ROAD TRANSPORT

Kia e-van launch Chinese trucks arrive Retro electric Renaults Milence charges in

A slogan that should be on the lips of all reformers is: “Don’t let the perfect be the enemy of the good.”

And there’s nowhere where that slogan could be better applied than in the process of decarbonising road transport.

We are now at last seeing serious investment in truck charging being promised by the private and public sectors, although the vehicles themselves are still very expensive, and doubts remain as to how the numbers can be made to stack up. The problem is that charging installations don’t come cheap, and to recoup that investment suppliers are going to have to resell (renewable) electricity to end-users at a handsome premium.

But the economic (as opposed to environmental) case for battery-electric trucks is that the energy costs of driving one a given distance must be substantially lower than the cost of driving a diesel truck a similar distance. It is the saving in fuel cost that will justify the substantial price premium of an electric truck, and also compensate for the dead time spent plugged into a charger.

None of this matters as far as the environment is concerned, because the need is to reduce CO2 emissions urgently. Kicking the can forward to 2035 or 2050 is of little help to the situation now.

Roll the clock back a couple of years, and HVO was being promoted as the “fuel of the future that you can buy now.” Most modern trucks could run on it, and it was made from waste fats from the food industry which might otherwise have been allowed to clog the overworked sewers of our fast-food fuelled cities.

Not only was it fossil free, it also burned cleaner than conventional pump diesel. A truck running on it could never be described as emissions-free but it still offered substantial environmental advantages.

The previous Government was so convinced that the benefits of HVO were self-evident that it was reluctant to offer any kind of incentive to operators to run on it. There would never be enough to meet demand, it was argued, and what supplies there were should be reserved for use by difficult sectors such as commercial aviation (a battery-powered Airbus A380 is still a little while away).

But without fiscal incentives such as reduced fuel duty, HVO was quite a hard sell into a market where margins are as thin as they are in road transport. This was made even tougher by the slightly different physical properties of HVO compared to fossil diesel: it yields less energy per litre than fossil diesel, although ironically in terms of energy per kg, it’s actually better. But we buy fuel by volume, not weight, so on a £ per km basis, you were paying more for less.

The situation was also not helped by suggestions that if demand for HVO took off, farmland might be diverted from food production, or natural forest areas cleared to make way for feeder crops. This would be counterproductive to say the least.

It now looks as though demand for HVO has stalled. Leading British supplier Green Biofuels went into administration in 2023, and was subsequently taken over by Certas Energy, and more recently one of the largest suppliers in Europe, Neste, announced job cuts because falling demand was driving prices down.

The latest news is that it may all be Donald Trump’s fault. He has apparently thrown Net Zero out of the window, and reaffirmed a drill, baby, drill, energy policy. All of which means that America’s HVO production is now being exported to the UK at discount rates, or so it is claimed.

The UK Trade Remedies Authority has now initiated an anti-dumping investigation and a countervailing investigation into HVO imports from the USA.

According to the agency, the investigation follows an application submitted by representatives of the UK biodiesel industry, including the Renewable Transport Fuel Association, Greenergy Fuels Ltd, Argent Energy Ltd, and Olleco. The stakeholders that requested the investigation cited concerns that the market has changed since a previous review in 2022, with recent evidence suggesting that the price cap has narrowed and HVO may now be competing directly with UK-produced biodiesel.

The investigations aim to discover if imported HVO is being sold at unfairly low prices or being subsidised and causing harm to UK industry.

It all sounds suspiciously as if the environmental baby is being thrown out with the economic bathwater. Surely the UK should be doing all it can to secure supplies of HVO at affordable prices and run as many trucks as possible on the stuff?

If the Yanks don’t want it, we’ll have it!

Matthew Eisenegger, Publisher

INFORMATION

EDITORIAL

Publisher: Matthew Eisenegger

Managing Editor: Richard Simpson

Designer: Harold Francis Callahan

Editorial Address: Commercial Vehicle

Media & Publishing Ltd, 4th Floor 19 Capesthorne Drive, Eaves Green, Chorley, Lancashire. PR7 3QQ

Telephone: 01257 231521

Email: matthew@cvdriver.com

ADVERTISING

Advertising Sales: David Johns

Telephone: 01388 517906

Mobile: 07590 547343

Email: sales@cvdriver.com

DESIGN

Art Editor: Harold Francis Callahan

Telephone: 01257 231521

Email: design@cvdriver.com

CONTRIBUTORS

Grahame Neagus

Harrison Thomas

PUBLISHED BY

Commercial Vehicle Media & Publishing Ltd, 4th Floor, 19 Capesthorne Drive, Eaves Green, Chorley, Lancashire. PR7 3QQ

Telephone: 01257 231521

NOTE

The publisher makes every effort to ensure the magazine’s contents are correct. All material published in Destination Net Zero magazine is copyright and unauthorised reproduction is forbidden. The Editors and Publisher of this magazine give no warranties, guarantees or assurances and make no representations regarding any goods or services advertised in this edition. Destination Net Zero magazine is published under a licence from Commercial Vehicle Media & Publishing Ltd. All rights in the licensed material belong to Matthew Eisenegger or Commercial Vehicle Media and Publishing Ltd and may not be reproduced whether in whole or in part, without their prior written consent.

Destination Net Zero Magazine is a registered trademark. © 2025

If you are not going to keep this magazine for

Plans for 54 new transport charging hubs have been announced by the Government. The new network of hubs will be integrated into the UK road system, but most will be located at privately-operated transport depots, and only 10 per cent at motorway services or on arterial roads.

Where possible, sites are being made megawatt-ready in preparation for future upgrades when trucks can accept 1MW charging rates.

Two hydrogen refuelling hubs will be sited on the M4 corridor at Avonmouth and Swansea: with the position of a third still being considered. While the 54 planned hubs will be constructed under the ZEHID programme, infrastructure collaborations with existing bus depots have been explored. For example, First UK Bus is designing its depots as shared spaces for buses, trucks, coaches and vans. To bring charging costs down, it has proposed an increase in charging volume from truck operators in return for cheaper charging costs.

This collaborative approach looks at how different consortia and businesses can work together to further the common goal to decarbonise road freight and the Government hopes it will give operators more confidence when planning the transition of their fleets to non-diesel vehicles.

Work is being done to develop digital solutions to support these hubs, including booking systems for charging and optimising charging costs. A key operational objective is to establish how the semi-public network of shared depot charging can be appropriately managed.

In addition, motorway services operator Moto plans to install up to 300 charging bays for electric trucks at 23 locations by 2030. Construction of the first two truck superhubs, at Exeter and Tamworth service areas, is due to start in April. Moto’s CEO, Ken McMeikan, said: “Just as we have done for passenger cars, where we now have over 1,000 EV charging bays, Moto will lead the way in creating a sustainable, accessible, and reliable charging network for trucks and lorries.

