21 minute read

Post-press…………………………………………………………............................…47 Back cover page

laboratory that will aid research because if we succeed in producing paper locally, a lot of burden will be taken off the naira.

GOVERNMENT AND PRINT INDUSTRY COLLABORATION FOR ECONOMY DEVELOPMENT-GDP GROWTH

Advertisement

Prinng in a depressed economy requires an urgent aenon. T h e p r i n t a n d g r a p h i c communicaon industry can join forces with the government to create a desired vibrant print and graphic communicaons sector that will aid the creaon of job opportunies in line with the Economic Recovery Growth programme of the Federal Government.

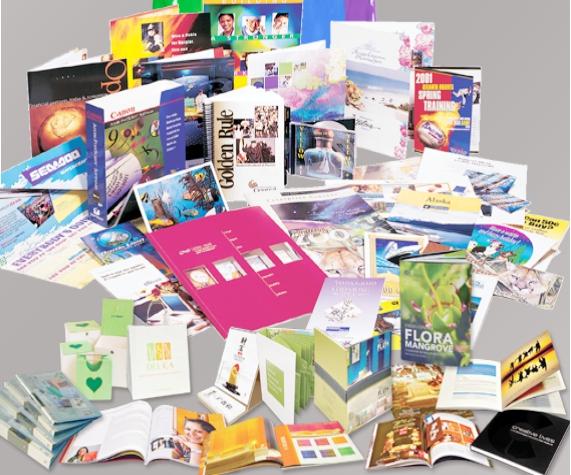

Print is part of everyday life. All that needs to be done is to go into the nearest store to buy any item. You idenfy the cereal, detergent or just about anything you want to buy by the packaging of the item. Print products in the same way holds sway in educaon sector since they are the fundamental tools that are used to pass on knowledge. You can carry this argument praccally through virtually every sphere of life; pharmaceucals, postage and courier services, signage just to menon a few. The Print and graphics communicaons sector can therefore be said to be an important partner to every other sector, service or industrial. Smithers Pira esmates the global print sector to top USD980 Billion in 2018. The potenal therefore in this sector is tremendous and Government can only ignore this sector at its detriment. For the purpose of this arcle, we would highlight three areas of focus for the prinng industry on the one hand and government on the other. Firstly, the industry must have lobby groups like the Polical Acon Commiee (PrintPAC) of the Prinng Industries of America whose role is impacng public policy direcon and debate pertaining to issues affecng p r i n n g a n d g r a p h i c communicaons companies. This advocacy unit will ensure that resources are dedicated to building and maintaining solid relaonships with and connually educang government about the challenges and opportunies facing the industry. Secondly, the industry must encourage longer-term contracts (where this applies) with their corresponding service level agreements between industry players and clientele including government. What currently is prevalent is that most print concerns cannot guarantee if they would get the next order from an organizaon. This does not allow planning, encourage further investment or engender the economies of scale that would allow the jobs be delivered more efficiently and affordable. Thirdly, the industry must collaborate with the requisite organizaons and bodies in the area of print educaon and print leadership to improve the quality of the print entrepreneur and human capital in the industry. This collaboraon must also focus on the next generaon in order to create the required interest and inflow of human capital into the industry.

Government on its part should consider implemenng the following:

Focus on the industry in the same way it's focusing on oil. The investment required to get some of the constuent sectors of the industry back off the ground are humongous. A large-scale chemical pulp (paper) mill with an annual pulp producon of around 1.4 million tons has an investment cost of about 2.5 billion USD if built from the ground up. (iea.org). Government can partner with the private sector by creang an enabling environment for investment in paper mills of various capacies. (Nigeria imported 1.2M tonnes of various 48

paper and paper products last year). The print sector must be i n c l u d e d i n t h e F e d e r a l Government plans for its Strategic Economic zones and free trade zones.

As part of its focus on Educaon, Government must work with the industry to improve the quality which students are being educated on prinng and graphics c o m m u n i c a o n s i n i t s u n i v e r s i e s , c o l l e g e s o f technology and vocaonal schools.

