PEOPLE / PAPER / PLANET

• MEET THE MILL: NORSKE SKOG BRUCK

• PRODUCT SPOTLIGHT: DELIPAC

• UP CLOSE & PERSONAL: WARREN CURTIS

• SUSTAINABILITY CENTRE : HUG A TREE TODAY

• A VISIT TO GREEN ROCK CUP MANUFACTURERS

• THE PRINTWEEK AWARDS ...AND MORE

• MEET THE MILL: NORSKE SKOG BRUCK

• PRODUCT SPOTLIGHT: DELIPAC

• UP CLOSE & PERSONAL: WARREN CURTIS

• SUSTAINABILITY CENTRE : HUG A TREE TODAY

• A VISIT TO GREEN ROCK CUP MANUFACTURERS

• THE PRINTWEEK AWARDS ...AND MORE

As we move into 2025 the paper market continues to be a challenge. This is mainly because of lower marketing spends and a lack of confidence in the economy. Also contributing is our government’s budget which has produced a backlash from businesses. (Thanks Rachel.)

All that said, there is still much opportunity for Denmaur, as we drive through new product innovation. Our efforts remain aggressive in new market sectors as well as delivering improved results from our traditional business. None of this is easy as our competition faces the same problems and is employing similar tactics.

The teams in Denmaur Publication Papers, and Commercial print are working hard on attracting new customers as well as filling credit headroom unused at certain clients.

Our teams are also pruning our product offerings to be more relevant to customers and the new emerging technologies; e.g., HP Indigo, ink jet and hi-speed jet presses.

We must also be vigilant with our credit as many businesses included in the sectors to which we sell struggle through the lower trading day months for cash. It really is a balancing act, but a big thanks to the wider teams for chasing down any invoice queries, complaints and cash collections.

Let’s put some meat on the bones in the market areas where we are increasing our presence.

Food carrier board – Delipac has still much to achieve and has mainly been successful in the cup and drinks market. It is still the highest certified board in its arena and new opportunities present every month for application. This is not a quick win but offers longevity when it occurs. I doubt that you will go to any festival this year without drinking from a Delipac cup!

Carton board – Formakote and Aura Fold champion this area for Denmaur with fresh food punnets and cartons for food travel (fresh fruit, mushrooms, tomatoes, etc.). We are still relatively new in this area of business but results in 2025 should show big growth over 2024.

Laminating Film – Growth continues in this category and 2025 should be ever improving with our product range.

Large Format - We are also increasing our presence with products for large format printers. This area is growing as retail continuously competes for market position for customers. Fast moving messages digitally, paper and board products are key marketing tools for supermarket stores to drive sales. Some posters in this field have a shelf life of just 5 days for their message to market before the next campaign starts the process all over again.

We have all purchased by this route based on, for example, 3 for 2 offers or Nectar retail campaigns saving customers money and enhancing customer loyalty schemes.

Supermarkets know what you buy and campaign on what you don’t, hence the need for quick blast messaging. May it continue to be encouraged.

We have also advanced our sales in converting and renovating paper for paper mills, agents, and customers’ stocks. This has brought new customers to Denmaur, who in the past have just been either suppliers, competitors or customers who were not aware of our full converting capability. Our Bescot site will continue to grow this area as well as promote new and higher sales in our Reel Fast programme.

Finally, let’s hope the spring brings better weather (4 storms down already) and the growth we foresee in 2025.

In case you haven’t already figured it out, Delipac, our exclusive and certified totally sustainable board product, is a big feature of this issue in conjunction with our presence exhibiting it at the Food & Drink trade show at the NEC in April. Read more about this elsewhere in the mag.

Our Meet The Mill section features Denmaur supplier Norske Skog while Charles Jarrold, CEO of BPIF, explains why his organisation is More Than Just A Trade Association in A View From The Outside.

What has turned out to be our super-popular personnel features in Up Close and Personal along with The Denmaur Family Corner allows you to get to know three of our team members, Warren Curtis, Ian Fry and Andy Livesey, better.

Our sustainability expert, Danny Doogan, delves into the often misunderstood process of forestry management in regard to harvesting raw material for paper while our CEO, Andy Buxton, gives his View From The Top opposite.

And, oh yes, since we pride ourselves on Denmaur being a family run business, our NED and house counsel, Robert Gould, gives a candid(?) opinion of what it is like to be a younger brother. We are sure our now retired former CEO, Nick Gee, will be reading it with keen interest.

This issue is printed on our Revive Natural Matt paper, 240 g/m2 with our “ Temptation X ” lamination (cover) and 170 g/m2 for the inside.