“I’m just some bloke who bought some electric lorries,” said Welch Group managing director Chris Welch as he introduced himself to the Microlise Conference in Coventry.

“We’ve been operating electric trucks for more than a couple of years – it works in our part of the industry. We are part of the ZEHID Government initiative.

“Electric trucks come with payload and distance penalties,” he warned. “Our electric trucks have done about 50,000 miles in three years: about what the rest of the fleet does in a week.”

He said the keys to electrification were to change the business model for electric trucks and not expect them to duplicate the productivity of a diesel, and to control energy costs. It was also important to establish that your service provider could handle electric trucks.

“It’s about intangible improvements and what you do behind the scenes.”

An important part of this was collaboration with other operators. Welch Group was a long-established member of the Transport Association. As such, it did not use fuel cards to refuel away from base, but purchased fuel for its 40 or so artics from bunkered stock at other TA member’s depots. He was now seeking to duplicate this business model by sharing the chargers installed at the premises of other transport concerns.

“Three years ago, we were the first electric truck operator in the UK to offer our truck charger for use by other operators,” he said.

“We need collaboration between operators, and not just truck operators. First Bus has been operating electric buses for 10 years, and its Leicester depot is open to truck operators for charging during the day,” he pointed out.

Electricity prices were also important. “We need a price in the high teens per kW to make electric truck operation viable, and currently it’s in the 20s. This puts fuel costs just about on a par with diesel.

“Customers are not very accepting of electric trucks yet, and I can think of only a couple who are prepared to pay extra for their use.”

He said lower-weight vehicles would go electric first, and operators could consider using parked vehicles charged with off-peak electricity as an energy source at weekends, although the inevitable toll that this would take on battery life would have to be taken into account.

Driver acceptability had not been a problem. “We have a queue of drivers waiting to drive our next electric truck,” he said.

“It’s one of the best things we’ve ever done.”

“The

installation of Truckfile into our workshop and fleet has been a real breath of fresh air and is helping the whole operation to run much more smoothly.”

Chris Thompson, General Manager at James Shaw & Son

Compliance. Done digitally.

Driver Check, Fleet & Workshop Management www.truckfile.co.uk

Sapphire Vehicle Services are excited to announce our Net Zero partnership with industry leader Wrightbus, Rightech’s launch of the 7.5t Battery electric Truck with the power of Sapphire’s 14 Regional workshops allow a more affordable options in the race to reduce emissions and decarbonise fleets.

The collaboration underpins our mission to champion new and emerging technologies within the industry helping to drive green initiatives whilst supporting Rightech with Sapphire’s UK wide network of workshops, & its industry leading expertise with decades of experience in maintaining thousands of commercial vehicles.

As a Level 3/4 EV accredited supplier, Sapphire is well positioned to be the partner of choice for Rightech Transport solutions. Sapphire’s fully trained technicians have the knowledge and skills to provide the best-in-class service to enable a smooth transition to alternative fuels and deliver sustainable standards of customer fleet requirements and objectives, providing consistent cost predictability, control and accountability.

Grant Tadman, Commercial Director at Sapphire said “Our aim is to help the transport industry drive carbon reduction with this partnership, integrating

electrified transport initiatives into existing innovative solutions and services to support those fleets making the imperative transition to alternative fuel vehicle operating profiles”

Jean-Marc Gales, CEO of Wrightbus and Rightech, said: “We are delighted to partner with Sapphire and we firmly believe their values and ethos mirror ours. The customer will always come first and we know that our partnership with Sapphire will give added peace of mind when it comes to servicing and support of all Rightech products.”

Iveco has launched a 6x2 version of its 500 hp CNG-powered tractor unit.

The S-Way Natural Gas CNG truck features an additional centre lift-axle manufactured by Iveco’s Astra Vehicle Technologies subsidiary using all Iveco original parts, and fitted with space-saving 17.5 in wheels. The tractor’s original wheelbase remains unchanged, meaning it can be easily integrated into mixed-fleet operations.

Iveco claims that the gas-powered 500 hp version of its X-Cursor 13 engine is the most powerful pure gas-fuelled engine on the market; and the engine itself is 10 per cent lighter than the predecessor unit. A new High Performance Engine brake is now 30 per cent more effective,

and is capable of substituting for a retarder in most mission scenarios, granting better efficiency. Because of the lower compression ratio of sparkignition engines, many previous gas-powered trucks required a transmission retarder to meet secondary braking requirements.

The UK tractor market is dominated by 6x2 vehicles, which make up 90 per cent of registrations but there are few 6x2 chassis available with either gas or electric power options, which is holding back efforts to decarbonise the national fleet.

When run on biomethane, CNG engines have the potential to reduce overall CO2 emissions by up to 95 per cent compared to a diesel truck.

The use of Iveco parts to achieve the 6x2 configuration allows the entire vehicle to be covered by normal manufacturer’s warranty and R&M packages, and maintained within the Iveco dealer network.

Low-floor buses have been with us since the 1990s, but until now truck chassis have been designed on the assumption that everything is loaded or unloaded at a standard-height warehouse dock.

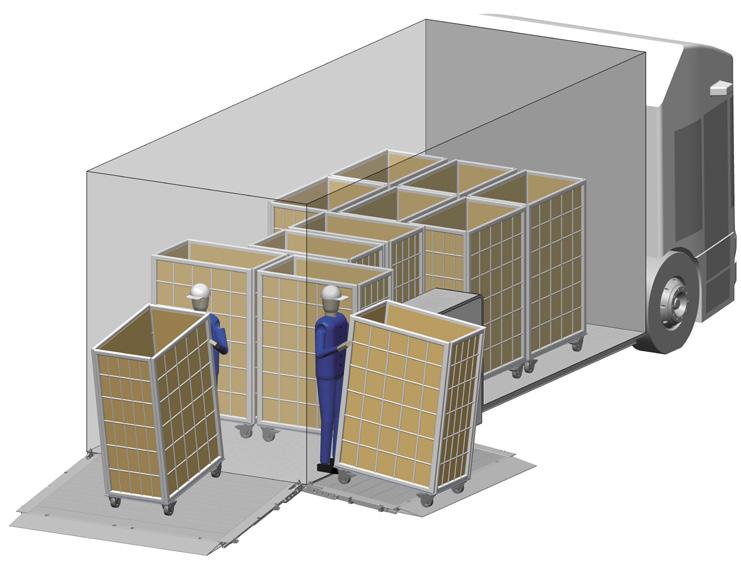

When it comes to high street and domestic deliveries though, unloading at ground level would be quicker, safer and more convenient. With this blinding truth in mind, FR8 Technology together with Volta Commercial Vehicles and FPW Axles, supported by a group of partners, have joined forces to develop the commercial vehicle industry’s first ultra-low floor electric commercial vehicle concept.

