hajducek, TOFTG began as one-time trip to the POWER Women in Industry Conference in Galveston last yearwhere she was hoping to get maybe 10 girls in the room - has morphed into what she calls a “movement.”

“That first year, we ended up bringing

Sinton-based This One’s For The Gals is looking to open doors to industry for young women all around the Coastal Bend. And founder Stephanie Hadjucek says they are evolving alongside industry.

over 200 girls from every high school in San Patricio County as well as Rockport-Fulton and Refugio,” Hajducek said. “Many of them had never stayed in a hotel, never been to a conference, never imagined that careers in construction, energy, manufacturing, or maritime were even an option for them. That night, I realized TOFTG was no longer just a field trip - it was a mission.”

As it evolves, Hajducek said TOFTG is now an expansive 501(c)(3) nonprofit which partners with school districts, industry leaders, community partners and workforce development organizations to connect young women to high-wage, high-demand careers. And it’s more than just an idea, according to Hajducek - it’s about introducing avenues they might not have known are available to them by which to enter those industries.

Those avenues include dual credit programs, certifications, degrees, internships, real-life mentorship, and more.

“Our mission is rooted in access and visibility. I always say ‘Girls can’t be what they can’t see.’ We want to reach them early - before the world convinces them that certain careers ‘aren’t for them,’” Hajducek said. “And we want to make sure they’re not just included but truly supported through every stage of life - whether they’re graduating high school, going back to school later in life, starting families, or stepping into leadership.”

The organization itself is not all that has evolved in the time since Hajducek founded TOFTG. She said since its inception, she has seen a significant shift in how industry views its role in education. Before, she said, outreach was a courtesy or charity.

Now, she said, industry is beginning to adapt to a role of being a strategic workforce development. And she said she recently spoke with a Vice President of Human Resources for an industry business who said they are viewing recruiting differently.

“That mindset shift is powerful,” Hajducek said.

And TOFTG, she said, is evolving alongside the industries they aspire to have

students be part of. The organization’s curriculum and programming now includes hands-on workshops, career and education expos, curriculum integration, and storytelling tools such as bilingual children’s books to meet students where they’re at.

It’s more than an organization - it’s a organization with a mission that it is dead set on completing to help every student they can reach their potential.

“This work isn’t just about workforce numbers or talent pipelines - it’s about changing lives. It’s about breaking cycles and building futures in communities that have long been overlooked,” Hajducek said. “And if one girl can walk away from a TOFTG event and say, “I didn’t know this was for me - but now I do,” then we’ve done

our job. And we’re just getting started.” For more information about This One’s For the Gals, community members can visit their website at thisonesforthegals.com.

n Landan Kuhlmann, Writer

Large carriers and vessels are shown making their way through the Corpus Christi Ship Channel and the Port of Corpus Christi. The Port recently closed its second quarter and first half shipping periods, with both marks setting new records for their respective periods in the Port’s history. (Photos from Facebook)

The Port of Corpus Christi has been on a record run of late in terms of moving products through its ports, and that trend continued as the Port recently closed its second quarter and first half shipping period of 2025.

On July 15, the Port announced that customers moved 51.1 million tons of commodities through the Corpus Christi Ship Channel in the second quarter of 2025 and 102.4 million tons through the first half of 2025 as of the end of June.

Both marks, according to a news release from the Port, were a second quarter and first tonnage record - respectively - for the Port in terms of moving product through. The previous second quarter record had been 50.6 million tons in 2024, according to the Port, while the previous first half record was 99.5 million.

A big part of why the tonnage has shot to record highs appears to be a byproduct of a widened and depended ship channel, according to the Port. Earlier this year, the Port completed work on a project which deepened the main channel to 54 feet from 47 feet, widened the channel to 530 feet in most places, and added barge shelves to the longest portion across Corpus Christi Bay.

The project was done, officials, previously said, in order to help accommodate larger vessels moving through the channel. The project and initiative, which ultimately cost about $625 million when all is said and done, was a joint venture between Congress and the Port of Corpus Christi with support from the U.S. Army Corps of Engineers (USACE) and private marine companies.

And the Port said the depended, widened waterway enables more efficient transport of crude oil, liquefied natural gas and other commodities.

Crude oil shipments in H1 2025 totaled 65.2 million tons according to the news release, which was up nearly 4% over the same period last year, while LNG volumes grew nearly 11% up to 8.5 million tons according to the Port.

“We are proud to support a community of customers who continue to rise to the demands of the evolving global market,” Port of Corpus Christi Chief Executive Officer Kent Britton said in the release. ““The Corpus Christi Ship Channel Improvement Project established this Port as the number one port for crude oil exports, and we remain committed to providing our customers access to the infrastructure needed to ensure continued economic growth.”

n Landan Kuhlmann, Writer

Gulf Coast Growth Ventures President and Site Manager

Paul Fritsch (second

presents a check to Buc Days representatives.

GCGV has partnered with the organization for STEM activities at Buc Days the last two years.

Good Neighbor

building long-term partnership with Coastal Bend GCGV IS PROUD TO BE PART OF THE COASTAL BEND. WE WORK HERE AND LIVE HERE WITH OUR FAMILIES, AND WE ARE INVESTED IN THE FUTURE OF THIS THRIVING COMMUNITY.”

