ALL THE NEWS ABOUT PRINTING, PACKAGING AND SUSTAINABILITY

Summer #2024

• FAREWELL TO A FOUNDER: NICK GEE

• PRODUCT SPOTLIGHT: REVIVE

• UP CLOSE & PERSONAL: MATT GROOM

• SUSTAINABILITY CENTRE

• VIDEO TOUR OF REEL FAST CONVERSION CENTRE

...AND MORE

Summer #2024

• FAREWELL TO A FOUNDER: NICK GEE

• PRODUCT SPOTLIGHT: REVIVE

• UP CLOSE & PERSONAL: MATT GROOM

• SUSTAINABILITY CENTRE

• VIDEO TOUR OF REEL FAST CONVERSION CENTRE

...AND MORE

In 2023 we celebrated 40 years in the trade; and just a year on, we’re still creating milestones, developing new areas of business and continuing to evolve successfully as a company in the 21st century.

My brother Nick’s well-earned retirement at the end of April certainly marks a new era for Denmaur, and although the senior brother, I still retain the appetite for the day-to-day opportunities and challenges that the industry brings.

Nick was with me from the absolute beginnings of my entrepreneurial crusade, which resulted in the company that we have today. Back in 1983 and leaning on my background in the industry (having previously worked for Charles Baker, Lepard and Smiths, Link Paper, Bowaters and M6 Papers), we concentrated on the supply of book publication papers for both publishers and printers before expanding into grades for the magazine sector - a thriving market from the mid-late 1980s, throughout 1990s and into the early 2000s.

Since then, and through a combination of acquisitions and organic growth, we’ve created a successful paper and board business with a diverse product range serving a variety of markets, and all coming together under one powerful brand - Denmaur. This first issue of the mag is meant to reinforce our brand position with information

about our company, customers, suppliers, industry and, most importantly, our people.

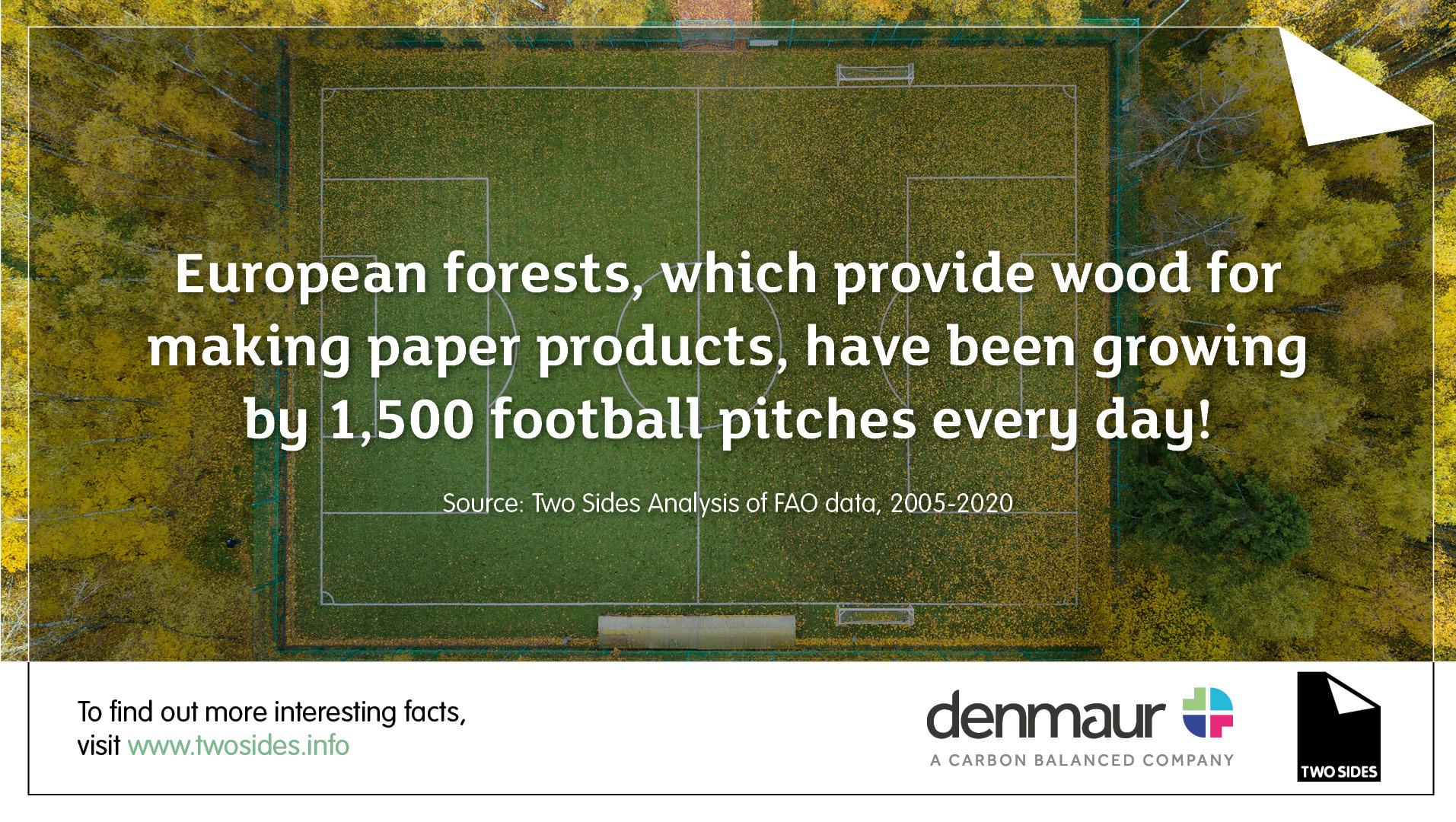

In recent years, Denmaur has also emerged as a brand synonymous with sustainability. We are the home of the Revive range of recycled papers, our Carbon Balanced Paper sales are well on the way to ¼ million tonnes and we’re the first merchant to have registered an SBTi recognised carbon net zero target. Through our actions, the realisation of our suppliers’ decarbonisation plans and the support of organisations such as Two Sides, the paper and board industry will command an important position in the circular economy as it contributes to the fight against climate change.

Lastly, this is an opportunity to say an enormous thank you to everyone who has made, and continues to make, this company the warm and wonderful organisation that it is. That thanks goes to my immediate family as well as to my friends who are customers, suppliers and our magnificent staff, past and present.

I hope you enjoy the mag now and in issues to come…. perhaps enhanced by the accompaniment of a recommended glass of wine.

ABOUT MIKE GEE

Mike Gee is currently the Vice-Chairman of Denmaur Independent Papers having previously been Managing Director from 1983 to 2018. Mike’s current role is mainly strategic and his focus is on seeking out and following up on opportunities for growth presented by potential mergers and acquisitions. Mike’s knowledge and experience of the paper industry and extensive network of contacts are invaluable.

mgee@denmaur.com

Welcome to the inaugural edition of the mag, Denmaur’s thrice yearly publication launched after the company’s 40th year to cover what is happening at our/your company with its people, customers, suppliers and in our industry.

