Cover page

Exam information: SD3 -Design Research Project - E23

Handed in by: Cristina Carola Campos Vetencourt

Student Nr: 20220439 ccampo22@student.aau.dk

Despoina Vasiliki Vastardi Student Nr: 20221137 dvasta22@student.aau.dk

Supervisor:

Hanaa Dahy

Assoc.-Prof. Dr.-Ing. M.Sc. Eng. Arch. Lektor, Institut for Bæredygtighed og Planlægning

hanaadahy@plan.aau.dk

Journal for Publication:

International Journal of Architecture and Infrastructure Planning

Hand-in Information:

Title: Applying Tailored Fibre Placement (TFP) to create structural biocompositebased active-bending lightweight modular units

Education: Msc. Sustainable Design Engineering

Semester 3

Project Period: 01 of September - 15 of January

Supervisor: Hanaa Dahy

Number of characters: 46,041 with spaces

Number of words: 6,469

Number of pages: 22

Group members:

table of contents

Abstract

Keywords

Introduction

Literature Review

Regulations and guidance for the construction industry

Design concepts

Architects working with conscious materials

Rhythm, Repetition and Parametric Design in Architecture

Use of Natural Fibres

State of Art

Research Design & Methods

Form Finding

3D Printing Prototyping

Physical Prototyping

Computational design: from components to unit Pattern Generation: Sewing Machine & TFP

Results and Discussion

Conclusion

Acknowledgements

References

0 Abstract

This research is a comprehensive investigation into the application of Tailored Fibre Placement (TFP) techniques, with a specific focus on developing structural biocomposite-based activebending lightweight modular units The primary goal is to contribute to advancements in sustainable construction methods by unravelling the intricate process of finding optimum geometries and TFP processes focusing on folding and bending patterns. The study employs a dual approach, integrating computational design and physical prototyping, to contribute to advancements in sustainable construction methods

1

Keywords

Tailored fibre Placement (TFP), computational design, lightweight structure, modularity, flax fibre, biocomposites, and design for disassembly (DFD)

2 Introduction

In the wake of the 2023 planetary boundaries update, revealing that Earth surpasses the safe operating space for humanity by crossing six of nine planetary boundaries (1), urgent measures are imperative Concurrently, the revised Energy Performance of Buildings Directive (IEA) outlines ambitious targets for the EU building sector—net-zero carbon by 2050, it estimates that direct building CO2 emissions would need to decrease a 50% reduction in direct building CO2 emissions and a 60% decline in power generation emissions by 2030 (2).

1

Given this context, an investigation into alternative design methodologies and the integration of materials and technologies from diverse industries, such as Tailored Fibre Placement (TFP), becomes pertinent. This research seeks to discern how such approaches can contribute to the development of more sustainable construction methods. The concept of sustainability, in this context, denotes the utilisation of lightweight natural materials together with TFP technology, thereby facilitating storage, transportation, and assembly processes on construction sites

Moreover, these initiatives seek to reduce the aggregate quantity of materials utilised, aligning with the overarching objective of promoting environmentally conscientious construction practices amidst the exigencies posed by global challenges.

3 Literature Review

The European Green Deal COM (2019) describes the actions to achieve a transformation of the European economy and society to take place until 2030 and 2050. This visionary communication underscores construction as a key European industry, integrating it into the European industrial strategy and circular economy, with a specific focus on products and relevant clauses within the construction sector It covers a new wave of renovation and addresses important topics such as the Energy Performance of Buildings Directive (EPBD), the Construction Products Regulation (CPR), and the possible implementation of a Building Emission Trade 3 1 Regulations and guidance for the construction industry

1 Planetary Boundaries Six out of nine crossed: Biosphere integrity, Climate change, Novel entities, Biogeochemical flows, freshwater change, Land system change. Not crossed: Ocean acidification, atmospheric aerosol loading, Stratospheric ozone depletion (1).

System (Building ETS) The paper also emphasises digitisation as a key factor in revolutionary change (3).

The Sustainable Development Goals, or SDGs, weave a global framework to address a variety of difficulties, including those posed by ageing societies and heavily urbanised populations, amid this expansive panorama of transformation (4). It becomes essential to share the newest information and technology with a wide range of people to accomplish sustainable development.

The SDGs, a comprehensive agenda defined by the United Nations, reflect this worldwide commitment and are fully aligned with the current objective Sustainable Cities and Human Settlements (SDG 11) emerges as a key performance indicator. Together, the Sustainable Buildings and Climate Initiative (UNEP-SBCI) and the United Nations Environment Programme (UNEP) form a coalition of public and private sector players in the building industry, to advance sustainable building practices and policies globally. Creating internationally accepted baselines using a life-cycle approach is one of the objectives; energy efficiency and greenhouse gas (GHG) emissions will be the focus first Efforts are now extending to encompass additional indicators, including materials and water (5).