“

— GULF COAST GROWTH VENTURES, A JOINT VENTURE BETWEEN EXXONMOBIL AND SABIC

Gulf Coast Growth Ventures, a joint venture between ExxonMobil and SABIC, is continuing its efforts to deepen its roots in the Coastal Bend region with its Good Neighbor Program – a wide-ranging community initiative aimed at improving health and safety, protecting the environment, investing in education and workforce development, and enhancing overall quality of life.

The program, developed in collaboration with local stakeholders, is part of GCGV’s philosophy of long-term, sustainable engagement with the community where it operates, according to the company. Since the early planning stages of the multibilliondollar petrochemical project, the company has held hundreds of meetings with neighborhood groups, local governments, civic organizations, and business chambers to identify local priorities and shape its social responsibility agenda.

“We’re here for the long term. We live here too,” the company stated, underscoring

its commitment to being not just an employer, but a community partner.

According to the company, every employee is highly trained to ensure safe and responsible operations, supported by modern equipment and an Operations Integrity Management System designed to minimize risk and uphold rigorous performance standards.

GCGV benefits from the broader safety culture of its parent companies. Both ExxonMobil and SABIC are certified Responsible Care companies under the American Chemistry Council, a recognition reserved for chemical manufacturers that demonstrate outstanding performance in environmental, health, safety, and security.

Responsible Care companies have: • A worker safety rate five times better than

the U.S. manufacturing sector,

• Reduced safety incidents by 51% since 1995,

• Lowered recordable injury and illness rates by 79% since 1990,

• And improved energy efficiency by 25%, while cutting greenhouse gas intensity by 29% since 1992.

GCGV says these industry-leading standards are embedded in day-to-day operations at its facility in San Patricio County.

GCGV’s environmental commitment extends beyond its facility’s boundaries. Its operations are guided by a robust Safety, Health & Environmental (SH&E) program that was integrated into the plant’s design and continues through operating procedures and investments.

The company works closely with local environmental organizations, including the Coastal Bend Bays and Estuaries Program, supporting habitat restoration, environmental research, and education programs. GCGV employees also regularly volunteer in shoreline cleanups, native planting projects, and community beautification efforts.

“We are safe, responsible stewards of our hydrocarbons,” the company says, “and our volunteer efforts aim to ensure the Coastal Bend remains a beautiful and resilient place to live.”

Recognizing that the future of the Coastal Bend depends on a skilled and educated workforce, GCGV has made substantial investments in local education and career readiness programs:

• $1.5 million was donated to Del Mar College to help establish a process technol-

ogy training center, equipping students with the skills needed for careers in industrial operations.

• The company awarded $114,000 in scholarships to students pursuing process technology degrees.

• An additional $100,000 went to the San Patricio Workforce Development Consortium, which supports vocational training and job placement in high-demand fields.

GCGV also engages students early, sponsoring STEM Days at area schools, providing school supplies and equipment, and forming partnerships with local high schools, colleges, and trade programs.

“We are committed to helping prepare tomorrow’s workforce — today,” the company stated.

Beyond jobs and infrastructure, GCGV’s fourth pillar focuses on making the Coastal Bend an even better place to live. The company supports local nonprofits, youth and

family programs, and community infrastructure improvements.

GCGV says its mission includes “enhancing quality of life across the region,” and it backs this up with support for neighborhood revitalization, public safety programs, local events, and disaster recovery efforts.

“GCGV is proud to be part of the Coastal Bend,” the company emphasized. “We work here and live here with our families, and we are invested in the future of this thriving community.”

As the facility transitions from construction to full operation, GCGV leaders say they will continue listening to the community and adapting the Good Neighbor Program to meet evolving needs. The initiative, they say, is not just a corporate responsibility checklist, but a long-term commitment to the wellbeing of the region.

From environmental restoration to workforce development and public safety, the company says it is positioning itself not just as an industry leader – but as a trusted neighbor.

The Valero Three Rivers Refinery, located halfway between San Antonio and Corpus Christi, continues to stand out as a vital part of South Texas—both as a major industrial operation and a cornerstone of community support.

The refinery began operations in 1974 and was acquired by Valero in 2002. Today, it spans 400 acres in the heart of Three Rivers and employs more than 300 workers. With a throughput capacity of 100,000 barrels per day (bpd), the facility plays a key role in regional fuel production and distribution.

The refinery produces a broad range of petroleum products, including gasoline, diesel, jet fuel, benzene, toluene, xylene, liquefied petroleum gases (LPGs), propylene, fuel oil, sulfur, fuel gas, and naphthenic lubricants. Crude oil, mostly sourced from West Texas and the nearby Eagle Ford Shale formation, arrives via third-party pipelines and trucks. Finished products are shipped primarily by pipeline to terminals in San Antonio and beyond.

The Three Rivers Refinery has also been recognized as an OSHA Voluntary Protection Program (VPP) Star Site, one of the highest workplace safety designations in the country. The site recently earned the American Fuel and Petrochemical Manufacturers (AFPM) Elite Gold Award, placing it in the

n $250,000 to Atascosa Health Center for a new medical clinic in Three Rivers

n More than $200,000 to the Live Oak County Boys & Girls Clubs over five years

n Funding for 100 laptops for local fifth and sixth grade students and their teachers

top five percentile for safety performance among its peers.

