Can we make mining and engineering more welcoming for women (and others too)?

Can we make mining and engineering more welcoming for women (and others too)?

Standard Machine designs and manufactures high quality gearboxes for all mining applications. From design concept to manufacture, whatever your critical equipment needs are we have the engineering experience and know how to get your equipment up and running.

Serving Western Canada since 1968

Saskatoon, Saskatchewan

306.931.2820

We’re ready to meet any of your protective coating and lining needs. We can work on your site or in our facilities, with large shops (53,000 sq ft),30 acres of yard space, and cranes and forklifts on site.

• Protective Coatings

• Plant Maintenance

• Shop and Field Service

• Tank Lining

• Environmental Containment

• Industrial Fiberglass

• Concrete Protection

• Structural Steel

• Spray Polyurethane Foam Insulation

• Fire Proof Coatings

• Stainless Steel Pickling and Passivation

• NACE Certified Inspectors on Staff

• Industrial Standard Quality Program

Message from the editor, Shayna Wiwierski– 6

Message from the Minister of Energy and Resources, the Honourable Jim Reiter – 8

Potash: Global demand, Canadian supply – 10

Potash industry update: From where I sit… – 12

Investing in Saskatchewan’s future: Nutrien’s commitment to education and talent development – 16

From potash to community: Mosaic’s impactful investments in Saskatchewan – 20

Prairie Clean Energy aims to support the Saskatchewan potash industry to decarbonize – 22

IMII funding new virtual mine lab with Saskatchewan Polytechnic – 24

One billion tonnes of crude salt extracted from the Hattorf-Wintershall mine – 26

What I have learned about new potash selective solution mining developments – 28

Getting the most out of mechanical assets – 32

An engineered approach to solving dust containment problems at conveyor transfers – 34

The renAIssance of today’s mining industry – 36

Whistleblowing’s significance in preserving ethical standards in mining – 39

PDAC 2024 convention welcomes the world to the premier mineral exploration and mining event in Toronto – 42

–

While every effort has been made to ensure the accuracy of the information contained in and the reliability of the source, the publisher in no way guarantees nor warrants the information and is not responsible for errors, omissions or statements made by advertisers. opinions and recommendations made by contributors or advertisers are not necessarily those of the publisher, its directors, officers or employees.

DEL Communications inc. and potashworks.com are extremely grateful to our advertisers for their support in this publication. Click here to download the media kit.

Welcome to Issue 1, 2024 of The Potash Producer e-newsletter. As we delve into the evolving landscape of potash production, we’re excited to bring you stories of innovation, sustainability, and progress within the industry.

One of the most pressing challenges facing the potash sector is the reduction of greenhouse gas emissions. In this issue, we’re thrilled to highlight the groundbreaking efforts of Prairie Clean Energy (PCE), a Saskatchewan-based company dedicated to revolutionizing potash production. Thanks to a generous $1.1 million grant from the Mining Innovation Commercialization Accelerator (MICA) Network, PCE is spearheading initiatives to slash GHG emissions by up to 80 per cent. Their approach? Harnessing the power of local, renewable resources, specifically flax straw, to create a sustainable alternative for potash production. This remarkable endeavour not only demonstrates PCE’s commitment to environmental stewardship, but also sets a new standard for sustainable practices within the industry.

Education and innovation go hand in hand, and in this issue, we’re proud to spotlight the International Minerals Innovation Institute (IMII) and their investment of $102,000 to establish a virtual mine lab for the Mining Engineering Technology program at Saskatchewan Polytechnic. This cutting-edge facility will serve as a hub for both students and industry professionals, providing immersive, hands-on experiences that bridge the gap between theory and practice. By fostering collaboration and knowledge exchange, initiatives like these are essential for cultivating the next generation of leaders and innovators in the potash industry.

Artificial Intelligence (AI) is revolutionizing the way we approach mining practices, and in the story from RESPEC on page 36, we explore how this digital canary is heralding a new renAIssance. With its ability to analyze vast amounts of data and provide actionable insights, AI is transforming everything from exploration and extraction to safety and efficiency. As we embrace this era of technological advancement, it’s imperative that we leverage AI to not only optimize operations but also prioritize sustainability and environmental responsibility.

As we navigate the complexities of a rapidly changing world, collaboration and innovation are more crucial than ever. The stories featured in this edition of The Potash Producer underscore the industry’s unwavering commitment to sustainability, education, and technological advancement. By working together and embracing new ideas, we can build a future where

potash production is not only economically viable, but also environmentally sustainable.

Lastly, I invite you all to actively engage with us, sharing your experiences, insights, and success stories. As we navigate an ever-changing world, innovation, sustainability, and collaboration will continue to be the driving forces behind the potash industry’s growth. We encourage you to explore the content in this issue, engage in the conversation, and share your thoughts with us.

With that, we would like to thank our contributors for this issue:

• Minister of Energy and Resources, the Honourable Jim Reiter

• Minister of Innovation, Science, and industry, the Honourable François-Philippe Champagne

• Nutrien

• The Mosaic Company

• Steve Halabura

• Prairie Clean Energy

• Saskatchewan Polytechnic

• Beechy Potash Products Corp.

• March Consulting

• Richwood

• RESPEC

• The PDAC

We invite all interested companies to share their news and editorial ideas with us. If you would like to contribute a story for future issues of The Potash Producer e-newsletter, please contact myself at shayna@delcommunications.com.

Finally, we also welcome you to help spread the message about our publication. In addition to The Potash Producer e-newsletter, we publish a handful of other mining-related e-newsletters. You can find out more and subscribe a www.delcommunications.ca/mining/.

Thank you for joining us on this journey of discovery and progress. Together, let’s continue to push the boundaries of what’s possible and shape a brighter, more sustainable future for the potash industry.

Shayna Wiwierski

shayna@delcommunications.com l

GMR Electric Motors started from small beginnings and, over the last 45 years, has grown into one of North America’s leading electric motor repair facilities. Our customers are coast to coast in Mining, Oil+Gas, Power, Marine and Agriculture. We work with our customers to find solutions with long-term partnerships in mind; we are here for the long haul. With our current facilities in Saskatoon and Estevan, we are proud to be part of the diversified and vibrant supply chain in Western Canada. Our customers, suppliers and, most importantly, our employees have gotten us where we are today; we are excited and looking forward to another 45 years of growth.

n behalf of Premier Scott Moe and the Government of Saskatchewan, I am pleased to share updates on the potash sector from the past year.

Saskatchewan potash producers continue stepping up to alleviate global food security challenges. In 2023, producers achieved a new record volume of sales of 14.5 million tonnes K2O, delivering sustainable Saskatchewan fertilizer to the world. BHP also made further commitments to its Jansen potash project, approving an investment of $6.4 bil-

lion for the construction of Jansen Stage 2 to follow up on the $12.4 billion that had previously been confirmed for the future mine.

The year was not without challenges. The prolonged port workers’ strike in British Columbia and a St. Lawrence Seaway workers’ strike in Ontario and Quebec disrupted supply lines. This impacted operations for Nutrien, Mosaic, and K+S Potash Canada and resulted in production curtailments. Despite these difficulties, potash producers finished the year with solid results.

QUALITY, SERVICE AND CUSTOMER SATISFACTION

Specializing in structural steel, miscellaneous metal & custom fabrication with carbon steel, stainless steel and aluminum. www.imwelding.com | info@imwelding.com | 306-955-4546

• Mine shaft rope steel

• Conveyor belt reclaim skids

• Pump skids

• Potash hoppers

• Underground conveyor drive frames

• Potash brine piping tower

• Pipe bridges

• Surge bin support beams

• Mosaic stadium rails

• Belt conveyor pulley frames

• Underground work platform

• Belt conveyor skirting

The potash industry plays an essential role in the Saskatchewan economy. The strength of the sector continues to keep Saskatchewan on track to meet the province’s 2030 Growth Plan targets and Critical Minerals Strategy objectives. The combination of world-class resources, a responsible development regime, and the commitment of our industry partners has strengthened Saskatchewan’s position as the number-one potash producer in the world.

