Design and Architecture

Portfolio

By Chanika Wijesekera

By Chanika Wijesekera

JAN 2024

PRESENT

Graduate Designer

Hello!

My name is Chanika, and I am an Australian-Sri Lankan from Sydney. This mixed background has fuelled my interest in cultural and political architectural design. Hence, I am passionate about design that is accessible to everybody and is a positive social intervention. I love good design.

FEB 2022DEC 2024

Visitor Interpretation Officer

Museums of History NSW

I communicate architectural interpretation and provide tours of historical houses, heritage buildings, and cultural exhibitions to different audiences. I also undertake maintenance and housekeeping of these significant buildings.

Exhibition Assistant and Gallery Host

Chatswood Art Space on the Concourse

I supported the curator(s) throughout the developmental process of cultural exhibitions, most notably collaborating with installers in the handling, assembling, displaying, and dismantling of original art and installations.

AUG 2022

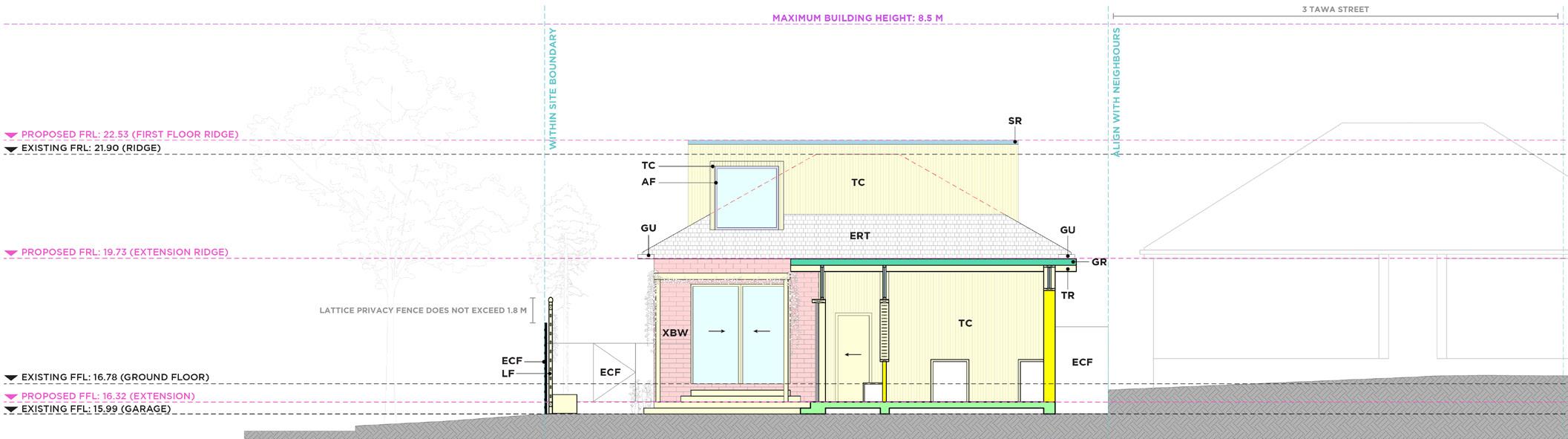

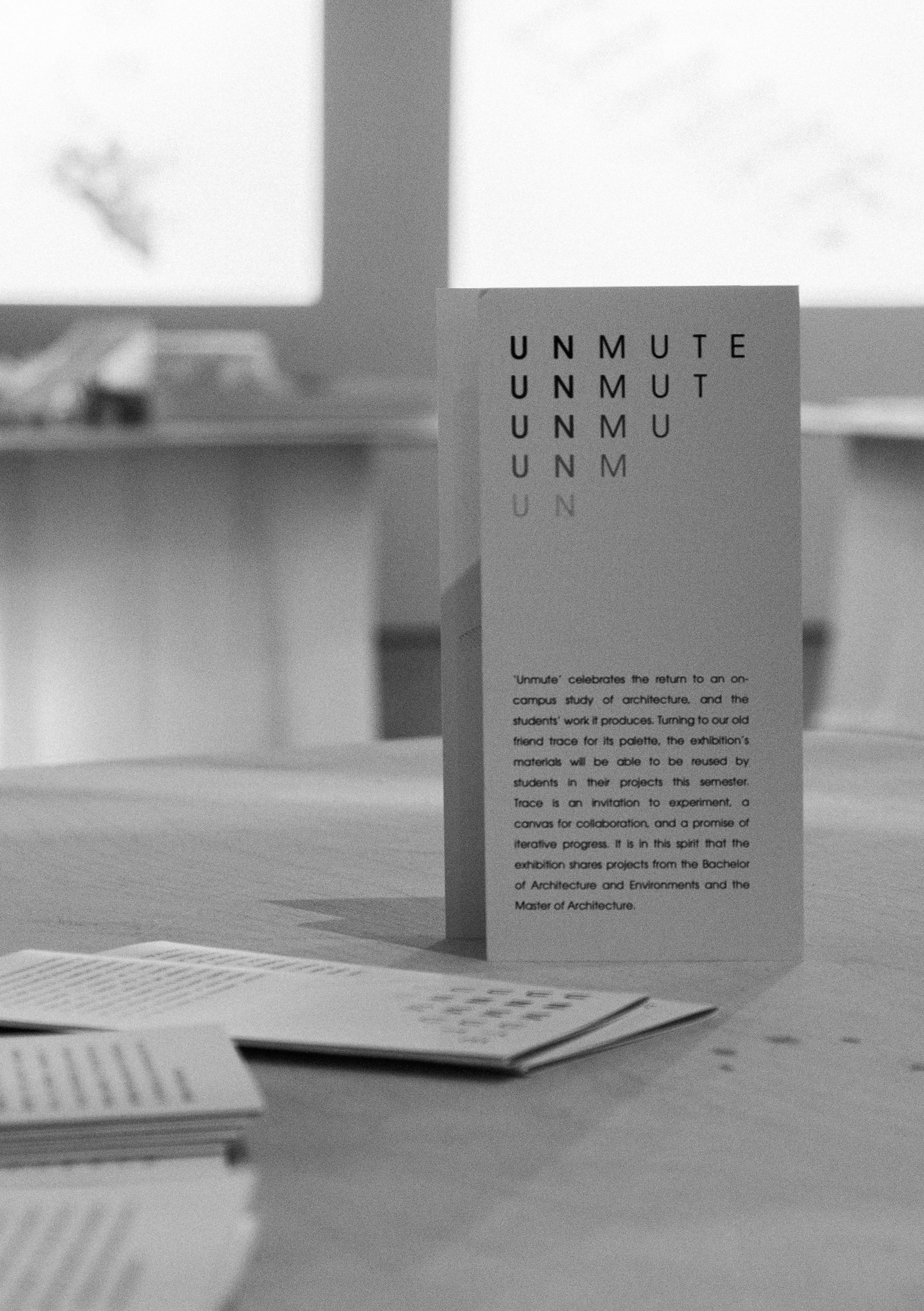

UNMUTE Exhibition Designer and Coordinator

The University of Sydney, Wilkinson Building

UNMUTE was a highly collaborative student exhibition where I designed interactive objects, lighting, multimedia, and displays to encourage audience engagement. Moreover, we ensured to meet the building and safety standards.

MAY 2018NOV 2019

Junior Draftsperson Internship

Algorry Zappia & Associates Pty Ltd.

Australian Born Citizen TO BE GIVEN UPON REQUEST

chanika.wijesekera@gmail.com

I was responsible for assisting in detailing and finalising interior and construction architectural drawings and specifications using ArchiCAD software. This process involved proofing my amendments with supervisors and engineers.