The Editors themag@denmaur.com

VIEW FROM THE TOP FROM THE EDITORS

MEET THE MILL: NORSKE SKOG BRUCK

A VIEW FROM THE OUTSIDE: BPIF UP CLOSE AND PERSONAL: WARREN CURTIS

SUSTAINABILITY CENTRE: HUG A TREE TODAY

PRODUCT SPOTLIGHT: DELIPAC DEPARTMENT NEWS

DENMAUR FAMILY CORNER: IAN FRY & ANDY LIVESEY

CUP MAKING IN WALES

DID YOU KNOW / NEW JOINERS / FOND FAREWELLS LONGEVITY LIST

HUMOUR : YOUNGER BROTHER SYNDROME

LOOK WHO’S HAVING A BIRTHDAY CARBON BALANCED MILESTONE: 250,000 TONNES

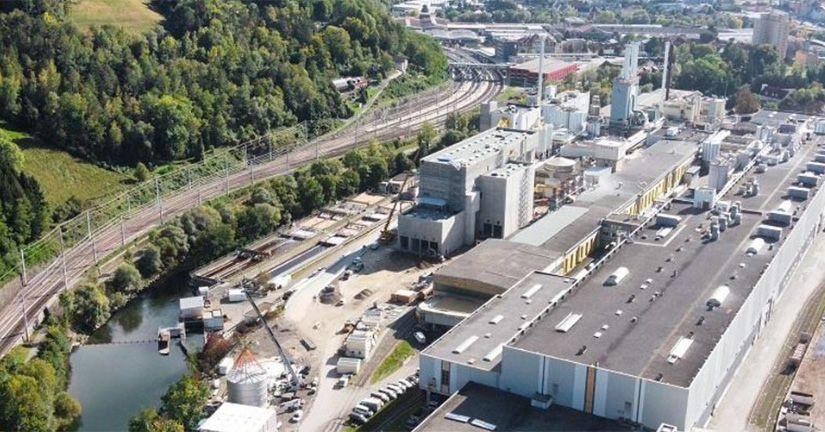

Norske Skog was established in 1962 by Norwegian forest owners and associated trades. The first Norske Skog factory became operational in 1966 producing newsprint. In the decades that followed a significant construction and acquisition programme saw the paper group expand its manufacturing footprint into Europe, Asia, South America and Australasia.

Today, Norske Skog has consolidated into just 5 Business units in four territories: Norway, France, Austria and Australasia. The Bruck mill, acquired in 1996, is located in Styria, Austria where a paper mill has been on site since 1881.

It produces the Nor magazine range of papers as well as recycled containerboard, making use of the direct rail line to the Port of Cuxhaven on its route to the UK.

As a valued Denmaur supplier, Norske Skog fits squarely into our sustainability profile with its “We create green value” policy of manufacture from recycled fibre.

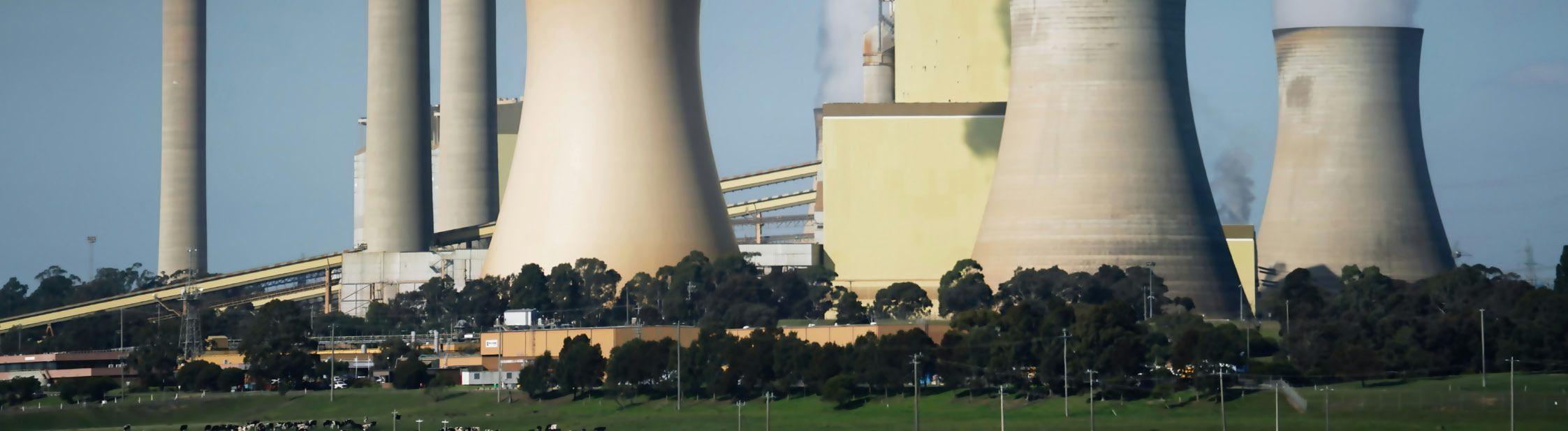

Its mills work continuously to reduce emissions and discharges believing that industry must participate actively in the process to control climate change.

420 Members of staff

265k Magazine Paper Capacity

210k Containerboard Capacity

Grade

Norcote

Norcote

Norcote

Norcote

Norcote

Norcote

Norcote Bulk

Norcote Bulk

150k CO2 – annual reduction since installation of waste to energy boiler in 2022

CO2 calculations provided by the mill

By Charles Jarrod, BPIF CEO

The British Printing Industries Federation (BPIF) has proven itself to be far more than a traditional trade association, particularly during recent challenging times. From Brexit and COVID-19 to energy price shocks and supply chain disruptions, times have certainly been interesting.

The breadth of expertise, the depth and level of engagement that the BPIF has across all aspects of UK print have meant that we’ve been able to play a vital role in supporting members and the wider sector.

As a sector Trade Association, we’re somewhat unusual, in carrying out the usual Trade Association activities, alongside a range of in-house premium “professional services” with sector experts covering employment advice, health and safety and environmental compliance support. With BPIF Training, we’re the principal apprenticeship training provider, a critical resource in ensuring the sector can address the perennial skills challenges.

Our core trade association activities encompass lobbying and government engagement, research and insight, alongside our work to bring together focussed networks and events. We meet regularly with the Department of Business and Trade, providing a constant channel to raise concerns on issues affecting the sector and to act as a sounding board for policy development. We play an important role in coordinating the sector’s response to government consultations, which help ensure legislation is crafted to avoid unintended consequences, and we work closely with government and the sector as new legislation is introduced.

Currently for example, we’re working intensively with government on the introduction of radical changes to packaging legislation, Extended Producer Responsibility (EPR), which is being adapted in real time with feedback from us and other sector stakeholders. Readers will also be aware of EUDR (EU Deforestation Regulations).

Our UK representative membership of Intergraf, the panEuropean Association of sector Associations, means that we have been well placed to support the successful call for implementation to be delayed for 12 months to the end of this year while now helping members understand their compliance responsibilities.