Over the past 18 years, the Saskatchewan potash industry has committed over $35 billion of capital investments in expansions and new mines. The sector is also a significant contributor to Saskatchewan families and communities. Nearly 6,000 potash workers and their families call Saskatchewan home with thousands more employed in the mining supply and service sector. In 2022, companies working in the province invested $35.5 million in community initiatives, programs, and causes that boost quality of life in Saskatchewan.

It’s also worth highlighting that the hundreds of millions to billions of dollars these companies contribute each year in royalties and taxes fund improvements to Saskatchewan’s infrastructure and government programs — emphasizing how the sector benefits the province.

As global populations grow and demand higher-quality food ingredients, I am confident that Saskatchewan will continue to step up and meet that demand in 2024 and beyond.

Thank you. l

It is no secret that potash is one of the most important resources. The crops that farmers grow around the world, and in Canada, would not be as plentiful and nutritious without it.

As the global population grows, so will demand for potash. And, with Canada being the world’s number-one potash nation, producing 10 million tonnes more than our nearest competitor, we are well placed to be a reliable supplier.

Our wealth of this valuable mineral, combined with our skilled workforce and expertise in sustainable extraction, presents a terrific opportunity. As well, with the current geopolitical situation, especially the war in Ukraine that disturbed the potash supply chain, our stable government and commitment to the rule of law make us an attractive source for the world’s potash needs.

A growing potash industry can create

high-paying, skilled jobs, and grow the economies of Indigenous, rural, and remote regions. And building sustainable infrastructure for these communities will help attract projects, which in turn will provide benefits for their residents and for all Canadians.

We must be bold and seize this moment. That is why we are making strategic investments to grow Canada’s potash industry. In January 2023, we officially

announced our government’s $100-million support to BHP’s massive new potash mine in Jansen, Sask. Our support will mean stronger, growing communities in Saskatchewan while helping us to meet our emission reduction goals. It will help the mine maintain 600 highly skilled jobs while providing over 100 co-op terms for students. As well, BHP has committed to support Indigenous communities through employment and economic opportunities in its supply chain, maintaining or establishing new business relationships with Indigenous-owned enterprises or First Nations bands in the province. When this facility comes online in 2026, it will further cement Canada’s global leadership in potash production.

Others see the potential of potash too. K+S Potash Canada, the Mosaic Company, and Nutrien Ltd. have all announced plans to increase production at their Saskatchewan facilities to support expanded exports to global markets. In June 2023, the Potash and Agri Development Corporation of Manitoba began producing potash at its solution mining facility in the community of Harrowby.

That potential is a key reason potash is included in Canada’s first Critical Minerals Strategy. This $3.8-billion plan will help Canada to consolidate our position as a strong, sustainable producer and global supplier of minerals and metals, such as potash. We see them as critical to the global economy, and central to Canada’s trading relationships, our strategic global position, and our economic well-being.

That said, the strategy is about more than strengthening our position in global supply chains; it’s about better lives for Canadians. It will get projects up and running faster while building sustainable infrastructure to support them. The strategy will drive the research, innovation, and exploration of Canada’s critical minerals, and it will help us to grow a strong, diverse work-

force while advancing reconciliation with Indigenous peoples.

Canada’s potash industry has the exciting potential to do more. That is why we are working with Canada’s potash companies to not only hold our position, but to extend our lead. In doing so, we are supporting the mining and agricultural sectors of Canada, while helping to build a stable, sustainable industry that creates good jobs and strong commu-

nities for generations to come. More so, our government knows that by working with companies on Canadian projects, we are ensuring that the world is seeing Canada as a trusted and reliable partner when it comes to potash supply.

Clearly, Canada’s potash industry is gaining momentum. Together, we can take this industry to the next level while helping to feed the world. Everyone in Canada can feel good about that. l

By steve halabura, P.geo., halabura Potash consulting Ltd.

By steve halabura, P.geo., halabura Potash consulting Ltd.

For potash markets, maybe the commotion of 2022 and 2023 is over. Maybe producers no longer worry about supply disruptions, the effects of war and economic sanctions upon production and demand. Maybe capital markets are stable and share prices will reflect the underlying true value of assets.

I’ve followed the general sector senti-

ment for the past years and as anyone who follows potash closely, we agree that if nothing else, it remains a somewhat opaque market. There is some consensus, this being that the effects of supply chain disruptions and sanctions against Russia and Belarus were probably short-lived and not really the bogeymen’s many pundits (including yours truly) who initially described them to be.

•

•

•

•

The high price points achieved in 2022 have faded away, and for the short period that prices were stratospheric, producers made out famously, as did those who underpinned potash financing, such as capital markets. However, as happened during the price spike of 2008, high prices destroyed sales, as the bulk of potash is sold to farmers who cannot afford major input costs. But like in 2009 and 2010, buyers return once prices settle back down.

What does the present look like when compared to the near past? Below are the Province of Saskatchewan’s figures…

In January 2024, the province’s mines produced 1,418,594 tonnes (K2O) of potash, as compared to the production of 1,156,699 tonnes (K2O) in January 2023. This is an increase of 22.6 per cent over the 12-month period.

Sales during the same period were $762,955,968 in January 2024 as compared to $920,098,455 in January 2023, which is a decrease of 17.1 per cent.

Realized pricing was $537.83 per tonne (K2O) in January 2024 as compared to $795.45 per tonne (K2O) in January 2023, which is a decrease of 32.4 per cent.

Compared to a year ago, while price per tonne has decreased, production has increased, which to me demonstrates that 1) demand destruction due to high prices is a factor, i.e., as price drops, farmers begin to buy again; and 2) Saskatchewan’s mines continue to produce, even with the significant price drop from 2022 highs.

I place significant weight upon the observation that the price decrease has not impacted the producers that much, and I attribute this to the efficiency of existing Saskatchewan producers and the fact that current mines are long-established and thus well tuned to respond to price volatility.

Given that almost all Saskatchewan mines (except newcomers such as K+S) are approaching 60 years of operations, it is very likely that they can achieve low cost-per-tonne production and can

make a healthy profit even at a price that is half of what it was in 2022. In other words, they remain fierce competitors in a global marketplace that still seeks out the lowest per-tonne product available.

Saskatchewan’s production numbers continue to show a two per cent increase in demand on a year-by-year basis. Given Saskatchewan’s dominant role in global markets, I think its safe to attribute a two per cent annual growth rate in demand for all markets, and this is probably conservative.

Unfortunately, the long-term stability of potash as a business is not reflected in the share prices of publicly traded companies that continue to trade lower than 2023 values. This could be the market’s reflection on potash pricing, but I think it may be more of a function of the producers being integrated fer-

tilizer manufacturers rather than pure potash plays.

In looking at these factors, it seems to me that the sector has returned somewhat to pre- COvID behaviour, where steady increase in demand may (or may not) lead to incremental increases in pricing, and producers focus upon being the lowest-cost producer on the block.

Nevertheless, all the above are not justification for complacency and “business as usual”. I do see storm clouds on the horizon:

1. Canadian producers face challenges related to decarbonization: Those of you who are not residents in Canada, be informed that the federal government has imposed a strong mandate to decrease the effects of climate change through curtailment of carbon emissions, which has an ef-

Poorly designed transfer chutes reduce productivity along your conveyor system — often increasing the chances of costly downtime.

The transfer chute is a critical piece of equipment in mining, quarrying, and other material handling operations. Considering all factors up-front will result in a transfer chute design that aids, rather than restricts, production.

