Quality and Testing Regulations for Office and Contract Furniture

Quality Assurance

RAL-GZ 430/8

Dated: January 2022

Quality Assurance

RAL-GZ 430/8

Dated: January 2022

Editor

RAL Deutsches Institut für Gütesicherung und Kennzeichnung e. V. Fränkische Straße 7 53229 Bonn

Tel.: (+49) 228 68895-0

Fax: (+49) 228 68895-430

E-Mail: RAL-Institut@RAL.de

Internet: www.RAL.de

Reprinting, even in parts or extracts, is not permitted. All rights, including those of translation into other languages, are reserved by RAL.

© 2022, RAL, Bonn

Quality and Testing Regulations for

Office Furniture

Quality Assurance

RAL-GZ 430/8

Deutsche Gütegemeinschaft

Möbel e. V.

Friedrichstraße 13 - 15

90762 Fürth

Tel.: +49 911 950 999 80

Fax: +49 911 950 999 850

E-Mail: dgm@dgm-moebel.de

Internet: www.dgm-moebel.de

These Quality and Testing Regulations have been established by RAL Deutsches Institut für Gütesicherung und Kennzeichnung e. V. (RAL German Institute for Quality Assurance and Labelling) under the principles for quality labelling in a recognition process together with expert groups and responsible authorities.

Bonn, January 2022

RAL Deutsches Institut für Gütesicherung und Kennzeichnung e. V.

RAL-GZ 430 has been the “gold standard” for good furniture quality for more than half a century. However, its contents require constant adaptation in order to meet the needs of changing consumer requirements on the one hand and technical as well as social developments on the other. Standards, laws, and other recognised rules of technology are constantly changing. They are an essential part of RAL-GZ 430, which in its quality requirements, however, often goes beyond normative basic requirements.

With the claim of a holistic quality standard for furniture, RAL-GZ 430 includes in testable form the topics of processing quality, utility and comfort, product safety, healthy living as well as sustainability in product design and material selection.

The previously proven requirements and test methods have been adopted largely unchanged in this new edition of the RAL. In detail, however, changes, updates and adaptations were necessary, based on the experience in dealing with this set of rules and due to changes in standards which are referenced in this RAL.

As the person responsible for the editorial processing of the results of the DGM working groups, I would like to express my special thanks to the staff of these working groups as well as to the editorial team of the DGM. Without the dedicated cooperation and competent contributions of the voluntary DGM working group participants, further development and updating of RAL-GZ 430 would not have been possible.

Reimund Heym Head of Technology and Standardisation

It all started with RAL-GZ 430. It is the basis for the “Golden M” certification, which focused on quality, function, and environmental compatibility early on. It was and still is a matter of consumer protection.

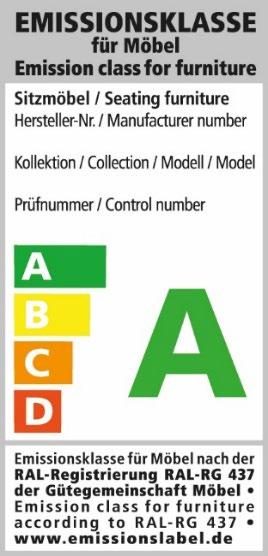

I am all the more pleased that the Deutsche Gütegemeinschaft Möbel e. V. recognised early on that quality, and thus durability, is an essential part of sustainability. Various certification offers in this area followed, whether it was climate neutrality or emission measurements of the products. Then, in 2019, very consistently, the Advisory Board for Sustainability was founded to meet the everincreasing pressure for change, which was also of a legislative nature. Today, sustainability is no longer a trend, nor is it a megatrend, but a must, an imperative.

We need to recognise that companies are part of the environment and part of society, that we are all part of a system with interdependencies, no matter what we do or don’t do. Sustainability management is a journey that never ends for companies. With its various certifications, the DGM offers companies goals and intermediate destinations for this journey, and thus also offers the end-consumer reliable information on the subject of sustainability. With this in mind, I am honoured to be able to shape the future with the wonderful people on the Advisory Board and I look forward to continued constructive discussions leading to results for the good of all.

Dr Susanne Steinhauer Chairwoman Advisory Board for Sustainability6.4.1.

6.4.3.

6.4.4.

6.4.5.

6.4.6.

6.4.7.

6.4.8.

6.5.

6.5.1.

6.6.

6.6.1.

6.6.2.

These Quality and Testing Regulations apply to the condition of furniture for the office and contract sector 1 that may be labelled with the RAL quality mark. All legal regulations must be observed as a matter of principle. In addition, quality assured furniture must meet the requirements as defined below. All standards relating to the scope of these Quality and Testing Regulations shall be consulted as well.

Only the most recent versions of standards or their relevant replacements are valid.

The requirements take into account as standard climate according to DIN 50014 a temperature of 23° C and a relative humidity of 50% and apply to furniture in new condition.

At the time of publication of these Quality and Testing Regulations, the DIN 68890 standard is being revised. Upon publication of this standard, the requirements contained therein shall be considered binding, provided that they do not fall below the values specified in these Quality and Testing Regulations.

Proper transport and professional assembly of the products are assumed.

The basic requirements for quality assured furniture are regulated by the relevant standards and guidelines of the Quality and Testing Regulations, compliance with which is mandatory as a prerequisite for initial testing according to Section 3.1.

Furniture that contains functional and constructional elements not included in RAL-GZ 430 must conform to current technological standards

Monitoring is divided as follows:

• Initial testing

• Internal quality control

• External quality control

• Repeat testing

• Testing and monitoring reports / Approval license

• Testing costs

1 Where the term office furniture is used below, this also includes furniture for the contract sector.

3.1.

• Inspectors

Passing the initial test is one of the requirements for the award and use of the quality mark of the Quality Association. Initial testing is carried out in the production facilities of the applicant. As part of this assessment, random laboratory test samples are taken from ongoing production by the commissioned third-party inspector. If the applicant can provide test certificates for supplied products or materials, the test procedure is reduced. It is, however, important that these documents (test certificates may not be older than 1 year) are based on the current technological standards and the tests were carried out by competent and neutral testing institutes.

3.2.

Ongoing internal quality control, which can be reproduced at any time, is mandatory for all quality mark users. Users must carefully record the results of internal quality controls, keep them for at last 5 years and present them to the appointed inspector for inspection upon request within the scope of external quality control procedures

3.3.

In order to ensure the consistent quality of quality assured products, external quality control is carried out every 2 years on the premises of the quality mark user. Within the first 3 years of awarding the quality mark/membership, external quality control is carried out annually. This test covers the inspection of the results of all quality control measures (e. g. internal quality control, test reports from competent, neutral testing institutes) and the inspection of the proper manufacturing of “quality assured office furniture”.

3.4.

If deficiencies in the quality assurance are detected during external quality control measures, the Quality Committee can order a repetition of the test, whereby the type, content and scope of this test are determined by the Quality Committee of Deutsche Gütegemeinschaft Möbel e. V. Should the repeat test also conclude with a negative result, the Quality Committee may, in agreement with the Executive Board, take further measures in accordance with Section 12.5 of the Implementing Regulations for the Award and Use of the Quality Mark

3.5.

The contracted external inspectors must draw up corresponding test reports on the tests and quality control procedures carried out; the applicant or quality mark user each receive copies of said reports.

Based on the passed tests, the DGM office issues an approval license for the furniture programs listed therein for a certain term

3.6.

The applicant or quality mark user must bear all arising testing or monitoring costs.

3.7.

The Quality Association appoints suitable, expert testing institutes to carry out tests and monitoring measures.

Institutes entrusted with this task must prove their identity to the applicant or quality mark user by submitting a written identification before starting their work.

Sustainability is to be understood as a development that is ecologically compatible, socially just and economically efficient.

Important in this context is a long product life, which can only be achieved through high quality, which contributes significantly to saving resources and which is therefore an essential part of sustainable economic activity. Another aspect of sustainability is the consideration of social impacts.

Sustainability as well as the environment and personal health are particularly important to consumers today. In close cooperation with leading testing institutes and taking into account more recent specifications of the Federal Environment Agency, the requirements were revised and adapted to the latest scientific findings.

These requirements apply to office furniture as purchasable by consumers in furniture stores. Manufacturers must ensure that all supplied materials (including those from abroad) comply with the statutory European and German regulations (e. g. Chemicals Act, Banned Chemicals Ordinance and Ordinance on Hazardous Substances, REACH POP) as well as additional DGM requirements.

In case of mandatory normative, legal, safety-relevant as well as contractual specifications regarding the use of materials, substances and requirements, the effects on the requirements according to RAL-GZ 430, especially in the contract sector, are not taken into consideration.

