BIOWOOD, PROBOARD, EVERDECK BY TIMBERLINK, EASTLAND AAC PANELS AND MORE GOT APPRENTICES? HERE’S HOW TO BACK THEM

BIOWOOD, PROBOARD, EVERDECK BY TIMBERLINK, EASTLAND AAC PANELS AND MORE GOT APPRENTICES? HERE’S HOW TO BACK THEM

At Dahlsens, we’re often described as a family business. That starts with the Dahlsen family, who have led for five generations. But for me, “family” runs much deeper than the name above the trade shed door. What makes this place special is how people treat each other, and our customers, like family. There’s little hierarchy here. Everyone’s contribution matters, and the business exists to help people grow, back themselves and have a crack. That’s a big part of why I choose to work here too.

I’m reminded of this every time I hear stories like that of our customer experience manager, Michael Mann. Mick has been with us for more than three decades. His son Bailey (pictured middle) for 7 years. His brother Geoff for 15, and Mick’s father, Stephen for 60. That’s over 105 years from one family.

That loyalty and commitment says a lot about what this business stands for.

I think that’s why builders trust Dahlsens. Not because we’re perfect, but because we stick around, know our stuff and work hard to have your back. Yes, we’ve got the strength of a national network, and we keep investing in safety, systems and supply. But at the end of the day, relationships matter most.

We know each other, we know you, and that makes the job easier. Thanks for choosing to work with us. We don’t take it for granted, and we’re proud to be alongside you.

Mark Cooper General Manager, Dahlsens

Over the past year, builders have shown remarkable strength in the face of mounting pressures. Rising construction costs, labour shortages, regulatory delays and building code changes have made delivering quality homes more complex than ever. Yet in every conversation I’ve had with our customers – from regional towns to the city – I’ve seen the same things: resilience and resourcefulness.

Market conditions have varied, bringing strong opportunities in some regions and headwinds in others. The recent interest rate reductions as well as the 5% deposit guarantee should stimulate an upsurge in activity but we don’t expect that to materialise until early 2026. We continue to battle increasing expenses, especially with property rentals, although this is starting to taper off.

We’re uncertain about the Government’s genuine commitment to housing affordability, given it remains a major revenue source, particularly in Victoria. For now, we’ll have to wait and see whether any

real changes emerge from the recent Federal Government workshop.

One of our major areas of focus this year at Dahlsens has been safety. We’ve welcomed a new team of safety experts and implemented new software, standards and training.

Across our network, we’ve already seen meaningful impact –reduced injuries, stronger compliance and safer sites for our teams and customers. It’s a credit to everyone involved.

I also want to acknowledge Peter Geard, who has recently stepped down from his role at Dahlsens to move onto new ventures. Over the past year, Pete led the business as CEO while I moved into the Executive Chairman position.

Pete’s contribution to Dahlsens over more than a decade has been immense. He played a key role in shaping our national merchandise strategy, strengthening supplier relationships, driving operational improvements, and guiding our business through a period of significant change and growth.

We thank him sincerely for his leadership, commitment and the positive impact he has made across the business, and we wish him every success in his next chapter.

As I return to the CEO role, I’m energised by the road ahead. We remain focused on strengthening our support for builders with professionalism, purpose and our family business spirit. We’re committed to delivering the kind of service that builders truly value – reliable, knowledgeable and personal. I also want to thank the dedicated Dahlsens team, whose hard work behind the scenes helps our customers succeed.

Thank you for your continued trust and partnership. It drives everything we do.

With carpenters in short supply and competition for skilled workers at an all-time high, builders across Australia are feeling the pinch. While many are struggling to find reliable trades, Buildoz has taken a different approach, investing in apprentices as a way to future-proof their business.

Founded in 1997, the company has grown from a small carpentry business into a major operation with more than 50 staff across carpentry and steel divisions.

But even with this growth, one of their biggest concerns remains the same as for many builders: where will the next generation of skilled trades come from?

Supporting the next generation starts early

“We used to have kids walk in the door looking for apprenticeships,” says Dana Spinks, HR leader at Buildoz. “But during and after COVID, that completely stopped. No one was asking about apprenticeships anymore.”

To change that, Buildoz didn’t wait around.

“We started showing up at schools, asking to speak with career advisors, and promoting carpentry as a real option again,” Dana explains.

To meet the federal government’s goal of building 1.2 million new homes in five years, the construction industry will need more than 83,000 additional skilled tradespeople, including 22,000 more carpenters. According to HIA, achieving this will require significant investment in training and apprenticeships, not just to meet demand, but to safeguard the future of the industry.

A long-term pipeline of new workers is essential. Training more apprentices now is the only sustainable way to grow capacity.”

ALL HANDS ON DECK: CONSTRUCTION WORKFORCE REQUIREMENTS, 2024

Now, they’re seeing results. Local schools refer students directly to Buildoz for work experience, and programs like VCAL and Head Start are helping connect interested students with opportunities.

A key part of Buildoz’s success is how they support apprentices once they’re on board.

“We’ve put a lot of legwork into it,” says Cameron Arthur, Buildoz Owner. “We offer better pay, fuel cards, and have support staff who check in weekly. We’ve even hired a full-time trainer who moves between junior crews to guide them on-site.”

For apprentices who arrive with skill gaps, or have been let down by previous employers, Buildoz has a unique solution.

“We’ll pair them one-on-one with experienced tradesmen, sometimes with 50+ years of knowledge. We make sure they’re not just ticking a box – they’re truly learning,” says Dana.

Buildoz sets high expectations, but balances that with support.

“We support without coddling them the whole time,” says Dana. “We want them to stand on their own two feet.”

“It’s not about using them as cheap labour. It’s about actually teaching them the trade,” adds Cam.

This approach includes:

Dedicated trainers

Fuel incentives and travel support

Hands-on mentoring

Engraved hammers upon qualification

Pathways to leadership roles

It all feeds into a culture of respect, pride, and progression.

The Buildoz team doesn’t expect new apprentices to arrive with all the skills. They just need the right attitude.

