Introduction:

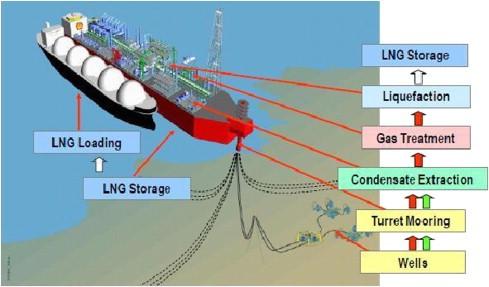

Facilities for 몭oating lique몭ed natural gas (FLNG) production, liquefaction, and storage o몭er an innovative method of doing so. These o몭shore platforms o몭er 몭exibility in accessing remote gas reserves because they are built to process natural gas at sea Heat exchangers are an essential part of FLNG systems and are essential to the liquefaction process The principles of heat exchanger design for FLNG, taking into account the particular di몭culties and requirements that these cutting-edge o몭shore installations present

Understanding the FLNG Process

In essence, FLNG facilities are 몭oating liquefaction plants that make it possible to extract, liquefy, and store natural gas at sea There are multiple crucial steps in the process:

Production platforms or subsea systems are used to produce natural gas from o몭shore wells.

In order to prevent contaminants from interfering with the liquefaction process, such as carbon dioxide, water, and sulphur compounds, the extracted gas is treated

The processed gas condenses into lique몭ed natural gas when it is cooled to extremely low temperatures, usually below -160 degrees Celsius (-256 degrees Fahrenheit) (LNG). The gas must liquefy in order to be transported and stored in smaller volumes.

The produced LNG is loaded into carriers to be transported to markets after being stored in aboard tanks