BPIF’s influence extends through close governmental liaison and cross-sector collaboration. We actively facilitate MP visits to member sites and provide crucial industry insights through our quarterly Print Outlook report and biannual Print Facts and Figures publication. Our Special Interest Groups serve various sub-sectors including cartons, labels, and books, while also addressing sector-wide challenges, for example with our Environmental Group.

Another distinctive feature of BPIF is our role as the primary provider of apprenticeship training in the print sector. Demand for apprenticeship training in our sector is consistently strong, and our expertise ensures we’re able

to ensure the sector has the skills for now and a pipeline for the future. As the government reviews the UK skills landscape, our dual expertise as both industry association and training provider enables us to advocate effectively for sector-specific needs.

We also offer comprehensive professional services, including HR support, employment legal advice, health and safety guidance, and commercial legal consultation. The sector is quite unique in being able to access these services delivered from sector experienced qualified and trained professionals who are able to provide tailored solutions that address the unique challenges and opportunities arising in UK print businesses.

As a membership organization, our effectiveness depends on active industry participation. We thrive on member engagement, which ensures we can focus our efforts to support a vibrant, successful, and progressive UK print sector.

Our sector has a long history of adaption and change and together, we can ensure the industry continues to thrive despite ongoing challenges.

Denmaur is a member of the BPIF and BPIF Cartons.

The Printweek Awards were held on March the 6th in London’s Brewery venue near the Barbican.

A total of 17 awards were presented at the black-tie event which was hosted by comedian, Suzi Ruffell, and ‘the voice’ of the National Lottery, Alan Dedicoat .

Denmaur sponsored Bespoke Publications Printer of the Year, with Denmaur’s Julian Townsend presenting the trophy to this year’s winners, Northend.

Hampton Printing were highly commended and Empress and Statex were shortlisted from the many entrants to this popular category.

With regard to the winning entry, Printweek summarised the judges’ comments as follows….

“The judges were so impressed by the sheer quality of Northend’s entry one asked ‘Can I take these home please?’”

The business, which was founded in Sheffield in 1889, is one of the UK’s oldest printing companies. Over the past 130 plus years it has successfully served a vast array of local and national customers by listening closely and meeting their evolving needs.

Their customer focus was underscored by Northend’s exemplary submission, which featured a dazzling array of work including it’s Grand Prix Calendar on the theme of ‘Once a Champion’, celebrating racing car drivers who won a single championship from the 1950’s to the present day.

It was printed litho whilst the calendar’s design enables images from each month to be individually framed and displayed.”

DIRECTOR

Warren has spent most of his life immersed in the world of print and paper lamination, though it wasn’t his original career path. He initially qualified as a Building Surveyor in the construction industry, but with the sector in recession, he found himself exploring other opportunities.

Responding to a job advert in a local newspaper, he began his journey at Mackays of Chatham as an adult apprentice in origination. It was early in his apprenticeship that he was introduced not only to origination but also to litho printing, print finishing, and binding. However, it was the finishing side of print that truly captivated him. In his own words, “lamination and finishing make print look pretty,” and from that moment on, he never looked back.

His career progressed as he took on various roles at Reflections Print Finishers, moving from Operations Manager to Sales Director. He then joined Film & Foil Solutions, where he advanced from Sales and Technical Manager to Sales Director, before making the move to Denmaur in 2022. With a clear remit to develop lamination film as a new product offering for the company, Warren has continued to cement his expertise in the field.

With an extensive technical knowledge of lamination and film, Warren is regarded as one of the leading experts in the industry.

the mag caught up with Warren at his desk in Sittingbourne to learn more about his journey.

tm: With so much emphasis in the paper industry on sustainability where Denmaur maintains a leadership position, where does lamination film fit into this movement?

WC: Lamination is not a kerbside throw away product. It is a film that protects, enhances, and preserves the print for many years to come. By creating this desire to preserve, lamination is, in its own way, very eco-friendly.

tm: Briefly describe how lamination works.

WC: There are three main types of print lamination:

a) Wet lamination – This involves applying a water-based cross-linking adhesive to the reverse of the film, bonding it to the print substrate.

b) Thermal lamination – A dry adhesive is pre-applied to the reverse of the film, which is then activated by heat and pressure.

c) Digital lamination – Similar to thermal lamination, but with a stronger adhesive to counteract the fuser oils and silicon content in digital and vegetable-based inks.

tm: What do you like about your job?

WC: I love the variety of my job, and meeting new people, whilst looking after customers I have worked alongside as a supplier for literally decades.

tm: What is your favourite piece of print, laminated or not, and why?

WC: Back in 1997 when I was a planner plate maker, I imposed an image of the Archbishop’s Palace in Maidstone as part of the invitation to my wedding. This was then printed at my then place of work, Mackays of Chatham. I don’t know if it was that invitation but my wife and I are still going strong to date.

tm: What occupies your time outside of work?

WC: I have been heavily involved for some 44 years in motocross from the very early days to the superbikes today. It’s something I absolutely love.

tm: What four people, dead or alive, would you invite to a dinner party and why?

WC: Firstly my grandad who was my be all and end all. Secondly, my father’s mum who I never met as she sadly died prior to my entry into the world. Thirdly, Margot Robbie because, why not?. Fourth and finally, Sir Winston Churchhill as a strong and powerful inspiration.

tm: How do you view the future of paper and board, laminated or otherwise?

WC: Lamination will always have a place in print. As I mentioned before, it protects, enhances, and preserves. That said, manufacturers and extruders are constantly searching for the ‘holy grail’—a fully plastic-free film that is both cost-effective and comparable to BOPP (biaxially oriented polypropylene) film. Right now, acetate is an 100% option (made from wood pulp with no plastics whatsoever, but it remains prohibitively expensive. However, we are in the throws of producing a recyclable / biodegradable film working alongside our single source supplier.

tm: There are other sources for lamination film so why should people buy from Denmaur?