“If someone shows up, is willing to listen, and wants to learn, we can teach them everything else,” says Cam.

“It’s about being teachable.”

Listen to your superiors. They’ve obviously got a lot of knowledge. Just work hard at your goals.”

Ben Robertson, Apprentice JACK AMERY CONSTRUCTIONS

Supporting apprentices has helped Buildoz grow and strengthen its reputation.

“We’ve had eight guys qualify in the last 18 months alone; we aim to get around six apprentices qualified every year,” Cam says. “Some stay, some go out on their own. But we know they’re doing it right.”

Apprentices who complete their time at Buildoz are often promoted, given leadership roles, and go on to train the next generation. It’s a full-circle approach that benefits the individual, the business, and the broader building industry.

So what stops other builders from doing the same?

“A lot of companies think, ‘I don’t want a kid who doesn’t know what they’re doing walking around on site,’” says Dana. “But if you invest in them, in a few years they’ll be a massive asset.”

Cam agrees. “You need to have the right mindset and a proper support structure. Apprentices need more than just a job – they need to be taught.”

Their biggest tip? Communicate.

“Talk to your team. Talk to your apprentices. Check in. Make time to catch up with them for a beer. It builds trust and it builds commitment.”

For Buildoz, backing apprentices has delivered stronger crews, loyal leaders, and a reputation for quality. For apprentices, it’s created clear pathways into a trade with a future. The message is clear: apprentices aren’t just an investment in young people, they’re an investment in your business. Buildoz has shown what’s possible.

Congratulations on leading the way, Buildoz!

Meeting client demand for higher-performing homes is no longer a “someday” challenge –it’s happening now. With the NCC moving to 7-stars as the new minimum, more homeowners are asking: Can we go further? Can we reach 8-stars?

The good news: it’s possible. A recent Wagga Wagga build is showing that with smart design, practical choices and support from supply partners, builders can deliver 8-star outcomes without excessive cost or complexity.

For former The Block contestant, interior designer, social media influencer, and homeowner Katrina Simmonds, the idea of building an 8-star home came from wanting a more sustainable, energy-efficient lifestyle.

“I thought it would be expensive,” Katrina admits. “But most of the gains came from smart design, not fancy products.”

Builder Jamie Carroll of Jamie Carroll Constructions agrees.

“When you break it down, it’s common-sense stuff like slab upgrades, insulation, orientation and window placement,” Jamie says. “The design phase makes the biggest difference.”

In this case, upgrades included:

y Slab insulation to reduce heat transfer

y Higher R-value wall and ceiling insulation

y Carefully placed double-glazed windows for natural light and passive solar gain

y Raked ceilings to improve ventilation and thermal performance

The takeaway?

Engage draftspeople early, plan orientation and materials carefully, and you can achieve strong energy results without over-complicating the build.

Katrina didn’t just want to build a home, she wanted to share the journey.

“I wanted a builder who was up for a bit of fun and willing to be part of the process,” she says.

“I found Jamie on Instagram. People said he was awesome to work with and they were right.”

For Jamie, the collaboration was straightforward.

“Katrina had a clear vision. We worked together on making it practical, keeping costs in check and still hitting 8-stars.”

The lesson for other builders: more and more of today’s clients are informed and involved. Bringing them into the process early helps manage expectations and creates advocates for your work.

Keep communication clear and consistent

Every builder-client relationship benefits from open communication,

y Slab insulation to reduce heat transfer

y Higher R-value wall and ceiling insulation

y Carefully placed doubleglazed windows for natural light and passive solar gain

y Raked ceilings to improve ventilation and thermal performance

but it’s even more important in high-performance builds where details matter.

“Each week, I send an update –what’s been done, what’s next, any hold-ups,” Jamie says.

“Keeping

clients in the loop avoids surprises. It’s key to a smooth build.”

Katrina agrees: “It gives us peace of mind. We know Jamie has things under control, and if something goes wrong, he’s onto it straight away.”

Behind every smooth build is a strong supply chain.

“Dahlsens has been fantastic,” Jamie says. “From estimating through to site deliveries, they’ve got my back. That flow makes a massive difference.”

For Katrina, this was also reassuring. “I didn’t think much about the supplier at first,” she says, “but once I saw how well Jamie worked with the team at Dahlsens, I felt more confident. They even visited the site to check things – there’s that extra level of care.”

With tighter thermal and material specifications, reliable supply and advice are critical. Builders can’t afford delays or guesswork when aiming for higher star ratings. That’s where Dahlsens helps with project planning support, on-time deliveries and access to quality products and advice from trusted brands.

Katrina and Jamie wanted the home to be aspirational, but also achievable for everyday families.

“We haven’t gone overboard,” Katrina explains. “It’s a four-bed, two-bath home. We spent where it mattered, like raked ceilings in the living, and kept the rest practical.”

Jamie agrees.

“Delivering energy-efficient homes doesn’t mean reinventing the wheel. It’s about making smart choices, not expensive ones.”

Jamie’s message to other builders preparing for 8-star requirements is simple: “Get involved now. It’s where the industry’s going, and it’s better for homeowners. With the right design and supplier support, it’s achievable without blowing the budget.”

Katrina adds: “Builders, don’t just show the glossy end photos.

Clients want to see how you work and how you communicate. That’s what makes them trust you.”

This Wagga build proves that highperforming homes can be delivered without high stress or cost blowouts. The key is:

y Good design and early planning

y Strong collaboration with clients

y Clear communication

y Reliable supply and expert advice

At Dahlsens, we’re here to help builders achieve 8-star outcomes.

Whether it’s sourcing the right insulation, windows, cladding or structural timber, or providing wholeof-house solutions, our team works with you to keep projects on track and budgets under control.

If your clients are asking about energy efficiency, talk to Dahlsens.

Together, we can recommend solutions that can help you bring their 8-star dream home to life.

is alive and well!