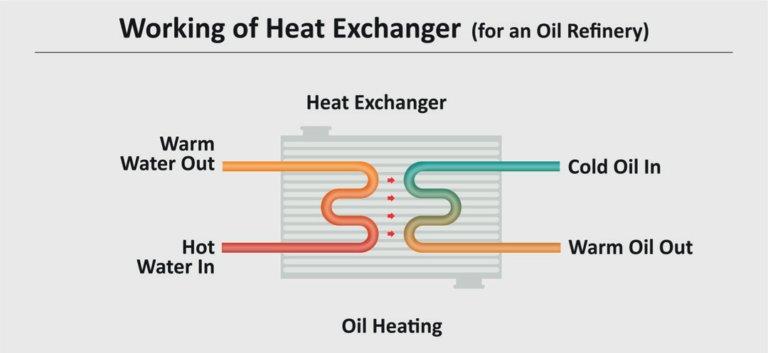

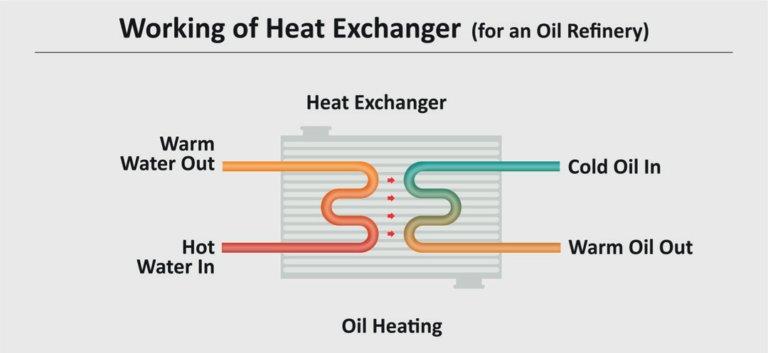

The Role of Heat Exchangers in FLNG

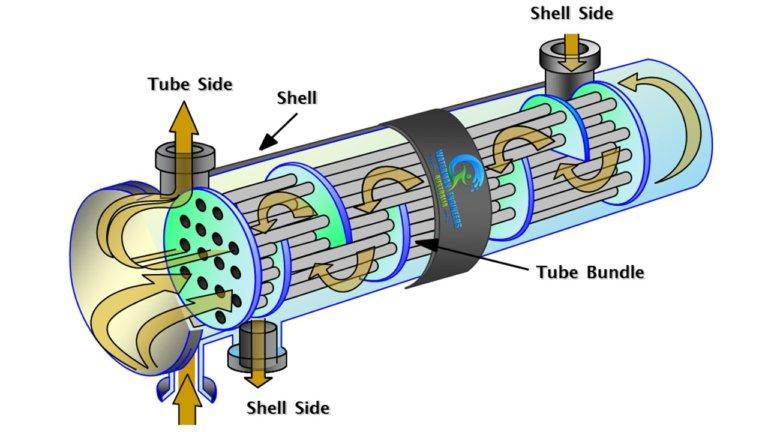

Heat exchangers play a crucial role in the FLNG facilities’ liquefaction process Managing the heat transfer necessary to chill natural gas to the liquefaction stage is their main duty This entails managing very low temperatures and making sure that heat is exchanged across various process streams e몭ectively Important considerations for creating heat exchangers for FLNG include:

1. Cryogenic Conditions:

Working at cryogenic temperatures during the liquefaction process is a part of FLNG activities. One of the main challenges is designing heat exchangers that can withstand and transfer heat e몭ectively in these harsh temperatures The choice of materials becomes essential Low-temperature materials such as aluminium alloys and stainless steels are frequently used In order to stop heat loss and keep the necessary low temperatures, insulation and thermal management strategies are also used.

2. Optimizing Liquefaction E몭ciency:

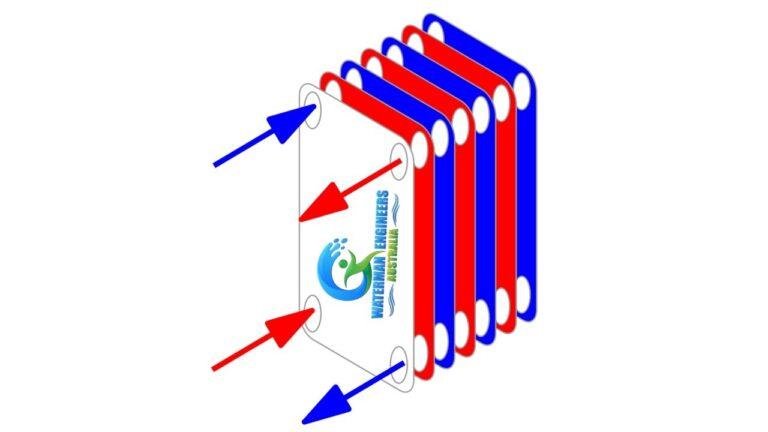

Economic viability depends on the liquefaction process reaching a high level of e몭ciency Heat exchangers need to be built with the least amount of energy consumption and the highest possible heat transfer e몭ciency By o몭ering a wide surface area for heat exchange in a compact design, modern heat exchanger topologies like spiral-wound or plate 몭n heat exchangers can improve e몭ciency. Simulators of computational 몭uid dynamics (CFD) are essential for optimising the design and arrangement of heat exchanger components.

3 Compact Design for Limited Space:

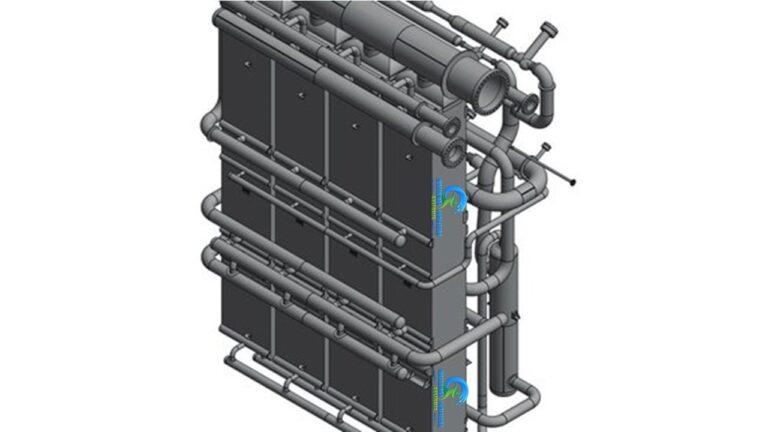

Because of the nature of o몭shore operations, FLNG installations frequently experience space limits It is essential to design heat exchangers that are both small and e몭cient For FLNG applications, compact heat exchanger designs like plate and frame or brazed plate heat exchangers are preferred With its high surface area-to-volume ratio, these designs enable e몭ective heat exchange in a compact space.