WC: The Denmaur range of lamination films are single sourced using the same base film thoughout. We do not offer differing films as we believe that consistency provides the highest quality with proven efficiencies when applying downstream applications. Additionally, our service includes free next day delivery for orders placed by 5pm with no minimum order quantity.

tm: What will Warren Curtis be doing ten years from now?

WC: In 10yrs from now my hope is that I’m still at Denmaur heading print lamination alongside new and differing projects, as I genuinely love my job.

2023-Present: 2021-2023: 2016-2021: 2012-2016: 2006-2012: 1995-2006:

Denmaur Sales and Technical Director

Sales Director – Film and Foils Solutions Ltd.

Sales Director – Reflections Print Finishers Ltd.

Technical Sales Manager – Film & Foils

Solutions Ltd.

Operations Manager – Reflections Print Finishers Ltd.

Colour Print Manager – CPI Books

BY DANNY DOOGAN

For many years the environmental spotlight has been on print. The take up of FSC® and PEFC certification has helped, as have offsetting schemes such as Carbon Balanced Paper. Now we have the ability to provide the carbon emission figures associated with the production and delivery of paper and print.

However, the common misconception that paper is responsible for mass deforestation remains, which means we’ve either been getting the wrong messages out or not completing the story at all. For me, I think it’s the latter.

Most people know paper is made from trees. Aside from that, the knowledge relating to forestry for paper production is minimal, allowing myths and facts inevitably to merge into misinformation.

Forestry practices are as old as time, but that’s not to say mistakes haven’t been made along the way. The Forestry Commission has only been in existence since 1919 after the UK’s forestry stock had drastically depleted due to the agricultural, industrial and transport revolutions, rocketing population levels and a number of wars. Print, notably, didn’t contribute to this forestry low point.

The UK is just over 100 years into its restorative programme, whereas other countries blessed with large forestry areas learnt about harvesting and regeneration much sooner, and long before the introduction of the FSC and PEFC schemes.

Today, commercial tree management starts at the nursery, where saplings are cultivated using the latest in science and technology so that they flourish into strong, healthy and resistant tree stocks.

Forest management involves regular coppicing and thinning (also serving as raw materials for pulp manufacture) enabling trees to receive the maximum amount of light to grow tall and straight. Furthermore, certified forest management schemes also require provisions to ensure native wildlife and biodiversity also flourish.

Trees grow through the absorption of atmospheric carbon – a process that stops at maturity. This is when they are harvested (with the stored carbon still retained) and saplings replanted.

Paper accounts for less than 14% of the world’s commercially harvested forestry. Paper pulp comes from the top ⅓ - ¼ of a tree, whereas the main part of a harvested tree is converted for timber. Eucalyptus trees are an exception in that they reach maturity within 10 - 12 years, with the original sapling able to regenerate up to 3 times. Grown only in specific parts of the world, the entire Eucalyptus tree will be used for paper manufacture.

Commercial forestry is growing in Europe and America, and with the implementation of the EUDR this year, paper (as with all other timber products) will be traceable to its exact geolocations.

So, paper is made from a traceable, sustainable, natural, renewable and managed resource. Hug a tree and celebrate the printed word.

Delipac is a multi-award winning and multi-certified paperboard that provides a natural and completely sustainable alternative to single use plastics, including PE lined boards that were, for many years, the convention in food and drinks packaging.

The anatomy of Delipac is founded upon research and development that began in 2012. Then, its mission was unconventional: “to provide a robust barrier solution for food and drink packaging, where its end of life can be treated alongside mainstream paper waste processing facilities.”

The result today is a completely sustainable paperboard, manufactured with a unique, integrated non-polymer barrier that is now being adopted by a number of reputable household brands within the food and drink market.

Amongst its many other certifications, Delipac is Food Safe, it is ovenable and microwavable, and it is chillable and freezable. As a paperboard it is a PEFC certified, so traceable to sustainable and legal raw material sources, and its production is offset via the verified World Land Trust Carbon Balanced Paper scheme. It has the coveted EU Flustix logo (for reduced and zero plastic content) and it is certified as PFAS free, so there are officially no ‘forever chemicals’ contained within Delipac paperboard.

Denmaur is the exclusive stockist and distributor of Delipac paperboard for the United Kingdom and Ireland, with sales going into printers and converters who will transform them into finished products ranging from salad boxes and trays to ice cream tubs, coffee cups and even coffee cup lids. From its inception, Delipac has always been about delivering a secure product that is also the definitive solution for sustainable packaging in the food and drinks sector.

Collaborations with waste collection and recycling organisations have been established in recent years to help make the end of product life process clearer and easier to understand. It remains an on-going journey but one that a number of household brands, as well as the general public, are starting to acknowledge.

Unlike other alternatives, Delipac does not rely on waterbased or aqueous coatings, nor is it produced using the dispersion method. Instead, it leverages patented technology to create a plastic-free, paper fibre barrier board that provides exceptional resistance to moisture, liquids, grease, and oils.

Through rigorous and independent testing, Delipac has been certified as fully recyclable, compostable (home and industrial) and biodegradable. So, depending on the circumstances of its end of life as a food or drinks packaging product, it can be processed into recycled paper pulp. In the worst case, if carelessly discarded and left out in the open, it will completely succumb to nature and start to disintegrate within its surroundings in a matter of weeks.

Delipac will be showcased at the Food and Drink Show, held at the NEC between 7 – 9th the April (Hall 17, stand PP269).

MICHAEL TOWNSEND mtownsend@denmaur.com

On February 5th, 2025, Reel Fast hit its one-year mark – and what a year it’s been. In just 12 months, we’ve sold over 1,500 tonnes across different grades, with great contribution from all areas of the business. It’s been a solid start, but not without its challenges.

Rising material costs and the pressure to stay competitive have impacted margins, but our fixed cost structure has helped us keep prices consistent for customers, making sure we retain their business. We’ve stayed true to our commitment of delivering exact sheet sizes, and by doing so, we’ve helped our customers cut waste and save money.

