Providing the metalworking industry with high productivity and competitively priced products in cutting tools, measuring equipment, toolholding, safety, lubricants/coolants, abrasives, grinding wheels and sharpening/regrind.

We can handle all your shop needs, offering more than just expert advice for your tool and supply purchases:

• Resharpening: Recondition your used cutting tools to extend the life of your valuable investment

• Special cutting tools: We specialize in fast turnaround of specialty ground cutting tools. Send a print, sketch, or call to discuss your specific application

• Coating: We can handle all of your coating requirements to best optimize your cutting tool performance

• Coolant Services: We will come to your shop and analyze the current state of your coolants and oils. This service includes refractometer readings, maintenance schedules and product recommendations in order to maintain optimum coolant performance. Contact us to schedule this service

• Tool Crib Management: Contact us to learn more about our Autocrib services

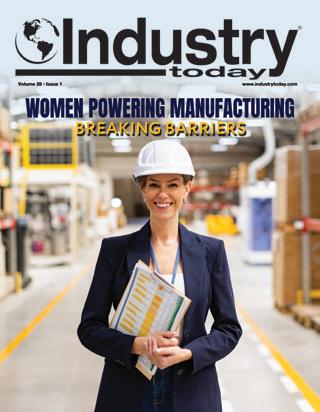

Here we are in the fourth quarter of 2025 already. There’s a lot of uncertainty about the economy, particularly as it relates to the effects of tariffs. What isn’t uncertain is our continuing in-depth coverage of manufacturers and the issues that confront them in this latest edition of the Industry Today digital magazine.

We profile five manufacturers from a variety of industry segments. In the food sector, we feature both a third-generation family owned maker of Hispanic deli meats, Cibao® Meat Products, as well as Coca-Cola Consolidated, the largest Coca-Cola bottler in the U.S. that brings a broad beverage portfolio to the Southeast, Midwest, and Mid-Atlantic regions.

Brownlee-Morrow is another family-owned business that provides air handling, liquid handling, process and motor control equipment and services. Read about how the company has grown over nearly 75 years, still pumped to meet the growing needs of municipal and industrial customers.

Wisconsin-based Urban Manufacturing designs and produces custom engineered and machined components. The company’s outstanding reputation for manufacturing and engineering know-how helps maintain its leading position as a supplier of choice regardless of changing economic conditions.

Maier America manufactures, services, and repairs rotary joints, what CEO Rob Kuehl touts as a “hidden champion”—a product that is not well-known but is extremely important to a variety of industry applications involving the transfer of liquid or gas media to stationary parts.

Shifting to the robust growth in Connecticut’s manufacturing sector, John Bourdeaux, President & CEO of Advance Connecticut, describes the next-generation pipeline of new corporate investment and expansions. In New Jersey, the state’s Strategic Innovation Centers offer a model for sustained and inclusive economic growth, as detailed by Kathleen Coviello, Chief Economic Transformation Officer for New Jersey Economic Development Authority (NJEDA). And Pittsburgh is powering the future of advanced manufacturing, where according to Stefani Pashman, CEO of Allegheny Conference on Community Development, the city is continuing its long standing reputation as a global center for manufacturing innovation.

Since 2010, the Reshoring Initiative has built and maintained the nation’s most comprehensive database of reshoring and foreign direct investment (FDI) cases. Harry Moser, Founder and President of the Reshoring Initiative® and Kathy Nunnally, President of Regions Recruiting® explain how it has been a vital resource for understanding and advancing domestic production.

Educating tomorrow’s workforce is a key challenge for manufacturers. Dan Quinonez - Chief Operating Officer of the Plumbing Heating Cooling Contractors (PHCC) National Association and the Executive Director of the PHCC Educational Foundation, describes how to motivate the next generation of trade professionals. And Ragnar von Schiber, Head of K-12 STEM education initiatives at Genentech, explains how the company inspires the biotech innovators of tomorrow to meet the challenges of advancing science for the greater good.

How do large-format additive manufacturing connects creativity and precision in today’s most demanding fabrication projects? Chris Lanio, CNC Programmer and CAMM Machinist at Dimensional Innovations provides details on how his company accomplishes it.

As always, you can get the latest updates on what is happening in manufacturing and industry on a daily basis at Industry Today. Thanks for reading and participating in the digital platform of choice for C-level executives and industry influencers.

www.industrytoday.com spoeton@industrytoday.com

Publisher: Susan G. Poeton

Senior Editor: David Soyka

Associate Publishers: James Ballam, Renata Ginter, Jonathan Listig, Brian McMillan

Digital Marketing & Operations

Coordinator: Melissa Burge

Marketing Director: Alice Anne Coakley

Art Director: Seema Mazhar

Contributing Designers: Jorge Leandro Rodrigues

472 Meeting Street, Ste C-156, Charleston, SC 29403, USA Ph. 973.218.0310

BROWNLEE-MORROW HANDLING BUSINESS

70 COMPANY PROFILES

Family-owned and diversified Brownlee-Morrow Enterprises provides air handling, liquid handling. process and motor control equipment and services.

CIBAO® MEAT PRODUCTS

A FAMILY BUSINESS ROOTED IN TRADITION, DRIVEN BY QUALITY

34

Cibao® is a third-generation family manufacturer of Hispanic-style deli-meats and a co-manufacturer for private labels.

COCA-COLA CONSOLIDATED REFRESHING BUSINESS

ECONOMIC DEVELOPMENT

ADVANCE CONNECTICUT

GLOBAL CLIMATE FUELS EXPANSIONS AND EQUIPMENT PURCHASES

106

Multiple factors are contributing to robust growth in Connecticut’s manufacturing sector, fueling a positive outlook for the years ahead.

ALLEGHENY CONFERENCE ON COMMUNITY DEVELOPMENT

STEEL CITY’S NEXT INDUSTRIAL REVOLUTION

60

Pittsburgh is powering the future of advanced manufacturing—where innovation, infrastructure and industry converge.

NEW JERSEY ECONOMIC DEVELOPMENT AUTHORITY

Coca-Cola Consolidated, the nation’s largest Coca-Cola bottler, offers a broad beverage portfolio to Southeast, Midwest, and Mid-Atlantic regions.

MAIER AMERICA

CREATING A MORE PERFECT UNION

14 98

Maier America, manufactures, services, and repairs rotary joints vital to a range of industry applications.

URBAN MANUFACTURING

GROWING MANUFACTURING 2.0

52

Wisconsin-based Urban Manufacturing designs and produces custom engineered and machined components.

HOW INNOVATION HUBS DRIVE TANGIBLE ECONOMIC GROWTH

44

Strategic Innovation Centers offer a model for sustained, inclusive economic growth - and New Jersey is putting that model to work.

DISCOVERY EDUCATION

DEVELOPING STEM CULTURE

Genentech inspires the biotech innovators of tomorrow to meet the challenges of advancing science for the greater good.

DIMENSIONAL INNOVATIONS

PUSHING THE LIMITS OF LARGE-SCALE 3D PRINTING

How large-format additive manufacturing connects creativity and precision in today’s most demanding fabrication projects.

MOSER ON MANUFACTURING

THE RESHORING INITIATIVE OFFERS A ROADMAP TO ACCELERATE RESHORING

Since 2010, the Reshoring Initiative has maintained a comprehensive database of reshoring and foreign direct investment (FDI) cases.

PHCC EDUCATIONAL FOUNDATION

PHCC EDUCATIONAL FOUNDATION: CHAMPIONING SKILLED TRADES

Motivating the next generation of plumbing and HVACR professionals through educational resources and competitions.

Since 2010, the Reshoring Initiative has built and maintained the nation’s most comprehensive database of reshoring and foreign direct investment (FDI) cases. It has been a vital resource for understanding and advancing domestic production.

By: Harry Moser, Founder/President, Reshoring Initiative® and Kathy Nunnally, President Regions Recruiting®

Reindustrializing America is impossible without reshoring, foreign direct investment (FDI), and strong industrial policy. The Reshoring Initiative’s 2024 Annual Report reveals tremendous progress with 2024 job announcements totaling 244,000. The cumulative job announcements are over 2 million since 2010, highlighting a long-term trend toward domestic production. The 2025

outlook is potentially strong but dependent upon a stable industrial policy.

Tariff uncertainty and workforce deficiency threaten U.S. manufacturing. The recent findings from the 2025 USA Reshoring Survey, a collaboration between the Reshoring Initiative® and Regions Recruiting®, underscore a compelling truth: the skilled labor shortage is a significant barrier to foreign direct investment

(FDI) and reshoring efforts. Evidence suggests that factory startup and expansion projects in the U.S. have experienced delays because of difficulties in finding skilled workers.

We encourage the Administration to utilize our data and insights to refine policies and measure their effectiveness.

Reshoring data from the Annual Report show company actions under real conditions; the survey insights reveal motivations and potential impacts across scenarios.

Based on the findings from these reports the

Pictured: The fundamental building blocks needed for U.S. reindustrialization are: a larger, more highly skilled workforce, the use of Total Cost of Ownership (TCO) when comparing domestic to offshore sourcing, lower costs, and preparation for geopolitical risk.

fundamental building blocks needed for U.S. reindustrialization are: a larger, more highly skilled workforce, the use of Total Cost of Ownership (TCO) when comparing domestic to offshore sourcing, lower costs, and preparation for geopolitical risk. These are the economic essentials needed for American reindustrialization.

Let’s chart the course.

The momentum to bring manufacturing back to U.S. shores is strong. Yet, as companies commit to domestic production, a critical challenge

often emerges: obtaining a skilled workforce. This isn’t merely a hurdle; it’s the bedrock upon which the success of reshoring efforts will ultimately be built.