Displayed for the first time at the Commercial Vehicle Show in Birmingham, the project is funded by The Department for Business and Trade, via the Advanced Propulsion Centre, supported by Innovate UK and delivered by the Niche Vehicle Network.

Almost all of today’s medium- and heavy-duty rigid curtainside and box-bodied trucks have a loading-bay optimised chassis height of about 1000 to 1200mm, with tail lifts for loading/ unloading in settings without loading bays. This causes inefficiencies and safety concerns, especially in urban deliveries: Tail-lift operation is time-intensive – from needing to find parking spots with sufficient space to deploy the lift platform, to lengthy lower and raising cycles, and accounts for up to 30% of time spent in a typical inner-city shift. From a safety point of view, about a third of truck operational accidents in the UK occurring during loading and unloading: including collisions with pedestrians or cyclists, or slipping, falling goods and other incidents on and around the tail-lift operation.

The consortium led by FR8 tackles these challenges by extending the innovative design of Volta’s low-floor cab, fullyelectric trucks to the loading floor. It delivers the first walk-in heavy-duty truck, independent of wheel-size and just a step up at 360mm, while still providing full air-suspension for the rear axle. The solution is specifically designed for urban distribution and allows:

• One-step entry to cabin and body – access possible from rear or kerbside

• Safe and fast loading/unloading of goods in complex and tight urban settings – for drivers, bicyclists, pedestrians, and all other traffic participants

• Ample internal space between wheelboxes for Euro pallet manoeuvring

Customer interviews have shown significant interest in this innovation. The ultra-low floor electric heavy-duty truck shows a path to safer, smarter, and more sustainable future for urban freight transportation. The consortium believes the concept not only significantly improve efficiency and safety in loading and unloading in the day of a truck driver but also increase payload by up to 500kg or volumetrically by about 50% – while potentially reducing overall product cost with a simpler body and ramp setup.

The vehicle displayed at the Destination Net Zero pavilion at Commercial Vehicle Show is a first concept demonstrator and planned to be developed into a dynamic, driveable demonstrator in the coming year to showcase and test in customer fleets under real-life conditions.

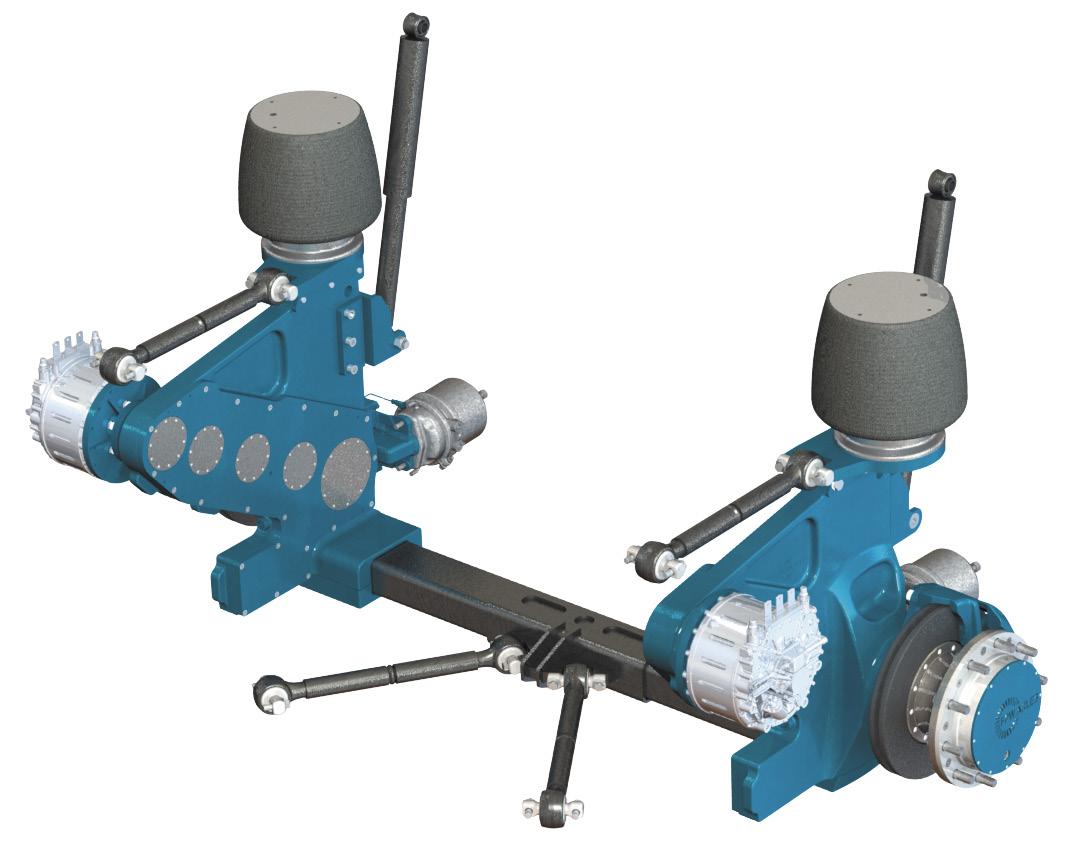

FR8 Technology is on a mission to accelerate the adoption of electric commercial vehicles through groundbreaking innovations such as the FR8 e-DRIVE. This patented driveline solution underpins an ultra-low floor load area for light, medium, and heavy commercial vehicles, providing greater efficiency, reduced costs, and increased earning potential for operators.

“FR8 Technology is on a mission to accelerate the adoption of electric commercial vehicles through groundbreaking innovations such as the FR8 e-DRIVE.”

Volta Trucks was founded with the vision of delivering the safest, most driver- and urban- friendly electric vehicle to UK and European customers. It is the manufacturer of the Volta Zero, the first purpose-built fully electric 16-18-tonne commercial truck, designed specifically for inner city distribution, known for its low-entry cabin and outstanding direct vision, safety features, and delivery efficiency.

FPW Axles has a proud history of gear and axle manufacturing that can be traced back to 1910. With continued investment in design and manufacturing technologies, the company was awarded a prestigious Queen’s Award for Enterprise in 2020. FPW Axles plays a pivotal role by producing the innovative

FR8 e-DRIVE axle system. This cutting-edge component ensures the optimal performance and structural integrity of the ultra-low floor truck, further reinforcing the collaboration’s commitment to technological excellence.

Tom Hughes, CEO, FR8 Technology, said: “Bringing this concept to life is a huge milestone for the commercial vehicle industry. We’ve reimagined what a truck can be - putting safety, efficiency, and sustainability at the core of our design. Seeing our ultra-low floor electric truck on display at the Commercial Vehicle Show is just the beginning.”

Asset finance is, for many firms, a form of funding they have used for many years. Yet still, for others, it’s not something they know much about. In this article Close Brothers Asset Finance takes a closer look at the different products and understand why it could be the perfect option when considering your next purchase.