What really sets Reel Fast apart is our ability to deliver any sheet size within just five days, a promise we’ve kept thanks to the hard work and dedication of the production and warehouse teams. The fact that we’ve maintained this fast turnaround while

ensuring top-notch service has been key to our success. Looking ahead, we’re focused on working with mills to secure more stable pricing in 2025. This should help us manage costs and protect our margins. And in May, we’re launching White GR, a new grease-resistant box board, which will be a gamechanger for food packaging.

Reel Fast has been a major driver of growth for us, even in a tough market. We’re committed to keeping an eye on stock levels to make sure we continue hitting those five-day turnaround targets, and we’re excited to see what the rest of 2025 brings with a number of large projects in development.

ANDY FAITHFUL afaithful@denmaur.com

The last few months in the Print & Paper sector seem to have mirrored our classic British Winter weather. Rather uninspiring!

With challenging market conditions continuing for all, the sunny interludes have been in short supply. However, with challenge brings change, and with change, opportunity.

I outlined in previous editions developments in our Large Format offering, which continues to be a standout growth sector for Denmaur.

Our investment in new product and stock in this area is proving to be a compelling offer for an increasing number of clients. With more product likely to follow in the coming months, this year looks well set for continued growth.

The introduction of Smart Pallets into our core Amadeus Silk range has been a huge success. Helping customers reduce costs and waste by replacing ream wrapped with half sized bulk pallets.

Our new products in the digital sector, Eurotak, IQ Premium and Figaro Preprint, are now well established and attracting regular business and there is much more to come with product development in the next edition.

So, as we look forward to the coming Spring, we have used this last period to put in place some important building blocks for future success. I am excited by the things we are currently working on which will be introduced in the coming monthsso much so I may have to buy the Editors a drink to gain some extra space! Now where did I put my wallet ….?

JULIAN TOWNSEND jtownsend@denmaur.com

Our Scope 3 reporting is progressing well and proving to be a significant element of our customer offering.

We are also actively engaged in planning for the much-delayed EUDR (European Union Deforestation Regulation). EUDR is now due to officially commence on the 30th December 2025 and although the UK is outside of the EU, EUDR will have significant indirect effects on both UK trade and our supply chain.

We eagerly await evaluating the official system, as well as working with our suppliers to ensure full compliance is in place well ahead of the deadline. Reassuringly, a number of our key suppliers were well ahead of the original 2024 deadline and we greatly value such sources for the future. It is too early to gauge how pulp sources from potentially high-risk regions will perform and we will be actively monitoring any potential impact on supply and demand.

EUDR is just one more indication that sustainability and environmental protection is very much here to stay. It is key to our values and Denmaur will continue to maintain its leadership in this area.

Beyond this, the rapidly evolving landscape of both our customers and suppliers continues to gain momentum.

We are currently working on a number of strategic initiatives, plus the expansion of our product ranges to ensure we increase market penetration and maximise our sustainable growth.

Cross selling our speciality products and services from across our group will also ensure increased visibility to both traditional customers and to new opportunities. Campaigns are actively in place, targeting sectors such as travel, charity and education. It has been fascinating to witness the evolution of our traditional publishing customers.

Having faced a range of significant threats since 2020, resulting in reduced demand due to increased digital/online content, declining print sales, subscription fatigue, etc., etc., a number of publishers continue to succeed with products such as high quality/luxury magazines, bookazines and a range of hybrid models. To paraphrase Mark Twain, reports of publishing’s death are greatly exaggerated.

Our service levels ensure we are well placed for the changing landscape. A series of collaborations and alliances are also in progress to meet the anticipated future trends within these sectors. Exciting times ahead.

CLIVE TOWNSEND

ctownsend@denmaur.com

Firstly, I’d like to extend a warm welcome to Mark Lees, who is the newest member of the Carton Board division as part of Mike Townsend’s Sales Team. Mark joins us from Goldwater Packaging where he has been working in all aspects of the business for the past 12 years. This has given him a good technical grounding in products, print, carton manufacture and general packaging knowledge.

Following the usual quiet Christmas period, it was good to see Carton Board sales pick up in January, with several new accounts being opened. Allyking and Aura Fold Plus continue to be our best-selling products with sales of Formakote Spectra starting to gain momentum. As a group, we have a wide range of carton board customers,

and we need to enhance and exploit the opportunities for further sales by introducing new products where needed.

We now have new promotional A5 Carton Board folders containing printed product cards and unprinted samples, and these are available from our Samples Department (samples@denmaur.com)

In addition, we should have the new printed product cards for Formakote Spectra Natural available by the time you read this. These will be great tools for the whole sales team, allowing customers to make informed decisions about exactly what carton board best meets their need.

Ian originally started out teaching dyslexic children in Suffolk before moving into the paper merchant field.

Starting originally with H H Pegg, then a few other companies, notably Burgo, he has been handling inside sales for publishing at Denmaur for the past 14 plus years.

How did you get into the paper industry?

What is your favourite thing about your job?

Holiday in the country, beach or elsewhere?

Who would play you in “Denmaur: The Movie”?

If you won the lottery tomorrow what would be the first thing you would do?

What is your most memorable piece of print?

What four people, famous or otherwise, would attend your dinner party?

If you have a preferred charity, what is it and why?

Name a memorable achievement outside of work?

When not working, Ian’s free time is occupied by his partner, Pam, and four children, two girls, Becky and Catherine, and two boys, Arthur and Henry, ranging in age from 17 - 31.

He also still finds time for the occasional round of golf in Hertfordshire.

Way back in the 1980’s while I was still teaching I saw an advert for a job at HH Pegg, a paper agent representing 11 paper mills. It was a great introduction to the paper industry.

Winning an order never gets old!

When the kids were young it was great fun at the beach but now I prefer the country, preferably with a golf course nearby.