The survey findings reveal that a highly skilled workforce is the number one enabler for companies considering reshoring. Conversely, a lack of skilled labor is a persistent deterrent. Given the resource of a skilled U.S. workforce in abundant supply, OEMs said they would reshore 30% of their products currently

offshored. If 15% tariffs were applied to all imports from all countries, OEMs said they would bring back 23% of what they currently offshore. This was followed by a 15% reduction of the USD (21%), corporate tax rate cuts from 21% to 15% (18%), and U.S. regulations set to match those offshore (17%). Figure 1.

This creates a clear imperative: robust workforce development must be integrated into every reshoring strategy from inception.

Reshoring will require establishing advanced manufacturing operations that demand a workforce adept in the best production techniques of their industry, but also automation, robotics, data analytics, and other Industry 4.0 technologies. For site selectors, this translates into a sharpened focus on several key workforce-related considerations:

• Existing Talent Pool and Skill Sets: relevant

to the reshoring company’s needs.

• Educational and Training Infrastructure: partnerships with community colleges, vocational schools, and universities with relevant programs.

• Workforce Development Programs and Incentives: ranging from grants for employee upskilling to tax credits for apprenticeship programs.

• Labor Market Dynamics and Flexibility: including opportunities for cross-training and internal mobility within the existing workforce.

• Quality of Life and Talent Attraction: including housing affordability, quality of schools, healthcare access, and recreational amenities.

When companies dig into the numbers — total

Pictured: Reshoring will require establishing advanced manufacturing operations that demand a workforce adept in automation, robotics, data analytics, and other Industry 4.0 technologies.

cost, not just price — they often realize they’re paying more than they think to stay offshore. Manufacturers often see reshoring savings in unexpected places like inventory, an average drop of 60–70% — and in one Illinois case, 94%. Reduced lead times enable companies to better align production with actual demand for lower inventory levels, less overproduction or stock-outs.

But only 30% of OEMs use Total Cost of Ownership (TCO) in comparing domestic to

Figure 2: 2025 Reshoring Survey

offshore sourcing. Seventeen percent continue to use Ex-Works or plant level costing, and 37% use Landed Cost. Seventeen percent use some other form of costing for their purchases. Frequently these methods result in a 20 to 30 percent miscalculation of actual offshoring costs. Figure 2.

Our TCO user data shows that shifting virtually all OEMs to a robust TCO system could reshore $200B of manufacturing with no government subsidies, no supply chain shock, no

Click here to access the full list of Reshoring resources offered by the Reshoring Initiative. To report your reshoring successes or to get help with reshoring, contact Harry Moser, Founder and President, Reshoring Initiative, harry.moser@ reshorenow.org, 847-867-1144.

tariffs, no retaliation and no impact on inflation after factoring in all global risks and costs.

The Reshoring Initiative’s Total Cost of Ownership (TCO) Estimator is a free online tool that helps companies account for all relevant factors — overhead, balance sheet, risks, corporate strategy and other external and internal business considerations — to determine the true total cost of ownership.

The control and reliability derived from localization are becoming more valuable than the traditional focus on low-cost. Having engineering near manufacturing resulted in one of the highest-rated benefits of the survey. The top three reasons given to reshore were locating

manufacturing near engineering (45%), the benefit of reduced freight and duty costs (45%), and avoiding geopolitical risk (38%).

Forty percent of OEMs were willing to pay 10% to 20% more for 5 weeks faster delivery. By working with domestic suppliers, manufacturers can receive inputs faster, minimizing downtime and accelerating the manufacturing process. Typical delivery time by surface freight from

Pictured: The control and reliability derived from localization are becoming more valuable than the traditional focus on low-cost;

right: Many large and substantial tentative announcements are contingent on clearer signals from the administration.

inland China/Asia to the Midwest is about 6 weeks. Other key takeaways and details on the 2025 Reshoring Survey results are available in the full Report.

The Reshoring Initiative 2024 Annual Report shows immense progress, but the U.S. must address workforce shortages, manufacturing cost disadvantages, and policy uncertainty to maintain this momentum.

1Q2025 data projected a potential drop to 174,000 announced jobs for the year. But as the

tariffs started to firm and the economy stayed steady in 2Q2025, the projection jumped to 223,000. That figure could climb rapidly if firms gain full confidence in the permanence of new tariff and industrial policies.

Many large and substantial tentative announcements are contingent on clearer signals from the administration. The Reshoring Initiative is tracking 20-30 major billion to $10 billion announcements in a variety of industries. But when you read between the lines you learn that many companies are going to move forward only when it’s clear that the tariffs will last for an extended period of time. Manufacturers are vulnerable to policy shifts because facility investments require years of planning with investments that are difficult to reverse.

Recent disappointing jobs data and anecdotal evidence from the Federal Reserve’s recent ‘beige book’ report concur with Reshoring Initiative findings. The report, a qualitative assessment of economic conditions across twelve Federal Reserve Districts said, “Looking ahead, many contacts expected to postpone major hiring and layoff decisions until uncertainty diminished.”

Likewise, a report released in August 2025 from the Joint Economic Committee Minority

Pictured: The best way to promote more reshoring and protect the U.S. from increasing geopolitical risks is to implement a true national industrial policy; right: The growing demand for skilled labor remains a major constraint to scaling reindustrialization efforts.

warned that tariff uncertainty could derail U.S. manufacturing investment by as much as $490 billion by 2029.

The best way to promote more reshoring and protect the U.S. from increasing geopolitical risks is to implement a true national industrial policy. Such a policy should focus on leveling the cost playing field through comprehensive actions, including massive skilled workforce investments, a 20% lower USD, encouragement of the use of the total cost of ownership (TCO) metrics and the retention of immediate expensing of capital investments which the Big Beautiful Bill has accomplished. If tariffs are used, they must be comprehensive: applied to all countries to avoid loopholes like transshipment for tariff avoidance. The Reshoring Initiative would prefer to see a more modest 10 to 15 percent tariff instituted on a long-term, e.g. 10 year basis, so that companies feel confident making investments. Instead of the complex and impermanent tariffs, we rec-

For expert guidance and support with talent strategies to advance your business, contact Kathy Nunnally, President of Regions Recruiting®, at knunnally@regionsrecruiting.com; Office Ph. 404-636-2161.

Learn more here: “Priority #1: Manufacturing Workforce Development” authored by Kathy Nunnally.

ommend a Value-Added Tax (VAT).

Workforce development is crucial

The growing demand for skilled labor remains a major constraint to scaling reindustrialization efforts. More automation, immigration of skilled workers, and recruitment and training of high school graduates will be necessary to increase output, improve competitiveness and fill the current skills gap.

The root cause of offshoring and the key barrier to reshoring, is that U.S. manufacturing cost is, on average, 10 to 50% higher than in almost all competitor countries. That price dif-

ference drives 80 to 90% of import decisions. A targeted revaluation of the U.S. dollar would improve cost competitiveness and drive both reshoring and more exports. More suggestions are available in our Competitiveness Toolkit.

Are you thinking about reshoring?

We encourage companies to implement the top priorities for reindustrialization revealed by the survey — build a strong talent pipeline, use total cost of ownership, and prepare for geopolitical risk. Have you reshored a metal component or product? Apply here for the National Metalworking Reshoring Award today. Awards will be presented at FABTECH 2025 and IMTS 2026.

Coca-Cola Consolidated, the nation’s largest Coca-Cola bottler, offers a broad beverage portfolio to Southeast, Midwest, and Mid-Atlantic regions.

Coca-Cola is an iconic American brand, first served in an Atlanta pharmacy back in 1886. For almost as long, the equally iconic Coca-Cola Consolidated has served distributors, retailers, and other partner companies the celebrated soft drink, along with more than 300 other non-alcoholic beverage brands and flavors across 14

states and the District of Columbia to more than 60 million consumers, with net sales exceeding $6.9 billion in 2024.

The company that became Coca-Cola Consolidated after merging with other regional bottlers was founded in 1902 by the current chairman and chief executive officer’s great-grandfather, J.B. Harrison. Publicly

Twenty-five years ago, T-TEK partnered with Coca-Cola Consolidated to enhance production line efficiencies by improving component durability and simplifying machine maintenance, resulting in a product handling revolution. By collaborating with Consolidated’s highly skilled team members, we improved control systems and case handling across all brands of palletizers in their network.

This partnership has been integral in establishing T-TEK as a leader in end-of-line automation for Coca Cola as well as other valuable customers.

Today, T-TEK designs, manufactures, and services high-performance palletizing and depalletizing systems trusted by top producers in the food, beverage, and consumer goods industries. Our servo-driven, high-speed palletizers offer unmatched speed, soft case handling, compact designs, and intuitive one-button changeovers. T-TEK delivers innovative equipment that improves your operational efficiencies and lowers your total cost of ownership.

Ready to elevate your production line?

Visit www.T-TEK.com or call 1-334-269-6970 to schedule a consultation with our automation experts today.

traded on NASDAQ (COKE), it continues as a privately controlled company and is the largest Coca-Cola bottler in the nation, headquartered in Charlotte, North Carolina with 11 manufacturing facilities and 60 distribution centers employing 17,000 teammates.

Coca-Cola Consolidated recently announced the $15 million expansion of its Regional Operations Center in Monroe, North Carolina. The expansion includes a new 42,000 square foot warehouse. “The Monroe facility was primarily used to refurbish equipment like coolers used in convenience stores and groceries,” explains Vice President of Manufacturing Steve Funderburke. “The expansion not only improves those services but also houses the Coca-Cola Consolidated Technical Academy which offers trade school-type training and certifications in refrigeration, electrical work, and plumbing.”