West River Conveyors pays careful attention to the properties of the material being conveyed — with an expert understanding of how it moves through the transfer chute. From the design stage forward, we can find a solution that fits your needs.

fect throughout the production and transportation process.

2. Access to unlimited water supply is threatened: The Canadian prairie provinces may be facing drought conditions this summer, thus increasing the competition for potable water between farmers, rangers, municipalities, and large industrial users such as the potash sector. I do not see this being different in other jurisdictions, such as the U.S.

3. Impact of inflation (and costs such as carbon tax) on cost of transportation: See factor one above. In Canada, a tax is imposed on a myriad of services, products, and activities, the intent being that this will provide an incentive to “decarbonize”.

4. The war in Ukraine continues without any resolution in sight: Could we see price spikes again if there is sig nificant escalation, or if Russian and Belarusian production decreases? Probably.

5. Replacement of aging mines: While the long-term nature of most existing mines is an asset, it also represents a potential threat. Yes, there are limits to growth (remember Esterhazy K1 and K2?) that require the replace ment of very expensive infrastruc ture, i.e. shafts.

6. Global climate change: Potash makes plants more drought resistant, which bodes well for demand growth. However, there is also the threat of desertification, which removes soil from agricultural purposes.

7. Cost of production and technology: Given the market pressure for “low est cost per tonne”, are existing pro ducers really using the most efficient mining and processing technology?

8. Replacement of existing centres of production: While I do not see as a

potential threat the “discovery of an enormous basis with extensive deposits of very rich potash” as being very likely, there are enough smaller basins with just enough potash in them that they could replace existing North American producers, if there is technology that allows for efficient mining. This is especially so if these “just good enough” basins are close to large buyers.

9. Sudden disruptions to demand growth: In this scenario, the somewhat stable annual growth in demand is disrupted by a sudden surge in production caused by intentional (or otherwise) production capability. This occurred in the late 1960s, where over-building of mines in Saskatchewan lead to an oversupply situation that damaged the fine balance between supply and de-

The above factors represent both positives and negatives, and it would be foolish to try to predict the outcomes for each case. But is there a strategy to derisk (or at least mitigate) some of these risks?

Maybe it’s these, for starters: rethink how new mines are to be built, and explore innovations in mining and processing technologies that decrease the need for scarce inputs such as energy and water. Embrace ruthless efficiency in slashing unnecessary expenses to ensure that low-cost production becomes a tangible reality, not just a fleeting notion. Shorten the supply chain by eliminating all market intermediaries and sell product directly to distributors.

Innovation and industry have been driving forces in Saskatchewan’s potash sector for decades, and Nutrien is reaffirming its dedication to fostering these strengths for the province’s resource sector’s future.

Recently, Nutrien announced a landmark $15 million contribution to Saskatchewan Polytechnic’s Time To Rise campaign, marking the largest corporate donation in the institution’s his-

tory. This commitment underscores Nutrien’s longstanding partnership with Saskatchewan Polytechnic and its investment in nurturing local talent to fuel the province’s economy.

“The importance of ongoing investment in continued education, particularly in institutions like Sask Polytech, cannot be overstated,” says Chris Reynolds, Nutrien’s executive vice-president and president, Potash. “Our collaboration

with Sask Polytech has demonstrated its significance time and again, providing a strong pipeline of skilled workers essential for advancing our purpose of Feeding the Future.”

The Nutrien School of Mining, Manufacturing and Engineering Technologies, made possible by this substantial contribution, will be an integral part of Sask Polytech’s major campus renewal. Situated in an Innovation Corridor near

Innovation Place on the University of Saskatchewan, the new campus will not only modernize learning environments, but also serve as a hub for innovation and industry collaboration.

“For over 40 years, Nutrien and Sask Polytech have forged a mutually beneficial partnership that plays a pivotal role in Saskatchewan’s economy,” says Dr.

Larry Rosia, president and CEO of Sask Polytech. “This transformative donation reinforces our commitment to preparing future leaders and ensuring they have access to cutting-edge resources and training.”

With approximately 300 current Nutrien employees in Saskatchewan being Sask Polytech graduates, this investment di-

rectly supports the development of a skilled workforce tailored to the needs of industry. Kyle O’Brien, a mine technologist at Nutrien’s head office, exemplifies the seamless transition from Sask Polytech to the workforce.

“As part of the first cohort of students in the Mine Engineering Technology program at Sask Polytech, I experienced firsthand the program’s industry-aligned approach,” says O’Brien. “The hands-on education and tailored curriculum prepared me for the challenges of the mining sector, ultimately leading to a fulfilling career at Nutrien.”

Nutrien’s commitment to supporting educational institutions like Saskatchewan Polytechnic not only benefits the company but also strengthens the local community. As a steadfast advocate for education and talent attraction, this investment and partnership with Sask Polytech reflects Nutrien’s commitment to fostering economic growth and building a skilled workforce for generations to come.

“Nutrien’s investment in education and workforce development demonstrates its dedication to the long-term prosperity of Saskatchewan,” says O’Brien. “As a Nutrien employee and Sask Polytech graduate, I’m proud to be part of an organization that prioritizes sustainable growth and invests in the future of our workforce.”

Nutrien is the largest potash producer in the world and the only Canadian company producing this critical mineral at our six mines in Saskatchewan. We call Saskatchewan home and have been working with post-secondary institutions like Saskatchewan Polytechnic for decades to ensure graduates have the right education, with the right tools, to move into a career with us. l

Pumps are at the heart of fertilizer production, and correct equipment selection that takes into consideration hydraulic design, materials, application knowledge, duty point and maintenance regime are critical to achieving reliable long-term pumping operation and maximum plant production. As an expert in solutions for corrosive and abrasive liquids, or those with high gas content, Sulzer offers a complete range of pumps, agitators, mixers and compressors for the fertilizer industry. Our innovative products are suitable for the production of potash, phosphate and NPK compound fertilizers as well as acids and industrial chemicals.

Sulzer’s global presence provides local support and expertise through a network of manufacturing facilities and service centers. Our solutions combine energy efficiency, low lifecycle costs, reduced environmental footprints and excellent reliability.

Contact us today to learn more.

Sulzer Pumps (Canada) Inc.

Phone (514) 836-3796, salah.attie@sulzer.com

www.sulzer.com

PCL.com

Edmonton: 780-733-6201

Regina: 306-347-4200

Saskatoon: 306-931-3322

Sudbury: 705-995-2225

Early Contractor Involvement

Sustaining Capex Projects

Large Complex Projects Maintenance & Turnaround

QUICK

We mobilize rapidly to adhere to aggressive fasttrack schedules meeting occupancy, turnover and all crucial milestones.

COMPETITIVE

Backed by one hundred years of experience, lean methods, advanced technology and in-house experts for the best price.

COMPLEX

Delivered in operational mission critical spaces with zero tolerance for disruption.

COMPACT

Smaller scale projects delivered by lean, specialized services teams.

Mosaic actively demonstrates its commitment to being a good neighbour, employer, and community partner in Saskatchewan by annually investing $7 million through partnerships in the communities where we operate.

“I’m proud to represent a company that instinctively prioritizes community engagement,” said Marnel Jones, director, Government and Public Affairs – North America. “By actively engaging and being a good neighbour, we’re ensuring longterm success for ourselves and the communities we operate near.”

Mosaic’s major community investments align with three pillars of giving: food, water and local.

Food: Our mission is to help the world grow the food it needs. This commitment extends beyond global agriculture; we also strive to support local farmers and address food insecurity within our communities.

“Mosaic is the Regina Food Bank’s longest food drive partner and has committed $5 million to the organization over the

next five years,” Jones said. “We have been very thoughtful about our community investments by ensuring they connect back to who we are and what we do.”