Bachelors of Architecture and Environments

The University of Sydney

Feburary 2020 - May 2023

81 WAM (Weighted Average Mark): Distinction

ADOBE CC

CAD + BIM

RENDERING

Full Driver’s License (New South Wales)

White Card

Rhino Beginner, Design and Advanced (ArchiStar Academy)

Accredited Vectorworks Associate Core Certification

Working with Children’s Check Employee

Working with Children’s Check Volunteer

HLTAID011 – Provide First Aid (972976) Course Certificate

TO BE GIVEN UPON REQUEST

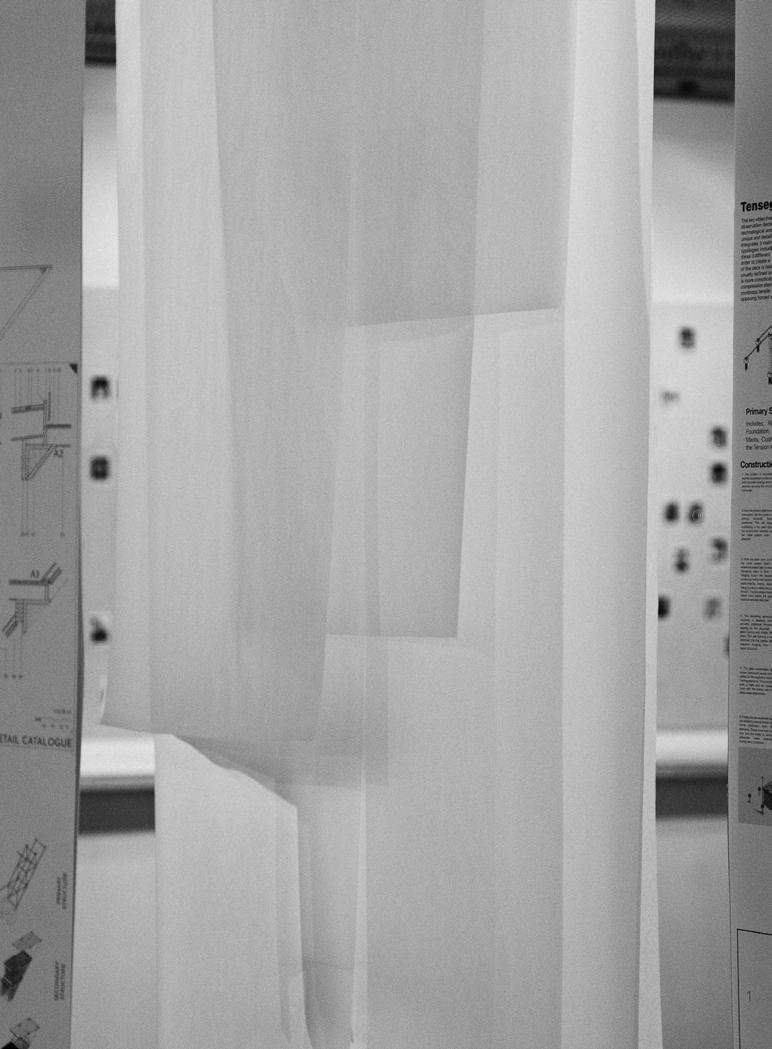

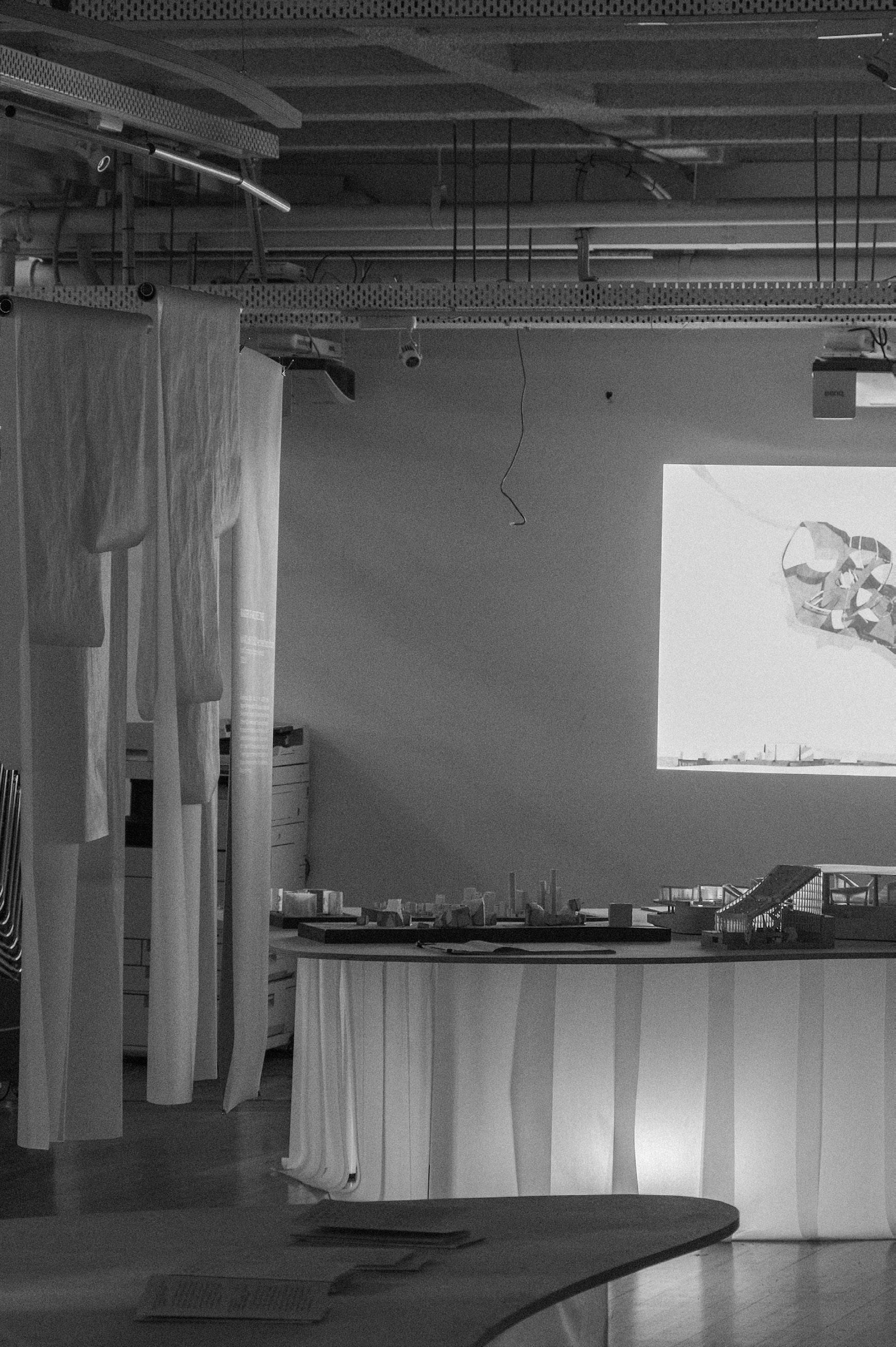

‘Unmute’ celebrates the return to an on-campus study of architecture, and students’ work. Students are now unmuting themselves and are hands-on.