Coca-Cola Consolidated has a strong focus on training and developing top talent through its Coca-Cola Consolidated Technical Academy, also using it to upskill current teammates. Another $90 million investment was also announced for a new 400,000 square foot distribution and warehouse facility, along with two 15,000 square-feet building for repair services and fleet maintenance on a 60-acre campus in Columbus, Ohio. The Columbus warehouse, which officially opened in February 2025, handles more than 16 million cases of product a year and, on average, about 75,000 cases a day. The investment has already created 25 new jobs.

Unlike the legendary secret Coca-Cola recipe, there’s no secret to the success of CocaCola Consolidated. The company’s Purpose statement is to honor God in all they do, serve others, pursue excellence, and grow profitably. That commitment is reflected in being named to America’s Greatest Workplaces for Parents & Families in 2025 by Newsweek. The award notes in part that, “For working parents across America, the ability of a company to respect and support their needs is a vital factor in determining where they choose to grow their careers.”

“Our culture is the number one motivation for our teammates - serving each other, our customers, and local communities. This is a great place to work with a lot of opportunities.

As someone who started out 27 years ago as a mechanic to eventually become a vice president, I can attest to that,” says Funderburke. “And my experience is by no means unique.”

Indeed, many teammates stress how training opportunities and mentorship programs help navigate career paths and grow into more responsibilities and leadership positions. One example is a maintenance apprenticeship program conducted jointly with Central Piedmont Community College. “It’s a one-year program

where we just had our first graduate, and we are about to start another class,” Funderburke says. “It’s a great opportunity for someone out of high school who isn’t interested in a two- or four-year college program and wants to learn practical skills and are guaranteed a job at Coca-Cola Consolidated.” Participants are able to earn while they learn, providing access to education and continued wages.

While much of the bottling process is automated, there are still a number of skilled jobs involved in manufacturing operations. “The difference maker for a lot of our automation is eliminating much of the heavy lifting,” Funderburke says. “In a company producing 300 million cases annually, that’s a lot of

territory to cover; automation helps us work more efficiently. Reducing physically-challenging processes allows our teammates focus on running the operations and maintaining our facilities. It makes us more productive.”

He adds that, “We’re always looking at new equipment and technologies that can potentially further improve our processes. I think we’re just beginning to see how AI can help take us to the next level. At the same time, you can’t replace the dedication of our teammates.”

The company purchases beverage concentrate

from The Coca-Cola Company as well as other brand owners, in addition to ingredients and materials from various suppliers. Concentrate and ingredients are blended and filled into sanitized bottles and cans that are then capped, date coded, and packaged and sent to warehouses for shipping. For the final delivery stage,

Coca-Cola Consolidated manages Coca-Cola Consolidated delivery trucks.

In addition to beverages, Coca-Cola Consolidated also operates a transportation and logistics subsidiary, Red Classic.

“The original reason we got into shipping was because of one-way freight,” Funderburke says.

“We were paying for a trailer to deliver product from Charlotte to say Nashville or some other location, but then we had to pay for the trailer to come back to us empty. Red Classic was a way for us to move freight more economically, as well as for us to have more direct control over shipping logistics.”

Also headquartered in Charlotte, Red Classic runs more than 80 hubs, terminals, and maintenance shops across the same service territory as Coca-Cola Consolidated.. “While we offer our freight services to other companies, Red Classic primarily provides logistics for Coca-

Cola Consolidated,” Funderburke notes.

Joachim Rogers, Vice President/General Central Market Unit, notes that the company has a product in every non-alcoholic beverage category, including teas, cold coffees, energy drinks, and waters, as well as Coca-Cola and other sodas and sparkling drinks. He notes that while the company does work in tandem with The Coca-Cola Company on certain marketing and promotional activities, it sells products through its own sales and distribution

network. “It’s true that the general public and even some of our customers may not realize we are a separate independent company,” he says, “But the important things is that we maintain the quality of everything we offer and are sure to provide sufficient supply to all territories and satisfy consumer demand.”

Funderburke notes, “We fulfill orders 24/7 in multiple packaging formats to ensure product is always where it is supposed to be, when it is supposed to be there.”

Rogers says that while consumer tastes have changed over the years, the company’s commitment to meet those tastes haven’t. “The major shift I’m seeing now is a general trend away from full-calorie selections. Today about 60 percent of our beverages are low- or zero-calorie. Probiotic drinks are also getting a lot of attention.” He is quick to point out, however, that, “We’re not looking to dictate what people should or shouldn’t drink. Consumers want choices, and we offer those choices. We have something for everybody.”

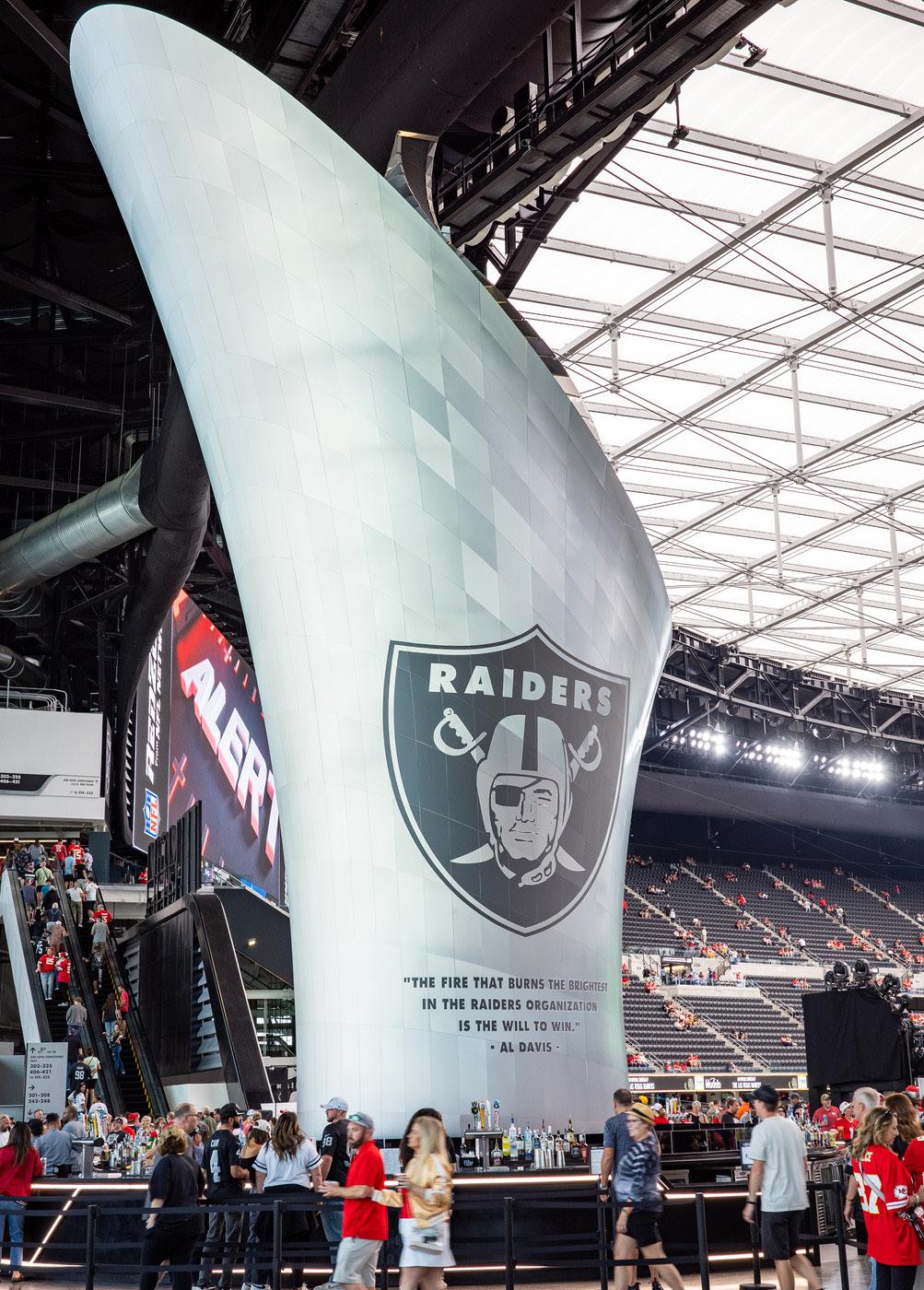

Pictured: Coca-Cola Consolidated teammates across its territory.

To that end, Coca-Cola Consolidated is always testing new products and innovative packaging solutions. “I think we’re the only bottler to offer micro-sized cans and bottles in smaller packaging,” Rogers says. “Many consumers still enjoy sodas but are looking for different sizes. At the same time, smaller convenience stores are looking for a way to distinguish themselves from the big retailers and groceries, so having more convenient packaging helps them do that.”

The company is committed to make the packaging as recyclable as possible, as well as partnering with local communities to collect and reuse materials that otherwise end up in landfills. Bottles and cans are not only made of recyclable materials but are also designed to be remade. Use of lighter weight PET (Polyethylene Terephthalate) reduces plastic in its 20 oz., 12 oz., and 500 ML products. Plus, there is a shift to 100% recycled plastic (rPET) across all 20 oz. Coca-Cola Trademark products and Dasani 20 oz. bottles.

As part of its Refresh. Recycle. Renew. program, the company works with a variety of climate-conscious partners, including universities and colleges, sporting and event venues, other businesses, and local community organizations.

Funderburke notes as another example, “Our concentrate comes in 50-gallon plastic barrels. When we’re finished with them, we also donate

these to be made into rain barrels throughout our territory.” So not only are the barrels recycled, but rainwater collection improves water usage and efficiency. Syrup barrels were recently converted into trash and recycling bins for use

at the Charlotte Motor Speedway during the Coca-Cola 600, which collected over three tons of bottles and cans sent to recycling centers. “Our manufacturing plants all work with recycling vendors to aim to be 100% landfill free,” says Funderburke.