In addition to industrial success, Valero has consistently demonstrated a strong commitment to local giving and service. Since 2017, the refinery has contributed more than $7.1 million to area charities and logged more than 20,000 hours of employee volunteer time. In 2024, refinery employees raised more than $583,500 for the United Way of the Coastal Bend. The Valero Texas Open Benefit for Children alone generated $240,000 in local donations this year, benefiting nine area children’s charities.

Among the refinery’s other recent charitable efforts:

• $250,000 to Atascosa Health Center for a new medical clinic in Three Rivers

• More than $200,000 to the Live Oak County Boys & Girls Clubs over five years

• Funding for 100 laptops for local fifth and sixth grade students and their teachers

In 2019 alone, the refinery provided $320,000 to local charities, generated $5.8 million in local property taxes, and employ-

ees volunteered 2,971 hours.

The site’s commitment to sustainability has also drawn praise. The refinery has reduced Title V events—related to air quality—by 80% since 2013, including a 30% reduction year over year. In 2019, the South Texas Energy and Economic Roundtable recognized Valero for Environmental Stewardship, highlighting the refinery’s innovative program that uses treated wastewater to irrigate 1,438 acres of local farmland, generating 3,000 bales of hay annually.

The refinery continues to invest in its infrastructure and workforce. A new 42,000-square-foot administration building is expected to open in 2020, enhancing operations and employee experience.

As one of the largest employers in the area and a key economic driver, the Valero Three Rivers Refinery remains focused on safe, efficient production and strong community partnerships—values that refinery officials say will guide its work for years to come.

n Dylan Dozier, Writer

Steel Dynamics recently announced each of the company’s steel mills achieved Global Steel Climate Council product certification.

In July, Steel Dynamics, Inc., announced that all of its steel mills have achieved product certification from the Global Steel Climate Council (GSCC), validating the company’s progress toward aligning with the Paris Climate Agreement’s 1.5°C emissions scenario.

The GSCC’s Steel Climate Standard certifies steel products based on their greenhouse gas (GHG) emissions intensity, providing customers with transparent, third-party-verified data to support lowercarbon purchasing decisions. The standard includes Scope 1, Scope 2, and upstream Scope 3 emissions through the hot rolling phase of steel production and is aligned with the International Energy Agency’s Net Zero by 2050 roadmap.

Each of Steel Dynamics’ steel mills had their 2024 emissions data verified by thirdparty firm KERAMIDA and certified by the GSCC.

“Steel is an integral component of the

Occidental Petroleum Corp. and its carbon capture subsidiary 1PointFive announced in May a strategic agreement with XRG, the investment arm of the Abu Dhabi National Oil Company (ADNOC), to evaluate a potential joint venture for a Direct Air Capture (DAC) facility in South Texas.

As part of the agreement, XRG is considering an investment of up to $500 million in the project, which would support the development of a DAC facility designed to capture 500,000 tonnes of carbon dioxide annually. The agreement was signed by Occidental President and CEO Vicki Hollub and ADNOC Group CEO Dr. Sultan Ahmed Al Jaber during U.S. President Donald Trump’s state visit to the United Arab Emirates on May 16.

“We are proud to advance our decadeslong partnership with ADNOC and XRG on our South Texas DAC Hub, which we believe will deliver game-changing technology to support U.S. energy independence and global goals,” said Hollub. “Agreements like this, along with U.S. DOE support, demonstrate continued confidence in DAC as an investable technology.”

The announcement follows a string of developments in Occidental’s carbon capture strategy, including progress on its first DAC facility, STRATOS, in West Texas, which is expected to begin commercial operations later this year. The company also recently received up to $650 million in U.S. Depart-

ment of Energy funding to support the South Texas DAC Hub.

The planned DAC hub, located on the historic King Ranch in Kleberg County, Texas, encompasses roughly 165 square miles and is situated near major industrial and energy infrastructure along the Gulf Coast. The site is expected to offer up to 3 billion tonnes of CO₂ storage capacity in nearby geologic formations.

“The U.S. is a priority market for XRG,” said Khaled Salmeen, Chief Operating Officer of XRG. “Our longstanding partnership with Occidental continues to drive scalable, high-growth and strategically attractive projects that create long-term sustainable value.”

Occidental and ADNOC have been collaborating on carbon capture and storage initiatives since signing a memorandum of understanding in 2023. The companies also partner on major energy developments in the UAE, including the Al Hosn Gas project.

The proposed DAC facility is currently in the front-end engineering and design phase.

Mark D. Millett, co-founder and chief executive officer of Steel Dynamics, Inc., was recently named Harbor Aluminum’s Gene Greenberg 2025 World’s Aluminum Executive of the Year.

The prestigious award honors individuals who have made significant technical advancements or transformative contributions to the aluminum industry while demonstrating integrity and leadership.

“Mark has driven innovation, while creating an entrepreneurial, passionate team that drives toward excellence in all that they do,” said Theresa E.

Wagler, executive vice president and chief financial officer of Steel Dynamics. “We are incredibly proud of him as he receives this peer recognition for his contributions to the aluminum industry so far, and for what lies ahead.”