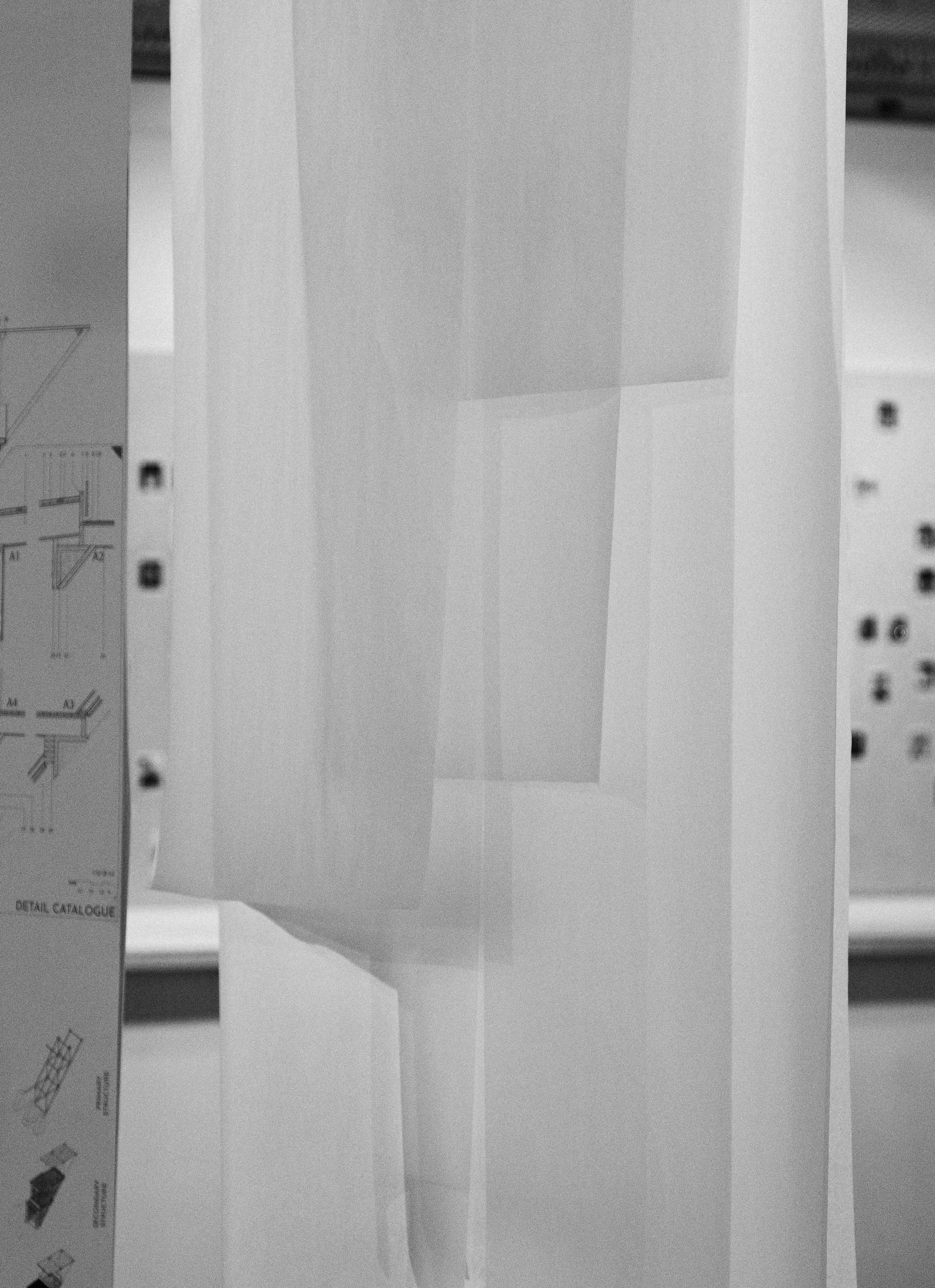

Turning to our old friend trace for its palette, the exhibition’s materials were reused by students for their projects that semester. Trace is an invitation to experiment, a canvas for collaboration, and a promise of iterative progress.

Key contributions: exhibition designer, producer, installation technician, furniture designer and panel graphical designer.

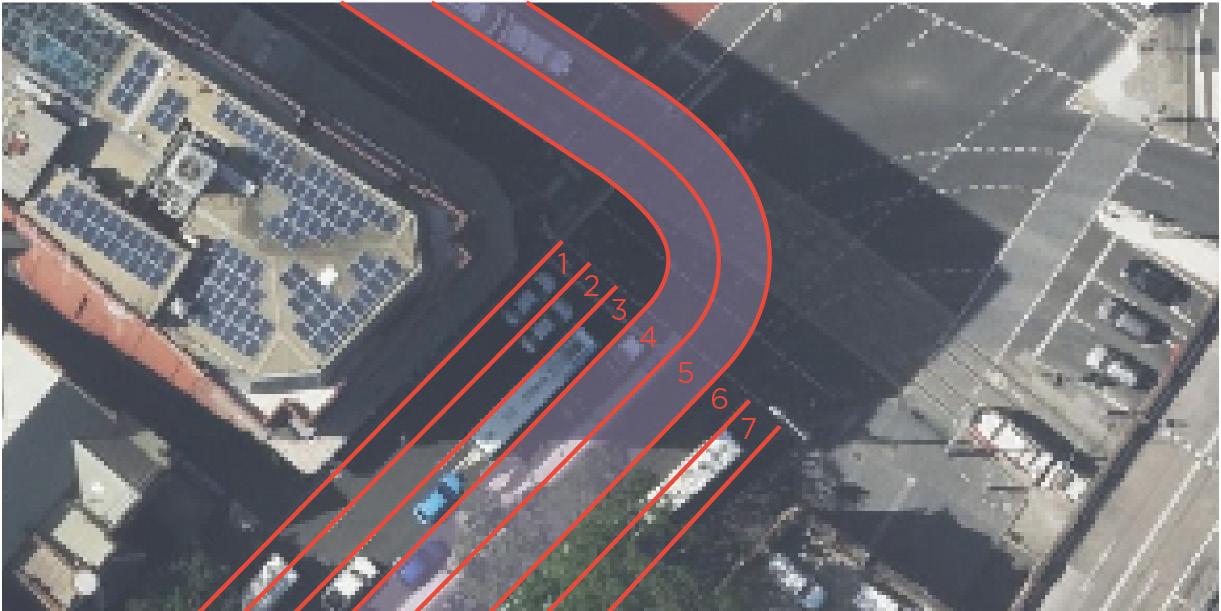

The first iteration of panel graphics resembled sound (i.e. UNMUTE), however, it was hard to uniqely transfer onto all the panels. Thus, thinking about the ebbs and flows of design, the final graphic was inspired by sound waves. I designed seven versions of dynamic waves that can be individually stretched and adjusted across the panels. Moveover, we staggered the panels follow the flow narrative. We also recived limited submissions, so we created dummy panels out of baking paper between each submission panel and fill up space.