Given that water is a main ingredient of all its products, water efficiency is a paramount goal, as well as minimizing packaging materials, reducing waste, and using available technologies to keep as much out of landfills as possible.

Coca-Cola Consolidated is also testing AI technology to identify water efficiencies in its sanitation processes. One example is a partnership with Vanguard Renewables that takes the sugar water from unsellable and destroyed beverage products mixed with other food waste and cow manure to produce natural gas, low carbon fertilizer, and bedding for cows.

Coca-Cola Consolidated also works with Atlantic Packaging to collect the stretch film used to wrap its pallets. By supporting a closed

loop” economy, Atlantic Packaging recycles Coca- Cola Consolidated’s clean, used stretch film into new stretch film over and over again that results in a new stretch film that has a 12% post-consumer recycle content.

“We’re an industry leader in beverage recycling,” Rogers says. “Reducing waste is not only good for the environment; it also reduces costs.”

Encouraging local recycling efforts is just one way the company seeks to serve its communities. It is also active in numerous organizations, sponsorships, and activities across the territories it serves and where its teammates live and work.

For example, after Hurricane Helene struck North Carolina in September 2024, the company teammates provided food and water, hygiene kits, and baby supplies to help with cleanup and family financial needs. Teammates also pitched in to remove downed trees, clear debris, set up food pantries and provide hot meals to everyone affected.

“We believe our enduring emphasis on the Purpose of our company remains the key to our success as a business and a community partner,” Rogers emphasizes.

We look forward to continuing to grow in serving our customers, our employees, and our local communities.”

All of which serves to demonstrate that things really do go better with Coca-Cola Consolidated.

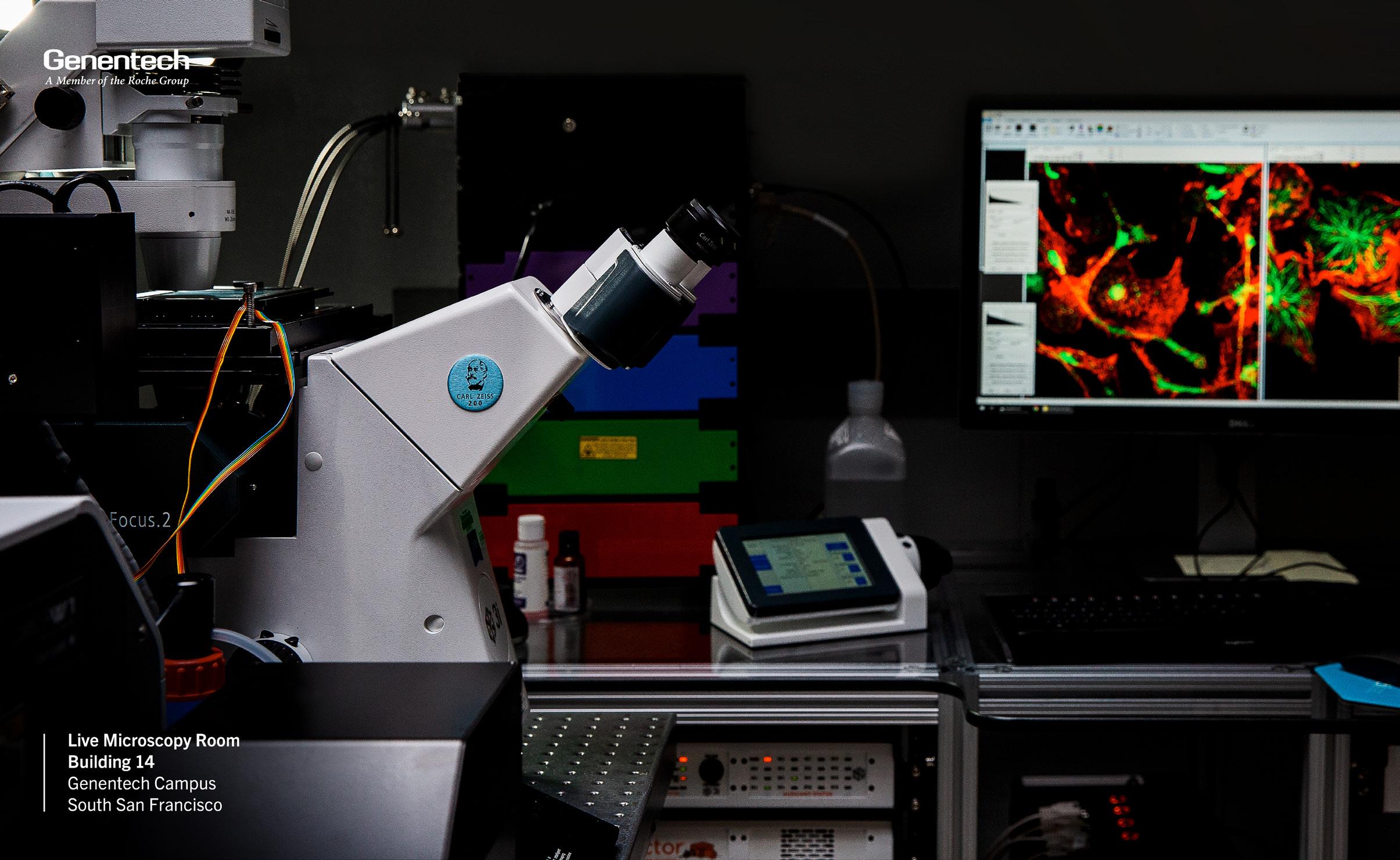

Genentech inspires the biotech innovators of tomorrow to meet the challenges of advancing science for the greater good.

By: Ragnar von Schiber, Head of K-12 STEM education initiatives at Genentech.

Genentech, a member of the Roche Group, develops medicines for people with serious and life-threatening diseases. The company’s ability to solve complex health challenges depends in part on developing the next generation of innovators to continue to achieve medical breakthroughs that that solve complex health challenges.

Ragnar von Schiber, Head of K-12 STEM education initiatives at Genentech, explains that, “I lead Genentech’s employee-giving strategy that drives engagement, unlocks our people potential, and helps realize Our Promise to serve society. I also head up our strategic K-12 STEM education initiatives, including Futurelab+, a nationwide, first-of-its-kind biotech curriculum and virtual volunteerism that aims to reach a million high school students across the U.S. by 2026.”

He adds that, “Giving back has been core to Genentech’s culture since our founding nearly 50 years ago. We’re proud members of the

communities where we live and work, and we believe we can have the greatest impact by focusing our efforts at the local level, through our charitable giving and by empowering our employees to volunteer their time and talent.”

As an example, von Schiber cites the company’s annual week-long Genentech Gives Back where employees volunteer and raise funds for local nonprofit community organizations “Since the program’s inception in 2010, we have volunteered over 134,000 hours and contributed more than $5.5 million through grants and individual employee contributions,” he notes.

“It’s that kind of commitment that drives last-

ing, meaningful change, von Schiber emphasizes. Underpinning achievement of that lasting change is Genentech’s active support and participation in K-12 STEM programs.

“Today’s students are the researchers, physicians and healthcare innovators of tomorrow, von Schiber says. “That’s why Genentech supports all stages of the K-12 education continuum, including industry-aligned career exploration in high school that sets the foundation for undergraduate and graduate education in science and medicine.”

He cites studies demonstrating clear benefits when the scientific and medical workforce understands the actual lived experiences of the

people it serves. These include greater access to care, improvements in patient experience and health outcomes. Equally important is developing student interest in biotech and healthcare careers that continue to foster these benefits.

To that end, Genentech’s Futurelab and Futurelab+ programs aim to build pathways into STEM fields for the next generation of talent.

Futurelab supports all 8,000 K-12 students in the South San Francisco Unified School District (SSFUSD) to get them excited to learn about science, improve their college readiness and inspire them to pursue careers in STEM fields. It offers four unique programs for students at different stages of their educational journey: Gene Academy, Helix Cup, Science Garage and Futurelab Scholarships.

Futurelab+ is a three-year, open-access biotech curriculum for high school students that provides professional development resources to teachers, helping to strengthen and scale biotech education across underserved schools. It provides a comprehensive biotech curriculum, including capstone year resources designed to support any student pursuing a year of independent research in support of the Career and Technical Education (CTE) pathway for

biotechnology. It also includes classroom activities designed to support a virtual classroom visit with a Futurelab+ volunteer on Career Connect, the workforce talent development resource.

Career Connect provides a convenient and easy means for Genentech employee volunteers to connect virtually with classrooms nationwide to share their career experiences and help educators make real-world applications to what they’re teaching. “Many of our Futurelab+

volunteers mention how vital mentors were in their own career journeys and appreciate that Career Connect provides a flexible way to make an impact on students’ lives,” von Schiber says. Through Career Connect, Futurelab+ volunteers have reached nearly 1000 students. In one Career Connect session, a teacher discovered that the Futurelab+ volunteer worked on a medicine that treated the type of cancer her husband was in remission from. “This was a full circle moment for both the educator and the employee.,” von Schiber points out. “The educator was happy to personally thank a per-

Discovery Education is the worldwide edtech leader whose state-of-the-art, PreK-12, digital solutions help educators engage all students and support higher academic achievement. Through award-winning multimedia content, instructional supports, and innovative classroom tools that are effective, engaging, and easy to use, Discovery Education helps educators deliver powerful learning experiences. Discovery Education serves approximately 4.5 million educators and 45 million students worldwide, and its resources are accessed in over 100 countries and territories. Through partnerships with districts, states, and trusted organizations, Discovery Education empowers teachers with essential edtech solutions that inspire curiosity, build confidence, and accelerate learning. Learn more at www.discoveryeducation.com.

son who helped save her husband’s life, and the volunteer was happy to hear the firsthand impact of her work!

von Schiber emphasize how Genentech views the classroom as key to cultivating a love of science in the next generation. “Helping students, especially those from low-income communities, find their way into science and medicine, not only creates pathways to well-paid, meaningful careers, it also ensures that these critical fields reflect the richness of our society,” von Schiber notes. “Increasing access to careers in STEM doesn’t just benefit Genentech, but it makes the entire industry stronger by ensuring that future talent is equipped to meet the challenge of our changing world.”