From early morning kick-offs to cheering from the sidelines, local sports clubs bring people together. Dahlsens is proud to support the teams, volunteers and families who make it all happen – helping keep the spirit of teamwork, fun and community alive on and off the fields.

AI (artificial intelligence) isn’t something that’s coming in the future, it’s already here. While some builders are yet to embrace its potential, many are finding practical ways to use it every day or are already using it without it being aware. Whether it’s confirming a calculation, keeping a site secure, or saving time on paperwork, AI is becoming another tool in the toolbox.

Here are some of the ways it can help on the job.

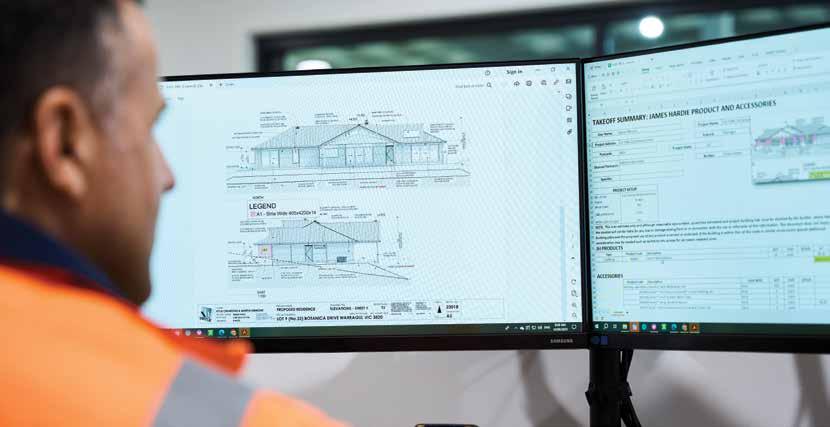

Quoting takes time. Programs like Cubit, PlanSwift, and Buildxact now use smart tech to get you started with estimates.

Many builders also use ChatGPT to check their numbers or respond to quotes. It can’t replace your skills or licence, but it’s like having a second set of eyes. You can ask it to run through a formula, explain codes in plain English, or confirm tricky measurements like Mark’s cantilever example below.

Some building software, such as Procore, are starting to introduce AI features that help spot delays before they happen. For example, if there’s rain in the forecast or a delivery is running late, the system can adjust timelines or send alerts.

This kind of technology gives you more control and fewer surprises, helping you keep jobs moving and customers happy.

Safety gear is non-negotiable, but checking everything can be a pain. AI cameras are now being tested that can pick up when someone’s not wearing a hard hat or when equipment gets too close to workers.

On the paperwork side, apps like SafetyCulture and SiteDocs use AI to scan forms, photos, and checklists, then store them neatly. Instead of filing stacks of dockets, you can take a photo and have it sorted automatically.

Have you tried any of these?

We’ve been using AI for visualising different aspects in the home. We’ve been taking photos of homes and mixing colours and tweaking designs”

Jamie Carroll, Director

JAMIE CARROLL CONSTRUCTIONS

Clients often struggle to picture the finished job.

AI image tools like Midjourney can turn a quick description eg: “brick veneer home with timber cladding,” into a realistic picture in minutes. It’s not a replacement for design work, but it can help everyone get on the same page early, avoiding changes later.

AI is also being built into gear tradies already use:

y Smart measuring tools that record dimensions straight to your phone.

y AI locks and cameras that improve site security.

y Voice-to-text apps that let you talk through your job notes hands-free.

All simple, practical ways to save time and cut errors.

If you run your own business, AI can help with the “other” side of building: winning work. ChatGPT or Canva’s AI features can draft quotes, social posts, or client emails. They don’t replace your voice, but they can polish things up and save hours at the desk.

“AI tools help you work more efficiently, like when lumberjacks switched from axes to chainsaws.”

VIVEK SHETTY, DAHLSENS BUSINESS SYSTEMS CONSULTANT

I’ve used AI on this recent project to help us see what the architect was trying to give us when the information wasn’t clear. It helps us keep moving. I asked ChatGPT to double-check my cantilever calculation. It gave me the same answer I’d worked out. A bit of peace of mind on a tricky job.”

Mark White, Project Manager JACK AMERY CONSTRUCTIONS

From admin to presentations, I use it daily.”

Blaise Fisher, Co-Owner/ Product Manager and Special Projects

SOUTHERN VALE HOMES

AI won’t replace you, but it can take on some of the admin jobs like quoting, scheduling, etc, so you can focus on the build and the relationships with clients. It can help keep sites safer, customers better informed, and businesses looking more professional.

As Mark, from Jack Amery Constructions said: “It’s so easy to access directly on your phone.”

With AI as part of your toolkit, the job gets a little faster, a little safer, and a lot smarter.

Buildxact is the estimating and job management software trusted by many builders across Australia and it connects directly with Dahlsens.

That means you can:

Get your Dahlsens account specific pricing right inside your estimate

Order materials online in just a few clicks

Save hours chasing quotes and reduce the risk of mistakes

Finish material takeoffs in a fraction of the time

It’s one more way Dahlsens helps you keep your jobs on time, on budget, and stress-free.

TALK TO YOUR DAHLSENS ACCOUNT MANAGER TO LEARN HOW BUILDXACT CAN STREAMLINE YOUR BUSINESS.

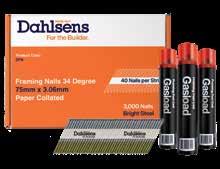

Dahlsens now offers collated framing nails, compatible with all leading pneumatic, fuel and battery powered nailers.

We’ve put these framing nails to the test on-site, and they deliver power-packed performance for heavy-duty framing. Available in Bright Steel or Hot Dipped Galvanised options, the 75 x 3.06 D Head collated nails are built for speed and efficiency.

Pair them with Dahlsens Gasload Fuel Cells for even greater savings and keep more money in your back pocket.

How do Dahlsens Framing Nails stack up?

y Compatible with 34 degree framing nailers

y Box of 3,000 framing nails

y Reliable results – won’t jam

y 40 nails per strip

y Great choice for frame, subfloor and timber fastening

y Pair with Gasload Fuel Cells for unbeatable value

Sharp v-groove joins with embedded render texture – a stackable textured board, built to last.