In 2023, Mosaic invested $1.7 million with local food partners who work to feed vulnerable people in our communities and ensure children have access to healthy food while at school. Here are our local food partners:

• The Regina Food Bank

• The Moose Jaw Food Bank

• Saskatoon Food Bank

• Moose Jaw Community Food Farm

• Hunger in Moose Jaw

• REACH Regina

• Mosaic School Nutrition Program

• Mosaic Community Food Farm in Wakamow valley

• The Salvation Army: Mosaic Backpack Program & Brown Bag Lunch Program

Water: Mosaic strives to be a good neighbour and a responsible steward of the land where we operate. Ensuring some of our community investments target the protection of land and waterways is a way we can give back to our bountiful province of Saskatchewan.

right: in 2021, mosaic announced a $2 million investment in the mosaic Child Life Program at the Jim Pattison’s Children’s hospital foundation.

Mosaic has supported the work with Ducks Unlimited, Saskatchewan Association of Watersheds, Nature Conservancy of Canada, Nature Saskatchewan, and Safe Drinking Water Sask.

“Mosaic’s Environmental Sustainability and Governance targets are focused on reaching net-zero company-wide by 2040, including reducing our water usage by 20 per cent per tonne next year,” Jones said. “Along with finding new ways to reduce our emissions, we’re also dedicated to organizations who have the same values we do, of being good stewards to the land.”

Local: Our locally focused investments extend largely toward the healthcare sector and focus on helping Saskatchewan residents get access to medical treatments and care. Our operating communities of Esterhazy and Colonsay are around 70 kilometres from hospitals in Yorkton and Saskatoon, and many of our employees live in rural communities.

• Mosaic has invested $10 million with STARS Air Ambulance since 2011, funding its initial capital campaign to establish a base. Mosaic continues to support operations, life-saving equipment, new helicopters, medical and operational staff, and emergency response training.

• In Saskatoon, Mosaic has given more than $10 million to the Jim Pattison Children’s Hospital to ensure that the Mosaic Child Life Program, which operates within the hospital, can provide children with activities focused on art, music, play, and literacy, all to make their time in care a little easier.

• Mosaic invested more than $4.5 million into the Mosaic Heart Centre at the Regina General Hospital with the Hospitals of Regina Foundation, which has brought life-saving medical equipment to the community, including the Cardiac Catheterization Lab, creating a centre of excellence right here in the Queen City.

“By recognizing the remoteness of our operations, we prioritize investing in healthcare initiatives that facilitate easier access for our employees, their families, and the whole province,” Jones said. “By choosing to invest in STARS and hospitals, we know those dollars have gone toward saving lives and ensuring children have advanced medical treatment in their home province.”

Locally, we also focus on investments with Indigenous organizations and communities.

• In 2022, Mosaic engineers designed and donated the funds to build an arbor for Cowessess First Nation to hold its community pow wows.

• In 2022, Mosaic committed $1 million towards the YWCA’s new Employment and Training Program inside its new facility, set to open in 2024.

• In 2022, Mosaic committed $1 million to Morris Interactive’s Digital Transformation in Potash Mining training program, rooted in reconciliation for First Nations, Métis, and Inuit individuals. Mosaic also provides Morris’ students with onsite practicums, mentoring, industry expertise, and course content consultation for the training program.

• In 2023, Mosaic invested $500,000 into Wanuskewin’s Ready for UNESCO campaign as it strives to become a UNESCO World Heritage site. This is Mosaic’s second investment with Wanuskewin. In 2018, Mosaic invested another $500,000 into Wanuskewin’s Thundering Ahead Capitol Campaign. Wanuskewin is a cultural heritage site that shares the history of the Northern Plains Indigenous Peoples.

“Potash production has a long history in Saskatchewan of more than 60 years, and we know that Mosaic will be part of this province’s future,” Jones said. “We recognize our role in this great province hinges on the invaluable contributions of our industry and the support of its residents.” l

Thanks to a $1.1 million grant from the Mining Innovation Commercialization Accelerator (MICA) Network, Saskatchewan-based business Prairie Clean Energy (PCE) is working towards reducing the potash industry’s greenhouse gas (GHG) emissions by up to 80 per cent using a local renewable and sustainable product made from flax straw.

This innovative GHG emission reduction project aims to revolutionize the decarbonization of the potash industry by turning flax straw into a pelletized form of biofuel that can generate low-carbon bioheat, replacing natural gas for heat generation. PCE has developed a dual patent-pending process to transform the flax straw into dense feedstock with consistent quantity that can be used in biomass boiler systems. These systems can be integrated into the existing energy assets of the potash industry, as well as other industries using natural gas or coal. PCE has proven through extensive testing that their flax straw pellets have a high caloric value that is ample for both heat and baseload power generation.

Used extensively in Europe, biomass boiler systems generate both heat and power through the combustion of biomass instead of natural gas, coal, or other fossil fuels. Modern bioheat combustion systems are highly engineered mechanical systems that provide space heat, domestic hot water, and steam for community and commercial buildings and industries. They can also generate electricity using steam turbines. Using renewable biomass as fuel, biomass boilers are a sustainable alternative to fossil fuel-based systems.

Flax straw is abundant – more than 1.5 million tonnes of flax straw are produced on the Canadian and U.S. prairies every

year – renewable, and a low-carbon solution, making it an incredible source of biomass and a promising pathway to decarbonization.

By utilizing PCE’s flax straw pellets, the carbon intensity of heat consumption can be significantly reduced in the potash industry. Prairie Clean Energy’s chief product and supply chain development officer, Dr. Mahmood Ebadian, states, “We estimate that by displacing fossil fuels with prairie biomass, we can support the potash industry in lowering greenhouse gas emissions significantly. This project focuses on deep decarbonization using a local renewable energy source and a proven bioheat technology.”

what iS Flax StRaw?

Flax straw is a waste by-product of harvesting flax seed. The straw has no nutrients, cannot be tilled into the soil, and has no market value. Farmers have almost no choice but to burn the straw in their fields. However, flax straw is an excellent fuel source. It burns clean and hot, generating low ash content and a high-net calorific value.

“Managing straw waste is a major challenge for flax producers,” says Mark Cooper, CEO of Prairie Clean Energy. “The only viable option before now was to burn the straw right there in the field. Using that wasted straw to provide an alternative low-carbon heat solution for the potash industry is the ultimate win-win.”

As an alternative to natural gas, bioheat generated from Prairie Clean Energy’s flax pellets will greatly reduce the potash industry’s carbon footprint. This switch from natural gas to bioheat can significantly help the industry meet its sustainability goals.

The $1.1 million MICA grant is being used by Prairie Clean Energy and Saskatchewan Polytechnic (Sask Polytech) to launch a living lab pilot operation at an agriculture field site near Moose Jaw, Sask. This collaboration serves as a testing ground to highlight the potential of renewable fuel derived from prairie biomass to heat buildings. The living lab pilot will include a demonstration biomass boiler system, which will be used to heat an equipment storage centre, while also providing teaching space for Sask Polytech’s Agriculture and Food Production program.

The partnership between PCE and Sask Polytech, made possible by the MICA grant, will assist the potash industry in reducing its carbon footprint and reaching its sustainability goals.

farmers have almost no choice but to burn the straw in their fields. However, flax straw is an excellent fuel source. it burns clean and hot, generating low ash content and a high-net calorific value.

By transitioning from natural gas to PCE’s flax straw pellets, using bioheat can be a game-changer for the potash industry.

If companies are interested in reducing GHG emissions and curious about the pilot project process with PCE or its pellets, they can contact PCE at info@prairiecleanenergy.com or visit www.prairiecleanenergy.com for more information. l

Providing innovative, engaging, and labour market relevant learning to students in saskatchewan

The International Minerals Innovation Institute (IMII) is pleased to announce an investment of $102,000 to build a virtual mine lab for the Mining Engineering Technology program at Saskatchewan Polytechnic to enhance student and industry learning.