As the narrative unfolds, the new European Bauhaus Proposal emerges as a compelling chapter intending to address climate change, pollution and biodiversity loss, the idea is to make sustainability more accessible, by considering these essential facts when designing spaces for European citizens (6) Within this context, a groundbreaking "innovation pool" takes centre stage, fostering an ecosystem that seamlessly connects science, technology, art, and culture. This innovative perspective strives to

breathe life into the historical Bauhaus idea of transversality, making it relevant in our contemporary times (7).

Sustainability concerns within the architecture field predominantly emphasise energy consumption, leaving the material dimension relegated to a domain of certificates vouchsafing recyclability or minimal environmental impact (8). Unconventional proposals, such as those put forth by (9), advocating for a steady state and proposing a moratorium on construction, disrupt established norms and align with a historical tradition cautioning against exceeding the planet's biophysical limits and critiquing capitalism's extractive nature. Beyond mere design innovation, the exploration of alternative materials in architecture represents a fundamental response to the urgent need for a paradigm shift rooted in the principles of bioeconomics. This transformative transition from a linear and extractive approach to a circular and regenerative one, holds the potential to redefine architecture's role in sustainable coexistence with our planet's finite resources, challenging the prevailing narrative and broadening the discourse in the architectural realm.

Among the dual challenges of ageing cities and societies, known as "double ageing," this question arises: how do we sustainably manage the built environment, primarily comprising urban infrastructure and buildings? Addressing these challenges requires the exploration of innovative ideas and techniques that can effectively nourish both society and individual lives in the long term, all within the constraints of limited human and natural resources (10) Sustainable development emerges as a pivotal factor in both urbanisation and urban regeneration In the design and planning phases, discussions should revolve around

approaches to sustain, manage, and rejuvenate cities and buildings, fostering sustainable development in the future

In the realm of sustainable design

Geissdoerfer et al , define a Circular Economy as a “regenerative system in which resource input and waste, emission, and energy leakage are minimised by slowing, closing, and narrowing material and energy loops This can be achieved through long-lasting design, maintenance, repair, reuse, remanufacturing, refurbishing, and recycling” (11)

Differently Nakajima, N , 2000, explains concepts such as circularity and servicebased systems as essential yet insufficient for a sustainable system. Other conditions, like a change of lifestyle, must accompany a closed-loop system to pursue long-term sustainability (12). Similarly, Evans, et al., 2009, characterises circular strategies as a choice alongside alternatives such as enhancing efficiency or dematerialisation. Understanding dematerialisation in the field of architecture as a design strategy aiming for reduced material and resource inputs throughout a building's lifecycle, ensuring operational performance and intended function remains unaffected (13) This

involves considering substitutions like renewable energy sources and bio-based materials while optimising existing inputs (14).

Challenging the foundations of neoclassical economics, the concept of the “bioeconomy” not only questions established economic theories but also extends into the domains of society, politics, and technology (9). Bioeconomics emerges as a critical lens for reevaluating the extractive essence of capitalism; an influence that has profoundly shaped the course of contemporary architecture (15) A highlight of GeorgescuRoegen, N (1977), contribution redefines economics as an integral component of human biological evolution Drawing from the second law of thermodynamics (law of entropy), he highlighted the interconnected flows of energy and materials in economic processes, expanding beyond the conventional factors of production such as labour and capital (9). It serves as a reminder that rather than creating materials, humans only manage them

Bioeconomics, with its focus on the biological foundation of economic processes, underscores the reality that humanity is confined to a limited stock of mineral resources, often unevenly distributed and violently appropriated (15). In the scope of architecture, a discipline traditionally based on aesthetics and static considerations, the consequences of these ideas are serious. As a discipline that relies on materials such as sand, stones, cement, glass and wood it contributes substantially to environmental entropy prompting a reconsideration of material choices and resource management (15) This exploration aligns with the overarching theme of our research, by emphasising the crucial connection between material choices, sustainability, and the transformative potential of innovative design strategies.

3 2 Design concepts

Within this research, the integration of Human-Centred Design (HCD) stands as a transformative methodology converging engineering and design into a cohesive discipline, encompassing technology, organisation, and human elements This interdisciplinary framework facilitates the formulation of well-suited high-level requirements, fostering the development of successful products Human-centred design acknowledges the presence of emergent properties in innovation and supports the gradual enhancement of the integration of technology, organisation, and people towards maturity Specifically, in the context of lifecritical systems, HCD relies on human-in-theloop simulations to comprehend the intricate connections among technology, organisation, and people, aiming to identify emergent properties (16)

The implementation of HCD necessitates the strategic placement of qualified individuals in key roles, emphasising the imperative role of socio-technical leadership across all organisational levels Competence, talent, and engagement become prerequisites for HCD success, reflecting a renaissance in engineering that prioritises people's safety, efficiency, and comfort A comprehensive understanding of the product life cycle, including design, obsolescence, and decommissioning, emerges as a crucial consideration within the purview of effective HCD (16).