Some of that value won’t even be in print as you will see QR codes dotted throughout the magazine that will take you directly to video content that supplements what we have written about. We hope that multi-media makes it multi-valuable.

This publication is also designed to show off our wares a bit as this first edition is printed on our signature Revive Silk stock (350 g/m² for the cover and 170 g/m²) highlighting our commitment to sustainability. Future editions will feature other signature Denmaur products.

And while we have spent a good deal of time creating the content you can read about in this issue, future publications will only be as good as the feedback we can get from you, the reader. Like or didn’t like a particular article or feature? Have any paper or personal news you would like to see in print? Thought of something we haven’t covered? We want to hear about it all whether you are a Denmaur team member, customer or supplier. It is super-easy to reach us at themag@denmaur.com and we promise that all commentary and suggestions will be considered and responded to.

So enjoy the mag. It is our attempt to improve communication within and outside the company. There is a lot to digest and a lot more to come.

The Editors themag@denmaur.com

VIEW FROM THE TOP FROM THE EDITORS FAREWELL TO A FOUNDER MEET THE MILL

VIEW FROM THE OUTSIDE UP CLOSE AND PERSONAL: MATT GROOM PRODUCT SPOTLIGHT DEPARTMENT NEWS

SUSTAINABILITY CENTRE READ ALL ABOUT IT

DID YOU KNOW / BIRTHDAYS

INDUSTRY FEATURE: THE FROGMORE PAPERMILL

FOND FAREWELLS

THE DENMAUR FAMILY CORNER

THE LONGEVITY LIST

DOWNTIME

Ileft school having completed my A levels with a view to going to university to study to become a dentist. Things do not always turn out as planned, however, and a summer job working with my brother’s newly formed company, Denmaur, turned into a 44 year journey in building a business in paper merchanting that looks very different today than it did then, as indeed does the whole industry.

At the start there was literally just Mike Gee and myself, with his wife Denise carrying out all the bookkeeping manually, I leave a business that now has over 130 employees and a turnover of around £150 million - I never even had an interview!

The company today, and indeed the industry, looks very different than it did in 1980. Remember, this was not only a pre-email world, there weren’t even fax machines in those early years and quite often enquiries would arrive and be replied to by post.

The most significant change I have witnessed in my career is the consolidation of both our supplier base and our competitors, and the speed with which business moves. In paper manufacture, there were literally dozens of mills to buy from - many of which were in the UK, and many of which would make bespoke products against our requirements. I remember visiting East Lancashire Paper Mill to discuss the supply of some blue coloured paper for a book publisher customer, the mill sales director had laid out on the table the 67 shades of blue they had made in the previous twelve months and was keen to point out that if none of them were suitable they could make a specific match.

In the early years, the skill of Denmaur was to match the needs of the customer to a particular mill or product, and it was our knowledge that our clients relied upon. We were once asked to provide a cream paper for a book about wildlife along the canals of France. It transpired, when the police arrived at our Sittingbourne office, that the paper was actually being used to print counterfeit American dollars!

Alas, like much of global manufacturing, only the larger, more efficient producers have survived the journey, and today the choices are far more limited unless you are able or prepared to pay a significant premium. The result is that today’s paper and boards, although produced more efficiently and certainly more sustainably than before, have become commodities.

Similarly, the world of paper merchanting has been subject to mergers and takeovers by larger players. Size isn’t everything though. In 2015, the UK’s largest paper merchanting group failed and completely changed the landscape for the remaining merchants. Denmaur took on some of its staff and we expanded our offering to the print market – almost immediately.

So, as I retire from a business that has been my only job, I look back with pride, not only at the fact that

a multimillion-pound company has been built from pretty much nothing, but the way we have done it. We have always tried to treat those that were part of the journey, be they employees, customers or suppliers, with decency and respect as people are the most valuable asset.

My decision to retire is not for the fact that I am bored or no longer love our industry, but to enjoy some leisure time without the responsibility of the business in my mind whilst my health, hopefully, still allows.

I have already been fortunate to see some exciting places around the world but my wanderlust remains and I intend to enjoy travelling whilst engaging in two of my life passions, skiing and sailing. I may even pick up a golf club to see whether it really is fun or just an excuse for a day away from the office!

Nick Gee Retired

Nick Gee has been the Managing Director of Denmaur Independent Papers since 2018. His role is to manage the business from an operational perspective, supported by the Directors who are responsible for the day to day management of each business area. Previous to this role he was Commercial Director and in both roles maintained excellent relationships with suppliers and key customers.

The Burgo Group is the industrial holding company of a group operating in the production and distribution of paper for the graphics sector, speciality papers (e.g., for food use) and containerboard, as well as in the production and sale of fibrous raw materials (chemical pulp, mechanical pulp, deinked pulp) and energy.

With 10 plants and 12 production lines, the Burgo Group is one of the leading European producers of graphic papers, speciality papers and containerboard for the packaging sector. Let’s take a closer look at one of these plants.

Part of the Burgo group since 1994 as the nearest woodfree coated producer to the UK, Burgo’s Ardennes is an integrated mill, producing paper, pulp and high-end coated paper for commercial print and publishing. The Burgo Ardennes plant consists of two production units: one for chemical pulp and the other for the production of woodfree coated paper, a crucial segment of Burgo’s portfolio of fine papers.

Located in the heart of Gaume near the Luxemburg border, Burgo Ardennes employs over 700 people, producing every year over 400,000 tons of chemical pulp and over 380,000 tons of high-end coated paper for the advertising and publishing sectors.

Most of the chemical pulp produced in the plant is used on site for paper production, while the remainder either supplies the other Burgo Group plants or is sold to

external paper mills. The production of coated paper is marketed 85% in sheets and 15% in reels..

With a net zero carbon target in the near future, Burgo Ardennes is at the very forefront of sustainability utilising a soon to be completed photovoltaic park to generate solar power combined with biomass fuel from waste wood and bark to accomplish totally fossil free power generation.

In commenting on the mill’s position in the UK market, Alberto Bertoluzzi, MD of Burgo UK, noted,

“The site of Burgo Ardennes is only 300 miles from the UK so this market is very much considered as a home market. With excellent road and rail links, this enables us to provide an excellent delivery service, whilst the mill’s location also enables transport emissions to be kept at very low levels, something that is becoming more and more important when considering environmental impact.”