INITAL PANEL GRAPHIC DESIGN

FINAL PANEL GRAPHIC DESIGNS

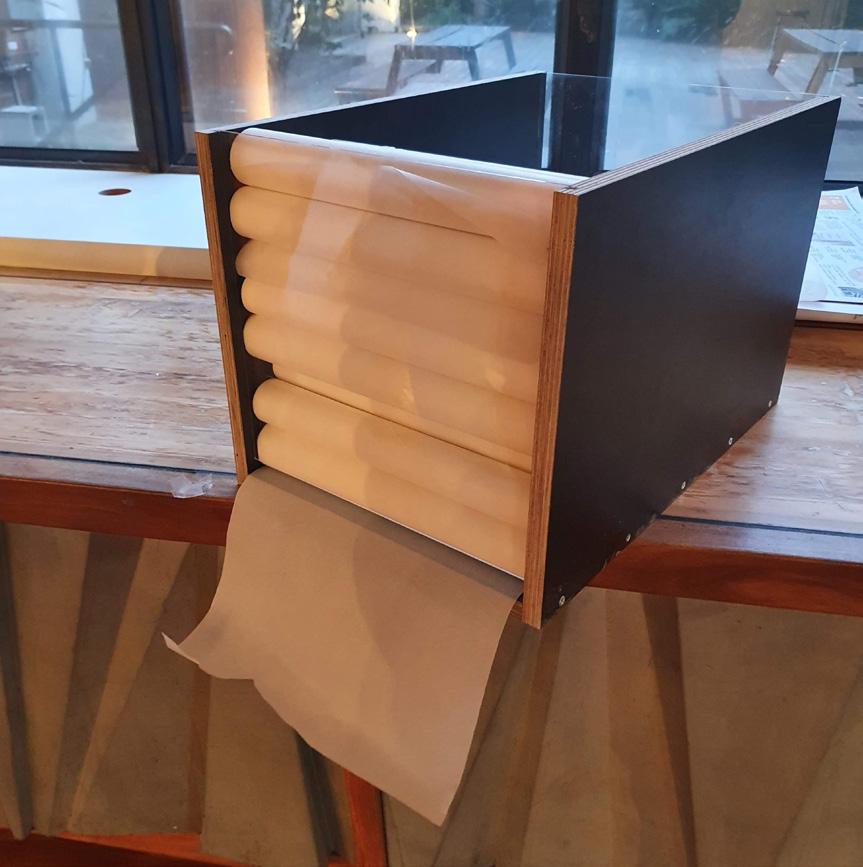

DUMMY PANEL PROTOTYPING

DUMMY PANEL FINAL DESIGN

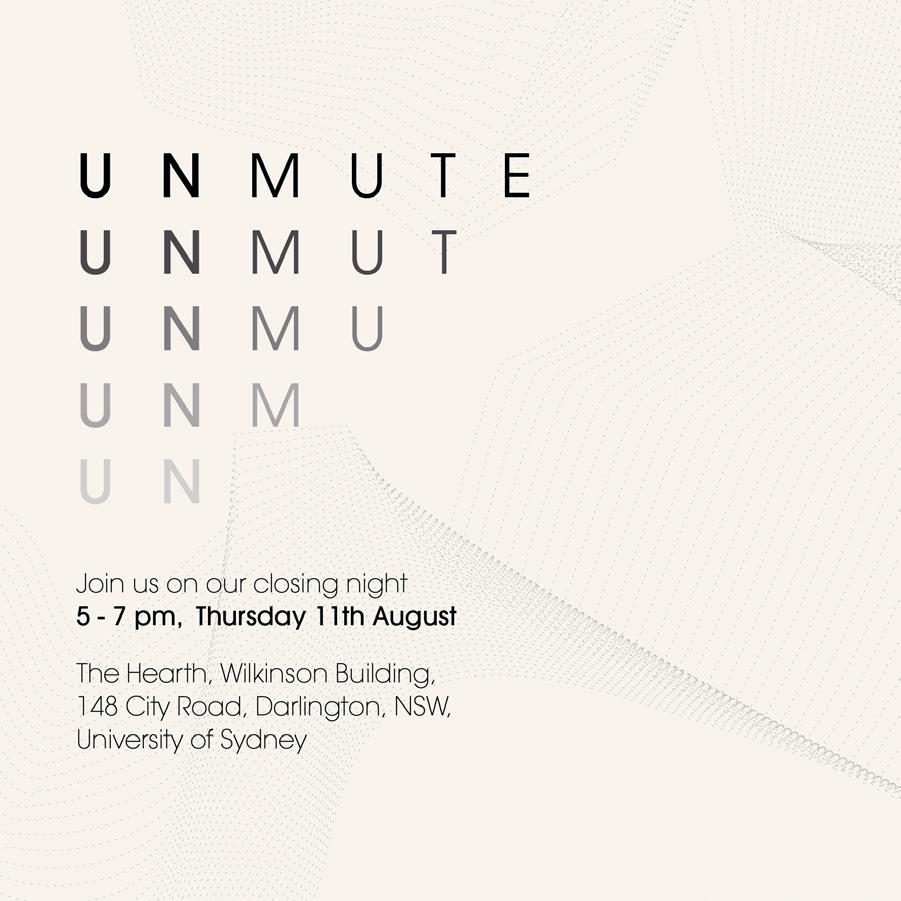

Promotion for UNMUTE was primarily through word-of-mouth and complimentary exhibition guides. However, our closing night was promoted through posters throughout the Archtecture Design and Planning (ADP) Faculty and on their Instagram page - to great success! Post-exhibition, we put the baking paper into a dispensary for students to use, continuing the functionality and legacy of UNMUTE. UNMUTE was the first student-led exhibition in the ADP Faculty. The exhibition has inspired many student-led campus exhibitions.

Materials: balsa, pine, spackling, acrylic paint, cork sheet, watercolor paper, plastic bag, cardboard variety, and aluminium foil. Handmade.