He adds, “At Genentech, our love for science is deep. We aim to ignite the same passion for science in the next generation. We want every student to feel the excitement of discovery and the promise of biotech careers and to see themselves in this work, because it takes so many skills and points of view to power our company and our industry.”

Genentech is committed to continue this outreach and support of K-12 STEM education. “Genentech will continue to expand the reach of Futurelab+, especially in Title 1 schools and

Career Connect promotes student curiosity by connecting classroom learning to potential careers. Through Career Connect, educators request virtual classroom visits from industry professionals, selecting from an array of job types, industries, languages, and locations. Then, students meet with professionals from industries like biotechnology, science, finance, computer engineering, human resources, education, and more, exploring potential career pathways through these interactions.

under-resourced communities,” von Schiber says. “Our Futurelab+ volunteers are connecting with classrooms to share their own career journeys and real-world insights to help students relate what they are learning in school to a future career, see what careers in STEM really look like, and discover the many paths to pursue those careers.”

von Schiber emphasizes that, “Connecting with students supports both our business and industry. When students are aware of the full breadth of opportunities available to them, they are inspired to explore new options. And when educators have the tools to introduce and foster a love of science, students are more prepared to pursue those careers.”

He believes that, “Bridging that gap from education to industry is something we all need to work on—every company, every school, every teacher and every volunteer. We at Genentech want to excite more students about biotechnology and help build a more inclusive future STEM workforce.”

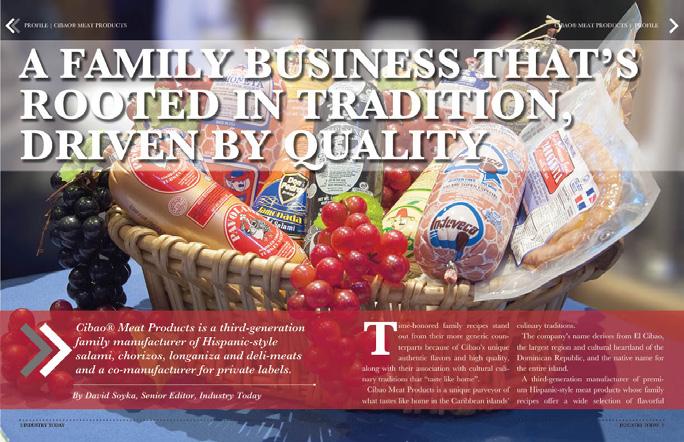

Cibao® Meat Products is a third-generation family manufacturer of Hispanic-style salami, chorizos, longaniza and deli-meats and a co-manufacturer for private labels.

By David Soyka, Senior Editor, Industry Today

Time-honored family recipes stand out from their more generic counterparts because of Cibao’s unique authentic flavors and high quality, along with their association with cultural culinary traditions that “taste like home”.

Cibao Meat Products is a unique purveyor of what tastes like home in the Caribbean islands’ culinary traditions.

The company’s name derives from El Cibao, the largest region and cultural heartland of the Dominican Republic, and the native name for the entire island.

A third-generation manufacturer of premium Hispanic-style meat products whose family recipes offer a wide selection of flavorful

salamis, smoked sausages, longaniza, and specialty cold cuts variously made with beef, pork, and/or poultry ingredients specifically tailored to Latin American tastes, Cibao Meat Products are produced under the strictest quality and safety protocols for their wholesale and retail partners.

“My grandfather started the business in 1969,” Cibao President Heinz Vieluf, Jr. says. “The first product was Salami Campensino, which was very popular within the Dominican community. It was made in a small facility in Washington Heights, New York, with about 20 employees. Over time, the company organically expanded, adding to our product line and our manufacturing capacity, all while maintaining Cibao as a family business now under third-generation leadership that continues our longstanding tradition of quality. We source from environmentally conscious farmers committed to provide high value and safety.”

He adds, “Cibao makes food products. But equally important, we make a cultural con-

nection that resonates not only with Latin American consumers, but also increasingly with mainstream American palates.”

Today, Cibao Meat Products operates from a 124,000 square foot headquarters and USDAcertified manufacturing facility in Rockaway, New Jersey, with a staff of approximately 200 people. “The company has evolved considerably over the years, growing from a maker of a single salami to producing a variety of meat products under the Cibao brand as well as providing contract manufacturing services to other brands,” Vieluf says. “We’ve added manufacturing space as well as new technologies such as robotics that add to our capabilities

Tracing Cibao’s roots as a leading U.S. producer of Dominican-styled meat products goes back to 1969 when Siegfried Vieluf started the company in a small, rented Washington Heights location in New York City. Originally under the name of Cima Meat Products, its first flagship product was Salami Campesino. During the 1980s, the company introduced new sausages such as Checo, Villa Mella, and Sosua, and created Induveca, a gourmet salami.

Its first major relocation took place in 1994 to a larger Bronx facility. That same year, it launched the slogan, “Tradition of Quality,” which it continues to use today. By 2011 the Bronx plant was, according to Cibao President Heinz Vieluf Jr., “busting at the seams,” leading to relocation to its present address in Rockaway, New Jersey.

“One of my fondest memories as a kid, was going to my grandparents and visiting my grandfather when he was in his late sixties, in a backyard shed grinding meat and experimenting with different spices,” says third generation family owner, and first American born, Vieluf. “My grandfather was what today we call a ‘foodie”, and that was my introduction to the family business.”

He adds that, “It was also instilled early on to me that tradition of quality is not just a slogan, but it’s our commitment. My grandfather would never cut corners in making our products and we never will cut corners.”

Cibao Meat Products continually innovates its product line to meet evolving consumer preferences. “We’re always

looking for what’s going on in the market and how we can adapt. Whether it’s low sodium or vegan options, I want Cibao to be able to offer any and all of these options,” Vieluf says. “I don’t want just what we were always good at, you have to constantly innovate.”

Recent examples include Salapeño Salami, which incorporates jalapeño peppers to for consumers preferring spicier taste, and Pavolami, a Spanish-style salami made entirely from turkey as a red-meat alternative appealing to health-conscious consumers.

Looking ahead, Cibao Meat Products aims to expand its product offerings to cater to the growing demand for diverse and health-conscious options and satisfy dietary trends while maintaining the authentic flavors that have defined its brand. “We want to be a company that appeals to the entire Latino community, meaning not just Mexican, which is what people sometimes think Latino means, but the whole variety of Hispanic culture, including the Caribbean islands, Spain, and South America. Our product development map is to create new recipes that appeal to all these different segments, as well as a more knowledgeable consumer that is interested in these cultural cuisines and to be sure we have something that appeals to everyone.”

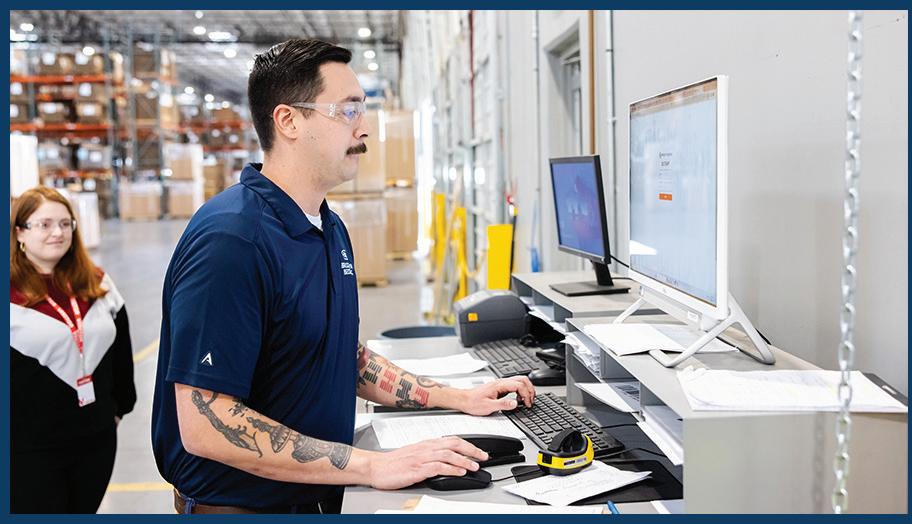

Pictured: Fresh sausages rolling out on automated production line; Advanced shipping and receiving facility ensuring efficiency and safety; Organized warehouse supporting fast, reliable distribution.

while maintaining the highest quality and safety standards consumers expect from us.”

He emphasizes that installing automated systems to improve process efficiencies and gaining higher uptime are not intended to force labor reductions. “We always look to upscale employees,” Vieluf says. “So, if we install a new robotics line to replace human assembly, we can typically reassign those people to maintain the new components and concentrate on higher value tasks.” As one example, centralizing and digitizing its data collection processes allowed employees to spend more time developing customer relationships and marketing efforts to boost customer satisfaction and grow the business.

At Casanova Meats, we offer more than just products—we provide the consistency, reliability, and service that our customers depend on. From USDA custom cutting and innovative packaging programs to our wide selection of beef, poultry, seafood, lamb, goat, and provisions, we are proud to deliver solutions that meet the needs of industry leaders like Cibao.