400,000 Pulp Capacity tonnes/year

380,000 Paper Capacity tonnes/year

90 - 350 Paper Weights g/m2

1,500,000 Wood from local forests tonnes/year

In-house energy sources

Biomass plants and steam cycle cogeneration plant

Location

Nearest WFC producer to the UK

BY DAN BRADBURY, DIRECTOR OF BRAND AND COMMUNICATIONS, WORLD LAND TRUST

At World Land Trust (WLT), our mission is to help people across the world protect and restore their land to safeguard the natural world. We achieve this by building close, long-term partnerships with local conservation organisations, supporting projects that directly protect and restore some of the planet’s most threatened habitats and the remarkable wildlife within them. We are able to carry out this crucial work thanks to our generous network of supporters and longstanding partnerships with businesses such as Denmaur Independent Papers.

Since 2016, Denmaur has been supporting WLT through the Carbon Balanced Paper programme, which provides funds for the ongoing management and protection of carbon-rich habitats in Ecuador, Mexico, Vietnam, and Guatemala. There, WLT and our conservation partners protect ecologically vital forests that would otherwise be under imminent threat of deforestation. We do this through a method known as Reducing Emissions from Deforestation and Forest Degradation (REDD+), a proven and effective method that tackles both the climate and biodiversity crisis.

There is recent concern that offsetting (balancing) carbon emissions is not an effective way of addressing climate. However, while it is true that we must do everything possible to decarbonise our society at every levelwhich is why we have a requirement for all businesses contributing to the Carbon Balanced programmes to evaluate their sustainability strategies and reduce emissions in the first instance - the benefits of naturebased solutions such as conserving standing forests reach much further. “We recognise that few (if any) of the global

carbon schemes are perfect. However, the real issue here is that funding for forest conservation has, for decades, been far below what’s required to protect these vital parts of Earth’s life support system. We must not let perfection be the enemy of the good.” WLT CEO Dr. Catherine Barnard.

WLT’s work has always been about the wildlife and people who benefit from our projects. Through the Carbon Balanced programme, WLT funds four projects in some of the most biodiverse regions in the world, which also suffer some of the most damaging effects of the climate crisis. In Mexico’s Sierra de Xilitla project, the high, misty cloud forests not only provide a home to iconic mammals including Jaguar, Puma, American Black Bear, and Ocelot, but also regulate the rivers and streams critical to the entire region. In Ecuador, the Nangaritza Valley is the last intact biological corridor between the Andean cloud forests to the west and the Amazonian rainforests to the east, and is teeming with rare and spectacular wildlife, from Jaguar to Orange-throated Tanager.

WLT strongly believes that the people living on the frontiers of environmental breakdown are the most likely to know the best solutions for their circumstances and possess an unrivalled knowledge, understanding of and right to those ecosystems’ conservation. By working with local people to maintain existing forests, WLT’s Carbon Balanced programme delivers tangible protection to these habitats and their wildlife, while contributing to one of the best defences against the worst effects of climatic change and delivering measurable climate benefits through emission balancing.

Many thanks to Denmaur and to their customers for their continued and much valued support.

The World Land Trust is an international (UK registered) conservation charity. Founded in 1989, amongst its patrons is Sir David Attenborough. For further information about the Carbon Balanced projects please visit www.carbonbalancedpaper.com For further information about the benefits associated with Carbon Balancing your paper, please visit www. denmaur.com/Group_Sustainability_ Carbon-Balanced-Paper

The Carbon Balanced Paper programme enables companies and organisations to reduce the environmental impacts of their paper-based media and communications.

Between 2016 and 2024, Denmaur, a proud Partner of World Land Trust, has achieved through the positive actions of its customers:

• 5,500 ACRES OF FOREST

• 41 THREATENED SPECIES’ HABITAT PRESERVED

Matt and his team in the finance department are kind of like the stage hands in a theatre: you don’t often see them but the show can’t go on without them. Matt, an FCCA credentialed accountant and English Literature graduate, has been with Denmaur since 2020 after a long career at a PE owned polystyrene products manufacturer and distributor where he finished as Group Finance Director. As a result of the company’s recently implemented succession plan Matt has been named Chief Financial Officer and taken on additional supervisory responsibility for IT, Procurement and HR to supplement his department’s core functions of credit control, financial reporting and banking relations. He is married to Celina and they have two children aged 10 and 8.

the mag caught up with Matt at his Sittingbourne office.

TM: How did you get into accountancy?

MG: I stumbled into it really. The first business I worked at was going through an IT ERP system change and needed someone to help them. I was only meant to be there for 6 months but quickly found I enjoyed it and there was lots to try and improve. After that I embarked on my ACCA qualifications and took over the running of the Finance department. The truth is I have a seen a lot of businesses with great people and great ideas or products fail because the non-customer facing departments weren’t strong enough. I am proud to have built several finance teams across different businesses, each one better than the last, that have been very strong and added value to the business.

TM: What is your favourite thing about Denmaur?

MG: I have a great team around me which makes things so much easier. Knowing that everyone knows what they need to do and is committed to achieving that goal allows me to continue to challenge the business in its strategic goals. It is also very rewarding when we set new challenges either individually or as a group and we then see the achievement benefits.

TM: What is the favourite thing about your job?

MG: The opportunities for change. There is so much that we do right as a business but there are always new ways of working or thinking about the needs of the business and its customers.

TM: Who would play you in the film ‘Denmaur’?

MG: A tricky one so I’m going with an actor I admire rather than necessarily a reflection of myself and that would be Christian Bale. His transformations for movies are legendary and for me the sign of his skill as an actor is that you very rarely watch him and think this is Christian Bale playing a part. He is the character.

TM: What is your favourite piece of print?

MG: Not necessarily a piece of print but I recently bought a new pair of shoes and I was really impressed by the way it was packaged. The quality of the materials and design was very clever as well as being highly sustainable. Rather than it just being packaging to transport the shoes in it was an extension of the brand and the brand values.

TM: Why should people continue to use paper and board?

MG: For me it is what stood out in my answer above. More and more companies are seeing the benefit of their printed marketing and packaging as an extension of their brand and brand ethos. It can be very powerful and really make a brand stand out from its competition. There is also the sustainability aspect of paper and board vs plastic. It is very noticeable when companies transition away from traditional plastic to a more sustainable source. Denmaur’s challenge is to remain at the forefront of this transition and to look to promote emerging product developments.

TM: If you were given £1000 to donate to charity, which one would it be?

MG: Blood Cancer UK. A few years ago my wife lost a good friend and mentor to leukaemia so we support where we can.

TM: What would be your specialised subject in Mastermind?

MG: It would probably be music and specifically rock and Metal. Statistics show that over the age of 33 people stop discovering new music and I make a point of seeking out new albums from emerging artists every week.

TM: Your favourite holiday destination?

MG: Not really a holiday destination but every year I go to Download Festival and the atmosphere and people are amazing.

TM: Why should people buy from Denmaur?

MG: Because Denmaur has positioned itself as the leader in the UK when it comes to when it comes to sustainability, the importance of which will only continue to grow through either legislation changes or cultural changes.