Strong and robust 14mm thick board with embedded render texture.

Easy and cost-effective

Concealed fix, no face fixing or patching required. Engineered to endure

Fire, rot, moisture, and termite resistant fibre cement.

Watch install here

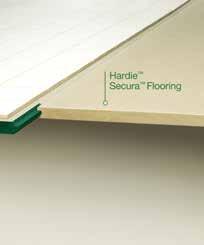

Need to hit 7-stars? Upgrading from particle board to Secura™ Flooring can help

Improved thermal performance

Durability and longevity

Versatile applications (bathrooms, decks, full-floor systems)

The NSW South Coast turned tropical when our Nowra and Ulladulla teams, with support from supplier partners, delivered a trade night to remember at the Nowra Golf Club.

Builders and suppliers joined in for an evening of good food, product showcases, and a holiday-themed party atmosphere with Hawaiian shirts, leis, lucky door prizes and drawing of the Build & Escape winners.

Huge cheers errupted when two of our loyal customers, South Coast Hotondo Homes and Contractors United, were announced as the winners of $15,000 dream holiday escapes! Three more builders also scored Visa gift cards, adding to the smiles.

The Build & Escape promo ran for three months, rewarding active Dahlsens Trade Account holders with prize draw entries every time they purchased qualifying trade or truss & frame products.

A huge thank you to all our supplier partners and especially to major sponsor Pryda for helping us make this promotion and event one to remember.

This is what being a Dahlsens customer is all about – feeling rewarded, supported, and part of something special.

In north-west Victoria, the celebrations kept coming with two Dahlsens grand openings.

At Mildura, more than 80 tradies packed out our brandnew, purpose-built trade store on Benetook Avenue. The highlight of the night? Brett Harvey from Brett Harvey Plastering winning a Quintrex F420 Explorer Trophy boat with a 50hp Yamaha motor, valued at over $35,000!

Just two days later, the party moved to Swan Hill, where another fantastic crowd of local builders joined us at our new Karinie Street location. And yes – another major prize! Long-time Dahlsens customer Mark Seneia sailed away with his very own boat package.

Both nights were packed with supplier showcases, product demos, great food, and plenty of laughs. The grand openings also marked a special moment, with fifth-generation Chairman Geoff Dahlsen officially cutting the timber in Mildura, joined by fourth-generation owner John Dahlsen who spoke about our ongoing commitment to regional builders.

A huge thanks goes to our major prize sponsors Pryda, Everdeck by Timberlink, Hyne Timber, James Hardie and Meyer Timber, along with every supplier who came along to showcase the latest solutions.

SERVICE PLUS! Why builders choose Dahlsens

Big nights and major prizes Access to the latest products and supplier know-how

local team that values every customer

Thanks for being part of the Dahlsens community!

Step into modern mediterranean elegance with the LUXE Range.

y Six elegant designs

y Engineered shaker-style construction

y Fluted, translucent or clear glass options, plus pre-primed MDF or routed batten inlays

Classic Roman-inspired design meets modern craft.

y Convex fluted MDF panel

y Glazed option with reeded glass

y Durable stile and rail joinery

y Primed for your preferred finish

Complete range of luxe internal hardware.

y Satin brass, satin gunmetal, satin bronze

y Matching levers, pulls, sliding components, door stops

y Durable PVD finish – 4x harder than chrome

Trilock Cove Harper & Trilock Cove Lianna

y Slim modern backplate design

y 3-in-1 lock tech (deadbolt, privacy, passage)

y Matte black, satin chrome, bright chrome

y Builder key compatible

Special Finishes Collection

Gainsborough Mode

y Unlock via keypad, fingerprint, RFID, voice control

y Passage or auto-lock mode

y Available in black or graphite

y Builder key compatible*

*Excludes

y Entrance and internal levers matched across the home

y Available in white, satin brass, matte black, satin chrome and satin graphite

y Builder key compatible

Kyra Smart Lock

y Push-pull design

y Auto lock

y Yale Home App enabled

Luna Pro+ Smart Lock

y Face recognition

y Fingerprint, PIN, RFID or app access

y Fast, smooth auto lock

ByYou Lock

y Fingerprint in handle

y PIN, RFID, or app unlock Apple Home Key built-in

In late August 2025, the Commonwealth government announced that it would be pausing non-essential changes to the National Construction Code (the NCC). This is an important announcement and one that is welcomed by HIA.

However, the announcement did cause some confusion. It was also criticised by some who have different priorities to HIA and other mainstream stakeholders.

This article clarifies what was actually announced and what is likely to happen to the NCC.

A lot of media reporting has been unhelpful. References to a “freeze” of the NCC are not accurate and create the unfair perception that the pause is a backward or negative step. And this description has been used by critics of the announcement.

The announcement is not a backward step. The already robust NCC which was significantly updated by NCC 2022 amendments remains in place. Homes built to NCC 2022 standards need to meet 7-star energy efficiency requirements and livable housing accessibility requirements.

These homes are significantly better than the bulk of the established homes that Australians live in.

What was announced was really a slowdown of the pace of change of the NCC. This allows the home building industry, including not only builders and trades but also manufacturers and suppliers, to have more time to implement recent changes like NCC 2022 and also more time to adjust to future NCC amendments. This will not only help the industry but also relieve pressure on the cost of home building and improve housing affordability.

The slowdown consists of two parts.

First, we have the NCC 2025 amendments which are yet to be finally considered by the Building Ministers who approve them. These amendments have been out for public consultation and are available on the Australian Building Codes Board. It is expected that these amendments will be reviewed and only essential amendments retained for approval by the Building Ministers. Unfortunately it is not yet possible to know which amendments will be retained.

Second, the next NCC round of amendments, which would have been NCC 2028, is now being pushed back to 2029. This slows down the pace of NCC changes by at least a year.