In short, asset finance is an alternative form of funding used by businesses to obtain the equipment they need to grow or access much-needed cash. Asset finance makes the otherwise unaffordable affordable because it gives businesses access to the equipment they need without incurring the cash flow disadvantage of an outright purchase. Agreements can also be customised to the business’s needs, with flexibility on both the term and repayment schedule.

There are various products that come under the broad umbrella of asset finance with one of the key ones being Refinancing, which is a proven way to make your assets work for you and release cash back into the business.

Refinancing uses the value of assets you already own to help your business. With Sale and HP Back – a type of refinancing – you sell your equipment to us, and we lend you the money you need to invest in your business.

You pay us back in line with what the equipment earns for you. Once you’re done paying us back, you own the equipment again.

This works whether you own the equipment outright or are already financing it with someone else.

Refinancing is for anyone looking to unlock the value of their existing assets to support their business. Whether you own equipment outright or are financing it elsewhere, refinancing can provide a quick way to access funds for things like new equipment, improving cash flow, or other business needs. It’s a flexible option suitable for businesses of all sizes, including sole traders.

• Get more cash easily - Asset refinancing is a quick and simple way to get extra money for your business needs. You get to keep using the asset you put up as security.

• Pay over a longer time - We can take over your current financing deal with another company and extend the time you have to pay. The costs are fixed, so there won’t be any surprises while you’re repaying the loan.

• Choose what’s best for you - Use the cash injection for your business or buy other things you need. It’s more flexible than some other financing options.

• Decide quickly - Getting cash from your assets helps you make faster decisions when dealing with business contracts. Use the money for hiring people, buying new things, or expanding your workspace.

Refinancing is for anyone looking to unlock the value of their existing assets. Whether you own equipment or are financing it elsewhere, refinancing can provide a quick way to access funds for new equipment, improving cash flow or other business needs.

We understand the industries we work with and we offer a choice of finance options that best suit your needs.

Contact us today

closeassetfinance.co.uk/dnz

Grahame Neagus, Head of LCV, Renault Trucks UK & Ireland

Today, as I write this, Morgan has unveiled its latest model, the all-new Supersport—a car that blends traditional values with an ever-changing world.

Notably, it retains a BMW-sourced 3.0 litre six-cylinder petrol engine, standing apart from the growing expectation that every new model must adopt an electric drivetrain. This move reflects a broader trend among brands like Aston Martin, Koenigsegg, and Porsche, which continue to invest in traditional powertrains as buyers remain hesitant to fully embrace EVs.

Despite ongoing efforts to drive electrification, the vast majority of UK and European LCV buyers choose ultra-clean ICE engines. SMMT data up to February 2025 shows that zero emission vehicles still fall short of the 16% of registrations required by the ZEV mandate. Without fleet and public sector adoption, this gap would likely be even wider, as private buyers remain hesitant.

While EV registrations are rising, the pace remains slower than expected. On paper, total cost of ownership (TCO) now often favours EVs over ICE—especially with access to low-cost electricity. Yet, there are clearly bigger issues at play here, creating a significant challenge for OEMs that is costing huge sums not only in R&D investment but also in heavy discounting and residual value risks.

So, is the situation as bleak as one might think? Well, let’s get one thing straight— from an LCV perspective, when used as designed, it is clear that an electric van can easily perform the same tasks as its ICE equivalent. Whether it’s regional dry freight distribution, service vans, parts distribution, minibus operations, or even bluelight applications, today’s technology means that for the vast majority of users, the transition

to electric can happen in 2025. Yes, there are—and always will be—some applications where it may not be a perfect fit, but for most, that’s not the case. So, why the stagnation?

Firstly, people resist change. Most stick with what they know, leaving big businesses and the public sector—who can afford the risk—to lead the transition while technology improves. Then there’s the issue of desire. Take Morgan, for example— enthusiasts are drawn to the brand because it sparks an emotional connection.

LCVs just don’t evoke the same passion. While lifestyle versions have gained traction, they sell more on practicality than emotional appeal. For most, switching to zero emissions doesn’t feel exciting or necessary, so they stick with what’s

“It’s a challenging balancing act, but the technology to make the leap with confidence is available today.”

familiar. To change that, OEMs need to create a compelling hook—something that sparks emotion and aspiration, making EV adoption feel like an upgrade rather than an obligation.

This approach is far more effective than relying on government mandates, which often feel heavy-handed. Take the Netherlands, for example, where a new carbon tax now applies to all new LCVs at a fixed rate of €74 per gram of CO2 emitted. Whether a van produces 10 g/km or 200 g/km, its purchase price rises—sometimes significantly—unless, of course, it’s a zeroemission vehicle, in which case buyers pay only the standard retail price.

Overnight, the price of a typical ICE midsize van jumped significantly, while its electric counterpart remained relatively stable due to its zero emission status. Suddenly, the sale price of the electric version appeared

much more financially attractive. However, this shift has sparked a few unintended consequences: firstly, a surge in ICE van purchases towards the end of 2024; secondly, buyers opting for nearly new ICE vans if they’re not ready for EVs; and thirdly, many holding onto their vans longer rather than being forced into an unwanted change.

This stalemate can’t last forever. While the change in purchasing dynamics is significant, it hasn’t exactly won over the majority of buyers. However, today’s sophisticated EVs are fully capable of performing the same tasks, so the transition remains viable.

Returning to the Morgan example, there’s more to this than meets the eye. Morgan’s engine supply agreement provides access to BMW’s significant R&D resources, including not only traditional petrol engines but also electric drivetrains and even hydrogen

• Grahame Neagus

technology currently being trialled in some of BMW’s own models.

This approach highlights how a brand can stay true to its heritage while adapting to the future. It’s about achieving the ultimate goal without losing the essence of what makes the brand special, and keeping customers loyal. In many ways, this contrasts with Jaguar’s recent clear directional changes.

However, in the commercial vehicle sector—large and small—customers prioritise continuity, choice, and above all, a practical, reliable solution that represents a sound investment and satisfies drivers, finance directors, and shareholders alike. It’s a challenging balancing act, but the technology to make the leap with confidence is available today. The key now is for us to lead the way and continue offering that essential choice.

The PV5 is Kia’s inaugural foray into the electric van market, marking a significant expansion of the South Korean manufacturer’s electric vehicle lineup.

Unveiled at Kia’s EV Day earlier this year, the PV5 is designed to cater to a diverse range of commercial and personal transportation needs, with Kia positioning it as a versatile and adaptable vehicle in the EV market.

Design and Platform

Built on the E-GMP.S platform—a modified version of Kia’s ElectricGlobal Modular Platform—the PV5 emphasizes flexibility and scalability. This architecture allows for various body configurations, including Passenger Van, Cargo Van, and Chassis-Cab, each tailored to specific operational requirements. The modular design facilitates efficient production processes and cost reductions, aligning with Kia’s strategic approach to EV manufacturing.