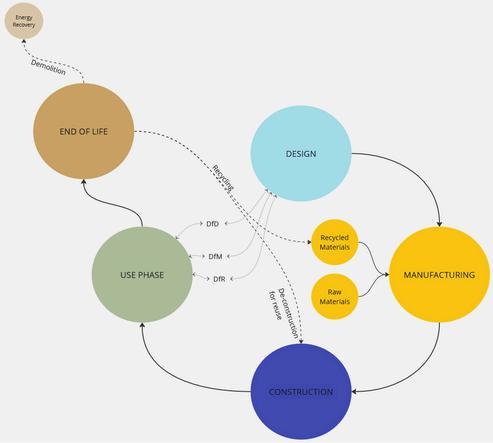

Aligned with the theme of our research, exploring Design for Disassembly (DfD), Design for Maintenance (DfM), and Design for Repair (DfR) becomes pivotal DfD is a design technique that permits for easy recovery of products, materials and parts, the main goal is to maximise economic value and reduce environmental impacts. The fundamental design approaches that integrate circularity into building structures encompass the principles of material 'upcycling' and 'design for disassembly' (DfD) These concepts embody the ideals of both input circularity and output circularity within a building system. Several existing Life Cycle Assessment (LCA) studies delve into upcycling in building design, exploring concepts related to repair, reuse, and innovative ideas for modest reductions in CO2 emissions while also considering alternatives to high-emission materials like concrete (17).

In the context of our research, which is centred around modular units, the emphasis on the repair or exchange of individual units becomes paramount This emphasis not only aligns seamlessly with the principles of DfD, DfR and DfM but also facilitates a streamlined process for the easy recovery of products and components This inter-

connected approach ensures that our research, rooted in modular units, actively contributes to the broader discourse on sustainable building practices and resource efficiency

Deployable structures demonstrate a high potential to meet market demands and sustainability goals, and do so by attempting to reduce construction time, complexity on site, storage, and material consumption (18) The application of Fibre Reinforced Polymers (FRPs) in standardised mass production prompts a research goal to simplify fabrication and allow a higher level of customization by eliminating costly moulds (6).

Moreover, inadequate storage facilities for construction materials can lead to damage and subsequent material wastage In light of this concern, the adoption of lightweight structures that facilitate easy deployment emerges as a commendable alternative. This approach not only accelerates construction timelines but also mitigates complexities at construction sites, minimises storage-related accidents, and diminishes overall material consumption (19)

A connected consideration within our research explores the benefits of Design for off-site construction, including the reduction of waste and significantly changing site operations, reducing the number of personnel on-site and site activities. All of this results in faster assembly resulting in environmental, financial and social benefits Prefabrication, referring to products manufactured, assembled, and pre-assembled in external facilities, is estimated to have the potential to

reduce between 65 and 80% of total construction and demolition waste (20) This multidimensional exploration aligns seamlessly with the research's objective of developing sustainable and innovative building practices

3 3 Architects working with conscious materials

In the context of sustainable architecture and material innovation, notable figures exemplify the intersection of creativity and ecological consciousness. The Living Architecture System Group (LAS) challenges conventional perspectives on building materials Their pioneering work explores materials that emulate living organisms, particularly protocells synthetic structures imbued with lifelike properties, capable of self-assembly, repair, and adaptation.

LAS integrates intelligent controls, machine learning, lightweight scaffolds, kinetic mechanisms, and synthetic biology systems in prototypes This research aims to transform both the physical structures supporting buildings and their technical control systems (21) Similarly, Neri Oxman's approach to sustainable architecture is based on the combination of biological principles, advanced fabrication techniques and material innovation Oxman's success at minimising waste by depositing materials precisely where needed and enabling the production of intricate geometries By fabrication methods like 3D printing and additive manufacturing to craft precise, customised designs (22)

In the pursuit of countering species extinction, Terreform ONE engages in innovative design initiatives, they do so by speculating on the impact of emerging technologies on future urban generations and biodiversity, focusing on ecological planning, biotech architecture, urban systems, and public art Their goal is to develop inclusive spaces and strategies that promote environmental and social justice for all (23).

profound exploration of rhythm and repetition Drawing inspiration from the Bauhaus movement, renowned architect Walter Gropius employed a repetitive arrangement of rectangular shapes and rhythmic windows in the iconic Bauhaus building in Dessau. This deliberate use of repetition transcended mere aesthetics, creating a harmonious flow and a visual cadence within the architectural space.