INEC PRINTING JOBS REMAINING IN NIGERIA

Mr Olugbemi Malomo is the reelected president and chairmanin-council of the Chartered Instute of Professional Printers of Nigeria has been so passionate about the campaign to keep Nigerian prinng jobs in Nigeria, recently he shares his view on ways of strengthening the local prinng industry and insinuate why INEC should print 2023 elecon ballot paper locally. He said “INEC has absolutely no reason to patronise porolio contractors, parcularly for what can be done in Nigeria. The elecon is for the benefit of Nigerians. We have an astute Nigerian professor as the umpire, we are going to elect a Nigerian as president, why should we choose a foreigner to print our ballot p a p e r a e r 6 0 y e a r s o f independence? So, why are Nigerian printers being denied their own dividends of democracy when they have the capacity to do so?

“By the law that set up CIPPON, nobody can pracse or earn income from prinng without being registered by us. What we are saying is that INEC should obey the law. Porolio contractors or brokers, if they must operate, should partner with local printers to print ballot papers in Nigeria. That's the only middle point or compromise acceptable to us. We will call them out by way of ligaon if we must, anyone not registered by the instute that is awarded ballot paper contracts”

“There are over 70 million voters across board and that is about 350 million ballot papers for the general elecons within four to five weeks. If we have six months to the elecon and are awarded the contract, I can tell you authoritavely that some of our members can print over 10 million ballot papers in a week, some 5 million in a week, some others can do one million copies in a week. The onus is now on INEC to prequalify more across the geopolical zones of Nigeria. Going to print ballot paper abroad at a period the global supply chain is challenged will certainly not address the logisc problem”

“ G o v e r n m e n t s h o u l d t a ke responsibility and must be deliberate about empowering Nigerians. We acknowledge the fact that the chairman has elecons to conduct, we acknowledge the fact that all of us should help him to conduct very successful elecons and we should do what is scienfic and praccable. The people taking those jobs abroad are not printers but mere contractors who don't employ anybody nor buy diesel; they are porolio contractors, and we should ask quesons if those people are ghosts”

JOB CREATION POTENTIAL OF THE PRINTING INDUSTRY IN NIGERIA

A quick check on the prinng and industry reveals that in the sevenes and eighes, the Nigeria prinng industry was the hub of prinng in West Africa. According to Malomo, “I can recall vividly how people from Francophone countries came to Shomolu (a suburb in Lagos State, South-West Nigeria) to print their French text books. But because successive Nigerian government had undermined this i n d u st r y a n d ca re l e s s o n safeguard her, that this sector and her potenals have suffered grave and connuous decline”.

An understanding of the prinng industry globally shows that it's a means of job creaon. In the United States, the sector is the third highest employer of labour, employing more people than the automobile industry. Similarly in Europe, the prinng sector is a m o n g t h e t h re e h i g h e st employers of labour. In Nigeria it is the second largest employer of labour aer tradional farming, yet it maintains such a low profile that rather than being a great giant, it could just about disappear from sight. It is a diverse, disperse swarm of small businesses employing as low as five people. “However, its great strength when examined holiscally shows one is faced with an enrely different monster comprising of thousands of small independent units” , added Malomo. Prinng touches lives constantly in the form of product packages, books, newspapers, magazines, office staonery and a wide variety of other printed items we use every day. We consume it without thinking about it. As further argued by Malomo, “to treat prinng as a stand-alone product, service, or process, is impossible. It is a manufacturing industry in the strictest sense but it is also a service industry” .

FOR THE LOVE OF GOLF… THE CHARITABLE SIDE OF DR. FALAIYE YOU DON'T KNOW

The chief execuve officer of AKFAR prinng and publishing limited, Dr. Mrs. Adesola Falaiye's charitable personal life revealed as she passionately shares her story on her love for golf; simply a charity drive to raise funds for the needy- helpless Paediatric Cancer paents. However, Dr. Falaiye's personal passion for golf sport brings about the iniaon and birth of 'The

Love Of Golf Charity tournament' These are a special class of humanity for which the tournament debuted in December 6, 2020. Yet, golfers will always be players, as the parcipants in the second edion of the event displayed their talents and skills on the course on the final day.

The Lions Club, of which Dr. Adesola Falaiye is a prominent member, played a huge role in the success

of the event, even as they also had a round on the course. But most importantly, this charity event lived up to expectaons when it went beyond donang items for the Paediatric Cancer Ward of Lagos University Teaching Hospital (LUTH) to adding destute from Orphanage home, Tripple G, also in Lagos, to the list.