Exterior design draws inspiration from Kia’s SUV lineup, featuring rugged cladding, sleek LED headlights, and expansive windows. This combination not only imparts a futuristic aesthetic but also enhances visibility and practicality. The Passenger Van variant is equipped with a single lift-up tailgate, while the Cargo Van features twin side-opening rear doors, optimizing loading and unloading processes.

Inside, the PV5 has a modern cabin equipped with a 7-inch digital instrument cluster and a 12.9-inch infotainment screen running an

Android Automotive-based operating system. The interior features durable, easy-to-clean materials, reflecting its utilitarian purpose. The Passenger Van configuration provides up to three rows of seating, which can be adjusted or removed to accommodate varying passenger and cargo needs. Additionally, Kia plans to introduce a Wheelchair Accessible Vehicle (WAV) model, featuring a side-mounted boarding system and third-row tip-up seats to facilitate accessibility for wheelchair users.

The PV5 is powered by a front-mounted electric motor delivering 161 horsepower and 184 pound-feet of torque. Customers can choose between three battery options: a 51.5 kWh

“PV5 allows for various body configurations, including Passenger Van, Cargo Van, and Chassis Cab, each tailored to specific operational requirements.”

or 71.2 kWh nickel-manganese-cobalt battery, and a 43.3 kWh lithium-ironphosphate battery, the latter primarily available in the Cargo variant. The Passenger Van with the 71.2 kWh battery is expected to achieve a range of approximately 248 miles on the European WLTP cycle, translating to around 211 miles under EPA estimates. The PV5 supports fast-charging

capabilities, allowing for a 10% to 80% charge in less than 30 minutes, depending on the battery configuration.

The Cargo Van variant of the PV5 is available in standard and long configurations, with an optional high-roof design. It boasts a loading height of just 419 mm, facilitating easy access. The cargo space can accommodate two Euro-

sized pallets, offering a maximum volume ranging from 3.4 to 5.1 cubic meters, depending on the configuration. An L-track mounting system is available to secure cargo effectively, and the vehicle-to-load (V2L) functionality allows the van to power tools and devices directly from the cargo area.

With an anticipated starting price of around £30,600 (excluding VAT), the Kia PV5 positions itself competitively against rivals like the Volkswagen ID. Buzz Cargo. Its blend of versatility, modern features, and practical design makes it a compelling option for businesses and individuals seeking an electric van solution. Kia’s commitment to expanding its PBV lineup, including future models like the larger PV7 and smaller PV1, indicates a strategic focus on meeting diverse transportation needs in the evolving EV landscape.

In conclusion, the Kia PV5 exemplifies Kia’s innovative approach to electric mobility, offering a versatile and practical solution for various transportation requirements. Its thoughtful design, flexible configurations, and competitive specifications position it as a noteworthy contender in the electric van market.

“The cargo space can accommodate two Euro-sized pallets, offering a maximum volume ranging from 3.4 to 5.1 cubic meters, depending on the configuration.”

Having already electrified its forklift fleet, Shred Station has now welcomed its first electric tractor unit in the form of a Volvo FM Electric. Words: Harrison Thomas

Norwich-based Shred Station has grown rapidly across the last two decades. From a single mobile shredding truck operating locally around East Anglia, it has expanded into not just one of the biggest names in the UK’s data destruction sector, but also the world’s largest independently owned shredding company.

Unsurprisingly, the business’ fleet has had to grow too. Today, Shred Station runs a 100-strong commercial vehicle operation which works across the length and breadth of the UK, underlining the company’s rapid progress. However, just like many other operators, it is bracing itself for the next transition – the move towards alternatively fuelled vehicles.

“We are always looking for ways to reduce our emissions,” explains Simon Franklin, Shred Station’s founder and managing director.

“Sustainability and reducing our environmental impact are core to our business ethos and our fleet is our biggest source of carbon emissions, contributing as much as 80% of our total output.

Having closely tracked our annual carbon and greenhouse gas output, we have already started to adopt smaller electric powered machinery such as forklifts, to eke out some key gains. However, there is certainly more to be done in the next few years.”

That drive has pushed the business towards trialling larger electric vehicles, and while several different models have been tested within Shred Station’s operations, it only recently found an electric truck that delivered both the emissions savings and functional performance it needs.

“After a few different trials we have settled on a Volvo FM Electric,” explains Franklin. “We had been exploring zero tailpipe-emission vehicles for a long time, testing different models with varying degrees of success. Some did not have the right

range, others could not handle the required load capacity, some were just not commercially viable, and some failed on all three counts. The Volvo though has finally met our needs. It delivers the right balance of range, charging capability, and operational efficiency, making it a viable solution for integrating electric vehicles of this size into our fleet.”

“Sustainability and reducing our environmental impact are core to our business ethos...”

Shred Station’s FM Electric – supplied by Karl Love, Sales Executive, Volvo Trucks – faces a busy workload. Paired with a double-deck trailer, the tractor unit is on the road five days a week, with its efforts dedicated to handling local contracts in East Anglia, including transporting paper destined for recycling mills. The FM has more than enough range for this localised workload, with the truck comfortably capable of transporting 50 pallets at a go.

“One of the biggest challenges with electric vehicles is the range, but that is not an issue for our FM Electric because we have strategically assigned it to routes that keep it within a manageable radius of our main depot,” says Franklin. “That way, it can operate efficiently throughout the day and return to base for charging as needed. This style of deployment has allowed us to replace a diesel truck without any compromise or disruption to

our existing workflow, making it an effective step forward in reducing our carbon footprint while maintaining the reliability of our services.”

The truck has also made a strong impression on Shred Station’s chosen driver, the highly experienced Jim Kerr. Previously, he was paired with one of Shred Station’s diesel Volvo FHs and despite him holding a fondness for the legacy technology, his new electric truck has made quite an impact.

“One of the first things you notice is how quickly the truck moves off – it is smooth and responsive in a way that feels completely different from a traditional diesel vehicle,” reports Kerr. “You get

the power and precision right when you need it, which is not always the case sometimes in conventional trucks. It is a more refined driving experience overall.”

This impressive performance is delivered by the truck’s three electrical motors, which can generate a total up to the equivalent of 666 hp, and 2,400 Nm of continuous torque. In addition, the FM Electric’s electromobility traction control system helps to manage power output on slippery surfaces, while different drive modes are available to set the desired performance, comfort, and energy usage levels. Just as with Volvo’s existing diesel range, the vehicle also uses the standard I-Shift gearbox to guarantee a smooth and ultra-quiet in-cab driving experience.

“You get the power and precision right when you need it, which is not always the case sometimes in conventional trucks.”