I’ve thought about this but I can’t think of an actor with the hairline of Jason Statham, the body of Homer Simpson and a face for radio.

Buy houses for my two kids who don’t currently have houses. It’s so difficult for kids to get on the housing ladder these days.

The Argos catalogue. In my teens I’d choose my Christmas presents from it.

My four kids. Sorry Pam, you’re first reserve.

Why should publishing customers come to Denmaur for their paper?

Cancer Research. What a horrible, indiscriminate disease.

I cycled 1,110 miles to Rome in 10 days to raise money for a good cause. We didn’t have a vehicle accompanying us so the tents and clothes etc were in our panniers which made the bikes really heavy, a true challenge when going over the Alps.

At Denmaur we provide reliable, impartial advice on a complete choice of viable paper grades and sources for customers as well as a dashboard of post-print analytics making those customers more efficient.

It was in the blood that Andy would make a career in the paper business, following in his father’s footsteps at the Star Paper mill. After ten years, Andy moved to paper merchant M6 where he first came across future Denmaur founder, Mike Gee, and Denmaur salesperson, Jean Stanley.

What was Denmaur like 17 years ago when you joined?

What are the favourite things about the company and your job?

What songs and artists would be on your Desert Island Discs collection?

What would be your category speciality in a pub quiz?

Who would play you in “Denmaur: The Movie”?

Beach, country or other holiday?

What did you buy with your first paycheck?

If you were able to make a substantial donation to charity, which one would it be and why?

What is your favourite piece of print?

Why should customers buy from Denmaur?

Andy joined Denmaur 17 years ago where he now manages commercial print sales.

Andy’s wife, Tracey, owns Leavers Bakery opposite Blackburn Rovers’ Ewood Park stadium. His son, Oliver, manages the Jo Malone store in Wilmslow. Andy is a devoted follower of Blackburn Rovers.

Denmaur was quite different in those days The publishing and merchant side of the business (Independent Paper) were separate. Now, we all work together.

Most of all, Denmaur is family owned, started by two brothers and from six years ago, continuing on with two brothers. You can speak directly to the decision makers. In my job, I love suggesting ideas to allow customers to achieve their goals.

I enjoy listening to all kinds of music from Neil Diamond through to The Cult. Mainly, though, I am stuck in the 80’s. My Favourite track would be Love Will Tear Us Apart – Joy Division

I have a little knowledge on a lot of subjects. In a pub quiz I would always go for sport or music and then be amazed how little I actually know.

I would say a cross between Tom Cruise and Brad Pitt (height-wise). Back in the real world, it is more likely to be Lee Mack who was also raised in Blackburn like me.

Either a beach or Cockermouth in the Lake District but both with some nice meals and good books.

A cheap holiday to Greece in a room underneath a nightclub. Never again! I have never been very good at late nights!

As a kidney transplant patient of 23 years, it would have to be The National Kidney Foundation.

The Guiness Book of Hit Singles and Albums. Great to find bands or songs you have forgotten.

In a few words, we will always go that extra mile to help a customer.

More specifically, it’s Green Rock making it happen.

In February, Harry and Robert Gould had the chance to visit Green Rock’s cup manufacturing facility in Wrexham joined by Denmaur’s Director of Marketing and Sustainability, Danny Doogan, and Delipac’s Sales Director, Mark Hirlam. They were hosted by Green Rock’s co-founders Steve Granville and Charles Gao.

It was an illuminating visit to both hear Steve and Charles describe their passionate vision for the company as well as see the entire process of how a reel of Delipac board supplied by Denmaur becomes various sizes of bespoke printed and totally sustainable cups at the rate of up to 2,250 per minute across the different produced Delipac cup sizes.

Green Rock’s rapid growth over the short three years since they started was evident as they have taken over additional units on the industrial estate in which they are located to house the ever expanding number of custom designed machines, currently 48, that can successfully handle the specific cup manufacturing requirements for Delipac board.

Of particular interest was Green Rock’s new effort to break into the vending machine market with Delipac cups as cups used in those machines have still different and highly specific manufacturing requirements compared to cups vended by hand.

The site visit tangibly demonstrated how the unique triumvirate partnership among Green Rock, Delipac and Denmaur can most effectively exploit the unequalled sustainability USP of Delipac cups to make ever increasing inroads in retail, transportation, festival and other markets by displacing plastic content cups.

As Steve Granville explained, the main barrier to gaining additional market share is educating the market as to what is truly recyclable and removing greenwash claims from the conversation. However, the newly formed Recyclable Food and Drink Packaging Alliance, of which Green Rock is a founder, is now countering greenwash misinformation with irrefutable factual content about how Delipac cups are one of the only accredited and certified curbside recyclable cup products on the market.

Stay tuned to hear about exciting new Delipac cup wins in the near future.

All of Green Rock’s wares will be on display at Denmaur’s/Delipac’s Stand PP269 in Hall 17 at the Food and Drink Show at the NEC 7-9 April.

Ben Lee

Duane Percival

Ian Michael

Neil Coleman

Samples Manager at Sittingbourne, became a father for the fourth (!) time on Christmas Eve welcoming daughter, Sawyer into the world.

Is reducing to 3 days a week with Denmaur from May 1st in order to allow him to spend more time where he is needed in a family supportive role.

Sales Manager-Graphical at Denmaur supplier Arctic Paper got married to Jane Michael on 27 December.

Former Denmaur employee, has been named as UK Sales Director at Denmaur supplier Burgo.

Welcome to the Denmaur family

Cathryn “Cat” Redstone

Internal Account Manager at Bardon

Mark Lees

Sales and Technical, Cartonboard at Bardon

Cameron Faithful

(Son of Commercial Print Manager, Andy Faithful) Sales Trainee in Sittingbourne

Rod James

Formerly Warehouse Supervisor at Bardon whose heart attack story featured in our last issue, has taken up a new position with Denmaur customer Sterling Press.