Colorbond Steel Roof, 5 mm

Colorbond Steel Roof, 5 mm

Foil-Lined Insulation Blanket R1.3

Foil-Lined Insulation Blanket R1.3

F7 Seasoned Softwood Rafter, 90 x 35 mm

F7 Seasoned Softwood Rafter, 90 x 35 mm

Polyethylene Membrane, 0.2 mm

Polyethylene Membrane, 0.2 mm

F7 Seasoned Softwood Roof Battens, 25 x 75 mm at 900 crs

F7 Seasoned Softwood Roof Battens, 25 x 75 mm at 900 crs

Galavanised Steel Framing Anchor to eng detail

Galavanised Steel Framing Anchor to eng detail

F7 Seasoned Softwood Ceiling Joist, 90 x 35 mm

F7 Seasoned Softwood Ceiling Joist, 90 x 35 mm

Gypsum Ceiling Board, 19 mm

Gypsum Ceiling Board, 19 mm

Contemporary Pine Cornice, painted white

Contemporary Pine Cornice, painted white

F7 Seasoned Softwood Top Plate, 90 x 45 mm

F7 Seasoned Softwood Top Plate, 90 x 45 mm

Galavanised Steel Framing Anchor to eng detail

Galavanised Steel Framing Anchor to eng detail

F7 Seasoned Softwood Ledger, 35 x 75 mm

F7 Seasoned Softwood Ledger, 35 x 75 mm

10 mm clearance

10 mm clearance

F7 Seasoned Softwood So t Bearer, 75 x 35 mm

F7 Seasoned Softwood So t Bearer, 75 x 35 mm

F7 Seasoned Softwood Studs and Noggins, 90 x 45 mm, 450 mm spacing

F7 Seasoned Softwood Studs and Noggins, 90 x 45 mm, 450 mm spacing

Polyester Insulation Batts R2.5

Polyester Insulation Batts R2.5

So t Lining, 4.5 mm

So t Lining, 4.5 mm

F7 Seasoned Softwood Lintel, 2/ 150 x 45 mm

F7 Seasoned Softwood Lintel, 2/ 150 x 45 mm

Gypsum Wall Board, 10 mm

Gypsum Wall Board, 10 mm

Clearance at window head

Clearance at window head

Bullnose Pine Architrave

Bullnose Pine Architrave

Pine Window Sill Lining

Pine Window Sill Lining

Dressed Turpentine Fascia, painted white, 190 x 25 mm

Dressed Turpentine Fascia, painted white, 190 x 25 mm

Colorbond Steel Quad Gutter, 115 mm

Colorbond Steel Quad Gutter, 115 mm

Casement window

Casement window

White powder coated Aluminium Window Frame

White powder coated Aluminium Window Frame

Pine Window Sill Lining

Pine Window Sill Lining

Bullnose Pine Architrave

Bullnose Pine Architrave

Recycled Burnt Clay Brick Sill

Recycled Burnt Clay Brick Sill

Anodised Aluminium Window Sill Flashing

Anodised Aluminium Window Sill Flashing

Cavity

Cavity

Galvanised Steel Wall Tie, spaced according to specification

Galvanised Steel Wall Tie, spaced according to specification

F7 Seasoned Softwood Studs and Noggins, 90 x 45 mm, 450 mm spacing

F7 Seasoned Softwood Studs and Noggins, 90 x 45 mm, 450 mm spacing

Polyethylene Membrane, 0.2 mm

Polyethylene Membrane, 0.2 mm

Polyester Insulation Batts R2.5

Polyester Insulation Batts R2.5

Gypsum Wall Board, 10 mm

Gypsum Wall Board, 10 mm

F7 Seasoned Softwood Top Plate and Bottom Plate, 90 x 45 mm

F7 Seasoned Softwood Top Plate and Bottom Plate, 90 x 45 mm

Contemporary Pine Skirting Board

Contemporary Pine Skirting Board

Radiata Pine Tongue and Groove Flooring, 19 x 85 mm

Radiata Pine Tongue and Groove Flooring, 19 x 85 mm

15mm Plywood Panel, Type A bond, structural grade

15mm Plywood Panel, Type A bond, structural grade

F7 Seasoned Softwood Cypress Pine batten, 60 x 90 mm, structural grade

F7 Seasoned Softwood Cypress Pine batten, 60 x 90 mm, structural grade

Anodised Aluminium Flashing at slab edge

Anodised Aluminium Flashing at slab edge

Weephole

Weephole

Sand bedding

Sand bedding

Compacted Fill to eng detail

Compacted Fill to eng detail

Polyethylene Membrane, 0.2 mm

Polyethylene Membrane, 0.2 mm

12 mm ø Galvanised Steel Mesh cast into RC Footing

12 mm ø Galvanised Steel Mesh cast into RC Footing

Polyethylene Membrane, 0.2 mm

Polyethylene Membrane, 0.2 mm

Deep Reinforced Concrete (RC) Footing, 400 x 300 mm to eng detail

Deep Reinforced Concrete (RC) Footing, 400 x 300 mm to eng detail

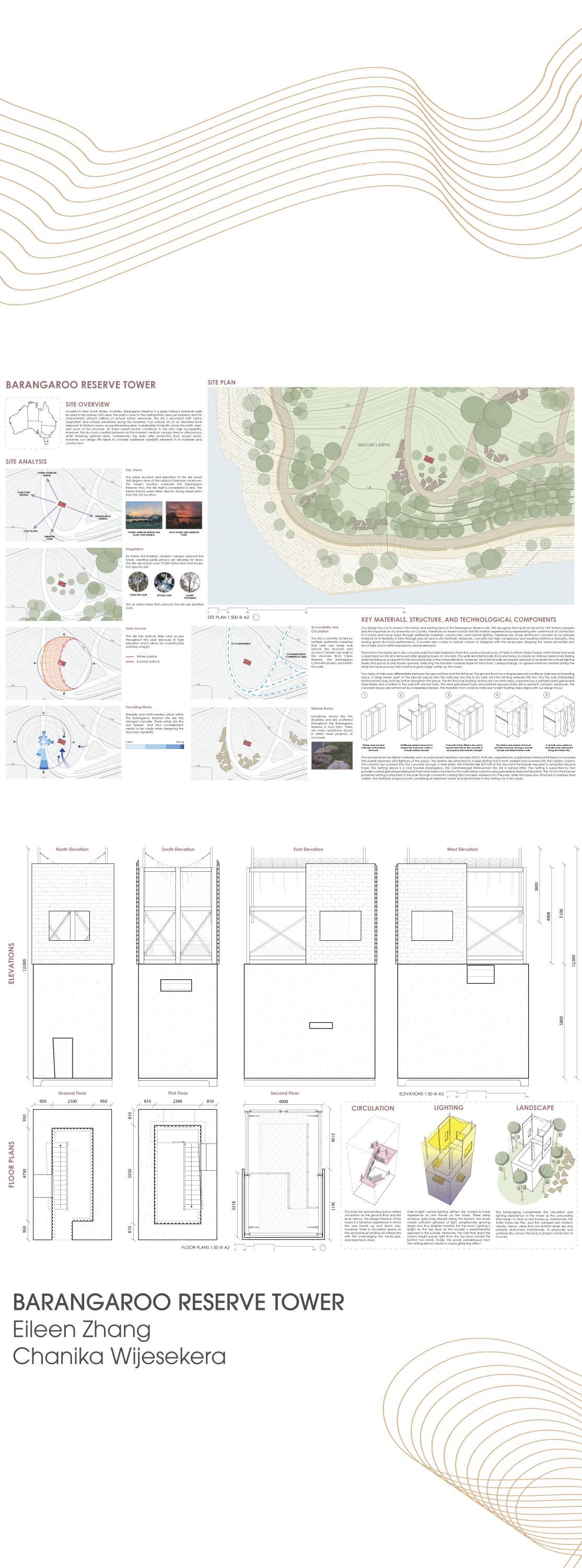

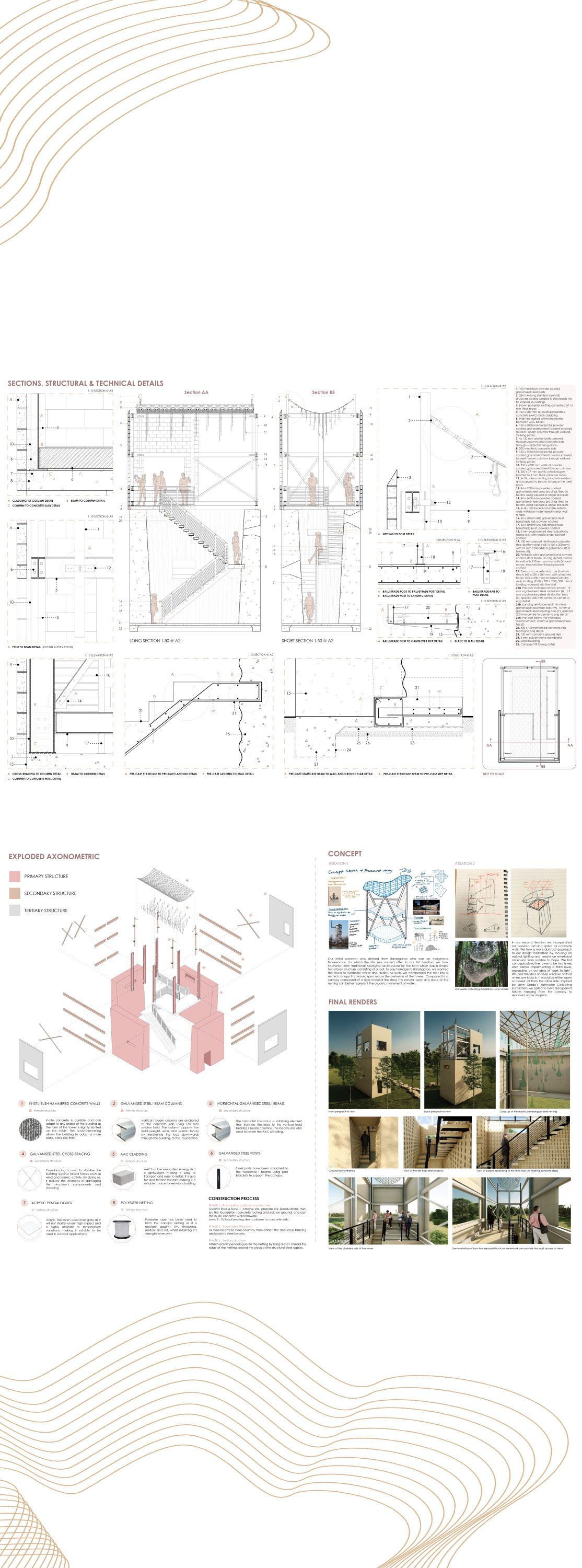