Shred Station’s new truck also features Volvo Dynamic Steering, the manufacturer’s ultra-responsive system designed to lessen driver steering force by up to 85%. The technology increases road safety and reduces driver fatigue by combining conventional hydraulic power steering with an electric motor fitted to the steering gear, offering perfect stability and control at all speeds.

The new arrival is decked out with a top-of-the-range Drive++ interior package. This adds dual armrests, leather upholstery and fully electronic air conditioning with sun, mist, air quality sensors and a carbon filter, all fitted to a spacious Globetrotter cab.

“The quietness of the truck really stands out, as does the in-cab experience,” says Kerr. “In a diesel vehicle, you do not always realise how much of an impact the noise and vibrations have on your day until they are gone. With the FM Electric, the silence and smooth ride makes the entire experience so much more pleasant.”

Shred Station also reports some practical benefits of switching out a diesel model for an electric equivalent. For instance, the company is saving time by cutting out the need to refuel before the truck can leave for its day’s work.

“Jim no longer has to stop at fuel stations or wait around while the truck refuels. Instead, it is simply plugged in at the depot and it is ready to go the next morning,” adds Franklin.

While it is early days for Shred Station operating an electric vehicle of this size, its team is highly optimistic not just for its first FM Electric, but to also continue accelerating its broader

decarbonisation plans. The business is already a lifetime CarbonNeutral certified company and is aiming to be Net Zero by 2030, but, as Franklin adds, it is always looking for ways to further reduce its carbon footprint.

“Finding a suitable electric truck has been on our radar for a long while now, especially given that our fleet is our largest emission source,” he adds. “Of course, not all of our routes are suitable – at least not today – for a switch to electric trucking, but that certainly does not mean that this FM Electric is the beall and end-all for us on this front.

“Just look at how electric vehicle technology has advanced in the passenger car sector over the last decade or so. We anticipate that future truck models will offer significantly greater ranges much like the way electric cars have evolved. Once those improvements materialise, we will have even more opportunities to expand our electric fleet and integrate these vehicles into longer routes.”

Even so, today the hope is that the FM Electric’s arrival will make a sizeable dent in Shred Station’s emissions output.

“When we switched our forklifts to electric, we immediately eliminated 10,400 litres of diesel consumption per forklift each year. The impact of electrifying a tractor unit is going to be even more significant given how much fuel they consume by comparison,” concludes Franklin. “By taking one diesel artic off the road and replacing it with an electric one, we’re making meaningful progress towards reducing our carbon footprint.

“We know we cannot eliminate emissions, but every step we take toward electrification moves us closer to our goal.”

“When we switched our forklifts to electric, we immediately eliminated 10,400 litres of diesel consumption per forklift each year.”

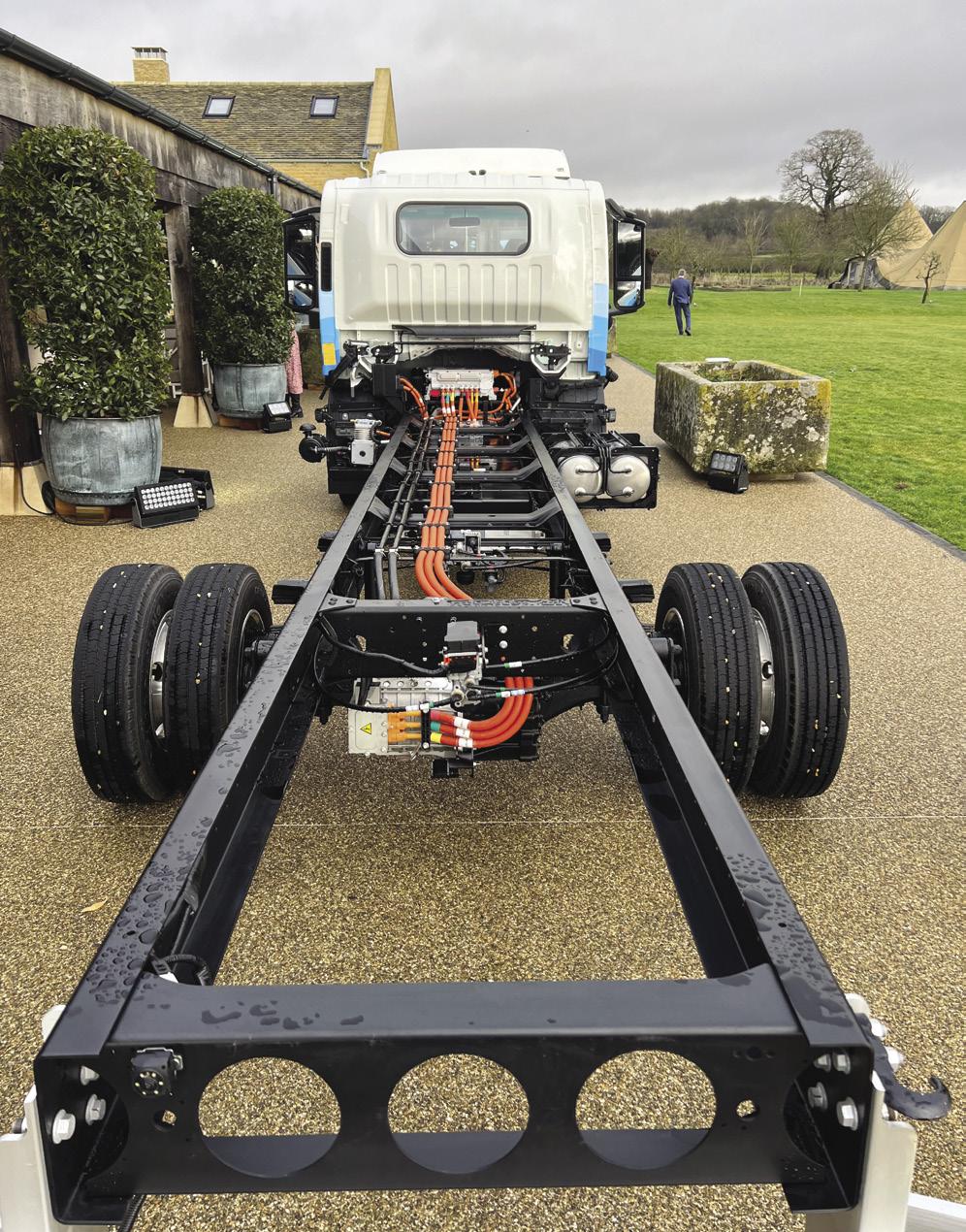

Wrightbus of Northern Ireland has launched a fully-electric 7.5-tonne truck as the company expands beyond buses and into the commercial vehicle sector. The Rightech RT75 is powered by a 107kWh CATL battery, delivering 144 miles under the WLTP test cycle. Its 90kW motor produces 550Nm of torque, with peak outputs reaching 171kW and 1050Nm. Charging is available via a CCS2 socket, offering speeds of up to 120kW (DC fast charging) or 11kW (AC charging).