Steve White

Is leaving Denmaur at the end of March after 17 years in Inside Sales at Sittingbourne, to seek a new challenge outside the paper industry. Did you know?

Formerly in Commercial Print Outside Sales-South, retired at the end of 2024.

Cheyanne Ennis

Former Transport Manager-Bardon, has left the company for a new opportunity.

David Gee

43 YEARS

Stephen Rathbone

41 YEARS

Mike Gee

37 YEARS

David Perry

35 YEARS

Kevin Walls

33 YEARS

Ricky Hirshfield

28 YEARS

Julian Townsend

26 YEARS

Martin Travis

Julie Crayford

24 YEARS

Paul Cooper

Adrian Beckett

Martin Best

Stephen Hampson

23 YEARS

Martin Wheeler

Doug Jessop

Nigel Somerfield

22 YEARS

Danny Doogan

Paul Jackson

Anne Attwater

Sarah Marshall

Mark Ashcroft

21 YEARS

Andy Faithful

Glynn Bunce

Sean Markham

Warren Jones

20 YEARS

Sarah Reed

David Richards

19 YEARS

Steven Evans

Karen Simms

18 YEARS

Andy Moore

John Russell

Henryk Dlugosz

17 YEARS

Andrew Livesey

16 YEARS

Jean Stanley Simon Cartwright

Lee McSweeny

15 YEARS

Mathew Tobin

14 YEARS

Ian Fry

Mark Harsent

Joshua Kilby

Sean Jackson

Sarah Erswell

13 YEARS

Parmjit Singh

Christopher Green

Brian Lawes

Eric Clee

Andrew Farmer

Graeme Richardson

Daryl Bird

11 YEARS

Jeanette Gray-Mitchell

Garreth Donnelly

10 YEARS

Ben Lee

Andrew Buxton

Zach Gargan

Duane Percival

Sam Mills

Jake Watson

Andrew Briars

Daniel Thompson

Neil Cobley

Gary Dacey

Alex Bradburn

9 YEARS

Andrzej Plawski

Anna Berrisford

8 YEARS

Jonathan Thompson

David Hensman

Malcolm Costelow

Jordan Richardson

7 YEARS

Inderjit Malhi

Michael Keating

Andrew Evans

Robert Thraves

Ruth Moore

6 YEARS

Alistair Nash

Ian Williams

Jason Darby

Nimesh Amrat

Daniel Butler

Piotr Klimczak

5 YEARS

Leon Griffiths

Harry Gould

Robert Gould

Stephen Bedworth

Vitalijs Vitkovskis

Alan Wilkins

Christopher Smith

Matt Groom

4 YEARS

Ben Ingall

Jon Cooper

3 YEARS

Staci Terry

Abdulhamid Aghe

Karlene Rolls

Anthony Hardy

Miriam Larkins

Suzanne Miles

Joe Barker

Nigel Poole

Jacek Orlowski

Helena Prusakevica

2 YEARS

David Plummer

Bradley Taylor

Keith Hedges

Phillip Ferguson

Molly Martin

Anthony Bennett

David Arnold

Warren Curtis

1 YEAR

Simon Bishop

Radek Cybulski

Holly McMullen

Ross Hampson

Klaudia Mik

Gregory Topliss

George Tarta

RECENT JOINERS

Ashok Tandel

Ram Tamang

Clive Townsend

Michael Townsend

Craig Bentham

Derrick Danquah

Terry Brookes

Gabriel Harbuz

Jamie Roberts

Cat Redstone

Anamaria Patrascanu

Cameron Faithful

Mark Lees

It’s not just big concert and food venues that are taking sustainability seriously. It’s also Newport Rugby Football Club, who play in WRU (Welsh Rugby Union) SRC (Super Rygbi Cymru).

Newport RFC is celebrating its 150th anniversary since formation by introducing bespoke Delipac cups bearing a special 150th anniversary version of the club’s proud crest along with its motto “The Newport Way” which outlines the club’s values of commitment, respect, teamwork, integrity, excellence and community.

Being able to dispense totally sustainable cups for its thirsty supporters on match day fits in naturally with the club’s core values.

The cups are supplied by Just Peel, sustainable cup supplier to many large UK concert venues, from its cupapeel range and manufactured at Green Rock in Wrexham from Delipac board supplied by Denmaur. The local manufacture was also part of the, er, appeal.

“It’s so pleasing to be able to mark our 150th season milestone with new initiatives which also help us do our bit for the environment. We’re delighted with the cups – as well as being more sustainable, they’re another great vehicle for us to be able to promote the values of Newport RFC. It’s a great way of shouting about what we stand for and we’re hoping that our supporters join us by adopting these values, too.”

tm: So what is this all about?

After featuring a very revealing interview with Denmaur’s Chairman, Harry Gould, in our last issue, your editors were more than a little surprised to receive a demand from our NonExecutive Director and Harry’s younger brother, Robert, for an equal time rebuttal in this edition.

Even after the interview we don’t quite understand exactly what Bob wants to rebut but far be it for us to deny any sibling commentary in a public forum. Besides, we have pages to fill so here goes.

RG: For far too long the pain and suffering of younger – in my case, young-est – siblings has been ignored. When there has been success in a family, the credit almost always goes to the older and usually oldest sibling. Sure, let’s laud Isambard Kingdom Brunel but what about his long lost younger brother, Swifty Tiny Village Brunel? Following in the engineering footsteps of his brother, he had the idea for constructing a Legoland even before Legos were invented. And who today remembers John Lewis’ younger brother, Ponzi, who was always knowingly oversold, or the somewhat misguided Cheapo Cadbury who tried to make a go with Curdled Milk chocolate?

Unless they are one, no one realises how stacked the odds are against younger brothers making their own way. I mean, hello, Prince Andrew?

tm: Well, I guess but how does this apply to you?

