CREW CUT LAWN & LANDSCAPING STACHLER CONCRETE MELCO FENCE CO

REVOLUTIONIZING TRUCKING WITH HYDROGEN FUEL CELL VEHICLES

DURABLE BY DESIGN

CHOOSING A FINANCING PARTNER: WHY RELATIONSHIPS & CONNECTIONS MATTER

WATCH + LISTEN + READ

CREW CUT LAWN & LANDSCAPING STACHLER CONCRETE MELCO FENCE CO

REVOLUTIONIZING TRUCKING WITH HYDROGEN FUEL CELL VEHICLES

DURABLE BY DESIGN

CHOOSING A FINANCING PARTNER: WHY RELATIONSHIPS & CONNECTIONS MATTER

WATCH + LISTEN + READ

Transform your fleet with the Switch-N-Go® interchangeable truck body system where a single truck does the work of three

The Switch-N-Go® system, from 9’ - 14’, plus interchangeable truck bodies, including dump bodies and dumpsters, will transform your truck into the greatest tool in your business.

Job specific solutions, lower cost of ownership, and smaller footprint are just a few of the advantages of the Switch-N-Go® system.

In the world of work trucks and vans, we have lots of tools - some of which are new(er) and some that date back to the origins of our business. But no matter the age of the tools we have at our disposal, it’s best to employ them in a fashion that best serves our customers, which will almost always be good for our business too; and this is true regardless of what your business is, from dealerships, to upfitters, to OEMs, to any vendor serving the commercial vehicle ecosystem.

Consider the story in this issue about Lance Leavitt/Melco Fence Co. and the truck body he purchased from Scelzi Enterprises more than 30 years ago that’s still going strong. According to Mike Scelzi, it’s a testament to the way they build their bodies and the quality of the materials utilized - or

said another way, it’s the tools they use in their business.

Or maybe it’s the tool of a completely different type, like the one mentioned by Will Brogan when he comments on how important it is to listen and become a resource for both customers and prospects. He even gives a great example of a question you can ask the next time you’re at a gas (or charging) station to get truly insightful feedback from the driver of the work truck or van fueling up. While not necessarily a tool one might think of in the truest sense, listening is something we can all do more of, and doing so frequently offers insights we simply can’t get otherwise.

And let’s not forget that those shopping for and buying commercial vehicles are almost always on the go. These owners / fleet

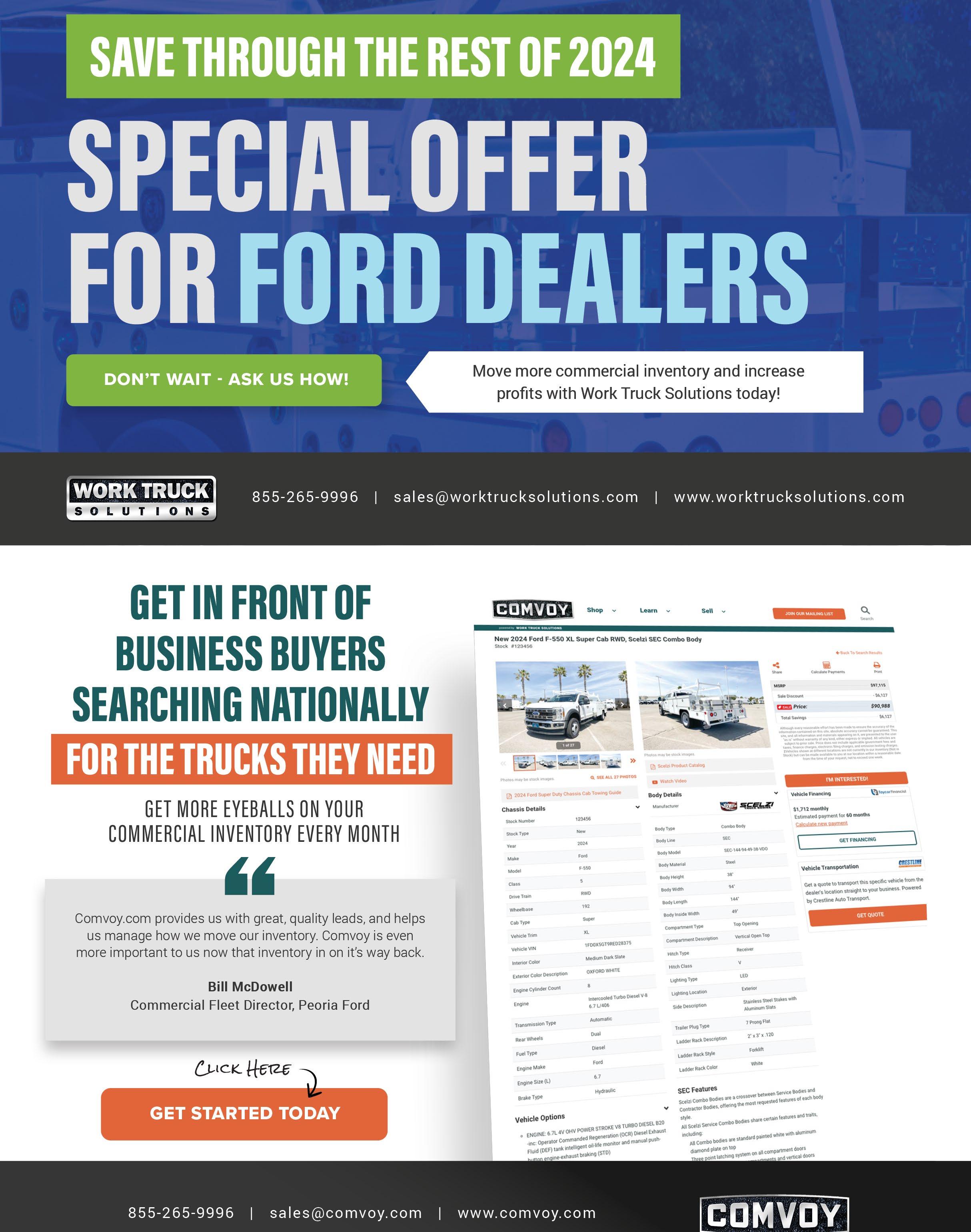

managers are focused on running their businesses, and serving their customers, so it’s important to use digital tools to engage/assist them. Using the digital merchandising tools covered by Shawn Horswill in his article are essential in providing these busy commercial vehicle shoppers the details they need to efficiently find the work trucks necessary to keep their businesses operating profitably.

As you read through this issue, hopefully you’ll find some tools that work for your business. Maybe you’ll even think of some others that we didn’t mention - if so, drop us a line and share your thoughts. Happy reading!