In addition, the Commonwealth government at the same time announced it would examine how to improve the process for the development of NCC amendments. This will be undertaken while before the NCC 2029 process is completed.

HIA will continue to provide input to governments around the country about the NCC and the amendment process. HIA members should look out for further information and guidance as it becomes available.

Keith Ryan EXECUTIVE DIRECTOR – VICTORIA

HIA offers a range of events and short courses. Members also get access to information sheets and can speak to our advisors. Visit hia.com.au to find out more.

A simple “thanks” goes a long way.

That’s why we’re asking our valued trade customers to share their great experiences with a Google review. Each month we’re drawing one winner to receive a $150 team lunch voucher. This could come as a gift card, a local food delivery credit, or similar. Whatever works best in your area.

How to enter

1. Leave a Google review for the Dahlsens store you’ve been serviced by

2. Take a screenshot of your review

3. Email it to: enquiries@dahlsens.com.au and include your name, business name and contact number or email

Entries close on the last day of each month. One winner is drawn on the first business day of the following month.

Autoclaved Aerated Concrete (AAC) is a highperformance, lightweight building material made from sand, cement, lime, and aluminium powder. Cured under heat and pressure, AAC is known for its excellent strength-to-weight ratio, fire resistance, thermal performance, and ease of installation making it an ideal solution for modern Australian construction.

Now available at Dahlsens, Eastland AAC is a premium AAC panel system used by builders around the world. Whether you’re working on a new home or a multiresidential project, Eastland AAC helps you get the job done right – and faster.

Why builders are switching to Eastland AAC

y Lightweight yet strong

y High thermal resistance – ideal for 7-star homes

y BAL rated, non-combustible, CodeMark certified

y Steel reinforced and corrosion protected

y Cost-effective and easy to install

y Versatile finish options

y Install in days, not weeks unlike bricks

y Suitable for external walls, boundary walls, party walls, and flooring

Product range

y 50mm panels: 2400mm - 3000mm

y 75mm panels: 2400mm - 3300mm

y 24mm & 35mm 4.8m perforated tophats

y Eastland adhesive 20kg

In stock at Dahlsens. Add to your 30-day account.

CLADPRO benefits:

y Licensed domestic builders with 50+ years experience

y Over 600 completed projects

y Expert installers trained to install to guidelines and Australian standards

y Managed via TRAK system for safety, compliance and documentation

y Ideal for new homes, recladding, multi-residential and commercial jobs

CLADPRO installs:

y External walls

y Boundary walls

y Party walls

y Flooring (AAC & Alphafloor)

Save time on site and keep your projects moving with professionally installed insulation, arranged directly through Dahlsens. Whether you’re building one home or managing multiple sites, our streamlined service takes the hassle out of insulation install, so you can focus on the build.

STEP 1

Send your plans to your Dahlsens contact.

STEP 2

Receive a free takeoff and quote to your specifications.

STEP 3

Approve the quote and provide your site supervisor’s contact details.

STEP 4

Your site supervisor works directly with Dahlsens to coordinate check, measure, install and final sign-off.

That’s it!

We take care of the rest.

We supply and install a wide range of insulation types including:

y Glasswool

y Rockwool

y Rigid board

Please note: spray insulation is not currently available.

You’ll have access to high-quality insulation products from industry-leading brands including Bradford and Fletcher.

One less thing to manage

After the order is placed, Dahlsens coordinates the install on your behalf

Save time and avoid delays

Free takeoffs, fast quoting and smooth install coordination with your site team

Expert support when you need it

Product advice and help with planning from the team you trust

Professional results

Quality insulation installed on time to keep your project on track

Talk with your Dahlsens account manager today to arrange insulation install for your next project.

When Johan Dahlsen uncovered gold in the late 1800s, he could never have imagined the legacy he was about to create.

During the 1877 Bairnsdale gold rush, Johan, a Danish immigrant, discovered not only gold but also opportunity in the booming economy. After selling an oversupply of his own timber, he recognised the town’s growing need for building materials and established a timber business to support regional Victoria’s growth.

Johan Dahlsen

What began as a small venture soon became a multi-generational legacy. Today, Dahlsens is proudly in its sixth generation, with more than 70 sites nationwide. Despite this growth, the business has never lost sight of its origins: supporting builders with quality materials, expert advice, and trusted relationships.

The values that started it all: integrity, hard work, and commitment, remain at the heart of the business. For the Dahlsen family, stewardship is both a privilege and a responsibility: upholding the name, supporting the industry, and helping other family businesses grow.

“Not many businesses make it past the second generation, let alone the fifth or sixth.”

“Not many businesses make it past the second generation, let alone the fifth or sixth,” says owner, John Dahlsen.

The focus today is on moving forward: investing in communities, expanding products, and constantly improving service. Yet one principle remains the same – helping builders succeed.

Builders have always valued more than price. They seek reliability, knowledge, and support. From firsthome builders to large operators, Dahlsens provides not just materials, but confidence. Many builders have partnered with Dahlsens for decades, even across generations.

Johan Dahlsen may have found gold, but the true treasure was the opportunity to build something that lasts.

Guided by the same values, the sixth generation continues to grow a business that helps builders succeed.

What would you do if you

At the moment, I’d probably pack up and do a lap around Australia. It’d be better than some of the things we usually dig up. So I’d be out of here.

Brad Stockley, Director and Builder STOCKLEY CONSTRUCTIONS

If I struck gold, I’d get GJ Gardner Albury to build me a giant house and I’d get a bigger boat.

Simon Cosser, Construction Supervisor GJ GARDNER ALBURY

I’d be outta here. I’d probably stop working.

Matt Gow, Builder MATT GOW CONSTRUCTIONS

Travis Knight, Director BUILT BY TK

If you’re looking for a quicker, safer and easier way to put together floors, or even a solid alternative to iJoists, Pryda’s engineered prefabricated floor trusses could be just what you need.

Manufactured by Dahlsens and delivered ready to install, Pryda floor trusses help keep projects on track by removing complexity onsite, saving time for trades and reducing the risk of errors or delays.