The initial and monitoring tests are to be carried out according to Point 3

The preparations (paints, adhesives, stains, coatings, etc.) must not contain substances of the following categories as formulation components:

Substances according to Regulation (EC) No 1272/2008 (CLP Regulation):

Categories Carcinogenic 1A and 1B, Mutagenic 1A and 1B, Toxic to reproduction 1A and 1B

a) Sensitising substances according to the Technical Rule for Hazardous Substances (TRGS) 907 and the EC Regulation 1272/2008, Annex VI

b) Substances which are of very high concern for other reasons, and which have been included in the list (so-called candidate list 1) established in accordance with REACH Article 59(1)

c) Acutely toxic (poisonous) of the category Acute Tox. 1 or Acute Tox. 2

d) Toxic to specific target organs of the category STOT SE 1, STOT SE 2, STOT RE 1, or STOT RE 2

Excluded from these regulations are:

a) Process-related, technically unavoidable impurities that are below the classification limits for mixtures.

b) Monomers or additives that react to form polymers or are chemically bonded (covalently) into the plastic during plastic production if their residual concentrations are below the classification limit for mixtures.

4.1.1.

The examinations in test chambers can be carried out both as whole-body tests and as component tests. The selection of test samples is to be agreed between the testing institute and the manufacturer and is to be carried out in such a way that all model variants awarded the quality mark are represented by the test

4.1.2.

The final products falling within the area of application differ in shape, materials and the number of materials used. Therefore, in each individual case, the test procedure and the selection of test samples must be determined by the testing institute responsible for the surveillance test in consultation with the manufacturer.

For furniture made of wood and wood-based materials with a three-dimensional surface, there are two ways of testing:

a) Whole-body testing, especially for small furniture, chairs, etc.

b) Component testing, especially for modular furniture and furniture programs with similar components.

1 Link to the candidate list of Regulation (EC) No 1907/2006 on the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH): https://echa.europa.eu/de/candidate-list-table

4.1.2.1.

The product to be tested must be taken directly from current production. Supplied parts may not be older than 10 days. A deviation from this specification is permissible if the manufacturer proves that individual supplied parts used in the normal production process are regularly older than 10 days.

Immediately after removal from production, the product must be placed in airtight packaging; modular furniture must be packed in closed state.

Note:

During component testing, it is permissible to use the following calculation formula to extrapolate the total concentration of complete products consisting of known area segments of the tested components, based on the established concentrations of volatile organic compounds of the individual components.

The proportionate areas of the total product must be calculated for each component and entered into the formula with the emission values determined:

Ccalc. = Calculated total concentration for complete product in µg/m³

n = Number of components tested

i = Compendent index

Ai (%) = Area share of the i-th component in %

Ci = Concentration of the i-th component in µg/m³

This method can be foregone if none of the tested components exceed the permissible emission values or if the entire product is tested

4.1.2.2.

In the case of component testing, e. g. for furniture programs, the testing institute selects the components to be tested in consultation with the manufacturer. The different materials used, in particular different coating systems, must be taken into account. The selection must be made in such a way as to ensure compliance with the requirements of the award criteria for the product to be tested. In the case of components with a total area share of no more than 5% of the product, sample analyses and emission testing are not necessary.

The components to be tested are be taken directly from the current production in sufficient quantity. Supplied parts may not be older than 10 days. A deviation from this specification is

permissible if the manufacturer proves that individual supplied parts used in the normal production process are regularly older than 10 days. In the case of flat components, at least 3 parts must be taken as a stack, of which only the middle part is used for the emission test. The testing institute has to be consulted about the exact sample quantity, taking into account the size of the component and the emission test chamber to be used. The samples taken from the same components must be immediately packed together in airtight packing. The individual samples should be placed as close to each other as possible in order to minimise unavoidable emissions during transport to the testing institute.

The packaged sample material must be transported to the testing institute as quickly as possible. No more than 7 days may elapse between packaging and arrival at the testing institute.

4.1.3.

Until the start of the test, the test sample or sample material must be stored at the testing institute in packaged form.

When preparing the test samples for the emission test, only those flat components should be used that are stored on the inside of the stack and not those on the outside.

Components and complete products can be tested in their original condition in a large test chamber. In this case, possible low results for semi-volatile compounds must be taken into account. As a rule, test samples are to be taken from the sample material which can be examined in a test chamber suitable for volatile organic compounds. The test samples should represent the materials used and the different surfaces of a complete piece of furniture. Any narrow surfaces exposed by cutting must be sealed with a suitable sealant.

Self-adhesive, low-emission aluminium foil has proven suitable for this purpose. Any selfemission of the aluminium foil must be determined in preliminary tests.

When calculating the emission area, the surfaces on both sides and the narrow surfaces (without surfaces subsequently sealed as a result of test sample cuts) must be included.

After completion of the test samples, they must be immediately placed in the test chambers or stored in packages until the test chamber is loaded.

For the manufacturer's own internal documentation, a sampling protocol (dates of production, packaging, shipping, etc.) must be created for each sample.

The time between packaging of the samples at the manufacturer and loading of the chambers should be as short as possible. According to DIN EN 16516, the test must be started within 8 weeks after sampling, provided that the sample is stored in the laboratory in the specified

packaging and under normal indoor conditions. Sampling, sample receipt and test start must be documented in the test report

4.1.4. Emission requirements for contract and office furniture

Table 1 – Emission requirements for contract and office furniture

Parameters

Other acc. to current list of LCI values 2)

TVOCspec. (C6 – C16) acc. to AgBB 2) Only box furniture < 3000 µg/m³ < 50 µg/m³ < 450 µg/m³ <

TSVOC (<C16 – C22)

µg/m³ < 600 µg/uh

CMR- substances 3) acc. to EU Cat. 1A and 1B ∑ < 10 µg/m³ < 1 µg/m³ per individual value < 1 µg/m³ per individual value < 1 µg/m³ per individual value

Odour (see explanations below) < 3.0 < 3.0 < 3.0

VOC without LCI

acc. to AgBB 2)

R value 4) < 1 < 1 < 1

1) The test can be terminated on the 7th day after loading if the required final values of the 28th day are reached and no increase in concentration of one of the detected substances can be detected compared to the measurement on the 3rd day.

2) Sum of all individual substances ≥ 5 µg/m ³) at test chamber concentration

3) The substance Dimethylformamide (DMF, CAS 68-12-2) is treated separately during the assessment of CMR properties. For DMF, a limit value (based on the LCI value) of < 15 µg/m³ after 28 days applies. The value after 3 days shall not be included in the total evaluation. For the calculation of the R value, DMF must still be taken into account. This regulation is valid for a transitional period until 31.12.2023. As of 01.01.2024, it will no longer apply.

Formaldehyde and acetaldehyde are excluded from the CMR assessment (classification: Carc. 1B).

4) The R value is based on the current list of LCI values according to AgBB; https://www.umweltbundesamt.de/sites/default/files/medien/4031/dokumente/agbb_bewertungsschema_2021.pdf

Definitions of TVOCspec und TSVOC

TVOCspec:

Sum of all individual substances found ≥ 5 µg/m³ in the retention range C6–C16 (between nhexane up to and including n-hexadecane). The determination is carried out in accordance with the currently valid AgBB scheme. Data in the AgBB scheme for C substances apply here to CMR substances of category 1A and 1B.

TSVOC:

Sum of all individual substances ≥ 5 µg/m³ in the retention range > C16–C22. In individual cases, LCI values have been derived for SVOC. The SVOCs for which LCI values have been determined are to be included in the R value calculation for the requirements after 28 days and are no longer subject to the sum SVOC value. The sum of the TVOCspec value and the sum of the individual SVOC with LCI value must not exceed the TVOC requirements after 28 days (AgBB procedure).

General information on TVOC and TSVOC:

The basis for measuring the emission of volatile organic compounds and formaldehyde is the BAM test method in the current version. The requirements for the test chamber procedure and the analysis are based on DIN EN 16516 in conjunction with the DIN EN ISO 16000 et. seq. series of standards.

4.1.4.1. Odour

The odour test shall be performed after a minimum of 3 and a maximum of 28 days of residence time in the test chamber. In case of a previous test according to Point 4.1.4 testing can be carried out after the previous test is completed. In the case of several tests, the result of the last test series (longest period in test chamber) is definitive.

Requirements:

Score to be maintained: Level 3.0

The majority of individual scores must not be above level 3.0. The average must be ≤ 3.0.

Testing:

Odour neutral room:

Temperature: 23° C ± 1° C

Humidity 50% r. h. ± 5% r. h.

Airflow rate: Depending on the type of test sample

Chamber volume: The chamber volume is based on the specified test chamber size (Table 1)

Room loading: Depending on the type of test sample

At least 7 test persons independently assess the odour intensity according to a 5-point scale:

1 = no odour

2 = weak odour

3 = distinctive, not unpleasant odour

4 = unpleasant odour

5 = unbearable odour

The following should be recorded:

• Age and sex of test persons

• Room size

• Room temperature

• Room humidity (rel. humidity)

• Date of assessment

• Time span between production and odour assessment

• Type of odour

Test persons: The test persons (at least 7 persons, at least 3 of them women) should spend at least 10 minutes in a room with clean air before the odour test. The odour assessment is performed undiluted. The test persons should not have any previous exposure to the odours to be evaluated.