Steve Henning

That’s what you get when you combine two of the nation’s leading upfitters.

Now that Driverge has acquired U.S. Upfitters, it’s not just a question of what we can do for you, but also of exactly where and when. Call us and let’s get started! (855) 337- 9543

SAFE FLEET DEBUTS ITS FIRST SAFETY-AS-A-SERVICE FACILITY IN HOUSTON, AND IT’S A BOON FOR THE LOCAL COMMERCIAL VEHICLE SCENE

July 31st, 2024

Houston, We Have Liftoff Months of planning, building, and heavy lifting have finally come to fruition!

Safe Fleet’s FIRST Safety-As-AService facility in Houston has opened, with a focus on better servicing work trucks and construction, agriculture, refuse, and recycling vehicles in the area.

Previously underserved by Safe Fleet, the city is now getting its fair share of attention--and deservedly so, since it’s home to major energy, manufacturing, and construction hubs.

Says Bryan Elzey, Sr. Director - Safe Fleet Commercial Vehicle:

July 16th, 2024

Quincy, Ill. – The Knapheide Manufacturing Company is expanding its headquarters at 1848 Westphalia Strasse in Quincy, Ill., through its Northeast Expansion project.

“It is one of many ongoing projects that we have right now to sustainably grow our company and will allow us to better serve our customers,” Bo Knapheide, president and CEO, said. The expansion is set to increase Knapheide’s existing facility by 153,797 square feet.

“I am very excited to broaden our showcase of the full Safe Fleet portfolio of commercial vehicle storage equipment, video solutions, and tarping systems to this local community in Texas. With this showroom and upfitting facility, we are the one stop shop for commercial vehicles, dump trucks and trailers to service everyone’s needs."

to Expect

With its portfolio of storied brands catering specifically to commercial vehicles and its 5 drive-in bays (with plans to expand to 8), Safe Fleet is pushing fully customized upfits and white glove service in this latest initiative.

Roll-Rite, Vango, and Pulltarps will provide a wide array of automatic, semi-automatic, and rolling tarp solutions that ensure payloads stay covered. To improve visibility and road awareness, Rear View Safety will supply backup cameras (including those with AI capabilities), side cameras, mobile DVRs, sensors, and

“The new building space will connect to our current shop and will become a dedicated area for material storage and shop offices,” Chris Russell, vice president operations, said. “By removing both from the heart of our production area, we are making our shop safer for employees and increasing assembly space, both of which will increase production and

monitors. The site will also provide organizational and safety solutions from American Van in the form of shelving, ladder racks, flooring, and partitions.

Two things you can expect are attentive assistance from the Service Manager and team at 7720 Bluff Point Dr, Houston, TX 77086, and to pick up a vehicle that will be safer than when you dropped it off.

See you soon, Houston!

Visit www.safefleet.net

reduce lead times.”

Construction for the Northeast Expansion began in April 2024 and will be completed in phases to minimize disruptions to the company’s manufacturing operations. The project’s final phase is expected to be completed in September 2025.

Visit www.knapheide.com

July 23rd, 2024

Work Truck Solutions®, the leading commercial vehicle authority, released its Q2 2024 Commercial Vehicle Market Analysis today. The Q2 data for new and used vehicles highlights that inventory levels, pricing, and sales numbers are, for the most part, following persistent trends. In contrast, the landscape of alternative fuels in the commercial vehicle market remains in flux.

• New: Average sales decreased by 4.8% QoQ and 7.3% YoY.

• Used: Average sales increased for the first time since Q1 2023, showing 2.9% QoQ growth, though it's still down 17.6% YoY.

• Hybrid/Electric work trucks and vans: Average movement of new hybrid/electric work trucks and vans increased significantly, up 35.0% QoQ and 28.6% YoY.

• New: On-lot inventory per dealer continued its upward trajectory, growing 9.7% QoQ and a substantial 66.6% YoY with quarterly growth being primarily early in the quarter, indicating a need to continue to closely monitor these numbers to see if a new trend is developing, or it's an anomaly. The growth was evenly distributed between mediumduty (51.8% of inventory) and light-duty (48.0% of inventory) vehicles.

• Used: On-lot inventory stabilized QoQ, following several quarters of decline, though it remains 18.5% lower YoY.

• Alternative Fuels: A significant 46.5% decrease in new stock of hybrid/electric work trucks and vans QoQ was observed, marking a 25.8% drop YoY.

• New: Average prices for new work trucks and vans increased slightly by 0.6% QoQ and more substantially by 6.8% YoY, reaching a record $58,470.

• Used: Average prices for used work trucks and vans experienced a 1.7% decrease QoQ and a more pronounced 6.1% decline YoY, averaging $33,804.

Average movement of new hybrid/ electric work trucks and vans increased significantly, up 35.0% QoQ and 28.6% YoY.

Work truck and van BEVs: The average price of battery electric vehicles (BEVs) decreased by 3.7% QoQ (from $53,612 to $51,643) and 11.0% YoY.

New on-lot inventory per dealership has been increasing, up 9.7% QOQ and substantially 66.6% YoY.

• New: Average Days to Turn (DTT) increased significantly QoQ (14.5%) and YoY (40%), reaching 119 days, the highest average level since 2020, largely due to increased inventory as well as increasing interest rates.

• Used: DTT remained stable QoQ and decreased 8.3% YoY, with an average of 55 days, suggesting a leveling-off trend.

Data from the commercial vehicle market is revealing an inexorable swing from the days of scarce inventory, with many of the corresponding ripples that come with increased availability.

Sales Dynamics: New vehicle sales continue to slow down, while used vehicle sales showed a slight uptick. Interestingly, the movement of hybrid/electric vehicles increased significantly.

"DATA FROM THE COMMERCIAL VEHICLE MARKET IS REVEALING AN INEXORABLE SWING FROM THE DAYS OF SCARCE INVENTORY, WITH MANY OF THE CORRESPONDING RIPPLES THAT COME WITH INCREASED AVAILABILITY."

Mixed Inventory Trends: The new work truck/van market continues to experience inventory growth, especially in medium-duty vehicles, while used inventory has stabilized. However, the electric vehicle segment saw a substantial decrease in new stock.

Price Adjustments: Prices for new and used work trucks continue to adjust, with slight increases in new vehicle prices and more significant decreases in used vehicle prices. Electric vehicle prices also declined both QoQ and YoY.

Vocation Types: Among the commercial van categories—new cargo, box, passenger, serviceutility, upfitted-cargo—cargo and passenger continued a general upward trend in availability and movement, while the others

continued a general upward trend in on-lot inventory, but a generally flat or declining sales trend. All van types are experiencing increased DTT, both QoQ and YoY.