He adds that, “Our team is committed to continuous improvement and we’re always receptive to employee suggestions. Cibao supports and encourages open dialogue in the workplace and takes active steps to elevate, respect, and encourage each other. Our employees are the ones working day in and day out and have the best handle on what is or isn’t working best. If they have a suggestion as to what might make something work better for them or make an operation flow more efficiently that makes sense, we’re always going to explore it. We’re always looking at new ways to accelerate the delivery process and to supply orders within 24

hours on a once or twice a week schedule.”

A robust logistics chain focused on B2B service ensures product freshness and consistency to all key markets. “We work with suppliers to ensure quality and stable pricing, “Vieluf says. “Our products don’t sit on shelves, they are highly popular and we strive to ensure our customers have the product they want, when they need it. Reliable distribution is just as important as providing a quality product.”

Vieluf notes that roughly half of the employees are bi-lingual. “Given the popularity of our products in the Latin American community, it helps to have a Spanish speaking staff to work with certain of our vendors.”

Cibao Meat Products markets to wholesale and retail customers in major metropolitan areas of the U.S., including Puerto Rico, as well as niche Hispanic markets. “We’re always looking to expand our partnerships with national distributors, grocery chains, and foodservice operators seeking culturally relevant products with strong consumer loyalty,” Vieluf says.

He adds, “Cibao has a strong brand identity that offers classic Dominican and Caribbean Island flavors that please both the Latin

Pictured left: Cibao team members processing meats with precision and care; below: Modern packaging system maintaining quality and consistency.

American community as well as mainstream American consumers looking for authentic, culturally relevant quality using proprietary recipes and blends. From spicy to savory, Cibao offers a wide variety of meat products in various packaging sizes ranging from large 10 oz. packages to snack packs that feature multiple flavors.”

Dedicated account support, bilingual marketing material, and private labelling help wholesale partners succeed. “We participate in tradeshows, radio and TV and other traditional marketing” Vieluf says. “But we are also active in social media marketing to extend brand awareness. If you are interested in traditional Caribbean-style meats, you are going to know

Pictured: Cibao Meat Products headquarters in Rockaway, New Jersey.

Vieluf says that what sets Cibao Meat Products apart is its premium ingredients, along with its authentic Dominican recipes that satisfy consumer expectations of quality and flavors, and we’re manufactured under the highest safety standards. “We’ve never had a recall in over 50 years of operation,” Vieluf points out.

“Our mission is to preserve the culinary traditions of the Caribbean while delivering consistent quality and safety that today’s foodservice professionals and retailers demand,” Vieluf emphasizes. “We’re proud to offer time-honored recipes, made in USDA-certified facilities, that meet modern standards without compromising authenticity.”

Strategic Innovation Centers offer a model for sustained, inclusive economic growth— and New Jersey is putting that model to work.

By: Kathleen Coviello, Chief Economic Transformation Officer, NJEDA

For decades, New Jersey has been synonymous with innovation—home to Bell Labs, the birthplace of the transistor and groundbreaking inventions that have shaped modern technology, and a thriving pharmaceutical industry that has helped define global health outcomes. Today, that legacy is evolving into a rapidly growing innovative economy, built not around single breakthroughs or inventions but ecosystems of entrepreneurship, research, and public-private collaboration.

Through the New Jersey Economic Development Authority’s (NJEDA) Strategic Innovation Center initiative, hubs across the state are anchoring this transformation by creating new jobs, attracting investment, and expanding opportunities across various sectors, including life sciences, hard tech, aerospace, and fintech. These centers are more than just physical spaces; they are launching pads for long-term economic strength.

Unlike individual development projects, strategic innovation centers are designed to integrate key elements of growth:

• Proximity to Talent and Research: Companies—from startups to Fortune 500s— benefit when they locate near research institutions and talent pipelines. Ideas move faster from lab to market, and employers gain quicker

access to a skilled workforce.

• Shared Infrastructure: Facilities like wet labs, high-speed data, testing equipment, and compliance resources are often too expensive for early-stage firms to access alone. Shared environments reduce barriers to entry and encourage continued growth.

• Cross-Sector Collaboration: When industry, academia, and government are co-located,

Pictured above: Governor Phil Muprhy joins additional state and city officials at the HAX Strategic Innovation Center in Newark, NJ in May of 2024; previous spread: Located in Jersey City, SciTech Scity is a collaboration between the City of Jersey City and Liberty Science Center, New Jersey’s most visited cultural institution, to bolster local education and economic growth in key STEM sectors.

partnerships form more organically — leading to breakthroughs that wouldn’t happen in silos.

• Regional and Sector Diversity: New Jersey’s model doesn’t rely on clustering all innovation in a single corridor or sector. It’s spreading capacity statewide, ensuring that innovation is both place-based and purpose-driven.

The success of an innovation center depends not just on placing startups and lab space together. A thriving center requires intentional design and execution, beginning with a clear alignment between regional strengths and emerging industries.

Access to funding, mentorship, and commercialization support is crucial for transforming ideas into viable businesses. By connecting founders to investors and facilitating collaborations between industry and academia, these

Kathleen Coviello

components can significantly influence the difference between slow growth and substantial scalability for early-stage companies.

The New Jersey Bioscience Center Incubator (BCI) in North Brunswick has demonstrated what sustained investment in innovative infrastructure can yield. Since 2002, BCI-supported companies have generated more than $9 billion in economic output and $4 billion in labor income. In 2023 alone, they contributed $32 million in state and local tax revenue and supported over 2,700 jobs.

The facility, located within a broader research corridor that includes Rutgers and Princeton, offers shared wet labs, educational programming, and long-term support.

Chief Economic Transformation Officer, NJEDA

Kathleen Coviello is the New Jersey Economic Development Authority’s (NJEDA’s) Chief Economic Transformation Officer. In this role, she oversees the Authority’s strategic sector, economic transformation products (corporate tax credit programs, clean energy and offshore wind products, innovation and venture products, and strategic innovation centers) and the Product Operations departments. The Division provides value-added business engagement and products targeted at commercial businesses within the state’s strategic sectors. As a leader across these departments, she works to support high-quality job creation, catalyze private investment, and build a diverse innovation ecosystem in New Jersey.

Kathleen most recently served as the NJEDA’s Executive Vice President for Technology, Life Sciences & Entrepreneurship, where she was responsible for working closely with the state’s emerging technology and life science companies and investors.

Website: https://www.njeda.gov/

Graduates include high-growth firms like Genewiz, a leading global genomics solutions provider, and Amicus Therapeutics, a biotech company on the forefront of advanced therapies to treat rare diseases, which both have roots in New Jersey and demonstrate how localized innovation support can lead to global impact.

Innovation as community infrastructure is central to New Jersey’s strategy. The newly

announced Aerospace Innovation Center (AIC) in Atlantic County is one strong example of this. Positioned near the Federal Aviation Administration research campus, the $19 million center is designed to attract aerospace and defense firms with access to federal resources, high-speed connectivity, and collaborative R&D spaces.

Even before its doors open, AIC delivers value. Moody’s and S&P reaffirmed Atlantic County’s strong bond ratings shortly after the project was

announced—an early indicator of how targeted innovation investment can strengthen fiscal health and local confidence.

Other centers are leveraging this same model in emerging areas. The HELIX in New Brunswick will bring together healthcare research, private-sector innovation, and aca-

demic talent under one roof—attracting companies like Nokia Bell Labs, which will relocate its HQ for better access to AI and healthcare collaborators.

And in Camden and Mullica Hill, a new Strategic Innovation Center in partnership with Rowan University, affiliated with Cooper

Pictured: Opened in March of 2025, the state-of-the-art, collaborative ecosystem will integrate world-class research, innovation, education, and workforce development. The NJ AI Hub will provide a physical location where AI start-ups can collaborate, helping to support new, diverse innovators and drive long-term economic growth.

University Health, and operated by Plug and Play will focus on medical technology. The facility will support device innovation and digital health tools. Situated in South Jersey, it extends the innovation ecosystem into a new geography—proof that these centers aren’t just about industry clustering, but also about geographic diversification.

No one center or program holds the answer to solving complex economic challenges. But when these efforts are linked—strategically, geographically, and inclusively, they can become a durable foundation for growth. States across the country are watching how models like New Jersey’s play out: not just in terms of job numbers, but whether they truly support innovation ecosystems that can evolve with the economy. Around the country, states are experimenting

with different models—often centered around research universities, tax incentives, or federal funding. Massachusetts, for example, has built a dense innovative corridor around Kendall Square and MIT, while North Carolina has used its Research Triangle Park to scale both life sciences and AI.

What distinguishes New Jersey’s approach is its deliberate effort to balance density with distribution. Instead of concentrating innovation in one or two elite zones, the state has strategically placed centers in diverse geographies— from urban cores like New Brunswick to regions like Atlantic County and South Jersey, often overlooked in traditional tech growth.

By taking a deliberate, inclusive, and sector-diverse approach, New Jersey is showing how innovation can be used not just to grow an economy—but to shape one that is resilient, equitable, and built to last.

Pictured: The HELIX will bring together New Jersey’s public, private, and academic sectors to create a world-class hub of innovation and a strong base of support and talent pipeline for innovative companies. The HELIX campus, consisting of three separate buildings, will provide 1.5 million square feet of multifaceted, state-of-the-art environments supporting the gamut of health and life science organizations and professions.

Wisconsin-based Urban Manufacturing designs and produces custom engineered and machined components.

By David Soyka, Senior Editor, Industry Today

Back in 1978 Alex Urbanchek bought a used manual machine tool to perform part-time work machining component prototypes in his garage; in a few years, he was operating a full-time business and became a GE certified supplier. Over four decades Urban Manufacturing grew into a more than $45 million enterprise producing custom parts for major manufacturers such as GE, Harley-Davidson, Eaton, and Smith’s

Medical. In addition, Urban Manufacturing provides high level mechanical assembly, finishing and delivery services of delicate parts and sub-assemblies.