Mean value:

Of all the individual values determined, one highest and one lowest are not to be used for averaging. Only the mean value is given in test reports

4.1.5. Additional material requirements

4.1.5.1. Chlorophenols

Pentachlorophenols / Tetrachlorophenols / Trichlorophenols

Test specimen: wood-based materials

Requirements:

Table 2 – Values to be maintained for individual biocides

Wood-based materials < 3 mg/kg < 3 mg/kg

Method of analysis:

The sample is heated with 1 m KOH in a drying oven. An aliquot of the extract is derivatised with acetic anhydride. The derivative is extracted with n-hexane and analysed on capillary GC by ECD. Other methods are permitted if comparability has been demonstrated.

4.1.5.2. Dispersion dyes and pigments

Requirements:

• Carcinogenic dyes

• Mutagenic or teratogenic dispersion dyes

• Potentially irritating dyes

• Dyes containing heavy metals are not permissible

Testing according to DIN 54231

Proof via manufacturer’s declaration possible.

4.1.5.3. PAH (Polycyclic aromatic hydrocarbons)

Testing and evaluation according to AfPS GS 2019:01 PAC

GS Specification “Testing and Evaluation of Polycyclic Aromatic Hydrocarbons (PAH) in the Award of the GS Mark” of the Product Safety Committee (AfPS) as of April 2020 or the respective current regulation.

Proof via manufacturer’s declaration possible.

4.2. Protection of environment and climate

4.2.1. Energy and eco-balance

The efforts of manufacturers to minimise the energy and atmospheric environmental impact associated with the transport of their products and supplier materials must be evident from appropriate documents.

The use of self-generated, renewable energy (e. g. burning waste wood) and the purchase of CO2 neutral energy are to be preferred.

To optimise the use of materials and energy with regard to a sustainable eco-balance, the implementation of a life cycle assessment based on the systematics of the standards DIN EN ISO 14001, DIN EN ISO 14040 and DIN EN ISO 14044 is suitable.

A life cycle assessment or environmental declaration of the products according to DIN EN ISO 14025 (EPD verification) is also recommended.

4.2.2. Human and ecosystem health

In addition to the legal regulations on the handling of chemicals that are harmful to humans and the environment (e. g. REACH Regulation), this Furniture Quality Assurance RAL-GZ 430 contains extensive testing requirements to ensure furniture that has been tested for harmful substances

4.2.2.1. Liquid coating systems

Operators of coating plants must comply with the requirements of the 31st Federal Imission Control Act (BlmSchV). This shall be proven via the manufacturer’s declaration

4.2.3. Use of materials

4.2.3.1. Solid wood and wood-based materials

Solid wood and wood-based materials must comply with EU Regulation 995/2010 and, as far as possible, originate from sustainably and legally managed forestry (FSC/PEFC documentation). When using waste wood in wood-based materials, the Waste Wood Ordinance must be observed. Proof of the pollutant limit values of the Waste Wood Ordinance according to testing in compliance with the EPF standard.

4.2.3.2. Plastic components

Plastic components > 50 g should be labelled according to DIN EN ISO 11469 and should not contain additives of other materials that conflict with recycling.

4.2.3.3. Adhesives

The VOC content of adhesives should not exceed 10% for water-based systems and 30% for solvent-based systems.

4.2.3.4. PVC

The use of PVC should be limited to furniture parts for which no equivalent other materials are available and for which the special properties of PVC are required.

The use of PVC must be indicated in the product information (PI). Dismountable PVC parts are exempt from this regulation if they are clearly marked as PVC parts

4.2.4. Circular economy

4.2.4.1.

The principles of recycling-friendly design (VDI 2243) must be observed. The use of recyclable and biodegradable materials is to be preferred.

For wear parts, a functional, compatible replacement is ensured over a period of at least 5 years.

The durability of the products shall be ensured by appropriate design.

4.2.4.2. Packaging

The packaging material must be suitable for reuse or recycling. The packaging must be designed in such a way that any volatile components of the furniture can outgas.

4.2.4.3. Reusability / recycling

With regard to reusability and recycling, no material preservatives (fungicides, insecticides, flame retardants) and no halogenated organic compounds may be added to the furniture, or the materials used for its production (wood-based materials, adhesives, coatings, etc.).

This excludes fungicides used solely for in-can preservation in water-based coatings and glues or flame retardants in which inorganic ammonium phosphates (diammonium phosphate, ammonium polyphosphate, etc.), boron compounds (boric acid, borates) or other waterreleasing minerals (aluminium trihydrate or similar) are used for flame retardation.

4.3. Social responsibility

With a view to sustainable human resources development and to ensure health, occupational safety and social working conditions, a company should, in accordance with good management practice, define and document responsibilities and procedural rules concerning this matter

• These include in particular:

• Fair hiring practices

• Continuing education of employees

• Social responsibility in company regulations

Social ethics may also include social measures for the local environment of the operating site (e. g. sponsoring cultural or charitable institutions).

Compliance with the requirements can be achieved through membership of the UN Global Compact 13.14 or equivalent certificates. The Deutsche Gütegemeinschaft Möbel supports the UN Global Compact and its 10 principles. These guiding principles for business and human rights are to be implemented by the quality mark users. The implementation is documented during the monitoring audits.

With regard to social responsibility for products of the supply chain over which the company has no direct influence, preference is to be given wherever possible to supplier companies that take social standards into account.

Advertising claims must not contain any statements such as “biologically tested” or similar statements that play down hazards as laid out in the EU Directive 67/548/EWG Article 23 (Designation) Section 4 (e. g. “non-toxic”, “no risk to health”, “free from ”).

It is a prerequisite for “furniture with the quality mark” that suitable materials and construction elements are used which are appropriate to the product and have been professionally processed. Safety, function, and utility are assessed according to the latest standards of technology at the time of product launch. Environmental and health protection as well as product information are essential quality features.

Deviations from the requirements laid out in the Quality and Testing Regulations may be made if an equivalent or higher quality and safety objective is achieved by other means. Suitable proof is required

Visual inspections are carried out under the following conditions (unless otherwise specified):

General assessment: At distance of 2 to 3 m

Detailed assessment: At distance of 0.7 ± 0.1 m

Assessment basis: normal vision; diffuse daylight (without direct sunlight or artificial light).

Parts that are not visible in the position of use or subordinate parts as well as irregularities that are only visible in grazing light are excluded from the assessment

The product information for office and contract furniture shall be made available to the retailer for marketing purposes and for passing on to the end customer and contains the following details based on RAL-GZ 430/8:

1. Product name

2. Product label*

3. Structural design

4. Materials

5. Surface treatment

6. Model variants

7. Dimensions

8. Weight

9. Maximum load

10. Cleaning and care instructions

11. User information**

*Labelling obligations according to the Product Safety Act (ProdSG) must be observed.

**User information in accordance with DIN EN 82079-1 must be supplied where necessary.

Visual inspection, laboratory test

In addition, the following information, if applicable, should be included in the product information:

• Information on wear parts and their repair or replacement, repair service if necessary (For wear parts, a functional compatible replacement of at least 5 years is guaranteed).

• Information on the type and origin of the wood predominantly used.

• Information on other materials (proportion > 3 weight percent)

• Information on the assembly of the products and disassembly for removal and subsequent material recycling. For special product groups, the Eco Design Directive (2009/125/EC) must also be observed.

• In the case of furniture that falls under the Electrical and Electronic Equipment Act (ElektroG, see annex 13.6), appropriate labelling must be applied to the furniture and the method of disposal must be indicated in the operating instructions.

• If PVC must be used, this must be stated in the product information.

6.1. General provisions

6.1.1. Material-specific characteristics

The material-specific characteristics of office furniture are regulated by special requirements according to DIN Technical Report 147.

Deviations in the panels and the coating material used must be recorded in the product information or agreed with the customer.

The requirements for office furniture must be met by all materials used (if necessary, proof by manufacturer’s declaration).

6.1.2. Safety and ergonomic characteristics

Office furniture shall in principle be designed and constructed in such a way that the ergonomic functionality and variability as well as the safety-related design enable an optimal office workplace.

In conjunction with the other testing regulations for office furniture, these functions and characteristics are to be designed for a long service life with appropriate use.

For cabinets intended specifically for the contract sector (e. g. accommodation, youth hostels, conference centres, etc.), the requirements according to DIN EN 16121 must be complied with to prove safety.

6.2. Applicable ergonomic, dimensional, testing and safety standards

(For the standards and regulations outlined below, the relevant current version applies.)