Chassis Types: New Cab Chassis inventory continued to climb both QoQ and YoY, while Cutaway Chassis inventory declined both QoQ and YoY, and Stripped Chassis availability was erratic. However, movement among all three chassis types either dropped or remained flat and are sitting on the lot longer.

“Although inventory is not back to pre-pandemic levels, we’re seeing indicators that suggest a run toward a buyer’s market is in the making,” said Aaron Johnson, CEO of Work Truck Solutions. “We noted the data shift in our Q1 2024 data report, and we can reasonably expect these trends to continue. Of course, all

of this is subject to emerging local and international affairs, which impact trajectories.” Regarding EVs specifically, Johnson commented, “With many OEMs producing fewer EVs, and sales spiking over the last quarter as buyers take advantage of government incentives, we’ll have to watch to see if this becomes a pronounced trend following the November elections.”

Wrapping up, Johnson noted, “The way end-users shop has evolved into a highly digital affair and is certain to remain that way, so it is wise for commercial vehicle dealers and upfitters to embrace modern merchandising technology.”

For more information, visit www.worktrucksolutions.com

of this is subject to emerging local and international affairs, which impact trajectories.” Regarding EVs specifically, Johnson commented, “With many OEMs producing fewer EVs, and sales spiking over the last quarter as buyers take advantage of government incentives, we’ll have to watch to see if this becomes a pronounced trend following the

Wrapping up, Johnson noted, “The way end-users shop has evolved into a highly digital affair and is certain to remain that way, so it is wise for commercial vehicle dealers and upfitters to embrace modern

Give your operation a lift with equipment you can depend on –durable, made in America, and ready to handle every challenge.

From light-duty electric cranes to full heavy-duty upfit packages, Venturo delivers the rugged performance your jobs demand.

Jun 13, 2024 | Dearborn

Learn more about how the city of Ionia, Michigan added a Ford electric van to its Dial-A-Ride transportation service to help close rural transport gaps.

Jun 20, 2024 | Boston, Mass.

The new program offers free commercial-grade Ford Pro chargers for home or worksite charging to software subscribers enrolled in the Massachusetts Clean Peak Energy Standard.

Jul 17, 2024 | Dearborn

California-based businesses can now get the Ford Pro Smart Charging Bundle, a new initiative to help make it easier for businesses to add electric vehicles to their fleet.

In Edgewater, Maryland, “Jay” Rohrbaugh, owner of Crew Cut Lawn and Landscaping, began transforming landscapes and beautifying properties just before the year 2000. Nearly 25 years later, Jay’s company continues to remain successful. But, what is his secret? The answer is hard work, exceptional service and the versatility of SwitchN-Go® work trucks.

Jay first came across SwitchN-Go® while searching online, particularly through a post on Lawn Site by early adopter Jarod Hynson, who loved and praised the system’s effectiveness on a Freightliner FL-70. Intrigued by the potential for a cost-effective, lightweight alternative to traditional hooklifts, Jay began considering the system’s benefits for his own business. It took several years of contemplation and research before Jay made the strategic decision to integrate Switch-N-Go® into his truck fleet.

When Jay finally made the leap of faith, he purchased a Switch-NGo® system and subframe unit and converted one of his fleet stake body dump trucks into a SwitchN-Go® truck. This transformation

was a game-changer for Crew Cut. This single unit proved its worth by simplifying operations. The ease of dropping the body to the ground and loading debris with minimal manpower was what these landscapers needed all along. Tasks that once required multiple workers could now be efficiently handled by a single person, drastically improving productivity and managing overhead.

it a lot easier for that one guy to load trash or yard waste into the body to haul it away versus normally we need two or three guys on a job site just to pick up the debris [and throw it] over the sides of the truck,” said Jay. By enabling the truck body to be placed on the ground, the system allowed a single worker to handle tasks that previously required a team, significantly reducing labor costs and improving operational efficiency.

"JAY’S JOURNEY WITH SWITCH-N-GO® IS ONE OF INNOVATION, EFFICIENCY AND COMMUNITY. HIS EXPERIENCE EMPHASIZES THE SIGNIFICANT IMPACT THAT ADAPTABLE, USER-FRIENDLY EQUIPMENT CAN HAVE ON A BUSINESS."

Before adopting Switch-N-Go®, Crew Cut Lawn and Landscaping faced significant challenges, particularly in job site efficiency. Loading trucks was labor-intensive, often requiring multiple workers to manage debris. This inefficiency was a bottleneck in their operations. Switch-N-Go® alleviated these issues, allowing for easier, more efficient loading and unloading. “One guy can drag his material into the dumpster for disposal, and it makes

The versatility of the Switch-NGo® system opened new business avenues for Jay and his team. With the ability to interchange truck bodies, Crew Cut Lawn and Landscaping grew their business and diversified their services. The same truck now could be used for landscape maintenance, power washing and seal coating on different days of the week. As Jay said, “That truck is not stuck just

sitting there [some] days because we are able to utilize the one truck chassis with multiple bodies.” The flexibility not only maximized the use of their equipment but also expanded their service offerings without the need for additional trucks.

When asked to pinpoint the best aspect of the Switch-NGo® system, Jay highlighted its interchangeability. The ability to “switch” out bodies - such as salters, seal coaters, power washers and dumpsters - enabled Crew Cut Lawn and Landscaping to operate as multiple companies with a single truck. This diversification is where the Switch-N-Go® system truly shines, providing unmatched flexibility and efficiency.

Jay’s enthusiasm for the SwitchN-Go® system extends beyond his own business.He actively runs a Switch-N-Go® owners group on

Facebook independent of SwitchN-Go® with about 20,000 members where people like Jay can network, discuss all things Switch-N-Go® and share innovations. “I try to get my other friends to do it because of how beneficial I’ve seen it for our company. It just makes you do things differently, and it’s not that much more of [an initial] cost,” said Jay. His advocacy has helped numerous other businesses realize the benefits of the Switch-N-Go® system, fostering a community of users who share tips, modifications and success stories.

Jay’s journey with Switch-N-Go® is one of innovation, efficiency and community. His experience emphasizes the significant impact that adaptable, user-friendly equipment can have on a business. By reducing labor costs, expanding service capabilities and fostering a community of like-minded professionals, Jay has not only improved his own operations but has also contributed to the broader landscaping industry.

In the words of Jay, “The

interchangeability of any body on one truck is the highlight of the system. You can be six different companies with one truck.” This statement encapsulates the transformative power of SwitchN-Go®, a system that continues to revolutionize the way businesses operate, one body at a time.

For those in the landscaping and maintenance industry, Jay’s story serves as an inspiration for leveraging innovative solutions to overcome challenges and seize new opportunities.