According to Mr. Ayo Aderiwale, an industrialist based in Lagos, said, 'having people like Dr. Falaiye, who iniated For The Love Of Golf C h a r i t y To u r n a m e n t , w h o remember their history and give back to the society that made them as giving to the needy is cultural in Africa. Joy Ayonote also shared the same senment,

He added,

“Falaiye is a leader with rich cultural background, who takes posive advantage of it for the good of the society. He reaches out to those who definitely cannot pay back and it is a welcome development that everyone, who cares for the needy, should support.” describing Falaiye as an outstanding personality with

a very posive drive.

She urged corporate bodies to support the iniave

to build a beer place for the needy, adding, “Care for

Busola Ladipo, the lady Vice Captain of Ikeja Golf Club, also applauded Falaiye, saying: “This second edion of For The Love Of Golf Charity Tournament is a huge success; it's an improvement on the first edion, which goes to show that the organisers have done their home work properly for what the event stands for. ” Ladipo said further that “I'll advise the organisers, led by Dr. Falaiye, concentrate on the Paediatric Cancer paents they started with. It will help them to be more focused and achieve beer results without those afflicted with cancer should not be a yearly

affair; it should be at regular intervals, at least

quarterly because the disease can be terminal and

the treatment is damn expensive. “This is why the iniave by Dr. Falaiye becomes very imperave for everyone to support it. I also believe that support can come by way of providing logiscs, manpower; trained personnel for the hospitals to be well equipped, rather than giving only money for buying of just drugs.”

distracon.”

An excerpts from one-o-one interview session with the Brandberg boss Mr. Ayodeji Ogundare, the head of operaon of Brandberg soluons has disclose the recent challenges facing Nigeria print industry and the needs to bring Nigeria print jobs back home.

Q: In research, we learnt that Brandberg is operang in prinng and branding only but lately now grooming as a media company too, so how long have you been in prinng industry?

A: We've been in operaon since 2020, we're just 2 years in the industry, I'm not the pioneer, I was invited to come and sr it up and create more value to the company.

Q: since 2020 now, how do you see print industry?

A: Me personally have been into prinng since 2 0 0 4 , i t ' s interesng and sll evolving and c h a n g e i s c o n s t a n t i n prinng, when I s t a r t e d p r i n t business, it was o n l y m u s h i n , S h o m o l u a n d Ogba that are dominant print hub but the fact is that Shomolu is n u m b e r o n e when it comes to prinng.

Nigeria? Q: What are the recent challenges f a c i n g p r i n t b u s i n e s s i n

A: Government is the cause of the whole challenges, our government taking print business abroad is affecng the industry so bad, for example the universal basic educaon sectors makes it compulsory for every student to have at least 5 books for themselves and the minimum price of prinng a notebook is #500, so instead of them to give it to us locally it's printed abroad, research shows that there are 22 millions students out of school in Nigeria, so let me juxtapose it 22millions mes 500 mes 5 books , you know how much it is, if all this jobs are given to us to do locally it won't only boost the economy but also develop the sector and naon at large. I could recollect when I was in secondary school back then in 1997 by then we have 400 schools in Lagos here, if you mulply the total number of books for student by then by the amount for prinng, it'll always be a plus for Nigeria economy, also prinng of ballot paper abroad is really affecng the industry and economy, those are wat we can easily do locally and benefits our naon. The reason why Nigeria is experiencing the current issue of high dollar rate is because Nigeria is not an export dependent c o m p a n y, w e ' r e i m p o r t dependent company, so when we take those jobs abroad, we're killing our naira and empowering those people there.

THE PSYCHOLOGY

OF COLOUR AND GRAPHIC DESIGN IN PRINT PRODUCTION

Colour plays a crucial role in graphic design and print producon at large, as does the psychology of how humans perceive colour. Here is a look at the ways that colour and psychology affect the graphic design process.

Colour psychology

Colour psychology is the study of how colours determine human emoons and behaviours. We react to colours based on a complex series of interacons between our personal tastes, our family upbringing, and our cultural background.

Colour can affect percepons in subtle ways; for example, it can enhance or detract from the way that food tastes. The right colors can even enhance

how effecve pills and placebos are; blue is used for calming or sleep-inducing pills whereas red or yellow are usually used for smulants.

Every brand and business use colours deliberately in their product designs, packaging, adversements, and websites. High-level graphic design relies in part on the ability to select colours that work with the brand and the company's mission. The psychology of color can and must be use to trigger the right responses from customers, and this is part of the graphic designer's goal.