6.2.1. Office work desks, cabinets, room dividing elements

DIN Technical Report 147 Requirements and testing of office furniture

DIN EN ISO 9241-T5

Ergonomic requirements for office work with monitors

Part 5: Requirements for workplace design and posture

DIN EN 527-1 Office furniture, office work desks, dimensions

DIN EN 527-2 Office furniture, office work desks, mechanical safety requirements

BGR 234 Storage equipment and devices

DGUV 215-410

Monitor and office workstations, guidelines for design

DIN VDE 0100, Part 713 Electrical installations in furniture

DIN EN 60335-1

Safety of electrical appliances for household use

BSO Guideline for electrical installation in office furniture Compilation of recognised rules of technology

DIN EN ISO 13857

Safety of machinery; Safety distances to reduce risk of

squashing/ clamping body parts in danger zones

DIN VDE 1000

General principles for the safe design of technical products, (identical to DIN 31000) minimum distances, crushing and shearing points

DIN EN 14073-2

DIN EN 14073-3

DIN EN 14074

DIN EN 15372

DIN EN 16121

DIN EN 16122

DIN EN 1023-1

DIN EN 1023-2

DIN EN 1023-3

DIN EN 1730

ZLS / EK5/AK3

ZLS / EK5/AK3

ZLS / EK5/AK3

ZLS / EK5/AK3

VDS 2024

6.2.2. Office work chairs

Office furniture, cabinets, safety features

Office furniture, cabinets, stability, and strength of construction

Office furniture, office work desks and cabinets; determination of strength and durability of moving parts

Tables for non-domestic areas, durability, and safety

Storage furniture for non-domestic areas - Safety, strength and durability requirements

Storage furniture for non-domestic areas – Test method for the determination of safety, strength, and durability

Room dividing element - Dimensions

Room dividing element - Mechanical safety requirements

Room dividing element - Testing

Tables – Test methods for determining stability, strength and durability

Basic principles for testing the safety and ergonomic features of sitting/standing work desks

Basic principles for testing the safety and ergonomic features of office furniture on casters

Basic principles for testing the safety and ergonomic features of the work surfaces of work desks

Basic principles for testing the safety and ergonomic features of screen support arms

Erection of electric installations in furniture and similar furnishings

DIN EN 1335-1 Dimensions

DIN EN 1335-2

DIN EN 16955

Safety requirements including user information

Testing of gas springs

6.2.3. Visitor chairs for the contract sector

DIN EN 1728

Seating furniture – Test method for determining strength and durability

DIN EN 16139

DIN EN 1022

DIN 68878

Seating furniture for non-domestic areas – Requirements

Furniture – Seating furniture – Determination of stability

Chairs for domestic use, performance characteristics –Requirements and test methods

6.2.4. To be considered in office planning

DIN 16555

DIN 4543-1 (withdrawn)

DIN 15906

Office workplace – Areas for communication places in office and administration buildings

Office workplaces – Areas

Conference facilities

The overall appearance of a piece of furniture is determined by the level of decorative design and the quality of workmanship. These criteria are examined and assessed as “technical quality features” according to objective aspects within the framework of furniture testing.

In contrast, the aesthetics of a piece of furniture depends greatly on the subjective perception of the observer or user. The aesthetics of a piece of furniture cannot be judged according to technical parameters. It is a question of individual taste, which is influenced by fashion trends, the environment, personal image needs, and art and taste sensations, among other things.

6.3.1. External design

Visual assessment of the overall appearance and metrological inspection of connections, dimensional accuracy, evenness, uniformity, colour design.

Essential test criteria:

• Dimensions for office work desks according to DIN EN 527-1

• Evenness of front and side surfaces, work surfaces

• Joint width (deviations)

• Alignment line of doors, flaps, and drawer fronts

• Design of corners and edges according to DIN Technical Report 147

• Uniform colour design

Requirements:

• Optimum external appearance

• Compliance with coordination dimensions or product information for other dimensions

• Perfectly fitting joints

• Uniformly even surfaces, max. permissible deviation 0.5% related to the distance between two corners

• Visually and technically good design of corners and edges, minimum radii 2 mm or 3 mm for desk top surfaces and topsides respectively

• Matching joints and parallel edges, deviation max. 2 mm per m edge length

• Matching alignment lines of doors, flaps, and drawer fronts; max. permissible deviation from alignment line 2 mm

• Good uniform colour design according to DIN Technical Report 147 (surface gloss max. 20 gloss units, surface resistance not less than 0.15 and not higher than 0.75)

6.3.2. Material selection and workmanship

Visual inspection of appearance, findings and quality of the materials used as well as the quality of workmanship

Essential test criteria:

• For solid wood: quality-reducing knots, tree edges, worm marks, wood rot

• For panel material: defects in coatings and veneers

• Uniform material quality

• Processing quality of the materials

• Selection, use and installation of high-quality fittings

Requirements:

• No imperfections

• No quality-reducing phenomena

• Visually and professionally flawless workmanship of all materials

• Correct selection, use and installation of appropriate fittings (for loads see corresponding standards)

6.4. Strength, durability

6.4.1. Hinged doors, swing doors, hinges

With regard to the testing and assessment of moving parts of the furniture (e. g. drawer runners) as well as other load-bearing construction elements (e. g. shelves or shelf supports), various requirements and test methods of DIN EN 14073/2-3 as well as DIN EN 14074 and DIN Technical Report 147 must be observed.

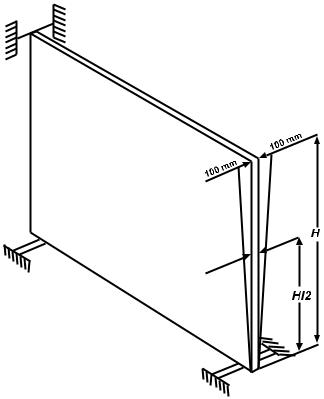

6.4.2. Room dividing elements

The same test conditions which apply to other office furniture also apply to room dividing elements For systems that are permanently connected to the structure (room dividers), the building regulations apply. Special requirements for movable partitions and partition systems: Additional testing according to DIN EN 1023/3.

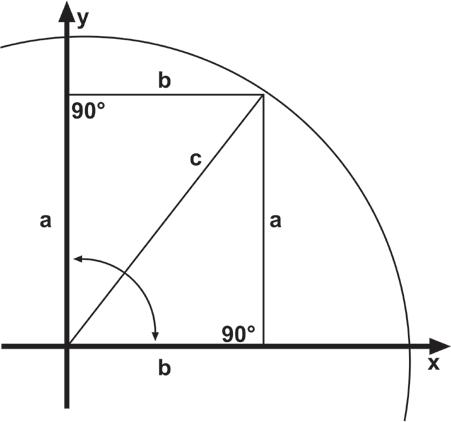

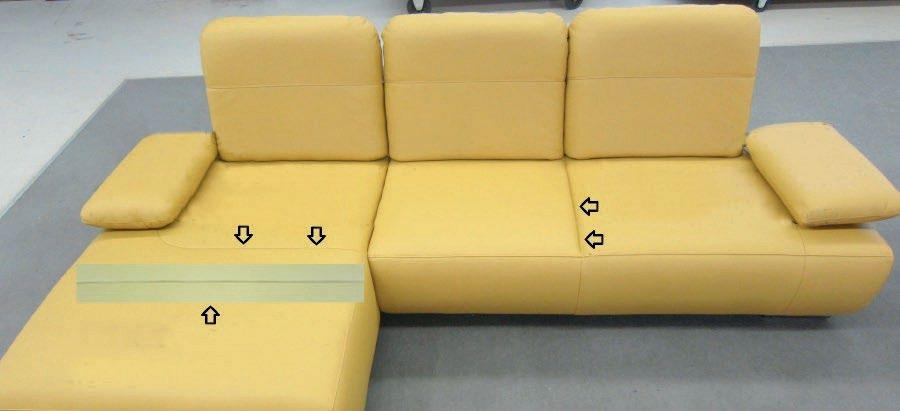

Static load capacity (deformation test)

Test conditions:

Movable wall fixed on one side at the top and bottom

Opposite side fixed at the bottom, at the top under horizontal load deflection of the movable wall by 200 mm or with a force 200 N – see picture, load after each side 5 min.

Requirements:

No permanent deformation after unloading, functional safety must be guaranteed.

Durability of the construction

Test conditions:

Movable wall fixed at the top and bottom on one side

Bending fatigue load test by applying a load of 200 N at half the height of the movable wall, on the side that is not fixed at the top – see picture

Max. deflection to each side: 100 mm

Load change: 1,000

Requirements:

No damage or fractures to the corner connections and positioning elements, unit should be fully functional after endurance test.

Dynamic load capacity

A dynamic load capacity test is carried out in the same manner as described in the drop test. In addition, the movable wall surface is tested against hard impact.

Test conditions:

Movable wall mounted horizontally with 2 longitudinal edges on a rigid base,

Impact body 1: steel ball 1 kg (ø 63 mm),

Impact body 2: sandbag with 20 kg (ø 200 mm),

Drop heights: 400 mm, 600 mm,

Impact load: 1 load per drop height and impact body with point of impact at the centre of gravity of the surface.

Requirement:

No permanent damage to the deformations

Stability

Testing of non-upgradable and upgradable room dividing elements according to DIN EN 10233 Point 6.

Strength of upgradable elements

The strength test of upgradable elements is to be carried out according to DIN EN 1023-3 Points 6.3. and 6.4.

