5.1.1.6. Specifications

Clear bay length: 750 mm (Outer dimension 840 mm, including two 40 x 45 mm nibs at bottom)

Rise of arch: 290 mm

Shell thickness: 25 mm

Unit weight: 50 kg per meter length

Length: Up to 5.4 m

Design mix: Cement: Fine Aggregate 1:2 to 1:3 by weight, M25 grade Water: Cement ratio 0.45 to 0.55 Fine Aggregate should be coarse sand confirming to grading Zone II as per IS Code 383-1970

Mesh reinforcement: 200 mm strip of MS weld mesh of 12-gauge, 25 mm square opening along crown of channel GI wire chicken mesh of hexagonal 12 mm opening, 22 gauge, throughout the shell and double layer of 1 m length at both ends of channel

Nib reinforcement: Roof application: from 6 mm for 3 m span to (1 no. In both nibs)12 mm for 5.4 m span Floor application: from 8 mm for 3 m span to 16 mm for 5.4 m span

Design load: As per BIS: 875 Load carrying capacity of FC Channel roof varies from 650 2 kg/m to 1200 kg/m depending on the reinforcement

5.1.1.7. Construction

6. CHECKLIST FOR PLACEMENT OF FERROCEMENT

6.1. Resource Management Parameters

1)Raw materials-

Reinforcement steel stored separately as per bars of different diameter, length, and grade wise with proper labelling.

Weld mesh roll is opened in the reverse direction of its curvature.

After cutting chicken mesh the ends of wires are folded back immediately.

Cement is fresh, free from lumps & stored in dry condition

Aggregates/Sand is clean, free from organic matter and relatively free from clay and silt

Water is fresh, clean, and potable. Admixture stored in covered storage area, cool, dry place, away from sunlight.

2)Equipment and tools-

Calibration of weighing balances satisfactorily done. All required sieves available are in satisfactory condition.

Condition of steel/mesh bending, cutting, welding machines satisfactory.

Condition of mortar mixer machine satisfactory

Availability of tools like piers, hooks, trowels, plumb with satisfactory condition

3)Testing and documentation-

Testing of cement as per inspection testing plan(ITP) satisfactory

Testing of sand/fine aggregates as per inspection testing plan (ITP) satisfactory

Testing of steel as per inspection testing plan (ITP) satisfactory.

Brand/make/age of admixtures as specified.

Testing of mesh as per inspection testing plan (ITP) satisfactory

Testing of mortar as per inspection testing plan (ITP) satisfactory

6.2. Site supervision

6.2 1. Pre-Placement

Inspection before placement of ferrocement

1 Centre line, Location of structural elements

2 Formwork & Staging

3 Construction joint location*

4 Steel diameter & coating

drawing

per the drawing & in exact plumb

the drawing

specification

6

7

9 All precast panels in level as per thickness.

6.3. Finished quality:

Sl. No Parameters

1 Quality of joint filling found ok

2 No damages observed in precast panels.

6.4. Note

All the empty space has to be filled and remarks if any shall be written in remarks column.

Date of inspection of pre-concrete, during placement and post-concrete placement shall be noted as these steps may not be performed on the same day.

Signature by contractor supervisor and engineer is done after each inspection.