It is also where the opportunities of the future lie.

2024-Present: Denmaur CFO

2020-2024: Denmaur FD

2012-2019: Group Financial Controller and then Group Finance Director at Jablite Ltd and Styropack Ltd

2010-2012: Group Financial Director at GML Group

2004-2010: Finance Manager at Highway Care Ltd

Revive is an exclusive range to Denmaur, representing a selection of recycled paper and boards designed to meet a combination of environmental and commercial requirements for publishing and print. Although the Revive family consists predominately of 100% recycled products, there are also a few 50% alternatives on offer - simply because they’re manufactured at the mill and, occasionally, they’re specified by customers.

Revive Silk and Offset, the first grades to launch the range for Denmaur in 2016, are 100% and 50% products. Both are high white grades, in weights and sizes to reflect the woodfree market. A Natural offset complements the uncoated range and is an ideal choice where a natural shade and feel suits the end result.

The Revive family covers a broad range of sectors and includes gloss, silk and matt grades for the publication sector as well as heavier, bulkier products for carton board

conversion; and as with all the Revive products, they are Carbon Balanced at Source – i.e. the mill funds the cost of offsetting the production emissions of each grade via the World Land Trust’s much respected Carbon Balanced Paper programme.

Particularly valued for their sustainability credentials, Revive products boast certifications like FSC® Recycled, quality, environmental and energy ISO’s, in addition to being Carbon Balanced. However, key to the range is its recycled pulp, which must be produced from postconsumer waste, demonstrating the recyclability of paper fibre and its place in the circular economy. To endorse this we provide a post-consumer waste recycled paper logo.

As with all families, growth is never out of the question. As new products become available, even finished paperfibre based items, the Revive range may well be open to expansion …. watch this space.

Do you have a suggestion about how the company might improve something? Or a question about why or how the company does something? Suggest and ask away at themag@denmaur.com. It is your chance to help make the company better, satisfy your curiosity or just get something off your chest. No names needed so be as anonymous (or not) as you like. Here are some examples to get you in thinking mode:

Suggestion: How about having a Denmaur pub quiz night?

Question: Will Denmaur be switching any of its delivery vehicles to EVs?

DOUG JESSOP

Within the Paper Management Division of Denmaur, we deal with many customer sectors including publishers, retailers, charities, tour operators, catalogue producers, and print management companies who have all become used to examining their scope 1 emissions (those that come from sources owned or controlled by themselves). But the news is that increasingly they are now turning their attention to scope 2 and 3 emissions, those which are indirectly related to their activity.

Many of our end user customers have (like Denmaur) set themselves ambitious carbon reduction and net zero targets. Reducing their scope 2 and 3 carbon emissions will play a big role in achieving their own reductions and commitments.

We can support this, because our mill suppliers produce carbon footprint statements and/or paper profiles, confirming the carbon emissions associated with their paper’s production. We can include these in our quotes and reports to help our customers make an informed decision.

We can also calculate the carbon emissions for delivery from mill to printer, taking into account distance and the mode of transport such as vessel, truck, or rail to provide our client with a total carbon emission figure for each job.

Another clever way to reduce the carbon footprint of a printed product, is to use a ‘bulky’ grade, which many paper manufacturers have developed. For example, a 1.3 bulk version of a paper grade that is competing with an option that has a standard bulk of 1, will offer a reduction in tonnage of up to 20%, meaning 20% less tonnes to be made, 20% less tonnes to be transported yet the product looks and feels exactly the same with the same quantity of copies and pages produced. This leads to a significant reduction in carbon footprint and can often also offer an equally significant reduction in total cost.

There is also the opportunity to use a bulky grade in specific sections of a publication – there can be a mix within a product that will still reduce the carbon footprint and the cost to the client.

This capability is more prevalent, although not exclusive, to our Paper Management Division. Overall, Denmaur has access to many other opportunities to offer environmentally friendly options to our customers from within our own ranges of products and services.

Sustainability has been at the core of our activities for many years now and our drive to reduce our own as well as our customer’s CO2 emissions will continue and only gather pace.

It is fair to say the previous 12 months have provided many challenges to a Commercial Print market that has seen supply issues persist and pressures on price, which have been amplified recently with the soaring price of pulp.

However, it is great to report a solid first half of this calendar year, with volumes and number of trading customers holding up well.

Product and service development never stops and I am pleased to say we have seen a raft of new ranges join the Denmaur portfolio over the last 12 months. From the hugely successful (and not so new now!) Film Lamination, to the launch of our Reel Fast conversion service.

More recent additions of IQ Premium and Figaro Preprint have been bought in to strengthen our offering to the growing Digital market. Further exciting new ranges are to come, which will include a host of products for the large format sector.

Movers, Shakers and Milestones!

We are blessed at Denmaur with some wonderful talent and none more so than the next two individuals. Congratulations go to Duane Percival and Josh Kilby who have been elevated to the positions of Director of Sales and Commercial Manager respectively, for the Midlands and North Areas; and to Dave Arnold and Sarah Marshall who have become Director of Sales and Commercial Manager, respectively, for the South and South West,

These appointments strengthen our Commercial Print team and ensure we are fighting fit for further growth in the coming year. Watch this space for more new developments!

And last but certainly not least – some memorable milestones have been reached by a number of the team recently. David Gee turned 40, (which he is not at all bothered by), and Jon Cooper & Duane Percival hit the big 60! There maybe others who have chosen to keep a low profile so congratulations to all the big birthdays!

We are now two years in from the acquisition of the Bescot Production and Storage facility by the Denmaur Group. Although I am sure that most have been introduced to the plant in some way, I thought that I would give a brief synopsis of what we are about.

Our 3 Pasaban sheeters can sheet from 300x310mm up to 1850x2200mm taking substances from 40 to 600 g/m². We have a Pasaban rewinder which can cut from 120 to 2450mm width from substances of 34 to 325 g/m². We also have 2 guillotines, a ream wrapping facility, pallet turner and heat shrink wrapper.

Working at full steam we can sheet up to approximately 2500 tonnes per month, subject to product mix, with shifts working up to 24/7 with weekend overtime.

Our dedicated team of operatives, most of whom have been with the business for many years, have a great breadth of experience

in our processes.

We have always prided ourselves in having a can-do outlook and are happy to look at any opportunities thrown at us.

We have recently been through a re-vamp of our appearance and in particular our procedural and health and safety practices with great help and input from Danny Doogan and Andy Moore in particular. This has resulted in a different feel to the facility and all of the staff have benefited from the changes made.

With the new conversion-dedicated Reel Fast paper and board products and processes coming on board we are looking forward to a far busier and brighter future.

ANDY MOORE

Let’s begin with our proposition: 2 warehouses - including 1 factory, covering 225,000 sq ft and 12 vehicles delivering more than 1500 tonnes every week. Impressive headline figures but there is a lot of other numbers behind the scenes that maintain the moving parts of our business.