To learn more about Switch-N-Go®, visit switchngo.com or call at (888) 311-0867

tachler Concrete, Inc. is a family-owned and operated concrete provider in St. Henry, Ohio. They specialize in residential and commercial interior and exterior concrete and stone work.

Stachler Concrete handles the footing, foundation walls, basement flooring, patios, driveways, sidewalks and more.

Andy Stachler, owner of Stachler Concrete needed to replace an outdated Auto Crane to continue keeping his projects on track. He needed a new crane with a smaller footprint that had the capabilities to not only move heavy slabs and other stone products, but to pick up heavy-duty equipment and power trowels, floor saws and generators.

Stachler discovered Venco Venturo through an online search and was pleasantly surprised to learn they were also located in Ohio.

Through his research, Stachler found that the Venturo ET6K would be an efficient and powerful crane to meet the needs of his concrete construction business. The crane has the small footprint he wanted, is budget-friendly and easy to use.

Stachler purchased the Venturo

ET6K electric crane, which comes equipped with the following:

• Capacity overload shutoff system

• 50 feet of 3/16” aircraft-quality wire rope

• Remote pendant with 20-foot cord

• Load block with swivel hook and safety latch

• Master disconnect switch

• 25-foot battery cable

The ET6K falls outside OSHA regulations for certified crane operators, allowing any operator to use the crane on the jobsite.

The team at Venturo also provides training on every crane.

“THE

to do that involves their legs and back,” Stachler said. “Instead of needing two people to lift 150 to 200 pounds of equipment, we have one person do the lifting without exerting as much physical effort. It also enables us to be more efficient with our crews as we don’t have to assign two people to a job site when the crane can do the work.”

Due to its small footprint, the Venturo ET6K is easy to mount on a truck.

“If I want to switch to another truck, it doesn’t take much to do that. It offers more flexibility if I decide to sell a truck, but I’d still want to keep the crane.”

VENTURO ET6K IS EXACTLY THE SOLUTION WE WANTED,” SAID STACHLER. “WE USE IT SEVERAL TIMES A DAY, EVERY DAY. WE USE IT WITH MULTIPLE CUSTOMERS AND CAN BRING IT BACK TO OUR SHOP AND EASILY CHANGE OR ADJUST FEATURES AS NECESSARY.”

The Venturo ET6K crane enables Stachler Concrete operators to pick up objects and equipment weighing up to 500 lbs.

Stachler said it needs only a single operator who often also has to pick up heavy tools and equipment with the boom.

“It saves physical labor and offers relief on the lifting employees have

For more information visit www.venturo.com

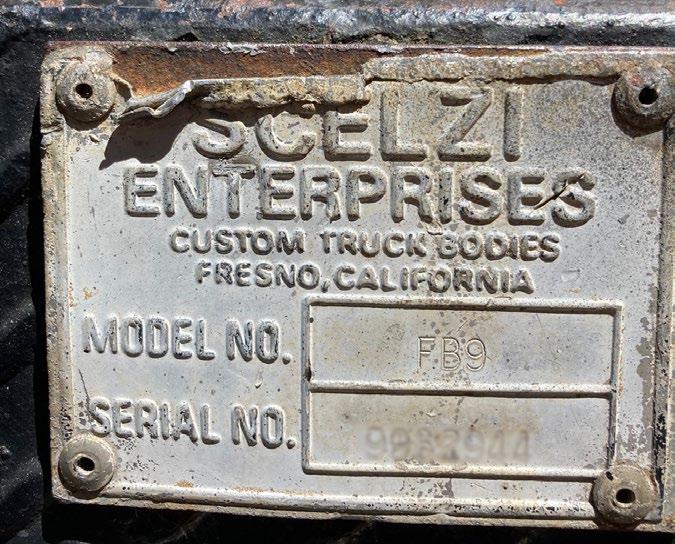

By Bill Vander Plaats, SCELZI PREMIUM TRUCK BODIES

AT A TIME WHEN STANDARDS SEEM TO BE DECLINING EVERYWHERE, MAINTAINING YOURS WILL SET YOU APART FROM THE CROWD

When a new work truck is delivered to the customer, we sometimes think the transaction is complete. But only if we do it wrong. A work truck is not a consumable item like pizza, or something that sits secluded in the corner of a garage like a hot water heater. A work truck is a mobile, interactive billboard that demonstrates your company’s commitment to quality every single day it stays on the road. It comes with an ownerdriver who will often readily volunteer the pros and cons of his decision to purchase that cab+body combination, and how it helps him perform his work at each and every work site each and every day. For the sales and support staff at Scelzi Enterprises – whose truck bodies often outlive the chassis cab they were initially mounted upon – these are usually very positive conversations. Take the recent request they received from the customer who wanted to replace the weathered Scelzi nameplate on his 1993 Scelzi flatbed. “We bought the body for our fencebuilding company,” states Lance Leavitt, previously with the Melco

Fence Co, “and it has been the best truck body we ever owned. We had just landed a big contract with a large water district in the California Central Valley, but none of our existing trucks were small enough to maneuver well in their tight flood control spaces, while still rugged enough to handle heavy loads of chain link steel fencing. So we contacted Scelzi to build us a custom 9-foot flatbed, and boy, did they deliver!”

More than 31 years later, the truck body is still a work horse. It has a new home near Tacoma and a new job now, but it still looks ready for anything. “It is ready for another 30 years of work,” Leavitt adds with a smile, “but that nameplate must have scraped up against a few too many embankments, and it bothers me how it looks on an otherwise great-looking body. So I asked the people at Scelzi if they could make a duplicate with all the original information included –and they were kind enough to do so. What we love most about our Scelzi flatbed is the one-piece rolled edges. This bed has withstood forklift sideloads for 30 years and shows no signs of damage”.

The new nameplate arrived several days later, and Leavitt is

looking forward to switching out the crusty original with the shiny new replacement. But first he is planning to repaint the original bed and make a few more cosmetic changes, “Just to make the whole thing shiny again,” he says. “There are so few things you can buy today that seem to last as long as they used to, it’s just really nice to own something that does.”

These are comments Scelzi owner Mike Scelzi has been hearing for over four decades, but he never tires of hearing them one more time. “We know there are accountants out there somewhere telling their truck body designers not to use so much steel, or to use cheaper materials, or to weld a faster way – but none of those people will ever work for me,” states Scelzi. “I love driving down the freeway or a country road and seeing one of our truck bodies at a job site or being driven to one. I can’t help but grin a little. And I have to admit, the older the Scelzi truck body, the bigger my smile.”

Standards that don’t get compromised. It’s still the standard for Scelzi Truck Bodies.