Hanaa Dahy, a registered architect, engineer, and material developer, is a distinguished figure in sustainability and architecture and is the founder of BioMat. Her work includes developing, designing, and manufacturing innovative sustainable building products showcased in international exhibitions, drawing industrial interest. Dahy's expertise spans biomimetic principles, sustainability, and their influence on architectural practice and applications. Beyond her contributions to innovative materials, she has actively addressed ecological concerns through teaching, publications, and collaborative research projects with industrial partners With pending patents, prestigious awards, and involvement in scientific and professional bodies, Hanaa Dahy has made significant strides in advancing sustainable practices within the field of architecture (24)

Pioneer of modern architecture, Le Corbusier, contributed the Modulor system to this rhythmic symphony. Rooted in human proportions and modular measurements, this system became the guiding force behind structures like the Unité d'Habitation (25).

Beyond its rhythmic aspects, the deliberate repetition of modular elements established a profound connection between architecture and the human scale Exploration of Islamic architecture revealed a rich tradition, exemplified by the mesmerising muqarnas, wherein intricate patterns and rhythmic repetition bestowed a sense of tranquillity upon the spaces they adorned

3 4 Rhythm, Repetition and Parametric Design in Architecture

Under the umbrella of architectural design, the unfolding narrative revolves around a

Rhythm and repetition in architecture go beyond simple stylistic decisions to create a language, a means of expression that appeals to both inhabitants and onlookers The visual poetry produced by the recurrence of elements directs the viewer's gaze and gives architectural settings an enduring resonance

Architects of the contemporary era intentionally employ rhythm and repetition, not only to pay homage to past styles but also as a deliberate architectural choice. Our natural need for continuity, order, and the connection is satisfied by this purposeful arrangement of the components. The timeless interaction of rhythm and repetition generates aesthetically pleasing areas imbued with the harmony of human experience as architecture changes

The London Serpentine Pavilion series defies conventional limits by showcasing the creative potential of parametrically constructed structures (26). The elegance that may be achieved with parametric design is exemplified by buildings like Frank Gehry's Guggenheim Museum and Zaha Hadid's Heydar Aliyev Center. Here, artistic media is created using digital modelling technologies, enabling the realisation of visionary ideas

The story of sustainable architecture also encompasses the facades of contemporary buildings, where parametrically designed facades play a prominent role. With its parametric sunscreens, the Al Bahr Towers in Abu Dhabi create a dance with the sun With a smooth integration of form and function, these dynamic facades that adjust to the passage of the sun maximise daylight and provide shade where it is needed.

Yet, the story ventures into the digital realm, where generative design tools, fueled by algorithms and artificial intelligence, propel architecture into uncharted territories (27) Architects use these tools as creative instruments, exploring a vast canvas of possibilities where efficiency, structural performance, and aesthetics converge in a harmonious dance.

3.5 Use of Natural Fibres

Natural Fibres and their composite materials have an important place in the field of material research because they have been one of the major alternatives and have been researched during the last few decades Natural fibres have many advantages such as inexpensiveness, lightweight and structural efficiency Given these characteristics, they have the potential to replace conventional synthetic fibre composites in architecture and engineering applications (28).

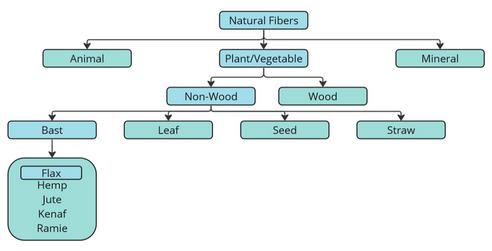

Flax fibre is a cellulose polymer collected from the fibrous bundles in the plant stem. It is considered the most important member of the bast family given its unique properties such as high strength, stiffness and low elongation, which makes it very relevant in composite material research Fibres can be categorised according to their source into plant fibres, mineral fibres and animal fibres These can be subdivided into non-wood and wood. Non-wood fibres can be divided into bast, leaf, seed, straw and grass fibres. The plant fibres are commonly used as a reinforcement for the composite industry (29).

Fibre-reinforced composites (FRCs) have been used in different industries such as nautical, aerospace and automotive, but have not been used that much in architecture. The advantage of working with composites is that allows for the strategic placement of material to create differentiated structure and geometry This is typically done in an additive process and can result in products with a

high specific strength that can translate into reduced material use, as well as reduced use of supporting materials, such as concrete or metals (30).

3 6 State of Art

The project Flex Flax Stool successfully designed and prototyped a stool that mimicked the structural and functional aspects of architectural constructions. It achieved this by integrating Tailored Fibre Placement and Continuous Fibre Winding techniques, creating spatial structures without complex moulds (31) The stool, capable of supporting 80 times its weight, resulted from a digital design and fabrication process combining the predictability of TFP performance with the aesthetic richness of CFW syntax. While the lightweight and smallscale design makes it suitable for modular sustainable construction, the fabrication process proved time-consuming and labourintensive. Notably, the project stands out for using Flax fibres as a sustainable alternative, avoiding the need for costly and rigid moulds associated with traditional composites. The overall performance and use of natural materials contribute to minimising environmental impact (11). Further exploration is suggested to simplify the shaping process without additional machinery