The truck will be available as a chassis-cab in two wheelbase lengths—3.85m and 4.48m—with order books now open and first deliveries expected in May.

“The Rightech RT75 is powered by a 107kWh CATL battery, delivering 144 miles under the WLTP test cycle.”

Developed in collaboration with Chinese manufacturer JAC Motors, the Rightech RT75 has undergone over 30,000 hours of development and testing by Wrightbus engineers to meet the company’s exacting standards. Modifications include a redesigned front grille and full homologation for UK and European markets.

To support customers, Wrightbus is offering a three-year, 62,000-mile warranty, with an extended six-year battery warranty covering up to 182,000 miles. Maintenance and servicing will be handled by Wrightbus’ extensive service network, which already includes more than 100 mobile engineers supporting its bus fleet. Additionally, a partnership with Sapphire Trucks has been signed to enhance UK market support.

Payload capacity for the chassis reaches a maximum of 4,170kg, with prices starting from £51,525 for the L2 model and £52,050 for the L3 version.

In addition to the 7.5-tonne RT75, Wrightbus plans to introduce a 4.25-tonne variant, leveraging the B-class licence derogation that allows standard car licence holders to drive electric vehicles above 3.5 tonnes.

The truck launch coincides with the introduction of two new Rightech electric buses: RB6 a 6 m zero-emission bus, and RB9 a 9 m electric model.

Wrightbus CEO Jean-Marc Gales explained that the move into electric trucks was a logical extension of the company’s expertise in zero-emission buses. “We need to decarbonise, and the operating model of a 7.5-tonne truck is essentially the same as a city bus—both return to depots and recharge overnight. This is a model we know well, and it’s why we are starting with a 7.5-tonne truck,” he said.

He also acknowledged the advances made by Chinese manufacturers in electrification.

“The Chinese manufacturers are way ahead of their European counterparts when it comes to electric vehicles. We’ve ensured that this truck meets the high standards of our brand and is ready for the UK and European markets.”

With Wrightbus’ record growth and increasing demand for affordable zeroemission solutions, the launch of Rightech RT75 represents a significant step in the company’s expansion into the electric commercial vehicle market.

“Wrightbus is offering a three-year, 62,000-mile warranty, with an extended six-year battery warranty covering up to 182,000 miles.”

Renault unveils new all-electric commercial van range in collaboration with Flexis

has announced a new generation of allelectric commercial vans, developed in partnership with Flexis, the independent joint venture created by Renault Group, Volvo Group, and CMA CGM Group. The lineup includes the Estafette E-Tech, Goelette E-Tech, and Trafic E-Tech, designed to cater to a broad spectrum of business needs.

Built on an innovative new “skateboard” platform with Software Defined Vehicle (SDV) architecture, the three models promise enhanced flexibility, efficiency, and customization. Renault highlights that these compact yet spacious vans are tailored for businesses transitioning toward sustainable energy and technology. With reduced running costs and improved safety, the new models mark a significant advancement in intelligent commercial vehicle design.

Trafic E-Tech Electric: A Modern Evolution of an Iconic Van First introduced in 1980, the Renault Trafic has sold over 2.5 million units worldwide. Now entering its fourth generation, the new Trafic E-Tech electric model retains its reputation for versatility while integrating contemporary design and cutting-edge technology.

With a compact, one-box design, the vehicle maximizes interior space thanks to an extended wheelbase and short front overhang. Despite its spacious interior, the van remains under 1.90 meters in height, ensuring easy access to underground parking facilities.

The Trafic E-Tech features a striking new front-end design with a backlit Renault logo and a high-tech lighting signature. The vehicle’s aerodynamic profile is enhanced by sculpted lines and grained black lower body protection, emphasizing both style and durability for daily commercial use.

Goelette E-Tech Electric: A Versatile and Robust Workhorse

Inspired by the classic Renault Goelette, which was a popular fleet vehicle from 1956 to 1966, the new Goelette E-Tech electric is designed to meet a wide range of business needs. It will be available in three configurations—chassis cab, box, and tipper—offering extensive customization options.

The modular architecture allows for seamless adaptation to various professional requirements. Its simple yet functional design ensures optimal usability, while a well-proportioned front section and elegant yet practical rear lighting enhance its modern appeal.

“Software Defined Vehicle (SDV) architecture, the three models promise enhanced flexibility, efficiency, and customization.”

Estafette E-Tech Electric: A Classic Reborn for Urban Logistics

Renault has revived another historic name with the Estafette E-Tech electric, a modern interpretation of the company’s iconic 1960s van. The original Estafette was a popular light commercial vehicle from 1959 to 1980, and the new model draws inspiration from the recently unveiled Renault Estafette Concept.

With compact dimensions (5.27m long and 1.92m wide) and a high roof allowing for easy movement inside, the Estafette E-Tech electric is designed for urban logistics and last-mile delivery. It features a three-piece panoramic windscreen for improved visibility and safety, along with a distinctive front lighting signature.

Practicality is a key focus, with an integrated sliding side door, ergonomic running boards on both sides, and a single-piece roller shutter at the rear for optimized cargo access. Reinforced bodywork ensures durability for high-intensity urban use.

All three models will be manufactured at Renault’s Sandouville plant in France, with production set to begin in 2026. More details, including technical specifications and pricing, will be announced in the coming months.

With this latest lineup, Renault is reaffirming its commitment to electrification and innovation, offering sustainable, adaptable, and high-performance solutions for the evolving needs of modern businesses.

“Renault has revived another historic name with the Estafette E-Tech electric, a modern interpretation of the company’s iconic 1960s van.”

Milence, the joint venture between Daimler Truck, Traton Group, and Volvo Group, has opened its first public charging hub in the UK. Located in Immingham, this launch marks a significant step towards decarbonizing heavy-duty transport.

Strategically positioned along the A180 with direct access to the M180, M18, and M1 motorways, the Immingham hub serves as a key link in the UK’s transport and logistics network. The nearby Able Humber Port facilitates over 30 Ro-Ro and Lo-Lo sailings each week, strengthening the UK’s trade connections with Northern Europe, Scandinavia, and the Baltic region.

The initial phase of the hub includes four high-performance CCS chargers, offering eight charging bays with power outputs of up to 400kW. Designed to support trucks and their drivers, the facility prioritizes security and convenience with fenced parking, controlled access, camera surveillance, and essential amenities such as toilets and vending machines.

Milence is dedicated to building Europe’s largest electric truck charging network and facilitating the transport industry’s transition to sustainable

“The initial phase of the hub includes four high-performance CCS chargers, offering eight charging bays with power outputs of up to 400kW.”

operations. By 2027, the company plans to establish at least 1,700 high performance charging points across the UK and Europe. Future expansion at the Immingham site will include the installation of Megawatt Charging System (MCS) chargers in the next phase of development.