As we consider the future of the commercial vehicle industry, it is clear that we are on the cusp of a new era. The future of commercial vehicles will be shaped by several factors, including the increasing demand for last-mile delivery and technological advancements.

However, one commonality within the dynamic field of commercial transportation is the inevitable move toward net-zero emissions.

We’ve heard, time and time again, about the importance of building relationships and establishing connections. Doing so helps you build trust with stakeholders, retain and grow business with existing clients, and develop referral business.

It sounds simple enough. Yet understanding how relationships and connections work, at every level, can change your core business approach – and in the process, drive your business to long-term, sustained success.

Many of us associate relationships and connections with identifying and developing new customers. While important, effective relationshipbuilding must take place with several types of stakeholders: customers, prospective customers, employees, suppliers, vendors, –and financing partners.

When it comes to financing, it’s particularly easy – and common – to grab the best-priced deal and sometimes that makes sense.

You need money to buy inventory or help a customer. But if you are in business, you know things like recessions come along. Pandemics happen. Markets change. The shift to electrification creeps up on you. You start to understand the value of longer-term relationships.

You also know that if you value a customer’s business, you need to engender their loyalty by meeting their needs – not just today or this month, but for the long run. To develop that type of loyalty, you must build strong relationships that are based on a good understanding of their business model.

Likewise, dealers need to build strong relationships with finance partners. A partner is different than a lender. A financing partner makes it a priority to learn about your business and your customers’ businesses before suggesting a financing method or program. They’ll learn your goals and your challenges. A commercial-only lender will understand the details of your inventory, your operations and your customer base.

Working with that knowledge, a partner will be creative in their approach to find the best options for you, rather than offer commodity solutions. A true partner is in it for the long run, looking to grow together with you, not at your expense.

These types of solid, long-term relationships are everything in this

industry. They can bear the weight of the inevitable ups and downs your business will experience. As tempting as it is to do business on a transactional basis – looking to get the most out of every individual deal – focusing on the long run is what produces real growth for a dealer business.

Connections generally refer to more casual associations than relationships, but are every bit as important for a dealer, as they represent the opportunity to “value up.” You can offer resources, insight and knowledge to your customers and other stakeholders when and where they need it. The broader and deeper your connections, the more valuable you become.

In financing, dealers benefit from working with a partner that has strong connections. In my company, the ability to lend into the entire supply chain – from inventory finance and vendor programs to equipment-as-a-service financing – is key, as we understand that a dealer in today’s market is going to need more than money to simply buy or sell a truck. In this complex economy, we know that we can’t be everything to everyone, but we can maintain a deep network of connections to meet every dealer’s needs.

Fleet electrification is one good example of the value of connections. Dealers need a wealth of information, knowledge and

resources before they can move forward. So we’ve built connections with expert consultants and companies that can help a dealer with anything from development of charging and other infrastructure to staffing changes and training, operations, insurance, government regulations and credits, and more.

Years ago, in the days before internet, cell phones and texting, financing professionals managed everything. I myself delivered checks by hand, handled all recordkeeping and maintained paper trails of documentation. Moreover, I made the effort to spend time with every dealer principal with whom I worked. Over weeks, months and years, we would learn about each other’s businesses, families and

challenges, and shoulder through the ups and downs of life and the economy. Through it all, I gained valuable insight and long-term working relationships – and learned how to serve my customers better in any given situation.

Today, we may work with more technology and operate at a faster speed, but those basics haven’t changed. Perhaps it’s just taking time to send a few text messages, pick up the phone or arrange an onsite meeting.

Smart dealers know that finding and capitalizing on the best opportunities for growth is a continuous process. Forging longterm relationships with a finance partner dedicated to growing with you will lead to positive bottomline outcomes and long-standing success over time.

By Kirk Mann, Executive Vice President and General Manager of Transportation, Vendor Solutions Mitsubishi HC Capital America

For more information visit www.mhccna.com

The technologies such as propanefed internal combustion engine (ICE) vehicles and battery electric vehicles (BEV) are two competitive options in the market as of now.

Propane, also known as liquid petroleum gas (LPG) or autogas, is a mature green technology enjoying renewed interest as emissions regulations tighten worldwide.

Battery electric vehicles (BEV) are another option for fleets looking to reduce emissions. Although commercial BEVs are relatively new, they have been gaining traction as availability, range anxiety, and charging infrastructure are being addressed.

In the quest for sustainable and cleaner transportation solutions, a third zero-emission alternative for commercial fleets is emerging: fuelcell electric vehicles (FCEVs).

A Fuel Cell Electric Vehicle (FCEV) operates by converting hydrogen gas into electricity through a chemical reaction within its onboard fuel cell. The vehicle stores hydrogen in

high-pressure tanks, which is then fed into the fuel cell stack. Once in the fuel cell, hydrogen molecules are split into protons and electrons through a catalyst.

Protons pass directly through a proton exchange membrane to the other side of the fuel cell, while electrons are forced through a circuit, creating a flow of electricity that powers the vehicle's electric motor. At the cathode side of the fuel cell, the electrons and protons reunite, combining with oxygen from the air to produce water and heat as byproducts.

This elegant operation allows FCEVs to run efficiently and emit nothing but water vapor, offering a compelling solution for zeroemission transportation.

When comparing FCEVs to BEVs and traditional vehicles, it's clear that FCEVs hold a unique position, especially in commercial applications where range and refueling time are critical factors.

Range anxiety has been a significant barrier to the widespread adoption of electric vehicles. FCEVs mitigate these concerns with their ability to travel longer distances between refueling, akin to conventional vehicles, while maintaining the benefits of electric propulsion. Commercial fleets across the globe are beginning to recognize the potential of FCEVs to enhance their operations, notably in long-haul transport, where range capabilities are paramount.

Given that FCEVs are typically lighter than their BEV counterparts, owing to the inherent efficiency and compact nature of fuel cells, there is a consequential reduction in tire wear. This not only translates to lower maintenance costs but also further bolsters the environmental benefits of FCEVs through reduced resource consumption.

The lighter nature of FCEVs, as opposed to BEVs, inherently increases their usable payload capacity. This is particularly advantageous in commercial settings where maximizing cargo load without compromising efficiency is paramount. The potential to transport more goods with fewer trips can significantly enhance operational efficiency and sustainability.

The surge in EV adoption poses notable challenges to the existing electrical grid infrastructure, primarily due to the increased demand for power. FCEVs, by utilizing hydrogen as a fuel source, mitigate this strain by reducing reliance on the grid.