There are two key truss types available to suit a wide range of residential and commercial applications:

Engineered open-web trusses designed for superior performance, longer spans, and deeper floor voids. Longreach trusses can take loads from above, removing the need for additional supports.

Ideal for shallower floor systems where slim profiles and easier service penetrations are required.

Both systems are designed with Pryda software, making sure they meet the latest building code rules.

They’re easy to approve with a clear certification process, and work smoothly with plumbing, heating, cooling and electrical services.

Pryda floor trusses are custom made to suit unique spans, wet areas or deeper floor systems. They arrive pre-cut which removes the need for further cutting, reduces errors, and improves safety. The top chord support also reduces joist hangers needed.

Extra-large holes and deeper voids make service installation faster and neater which saves time and money onsite.

The Pryda floor trusses are fully NCC compliant and designed using

industry leading Pryda software. One supplier means complete traceability and simplifies the approval process.

The strong, stiff Pryda floor trusses manufactured by Dahlsens are engineered to reduce bounce and provide a superior result.

Multi-storey homes

Great for houses with more than one level. Space for ducting, plumbing, and electrical. Reduces floor bounce and improves sound performance.

Sloping sites / split-level designs

Makes it easier to create flat, level floors over uneven ground.

Renovations and extensions

Handy when clear spans are needed over existing structures.

Townhouses, duplexes, units

Speeds up installation across repeating designs and allows simple service integration.

Architectural homes

Perfect for open-plan spaces needing long spans, fewer supports, and hidden services.

Small-to-medium commercial builds

Offices, childcare, aged care, etc. Trusses give clear spans for flexible layouts and easy fit-outs.

Wet areas

Bathrooms and laundries needing set-down floors (especially with Pryda Longreach Trusses).

Basements / subfloors in reactive soils

Works well with suspended floor systems.

Why builders choose Pryda engineered floor trusses from Dahlsens

Quick to install: Delivered pre-cut with big service holes, so less cutting and drilling on-site

Less labour, safer sites: Fewer cuts mean fewer risks and faster build times

Flexibility: We can design and manufacture any height of floor truss between 190mm and 500mm

Shower set downs to measure: Floor trusses can be specifically designed with set downs for each shower

Big open spaces: Long spans mean fewer internal walls and more design freedom

Built to code: Engineered for strength, sound, and fire safety

Reliable support: Backed by Dahlsens’ expert team and national network

From favourite tools to big dreams, we love hearing from you. Your passion and dedication to the trade makes our industry better.

What’s your favourite tool?

“The nail gun. We’d be lost without it.”

BRAD STOCKLEY, DIRECTOR, STOCKLEY CONSTRUCTIONS

“A circular saw.”

SIMON COSSOR, CONSTRUCTION SUPERVISOR, G.J. GARDNER ALBURY

“The trusty old jackhammer. It does the most damage.”

BEN ROBERTSON, APPRENTICE, JACK AMERY CONSTRUCTIONS

“Paslode. It’s the one we use the most.”

MATT GOW, BUILDER, MATT GOW CONSTRUCTIONS

“A handsaw and laser level. Simple but effective.”

JAMIE CARROLL, DIRECTOR, JAMIE CARROLL CONSTRUCTIONS

What music gets you pumped for the day?

“I admire the old blues. Johnny Cash and Kris Kristofferson.”

MARK WHITE, PROJECT MANAGER, JACK AMERY CONSTRUCTIONS

“This morning I had Hilltop Hoods’ The Nosebleed Section cranked –and that got me going.”

BLAISE FISHER, CO-OWNER/PRODUCT MANAGER AND SPECIAL PROJECTS, SOUTHERN VALE HOMES

“Anything Dom Dolla. He’ll get you pumped.”

BRAD STOCKLEY

“I’ve started listening to country music... Morgan Wallen songs get me going.”

BEN ROBERTSON

What’s your standard breakfast?

“Varies. Sometimes cereal, sometimes fruit.”

TRAVIS KNIGHT, DIRECTOR, BUILT BY TK

“A couple of pieces of toast and a strong coffee.”

SIMON COSSOR

“Peanut butter on toast, or a pre-workout and gym, then off to site”

BRAD STOCKLEY

If you had an extra hour in the day, how would you spend it?

“Fishing or playing golf”

SIMON COSSOR

“Bit more daylight to hang with the kids in the afternoon.”

MATT GOW

“Time with my young daughter.”

BRAD STOCKLEY

“More housework – working on the garden and lawns.”

BEN ROBERTSON

“Out on the water with the kids in summer.”

BLAISE FISHER

What’s your proudest project?

“My own home. It’s been our biggest project to date, and the feedback has been fantastic.”

BRAD STOCKLEY

“A log cabin in the bush with just a chainsaw and an axe, that was fulfilling.”

MARK WHITE

“My own house, using my own hands.”

BEN ROBERTSON

Thanks to all the legends who shared with us. We love dropping in, getting to know you and seeing the amazing projects you’re working on!

Available at

In a building industry increasingly dominated by corporates, many builders are choosing to stay independent, and are looking for suppliers who do the same.

Dahlsens has been proudly family-owned for almost 150 years. Independence is how we operate, and this model gives builders the support and flexibility they need to succeed.

“As the owners and operators, we understand the success of our business depends on the success of our customers,” says Geoff Dahlsen, CEO and fifth-generation family member. “We don’t have anonymous shareholders demanding profit. We’re in this for the long haul – focused on providing jobs, futures and value.”

“We’re in this for the long haul – focused on providing jobs, futures and value.”

Competitive supply, independent service

“We are a member of independent buying groups; Natbuild, Plumbing Plus and Steeline. This provides national scale buying power so we can offer the best pricing.”

“Buying groups help us secure competitive pricing and trusted supply partnerships, so builders get the best of both worlds – great value and reliable support, without losing the local service and know-how that comes from working with an independent,” says Geoff.

Dahlsens works with thousands of builders, many family-run, owner-operated and growth focused.