Requirement:

No damage when lowering 1/100 of the depth of the element.

6.4.3.

Locks must be positioned in such a way that injuries are avoided. According to DIN Technical Report 147, locks on cabinets and base units must be fitted at the front. As a matter of principle, no locks must protrude in the leg space of tables.

The effect of all loads occurring in practice, such as transverse forces, counterforces when closing on the latch, etc., are taken into account in the test.

The test is carried out on the finished furniture in accordance with DIN EN 16014.

Locking systems must allow at least 100 different lockings or the different number of lockings must be agreed.

Test conditions:

Torque and closing resistance are determined before and after the durability test:

10,000 operations without additional load

3,000 operations with 0.5 kg additional load

2,000 operations with 1.0 kg additional load

Additional load applied to the original key shaft or rotary knob in each case

Requirements:

Functional safety guaranteed, locking resistance max. 50 Ncm (with door open).

Overtightening test

Test conditions:

According to DIN EN 16014 the lock is overtightened with 160 Ncm.

Requirements:

Functional safety guaranteed.

Pull-out resistance

Test conditions (acc. to DIN EN 16014):

Test force on lock: 300 N

Test force on rod bearing: 200 N

Load duration: 10 s

Unloading duration: 120 s

Cycles: 5 loads

Requirements:

Max. permissible lift-off from the support material 2 mm

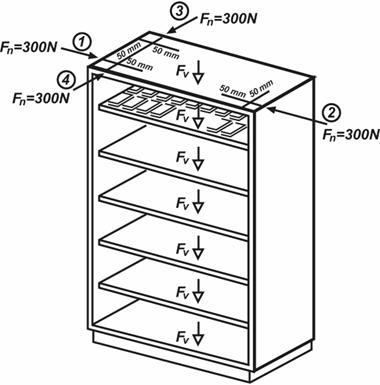

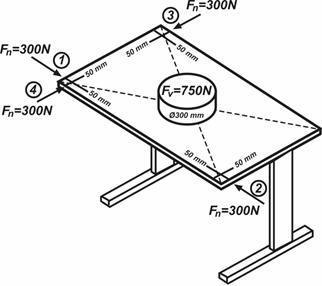

6.4.4. Durability of the construction joint

Durability test

Test conditions:

• Individual pieces of furniture fixed to the floor with 10 mm open adjusting elements, without preventing movement.

• Additional load for tables Fv = max. 1,000 N (centre of surface, evenly distributed), Test weight ø 350 mm

• Additional load for cabinets: F = 1.5 kg/dm2 (all shelves evenly loaded)

• Horizontal force (alternating load): 300 N

• Force application: see picture

• Step sequence: 1, 2, 3, 4 (lengthwise, lengthwise, crosswise, crosswise)

• For round or oval conference tables, the force application is analogous.

• Cycles: 5,000

Requirements:

Max. permissible deflection under horizontal load max. 2% related to the force application height.

Note: Retightening of fastening screws permissible.

Dynamic test (drop test)

Test conditions:

Individual pieces of furniture (office desks and cabinets) tilted over narrow side according to picture (test based on DIN EN 1730 Point 6.9.)

Drop height according to DIN EN 527-2

Frequency: 2 times over each of the two narrow sides

Test surface: concrete floor with PVC overlay (1.5 mm thick)

Requirements:

No visible changes permitted; functional safety must remain unaffected.

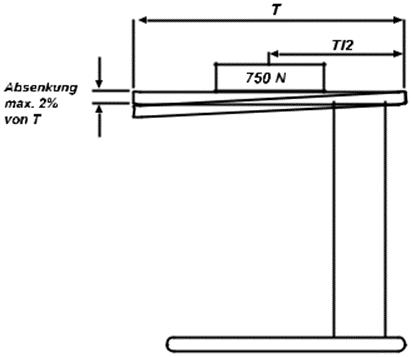

Static load capacity, deflection of table and work surfaces

Test conditions:

• Static load of drawers, pull-outs, shelves, and inserts

• Static load of table and work surfaces (deviating from DIN EN 527-2)

• Table or work surface centre loaded with test weight

• Test weight: 75 kg, outside ø 350 mm

• Additional load: for office desks, cabinets with work surfaces etc., the additional load depends on the respective loads of the containers.

• Load duration: 7 days

Requirements:

• Max. permissible deflection under test load: 1/100 (related to panel length)

• Max. permissible permanent deformation: 3 mm

• Max. permissible inclination of the work surface for skid tables: 2%, measured at test load (see picture)

Note: Protruding tabletops and their fastening must be constructed in such a way that the unloaded table (dead weight) can be lifted at any point on the tabletop (requirement according to DIN Technical Report 147) and that it is possible to move the table in the room

Strength and fatigue under vertical force application

Testing according to DIN EN 527-2

Requirement:

No visible changes, functionality must remain unaffected

6.4.5. Furniture casters

Casters adapted to the weight of the loaded furniture must be used. The casters must meet the requirements of DIN EN 12528 or DIN EN 12530

6.4.6. Durability of pull-out stops

Test conditions:

Pull-outs loaded with payload; 1 pull-out fully extended; further pull-out on the actuating element loaded with tensile force to the outside.

• Tensile force: 100 N (threshold load)

• Load frequency: 5,000

• Test frequency: 15 min-1

Requirements:

Pull-out stop functionally reliable, actuating elements without damage

6.4.7. Freedom from vibrations

Test conditions and requirements based on DIN Technical Report 147.

The design must ensure that no disturbing vibrations occur in office work desks. This requirement is deemed to be fulfilled if the values for the permissible deflection (S permissible) given in Table 1 (DIN Technical Report 147) are not exceeded during the test with a pendulum impact hammer with an energy of 10 Nm.

Permanent deformation must not occur.

6.4.8. Foot levelling and floor loading

Office furniture must include a device to compensate for floor unevenness.

Test conditions:

The surface pressure is calculated over the supporting surfaces of the loaded furniture (loading according to DIN EN 14073-2). Supporting surfaces are pedestals, legs, and casters

Surface pressure = F1 + F 2 N/mm2

F1 = Dead weight force (N)

F2 = Specific load (N)

A = Total supporting surface of the stand elements (mm2)

Requirements:

Floor levelling min. 10 mm

Surface pressure = max. 4 N/mm2

Other values are to be specified in special agreements. In case of dynamic loads, e. g. due to vibration, pedestal constructions are recommended to avoid floor damage.

Office furniture, contract furniture and work furniture of all kinds are subject to the provisions of the Product Safety Act (ProdSG). Accordingly, the basic safety, occupational health and ergonomic requirements laid down in the relevant standards and safety regulations apply bindingly to all such furniture.

In addition, the goal for high-quality office furniture is to achieve optimum ergonomic functionality and variability.

6.5.1. External design, corners, edges, shaping, surface

Test conditions:

Haptic, metrological, and visual testing:

• Corners and edges of work surfaces (all accessible working edges) with which the user comes into contact during intended use and reasonably foreseeable misuse

• Shaping in leg area and head area (wall cabinets)

• Shaping in containers (drawers, shelves, baskets, etc.)

• Shaping of accessible fitting parts

• Surface finish with regard to roughness

• Surfaces with which the user is in constant contact, especially the worktop, must not allow any unwholesome heat dissipation

Requirements:

• Accessible corners and edges with minimum radius 2 mm

• Accessible corners and edges of tabletops with minimum radius 2 mm

• Material thicknesses not permitting these values must be free of burrs (see DIN ISO 13715)

• Avoidance of projections, corners and edges in the extended leg area, construction parts shaped with generous radii, no construction parts in the direct leg area, generous shaping in the accessible area of the head (wall cabinets in system furniture)

• No sharp-edged construction parts in containers

• Burr-free, optimally shaped, and rounded fittings

• Smooth and even accessible surfaces (except for design-related deviations that are not ergonomically disturbing)

• No unacceptable heat dissipation from work surfaces (thermal conductivity

≥ 0.7 watt/mK)

• Safety glass must be used for freely accessible vertical glass surfaces.

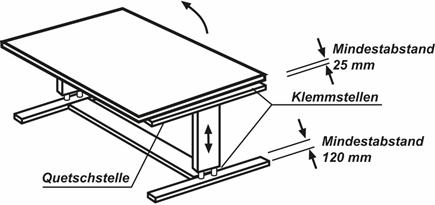

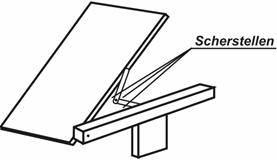

Safety distances, avoidance of pinching, crushing, and shearing points

Office furniture must be designed in such a way that, when used properly and in a foreseeable manner, there are no pinching, crushing, or shearing points on moving parts that could cause injury.

Based on DIN EN ISO 13857

Test conditions:

Testing of safety distances for moving parts:

• Adjustable tables, sitting/standing work desks

• Flaps, scissors, actuators

• Sliding doors

• Furniture with motorised adjusting parts, e. g. sitting/standing work desks

• Swivel and pull-out fittings

Requirements:

Opening width for fingertip < 8 mm or > 25 mm

Opening height for feet > 120 mm

Doors, flaps, and pull-outs including their hardware parts are excluded from this. The safety distances also apply to the distance between handles, knobs, and other parts.