RG: How doesn’t it apply to me! You try having brothers eight and five years older. I mean wearing bell bottom trouser hand me downs long after they have gone out of style. I still have nightmares. And don’t even get me started on Nehru jackets. The horror, the horror.

Plus all the time growing up I had to hear from my two older brothers how easy I had it compared to them but I’m not buying it. I mean did they really have to walk up hill to school – both ways? And fearful of wild animals en route? We lived in Manhattan for God’s sake!

tm: So how would you change things to combat what you call “Younger Brother Syndrome”?

RG: For one thing, we should get rid of this whole “primogeniture/rights of the first born” thinking and replace it with “ultimogeniture” – the rights of the last born. It only makes sense. Look, you don’t want to use a new software update while it is still in beta, do you? You wait for it to improve as it gets refined. Same with siblings. It’s just a law of nature, we save the best for last. (OK, maybe not with Prince Andrew but you get the point.)

And we have to call out this whole “Jr.” naming thing for what it really is. Harry is a Jr. because he was named after our father. OK, maybe that makes sense at birth and while growing up but as an adult what does that say about you? I mean Junior is the kid you ask to go get the car or paint the fence. Or the funny sidekick in a sitcom. Even my brother understands this because our Dad has been gone for a long time and Harry no longer uses “Jr.” But c’mon, you don’t change the spots on a leopard, you know what I’m saying?

tm: So what do your brothers say about YBS?

RG: Well, they tend to focus on the “BS” of that acronym. However, deep down I think they know that I have suffered in silence all these years.

But no more!! I am loud, proud and call on all other younger brothers to stand up for themselves. Trump may have his Proud Boys but I am hereby announcing the Proud Bros. Younger brothers of the world unite! You have nothing to lose but your false inferiority complexes.

tm: Very moving. But you haven’t said much about your middle brother, Peter, in all of this. Is he part of YBS?

RG: No, he has his own challenge to confront, MBS, but he will have to get his own company magazine to do that. I have my hands full letting my oldest brother think he is still in charge at Denmaur.

Look who’s having a birthday cake

March

April

May

June

Nimesh Amrat / Jon Cooper / Andrew Evans / David Hensman / Ben Ingall / Andrew Livesey / Ruth Moore / Sarah Reed / Jonathan Thompson / Inderjit Malhi / Radek Cybulski / Ram Tamang

Karlene Rolls / David Plummer / Daniel Butler

Kevin Walls / Sean Markham / Abdulhamid Aghe / Anthony Bennett / Michael Townsend / Derrick Danquah

Martin Best / Paul Cooper / Andrew Farmer / Robert Gould

Joshua Kilby / Duane Percival / Joe Barker / Vitalijs Vitkovskis / Warren Jones / Simon Cartwright / Nigel Somerfield / Molly Martin / Warren Curtis / Jamie Roberts

Stephen Bedworth / Gary Dacey / Leon Griffiths / Jean Stanley / Garreth Donnelly / Anthony Hardy / Simon Bishop / Craig Bentham

In January 2025, Denmaur reached the 250,000 tonne milestone of Carbon Balanced Paper sales since adopting the scheme in 2016.

One of the best-known carbon programmes in paper, print and publishing, Carbon Balanced Paper is an effective and measurable solution for organisations to reduce the carbon impacts of their printed media and communications.

The scheme supports the activities of the World Land Trust (WLT): namely the protection, conservation and regeneration of some of the planet’s most important forests and biodiversity, as well as protecting the habitats of a number of critically endangered species.

A simple and transparent mechanism for balancing the production emissions of graphical paper and carton board, the scheme enables a direct investment into the World Land Trust projects. In return, customers can use of the new WLT Carbon Balanced logo as well as an official WLT certificate to confirm the carbon savings and the amount of conservation land that has been protected.

Catherine Barnard, CEO of the World Land Trust, provided a statement in recognition of Denmaur’s milestone, “The global climate is changing at an unprecedented rate due to humancreated climate change. So, we are delighted to see that Denmaur celebrate this achievement as part of their contribution to society’s transition to a low-carbon economy.”

Many of the products within Denmaur’s stock portfolio are Carbon Balanced at Source – this includes the Amadeus and Revive ranges. Here, the mill of manufacture funds the cost of offsetting and so there is no additional cost to the customer at point of sale. All other paper and board products purchased from Denmaur can be Carbon Balanced at a very affordable cost.

Denmaur’s Marketing and Sustainability Director, Danny Doogan, said, “It gives us great pride at Denmaur to have achieved this level of Carbon Balanced Paper sales in just under 9 years of working with the World Land Trust.”

He commented further on the growth of the Carbon Balanced Paper scheme, “Its popularity has grown significantly in recent years amongst printers and end users who use Carbon Balanced Paper to complement their own carbon reduction programmes.”

Denmaur’s 250,000 tonnes of Carbon Balanced Paper sales equates to the removal of 152,000 tonnes of atmospheric carbon emissions as well as protecting 6,835 acres of critically threaten forestry!

The current Carbon Balanced Paper projects are now in Uganda, Mexico and Guatemala. Scan the QR code to learn more about them.

Issued:

Department News

Up Close and Personal

Meet the Mill

Sustainability Centre ... and much, much more

BARDON OFFICE: 01530 275500

BARDON WAREHOUSE: 01530 447068

BESCOT OFFICE: 01922 633333

BESCOT WAREHOUSE: 01922 929547

BRISTOL OFFICE: 01173 320863

SITTINGBOURNE OFFICE: 01795 432100

This is your magazine and can only be as good as the newsworthy items we know about. So please don’t be shy. All, and we mean, all news items, comments and suggestions are welcome. Just drop a line to themag@denmaur.com. Like an Australian boomerang, the mag will return with more of what you love:

SITTINGBOURNE HEAD OFFICE Bonham Drive, Bourncrete House Sittingbourne, Kent ME10 3RY

MARKETING: 01795 502144

SAMPLES: 01795 432160