GM is collaborating on a solution for low-emissions worksites with its fleet of fuel cell-powered medium duty trucks and supporting infrastructure

especially as the Department of Energy has invested billions of dollars in incentives for hydrogen development, encompassing funding, research, and infrastructure support. By alleviating initial challenges, such as high costs

Recharging is a primary concern for any organization considering fleet electrification. For FCEVs, however, the concern is hydrogen refueling. The good news is that for the enduser, hydrogen refueling is much the same as for traditional fossil fuel vehicles.

The not-so-good news is that hydrogen refueling infrastructure is even less advanced than BEV recharging infrastructure. This is all changing rapidly, though,

and limited infrastructure, these incentives are setting the stage for a more pronounced presence of FCEVs in the commercial sector, benefiting manufacturers, fleet operators, and the broader transportation ecosystem.

FCEVs maintain a promising outlook, but adoption faces hurdles regarding infrastructure development, commercial usage

feasibility, and upfront costs. The journey towards green transportation is multifaceted, and FCEVs are at the forefront of this transformation. Major players like Nikola, Hyundai, and Hyzon are pioneering the change and revolutionizing the commercial sector by effectively addressing range anxiety and reducing grid load. Their rise not only represents a significant leap towards sustainable transportation, but also highlights the collaborative efforts required to make a cleaner, greener future a reality.

The recent announcement that Honda will collaborate with General Motors to produce a Class 8 vehicle punctuates the point that synergies will be key to achieving sustainable transportation.

Together, these companies embody the collaborative efforts and technological advancements propelling the commercial sector towards a zero-emission future, highlighting a collective commitment to making sustainable transportation a practical reality.

As the automotive industry shifts toward sustainability, electric vehicles (EVs) are becoming increasingly prevalent in commercial fleets. This transition highlights the importance of reevaluating the components that ensure a vehicle's efficiency, safety, and longevity— specifically, the tires. For business owners and fleet managers who already use commercial EVs or are considering fleet electrification, comprehending the nuances of EV tire design and selection is indispensable.

Commercial electric vehicles have demands that differ significantly from those of their internal combustion counterparts. The immediate torque delivery and heavier weight due to large battery packs put additional stress on the tires, which can lead to premature wear and tear.

These characteristics necessitate tires that can withstand additional load and minimize rolling resistance, contributing to the vehicle's overall range and efficiency.

Additionally, the silence of electric motors amplifies road noise, making tire noise a crucial factor for operator comfort—a vital consideration for vehicles in continuous operation, such as buses and long-distance delivery trucks/vans.

When selecting tires for a commercial electric fleet, it is crucial to prioritize durability, performance, and noise reduction. Fortunately, tire manufacturers are incorporating emerging technologies to develop tires specifically designed for electric vehicles.

Durability: The construction must be robust enough to handle the extra weight of EVs without compromising performance. These tires feature reinforced sidewalls that improve

rigidity when cornering and advanced materials engineered to manage the high torque output typical of electric motors.

Performance: Tires with low rolling resistance are an increasingly important technological advancement. Manufacturers are developing new materials that reduce the energy loss as tires roll, enhancing the vehicle’s range between charges.

Noise reduction: Innovations in tire technology, such as improved tread designs, rubber compounds, and foam baffles, are emerging to help reduce road noise. These advances are crucial for enhancing driver comfort and reducing noise pollution in urban environments. Road noise from tires in an ICE vehicle is usually masked or drowned out by the sound of the engine. Not so with an EV.

The rise in EV adoption has not gone unnoticed by tire manufacturers that recognize the unique needs of commercial EVs.

For example, Goodyear has introduced several innovations tailored specifically for commercial electric vehicles (EVs) to improve performance, efficiency, and durability. These innovations are showcased in Goodyear’s RangeMax RSD EV tire. Engineered to offer lower rolling resistance than standard tires, this tire enhances energy efficiency across all types of drivetrains, while also being designed to handle the higher load capacities typical for electric vehicles, thus delivering better range and durability.

Michelin is also introducing technological advancements in the commercial EV tire sector with offerings like the MICHELIN X® INCITY™ Z / EV Z tires. These tires are specifically designed for electric buses, but optimize performance across traditional buses as well. Key features include improvements in load capacity (up to 8 tons), reduced rolling

resistance (up to -13%), and enhanced mileage (up to +10%).

Furthermore, some tire manufacturers are integrating sensors that monitor conditions such as tire pressure, temperature, and tread wear in real-time. These smart tires can significantly contribute to safety and maintenance scheduling, ensuring that the tires are always in optimal condition and thereby reducing maintenance downtime.

According to Continental, advanced tire sensor systems can extend tire life by 4,660 miles, improve fuel mileage by up to .6%, and reduce fuel consumption by as much as 3%.

Investing in high-tech, EV-specific tires may come with a higher upfront cost, but it can lead to considerable savings in the long run. Enhanced durability reduces the need for frequent replacements, while the improved fuel efficiency achieved with lower rolling resistance tires contributes to decreased operational costs over the vehicle's lifespan.

For customers considering transitioning to electric fleets, incorporating the right tire strategy into an electrification plan is essential. Evaluating a fleet's specific needs, the type of vehicles, their routes, and load requirements is a good starting point. Prioritizing tire selection can help ensure a smoother shift to electrification, reducing potential roadblocks and optimizing ROI from the start.

“THE ONLY SOURCE OF KNOWLEDGE IS EXPERIENCE.”

– Albert Einstein

In today's competitive market landscape, businesses in every industry are increasingly recognizing the pivotal role that end-users play not just in purchasing decisions, but in shaping the entire product lifecycle. Your effort to establishing meaningful relationships with these end-users – those who drive and utilize your vehicle on the job site –goes beyond customer service and putting out fires; it involves actively seeking and utilizing their feedback to enhance overall strategies and to drive product innovation with your partners, like upfitters and maybe even your manufacturer!

The relationship between a company and its end-users is no longer one-directional. Instead, it has evolved into a dynamic exchange where customer experiences and opinions hold significant sway over business outcomes. If you put value and time into constructing a genuine connection with end-users, you can gain invaluable insights into their preferences, pain points, and expectations. This deeper understanding forms the core for tailored solutions that resonate with the target audience – something that several upfitters take to heart to become the preferred vendors of small businesses and massive fleets alike.

Through various interactions with their employees, businesses can pinpoint areas for improvement and

innovation. When it comes to their vehicles, you have a chance to not only be involved, but be proactive. In our Ultimate Boot Camps, one of the words that comes up time and again is “Resource” – which is something we recommend you be for your customers and prospects as often as opportune. The more of a listening ear you can provide for your business’ end users, the more of a valued resource you become. That goes a long way to establishing a relationship on a solid foundation. Hey, by the way, the next time you go to a gas station and see a work truck driver, ask them a very simple question: “What do you like most about your vehicle?” Congratulations, you just started a conversation with a person who can give you tons of insights, and is not trained to be a gatekeeper!