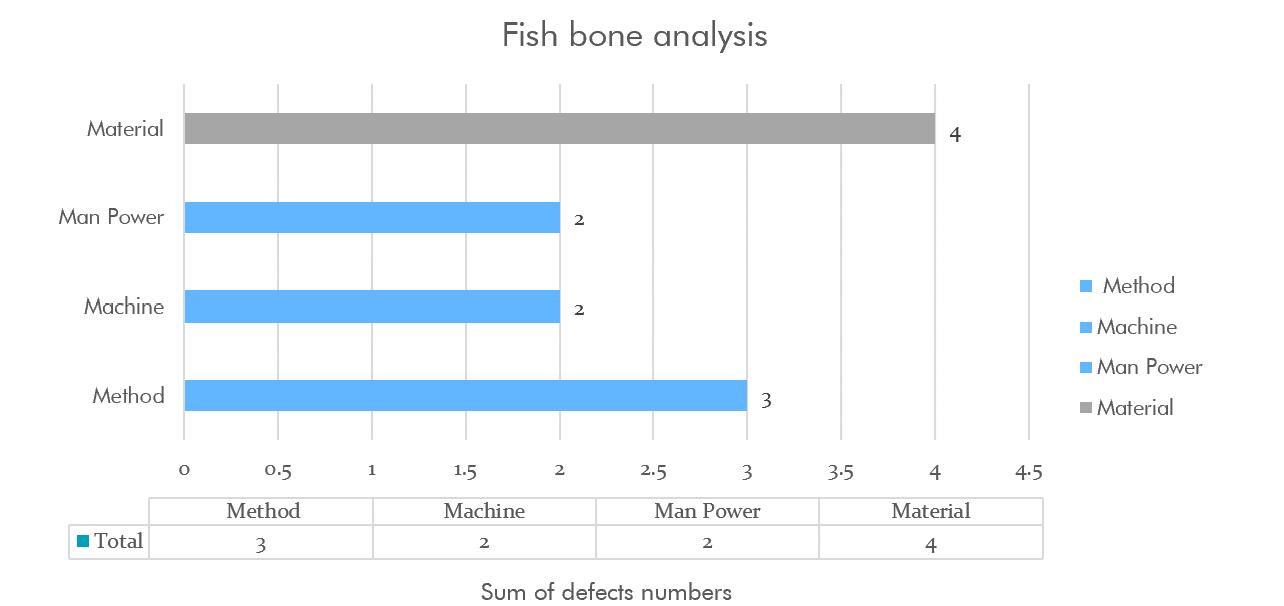

7. QUALITY TOOLS

Quality Management tools help employees identify the common problems which are occurring repeatedly and also their root causes. Quality Management tools play a crucial role in improving the quality of products and services.