Great graphic design also ancipates cultural differences in the way colours are perceived. The same colour can mean very different things to different audiences; for example, in most cultures yellow has a bright, cheerful connotaon, but in China it may have vulgar or adult connotaons. In the US white symbolizes purity and is oen used for bridal branding, but white is a mourning color in Japan, India, China, Korea, and the Middle East. The boom line here is to know your audience and choose wisely.

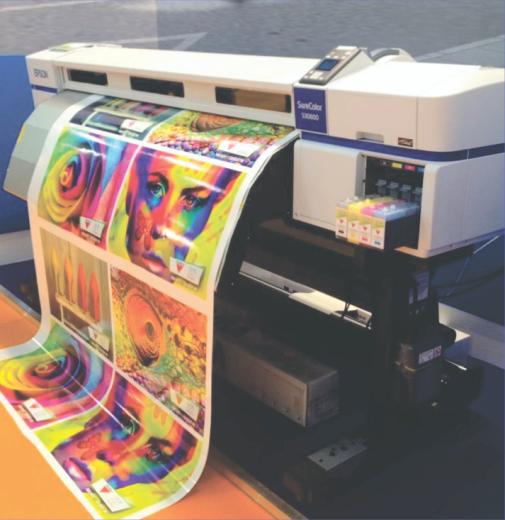

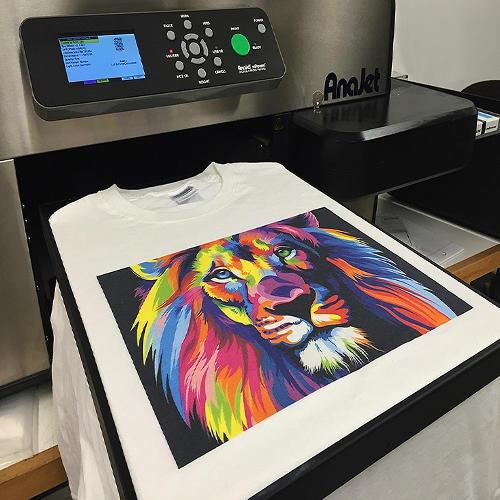

THE POWER OF DTG DIRECT-TO-GARMENT PRINTING

irect-to-garment prinng(DTG) is a process Dof prinng on texles using specialized aqueous ink jet technology. DTG printers typically have a platen designed to hold the garment in a fixed posion, and the printer inks are jeed or sprayed onto the texle by the print head. DTG typically requires that the garment be pre-treated with a PTM or Pre-treatment machine allowing for the following: · Stronger bond between garment fibers and the pigmented inks · Lays down loose fibers to provide for a smoother substrate · Chemically reacts with the inks to promote drying and curing Since this is a digital process, the print is sharper and has a higher resoluon, or DPI, than tradional prinng methods such as screen prinng. However, unlike screen prinng, there is no long setup or cleanup process, and DTG has the ability to print just one single shirt for minimal cost.

Prinng process: DTG printers use aqueous texle inks (water-based chemistry) that require a unique curing process. Since D2 inks are water-based, they work best for prinng on natural fibers such as coon, bamboo, hemp, and linen. In addion, pre-treatment is typically applied to the garment before prinng. The pre-treatment is heat-pressed into the custom t-shirt causing the fibers of the shirt to lay down. The pre-treatment also allows the water-based inks to bond more fully to the garment. This is especially important when using white ink on dark garments.

Once the custom garment -for instance a t-shirt- has been properly pre-treated, the shirt (or garment) is then posioned onto a plaen system designed to hold the shirt in place. The shirt is then digitally printed according to the design in the printer queue. Direct-to-garment prinng in the United States began in 1996 with the introducon of the first commercially available DTG printer named "Revoluon", developed by DIS of Bradenton, Florida, and based on an invenon of Mahew Rhome. Rhome had been working on the DTG project for some years and applied for a patent in July 1996. This patent was granted by the US patent office in August 2000 making it the first DTG patent. The Revoluon printer was offered for sale unl 1998 when Rhome le the company to start development of the first Brother DTG printer, which came to market in 2005.