The rapid evolution of technology and industry is transforming job descriptions, roles, and skills needed for a career in mining. One area experiencing significant change is 3D digital mining and simulation with virtual reality (VR) headsets. The virtual mine lab at Sask Polytech will simulate a real mining

environment and equip students with the skills needed on a jobsite. VR headsets offer an unparalleled advantage in training students, creating immersive simulations to explore mining environments without physical risk, fostering a deep understanding of safety protocols and emergency procedures.

“Saskatchewan’s minerals industry is on an upward trajectory with announced and planned investments in new operations,” said Al Shpyth, IMII executive director. “Existing operations, as well as those being built, are becoming increasingly digital, and the opportunity to experience new digital technologies, such

VR headsets offer an unparalleled advantage in training students, creating immersive simulations to explore mining environments without physical risk, fostering a deep understanding of safety protocols and emergency procedures.

as augmented and virtual reality while in school, will provide industry with employees who are better trained for the job at hand and the dynamics of an industry undergoing a transformation.”

This new technology will positively impact the student learning experience.

“Thank you to IMII for this important investment in our Mining Engineering Technology program,” says Dr. Larry Rosia, president and CEO at Saskatchewan Polytechnic. “Simulation learning enhances education by providing hands-on experience with equipment, safety procedures, and problem-solving scenarios. It allows students to practice

of Technology and Skilled Trades and School of Continuing Education. The lab will also be available to outside institutions such as the University of Saskatchewan, University of Regina, high schools, First Nations communities, colleges, and mining company worker upgrade programs.

system from ICOM Productions. Realistic scenarios will enable hands-on practice in equipment operation, enhancing technical skills and reducing the learning curve. Additionally, students can access remote or otherwise inaccessible locations, broadening their exposure to diverse mining conditions. The virtual mine lab will be piloted in the Mining Engineering Technology program next fall. l vr controllers enable students to interact with the virtual mine and perform tasks while ensuring safety through the virtual environment where errors can be easily corrected.

skills repeatedly and facilitates access to realistic, geographically diverse mining scenarios, preparing students for a successful mining career.”

Sask Polytech students will use VR headsets to complete virtual survey labs and coursework. The headsets allow students to feel as if they are working in a mine. VR controllers enable students to interact with the virtual mine and perform tasks while ensuring safety through the virtual environment where errors can be easily corrected.

The lab will include full assessment packages to support instructors in determining student competence. Once the virtual underground mine is created and has been successfully implemented in the VR headset, the Mining Engineering Technology program can continue to build a library of labs for different immersive learning experiences. These labs can include geological face mapping, underground safety checks, dip and dip direction, ground control, and blast patterns.

Sask Polytech will be responsible for designing, building, and delivering a complete 3D mixed AR/vR lab to provide students and the Saskatchewan mining industry with diverse education, training, and upskilling options. This virtual lab will include a library of 3D “Open Space” site visual models of Saskatchewan potash, uranium, gold, and copper mines. Outside of the core program hours, this lab will be available to other programs in Sask Polytech’s Faculty

Sask Polytech plans to purchase 20 to 30 VR headsets powered by a software

one billion tonnes of Crude salt extraCted from the hattorf-wintershall mine

K+s Werra potash plant celebrates outstanding production anniversary

It’s an anniversary of a special kind: one-billion tonnes of crude salt have been extracted from the Hattorf-Wintershall mine of the K+S Werra potash plant in eastern Hesse since 1903. The billionth tonne was brought to the surface during the midday shift on January 18, 2024. If the total quantity were loaded onto bulk goods railcars, the train would reach around the equator seven-and-a-half times.

“Many generations of miners have contributed to celebrating this outstanding mining anniversary today,” says Gerd Kübler, plant manager. “We are proud of this achievement, with which our employees underground and above ground have been helping to feed a growing world population for 120 years, even though the area under cultivation is constantly decreasing.”

Almost half of the potash products manufactured in the EU come from the K+S Werra plant with its two active mines and three factory sites. From there, they are delivered all over the world by train and vessel.

“Our mineral treasure can be found in over 10,000 different products. All of us come into contact with them every day,” says Kübler. The minerals are indispensable basic materials for industry, for high-purity salts in medicine, and for fertilizers. Alongside nitrogen and phosphorus, potassium is one of the three most important plant nutrients essential for achieving the optimum crop yields in agriculture. In particular, it ensures better plant tolerance to drought and water shortages, which is becoming increasingly important in light of climate change and the associated weather extremes.

mining began at the gRimbeRg ShaF t in the SummeR oF 1903

Potash mining on the Hessian side of the Werra-Fulda region began with the sinking of the Grimberg shaft in Heringen by the Wintershall mining union and the extraction of the first tonne of crude salt in the summer of 1903. Five years later, the Hattorf mine in neighboring Philippsthal, which was still separate at the time, began production. The two mines have been connected since 1979. They now cover a combined area of around 150 square kilometres. The crude salt is extracted from the rock by drilling and blasting on two levels and transported through the Grimberg and Hattorf shafts to the Wintershall (Heringen) and Hattorf (Philippsthal) factories, where the valuable materials potassium and magnesium are separated from the non-usable part (rock salt and other secondary minerals).

Technical innovations such as the electrostatic separation system (ESTA), patented by K+S and high levels of investment, have enabled us to continuously reduce the environmental impact of potash mining.

“In the past 15 years alone, we have invested around $1 billion euros in environmental measures, and with the Werra 2060 project, we will fundamentally transform potash production in the Werra Valley to supply agriculture with green potash,” says Kübler.

Werra 2060 stands for sustainable potash mining in the Werra valley and will help to significantly reduce the CO2 footprint

“in the past 15 years alone, we have invested around $1 billion euros in environmental measures, and with the Werra 2060 project, we will fundamentally transform potash production in the Werra valley to supply agriculture with green potash.”

of production, the generation of liquid residues, and the storage of solid residues on tailings piles.

The future of mining in the Werra Valley stretches from the Eitra Valley southwards over an area of around 100 square kilometres to the gates of Fulda.

“We can therefore supply our sites with crude salt until the 2060s, provide work for future generations in Hesse and Thuringia in the Werra-Ulster region, remain a reliable partner for the region and continue to help feeding the world,” says Kübler.

We make an important contribution to society: We enable farmers securing the world’s food supply. Our products keep numerous industries running. We enrich consumers’ daily lives and ensure safety in winter. With around 11,000 employees, production sites on two continents, and a global distribution network, we are a reliable partner for our customers. At the same time, we are realigning ourselves: We are focusing

even more strongly than before on fertilizers and specialties. We are becoming leaner, more cost-efficient, more digital, and more performance-oriented. On a solid financial basis, we are tapping into new markets and business models. We are committed to our responsibility towards society and the environment in all regions in which we operate. Learn more about K+S at www.kpluss.com.

The Werra integrated plant, with its sites in Hattorf and Wintershall in Hesse and Unterbreizbach, and Merkers in Thuringia, is the largest site of K+S Minerals and Agriculture GmbH. Besides fertilizers, the Werra potash plant also produces preliminary products for a wide range of technical and industrial applications, as well as for the pharmaceutical, food, and animal feed industries. It employs almost 4,400 people, including 300 trainees. This makes it an important employer and training company in the triangle of towns between Bad Hersfeld, Bad Salzungen, and Eisenach. Furthermore, it is an important client for the local small- and medium-sized businesses and makes a significant contribution to value creation in the region. This makes it a key component for the economic and demographic development of the East Hesse/West Thuringia region. l

The development of new selective mining technology should revolutionize the industry. There is a realization, that while the new potash megaprojects are an attractive short-term economic “gold mine” for the province, the longterm viability of these projects will be challenged by improved technology, dramatically reducing energy costs, greenhouse gas emissions, and addressing potential impending water shortages.