The aim is to make electric truck charging as straightforward as possible. Multiple payment options, including mobility charge cards and bank cards, are available. Pricing is transparent, with a default tariff of £0.399/kWh clearly displayed at each charging point.

Milence is committed to sustainability, ensuring that all charging stations operate using 100% green energy. The construction process also prioritizes CO2 reduction, using innovative concrete solutions designed to last 30 years with minimal environmental impact. The hub’s location within AHP further reinforces its commitment to green energy, as the port is a dedicated hub for offshore wind and renewable energy, featuring over 1,000 meters of planned heavy-duty quays.

Anja van Niersen, CEO of Milence, emphasized the significance of the launch: “Opening our first UK charge hub in Immingham is a major milestone in the UK’s transition to electric road transport.

This strategically located site demonstrates our commitment to providing reliable and accessible charging infrastructure for electric truck operators. This is just the beginning of our UK expansion, and we look forward to working with stakeholders to accelerate the shift toward a sustainable transport industry.”

Lilian Greenwood, UK Future of Roads Minister, highlighted the government’s support: “Decarbonizing road freight is essential for reducing transport emissions, and it’s fantastic

to see Milence launching the UK’s first dedicated charging hub for electric lorries. To support this transition, the government is investing up to £200 million in zero-emission trucks and infrastructure, helping to create high-paying jobs and establish the UK as a green energy leader as part of our Plan for Change.”

Peter Stephenson, Founder and Executive Chairman of AHP, also underscored the hub’s importance: “The Milence charging hub at Able Humber Port is a key asset in our mission to decarbonize port operations and the wider region. We are proud to collaborate with Milence on this initiative, which marks a significant step forward for sustainable transport in the UK.”

With this launch, Milence is laying the foundation for a nationwide network of electric truck charging hubs, driving forward the transition to a cleaner and more sustainable future for the transport industry

“Milence is committed to sustainability, ensuring that all charging stations operate using 100% green energy.”

Explore Transport, a leading logistics specialist with over 50 years of experience in the construction, rail, aerospace, and nuclear sectors, is trialling the UK’s first Scania FCEV (Fuel Cell Electric Vehicle) prototype. This marks a significant step in advancing net-zero transport solutions for tier one contractors and large scale infrastructure projects across the country.

The initiative puts Explore Transport at the forefront of ‘Scope 3’ emissionsreduction: delivering sustainable logistics without compromising efficiency or

reliability. As part of the UK Government’s Zero Emission HGV Infrastructure Demonstrator Programme (ZEHID) funded by the Department for Transport (DfT) and delivered in collaboration with Innovate UK, Explore Transport and HyHAUL are driving innovation in zeroemission logistics. Through this initiative, Explore Transport is demonstrating hydrogen fuel cell technology in realworld conditions, gathering essential data on performance, efficiency, and longterm viability for construction logistics.

Chris Gatheridge, operations director at Explore Transport, emphasized the company’s commitment to sustainability: “Our investment in the Scania FCEV prototype is a significant milestone in our journey toward net-zero transport solutions. By adopting this cutting-edge technology from an industry-leading OEM, we are not only taking proactive steps to reduce our own carbon footprint, but we are also offering our customers an alternative that is not yet widely available in the logistics sector: cleaner, greener, zero emission transport solutions.

“Hydrogen has the potential to meet the demanding needs of construction logistics, providing the performance and capability required for heavy loads. By securing the first Scania FCEV prototype in the UK, we are reinforcing our commitment to a greener future in logistics. This unit is expected to be operational by Q1 2026.”

Mark Bridgland, sales director at Scania UK, highlighted the importance of collaboration in achieving sustainability goals: “We are delighted to be working with Explore Transport on their decarbonisation journey. As manufacturers, it’s essential that we partner with our customers to develop cont.

“Our investment in the Scania FCEV prototype is a significant milestone in our journey toward net-zero transport solutions.”

solutions that not only reduce emissions but also support profitability and operational efficiency. Through our Pilot Partner team, we are working closely with Explore to ensure the FCEV prototype meets their specific needs. The real-world insights gained from this project will be invaluable in shaping the future of hydrogen-powered logistics.”

Kyle Arnold, managing director at HyHAUL, added: “HyHAUL is at the forefront of the hydrogen heavy transport supply chain, demonstrating the feasibility of H2 FCEVs in real world conditions. Our collaboration with Explore Transport and Scania underscores our commitment to decarbonising the heaviest transport sectors. By providing expert analysis, operational support, and strategic implementation of hydrogen refuelling infrastructure, we are ensuring that zero emission transport solutions are both practical and scalable. Having Explore as the first customer is a significant milestone, reinforcing the UK’s transition towards a greener future. This partnership is just the beginning of a transformative journey.”

“HyHAUL is at the forefront of the hydrogen heavy transport supply chain, demonstrating the feasibility of H2 FCEVs in real world conditions.”

Scania’s Pilot Partner division in Sweden has developed a series of fuel cell prototype tractor units designed to test the viability of hydrogen for logistics operations similar to Explore’s. The 6x2*4 tractor unit is based on Scania’s battery electric platform, featuring:

• A 400kW electric machine

• 416kWh battery capacity

• A fuel-cell motor with cooling fans

• 56kg hydrogen storage tanks, providing an estimated range of up to 850 km

Explore is a specialist provider of transport and plant hire services in the UK, operating a fleet of 200 trucks. It has 6000 items of plant for hire from a nationwide network of seven depots. Over 300 people are employed, and annual turnover exceeds £70 million.

The company’s transport division has over 50 years of expertise in construction logistics and haulage, while its plant and rail division offers one of the UK’s largest and most diverse equipment ranges. Both divisions provide bespoke, end-to-end solutions tailored to customer requirements.

• Left to right: Warren Wilkinson (Explore Operations Director), Tim Edwards (ZEHID Lead & Regional Sales Manager at Scania UK), Bradley Cooper (Explore Finance Director), Karima Haji (Managing Director at Scania Financial Services UK), David Cox (Explore Managing Director), Chris Gatheridge (Explore Operations Director), and Mark Penn (Transformation Director at Scania UK).

Enhance

Proactively identifies risks

Automatically checks tens of thousands of incidents when taking a booking, empowering informed decisions.

Streamlines reporting

Fully integrated to enable swift incident recording and future authorisation by appointed users.

Enhances industry safety

Reduces industry-wide risk by enabling the sharing of incident data across the Prohire community.

Our gas trucks keep on giving. We’ve enhanced the line up to include 420 and 460 hp with the 13L engine. With a range of up to 1,800 km, and biogas reducing CO2 emissions by up to 90% compared to diesel, you can strike the perfect balance between low emissions, power and range.

scania.co.uk/gas