Securing moving parts (e. g. drawers and doors)

Test conditions:

All detachable and moving furniture components are tested.

Essential criteria:

• Secure locking

• No automatic opening and closing of drawers, pull-outs, roller shutters and doors (with the exception of the self-closing mechanism)

• Drawers and pull-outs must be shock-absorbing to prevent them from being pushed in too far and to prevent them from falling out

• Doors, roller shutters, pull-outs and drawers must not be removed or unhinged when locked

• The securing of the moving parts must be sufficiently durable (verified by the functional life and wear test)

6.5.3. Ergonomic design

Ergonomic design of office furniture means that construction, conception, execution ,and use are carried out in such a way that an optimal adaptation to the working person is achieved.

Desk heights, legroom design

Test conditions:

Testing according to DIN EN 527-1, BGI 650

Requirements:

The minimum ergonomic dimensions must be observed.

Surfaces, surface gloss, surface brightness, heat dissipation

In the field of vision, glare due to shiny surfaces must be avoided and disturbing contrasts due to surfaces that are too bright or too dark must be ruled out (DIN Technical Report 147).

Test conditions:

• Testing of accessible and visible surfaces

• Condition (finish)

• Surface gloss: Exterior surfaces in the field of vision must not be glossy (gloss degree tables or reflectometer)

• Surface brightness: Exterior surfaces in the field of vision must not be too bright or too dark (reflectance tables or brightness metres)

• Heat dissipation

Requirements:

• Smooth surfaces that cannot cause injury when touched or permit distraction-free work (e. g. writing on work surfaces)

• Surface brightness (colour reflection) between 0.15 and 0.75

• Surface gloss max. 20 gloss units at 60° light incidence angle

• No unacceptable heat dissipation from surfaces with which the user comes into contact (thermal conductivity ≥ 0.7 watt/mK)

Noise generation of moving parts

Test conditions:

See test specifications for seated/standing workplaces

For partition walls, movable wall systems; testing of sound absorption for special equipment

Requirements:

For appropriately declared partition walls, room dividers and partition wall systems, sound absorption in accordance with the delivery agreement. The rating level at office workplaces should be as low as possible, taking into account the noise from outside.

Test conditions: (test criteria)

• Access area or access space for cabinets

• Access space for partial pull-outs

• Coordination dimensions with regard to file heights DIN A4 or hanging files DIN A4/A5

• Position of wall cabinets

Requirements:

Doors, sliding doors and roller shutters must be able to be opened to such an extent that the entire useable space can be accessed without hindrance (even when doors are open 90°, fixtures must be functional).

Partial pull-outs must allow at least 70% unhindered access.

Full-extension pull-outs must allow unhindered access to the full useable space.

The interior design of cabinets is free.

Test conditions:

The stability of office furniture must be guaranteed in every operating condition. This means that testing is carried out in the worst possible case, e. g. when all drawers, clothes rails, shelves etc. that can be pulled open at the same time are pulled out.

The furniture is loaded with loads from DIN EN 14073-3.

The stability test is carried out according to DIN technical report in deviation from DIN EN 5272 for tables and DIN EN 14073-3. In addition, the basic principles for testing the safety and ergonomics of office furniture on casters (except office seating) are to be applied. Furthermore, BGR 234 must be observed.

Requirements:

Furniture must not tip over.

Tables must be stable, even when loaded with 75 kg at the most unfavourable point of the tabletop.

Provided that they have sufficient load-bearing capacity and are set up vertically, the following can generally be considered stable:

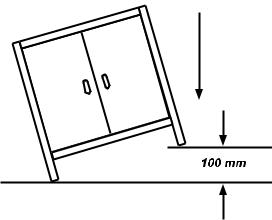

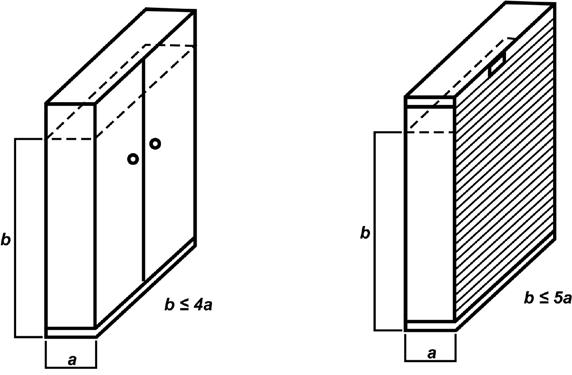

Cabinets with hinged doors, if the height of the uppermost shelf is not more than 4 times the plinth or frame depth (see picture).

Cabinets without doors, sliding or roller blinds, if the height of the top shelf is not more than 5 times the plinth or frame depth (see picture).

Room dividing elements

A device is used to apply a uniform increasing horizontal force, most unfavourable position, along a horizontal line of 1300 mm.

The applied force shall be increased gradually until either a maximum of 200 N is reached or the partition element is deflected 200 mm at the point of application of the force.

Note: Stability can be achieved by appropriate dead weight of the tables and cabinets, by pullout stops, by counterweights or wall fastening (here, holes must be drilled for the stable connection of the cabinets to each other or to structural elements).

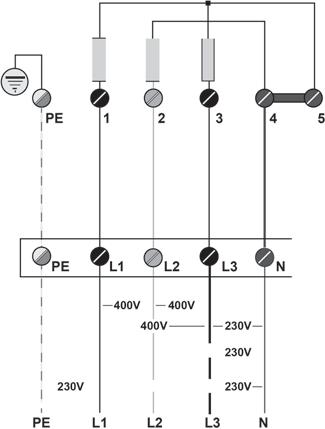

6.5.5. Electrical safety

Electrical safety in general

Test conditions:

VDE 0100, Part 713, applies, with all tangential regulations depending on the equipment, as well as the BSO guideline for electrical installation in furniture.

Office furniture with electrical equipment and office furniture prepared for electrification are tested.

In the case of furniture subject to registration under the Electrical and Electronic Equipment Act (ElektroG), an appropriate marking must be made on the furniture and the type of disposal must be indicated in the operating instructions (see Guideline for electrical equipment / components in furniture 13.6).

Essential criteria:

• Cables, cable cross-sections

• Plug connections, other connections

• Mains connections

• Sockets

• Luminaires, other devices

• Installation ducts

• Installation requirements

Requirements:

The requirements according to the applicable VDE regulations must be adhered to.

Conductivity of electrostatic charges (special furniture)

Special workplace conditions require dissipative office and work furniture

Test conditions:

Testing is carried out in accordance with DIN EN 61340

Measuring voltage: 500 V DC

Conditioning: 24 h at 25° C, 30% rel. humidity

Measurement in conditioning climate

Or

Testing is carried out in accordance with DIN EN 12527 for wheels and casters according to ESP (Expertise Service Providers).

Requirements:

Good discharge capacity is present at discharge resistances: 103 Ω < R abl. < 109 Ω

6.6. Function and handling

6.6.1. Function of moving parts

Test conditions:

The function of all moving parts is tested under normal operating conditions on loaded and unloaded furniture, also after the durability test.

Requirements:

• Actuating forces max. 50 N, for payloads > 400 N max. 12.5% of the payload

• Low-noise

• Smooth-running

• Functionally reliable

• No soiling due to greased, oiled, or otherwise treated parts

• Unhindered function under load

• No functional impairment after durability test

• With convertible office furniture functional reliability even after 10-fold conversion

6.6.2. General and special requirements according to DIN Technical Report 147

Test conditions:

• Testing of ergonomic requirements for function and handling

• Floor levelling according to DIN Technical Report 147

Requirements:

• Ergonomic functionality

• Floor levelling of tables and cabinets (except pedestals): 10 mm

6.6.3. Cleaning, care, assembly and installation instructions

Factual technical information should contain all the following details required by the user (IEC/IEEE DIN EN 82079-1):

• Permissible working loads

• Surface resistance

• Care and maintenance

• Assembly, if necessary

• Operation

Accordingly, the effectiveness and conformity of the technical information for the respective office furniture or office furniture programme is checked.

6.7. Surface properties

6.7.1. Chemical and mechanical stress

The following stress groups correspond to requirements for normal conditions of use. In case of deviations, appropriate product information is required:

6.7.1.1. Painted materials

stress

68861 Part 2

68861 Part 4

6.7.1.2. Melamine resin coated surfaces (MFB, HPL, KF panels)

Requirement / testing acc. to DIN 68861

68861 Part 1

68861 Part 2

68861 Part 4

EN 438-2

6.8. Corrosion resistance of fittings and office steel furniture

Test conditions according to DIN EN ISO 6270-2: AHT (condensation alternating climate)

1 cycle: 24 hrs, in total 2 cycles

8 hrs: 40° C ± 3° C, 100% rel. humidity

16 hrs: 18° C (up to 28° C) with 100% humidity (e. g. 75%)

Requirements: No signs of corrosion on visible parts

7.1.