Another example is the Elastool, this project aimed to develop a flat reinforced system that was programmed to stretch and bend into a spatial object to avoid moulds and frames reducing construction time and steps and on-site labour intensity (18) The utilisation of an elastic base fabric with unidirectional elasticity significantly enhanced the TFP machine's performance, reducing thread breakages without complicating handling after laying. Despite the improved precision at lower speeds, compared to coreless fibre winding and other systems like Flex Flax (31), the system remained easily adjustable, robust for its weight, and showed potential for swift and straightforward assembly and erection. It is believed that this method allows the production of a diverse range of models under similar fabrication conditions, enabling transportation in a flat state and subsequent on-site post-processing, assembly, erection, and locking (18).

Other example of moldless structures is the Curved Foldable Tailored Fibre Reinforcements project In this project, complicated three-dimensional shapes through a flat reinforcement underwent resininfusion subsequently being curved and folded into a spatial object before solidifying The structural stability was achieved by the use of geometries with closed crosssections, this was possible by choosing the use of TfP as a resource-saving additive fabrication technique, as this method permits the deposition of precise fibres, and enables

the possibility of making a programmed anisotropic behaviour of the material (32) The result was that a collection of customised components was possible to produce without increasing the design and manufacturing effort together with the aesthetic qualities achieved by the lightweight structure and appearance of components, in this regard opening the window of possibilities of new ways of architectural expressions, gathering benefits directing future sustainable architecture (32)

4 Research Design & Methods

The development of the project follows a bottom-up design approach, progressing systematically from material exploration to prototyping and fabrication. This method involves three key steps: Synthesis, where we plan how our fibre units behave; Modeling and Analysis, creating a model to predict overall behaviour; and Optimisation, using prototyping technologies and design optimisation (38). The research integrates computational design and physical prototyping, emphasising innovation and precision in tailored fibre applications. The materials that were used and developed designs and fabrication methods are described in detail in the next sections.

4.1 Form Finding

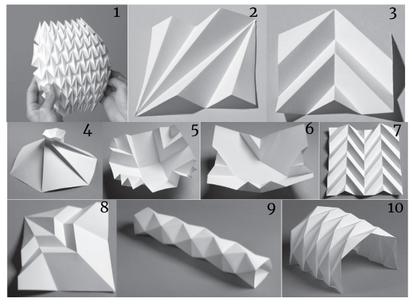

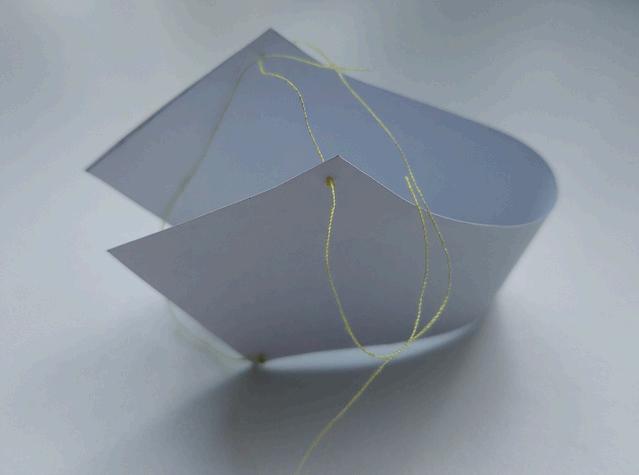

In our pursuit of initiating experimental designs to assess foldability, an extensive exploration of folding techniques led us to delve into the book "Folding Techniques for Designers" by Paul Jackson (39). This comprehensive resource focuses on folding methodologies capable of transforming twodimensional sheets into three-dimensional forms. The book elucidates fundamental techniques, such as pleated surfaces, curved folding, and crumpling, providing a robust foundation for our research.

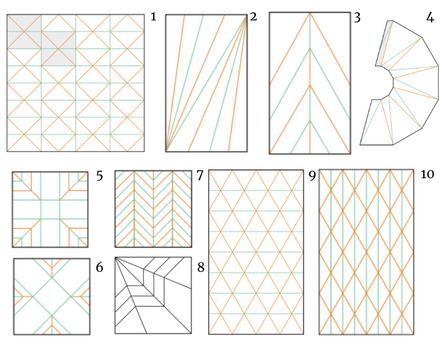

Our selection was guided by the intention to study and subsequently use these patterns as a foundational reference for the creation of innovative designs, integrating our own modifications and adaptations This deliberate procedure aimed to leverage existing patterns as a starting point, allowing us to infuse our unique insights and refinements into the evolution of the design,, thus contributing to the development of distinctive and customised outcomes