“Even those building hundreds of homes a year still have that entrepreneurial mindset,” says Geoff. “The best relationships are the ones where both sides see the world in a similar way.”

Our people-first approach supports:

y Builders with expert advice and supply reliability

y Supply partners with strong, respectful partnerships

y Our team with the empowerment to act and solve problems

y Our communities through local contributions

“We’re not about transactions. We’re about real relationships built on trust, respect and doing the right thing,”

Geoff Dahlsen CEO

Independent builders deliver flexibility, personal service, and strong community ties. Dahlsens operates the same way.

“Because we’re involved in the business day in, day out, we can make the right decision on the right day,” says Geoff.

Whether it’s rescheduling deliveries, sourcing unique products, or solving last-minute issues, Dahlsens acts fast, because team members are empowered to.

The team at Dahlsens are excellent to deal with. They’re good and honest people, who go above and beyond for us, make sure our products arrive on time, and always stick to their word. I really can’t ask for more than that.”

ALLCHIN BUILDERS, 2025 MASTER BUILDERS RESIDENTIAL REGIONAL BUILDER OF THE YEAR

In a fast-moving environment, reliable supplier partnerships make all the difference.

“We don’t just say we care, we show it,” says Geoff. “Our customers are partners, not numbers.”

Whether you’re building five homes or five hundred, Dahlsens brings the same care, consistency, and commitment to every relationship.

Dahlsens is proud to support the builders who choose to stay independent, and we work every day to earn your trust.

If you’re looking for a decking solution that’s easy to work with, made for Australian conditions, and adds value to your builds Everdeck® by Timberlink is worth a serious look. Now available through all Dahlsens stores, Everdeck is a high-quality, sustainable wood composite decking made in Tasmania from a blend of recycled Australian plastic and plantation wood fibre. It’s designed to last, looks great, and keeps maintenance to a minimum – all at an affordable price - exactly what your clients are asking for.

“We would definitely recommend Everdeck to other builders,” says Kai Wong from Riser Bespoke Builders. “It’s really easy to install, and we’re impressed with the outcome.”

With its concealed fixing system and dual-colour design for flexibility, Everdeck is made for clean, fast installs and modern finishes. Use the free online Everdeck Planner tool to design your layout, explore colour options, and get a materials list to send straight through to your Dahlsens store.

Crafted in Tasmania, Everdeck is engineered to handle harsh sun, rain, and everything in between. With a 20-year warranty for residential applications, you can offer clients peace of mind and a beautiful finish that will last.

With a natural timber-grain finish and six modern colourways inspired by the Australian landscape, Everdeck helps you create stylish, low-maintenance outdoor spaces that your clients will appreciate for years to come.

“You don’t really need ongoing maintenance,” says Kai. “Just your normal sweep and wash down – and it still looks absolutely beautiful.”

Made in Australia: Using at least 50% plantation timber residue such as wood shavings

Easy to care for: No need for sanding, sealing or staining

Simple to install: Concealed fixings for a clean finish

Great value: Great value that lifts the look of your builds

20-year warranty: For residential applications meaning long term durability you can count on

We’ve been getting good feedback from clients... We’ll definitely be using Everdeck again.”

Kai Wong

SITE SUPERVISOR, RISER BESPOKE BUILDERS

Everdeck decking boards, edge boards and concealed fasteners are available through all Dahlsens stores across Victoria, New South Wales and the ACT.

Contact your Dahlsens Account Manager or store to get started, request a sample or quote.

Try the Everdeck Planner or order a sample here:

Because like Dahlsens, they’ve built a reputation on reliability, relationships, and innovation that makes life easier for builders.

A legacy of trust

50 years supporting Aussie builders

Family owned and operated

Reliable supplier of compliant timber

When you use meyWALL for framing you get:

y Consistently straight timber that won’t bow or warp

y Equivalent stiffness but higher strength than MGP10

y Permanent weather protection, anti-mould and UV resistant

y H2 termite treated

y Compliant to Australian standards

y Eased edges: Safer to handle, smoother to install

Meyer Timber has grown from a one-truck timber supplier to a leading force across the east coast of Australia. Their commitment to smarter building products, like meyWALL, aligns perfectly with Dahlsens’ promise to deliver quality materials and advice, when and where you need them.

Dead straight LVL = dead straight walls

Save time and labour straightening walls

Keep projects moving to lock-up

meyWALL helps keep projects on schedule and on budget.

Ask your Dahlsens account manager about how meyWALL can help streamline your next build.

Aussie made weatherboards and cladding made for Aussie jobsites.

Codemark & Platinum Global GreenTag certifications

100% natural with NO chemicals, NO silica and NO glues

Quick, less wastage & easy to install using standard carpentry tools

Lightweight, flexible and safe to use

For advice on your next project or a FREE Weathertex takeoff, speak to your local Dahlsens representative.

Why did Katrina Simmonds, interior designer and former contestant on The Block, choose Weathertex for her own home?

”Weathertex was selected not just for its low carbon footprint, but also because it’s Australian made, toxin free and incredibly durable. It aligned perfectly with the sustainable design principles we were aiming for. I’ve seen first-hand how well it performs in real builds, and now I often recommend it to clients looking for beautiful and ecofriendly cladding solutions.”

See how Katrina’s house is coming together on page 6.

Looking for a wall wrap that ticks all the boxes for moisture control, durability, and code compliance? VapourFlex® vapour permeable membrane (VPM) delivers.

Vapour out, sealed

Class 4 vapour permeable with a built-in water barrier to reduce condensation risk.

Strong and flexible

Lightweight, durable, and tear-resistant: easy to handle on-site.

Built to last UV resistant for up to 90 days and low flammability (≤5) for bushfire compliance across all BAL zones.

Versatile

Ideal for all cladding types: brick veneer, weatherboard, timber, and fibre cement. Use on residential and commercial sites.

Compliant where it counts

Meets NCC 2022 condensation management, sarking-type exemptions, and bushfire regulations.