The promise of the new technology will become a reality in the next couple years. The technology is well documented and close to being “proven”. Work continues to make it even better.

The progress of this technology has been impeded, as several companies, catering to investor expectations, have championed numerous projects across Saskatchewan that lack robust scientific backing. These companies saw the Beechy presentations on selective mining, starting in 2010 and they liked the idea of low-cost production. They then went to their friends and consultants and put together expensive projects, full of investor “candy” without taking the time to understand what was really involved.

Over the past 10 years, I have studied the publicly available data on each of these new potash proposals. We see

complicated processes, some produce by-products, use cogeneration, use cooling ponds, use submerged combustion heaters, or do downhole heating and fracking. Now we have one company “using vapor recompression evaporation”, but no indication of how it fits into the process or what will happen to salt produced. While all these “good ideas” have application somewhere, none of these ideas are particularly relevant to a simple selective potash mine. The management, consultants, and former potash executives have been well served by these schemes, all at the expense of shareholders. But no product yet.

What, then, has to be done to make this technology a reality?

The first thing is to get a competent management team to build and run the mine. A mine manager is a team leader. He/she may not be an expert in corporate finance or marketing, or necessarily have 30 years in the industry. A successful new mine will need a unique manager who is a competent team leader and builder. The nature of a small mine requires a lot of management expertise in a small team, maybe even more than for a large mine. This will include technical, safety, human relations, and purchasing and accounting disciplines, as well as handling regulatory issues with environment and health and safety. It is critical that

management standards, cost control, and operating procedures are set up at the outset. This is not simple. The management culture that is established now will determine the ultimate long-term success of the company. Today, there are large, well equipped potash mines that simply do not produce anywhere near capacity due to long-term management deficiencies.

A successful mine will need to develop technical and operating expertise. This cannot be outsourced. The consultants have proved to simply promote the same old ideas that have not worked. While carrying professional accreditation, my experience over the last 50 years is that they often have limited knowledge of the basics of potash technology. They have to be directed. Selective mining is a unique approach to potash mining. It is simple, but also draws on years of experience in process design, equipment selection, and corrosion control.

The advice of the retired CEOs and oilfield experts may not have much to offer either, especially on technical matters. In fact, in many cases they have been an obstruction. We need a good scientific approach based on a solid understanding of the technology, sound engineering, and computer modelling of the process.

The project depends on an ore reserve. A potential resource has to be identi-

fied, based on well core data and seismic information. A selective mine will require a critical reassessment of the ore body, since only selected high-grade ore layers will be mined. These high-grade layers need to be identified and quantified. Core samples need to be tested to determine ore liberation and cut-off grade. Mining sequence has to be determined. Selective mining proceeds primarily horizontally, with vertical development from the drilled hole, in “high grade”, up to “cutoff grade” or a salt formation. Ore reserves need to be recalculated to reflect selective mining of only the “high-grade” ore zones.

The site for the mine should be selected based on site access to utilities, to road and rail, but more importantly, on a careful evaluation of the best information on the ore deposit, considering the slope of the deposit and any identified anomalies. Site selection must match the mine plan. A long-term mine plan is required.

Mistakes have been made in the past. One proposed mine was located on the extreme corner of the lease between two rail lines and roads as far away from power lines and gas lines as was possible. One of the new mines appears to been poorly located on the south edge of a narrow, 10-metre-deep valley (in the red beds). Wells will have to cross the valley as they are drilled from the plant site making drilling very difficult, and a successful outcome unlikely. Another site was selected to access carnallite ore which is far more difficult to mine than sylvinite.

The Beechy patented plan uses curved flow patterns. Beechy can collaborate with new licensed operations on their plans and significant advances have been made in the last year to improve our understanding of these designs. In addition, an inexpensive system, using passive seismic, is being considered for continuous monitoring cavern development.

Design and drilling of caverns need careful attention. The design must be done based on the requirements of potash mining, not those of oil production. Most importantly, the drill must have a steering head with the gamma detector as close to the bit as possible. In Manitoba, the high-grade ore is thick, but with one-and-a-half degree offset directional control, the drill was out of the zone 10 to 20 per cent of the time. (A steering drill should have been used.) One of the consultants tell us that with the “Moab” plan, the expectation is that the drill will be out of the zone 50 per cent or more of the time. This won’t work for selective mining. There is no reason that with the right equipment, the drill will be in the zone from start to finish. Incidentally this should also greatly improve the likelihood of connecting horizontal wells, even without a ranging tool.

The gamma detector should be accurately calibrated. If the directional people simply adjust the calibration ran-

domly, the results are always suspect. Real-time laboratory analyses should be done on the drilling mud, as well as on the chips as the holes are being drilled. (Simple, low-cost X-ray spectrometers are available that will handle this.) A careful analysis of the brine, and evaluation from a phase diagram, will dramatically reduce salt addition to the mud, and reduce disposal requirements. Chip analyses will verify gamma readings and ensure drilling is on target. No deviations will be allowed from the target zone, even if the drill has to be backed up and deflected.

Care must be taken in designing curvature from the vertical into the horizontal potash zone. If the curvature is too short, problems can occur with stuck drills and difficult casing installation. There is no reason to limit the start of the curvature at 300 (or even 600) metres above zone.

The design of the processing plant should be developed from the simplic-

ity of the phase chemistry. The mine operation must produce a saturated, equilibrated brine. That means the maximum amount of salt and potash dissolved for a given temperature. Brine temperature from the mine should be a few degrees above surrounding rock temperature to minimize heat loss to the formation.

This brine is cooled to produce pure potash crystal. Part of the heat removed from the crystallizers (up to 60 per cent) can be recovered to heat the brine returning to the mine. Though cooling ponds have been used in Saskatchewan solution mines, they are really not a continuous operation, with the best production at below -20 degrees C. There is no heat recovery. Vacuum crystallizers do not work very well at low temperatures, so the best option is some kind of contact-cooled crystallizer. The simplest and least expensive of these is the patented Beechy wiped surface crystallizers. Optimization of any crystallizer system requires careful study and control.

Cooling water is typically supplied by cooling towers or large cooling ponds. Either of these methods consume a lot

of water and are difficult to manage in winter conditions. With the Beechy crystallizers, air-cooled fin fan units are recommended for all but the hottest days. This minimizes water consumption. The operating plan can be adjusted in warm weather, using higher mine temperatures on these days or accepting reduced production. A cooling tower could be used to supplement contact cooling in the hottest days.

Brine heating is done using a high-temperature water heater, about 15 to 20 PSI, 250 F (125 C.). This simplifies the heating with minimal water treatment required, no steam traps or condensate treatment or piping. The brine is heated with hot water in a titanium plate heat exchanger.

The application of heat pumps could supplement the boiler heat, while providing additional cooling for crystallization (additional cooling, especially in summer months). Heat pumps will increase capital cost but significantly reduce GHG (with hydro power) to near zero.

The simple mine design requires low pump pressures. The majority of the

head is from flow resistance in the piping to the well, in the casing to the formation level, then in the return casing to surface and back to the plant. The brine returning from the mine is higher in density than the hot brine to the mine. This adds a small additional head based on mined depth, brine concentrations and temperature. At 1000- metre depth, pump pressure should be 250 to 400 psi (depending on line sizing and resistance).

Consideration should be given to optimum sizing of well casing and surface lines. The wells should be as close to the plant as possible. This should all be weighed against the additional cost for larger wells or additional pumping capacity. A higher head on the pump (smaller lines) results in heat being produced in the pipelines which could be a good thing in this application with heat-sensitive saturated brines. Corrosion control is important with cathodic protection recommended for the wells and corrosion inhibitors for casing and pipelines.