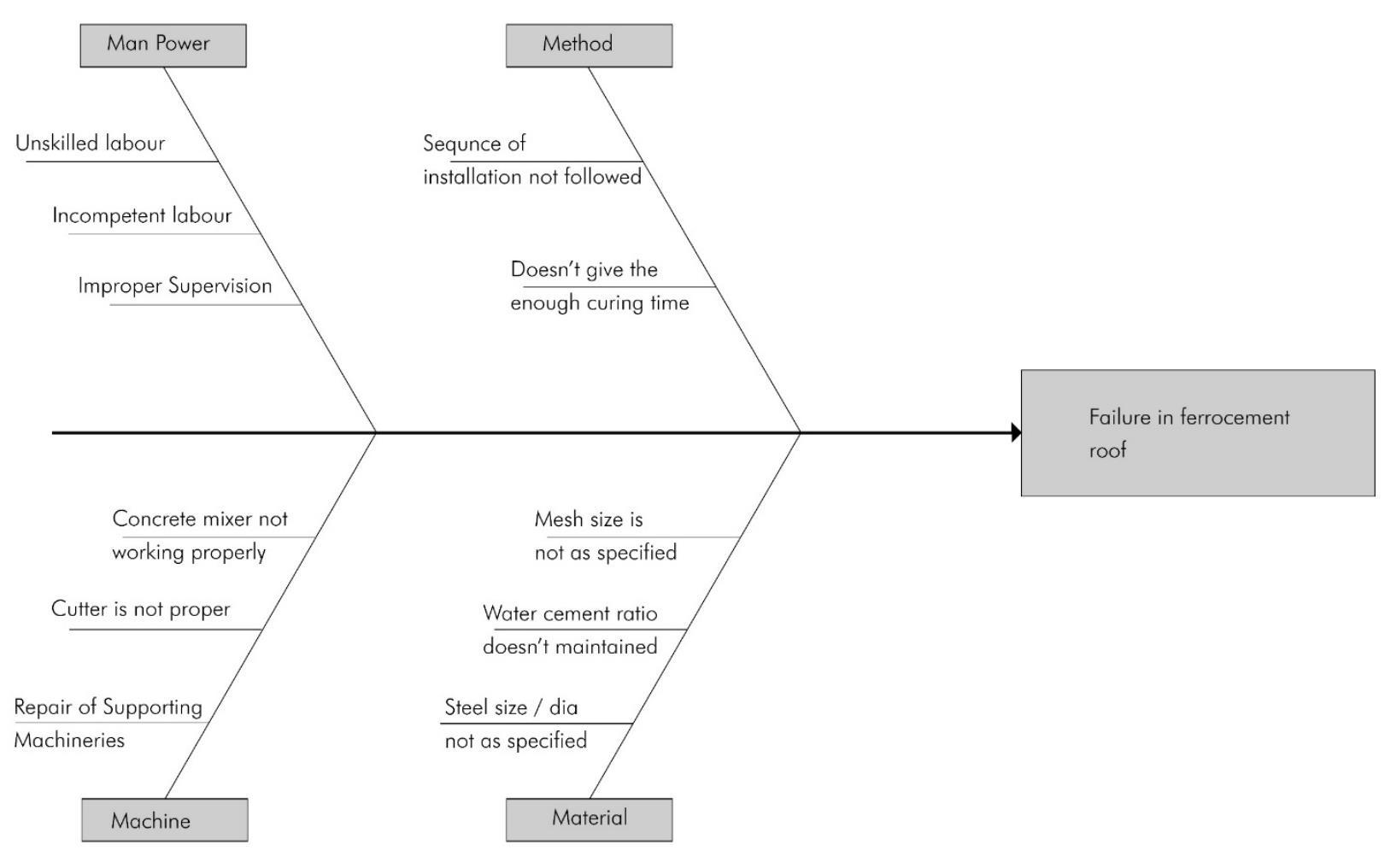

A cause-and-effect diagram is also called an Ishikawa diagram, after its developer

Kaoru Ishikawa, or a fishbone diagram

It is used to identify possible causes and effects in processes. It is used to explore all the potential or real causes that result in a single output

The causes are organized and displayed in a graphical manner to their level of importance or details.

The diagram is a graphical display of multiple causes with a particular effect.

The effect or problem being investigated is shown at the end of the horizontal Arrow

The causes are organized and arranged mainly into four categories.

7.2. Flow chart

Inspect the ferro cement roof ( recast/ n site )

Checking for the h sical ama e in the roof or precast panels Improper finish, eflection in panel

Re ection 1

Checking for the Chemical ama e in the roof or precast panels Concrete degradation

Re ection 2

No No

Checking for the tructural ama e in the roof or precast panels

Re ection 3

No

es es es

Employ physical resistance principles

Employ chemical resistance principles

Employ structural resistance principles

roceed the panel for Construction

Flow chart to determine the employable repairing principles of ferrocement

Rejection Percentage - Project 1

Rejection 1 - Physical Properties

Rejection 2 - Chemical Properties

Rejection 3 - Structural Properties

Rejection Percentage - Project 2

Rejection 1 - Physical Properties

Rejection 2 - Chemical Properties

Rejection 3 - Structural Properties

Rejection Percentage - Project 3

Rejection 1 - Physical Properties

Rejection 2 - Chemical Properties

Rejection 3 - Structural Properties

COMPARISION OF THREE PROJECTS

Compared to three projects defect in rejection physical properties gives more impact in the project