Although less than an hour apart, our Bardon and Bescot sites are ideally located for servicing next day, nationwide stock deliveries. Both sites are certified for FSC, PEFC, ISO 9001 and ISO 14001, Bardon is BRCGS certified (Bescot is in preparation for this accreditation at the time of writing) and we’re also working on a groupwide Health & Safety standard. So, both sites will eventually share 6 major certifications, requiring 6 external audits and at least 8 internal audits each year.

In the warehouses, the working day begins at 07:00 - the start of 2 shifts that operate 5 days a week - but the first shift in the Reel Fast factory in Bescot starts at 06:00. Combined, both warehouses employ 35 people and 12 drivers, with an additional 24 people running the Reel Fast conversion operation.

On average, we receive 55 goods inwards vehicles at Bardon every week. A fully loaded vehicle is 24 tonnes, equating to 35

pallets of sheets or 20 reels of cut-star reels. It will take up to 3 hours to offload and re-rack a full load of pallets, and about 45 minutes to offload and stack a full load of cut-star reels. Cutter reels vary in size and weight and being heavier and larger than print-ready reels, fewer of them are needed to register a full load. That said, it will also take 45 minutes to offload and floor stack a full load of cutter reels.

Both warehouses can rack a maximum of 33,500 pallets, with enough dedicated floor space capacity at both sites to store around 2,000 tonnes of reels and sheets when completely full.

Bescot has 3 sheet conversion machines, 1 rewinder and 2 industrial guillotines. To physically manage stock in both warehouses, we have 6 electric VNA (Very Narrow Aisle) machines, 6 gas powered folk lifts, 3 clamp trucks and 4 electric powered pallet trucks.

So, lots of numbers throughout each working day. However, perhaps the most important number is that of the dedication and commitment of the staff directly connected with the moving parts of our business, and that number is 10….out of 10.

After a period of interesting (and challenging) market conditions in terms of supply and demand over the past couple of years the business has now established our ongoing range of products.

These represent a broad spectrum of products for the packaging, graphical and commercial print sector. Many of these are exclusive to Denmaur for the UK market. We continue as a team to seek out further potential lines of supply to expand the portfolio.

Since our acquisition of the Bescot site we have launched the Reel Fast service for both the Aura Fold Plus (folding boxboard) and Formakote Spectra (white lined coated kraft), both exclusive to Denmaur. This is much more than a “standard” sheeting offer, but a new service concept offering an easy way for the customer to order.

• The customers have their own price schedule, accessing the Reel Fast website to work out their price per 1000. Orders can then be placed for delivery in 5 working days.

• A deckle free service, deliveries to beat European based lead times.

• Reduces waste and processing time. Simple, quick and efficient.

This has enabled us to both expand the offering to our existing customers and to engage with new customers, particularly with the addition of the Formakote Spectra line. The initial response and resultant sales have been excellent since the launch of the service.

The combined carton board industry knowledge and experience we now have within our sales team along with the great range of products and services we can offer means that we can look forward to continuing success with our footprint in the market.

BY DANNY DOOGAN

In June 2023, Denmaur became the first paper merchant to register an approved near-term reduction target of 2030, with the Science Based Targets Initiative (SBTi). We took our commitment a stage further this year and also registered our Net Zero date, 2045.

Science Based Targets Initiative (SBTi) is a partnership between the Carbon Disclosure Project, the United Nations Global Compact, the World Resources Institute and the World Wide Fund for Nature.

In October 2021 the SBTi launched the world’s first net zero standard, providing the framework and tools for companies to set science-based targets and limit the global temperature rise (above pre-industrial levels) to 1.5 °C, in accordance with the Paris Agreement.

We are one year into our near-term reduction target, aiming for a 46% reduction of our 2019/20 Scope 1 and 2 emissions by 2030. The 46% target aligns our reduction with the 1.5ºC Paris Agreement.

We partnered with carbon specialist Nero to validate our historical and current emissions before submitting them to the SBTi for approval and registration – it’s worth noting our 2019 Scope 1 and 2 figures also include Bescot’s

activities, even though Denmaur acquired the site in 2022. In order to retain our SBTi status, we are required to report our operational emissions annually.

Changes to hybrid and fully electric company cars, as well as switching to energy efficient lighting systems at Bardon and Sittingbourne are recent examples of how we’ve been addressing our carbon emissions. Discussions on additional infrastructure and equipment investments is on-going. To date, we are on course to achieve our 2030 reduction target.

Scope 1 emissions are direct greenhouse gas emissions from owned or controlled sources, including fuel combustion in company vehicles and facilities, and process emissions from industrial activities.

Scope 2 emissions are indirect greenhouse gas emissions from the generation of purchased electricity, steam, heating and cooling.

Carbon Net Zero is defined as balancing carbon emissions with an equivalent amount of carbon removal, thus achieving no net increase in the atmospheric levels of carbon. SBTi Net-Zero targets mandate at least a 90% reduction in scopes 1, 2, and 3 emissions by 2050. Carbon offsetting becomes relevant after achieving a Net Zero target as a means for compensating for remaining emissions.

Denmaur is committed to a 90% reduction by 2045 of their 2019/20 scope 1, 2, and 3 emissions.

Scope 3 emissions are indirect greenhouse gas emissions from a company’s value chain, including capital investment and employee commuting as well as upstream and downstream activities such as purchased goods, transportation, waste disposal, and product use.

How will we reach our 2045 target?

In terms of our scope 1 and 2 it’s simply a case of continuing our near-term reduction target activities, up to and beyond 2030. Work on addressing our scope 3 emissions has commenced with an obvious and significant scope 3 (as is that of our customers) being the emissions associated with paper and board production.

Accordingly, we are reliant on those who manufacture the products we sell to decarbonize the production and transportation activities of their grades. In fact, we are already beginning to see published reduction and Net Zero plans from a number of mills and in some cases we’re advised to expect zero paper production emissions before 2030!

Continuous engagement with suppliers is essential going forward, as is continuing to look deeper within our own operations and discussions with our customer base and the wider stakeholder community in terms of end-of-life recycling programmes.

Once fully audited, updated results of our progress will be published on the Denmaur website. Otherwise, we’ll continue to keep you informed of our sustainability driven investments and initiatives along the journey.

Sustainability for Denmaur is not just a phrase, it is a mission.

Delipac: the star of the show

The Packaging Innovations trade show was held over 2 halls at the NEC this year with the Delipac stand enjoying yet another successful show.

Denmaur’s Duane Percival and Danny Doogan were on the stand for the event, along with Mark Hirlam, Paul Spring and Shelly Spring from Delipac UK.

The draw for the stand this year was a giant floor standing cup which was filled with Delipac cups in a range of practical sizes – including pint cups. However, the preparation that goes into hosting the stand takes several months, culminating in the day before the show with the team setting up the 20 square meter stand from scratch.