Basic utilities should be in place from the start. Commissioning a new plant is not easy. Having to operate with temporary utilities complicates the operation. While brackish water sounds like a good idea, a supply of fresh water is absolutely required anyway, whether from a separate source or by reverse osmosis. With proper process design, water use is minimal for the mining operation. In some locations the cost of bringing in natural gas is very high. With the Beechy method, the whole plant could be operated on electric power (possibly supplemented with some propane) with the extra capital cost offset in part by the cost of gas lines, and operating cost offset by low carbon emissions.

Product drying can be done in a conventional rotary or fluid bed dryer. Beechy is working on an alternate contact heated dryer with electric heating, which allows reuse of most of the energy

input. More important, it eliminates the need for a stack and stack scrubber and associated GHG.

When granulation is required, wet granulation methods should be considered, especially in small plants. Product, direct from the centrifuge, can be granulated on a pan, or in a drum or pin granulator. Granules are then dried and sized. This provides a simple low-cost but very flexible granulation system producing a high-quality end product.

Most presentations on new projects emphasize arrangements for marketing of product. We believe that selective mining design supports our claims of dramatic reduction in operation costs, capital cost and GHG reduction. This makes the product extremely marketable on its merit. The emphasis should be placed on getting a consistent highgrade product from the technology, as soon as possible.

Harvey Haugen is 79 years old and has worked in potash and related processes since June 1969. He worked for the big mines until 1987, then primarily on smaller grassroots developments, including Big Quill Resources at Wynyard, the first ion exchange potassium sulphate plant. He has developed the Glasserite potassium sulphate expansion at Wynyard, a sodium sulphate mine, a magnesium sulphate mine, sodium carbonate production from pulp mill waste, and Biodiesel technology. Since 2009, he has worked primarily on selective solution mining.

Our approach to technology has been to develop the process, starting at basic chemistry and phase diagrams, production of detailed computer modelling of the process, supported by extensive laboratory and pilot studies to verify the models.

Our patented system has been in place now for 15 years. We have attempted to find application for the technology by presenting papers at SMRI, and have made presentations to government, engineering companies, and prospective potash mines.

The prevailing sentiment appears to lean towards a fascination with mega projects, while the notion of a $20 to $40 million endeavour is deemed unremarkable, despite its potential for equivalent production and lower costs compared to the billion-dollar ventures. Conversely, there’s an alternate perspective wherein some individuals find it effortless to adopt information and then claim it as their own idea. However, it’s important to note that while it may seem straightforward, it’s not quite as simple as it appears! l

After a period of high prices through 2022 and 2023, potash prices have fallen and are expected to plateau through 2024 and 2025. Though prices are not expected to reach pre-2022 levels, the drop from the heights of 2022 has already had an impact on Canadian production with major producers slowing their expansion plans.

… but volatility Still exiStS making FutuRe pRiceS unceRtain

However, even though prices may be lower after the record high prices of 2022, the global uncertainty that, in part, drove high prices remains. Canadian producers are positioned to take advantage of any favourable price uncertainty as some of the next largest producers are subject to export sanctions (Russia, Belarus) or are large potash importers themselves (China).

With producers reticent to commit to large capital expenditures or slowing expansion to preserve cashflow, there is an opportunity to refocus on existing assets and operations and ensure that they are prepared for a future with increased demand. Investing in asset integrity strategies, processes, and technologies can ensure the reliability and performance of critical assets needed to meet production targets and minimize risks.

Bins are ubiquitous in potash operations and are critical in the handling and storage of potash. Bins and boxes fill multiple roles, from adding surge capacity and storage to mixing where high material flowrates can result in significant wear. Additionally, bins also represent

a unique risk as anything more than a minor failure can result in serious injuries to personnel, long production downtime, and a significant clean-up job. The highly corrosive environment presented by potash, coupled with temperature and humidity fluctuations common in Saskatchewan, means that bins are constantly at risk of wear, corrosion, and degradation.

An assessment of existing bins on site is often the first step in deciding the best approach to maintaining the equipment and ensuring continued operation. March Consulting Associates’ (March) approach has been to conduct an inspection of bins and assess the current state of the bin. Potential threats such as corrosion, likely areas of mechanical failure, environmental factors, and regulatory compliance are considered. The result of an assessment is a prioritized

list of recommended actions, such as changes to maintenance techniques, adjustment of operating conditions, repair and reinforcement, or replacement.

Unless mechanical failure is imminent and reinforcement options limited, replacement is rarely the most attractive option. March looks to leverage expertise and technology to find more attractive options for operators. Using Discrete Element Modeling (DEM) to analyze the state of existing equipment, as well as exploring potential operational changes, can minimize future degradation. Two examples are outlined below:

Both failure and premature replacement of bins can be very costly. Not only are the bins themselves expensive, but their size also often requires a shutdown with extensive planning and modification to the structure they are housed in. Therefore, determining the remaining life of assets, such as bins, is valuable in creating maintenance and replacement plans.

March can employ DEM to identify the locations of the greatest wear on a bin and, given its current state, calculate the remaining lifecycle of the equipment. Understanding wear characteristics on a bin can influence repair/replacement decisions and can also feed into targeted maintenance monitoring plans. Though the example above shows the influence of wear on the interior of the bin, DEM can also be used to show wear on the structural components supporting the bin or to model the forces on the structural members themselves.

In addition to corrosion and wear, potash can clump together causing adverse effects to flow, reduced throughput, and increased wear.

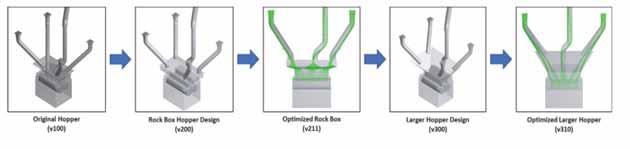

March performed iterative design improvements on a feed hopper to improve throughput. This type of analysis has also been used to improve potash load-out facilities that were having issues evenly loading rail cars with finished product.

As local potash producers adapt to the change in pricing and debate delaying

large expansions, it will become important to get the most out of existing assets. Inspecting and prioritizing repairs to existing assets can help ensure that should price volatility turn favourable and that there are no unexpected roadblocks preventing full production. Adding Discrete Element Modeling to this analysis can not only identify at-risk assets, it also offers the potential to locate and fix production bottlenecks.

With 25 years of continuous of experience helping the potash industry in Canada, March has expertise in finding cost-effective maintenance strategies and process improvements that help assets function in the challenging potash environment. l

Another use for DEM is as an exploratory tool for equipment optimization. We

Safety and health hazards make containing dust and fines non-negotiable in today’s mining environment. Additional problems associated with dust include environmental risks, increased house-keeping, and damage to equipment, as well as loss of product.

Identifying root causes is the first step to successfully solving the problem of airborne dust. Any time conveyed product is in motion it has the potential to generate dust. Dust and fines can be assumed if the product is moving, if there is an area of material free fall, and at any conveyor transfer areas. Our focus will be on dust that is specifically created at transfer areas where the conveyor is receiving material.

Engineered Passive Dust Containment is a system design that allows airborne dust to “settle” into the main stream of product without auxiliary equipment or additives to suppress or collect the dust particles. The Passive System does not require traditional methods of dust suppression such as water or chemical sprays or vacuum dust collection.

A Passive Containment System keeps material on the belt throughout the length of the conveyor transfer. It employs a series of chambers that are designed to reduce air velocity and allow dust particles to settle back down to the belt before exiting the transfer area.

The Passive Dust Containment System uses guidelines from CEMA (Conveyor Equipment Manufacturer’s Association) to determine the recommended time and distance for material settling at the load zone. This helps determine the general length of the skirtboard beyond the impact zone.