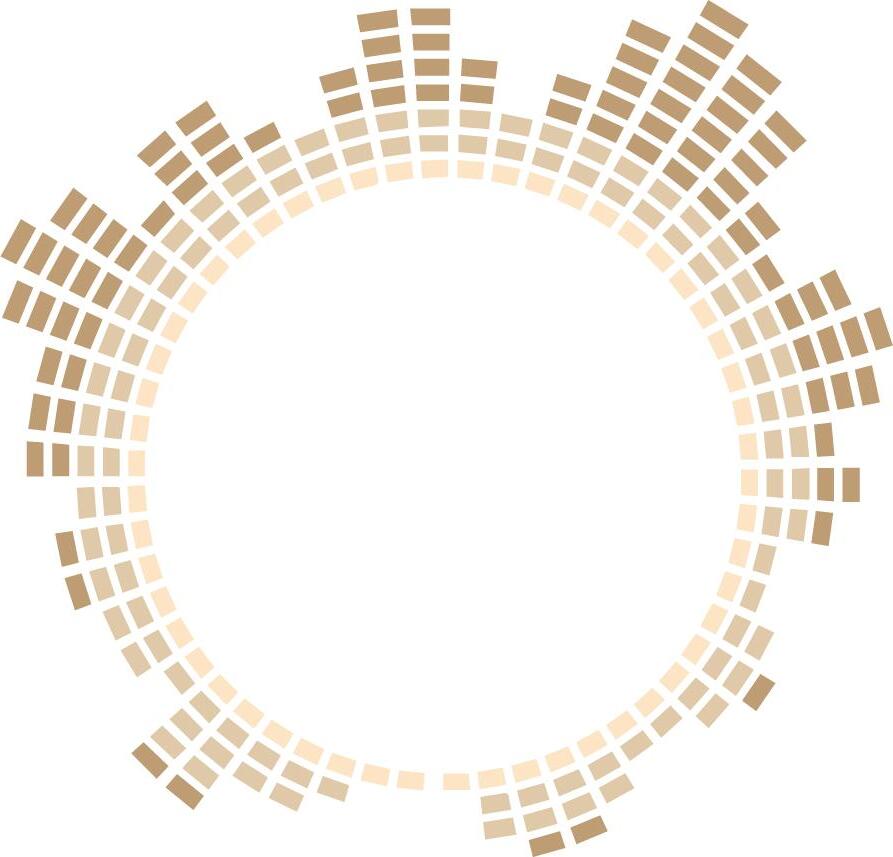

The brief is to design a 4 m x 8 m x 12 m tower in a significant location of choice. Differences in materials, construction methodology, and structural typology are to evoke an emotional and sensory experience as one transitions upwards and descends back down.

The Tower utilises views and sunlight to define the spatial transition between floors, enhanced by materials and construction. The lower two levels have in-situ concrete walls that slope upwards to create melancholic mood that gradually dissapates as one traverses up; a lightness from the progressively larger windows. This shift is reinforced by the change from heavy to floating steps. The final floor walls are light autoclaved aerated concrete (AAC) and galvanised steel frames. The exposed walls and vista views cultivates hope within.

IN-SITU CONCRETE WALL CONSTRUCTION

Interior formwork of timber studs first support the exterior formwork, creating a smooth external facade.

Concrete is filled in-situ and in layered intervals for the concrete to set properly and maintain strength.

The interior and exterior formwork are then removed, leaving a smooth facade and ribbed interior walls.

Finally, a smooth wavy pattern is manually bush-hammered along the interior ribs.*

*Precedent: Campbell Park Offices by Theo Hirsch and James McCormick, 1969-1976

1. 100 mm black powder coated galvanised steel posts

2. 284 mm long stainless steel (SS) structural cables welded to steel posts via fin shaped SS castings

3. Brown polyester netting comprised of 16 mm thick ropes

4. 100 x 200 mm autoclaved aerated concrete (AAC) brick cladding

5. Wall ties seated within the mortar between AAC bricks

6. 130 x 3000 mm horizontal powder coated galvanised steel I beams screwed to steel I beam columns through welded SS fixing plates

7. 4x 150 mm anchor bolts screwed through columns and concrete slab through welded SS fixing plates

8. 200 mm thick concrete slab

9. 130 x 1530 mm horizontal powder coated galvanised steel I beams screwed to steel I beam columns through welded SS fixing plates

10. 250 x 4700 mm vertical powder coated galvanised steel I-beam columns

11. 200 x 77 mm acrylic pendalogues knotted to 4 mm thick polyester ropes.

12. 4x SS pole mounting brackets welded and screwed to beams to brace the steel posts

13. 84 x 3780 mm powder coated galvanised steel cross bracings fixed to beams using welded SS angle brackets

14. 84 x 2600 mm powder coated galvanised steel cross bracings fixed to beams using welded SS angle brackets

15. In-situ reinforced concrete exterior walls with bush-hammered interior wall render (see diagram for reference)

16. 60 x 30 mm RHS galvanised steel balustrade rail, powder coated

17. 60 x 60 mm SHS galvanised steel balustrade post, powder coated

18. 6 mm ø galvanised steel balustrade railing-rods with tensile ends, powder coated

19. 100 mm precast reinforced concrete step (bottom step is 687 x 250 x 200 mm) with 96 mm embedded galvanised steel ferrules (U)

20. Prefabricated galvanised and powder coated steel blade (to eng detail), bolted to wall with 150 mm anchor bolts (V) and epoxy, exposed bolt-heads powder coated

21. Pre-cast concrete staircase (bottom step is 600 x 250 x 200 mm) with attached beam (300 x 300 mm) recessed into the wall, landing (2100 x 700 x 200); 200 mm of landing recessed into the wall

21a. Pre-cast staircase reinforcement: 16 mm ø galvanised steel main bars (W), 12 mm ø galvanised steel distribution bars (X), spaced 200 mm centre-to-centre to eng detail

21b. Landing reinforcement: 16 mm ø galvanised steel main bars (W), 16 mm ø galvanised steel bonding bars (Y), spaced 200 mm centre-to-centre to eng detail

21c. Pre-cast beam (for staircase) reinforcement: 12 mm ø galvanised steel ties (Z)