A lot has happened over these years in terms of technologies, customers, and general business operating conditions. As successful as Urban Manufacturing has been since its inception, 21st century business demands required a reassessment of how it operates and responds to

customer needs for specialty machined products that achieve close tolerances using the most demanding materials.

Which is why in 2022 when Alex retired and his son Tom took over the reins, the company embarked on what it termed its Urban 2.0 Stratagem to improve operational efficiencies and customer relationships and more effectively deploy personnel resources, new equipment, and automation.

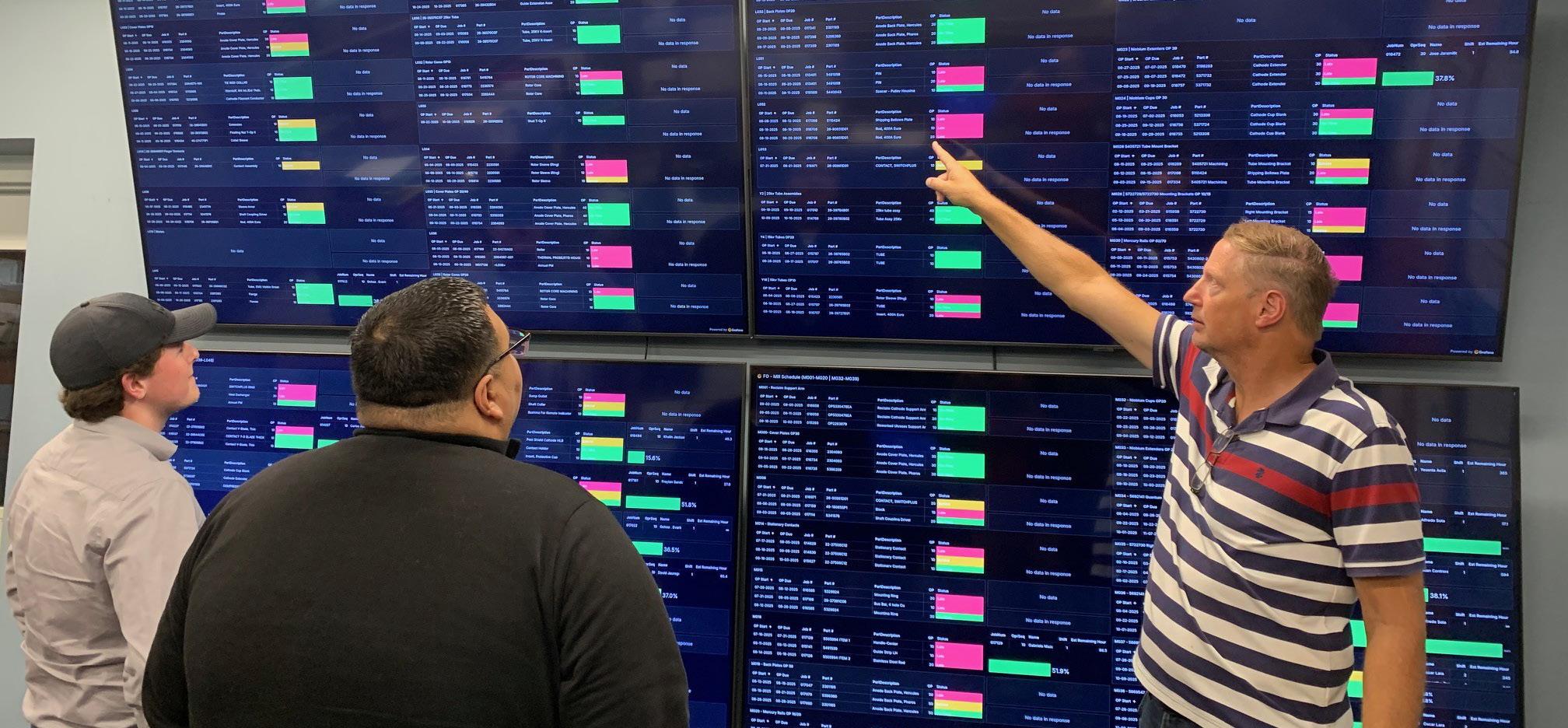

Underlying the Urban 2.0 Stratagem was upgrading to more modern ERP (Enterprise Resource Planning) systems that integrate with manufacturing systems and use real-time monitoring to evaluate process flows. “Epicor is a great system for mid-sized businesses such as Urban Manufacturing,” comments Joel Anders, Supply Chain Manager. “Just one example of

what we’re now able to do more efficiently is parts tracking. Customers want to know if their part is going to be arriving on time. Under the old system, there was a kind of makeshift numbering system where you had to go through a lot of workarounds to try to figure out where a component actually was in the production process. That’s obviously time-consuming for us, and frustrating to customers when they aren’t getting immediate updates.”

Anders points out that, Under the new system everyone is trained and uses the shop management system that generates real-time data. I can know exactly the status of my jobs and ensure

Pictured: Smart use of automation deployed in the plant targeting repetitious tasks; right: Operational work spaces are cellular so multiple machines are run with a single operator.

they are on track. And if any aren’t on track, I can quickly identify the roadblocks and work to get them resolved. The technology allows us to track, measure, and monitor our manufacturing and business processes with greater visibility all the way from sales and purchase orders to the shop floor to the customer.”

Automation of these processes helps Urban Manufacturing reduce waste and achieve faster

lead times, thereby increasing customer satisfaction and improving cost efficiencies. This is further improved with the use of emerging artificial intelligence technologies. “We used to generate a lot of paper and a lot of time managing all that paper,” Anders says. “AI has reduced all that, doing all the tracking of sales orders and other support functions that we were doing manually. Instead of time spent doing

paperwork, we have more time to spend with customers.”

Another example of AI application with Internet of Things (IoT) integration with its equipment to enable predicated maintenance to reduce downtime and process optimization to improve throughput. “These are Industry 4.0 advancements that are truly revolutionizing manufacturing,” Anders says. “They result

in improved productivity, improved product quality, and helps us to maintain margins as the business faces inflationary pressures.”

Urban Manufacturing’s ERP and other integrated business systems assure tight control over the full range of sales and manufacturing processes. Key benefits include:

• Accurate rate estimating and effective cost tracking provide customer confidence in pricing

• More efficient order entry and tracking

• Job routing helps plan effective information and material flow

• Scheduling and shop loading to keep delivery promises

• Shop floor control that supplies real-time production data collection

• Quality assurance module providing integrated reports and traceability

• Shipping reports ensure accurate fulfillment

“We’re making capital investments to replace time-consuming manual processes and oldschool technologies,” Anders. “This allows us to work better with our core customers and

Since 1983, Sequoia Brass & Copper has been a multigenerational, family-owned distributor of nonferrous metals. We supply an extensive range of alloys in plate, bar, sheet, rod, and tube forms, with custom in-house cutting capabilities to meet customer specifications.

We are proud to have served Urban Manufacturing for over 14 years and look forward to continuing this trusted partnership.

Pictured left top: Urban has about 100 machines under the main roof; left below: Engineering staff at Urban Mfg; above: Fixture design area; Aerial view of Urban manufacturing; MA-8000H horizontal machining center delivers high productivity without compromising on accuracy.

suppliers and simultaneously bring on new customers and capabilities to introduce new products.”

An equally important technology is the equipment used to make custom engineered and machined components. Urban Manufacturing maintains over 110 CNC (Computer Numerical Control) machines as well as state-of-the-art precision measuring equipment capable of measuring at a sub-micron level including five CMMs (Coordinate Measuring Machines), three vision systems, and an XRF for verification of raw materials.

This equipment is housed in a 100,000 square foot facility in Pewaukee, WI west of Milwaukee. Urban Manufacturing is ISO 9001: 2015 certified. Also as part of its Urban 2.0 Stratagem, the company operates an 85,000 square foot facility in nearby Brookfield under subsidiary Oliver Manufacturing to deliver advanced CNC milling, Swiss screw machining and a dedicated tool

and die work to as a scalable, high-performance partner for industrial OEMs.

Urban Manufacturing employs about 160, including 20+ journeyman machinists and two apprenticeships; 80% of journeymen machinists trained in the apprentice program stay with the company.

“We have a diverse workforce with a very low attrition rate,” Anders says. “Most of our employees have been with us over ten years, and more than 30 employees have been with us for more than 20 years. Urban Manufacturing has never laid anyone off in its history, which says a lot about our commitment to training and retaining our people. We’re a family-owned

Pictured above: Real time shop floor analytics w/ colored job status; right: A precision machined stainless steel part; Urban’s Modern vertical machining center.

business that treats its employees like family.”

The company’s reputation for manufacturing and engineering know-how helps maintain its leading position as a supplier of choice regardless of changing economic conditions. “If there’s a price increase of maybe 5%, the OEMs aren’t going to go out looking for new suppliers. If it is 20 or 30%, then they are going

to look at offshore alternatives. So far, even with the tariffs, we haven’t experienced a lot of pricing pressure, so it’s not much of an issue for us.”

Most importantly, Anders points out that, “We’re a Tier 1 OEM supplier with vendor numbers that in many cases go back 40 years,” Anders says. “The future of modern manufacturing involves high tolerance machining with precise measurements to ensure high accuracy and quality that satisfied intricate designs and performance standards.”

He adds, “Urban Manufacturing isn’t just some contract machine shop, we employ proprietary intellectual property combined with experienced machinists using the most advanced tools to produce complex parts, often using exotic materials. That’s a significant competitive advantage that becomes more so as we continue to employ new technologies that make us more efficient, more customer responsive, and more capable to provide critical parts to a range of industrial partners.”