Millett, who co-founded Steel Dynamics in 1993, has guided the company’s evolution into one of North America’s leading industrial metals firms, with more than 13,000 employees. While best known for his leadership in the steel sector, Millett has recently overseen the company’s strategic expansion into aluminum, including

the development of a state-ofthe-art recycled aluminum flat rolled products mill and two aluminum recycling slab centers.

He has served as Steel Dynamics’ CEO since 2012 and was named chairman of the board in 2021.

Harbor Aluminum’s Gene Greenberg award recognizes individuals who have reshaped the aluminum industry through innovation and long-term vision. Millett’s recognition highlights Steel Dynamics’ growing footprint in sustainable metals and its commitment to technological progress in both the steel and aluminum sectors.

Mark D. MIllett

Steel Dynamics, Inc., recently received a Volkswagen Group Award for sustainability, recognizing its proactive efforts in low-carbon steel production and circular economy practices.

Volkswagen Group honored Steel Dynamics as part of its annual supplier awards, which recognize outstanding performance and long-term collaboration across 10 strategic categories within its global supply network.

“We value the long-term collaboration with Volkswagen Group and are proud to be recognized for our sustainability leadership,” said Mark D. Millett, chairman and chief executive officer of Steel Dynamics. “This recognition is due to our team’s ex-

traordinary drive, innovation and commitment to excellence.”

In a separate honor, Millett was named Harbor Aluminum’s Gene Greenberg 2025 World’s Aluminum Executive of the Year. The award recognizes industry leaders with integrity who have made significant contributions to improving or transforming the aluminum sector.

“Mark has driven innovation, while creating an entrepreneurial, passionate team that drives toward excellence in all that they do,” said Theresa E. Wagler, executive vice president and chief financial officer. “We are incredibly proud of him as he receives this peer recognition for his contributions to the aluminum industry so far, and for what lies ahead.”

Millett co-founded Steel Dynamics in 1993 and has led the company as CEO since 2012, becoming chairman of the board in 2021. Under his leadership, the company has grown into one of North America’s largest steel producers and metal recyclers and has recently expanded into aluminum with investments in a state-of-the-art recycled aluminum rolling mill and two aluminum recycling slab centers.

Headquartered in Fort Wayne, Indiana, Steel Dynamics operates a circular manufacturing model, using recycled scrap to produce lower-carbon steel and aluminum products for the automotive, industrial, and beverage markets.

In the wide, flat fields of South Texas, usual to see rows of crops vanish into the as guitar strings.

It’s not just a testament to a steady ing wheel, it’s also the work of GPS-guided smart planters.

“Nearly every farmer has GPS on their They don’t even drive the tractors anymore them around. That’s about it,” said Bob cio County’s Texas A&M AgriLife extension ogy has taken over the operation. That’s hardly ever see a crooked row.”

The integration of this type of smart idly changing agriculture as we not-so-long-ago

Texas, it’s no longer unthe horizon straight steady hand on the steerGPS-guided tractors and their tractors now. anymore except to turn McCool, San Patriextension agent. “TechnolThat’s the reason you smart technology is rapnot-so-long-ago knew it,

and it isn’t just revolutionizing farming. Ranchers in South Texas are also beginning to implement smart systems to manage livestock and their pocketbooks.

“It's all about efficiency and getting things accomplished in a short period of time,” McCool said.

In many crop fields, machines still hum, but they’re humming with artificial intelligence, smart sensors, and automation at their core. McCool has had a front-row seat to witness this transformation over the last several years, and he says it’s not just a passing trend.

“The smart planters raise and lower and they do things that we don’t really pay attention to anymore,” McCool

said. “But once they set it to two inches – if they hit a hard or soft spot – the planter picks itself up. It’s crazy.”

The sensors also adjust power usage depending on field conditions.

“There are sensors that tell them if they’re running really shallow and going really fast, and the horsepower cuts back automatically,” McCool said. “Instead of burning 10 gallons of fuel an hour, it’s only burning six gallons of fuel an hour.”

One of the more futuristic tools now gaining traction is the use of drones. While drone technology is

For high school seniors and other students aiming to enter the workforce with a two-year degree, Coastal Bend College’s Industrial Mechanics program offers a clear and hands-on path to a career in the industrial sector.

“We’re operating on all different types of industrial machinery that can coincide with all fuel refineries, manufacturing, production and even renewable energy,” said Industrial Mechanics Professor Robert Molina. “We offer that here at the Alice campus … We have a brand new state-ofthe-art industrial mechanics lab. We have a dedicated lab for every course that we offer in the industrial mechanics program. And another great plus is that we also offer it online as well.”

Located in a region long associated with oil and gas production—and now attracting a growing number of manufacturing and renewable energy projects—Coastal Bend College is positioned to meet the rising demand for skilled industrial workers.

“The great thing about it is that there’s

From PREVIOUS PAGE

still developing, its presence on the farm is steadily growing.

“They can count bolls on cotton with drones. They can tell you how tall and how healthy the plants are,” McCool said. “They’re also doing some actual agricultural spraying with drones.”

While traditional crop dusters still have a place – especially for urgent jobs or when fields are too wet to drive machinery –many farmers have opted to invest in large automated sprayers and applicators with extensive boom arms.

“Just nearly every farmer that has very many acres has a spray machine,” McCool said. “They can run 15 miles an hour through those fields with 120- to 150-foot widths. There are even spray machines that only spray if they spot a weed.”