Custom branding available

Use your builds as billboards for your brand.

y External wall and gable applications

y Behind all cladding types

y In climate zones 2–8

y When you need to start internals before cladding goes up

y 2740mm x 30m (82.2m²)

y 1500mm x 30m (45m²)

y 1370mm x 30m (41.1m²)

Ask your Account Manager or visit your local store.

When the pressure’s on and it feels like life keeps throwing curveballs... don’t tough it out alone. TIACS provides free, confidential counselling to tradies, truckies, farmers, blue collar workers and their loved ones.

Proudly supported by

TIACS is the home of blue collar counselling for tradies, truckies, farmers, blue collar workers and their loved ones, Australia wide.

Text or call 0488 846 988 Mon to Fri – 8am-10pm

If fire-rated party walls are slowing down your builds, costing too much in labour or needing repairs, it’s time to take a serious look at ProBoard, a faster, more cost-effective wall system now available at Dahlsens.

Developed specifically for medium-density and multi-res projects, ProBoard saves you hours on-site, reduces call-backs, simplifies compliance and puts more money in your back pocket.

No fiddly metal channels or complicated systems. Just a smart, durable system that installs fast and stands the test of time.

“It’s very simple and quick to install,” says Daniel Khalaf from ProBoard.

“There are only three components in addition to the panels. The panels are lightweight and chippies find it straightforward to install. You don’t need any specialty trades involved.”

Most building companies I know have been waiting for a product like this, as conventional methods are outdated. It truly ticks all the boxes. The real bonus, however, is the cost savings. Our clients achieved substantial savings using ProBoard compared to other systems, without compromising on performance or compliance.”

Robert D’Ambrosio MANAGING DIRECTOR

D’AMBROSIO

CONSTRUCTION GROUP.

Significant savings

Compared to traditional, plasterboard party wall systems, ProBoard is 15% cheaper on average –and that’s just for the product.

Save time on-site

The shiplap design eliminates the need for metal C-channels and complex fixing systems.

ProBoard has just a simple, three-component installation system.

“There are no channels,” Daniel explains. “It sits directly on the slab with a bead of fire-rated sealant.”

Lower your installer costs

Lightweight panels that install with standard carpentry tools mean faster installs with your existing crew of chippies. No specialists needed.

Impact resistant

As a magnesium oxide (MgO) panel reinforced with fibreglass mesh, ProBoard is extremely durable and built to withstand impact that may happen on site.

Reduce call-backs and improve peace of mind

ProBoard is mouldproof and water resistant. You can leave it out in the weather and never worry about call backs due to mould at a later date.

“It’s designed to reduce labour costs and eliminate all repair costs,” says Daniel.

Compliant and proven

ProBoard is CodeMark certified for steel and timber framing, fully non-combustible (AS 1530.1) and achieves FRLs of 60/60/60 and 90/90/90, helping you meet code with confidence.

Lighter, smarter, greener

ProBoard is very easy to lift and cut. It’s also made from responsibly sourced MgO, with a lower carbon footprint than traditional alternatives. Choose the system that suits your build.

y 18mm ProBoard shiplap = 60/60/60 FRL

y Designed to resist water and mould

y Simple install — just screw off at 200mm centres

y 10mm ProBoard = 60/60/60 FRL

y 14mm ProBoard shiplap = 90/90/90 FRL

y Ideal for boundary and external walls

“Finally, a better alternative to plasterboard is here.”

ProBoard systems, aluminium accessories and install manuals are available through Dahlsens stores in Victoria and only available through Dahlsens in NSW and the ACT.

Builders are turning to Biowood, an architectural composite cladding that gives a beautiful finish without hassle.

In a class of its own, Biowood stands out amongst other composite timber products thanks to its composition – Biowood has a high wood content at 69% PEFC-certified recycled wood and is made from 23% hard PVC – not soft PVC like other wood composites.

This makes Biowood a lighter, more durable option, that is cooler to touch in the sun. It’s also CodeMark certified, has a BAL 29 compliant option, and is backed by a 15-year warranty – giving you and your clients total confidence.

One of the most compelling features of Biowood is that it can be sanded and resealed thanks to its high wood content. While it promises long lasting good looks, Biowood can be refinished if it’s damaged on site.

y No special tools required –cut with a standard timber blade

y Faster installs and fewer crew needed

y Curves achievable with castellated and shiplap profiles

y Ideal for integrated garage doors

y Minimal colour fade (only 5% over 5 years)

y Can be sanded and resealed

y Lightweight and durable cladding built to withstand Australia’s harsh climate

“Cladding is my bread and butter. I had my doubts at first, but when we finished the job with Biowood it looked beautiful – no errors, no scratches. It’s the best.”

Harman Kataria CARPENTER, WILLOWTREE CONSTRUCTIONS

Biowood is made to perform, indoors and out:

y Won’t splinter, crack, or warp

y Under 0.05% water absorption – perfect for marine or poolside projects

y Very low VOC emissions –safe for childcare and healthcare facilities

y Global Green Tag Platinum Health certification

y Wide range of colour options available:

Ì Natural oak

Ì Western red cedar

Ì Lexicon white

Ì Black Japan

Ì Spotted gum

Ì Deep walnut

“The strength and durability is really nice. It holds secure. The finish here is like an industrial look, but you can make any finish you want with the range of Biowood products.”

Harman Kataria

“We saved so much time using Biowood. It was quick as. Because of the small sizes, just one or two guys are needed. You don’t need a big crew.”

Harman Kataria

It’s not just trades on the tools who see the value. Estimators are backing Biowood too.

“The main reason we went for Biowood was that it comes in the right look, the right feel and the right price.”

Haris Brkic, SENIOR ESTIMATOR, PEMBROOK HOMES

“The owner and the builder were so happy with the installed product. Once they saw it, they loved it.”

Harman Kataria, CARPENTER, WILLOWTREE CONSTRUCTIONS

Thanks to Pembrook Homes and Willowtree

Constructions for the great feedback. We’re so pleased you were happy with your choice and service from the team at Dahlsens Laverton.