4. Durability in Harsh Marine Environments:

Heat exchangers in FLNG installations are subjected to severe maritime conditions, including high winds, salinity, and possible wave action The longevity of heat exchangers in maritime environments depends on corrosionresistant materials and coatings Systems for monitoring and routine maintenance are put in place to identify and handle possible corrosion problems

5 Operational Flexibility:

Variations in gas composition, 몭ow rates, and environmental variables can occur during FLNG operations. For heat exchangers to adapt to these changes, operational 몭exibility is a must The 몭exibility needed for dynamic o몭shore operations is ensured by designing heat exchangers with customizable features, control systems, and the capacity to withstand variations in operating circumstances

6 Safety Compliance:

FLNG plants are subject to strict safety rules and guidelines. It is imperative that heat exchangers are engineered with safety precautions to avert incidents like leaks or over pressurization For FLNG heat exchangers to be safe and compliant with regulations, they must have emergency shutdown mechanisms, temperature and pressure monitoring systems, and safety relief valves

7 Integration with Other Systems:

Heat exchangers must operate in perfect harmony with other parts of FLNG facilities, which are made up of numerous interconnected systems, including storage tanks, separators, and compressors. E몭cient integration and optimal performance of the FLNG facility necessitate collaborative design techniques and meticulous evaluation of

Steps in Designing Heat Exchangers for FLNG

Identify the precise conditions needed for the liquefaction process, such as the ranges of temperatures, pressures, and compositions of the gases

Select materials that are corrosion-resistant in marine situations and suitable for cryogenic environments

Make use of design optimization methods, including CFD simulations, to build a heat exchanger that is both small and e몭ective.

To guarantee adherence to safety regulations, incorporate safety elements like monitoring systems and relief valves

Provide features that can be adjusted in heat exchanger designs to account for changes in operating conditions

Operate together with the FLNG system architecture as a whole to guarantee smooth integration and best possible performance

To improve durability, use corrosion-resistant materials and coatings in conjunction with strong maintenance and monitoring systems

Waterman Engineers Australia design of heat exchangers for FLNG

Leading the way in creative engineering solutions, Waterman Engineers Australia has experience designing heat exchangers speci몭cally for applications involving 몭oating lique몭ed natural gas (FLNG) Through their specialised heat exchanger designs, Waterman Engineers Australia has e몭ectively contributed to the optimization of FLNG plants, all while upholding the highest standards of excellence, sustainability, and safety.

When it comes to handling the special di몭culties that cryogenic conditions in FLNG operations provide, Waterman Engineers Australia is unmatched Their team of professionals is knowledgeable about the complexities involved in creating heat exchangers that can e몭ectively withstand extremely low temperatures, which is a necessary condition for the liquefaction process To achieve the best possible heat transfer, this calls for the careful selection of materials that can resist cryogenic temperatures as well as the application of thermal management and insulation techniques.

For their heat exchangers, Waterman Engineers Australia uses creative and space-e몭cient design solutions because FLNG is an industry where space is frequently at a premium By utilising sophisticated computational 몭uid dynamics (CFD) models and optimization methods, they manage to strike a compromise between e몭ectiveness and compact size In order to accommodate space limits on FLNG platforms without sacri몭cing performance, compact heat exchanger designs are essential.

Safety is given top priority by Waterman Engineers Australia while designing heat exchangers for FLNG. Their designs integrate strong safety elements since they are aware of the strict safety standards and regulations that apply to

o몭shore activities To maintain the integrity of the heat exchangers and adherence to industry safety standards, they include emergency shutdown mechanisms, temperature and pressure monitoring systems, and safety relief valves.