Smart technology is also evolving the role of an American icon. Thanks to AI and other emerging technologies, many cowboys are now analyzing data on their cell phones as much as lassoing dogies.

“They’ve got virtual fences where they put basically a low-voltage shock collar on cows,” McCool said. “You can just put a GPS fence around an area. If they’ve been some-

WE’RE OPERATING ON ALL DIFFERENT TYPES OF INDUSTRIAL MACHINERY THAT CAN COINCIDE WITH ALL FUEL REFINERIES, MANUFACTURING, PRODUCTION AND EVEN RENEWABLE ENERGY.”

— INDUSTRIAL MECHANICS PROFESSOR ROBERT MOLINA “

obviously a really high demand in the industrial field … The program is very broad, right? So let’s say you’re taking the weld-

what trained with that collar, they won’t go past where you want. You don’t have a fence there, but it keeps them in an area.”

Ranchers are also employing advanced water monitoring systems, which can be lifesavers both literally and financially.

“They’ve got what they call a RanchBot,” McCool said. “It’s put on your water system and it satellites back to your phone. It lets you check your water troughs and water sources. If there’s a problem, it shows up on your phone.”

This remote capability is especially useful for large ranches where it might otherwise require hours of driving to check water tanks in person.

“Those systems are still pretty expensive, though,” McCool said. “Only big places that can justify not having to have full-time hands checking water every day can afford them at this moment in time.”

Perhaps the strangest development in ag-tech is facial recognition – of cattle.

“They can actually facially recognize cattle to 99% positivity,” McCool said. “It has been tested and is very reliable. It just hasn’t hit big on the market yet. But it will.”

While it may have taken some time for older farmers and ranchers to embrace this new wave of smart technology, most have come around.

ing program … Well, you’re pretty much pigeonholed into welding,” Molina said. “Same thing with other different programs, but with industry mechanics, it’s so broad with the oil field, the refineries, manufacturing, production, assembly lines and even the wind farms and the solar farms. So you’re literally learning different traits of industry.”

Students pursuing an Associate of Applied Science (AAS) degree in Industrial Mechanics at CBC gain both classroom knowledge and hands-on experience. The curriculum is designed to prepare graduates for careers involving the maintenance, operation and troubleshooting of complex industrial equipment.

Coursework includes Industrial Maintenance, Electrical Theory and Circuits, Hydraulics and Pneumatics, Motor Controls, Process Control Theory, Programmable Logic Controllers (PLCs), Pumps, Compressors, Mechanical Drives, Wind Power and Industrial Troubleshooting.

F See CBC, Page 32

“Several years ago, no. Now? They’ve all adapted unless they’re a smaller farmer or rancher, and there’s not very many of those left,” McCool said.

Still, even for those who are fully onboard, it can be a learning curve.

“These systems are very complicated,” McCool said. “Even the tractors. A lot of those guys spend time on the phone with consultants from whatever company their technology came from. It's just like knowing the pathways on your computer. It may take you learning several steps you’re not familiar with.”

As more data becomes available and prices for these advanced tools come down, it’s likely that even more of South Texas’ ag operations will adopt AI-driven platforms, drones, and smart monitoring systems.

Keeping up with the latest in technology has also become increasingly important as older generations of farmers and ranchers retire and fewer hands are available to work the land. With technology, one operator can do the work that previously took several laborers.

“There is so much out there,” McCool said. “There’s just lots and lots of the farms and ranches that are done with some sort of technology now. There are very few nonautomated systems out there anymore.”

n

Coy Slavik, Editor

The shrimping, fishing, and oystering industries are cornerstones of life in Aransas and San Patricio counties, sustaining the economy and cultural heritage of communities. Despite facing significant challenges, the three industries remain defining features of the Coastal Bend.

A 2023 Texas Sea Grant report estimates that the shrimping industry supports approximately 5,000 jobs statewide and generates $265 million annually, with Aransas and San Patricio counties contributing significantly through active harbors like Conn Brown in Aransas Pass. The industry supports not only shrimpers but also related businesses, from boat maintenance to seafood processing, making it a vital part of the Coastal Bend’s economy.

Shrimpers face mounting pressures from global competition and rising costs. Over 90% of shrimp in the U.S. market comes from imports, primarily from countries like Ecuador, India, and China, driving down prices for local shrimpers.

“The price of shrimp is so low now, it’s like giving it away,” said Long Nguyen, a longtime Rockport shrimper.

High fuel costs, often exceeding $3 per gallon, and federal regulations, such as the annual closure of federal waters from May 15 to mid-July, further erode profitability.

“You go out at six in the morning, but you have to come back by two,” Nguyen added.

“It’s hard to make money like that.”

Shrimping is deeply embedded in the region’s identity. The annual Aransas Pass Shrimporee, held every June at the Civic Center, celebrates this heritage with food, music, and family-friendly entertainment, drawing thousands and providing a seasonal boost to local businesses. Events like the Rockport-Fulton Seafair also highlight shrimping, featuring shrimp-based dishes and fostering community pride. These traditions keep the industry’s legacy alive, connecting generations of coastal residents.

The same Texas Sea Grant report states the Aransas Bay System alone generates $122.7 million annually from the fishing industry, which supports over 1,200 jobs in roles such as fishing guides, lodging providers, bait shops, and tackle suppliers.