Involving end-users in the iterative process of product enhancement fosters a sense of ownership and loyalty. Sure, this is not going to happen on a large scale with your manufacturer. However, we’ve seen examples of drivers absolutely loving certain components of a vehicle, and not wanting to change to a different product.

We’ve experienced drivers sharing the real “expiration” of a vehicle’s use, which helps to refine their fleet’s cycling process. Therefore, it’s no surprise that those who feel heard and valued are more likely to advocate for the brand, potentially amplifying organic growth through positive word-of-mouth with the decision makers you interact with on a regular basis.

This component of our industry –when a dealership, upfitter, business, and end-user come together to create a unique solution – is

absolutely my favorite component of what we as an industry do. The creativity, innovation, and general “answering of the call” nature of these solutions is so much fun to observe.

I look forward to hearing about your next impactful interaction and partnership with the real drivers of your business!

By Will Brogan, Commercial Truck Training

ccording to Wikipedia, “Workhorse Group Incorporated, originally AMP Electric Vehicles, is an original equipment manufacturer and technology company headquartered in Sharonville, Ohio, U.S. Workhorse makes commercial electric vehicles and telematics software designed for last-mile delivery. Their products include commercial electric vehicles and the Metron telematics software system.” But that just scratches the surface of what’s happening at the four facilities Workhorse operates.

For most of its history, Workhorse had been more of an R&D company that was developing advanced technology.

Around 2020, the company made the decision to establish itself as an OEM that could produce in volume a steady, reliable commercial EV product to the market.

“I came to the company about three years ago because we wanted to develop a brand-new product and relaunch as a full OEM,” says Josh Anderson, the CTO at Workhorse, "Workhorse is an electric lastmile delivery truck and chassis manufacturer with a long and varied history. The company has been around for about 10 years in its current configuration, but the history of the company goes back almost 100 years.”

The type of chassis Workhorse builds are purpose-built for commercial electric vehicles (EVs). Purposebuilt chassis offer a multitude of advantages that can significantly improve the performance, efficiency, and overall value of these vehicles. Unlike repurposed internal combustion engine (ICE) chassis, EV-specific chassis are designed to maximize the benefits of electric powertrains.

“One of the key innovations of Workhorse's flagship product, the W56 Stepvan, is its regenerative braking system,” explains Anderson.

“This system differs from traditional braking systems in that it captures kinetic energy during braking and converts it back into electricity to recharge the battery. This not only reduces wear and tear on the brakes, but also increases the range of the vehicle.”

Looking at three of the benefits associated with EV purpose-built chassis, and regenerative braking specifically, we see two obvious benefits and one hidden gem.

By converting kinetic energy into electricity during deceleration, regenerative braking reduces the reliance on traditional friction brakes, resulting in significantly less wear and tear on components like brake pads and rotors, thus extending their lifespan and reducing maintenance requirements.

Regenerative braking systems can be seamlessly incorporated into the vehicle's architecture, allowing for more efficient energy recapture during deceleration.

“The amount of energy recovered through regenerative braking depends on various factors, including the weight of the vehicle and driving habits. Workhorse has seen a 30% recovery rate in many of its delivery routes.” says Anderson. “With a diesel truck, you can’t put fuel back in your tank by stepping on the brakes. But with regenerative braking, you can.”

Ironically, learning to get the most ROI from a regenerative braking system translates to brake longevity with traditional brakes as well.

“Some people may just use traditional

braking habits because they're not really confident in how regen brakes work,” opines Anderson. “If you slam on the brakes all the time, you may not see any benefit at all. But people who learn to let the motor do the work can really see substantial savings, particularly with stop and go delivery.”

As drivers learn to pay more attention to how their vehicle behaves under different load and braking conditions, they tend to be easier on brake parts, no matter whether traditional or regenerative.

Regenerative braking and EV purpose-built chassis have aspects that contribute to reduced total cost of ownership (TCO), and Workhorse’s W56 Stepvan has been well-received in the market, with fleets appreciating its reliability and performance.

Workhorse is currently focused on expanding the portfolio of the W56 by offering multiple wheelbase versions, adding features, and developing specialized versions such as refrigerated units. The company is also exploring adjacent markets for its powertrain technology.

This article is excerpted from a podcast conversation between Kathryn Schifferle, Founder & Chief Vision Officer at Work Truck Solutions, and Jackson Haskell, Director, EV Infrastructure of Guardian Fueling Technologies.

The automotive industry is undergoing a shift towards electrification, and businesses and fleet operators are increasingly exploring the potential of electric vehicles (EVs). Although the transition presents exciting opportunities, it also raises the issue of adoption anxiety. Let’s look at three viewpoints that impact EV adoption within the commercial vehicle industry.

The development of electric vehicles (EV) has involved brand new technologies, new ways of utilizing existing technologies, and a synthesizing of the two; integrating the established aspects of conventional vehicles with the latest EV tech.

The development of EV charging infrastructure is a mirror process. And while there’s no shortage of business startups based on emerging tech, wellestablished companies are leveraging their experience to build out the much-needed charging infrastructure crucial for EV adoption in commercial transportation.

For instance, Guardian Fueling Technologies, a trusted name with a 50-year legacy in the petroleum industry, is now leveraging its vast experience in fueling solutions to drive the development of EV

charging infrastructure. With a deep understanding of fuel systems, regulatory compliance, and site construction, Guardian is uniquely positioned to navigate the complexities of EV charging installations.

really is sort of finding itself fitting into those existing molds of infrastructure construction and maintenance. We see no need to reinvent the wheel when it comes to EV charging.”

THE SHIFT TOWARDS ELECTRIC VEHICLES IS A MULTIFACETED CHALLENGE THAT REQUIRES COLLABORATION BETWEEN INDUSTRY LEADERS, POLICYMAKERS, AND CONSUMERS.

The company's expertise in petroleum-based refueling installations translates well to the placement of EV charging equipment. Guardian's established relationships with regulatory bodies also streamline permitting processes, accelerating project timelines. By repurposing its extensive knowledge and resources, Guardian Fueling Technologies is playing a pivotal role in building the future of sustainable transportation.

Guardian’s tactic of leveraging existing fueling infrastructure is a practical approach that minimizes waste.