Waterman Engineers Australia develops heat exchangers with an emphasis on operational 몭exibility since they are aware of the dynamic nature of FLNG operations Their solutions provide the 몭exibility needed in the ever-changing o몭shore environment by accounting for 몭uctuations in gas composition, 몭ow rates, and environmental factors Their choice of materials that resist corrosion and their application of maintenance techniques to extend the life of their heat exchangers in the demanding marine environment further demonstrate their dedication to durability.

The collaborative design method employed by Waterman Engineers Australia guarantees the smooth integration of their heat exchangers into the larger FLNG system They actively participate in the design of the FLNG system as a whole, which helps to optimise the entire facility By working together, they make sure that their heat exchangers complement one another and work as a whole to maximise the e몭ciency and performance of the FLNG facility.

The heat exchangers designed for FLNG by Waterman Engineers Australia demonstrate a thorough comprehension of the intricacies involved in o몭shore liquefaction procedures Their leadership in o몭ering state-of-the-art heat exchanger solutions for the changing FLNG operating landscape is attributed to their cryogenic knowledge, safety commitment, compact design solutions, and collaborative integration strategy

Choose Waterman Engineers Australia Heat Exchangers for Floating Lique몭ed Natural Gas (FLNG) that elevate your industrial processes to new heights Contact us today to explore how we can optimize your heat transfer applications and contribute to the success of your operations

Yes! I am interested

Sustainable Development Goal Progress Analyser

De몭nition: “The SDGs (Sustainable Development Goals), then recognized as the Worldwide Objectives, are a worldwide noise to act to 몭nish de몭ciency, read more

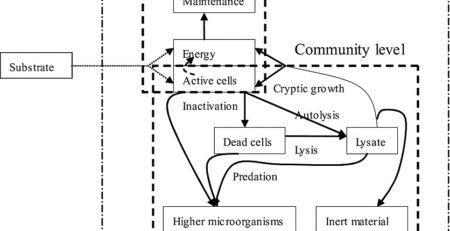

Biological Wastewater Treatment Systems -Natural Endogenous Respiration Vessel (NERV)

Biological Wastewater Treatment Systems

Overview Due to rising population needs for clean and safe water supplies, biological wastewater treatment systems... read more

Nanotechnology- Adsorption kinetics to treat industrial wastewater

Introduction: Due to excessive use of water in the manufacturing of industrial products, it puts a lot of pressure on read more

RECENT POSTS

Waterman Engineers Australia is a manufacturer, exporter and supplier of water wastewater treatment plants, RO plants (Reverse Osmosis Plant), Desalination plants, E몭uent recycling Systems, Zero liquid discharge systems (ZLD System), Caustic recovery plants, Water 몭ltration systems, Drinking water plants, Arsenic removal systems for drinking and industrial water, Mineral water plant, Sewage treatment plants, Solid & Liquid waste incinerator systems, Textile Mining Pharmaceutical e몭uent treatment plants, Solar based water wastewater sewage treatment plants etc., with decades of experience in water wastewater treatment from concept to commissioning.

QUICK LINKS

Reverse Osmosis Plant

Water Treatment Plant

Pharmaceutical Water Purifying Plant

Arsenic Removal System

ZLD System

Per- and Poly-몭uoroalkyl Substances (PFAS)

Biogas Upgradation Plant

Plasma Pyrolysis System Manufacturer

Solid/Liquid Waste Incinerators

Desalination Plants

Caustic Recovery Plant

Paddle Dryer / Screw Press / Filter Press

QUICK LINKS

Hard Water Softeners

Soft Drink Manufacturing Machine

Vitamin Water Projects

Fruit Juice and Beverages Machineries

Solar-powered RO System

Mineral Water Treatment & Packaging Plant

Sewage Treatment Plant

Metal Recovery From E몭uent

High Energy Venturi Scrubber

Heat Exchangers

Flue Gas Desulfurization (FGD) Scrubber

FOLLOW US