Rockport-Fulton, known as the “Redfish Capital of Texas,” attracts anglers nationwide, boosting tourism and infusing millions into the local economy. Events like the RockportFulton Fishing Expo and Port Aransas’s Deep Sea Roundup, now in its 89th year, further enhance economic

activity by promoting sportfishing and coastal tourism.

Fishing is deeply woven into the fabric of the local coastal communities. Traditions, such as the RockportFulton Seafair held every October, celebrate the region’s marine heritage with seafood tastings, boat parades, and fishing-related activities. Monthly Rockport-Fulton Market Days at the festival grounds near Rockport Harbor provide a platform for local fishermen to connect with consumers, reinforcing community ties.

Nguyen said he sees his sons carrying on the tradition as recreational fishing guides.

“They’re taking what I taught them and building something new,” he said. “That’s what keeps the

tradition alive.”

The fishing industry faces challenges, including environmental threats like declining water quality and habitat loss. Initiatives like Texas Sea Grant’s ForHire Fishing Guide certification promote sustainable practices, while the Aransas County Navigation District emphasizes the importance of clean water to maintain healthy fish populations.

Community-driven events and conservation programs ensure that fishing remains a viable industry, blending tradition with efforts to protect the marine environment.

With ongoing support from local organizations like the Aransas Pass Chamber of Commerce and continued investment in conservation, the fishing industry is poised to remain a vital part of the Coastal Bend’s economy and culture. The resilience of families like Nguyen’s and the region’s commitment to its marine heritage ensure a bright future for fishing in Aransas and San Patricio counties.

From PAGE 16

global economy and foundational to the world’s essential infrastructure,” said Mark D. Millett, chairman and chief executive officer. “The GSCC product certification is recognition that lowerembodied carbon steel products necessary for the transition to a lower-carbon global economy are available now.”

Steel Dynamics, one of North America’s largest steel producers and recyclers, has made aggressive progress toward its sustainability targets.

The company met its 2025 GHG emissions intensity and renewable electricity goals ahead of schedule in 2023 and introduced science-based emissions targets certified by the GSCC in 2024.

“Even though our emissions intensity is already among the lowest in the industry, these achievements and our actionable path forward highlight our commitment to further reducing our carbon impact,” Millett said.

The GSCC is a non-profit organization focused on establishing a globally applicable, science-based standard for emissions reduction in the steel industry.

Oystering provides essential employment in harvesting and processing, particularly in areas like Rockport-Fulton and Aransas Pass. While specific economic data is limited, restoration efforts in bays such as Carancahua and Tres Palacios highlight the industry’s importance.

A $399,816 oyster reef initiative in Tres Palacios Bay, funded by groups like the Matagorda Bay Mitigation Trust, underscores the dual role of oystering in supporting jobs and rebuilding marine habitats, which in turn enhances ecotourism and fishing opportunities.

The oystering industry contends with numerous hurdles, including labor-intensive work, dependence on weather conditions, and environmental threats like habitat loss and declining water quality. Ghost fishing losses, estimated at $170,000 annually in nearby bays, add further pressure. Programs like Texas Sea Grant’s annual crab trap removal initiative help mitigate these losses, but ongoing efforts are needed to ensure the industry’s sustainability.

Oystering is celebrated as part of the region’s broader marine heritage. The Rockport-Fulton Seafair, held annually in October, features seafood tastings that

showcase local oysters, drawing thousands of visitors and boosting small businesses. Monthly Market Days at Rockport Harbor also provide oyster harvesters a direct-to-consumer outlet, strengthening community ties and promoting the industry’s cultural value.

Local organizations, including Texas Sea Grant and the Aransas County Navigation District, are working to support oystering through habitat restoration and water quality initiatives.

“If the water isn’t clean, the oysters suffer,” Nguyen said.