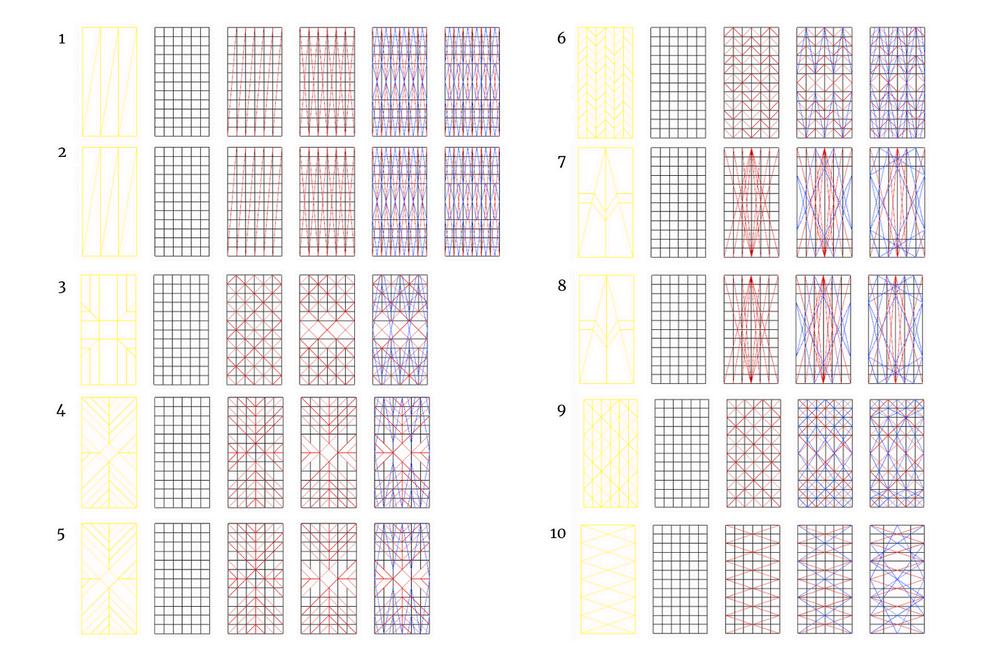

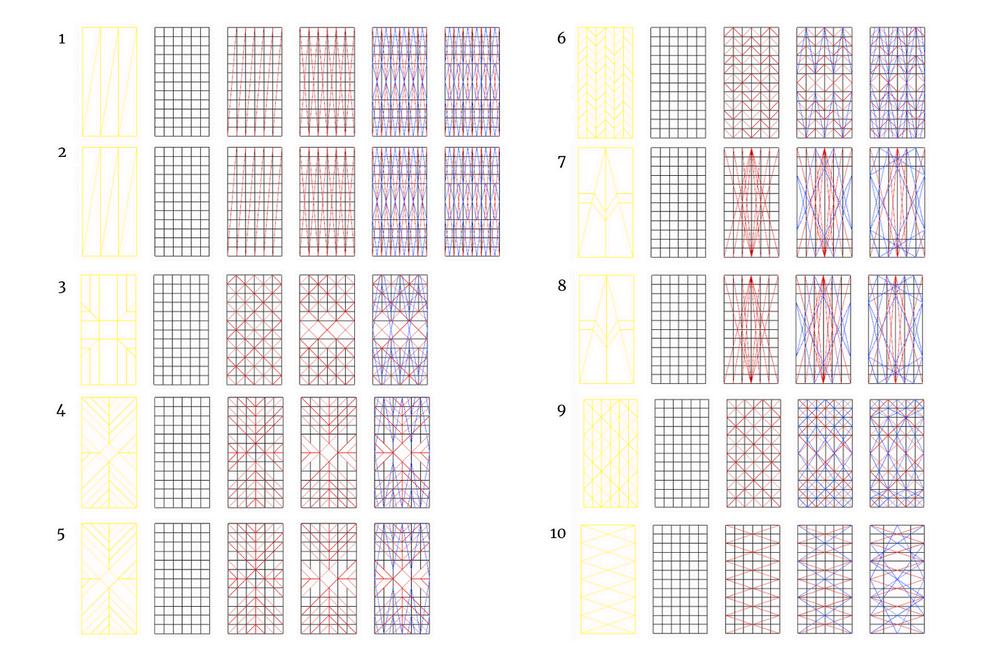

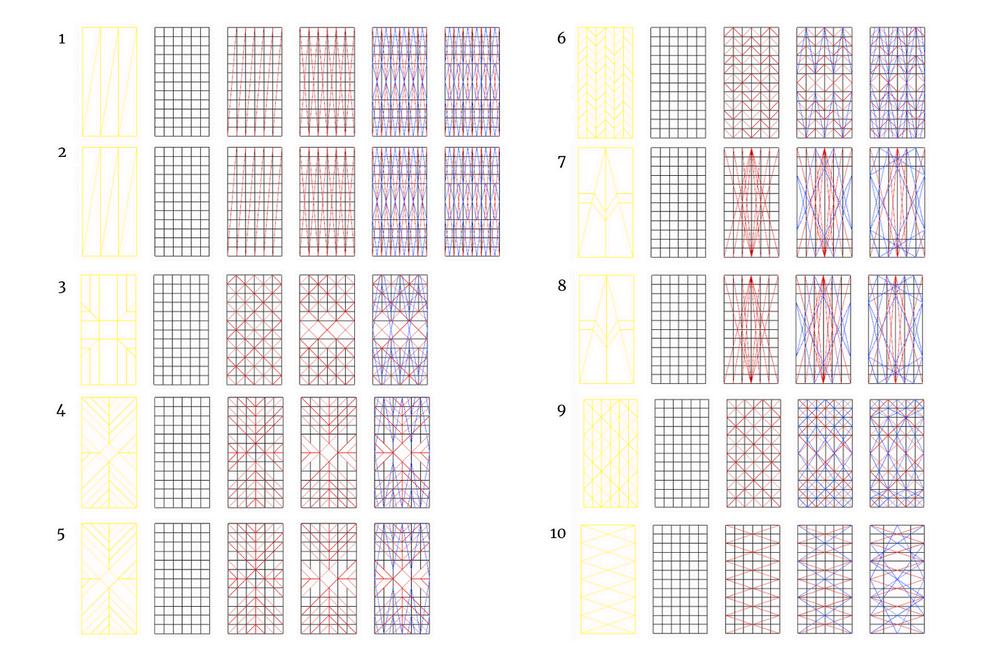

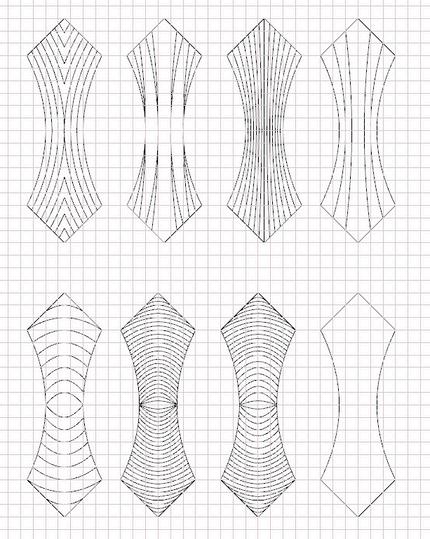

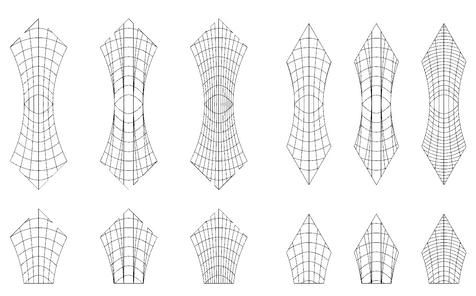

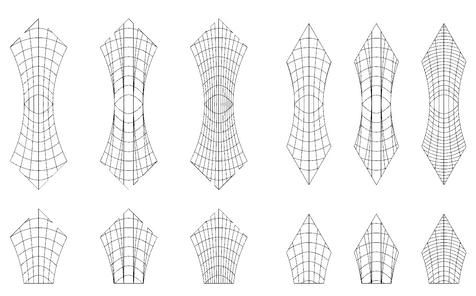

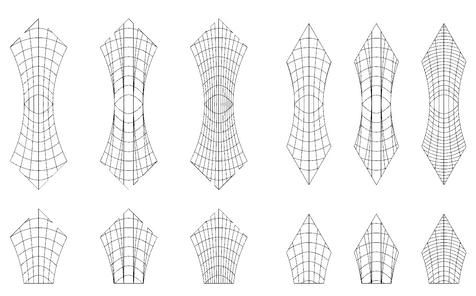

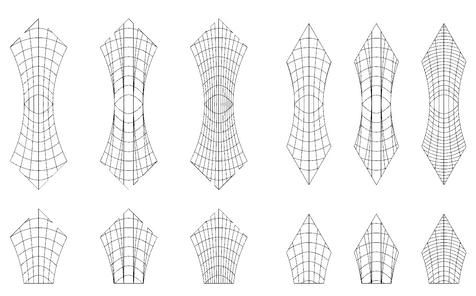

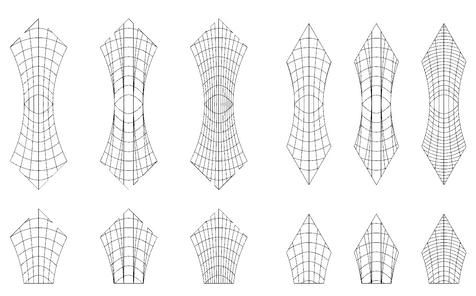

2 1.Symmetrical Repeats: Glide Reflection, 2. Stretch and Skew: Stretch, 3&4. Stretch and Skew: Stretch,, 5&6. V-Pleats: VariationsCoexisting Vs, 7. V-Pleats: Multiple Vs - Making by Hand, 8. V-Pleats: Multiple Vs - Variations, 9&10. Spans & Parabolas: X-form Spans