This engineered system is built on three essentials:

1. Establish correct belting elevation for consistent support. The impact-resistant cradle-shaped Impact Saddle with seal bar is recommended along with the use of Cushion Arc impact idlers placed before and after the Impact Saddle bed. According to CEMA standard 575, Impact Saddles are directly interchangeable with impact idlers and have the benefit of providing full trough support. The full support surface eliminates pinch points or gaps to provide the best foundation for sealing characteristics. Correct belt support and elevation are fundamental to a successful material containment system.

2. Next, a multi-layered approach that contains bulk material with internal wear liners and external skirting media is used to seal dust. Additional components including skirtboards or skirt clamps in a variety of configurations and rubber. Ceramic or rubber/ceramic matrix Canoe Liners can be recommended based on the needs of the application.

3. And lastly, once a solid base is in place and bulk materials and fines are contained, additional dust control components, such as entry and exit dust curtains, dust-settling chambers, and end pieces, are added to effectively create a total system design.

When fitted with an Engineered Passive Dust Containment System, busy transfer areas can be well equipped to handle the demands of efficiency, productivity, and safety that are required.

PICA provides excellent information on the condition of your pipeline assets. www.picacorp.com

Reliable, worry-free transfer areas are engineered every day at Richwood. To learn more about dust and material containment solutions, visit www.richwood.com. l “Good

For over 40 years, the largest mining companies in the world have put their confidence in Richwood’s innovative material handling solutions.

When it comes to solving problems with dust and material containment, Richwood achieves success with engineered passive dust containment systems. Application-specific solutions optimize efficiency through sealed and protected load zones without the need for vacuums, filters or other additional equipment. The reduced wear and tear on equipment and controlled dust and spillage create a safer and more productive work environment. Worry free load zones are designed and built by Richwood every day.

What would it mean for your productivity if dust and spillage issues were eliminated? Contact Richwood today for a review of your application.

By camilo rojas

By camilo rojas

ai-enabled technologies easily navigate the harsh underground environment, resulting in a significant uptick in productivity and safer work environments, as they reduce the need for human presence in potentially dangerous mining conditions.

Beneath the Earth’s surface, a composition of rocks and fluids capture the evolution of time, punctuated by mineral deposits and analogous to hidden harmonies within the stratified layers. Geoscientists interpret these cryptic notes to trace Earth’s history. Miners delve into shafts and tunnels, with their drills resonating through the rock to uncover hidden treasures. Artificial Intelligence (AI), a digital canary revolutionizing mining practices, heralds a new renAIssance through data-driven insights and technological advancements.

For those in the potash industry, staying ahead of the curve means embracing innovation, particularly the kind that AI ushers. AI can potentially transform the potash industry, offering practical applications that streamline operations, enhance safety, and promote sustainability.

The first value-chain step of potash production is exploration—a phase where precision equates to cost savings and reduced environmental impact. AI promises to excel in this phase of your operation, with the ability to analyze

geological data to delineate potash deposits, helping geologists and engineers make informed decisions to increase resource definition and utilization. Three-dimensional, hyperspectral systems capture the mine walls and ceiling in underground spaces like mine shafts and tunnels, offering valuable mineral composition and distribution data. This application merges spectral imaging with the geometric information collected using instruments such as Stonex’s X120 SLAM laser scanner, currently used by RESPEC geologists and engineers, which can

produce colourized point clouds and Digital Elevation Models (DEMs) without the aid of light or global positioning systems. With less guesswork and more efficient drilling, you can allocate resources wisely and get the most out of your exploration budget.

From exploration to extraction, the role of AI becomes even more pronounced. AI-enabled technologies easily navigate the harsh underground environment, resulting in a significant uptick in productivity and safer work environments, as they reduce the need for human presence in potentially dangerous mining conditions. Major corporations, such as Rio Tinto, leverage mine automation systems to oversee operations, while predictive maintenance algorithms preemptively identify equipment failures.

With safety as a top priority, AI’s im-

pact exceeds efficiency. AI-powered ventilation systems optimize airflow in your mines, providing clean air where needed most while conserving energy.

RESPEC’s mine ventilation system experts aid operators in making intelligent, data-driven decisions that pri-

rEsPEC geoscientists use ai algorithms to analyze hyperspectral and geospatial datasets collected by drones to help identify brine deposits in remote areas and map arid salt flats.

oritize safe conditions by forecasting energy peaks and developing predictive models for underground airflow patterns. These models guide the mine ventilation strategies, ensuring fresh air reaches critical areas and contaminants are extracted, creating a health-

ier environment for your miners and translating to savings on energy bills.

The effects of AI are not confined to the mines—they extend to the broader environmental context of potash production. AI-driven tools monitor and predict the ecological impacts of mining, helping producers operate within regulatory standards and public expectations. RESPEC applies geospatial AI, satellite imagery, and advanced rock mechanics to assist North American underground mine operators manage surface damage induced by subsidence from evaporite extraction. RESPEC engineers have devised 100-year subsidence forecast models to ascertain whether mining operations will breach the vertical displacement limits set by regulators in underground mine lease agreements. Leveraging our technology helps clients avoid the repercussions of non-compliance, such as fines or operational halts, and, instead, establish themselves as proactive, environmentally conscious industry leaders.

Building on environmental stewardship, our clients have also benefited from the ariel advantages of advanced drone technology. Drones equipped with AI, like the Trinity F90X+ used by RESPEC, can map and monitor mining sites efficiently and safely. These drones can cover up to 700 hectares at a ground sampling distance of 3.2 centimetres per pixel from a 120-metre altitude while avoiding other aircrafts, which meets the standards of Transport Canada’s Drone Strategy Plan. RESPEC geoscientists use AI algorithms to analyze hyperspectral and geospatial datasets collected by drones to help identify brine deposits in remote areas and map arid salt flats. AI is also used to model temperature variations, which provides valuable insights into mineral crystallization and accumulation rates, providing clients with the information needed to elevate their operations.

With AI’s ability to transform waste management and transportation logistics, you can improve your operation’s environmental footprint and boost

profitability. For example, AI systems are refining transportation routes in the Amazon for resources extracted from secluded areas. By improving route planning and logistics, Brazil will increase its domestic potash production in a manner that supports economic growth and environmental sustainability.

Embracing AI in potash means you are not just keeping up with the industry— you are positioning your operation to lead it. AI’s precision in exploration and extraction processes boosts efficiency and aligns with Environmental, Social and Governance (ESG) by minimizing environmental impact, improving resource management and worker safety, and ensuring operations are compliant with regulations and sensitive to community concerns.

By adopting AI-driven solutions, potash companies can contribute to a more sustainable and equitable world, fulfilling ESG commitments and securing a competitive advantage in a constantly changing marketplace. l

When it comes time to speak up about a workplace issue, feeling safe and secure in the act of speaking up is paramount.

At its core, ethical mining rests on the assumption that mining companies will implement and abide by clear policies to guarantee the safety and wellbeing of all workers. Provincial, territorial, and national laws and regulations create a complex framework for mines in Canada to operate under. Maintaining compliance and a high standard of ethical behaviour

requires being alerted to any wrongdoing or compliance concerns at every site before they can manifest into larger safety issues.

Through the Safe, Healthy, and Respectful Workplaces Protocol, the Mining Association of Canada works to bridge territorial gaps in regulations and raise the standard for eth-

ical mines across the country. Commitments and Accountability, Safety and Health Management Systems, Psychological Safety and Respectful Behaviour, Training, Behaviour, and Culture, Monitoring and Reporting, and Physical Safety and Health Performance are highlighted as core pillars with a set standard of conditions for mining companies to adhere to.

Even with comprehensive regulations