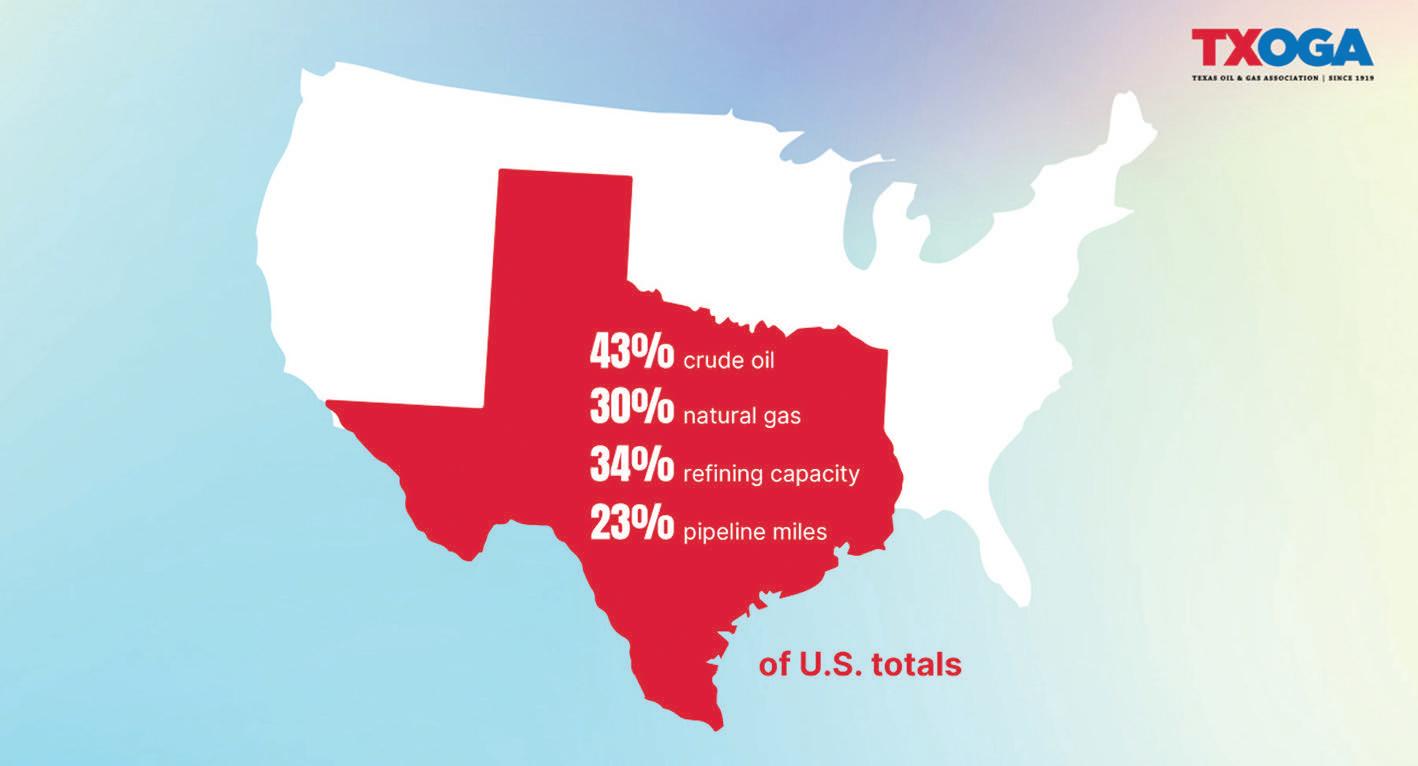

The Texas oil and gas industry continues to anchor the state and national economy, delivering record production, tax revenue, and energy security, Texas Oil & Gas Association President Todd Staples said during a presentation on July 28 at the Coastal Energy Series.

Speaking to a gathering of energy professionals and community leaders, Staples emphasized the industry’s expanding impact, pointing to record-high oil and gas production and surging exports from the Gulf Coast.

Staples spoke specifically of the Coastal Bend region’s natural gas exports.

Safety practices are a key part of the program, with students learning proper use of safety equipment and procedures in both lab and industrial settings. Instruction also covers workshop maintenance, tool storage, and safety guidelines for equipment operation.

Students apply these principles through lab-based training, performing Preventive and Corrective Maintenance on rotary equipment, wiring systems, mechanical drives, and VFD/PLC communications. Advanced topics include Laser Alignment, Vibration Analysis, and Process Control

Students also learn to work with AC/ DC voltage and current in both series and parallel circuits. They practice using measurement tools, circuit protection devices, control relays, and metering equipment to diagnose and repair electrical, mechanical and electromechanical systems. Additional instruction includes Basic PLC Programming, Motor Controls, Ladder Diagrams, Lockout/Tagout procedures, Controller Operations, Power Supply Filtration, and Basic Hydraulics and Pneumatics.

All lab courses are designed to simulate real-world industrial environments, equipping graduates with the practical skills needed to move directly into the workforce.

In addition to standard tuition, students

“Exports of natural gas across the globe is changing the global landscape, much of that through LNG right here with Cheniere in Corpus Christi,” he said. “So we want to celebrate the things that are making the Texas economy strong but also stabilizing our world with global energy security.”

When questioned about the possibility of new energy facilities in the region, Staples stated that the state possesses the required resources and capacity.

Texas currently ranks third in the world for natural gas production – behind only the United States as a whole and Russia – and fifth globally in crude oil production. The state has also become a critical hub for liquefied natural gas (LNG) exports, helping meet rising demand from U.S. allies in Europe and Asia.

According to TXOGA, LNG exports from the U.S. are expected to reach 24 billion cubic feet per day by 2030, with nearly half of that volume flowing through Texas ports.

Staples also defended the industry’s environmental record, citing reductions in methane emissions and increased investment in carbon capture, utilization and storage (CCUS) technologies.

The Coastal Energy Series continues as part of the association’s broader effort to promote dialogue and insight across Texas energy sectors. This year’s event, held in Corpus Christi, focused heavily on innovation, infrastructure and workforce development.

are responsible for lab fees tied to hands-on courses. These fees cover materials, tools, and consumables used in training. The exact cost depends on the specific course and student requirements, and detailed information is provided in course syllabi. Faculty members are available to answer questions regarding fees and course expectations.

The AAS in Industrial Mechanics program at Coastal Bend College blends academic instruction with practical application, giving students the tools they need to succeed in industrial maintenance and operations across a wide range of sectors.