Duane Percival commented “We had several household names come onto the stand over the two days enquiring about the use of Delipac for their products, whether it be on-the-go food packaging, cups and even lids.”

Delipac is one of the most certified products in Denmaur’s stock portfolio, including PFAS Free and No Plastics accreditations that ensure Delipac products are completely recyclable as well as completely compostable and biodegradable, leaving no harmful effects to the environment.

The last 12 months has witnessed a tremendous increase in the commercial uptake of Delipac cupsparticularly at events. Danny Doogan added, “It’s exhibitions such as this that gives Delipac its exposure to end users who, in turn, will drive demand for the product.”

Delipac will return to the NEC in April 2025 at the three-day UK Food and Drinks Show.”

Denmaur signs exclusive deal with New Zealand mill.

In January Denmaur inked a deal with New Zealand’s Whakatane Mill to be the exclusive UK distributor for its FORMAKOTE™ line of coated paperboard products for the packaging market.

Part of the Smurfit Consortium since 2021, the mill has undergone a substantial refurbishment and upgrade to be able to produce 150,000 tonnes annually of clay coated folding boxboards products combining virgin kraft pulps and mechanical fibres. A key market for FORMAKOTE™ products is in the food service sector, a growing market for Denmaur.

Andy Buxton noted, “The Whakatane line of products will allow us penetrate converters and brands in food service as a perfect complement to the inroads we are already making with Delipac.”

Clive and Michael Townsend On Board With Board

On 1 July, Clive and Michael joined Denmaur directly to lead our new Carton Board division and its Reel Fast program. Clive heads up the division bringing an unparalleled knowledge of both supply routes and customer base in the carton board sector.

He will be responsible for the division’s strategy, budget and product portfolio. Michael is Head of Sales for both Reel Fast and Denamaur’s expanding range of Carton Board products.

Clive and Michael had a major part in creating Denmaur’s unique Reel Fast service and its strapline “Reduce: size | cost | waste | carbon” which sits well as a sustainability driven, value added service for customers.

Reel Fast’s first product offering was Amadeus Silk, providing a complete and unique product offering on one grade - from web offset through to digital sheets via stock, mill direct and now UK bespoke sheet conversion.

However, the carton board division has particularly identified an advantage through offering a deckle free proposition for this year’s launches of Aura Fold Plus and Formakote Spectra. Bespoke sheet dimensions are much more common in this division given the vast array of different box packaging sizes out there.

Reel Fast reduces minimum quantities (500kgs for carton board products) and will deliver within 5 days of receipt of order.

As it has for a number of years, once again Denmaur lent support to the Roger Daltry curated Teenage Cancer Trust series of concerts at the Royal Albert Hall by donating stock paper (Ultra Fine Offset this year) for the concert programs printed by Pureprint Group. This concert series provides financial support for specialized care needed by young people with cancer in the UK.

In addition to The Who with Roger Daltry and special guests, Squeeze, other performers included rock legends Robert Plant and Paul Weller, Noel Gallagher’s High Flying Birds and The Chemical Brothers along with top comedians Kevin Bridges, Rob Beckett and Joe Lycet.

Denmaur rocks on!

New laptops on the way

Now Being Served In Major Food Outlets and Outdoor Event Venues

Cups are the 500kg gorilla in the food service packaging sector and Delipac keeps going from strength to strength when it comes to convincing large volume cup consumers of its unparalleled sustainability credentials to win business. Currently in use by major UK brands on a trial or gradual roll-out basis in both the UK and Europe, the next market to be addressed is the US with expected similar results.

Paul Spring, Delipac’s CEO, remarked, “With our unmatched sustainability credentials and certifications and Delipac’s ability to be used in freezable, chillable, microwavable, ovenable and selfsealable environments, the product pretty much sells itself.”

Ricky Hirshfield announced that the company has purchased new Lenovo Thinkbook laptops to be distributed to all sales and admin personnel who have regular need for them. Ricky further elaborated, “For the first time the company will have a common computer profile that will allow for more efficient IT management and enhanced cyber security.” As part of the new computer distribution the company will also be establishing a computer policy to govern usage.

Josh Kilby

Duane Percival

Chris Green

Sean Markham

Andy Faithful

Commercial Manager for the Midlands and North, won Player of the Season at Syston, the semi-pro rugby team for which he plays, and has been capped for the county team in the process.

Director of Sales, North England, played with Leeds United intermediates alongside former England keeper David Seaman before joining the paper industry.

Transport Manager, and his wife, Susannah, are the proud parents of brand new daughter, Georgia, born at the end of March.

Our Credit Risk Manager’s son, Jamie, raised over £2,000 for Age UK by running the London Marathon.

Director, Commercial Print, has overseen Denmaur’s contribution of paper for Arts Against Knives.

Neil Cobley / Ian Fry / Doug Jessop / Brian Lawes / Sarah Marshall / Chris Smith / Martin Wheeler / Sean Jackson / Parmjit Singh / Tafari Ebanks / Dave Arnold

Sarah Erswell / Ben Lee / Jason Darby / Mark Ashcroft / Glynn Bunce / Eric Clee / Steve Rathbone / Keith Hedges / Greg Topliss

Jeanette Gray-Mitchell / Matt Groom / Christine Luckhurst / Andy Moore / Alistair Nash / Julian Townsend / Jake Watson / Alan Wilkins / Adrian Beckett / John Russell / Daryl Bird / Alex Bradburn / Lee McSweeney

Anne Atwater / Julie Crayford / Suzanne Miles / Martin Travis

Some of us will have recently completed paper courses at this very historic site, once owned by the British Paper Company it is also home to the first commercial recycled mill, and still produces recycled papers today, although (we hasten to add) not any of the Revive ranges!

The mill is now owned by the Apsley Paper Trail (APT), a charity dedicated to preserving the rich paper-making heritage of the Gade Valley. APT manages Frogmore Paper Mill, the world’s oldest continuously operating mechanised paper mill, dating back to the 13th century and the birthplace of mechanised papermaking in 1803. This innovation fuelled the communication and education revolutions of the 19th and 20th centuries.

Frogmore Paper Mill is now a unique industrial and heritage site welcoming 15,000 visitors every year. The mill features two historic Fourdrinier Machines and a comprehensive archive of over 10,000 objects and documents. Visitors can enjoy tours, community events, workshops and learn endangered heritage skills such as papermaking, bookbinding and letterpress printing which promote wellbeing, creativity and skills development.

After a devastating arson attack in January 2022, APT is now restoring and repurposing the mill’s surviving historic buildings into a vibrant community hub. This new facility will include a pop-up museum, events area, education zone, and a sustainable café operated by Sunnyside Rural Trust, which uses local and organic

produce and offers training and employment for people with disabilities. The expanded offering will enhance our educational programs for schools, engaging over 10,000 children annually. It will align with the new National History curriculum, focusing on local wildlife, conservation and sustainability.