Office work chairs and visitor chairs must be designed in such a way that there is no risk of injury during use and that the ergonomic properties are fulfilled according to the state of the art.

This is ensured if DIN EN 1335-1, -2, DIN EN 16955 are complied with for office chairs and DIN EN 16139 for visitor chairs and DIN 68878 (20,000 cycles per load direction, 750 N overload) is also adhered to.

The tilt drop test is only to be carried out for four-legged chairs and conference chairs.

Note: For office chairs the bending fatigue method according to DIN EN 1335 Part 3, edition August 2002 (withdrawn) is applied.

Caster resistance test:

The caster resistance test for hard casters remains in deviation from the current version of DIN EN 1335 (requirement according to DIN 1335, Part 2, edition August 2012, withdrawn).

In addition to the legal requirements, office work chairs must also have the following features:

Minimum suspension

The chair must be equipped with a minimum suspension.

Testing:

The chair is adjusted once to the lowest seat height and once to the middle seat height, then a weight of 75 kg is dropped onto the seat surface from a height of 40 mm in each of these positions.

Adjust the drop height from the static sink-in point upwards. The dynamic reaction force must not exceed 4,500 N.

Surface pressure

Measurements with sedometer according to Ergonomic Testing Programme PfG 947/03.04 (TÜV Rheinland) Point 4.2; Requirement: < 3.0 N/cm2

Lifting the front edge of the seat

The front edge of the seat must not lift more than 20 mm when the backrest is tilted to the rearmost position.

Testing: according to PfG 947/03/04

Shirt-sliding effect

When leaning against the backrest, the relative movement between the back and the seat backrest must be limited.

Testing: according to PfG 947/03.04; relative movement < 1.5 mm/°

Upholstery / cover

Upholstery and cover must be permeable to air and water vapour.

Restoring force

The backrest must not spring forward in an uncontrolled manner.

7.3. Cover materials

Requirements and test methods

The respective requirements are taken from DIN EN 14465. The requirements take into account a wide range of different qualities.

Note: Special materials that do not meet the following requirements due to their designoriented conception and are nevertheless processed may not be associated with the RAL quality mark unless the deviating usage properties are clearly pointed out in the product information.

7.3.1. Fabrics for office and contract furniture

7.3.1.1. Tensile strength

This characteristic must be determined for all fabrics except knit and non-woven fabrics.

DGM plus requirement: At least 400 N

Testing according to DIN EN ISO 13934-1

7.3.1.2. Tear resistance

This characteristic must be determined for all fabrics except knit and non-woven fabrics.

DGM plus requirement: At least 30 N

Testing according to DIN EN ISO 13937-3

7.3.1.3. Resistance to seam slippage

This characteristic must be determined for all fabrics except knit and non-woven fabrics.

DGM plus requirement: Max. 5 mm

Testing according to DIN EN ISO 13936-2

7.3.1.4. Abrasion resistance

Abraded” or “completely abraded” means significant changes in structure or appearance such as loss of pile loops, loss of fibres in the flock layer, or destruction of three or more pile loops. These should be indicated in the test report, as should the evaluation interval at which they occurred. This information is purely informative.

With regard to colour change, all upholstery fabrics listed below must achieve at least fastness rating 3 after 3,000 abrasion cycles. The assessment is to be carried out using the grey scale according to DIN EN 20105-A02.

Destruction of the test sample is usually achieved when three threads in a flat woven fabric are completely destroyed.

Assessment according to DIN EN 14465

DGM requirement: ≥ 30,000 abrasion cycles

Testing according to DIN EN ISO 12947-2

Destruction of the test sample is usually achieved when three threads in a chenille fabric are completely destroyed or when the chenille layer is completely abraded (whichever occurs first).

Assessment according to DIN EN 14465

DGM requirement: ≥ 30,000 Martindale cycles

Testing according to DIN EN ISO 12947-2

Destruction of the test sample is usually achieved when a hole appears in a knitted fabric (without pile) due to a completely destroyed thread.

Assessment according to DIN EN 14465

DGM requirement:

≥ 30,000 Martindale cycles

Testing according to DIN EN ISO 12947-2

Loop pile fabric

Destruction of the test sample is usually achieved when the pile is completely abraded in a loop pile fabric.

Assessment according to DIN EN 14465

DGM requirement:

≥ 30,000 Martindale cycles

Testing according to DIN EN ISO 12947-2

Pile fabric

Destruction of the test sample is usually achieved when

• in a pile fabric the pile layer is completely abraded without destroying the warp/weft threads.

• in a knitted pile fabric, the pile layer of 5 mm2 is completely abraded without destroying the warp/weft threads.

Assessment according to DIN EN 14465

DGM requirement:

≥ 30,000 Martindale cycles

Testing according to DIN EN ISO 12947-2

Destruction of the test sample is usually achieved when the fibre layer of the flocking material is completely abraded or detached without the carrier fabric being frayed or abraded.

Assessment according to DIN EN 14465

DGM requirement:

≥ 30,000 Martindale cycles

Testing according to DIN EN ISO 12947-2

Non-woven fabric

Destruction of the test sample is usually achieved when a hole is observed in a non-woven fabric. A hole means that the top layer is abraded in such a way that a different looking layer or the base fabric is visible.

Assessment according to DIN EN 14465

DGM requirement:

≥ 30,000 Martindale cycles

Testing according to DIN EN ISO 12947-2

Napped fabric

Destruction of the test sample is usually achieved when the fibre layer of a napped fabric is completely abraded.

Assessment according to DIN EN 14465

DGM requirement:

≥ 30,000 Martindale cycles

Testing according to DIN EN ISO 12947-2

7.3.1.5. Pill formation

Must be determined for flat woven fabrics, knitted fabrics (without pile), loop pile fabrics and non-woven fabrics.

A scouring agent fabric made of wool (according to DIN EN ISO 12947-1) must be used and the category must be determined after 2,000 abrasion cycles.

DGM requirement:

At least grade 4

Testing according to DIN EN ISO 12945-2

7.3.1.6.

Light fastness

For light colours, a tolerance of a fastness rating of 0.5 applies.

DGM requirement:

At least fastness rating 5

Testing according to DIN EN ISO 105-B02 Procedure 2 (Procedure 3 may be used for quality control purposes.)

Correction of the test procedure referencing was made on 15/05/2024

7.3.1.7. Rubbing fastness dry

DGM requirement:

At least fastness rating > 4

Testing according to DIN EN ISO-105 X12

7.3.1.8.

DGM requirement:

Rubbing fastness wet

At least fastness rating 3 to 4

For dark and brilliant colours and blends, for natural and viscose fibres the following applies:

DGM requirement: At least fastness rating 3

Testing according to DIN EN ISO-105 X12

7.3.1.9. Colour difference

Permissible colour difference between the supplied material and the sample material according to greyscale (DIN EN 20105-A02)

Upholstery fabrics:

DGM requirement: At least level 4

Micro fibre fabrics:

DGM requirement: At least level 3 to 4

7.3.1.10.

Flammability

Cigarette test according to DIN EN 1021-1 must be passed.

Testing according to DIN EN 1021-1

7.3.2. Leather for office furniture

The following test requirements apply to new, unused leather. For used leathers, the tests and test results are only a guide.

Note for incoming goods inspections, see appendix 13.8

Point 3.2 Internal quality control must be observed as well.

7.3.2.1. Definition leather

Definitions of terms related to leather according to DIN EN 15987, RAL 060 A2 and RAL 061 A1 as well as DIN 68871.

Labelling regulations for products related to leather according to RAL 060 A2, RAL 061 A1, DIN 68871 and DIN EN 16223-1 must be observed.

7.3.2.2. Colour migration

Determination of colour migration fastness to plasticised polymers.

Requirement: grey scale ≥ 4

Testing according to DIN EN ISO 15701

7.3.2.3. Light fastness

For all types of leather, at least light fastness level 3 (fastness rating 3) must be demonstrated, unless listed separately below.

Aniline leather, natural

Aniline leather, refined (optimised for use)

Semi-aniline leather, lightly pigmented

Leather, pigmented

Ful grain leather / nubuck

≥ Level 3

≥ Level 3

≥ Level 4

≥ Level 5

≥ Level 3

If particularly high usage properties are advertised, at least level 6 must be demonstrated in each case.

Testing according to DIN EN ISO 105-B02 Exposure method 3

White leathers must not show any yellowing after three days of (dark) storage at 50° C.

Visual assessment according to DIN EN ISO 20105-A02; grey scale at least level 4 to 5

7.3.2.4. Rubbing fastness

Requirements:

Full grain leather / nubuck / aniline leather, natura

Felt dry

Felt welt

Felt moistened with alkaline sweat solution

(pH value 8)

(Colour black: at least level 2)

3

3

Note: With the colour black, no higher value than at least level 2 is currently achievable according to the state of the art.