For more information, visit http://coastalbend.edu/industrialmaintenance/. n Dylan Dozier, Writer

For students chasing the American Dream, Del Mar College (DMC) offers a gateway to high-demand careers right in the Coastal Bend’s industrial sector. With advanced training programs based at its Windward Campus on the city’s west side, DMC is helping shape the region’s workforce in fields like petrochemical, manufacturing, and energy.

DMC’s industrial technology programs offer Associate of Applied Science degrees and certificates in areas such as welding, process technology, instrumentation, envi-

ronmental lab technology, millwright maintenance, and nondestructive testing. These programs provide hands-on experience with the latest equipment and direct pathways to well-paying technical jobs.

“Employers know our graduates are job-ready,” said Sonny Vela, welding professor and chair of industrial technology. “Our students gain real-world skills that drive the local economy and improve their quality of life.”

Backed by strong workforce outcomes, DMC ranks in the top 10% of U.S. colleges

for upward mobility, according to a New York Times study. The college also ranks 34th among 123 Texas institutions in mobility performance, making it a key player in transforming lives through education.

Among the standout programs is the environmental/petrochemical lab technology track, which trains students for lab technician roles in the chemical process industry. The two-year curriculum focuses on chemical knowledge, lab operations, and teamwork.

WE ARE DELIGHTED TO BE A PART OF THIS DYNAMIC ECONOMIC AREA AND SALUTE ALL INDUSTRY INCLUDING OUR CAMPUS PARTNERS.

DEL MAR

From PAGE 34

The instrumentation program trains students in automation and controls, aligning with demands from the Eagle Ford Shale and other energy developments. Meanwhile, the millwright program prepares graduates to maintain industrial equipment like turbines and pumps, skills vital in refineries and power plants.

In nondestructive testing technology, students learn to evaluate the safety of infrastructure using radiographic and ultrasonic methods – skills in high demand across industries. Similarly, the process technology program prepares plant operators through training in safety, systems, and hands-on plant simulation.

Welding students master all major techniques, from blueprint reading to certification-level skillsets. “Our welding grads meet industry standards and are ready to work on day one,” said Vela.

DMC also offers a fully online Bachelor of Applied Science in Organizational Management and Leadership (BAS OML). This stackable degree builds on any applicable associate degree and supports working professionals aiming for leadership or entrepreneurship roles.

“

EMPLOYERS KNOW OUR GRADUATES ARE JOBREADY. OUR STUDENTS GAIN REAL-WORLD SKILLS THAT DRIVE THE LOCAL ECONOMY AND IMPROVE THEIR QUALITY OF LIFE.”

— SONNY VELA,

WELDING

PROFESSOR AND CHAIR OF INDUSTRIAL TECHNOLOGY

Fall registration is now open for both on-campus and online classes, with the semester beginning Aug. 25. For more information, visit www.delmar.edu/registration, call 361-698-1290, or email enroll@delmar.edu.

“There’s no better time than now to enroll,” Vela said. “Our faculty are ready to prepare students for fulfilling and wellpaying careers.”

Gregory-Portland ISD students are shown taking part in welding and other

For most students, school curriculum includes basic math, science, social studies, and more that is repeated on a test. But for students in the Coastal Bend, and particularly in Gregory-Portland ISD, students have a bevy of options for industry-based certifications and more.

“

INDUSTRY PREPARATION EXPOSES STUDENTS TO HANDS-ON EXPERIENCES, CERTIFICATIONS, OR TECHNICAL TRAINING THAT CAN IMMEDIATELY LEAD TO JOBS. ”

— HILDA SALINAS, G-PISD’S DIRECTOR OF CCMR AND COUNSELORS

According to the district, GPISD offers a variety of Career and Technical Education (CTE) programs through which students can develop practical skills and earn Industry-Based Certifications (IBCs) that are highly valued by employers.

G-PISd students can explore and prepare for careers in career clusters such as manufacturing and engineering, business, energy, health, and more, according to the district. Within those clusters, there are even more specific and specialized programs of study including automotive and collision repair, welding and engineering, refining and chemical process, and more.

“Workforce alignment is important in any community. Preparing students for industry ensures that what they’re learning aligns with current job market needs, helping reduce unemployment and underemployment,” said Hilda Salinas, G-PISD’s Director of CCMR and Counselors. “Industry preparation exposes students to hands-on experiences, certifications, or technical training that can immediately lead to jobs. Additionally, it helps to promote skills such as time management, responsibility, collaboration, and professional conduct.”

Through the district’s CTE programs, G-PISD students can graduate with industry-based certifications which prepare them for the workforce or postsecondary training in their chosen industry and field.

Among the available certifications for G-PISD students are Automotive and Welding certifications such as ASE Entry-Level Automotive, AWS Welder, AWS D9.1 Sheet Metal, and NCCER Core. The district also offers Engineering and Robotics certifications including AutoCAD, Fusion 360, and FANUC Robot Operator 1 as well as certifications in healthcare, hospitality & design, technology & digital media, and more.

“Career and Technology courses also encourage goal-setting and informed decision-making about post-secondary plans — whether college, trade school, or entering the workforce,” Salinas said. “Here at Gregory-Portland ISD, we want to ensure that students leave school not just with diplomas, but with direction, skills, and a clear path toward a meaningful, self-sustaining career.”

n Landan Kuhlmann, Writer

Consider participating in The Industry Committee meetings and events.