Aer the release of the Revoluon printer, there was a lot of development but not much sales acvity in the market unl 2004 when Mimaki introduced their printer at the ISS show in Chicago, Illinois and, later that year, when kornit and US Screen displayed their offerings at the SGIA show in Minneapolis, Minnesota. In 2005, at the ISS Atlanc City show, Brother Internaonal introduced the GT-541 Garment Printer to the market making it the first “ground up” DTG printer offered. This printer had print heads, ink, and electronics developed specifically for DTG prinng.

At the Chicago PRINT 2013 show Epson introduced the F2000 printer. The release of this printer was notable as it addressed many of the issues prevalent in DTG prinng at the me. One of the most important features of the Epson F2000 was its ink set as it had a two-year shelf life and did not have the seling or clogging issues of previously introduced DTG inks.

By May 2019, the North American DTG market was currently valued at over $2.5 billion with a compound annual growth rate of 10.5% through 2021.

INCREASE YOUR PROFITS, CUT PRODUCTION TIMES AND DIFFERENTIATE YOUR PRODUCT – WITH INLINE FINISHING

Providing inline finishing capabilies lets you increase your profit margins on print jobs, whilst at the same me shortening your own producon mes, reducing labour costs, improving quality control, cung back on waste and saving energy.

Tradionally viewed as an aerthought and producon boleneck, finishing is now being viewed as a crical stage in producon and a way to differenate products and create added value. It is not unusual for finishing to generate as much as 40% of producon costs, and for poor quality control at this stage to destroy a great deal of added value.

With updates in digital producon technology, SME printers have woken up to the fact that invesng relavely modest sums in finishing equipment can lead to significant producvity improvements and reduce costs. Results from a recent drupe global trend report show that 48% of respondents were planning to invest in finishing equipment, and 40% are invesng to drive efficiency improvements.

Digital inline finishing features a variety of different workflows. These are all about automaon, making in-line and near-line equipment crical, but somemes an offline approach will be more applicable.

So how should you be invesng? In inline finishing, the press and inline finishing equipment are directly connected and closely integrated using front-end management controls. This is the soluon for you if you produce a defined range of products in standard formats such as stched booklets, reports, calendars and book blocks. The overall producvity of a digital press with in-line finishing capability is determined by the speed and efficiency of the finishing components, so it is essenal that these don't detract from the rated speed of the digital press.

An offline finishing workflow is more common when a printer has a range of digital and offset equipment,

but this increases labour costs. Somemes the higher speed of off-line finishing equipment will more than compensate for the increased operator invenon. It all depends on the type and quanty of jobs you need to finish.

In contrast to in-line and off-line, near-line offers greater flexibility. There is no physical connecon between equipment in this case, but the finishing line knows the requirements of each job, from OMR (opcal mark recognion) technology or from a direct interface with the press's print server, through JDF. This enables the finishing line to manage the printed output from a variety of presses and create an audit trail, which is crical to personalized products like mailshots or transaconal documents.

Choosing the right finishing workflow will depend on understanding not only your workload, but also how you can apply different finishing soluons to improve efficiencies and add value through new products. However, one major benefit that has been largely overlooked by the printer and has not been sold effecvely to the customer is inline finishing.

What exactly is inline finishing'?

Inline finishing is the process of bringing services such as folding, saddle stching, side stching, case binding, punching and other post-processes in-line, so they are accomplished at the same me as the prinng. A wide array of finishing equipment is now

available to be connected directly to digital producon printers to achieve this,

Providing these services in-line not only saves on labour costs; it also prevents missing pages, imperfect collaon, and other common mishaps. It makes prinng extremely small lots possible – even a single copy – and extends the range of just-in-me services from fliers to catalogues, manuals and other high page-count projects. Inline finishing in the print industry gives you benefits including: • Labour-intensive post-processing completed at same me as prinng. • One-pass producon of high page-count materials. • Flawless binding, free of missing pages and imperfect collaon

Differenate your product hugely and create stronger customer loyalty

Inline Finishing means your customers will benefit from already-finished print products, shorter producon deadlines for more complex print products and a 'one-stop shop' offering everything from a single source. For smaller printers and in-house print departments, reducing the amount of work that is outsourced gives greater producon flexibility and control. (A good example of this are W2P systems, providing a steady but unpredictable flow of digital short run ondemand jobs, which cannot be outsourced and have to be completed in-house.) Essenally, the more aspects of a print job you can control internally and offer on-demand, the greater your growth will be and the more customer loyalty you will generate.