By Stefani Pashman, CEO, Allegheny Conference on Community Development

Nippon Steel’s $14.1 billion purchase of U.S. Steel—and its commitment to keep the company anchored in the region—reinforces a long-standing truth: Pittsburgh is a global center for manufacturing innovation.

This is nothing new. Pittsburgh has been shaping the manufacturing industry for over 150 years, from the steel giants of the Gilded Age like Carnegie and Westinghouse to today’s legacy companies like U.S. Steel. Today’s success is rooted in the region’s industrial legacy— redevelopable sites, a skilled workforce, top-tier universities, and a culture of resilience and reinvention.

This summer’s inaugural Energy and Innovation Summit, hosted by Pennsylvania Senator Dave McCormick, put Pittsburgh firmly in the spotlight. Held at Carnegie Mellon University, the first-of-its-kind regional event brought together top energy and AI executives, major global investors, leading labor

and trade representatives, and senior government officials—alongside Pennsylvania Senator McCormick and President Trump—to explore the future of innovation and economic growth.

Here, 20 companies announced over $90 billion of investments in data centers, energy and power infrastructure, and workforce and AI training projects. These commitments will create tens of thousands of construction jobs and thousands of permanent jobs, signaling Pennsylvania’s readiness to power the AI and energy revolution.

GE Vernova, for example, announced up to $100 million of investment in Pennsylvania facilities at the summit, including creating 250 new jobs by expanding a power grid equipment manufacturing plant in the Pittsburgh region. This came on the heels of plans announced earlier this year to invest more than $10 million in its Pittsburgh facility to expand capabilities across its electrification segment. This includes funding to house a new domestic manufacturing line for the company’s FLEXINVERTER technology, which will enable utilities to seamlessly connect renewable energy sources to the grid, ensuring stable and consistent energy supply for homes and businesses. With a footprint of more than 2.7 acres, the expanded Pittsburgh facility will also boost engineering and field operations for sectors like steel, oil and gas, marine and

renewable energy.

Other projects announced during the event include the Energy Innovation Center’s Infrastructure Academy, which plans to build a first-of-its-kind regional training facility for energy and AI infrastructure workers with the potential to train more than 7,000. Westinghouse Electric Company plans to have 10 new, large nuclear power plant reactors under construction by 2030, generating what is currently estimated to be $6 billion in economic impact and

Pictured: Robotics Innovation facility as part of the ARM Institute;

The Advanced Robotics for Manufacturing (ARM) Institute is located in Mill 19 in Pittsburgh’s Hazelwood neighborhood.

15,000 new jobs in the state.

Here’s how Pittsburgh is building on its legacy to drive the future forward and what other destinations can learn from its efforts.

Pittsburgh’s recent investments point to the proliferation of autonomy across all sizes of manufacturing companies. Home to nearly 3,000 manufacturing companies employing more than 91,000 people, Pittsburgh’s manufacturing expertise is now powering critical sectors of the global economy, from robotics and energy to life sciences and advanced materials.

The integration of AI and advanced robotics is poised to revolutionize the manufactur-

ing landscape. In 2022, the U.S. Economic Development Administration awarded the Pittsburgh region a $62.7 million cluster challenge grant to accelerate the commercialization of robotics technologies. As it enters its final year of funding, this initiative will strengthen the region’s leadership in smart manufacturing and further embed AI into industrial processes across key sectors.

The New Economy Collaborative (the Collaborative), formed to pursue the funding opportunity, is driving this charge. The Collaborative is an 11-county coalition com-

prising more than 90 organizations—including community-based groups, labor unions, educational and research institutions, economic development partners and leaders from the private, public and philanthropic sectors. Through its de-risking and adoption mission, the Collaborative—in partnership with Catalyst Connection, the ARM Institute and regional innovation accelerators like the Digital Foundry at New Kensington and Indiana University of PA’s STEAMSHOP—is empowering small and medium-sized enterprises (SMES) to embrace advanced manufacturing, robotics and auton-

omous systems to secure a more sustainable future for the region’s manufacturing sector. No-cost prototyping, proof-of-concept demonstrations and hands-on guidance enable SMEs to explore robotics solutions with minimal risk before committing to full-scale adoption. This allows them to enhance productivity, efficiency, and competitiveness in the evolving market. Success is starting to show. Keystone Ridge Designs, a local manufacturer of steel benches and site furniture, worked with the ARM Robotics Hub and Catalyst Connection to test whether robots could grind their steel products. After attending a workshop in February 2024,

they felt ready to try it. They tested parts and ran trials at ARM’s Mill19 lab, adjusting the process to get the right finish.

ARM’s consultation helped them figure out exactly what the system needed. With that information, ARM received quotes from different suppliers, and Keystone Ridge chose a solution that made financial sense and increased their manufacturing throughput.

As of 2024, 571 SMEs have been engaged through these projects, representing over $2 million in modernization investments.

Manufacturers increasingly ask: Where’s the pipeline of mid-skilled talent—not just college graduates, but industry-ready employees?

Pittsburgh’s higher education ecosystem is one of its greatest strengths. World-renowned institutions like Carnegie Mellon University (CMU) and the University of Pittsburgh (Pitt) consistently rank among the top in fields such as computer science, AI, engineering and life sciences. These universities produce a steady pipeline of highly skilled talent and cutting-edge research, drawing both startups and Fortune 500 companies to the region. However, the region is putting an additional emphasis on workforce programs to upskill new workers outside of the traditional four-year degree.

Another of the Collaborative’s main missions is focused on upskilling and workforce development, training thousands in the region for robotics-related careers through over 15 training and certification programs, offered by 18 funded partners. Supportive services to help remove

employment barriers like transportation, childcare, scholarships, flexible class schedules and wraparound resources are offered, with a focus on the underserved and coal-impacted areas.

In particular, the Expanded Pathways to New Economy Careers project emphasizes job training, career placement and supportive services. The project has hosted multiple training and outreach events, distributed scholarships and placed students in robotics internships and apprenticeships.

So far, 5,537 students, 1,286 manufacturing workers and entrepreneurs, 751 apprentices and teachers and 1,189 businesses have been supported through these resources.

Several major commercial real estate projects in the region have been centered around the

Stefani Pashman is the chief executive officer of the Allegheny Conference on Community Development, an 80-year-old public-private partnership driving economic growth and quality of life for the 10 counties of southwestern Pennsylvania. Under her leadership, the Conference is repositioning downtown Pittsburgh for future investment, accelerating decarbonization strategies, improving business competitiveness through strategic policies and public investments, and strengthening the region’s robotics and autonomy cluster through the successful execution of the Conference’s first federal grant ($63 million from the U.S. Department of Commerce). Stefani is active in the community, currently co-chairing the 2025 Maccabi games bringing 2,000 athletes to Pittsburgh. She holds an M.B.A. and a master’s in health administration from the University of Michigan and a B.A. from Washington University in St. Louis. She was elected to the International Women’s Forum and is a member of YPO. Stefani and her husband reside in the Squirrel Hill neighborhood of Pittsburgh and have three college-aged children. spashman@alleghenyconference.org | Website: https://pittsburghregion.org/

long commitment to support adaptive reuse for manufacturing partnerships that support key industry sectors.

For example, the historic Bethlehem Steel manufacturing factory is now home to JM Steel, which produces the necessary steel torque tubes for Nextracker’s large-scale solar power arrays. Hazelwood Green, a historic former steel mill, has been redeveloped into a global center for advanced manufacturing, robotics innovation and biomanufacturing.

The Strip District, also known as “Robotics Row,” was a former location for industrial factories and is now home to notable robotics and AI companies, including Carnegie Robotics, Bloomfield Robotics, Aurora, Honeywell,

Bosch, among others. The Robotics Factory serves as a dynamic hub for emerging technology companies, providing not only collaborative spaces, but also critical manufacturing capabilities necessary for effective scaling. It’s located at Tech Forge, a property of the Regional Industrial Development Corporation, nestled within the Lawrenceville Technology Center, a transformed 14-acre industrial steel site.

In addition to these specific areas, Pittsburgh generally offers manufacturers a strategic location within a day’s drive of more than half the U.S. population, giving companies direct access to major East Coast, Midwest and Canadian

Row in Pittsburgh’s Strip District.

markets. The region’s robust infrastructure— from multimodal transportation networks to reliable utilities—supports efficient production and distribution at scale.

Perhaps most importantly, collaboration is a hallmark of the Pittsburgh approach, with public and private sectors working in lockstep to align investments, resources and workforce strategies. This spirit of partnership is reinforced by a business-friendly climate, where competitive costs, streamlined permitting and supportive policies create a stable environment for growth. Together, these advantages position Pittsburgh as an ideal base for manufacturers seeking both operational efficiency and longterm success.

As the manufacturing sector continues to gain momentum, we’re taking a close look at what it will take to sustain this growth while driving greater operational efficiency. Two critical factors are rising to the forefront: energy and technology, particularly AI.

To support long-term manufacturing expansion, we must ensure consistent, reliable access to the energy required to power modern industrial facilities. That’s why we’re making a concerted effort to diversify and strengthen the region’s energy infrastructure, with an emphasis on sustainability. Several key projects are already underway:

• Hitachi Energy is expanding its Mount

Pleasant plant in Westmoreland County with a $70 million investment to double its high-voltage equipment production. This project will include renovations, production line expansion and upgrades, and a new training center. This initiative will dramatically increase the Pittsburgh facility’s ability to produce key equipment such as Dead Tank Breakers (DTB), Plug and Switch Systems (PASS), and other high-voltage products and components.