22. 400 x 400 reinforced concrete strip footing to eng detail

23. 100 mm reinforced concrete ground slab

24. 2 mm polyethylene membrane

25. Compact dirt and rock fill to engineer detail

26. Compact sand bedding to engineer detail

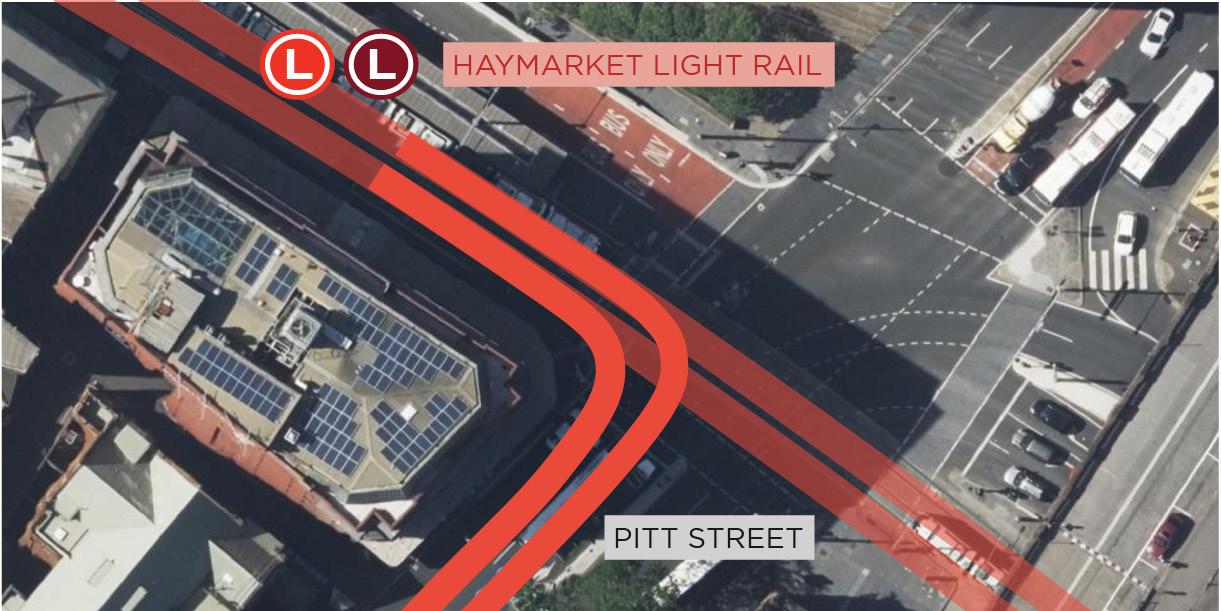

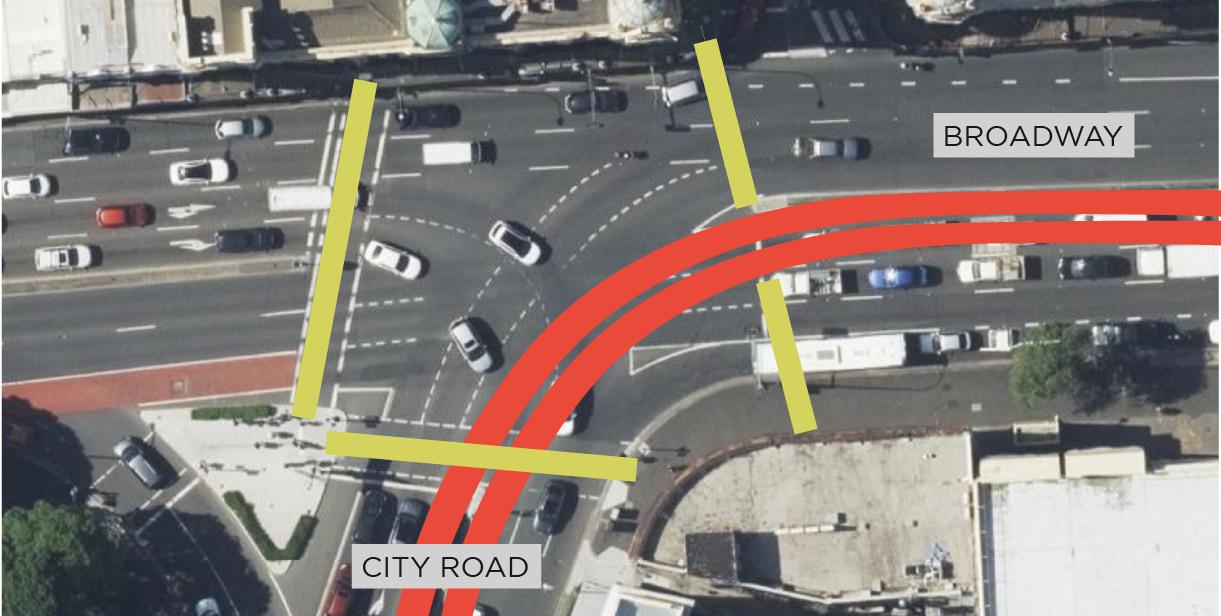

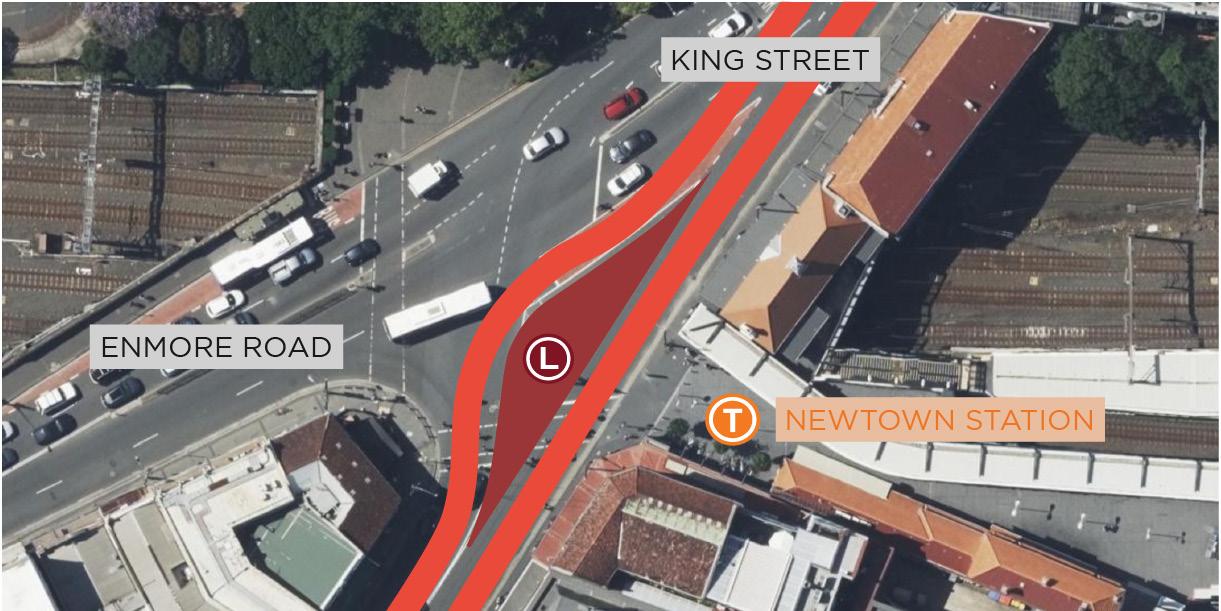

Newtown Revitalisation is the urban design proposal of a new Light Rail route along King Street and junction plaza. This proposal is part of a larger-scaled intervention which includes renovating Camperdown Memorial Rest Park and implementing green alleyways with community gardens.

Newtown, a vibrant hub in Sydney is centred around King Street. Thus, the area faces challenges with high pedestrian activity on cardominated King Street, making it less walkable due to lack of footpath space. Most residents rely on public transport, particularly the conveniently located Newtown Station on King Street. To address congestion and enhance pedestrian space, a proposed Light Rail line along King Street aims to encourage more public transport usage, aligning with the historical tram network in the 1950s.

THE PROPOSAL: A CLOSE UP

The canopy, wayfinding, and public domain infrastructure are designed with pedestrians in mind, successfully integrating the previous under-utilised spaces into a unified plaza with public transport at its core. Flexible seating are for different groups of people, food stalls, live bands, and other events. The canopy has glazed perforations and illuminates at night for protection from harsh weather and easy night navigation. Other safety elements are the signage, tactile paving, perimeter vegetation, and concrete barriers.