We partner with organizations like LUSH, The National Trust, Hatfield House, The Royal Ballet, and Longleat Safari Park to develop sustainable papers and products. As the first mill to commercially recycle post-consumer waste paper in the 1890s, we continue this legacy by hosting important industry trials to research and develop papers using alternative fibres such as banana stem, agricultural waste, straw, seaweed, and elephant dung. We also produce UK Native Wildflower seed paper for greeting cards and stationery that can be planted after use.

Denmaur Driver, Molly Martin, making a delivery to Frogmore Papermill in May this year.

As an entirely self-funded charity, we rely on donations of white wastepaper for the majority of our heritage papers. Denmaur has been a major donor and we wish to thank them for their support.

For more information about our exciting future plans and to find out how to help, please contact APT’s CEO Elena Lewendon or visit www.frogmorepapermill.org.uk.

Dennis Luckhurst

After a 29 year career making the Denmaur sample department the envy of the industry, Dennis retired last July. Many colleagues, customers and suppliers came along to say farewell to Dennis at a company BBQ in Sittingbourne before he embarked on a well-deserved opportunity to enjoy a more relaxed life. While hard to imagine Denmaur without Dennis, he had left his department in the very able hands of Ben and assistant, Klaudia.

Perhaps a tad belated, but we could not have launched issue #1 of the mag without paying tribute to a true legend. We wish Dennis well in retirement.

Jason Middleton

As the MD of Middleton Vision Paper for almost all of its existence, Jason was a key reason for Denmaur’s acquisition of that business in July 2022. He also played a major role in ensuring that the ownership transition has gone as well as it has. With that job mostly done, Jason took the opportunity last December to enjoy more of his personal pursuits and seek new professional options after 40 years in the paper business. He has promised to stay in touch and we look forward to hearing all about how the next phase of Jason’s life turns out.

While Nick is covered in greater depth elsewhere in this issue, we would certainly not want to overlook a fond farewell to both Nick and his wife, Emma, who was the company’s HR person for the past 10 years. A gala farewell luncheon at the Army & Navy Club just before their departure from the company in April served as a fitting endpoint to their careers at Denmaur and before they look forward to a life of travel, skiing and well deserved rest.

As most of you know, Ben had to step into some very big shoes last year when former samples manager, Dennis Luckhurst, retired after many years of loyal and unrivalled service.

Dennis had set a very high bar for our samples and dummies service, but almost immediately, Ben has more than proved he can match this level of service, a service that contributes

How did you get into the paper industry?

Favourite thing about Denmaur?

Favourite thing about your job?

Who would play you in the film ‘Denmaur’?

What is your favourite piece of print?

Why should people continue to use paper and board?

If you were given £1000 to donate to charity, which one would it be?

What would be your specialised subject in Mastermind?

Favourite holiday destination?

Why should people buy from Denmaur?

to us winning orders and maintaining important business.

Ben is married to Karla with three children, Maison 10, Violet 3 and Archer who is 1. Outside of the office, family duties consume most of his time but he does describe himself as a big Arsenal fan…….he’ll never be a number 2 in our eyes

I actually started at 15, when you could, working as an apprentice engineer for a company that had contracts with paper mills, including Smurfit Townsend Hook. So, I knew about paper from an early age. However, I got to meet Nick Gee through a friend who worked at Denmaur, and he offered me an opportunity as a Samples Assistant and I haven’t looked back since.

Very easy - the people. It truly is a great company made by great people.

The chance to be able to create and make something from nothing with my own hands.

Robert Downey Jnr.

A book based off a computer game called Bioshock.

Even in a digital world of 2024, paper is still a favourable form of media for many and I believe the younger generation will still want to have paper based media products in the future.

Great Ormond Street Hospital. My daughter stayed there for the first month of her life. We owe them everything.

Bioshock

Kent. Although yet to properly explore the wider world beyond the boundaries M25.

We are forward, progressive thinking company with a deep ethic in the environment and recycling. Paying it forward for the people of tomorrow.

Originally from County Meath in Ireland, Cheyanne moved to the UK in 2022 and resides with her partner in Leicestershire. Her working career began riding racehorses (as an exercise rider – not a jockey) whilst studying for Accounting and Finance degree. Upon moving to England, however, the early mornings, working in all-weather types, along with the physical demands of the job led to the

decision of horses as a hobby rather than a job.

Cheyanne is a keen runner, turning out for Coalville’s Hermitage Harriers at weekends. Also an enthusiastic artist, Cheyanne makes time for music concerts as well. Although a self-confessed social media addict, she is an avid supporter of all things paper and print.

How did you get into the paper industry?

Favourite thing about Denmaur?

Favourite thing about your job?

Who would play you in the film ‘Denmaur’?

What is your favourite piece of print?

Why should people continue to use paper and board?

If you were given £1000 to donate to charity, which one would it be?

What would be your specialised subject in Mastermind?

Favourite holiday destination?

Why should people buy from Denmaur??

Having lost the passion for race horse work, I decided an office job was the way to go. I just moved to Leicester, Denmaur was one of my first interviews and straight away I think we both realised this was going to work.

The company has always felt close knit, like a family. No matter how much it has grown over the years, everybody knows everybody, and you are always met with a friendly face, no matter where you go in the business.

I enjoy the structure. I know generally what will need to happen each day with a set routine of jobs I do each morning. No doubt curveballs are randomly thrown in during the day, however!

Jenna Fischer, as she plays Pam in The Office, with a bit of Angela Kinsey mixed in - and a wider, more colourful range of vocabulary.

Julian Townsend sent me a copy of Rolling Stone magazine, the front cover of which featured Harry Styles (almost) topless and wearing pink shorts. Need I say more?

It has a huge positive environmental impact. It is biodegradable, recyclable and a much friendlier option to single use plastic. I believe paper and cardboard is the way forward in the food packaging industry.

LOROS! I have people close to me who work for LOROS and what they do is amazing, delivering free compassionate care to terminally ill patients.

21st century Pop Stars.

Torremolinos. Great atmosphere, gorgeous beach, amazing food and the promenade goes for miles.

Buying from Denmaur supports the amazing team of people behind it who are like a family and always give customers their best.