“When I came to Guardian, it was in part to move us in the direction of enabling electric fueling (EV charging)," explains Jackson Haskell. “Although EV charging is just another means to provide the energy to move a vehicle forward for commercial use, it had sort of been built off to the side as an industry, and I think part of me joining Guardian was to pull EV charging into the standard portfolio of fueling. It’s been educational for me to see how much of that is actually very easy to transpose over and actually how much EV charging

From Haskell’s viewpoint, the similarities between traditional fueling and EV charging in terms of terminology, software, systems, hardware, and payment methods suggest that integration, rather than reinvention, is the most efficient path forward.

The speed of EV adoption and fleet electrification is heavily influenced by use-case viability and how userfriendly it is.

“Range anxiety is still a big deal,” says Kathryn Schifferle. “Cost is also a significant factor in adoption. However, the commercial space is really unique in that it's purposebuilt. It's not like, ‘Is it faster or the right color?’ or whatever. Commercial buyers want to know, ‘Will it do this particular job for me?’ So it’s really beneficial for EV stakeholders to take the time to determine their commercial buyer’s needs and be able to recommend the exact perfect model for it.”

"We need to start with what the customer needs, not with what we want to design,” says Haskell. “We’re working to ensure a seamless transition for drivers and fleet operators by adapting familiar technologies like tap-to-pay credit cards and mobile payment apps and integrating EV charging into existing fueling management software.”

While technological advancements and customer-centric solutions are crucial, Haskell acknowledges the role of government incentives in accelerating EV adoption. He suggests a combination of incentives (carrots) and mandates (sticks) to encourage businesses

and fleet operators to make the switch. Additionally, he emphasizes the importance of considering the total cost of ownership, including maintenance and fuel costs, when evaluating the long-term benefits of EVs.

The shift towards electric vehicles is a multifaceted challenge that requires collaboration between industry leaders, policymakers, and consumers. By leveraging existing infrastructure, adapting familiar technologies, and prioritizing customer needs, companies like Guardian Fueling Technologies are helping pave the way for a smoother, more efficient transition to a sustainable future.

Plymouth, MI — September 24th, 2024

Registration ›››

The commercial vehicle community will gather at Saint John’s Resort in Plymouth, Michigan, for NTEA’s Executive Leadership Summit, featuring a full-day program Sept. 24, 2024, and an evening reception Sept. 23. This annual conference addresses marketplace dynamics currently impacting work truck industry companies. During this event, chassis OEMs, economists, data analysts and industry leaders will share targeted information, including key trends, forecasts and insights.

Sandusky, OH — October 15-16, 2024

Registration ›››

NTEA's Commercial Vehicle Upfitting Summit brings together the vehicle upfitter community with chassis manufacturer technical and engineering experts. This annual conference offers work truck industry professionals the chance to

• Preview commercial vehicle updates

• Engage with OEM engineers on critical upfitting issues

• Learn about changes to powertrains, electrical systems, chassis structures and other vehicle systems

• Speak directly with chassis OEM technical representatives and product specialists

Shawn Horswill - Work Truck Solutions, SR VP of Product

Intoday's fast-paced business environment, commercial vehicles are the lifeblood of countless enterprises. From bustling construction sites to efficient delivery fleets, these workhorses are essential for transporting goods, providing services, and driving economic growth. For the business owners and fleet managers who rely on these vehicles, the purchasing process is a critical decision that directly impacts their operational efficiency and bottom line. In the digital age, customer expectations have evolved dramatically. The days of browsing through dusty brochures and relying solely on a salesperson's pitch are long gone. Today's savvy buyers demand transparency, convenience, and a seamless experience, both online and offline. This is where modern merchandising practices come into play. By embracing up-todate strategies, commercial vehicle dealerships can not only meet, but exceed customer expectations, ultimately driving sales and fostering long-term loyalty.

Business owners and fleet managers are not impulse buyers. They approach vehicle purchases with a critical eye, considering factors like payload capacity, fuel efficiency, upfit options, and total cost of ownership. Their time is valuable, and they seek dealerships that offer a streamlined, informative shopping experience. Modern merchandising practices, such as providing detailed vehicle specifications, clear pricing, and abundant visuals, cater directly to these needs.

By empowering customers with the information they need upfront, dealerships can significantly reduce

friction in the buying process. A wellinformed customer is more likely to feel confident in their decision, leading to faster transactions and a higher likelihood of repeat business. Moreover, a positive customer experience can generate invaluable word-of-mouth marketing, further amplifying a dealership's reach.

Modern merchandising for commercial vehicles encompasses a multi-faceted approach, focusing on several key elements:

• Accurate Pricing: Transparent and competitive pricing builds trust with potential buyers. Clearly displaying the total cost, including any fees or taxes, eliminates unpleasant surprises and fosters a sense of fairness.

• Abundant Images: High-quality photos and videos are essential for showcasing the vehicle's features and condition. Multiple angles, interior shots, and even 360-degree virtual tours can give customers a comprehensive view without physically visiting the dealership.

• Complete Details: Providing detailed specifications, upfit information, and customization options empowers customers to make informed decisions. This information can be presented through online configurators, interactive brochures, and knowledgeable sales staff.

• Pre-order Segways: Integrating pre-order options allows customers to secure vehicles that meet their specific requirements. This is particularly valuable for businesses with unique upfit needs or those seeking the latest models.

• Digital Merchandising: A userfriendly website with intuitive navigation, mobile compatibility, and detailed vehicle listings is a must. Online tools like payment calculators, trade-in estimators, and financing and delivery options further enhance the customer experience.

Dealership success is ultimately measured by customer satisfaction and loyalty. Modern merchandising practices are not merely cosmetic enhancements; they are strategic investments that yield tangible results. Dealerships that embrace these practices often see increased sales, higher customer retention rates, and a stronger brand reputation.

Data reports from Work Truck Solutions have highlighted a growing competitiveness in commercial vehicle sales, and modern merchandising is necessary for dealership success. By anticipating the needs of your end-users and embracing innovative practices, your dealership can create a seamless, informative, and pleasant buying experience. The result is increased sales and a loyal customer base that will return for future purchases and recommend the dealership to others.

The modern buyer is well-informed, digitally savvy, and expects a personalized experience. Fail to adapt to these evolving expectations, and you risk being left behind. Embracing modern merchandising is not just a trend; it is the key to unlocking longterm success in the dynamic world of commercial vehicle sales.

specialty, and their do so seamlessly for van models like Ford Transits, Mercedes Sprinters, RAM ProMasters, Chevy/GMC Vans and much more. Used to carry heavy-duty tools and equipment in their day-to-day operations, their pre-assembled shelving units:

• Arrive ready to install

• Are anchored by dozens of 5-star reviews

• Are made from heavy duty powder-coated steel and bright aluminum, enhancing storage capacity while maintaining a clean, professional look

Start Maximizing Your Van’s Cargo Storage Capacity