Aniline leather, refined (optimised for use)

Felt dry

No. of cycles Level

3

Felt welt 40 3

Felt moistened with alkaline sweat solution

30 3 (pH value 8)

(Colour black: at least level 2)

Semi-aniline leather, lightly pigmented

Felt dry

Felt wet

Felt moistened with alkaline sweat solution

No. of cycles Level

500 4

80 3 to 4

50 3 to 4 (pH value 8)

(Colour black: at least level 2)

Pigmented leather

Felt dry 500 4

Felt wet

3 to 4

Felt moistened with alkaline sweat solution 80 3 to 4 (pH value 8)

Note: If particularly high usage properties are advertised, at least level 4 to 5 must be demonstrated for all types of leather.

The colouring of the felt is assessed using the grey scale DIN EN 2015-A03; the damage to the surface is also assessed according to DIN EN ISO 11640.

7.3.2.5. Permanent bending strength

Semi-aniline leathers and pigmented leathers must not show any cracks, grey fracture, or detachment even after 50,000 buckling cycles.

This test is not necessary for suede/nubuck.

Aniline leather and aniline leather, refined (optimised for use) must not show any cracks, grey fracture, or detachment even after 20,000 buckling cycles.

Testing according to DIN EN ISO 5402-1

7.3.2.6. Adhesion of the finish

Minimum value for the adhesion of the finish for smooth leather ≥ 2.0 N / 10 mm strip width.

Separation within the finish layer is not permitted, even if the force is greater than 2 N/10 mm.

Testing according to DIN EN ISO 11644 in N/cm; at least 3 samples from different locations

7.3.2.7. Tear propagation force

The tear propagation force must be ≥ 20 N.

Testing according to DIN EN ISO 3377-1

7.3.2.8. Cold fracture resistance of the finish

No fractures of the finish may occur.

Testing according to DIN EN ISO 17233 up to -15° C

7.3.2.9. Water drop fastness

Testing and requirements based on DIN EN ISO 15700

Evaluation of water drop penetration time

Test duration:

Aniline leather, natural

Aniline leather, refined (optimised for use)

Semi-aniline leather, lightly pigmented

Pigmented leather

Full grain leather / nubuck

Grey scale at least level 3, no permanent swelling

7.3.2.10. pH value of the leather

According to DIN EN 13336 ≥ 3.5

Testing according to DIN EN ISO 4045

At least 10 min.

At least 10 min.

At least 10 min.

At least 30 min.

At least 10 min.

7.3.2.11. Dyeing for leather

Leather must be dyed throughout. Absolutely 100% colour uniformity between surface and inner zone is not possible due to processing reasons. Slight differences in colour are permissible. The colour of the crust (uncoated leather) must match the top layer.

Visual assessment

Colour difference

Permissible colour differences from the delivered material to the sample material as well as within a leather hide and on the processed upholstered furniture according to grey scale DIN EN 20105-A02.

Requirements:

Aniline leather, natural

Aniline leather, refined (optimised for use)

Semi-aniline leather, lightly pigmented

Pigmented leather

Full grain leather / nubuck

Visual assessment

7.3.2.12. Water vapour permeability

At least level 3

At least level 3

At least level 4

At least level 4

At least level 3

Measured in mg (cm² x h). This test is currently still considered a recommendation.

Requirements:

Aniline leather, natural ≥ 3

Aniline leather, refined (optimised for use) ≥ 2

Semi-aniline leather, lightly pigmented ≥ 3

Full grain leather / nubuck ≥ 10

Testing according to DIN EN ISO 14268 (without pre-treatment)

7.3.2.13. Water vapour uptake

Measured in mg (cm² x h)

Test climate 23° C / 50% rel. humidity

This test is currently still considered a recommendation.

Requirements:

Aniline leather, natural 8

Aniline leather, refined (optimised for use) 6

Semi-aniline leather, lightly pigmented 6

Full grain leather / nubuck 10

Testing according to DIN 17229

7.3.2.14. Elongation in the tensometer

Measurement of the permanent elongation in the tensometer according to DIN 53323 or JUP 13.

Within 30 ± 10 s bring the pressure up to 5 bar, hold for 10 s, release for 30 s, then read off the permanent elongation at 1 bar.

Requirement: < 20%

7.3.2.15. Resistance to ageing and temperature

Visual assessment of colour shade and surface. No changes must be detectable after the test, e. g. no cracks, colour changes, strong shrinkage, changed grain.

Evaluation of a colour change with the grey scale according to DIN EN 20105-A02: at least level 4 to 5.

Testing after 3 days at 60° C in a heating cabinet

7.3.2.16. Leather processing

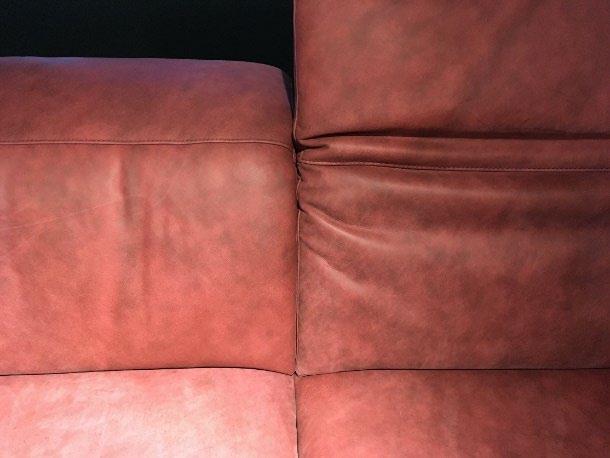

Leather cuts and seam designs may have additional dividing seams for leather processing due to material and processing reasons (product information).

Natural and growth characteristics

Natural and growth characteristics include all fused and closed injuries and features which have occurred on the living animal. These may be processed while maintaining the usual durability and harmonious overall appearance. Open, not overgrown and subsequently developed damage to the skin is considered a defect. This includes tanning and finishing defects as well as storage damage.

Split leather

Split leathers such as split velour and covered split leather as well as leather fibre materials are not permitted for use surfaces (seat, back, armrest inner surfaces, armrest tops).

If types of leather are used on the main body of the furniture item or the reverse side, then the item of upholstered furniture must be clearly labelled (product information).

According to DIN 16922, artificial leather is a coated textile. For the purposes of RAL-GZ 430, artificial leather in the narrower sense is understood to be a coated textile with a leather-like surface and/or leather-like characteristics. The composition of the coating materials must be stated, also in the product information (e. g. 95% PVC, 5% PUR).

If used for the seat surface of seating furniture, artificial leather must show comparable characteristics to natural leather in terms of water vapour permeability.

7.3.3.1. Surface characteristics

Rubbing fastness

Dry

Wet

Testing according to DIN EN ISO 105-X12

Fastness rating ≥ 4.5

Fastness rating ≥ 4.5

In principle, all artificial leathers must correspond to at least level 5.

If particularly high usage properties are advertised, at least level 6 must be demonstrated.

Testing according to DIN EN ISO 105-B02 Exposure method 3

Light-coloured or white artificial leathers must not show any yellowing after 3 days of (dark) storage at 50° C in a circulating air oven:

Requirement: ∆b ≤ 0.5 according to the CIELAB system against the zero sample.

Storage conditions according to DIN EN 12280-1, Procedure 1

Colour measurement with a suitable colour measuring device according to DIN 5033-7

7.3.3.2. Strengths

Tear resistance

Longitudinal ≥ 25 N

Transverse ≥ 20 N

Testing according to DIN EN ISO 4674-1, Procedure B

Maximum tensile strength

Longitudinal ≥ 380 N/5 cm

Transverse ≥ 280 N/5 cm

Testing according to DIN EN ISO 1421, Procedure 1

Adhesion strength of the coating to the substrate

Longitudinal ≥ 25 N/5 cm

Transverse ≥ 20 N/5 cm

Testing according to DIN EN ISO 2411

7.3.3.3. Wear characteristics

Rubbing resistance according to Martindale

Martindale 51,200 cycles dry

Martindale 25,600 cycles wet

Level ≤ 2

Level ≤ 2

Testing according to DIN EN ISO 54702, Procedure 1 with wool fabric*

*In deviation from the standard DIN EN ISO 5470-2, significant colour changes due to rubbed-off print application must be assessed with level 3 and are therefore not permissible.

Continuous folding behaviour Ballyflex 23° C 50,000 cycles

Longitudinal

Transverse

Testing according to DIN EN ISO 32100

Level ≤ 1

Level ≤ 1

7.3.3.4. Hydrolysis test (only for PUR artificial leather)

Evaluation of surface condition: no cracks, no detachment

After testing 21 d / 70° C / 95 to 98%: no delamination and no stickiness

Continuous folding behaviour Ballyflex 23° C 15,000 cycles

Longitudinal

Transverse

Testing according to DIN EN ISO 32100

7.4.

Level < 2

Level < 2

Seat supports, casters, foot crosses, mechanisms, gas springs, etc.

If supplied components with a safety function are used, evidence of component testing is required.