42 YEARS

Stephen Rathbone

36 YEARS

David Perry

Mike Gee

34 YEARS

Kevin Walls

32 YEARS

Ricky Hirshfield

29 YEARS

Christine Luckhurst

27 YEARS

Julian Townsend

25 YEARS

Martin Travis

Julie Crayford

23 YEARS

Paul Cooper

Adrian Beckett

Martin Best

Stephen Hampson

Martin Wheeler

22 YEARS

Doug Jessop

Nigel Somerfield

Danny Doogan

Paul Jackson

21 YEARS

Anne Attwater

Sarah Marshall

Mark Ashcroft

Andy Faithful

Glynn Bunce

20 YEARS

Sean Markham

Warren Jones

Sarah Reed

19 YEARS

Robert Shaw

David Richards

18 YEARS

Steven Evans

Karen Simms

17 YEARS

Andy Moore

John Russell

Henryk Dlugosz

16 YEARS

Andrew Livesey

David Gee

Deborah Smith-Briars

15 YEARS

Jean Stanley

Simon Cartwright

Andrew Faithful

Lee McSweeny

14 YEARS

Mathew Tobin

Ian Fry

Mark Harsent

13 YEARS

Joshua Kilby

Sean Jackson

Sarah Erswell

Parmjit Singh

Christopher Green

12 YEARS

Brian Lawes

Eric Clee

Andrew Farmer

Graeme Richardson

Daryl Bird

11 YEARS

Stephen White

10 YEARS

Garreth Donnelly

Jeanette Gray-Mitchell

Ben Lee

9 YEARS

Andrew Buxton

Zach Gargan

Ann Philip

Duane Percival

Sam Mills

Jake Watson

Andrew Briars

Daniel Thompson

Neil Cobley

Gary Dacey

Marc Savage

Alex Bradburn

8 YEARS

Andrzej Plawski

Anna Berrisford

Deborah Alford

Rod James

Jonathan Thompson

David Hensman

7 YEARS

Malcolm Costelow

Jordan Richardson

Inderjit Malhi

Michael Keating

6 YEARS

Andrew Evans

Robert Thraves

Ruth Moore

Alistair Nash

Ian Williams

Jason Darby

5 YEARS

Nimesh Amrat

Daniel Butler

Piotr Klimczak

Leon Griffiths

Harry Gould

Robert Gould

Stephen Bedworth

Vitalijs Vitkovskis

Alan Wilkins

4 YEARS

Christopher Smith

Matt Groom

3 YEARS

Jon Cooper

Ben Ingall

Cheyanne Lynch-Ennis

Staci Terry

2 YEARS

Abdulhamid Aghe

Karlene Rolls

Lois Lee

Anthony Hardy

Miriam Larkins

Suzanne Miles

Joe Barker

Nigel Poole

Jacek Orlowski

Helena Prusakevica

David Plummer

Bradley Taylor

Keith Hedges

Phillip Ferguson

1 YEAR

Molly Martin

Jennifer Stringer

Tafari Ebanks

Robert Kuklo

Anthony Bennett

David Arnold

Warren Curtis

Simon Bishop

Radek Cybulski

Holly McMullen

Ross Hampson

Klaudia Mik

RECENT JOINERS

Gregory Topliss

George Tarta

Ashok Tandel

Ram Tamang

After supervising and running Passaban conversion machines for years one would think that Martin’s downtime would be anything but mechanical. But you would be wrong.

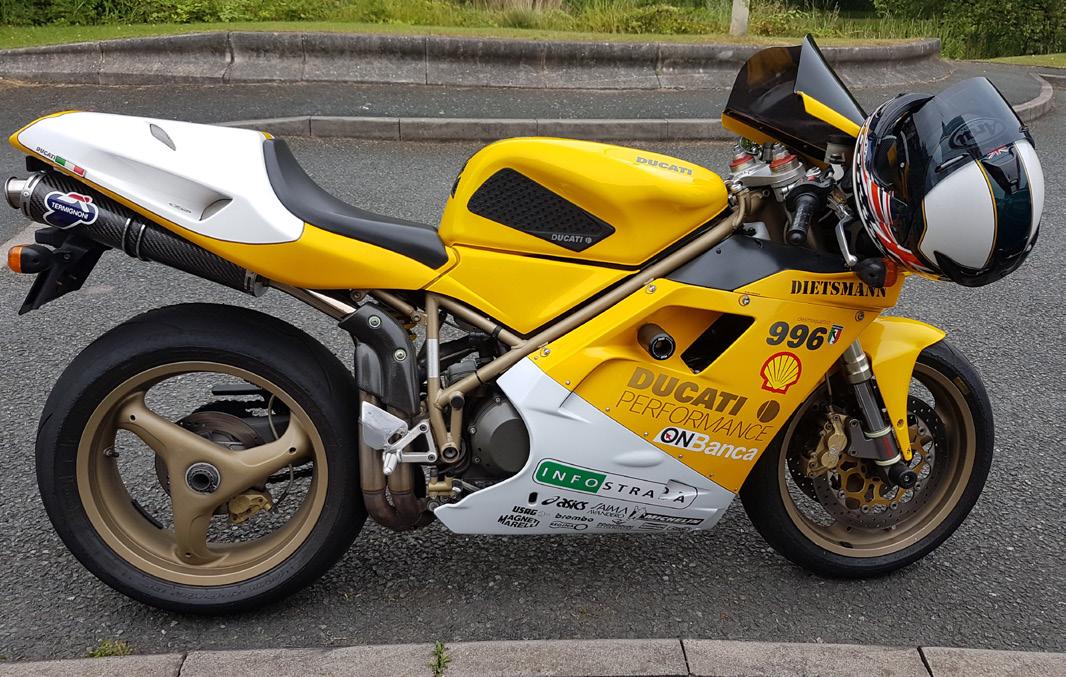

Martin has a collection of 3 cars and 5 motorcycles that he maintains and his most recent labour of love was restoring to pristine condition his dad’s 2006 BMW Z3 when he inherited it after his dad passed. That’s when he is not racing on his Ducati motorcycle. We guess it’s true what they say about spanners and wrenches being in the blood.

On something of a whim when talking with Danny Doogan about Denmaur’s 40th anniversary last year, Paul decided to bike and walk 4,000 miles(!) while raising over £1,000 pounds for Kent, Surrey and Sussex Air Ambulance. Of course. Wouldn’t anyone?

In the end and over the calendar year of 2023 Paul cycled 2,706 miles and walked 1,321 miles exceeding his goal by 27 miles. Apparently, Paul likes to over achieve in exercise as much as he does in sales.

Read all about it

BARDON OFFICE: 01530 275500

BARDON WAREHOUSE: 01530 447068

BESCOT OFFICE: 01922 633333

BESCOT WAREHOUSE: 01922 929547

BRISTOL OFFICE: 01173 320863

SITTINGBOURNE OFFICE: 01795 432100

ST ALBANS OFFICE: 01727 738750

This is your magazine and can only be as good as the newsworthy items we know about. So please don’t be shy. All, and we mean, all news items, comments and suggestions are welcome. Just drop a line to themag@denmaur.com. Like James Bond the mag will return in November 2024 with more thrills, spills, chills and:

SITTINGBOURNE HEAD OFFICE Bonham Drive, Bourncrete House Sittingbourne, Kent ME10 3RY

MARKETING: 01795 502144

SAMPLES: 01795 432160