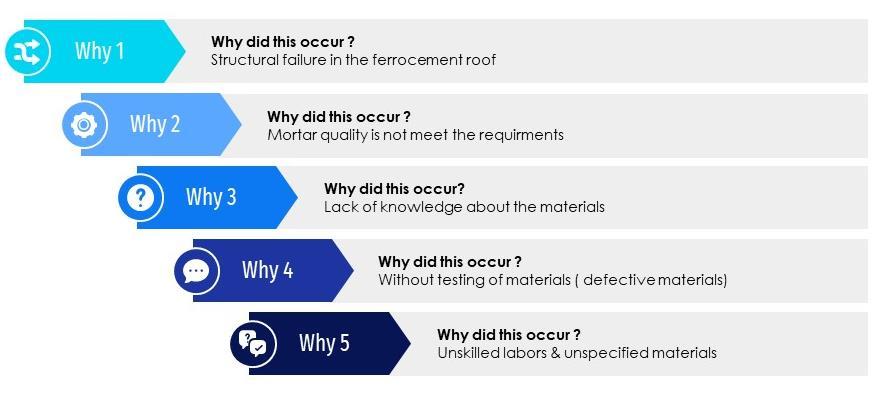

7.4. Five why analysis

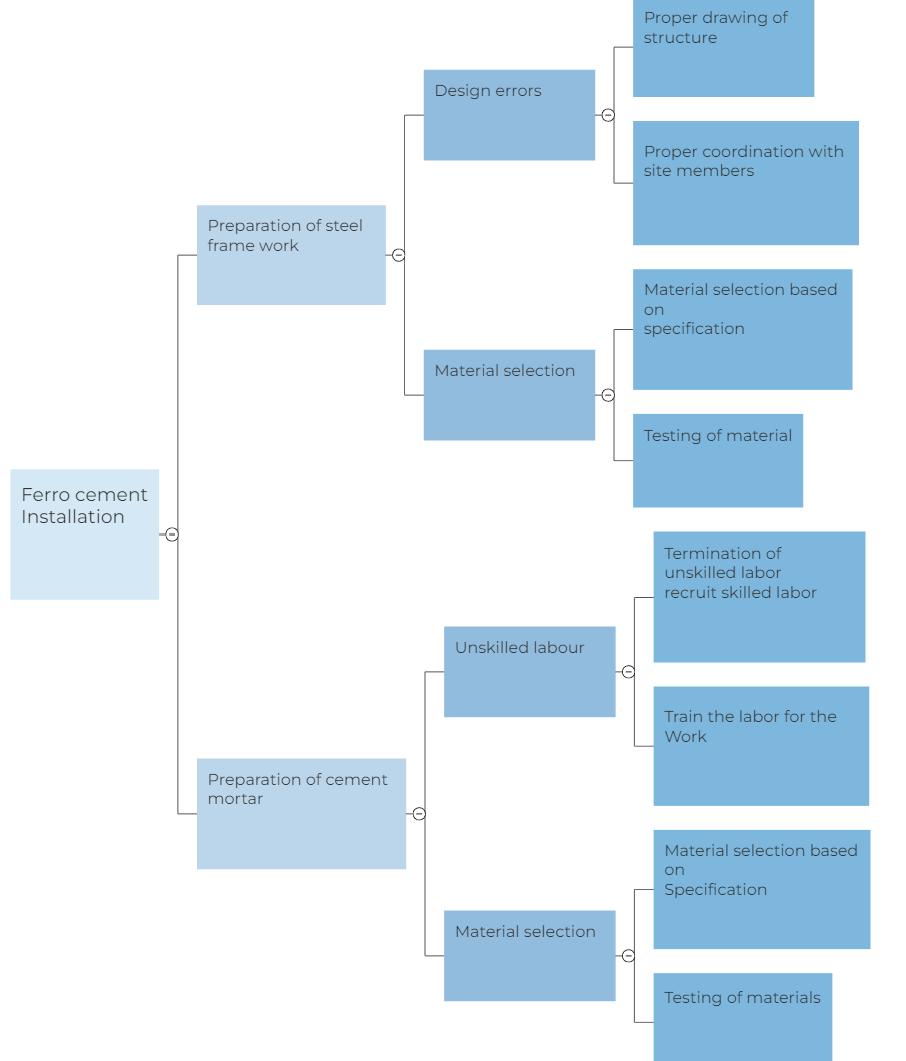

7.5. Process diagram objective

Task

Possible mistake

Contingency Plan

7.6. Comparison chart

Therefore, cost for 3m ferrocement roofing channel roofing = 1417 Rs.

Consider Room size: 10ft. × 10ft.

No. of ferrocement channel required = 8 Cost of channels required =8×1417 =Rs.11336

Cost of gap filling between channels and installation=1500Rs.

Total cost required for 100sq. ft. =12836 Rs.

Therefore, Total cost using ferrocement channel roofing system = 128 Rs. /sq. ft

Total cost using conventional (R.C.C) roofing system = 200 Rs. /sq. ft

COST COMPARISON

Ferrocement Rcc