STREET SITE VISIT: DISCOVERED CONCERNS

PROPOSED PLAZA: SECTION A

PROPOSED PLAZA: SECTION B

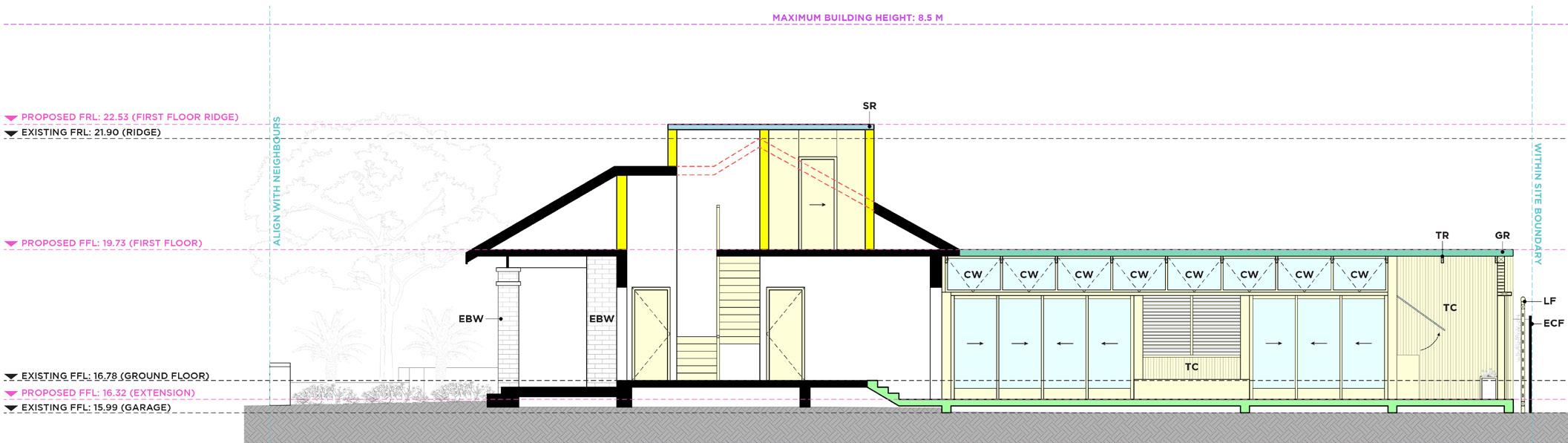

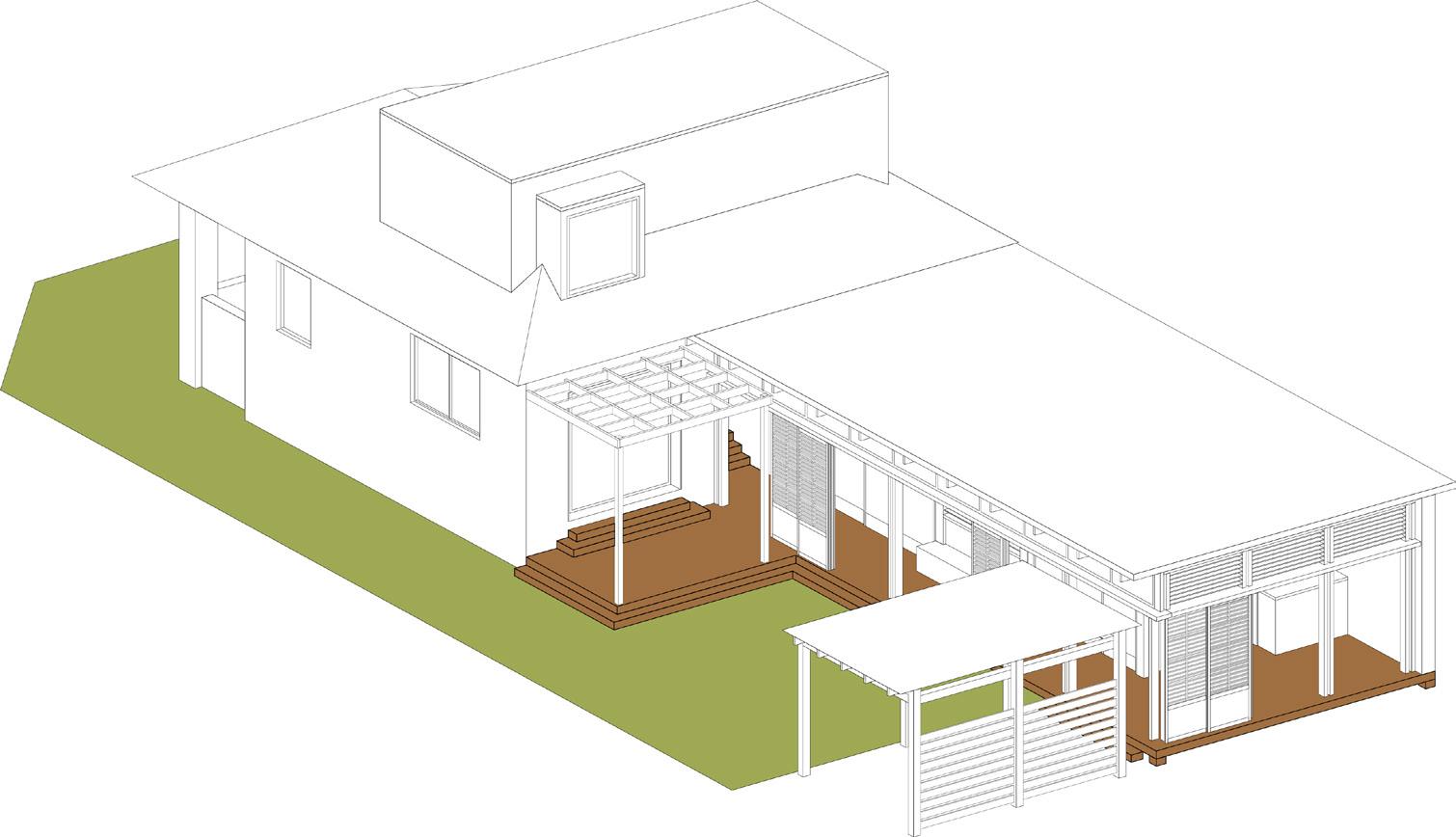

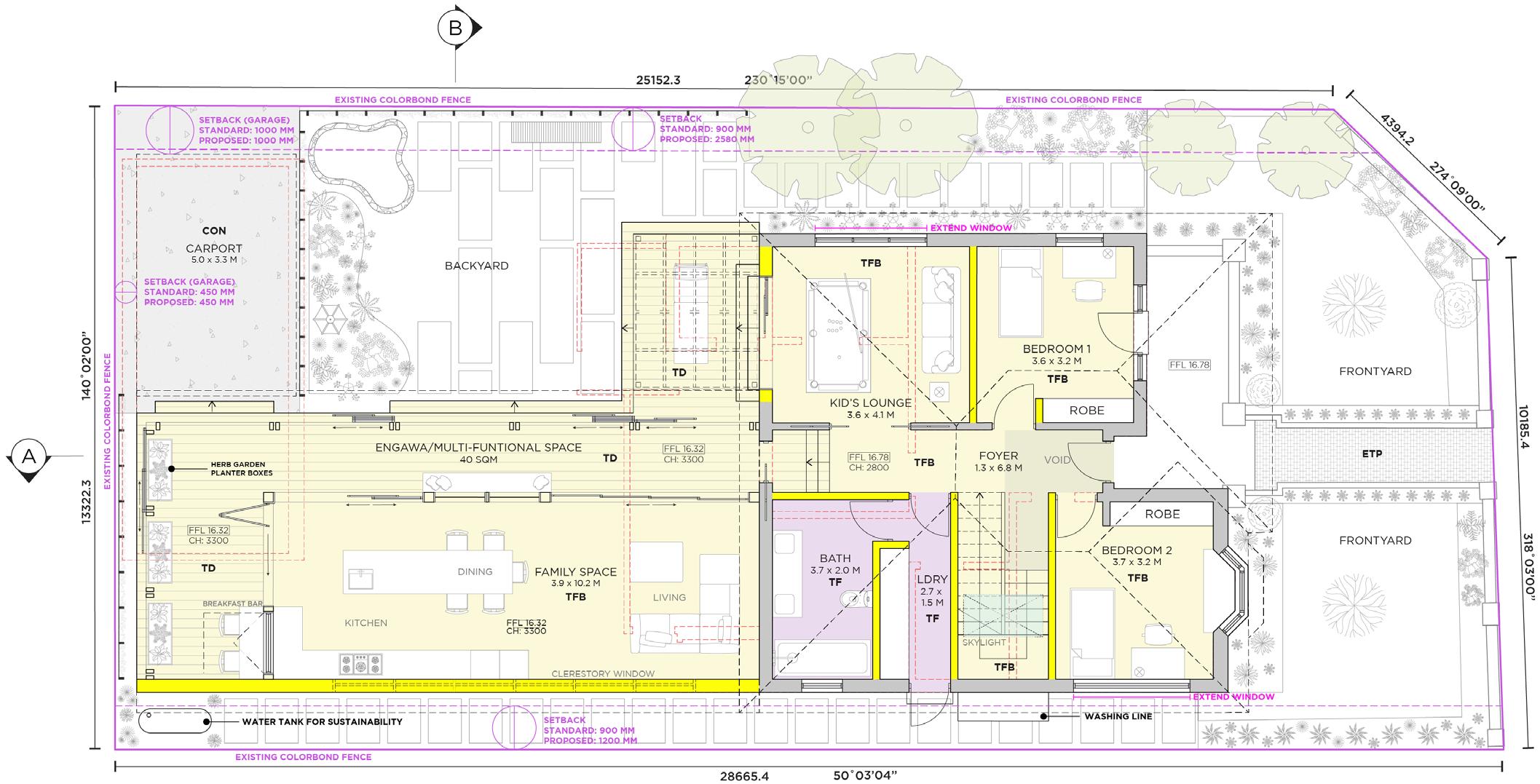

A family of four need an extension of their small home in Ashfield. They requested increased internal sunlight and improved connection to the backyard. This design addresses their needs and complies with the Ashfield LEP 2013 and Inner West DCP. A DA form was prepared.

The home honours the “Shakkei” concept of burrowed scenery. Thus, the Engawa (Japanese verandah) is the central axis that connects the cleint to the backyard garden regardless of their location inside. The Engawa’s outer edge has partially glazed timber sliding louvres and the inner edge has sliding doors; enabling views and internal climate control. Moreover, the Engawa allows cool north-easterly summer winds to circulate. The garden is has native and Japanese plants, aligning with Skakkei and the Australian context.