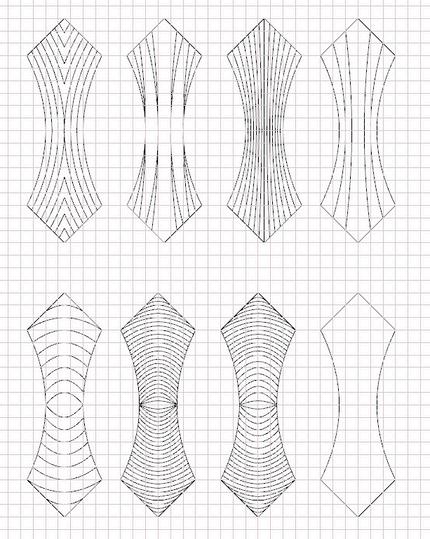

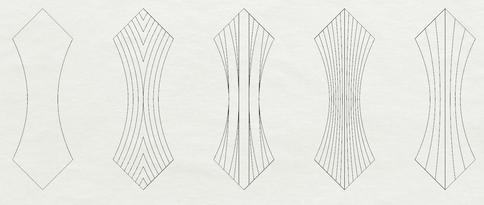

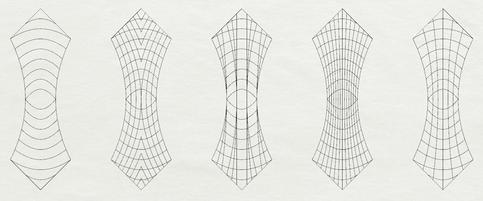

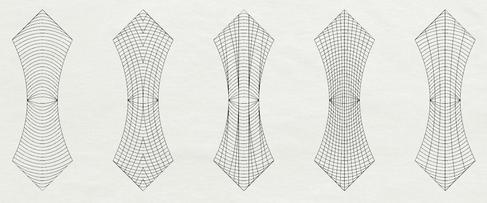

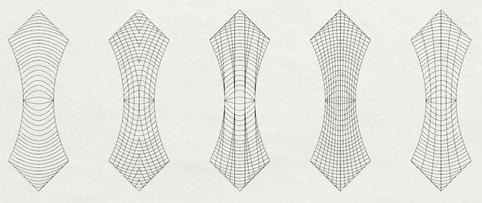

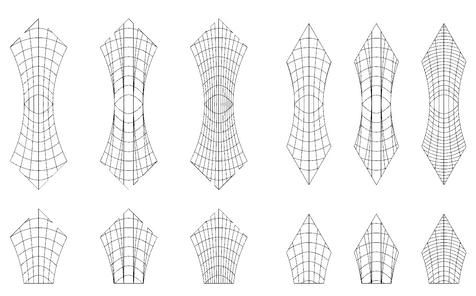

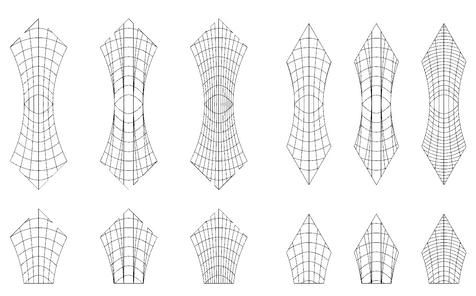

Our objective lies in deviating from the prescribed curved and folded outcomes outlined in the book, aiming instead to introduce specific bending zones within our patterns By incorporating the selected patterns, implementing a defined grid, and introducing tailored modifications, we have successfully generated new alternative patterns These patterns, outlined below, serve as our initial testing ground to observe and understand how bending behaviours unfold

They represent the starting point in our iterative process towards developing designs that align with our goal of achieving precise bending, diverging from the inherent curvature and folds emphasised in the reference material Through systematic experimentation and observation of these patterns, we aim to gather valuable insights that will inform subsequent refinements and guide us toward the realisation of our overarching objectives.

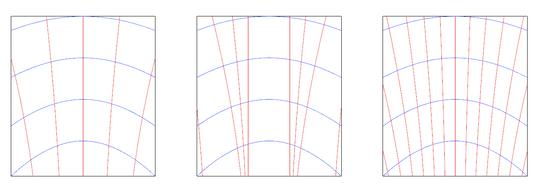

The design process is shown in image 18, h hibit th l ti f th

the underlying grid.

Moving beyond, subsequent column D delineates the sequential step where deliberate changes were implemented and column E represents the final pattern design These alterations were meticulously crafted to align with our envisioned outcome It is relevant to note that the introduction of red and blue colours in the subsequent columns is purely for our internal facilitation, signifying specific modifications without implying a functional distinction between the lines. This systematic approach allowed us to refine and tailor the patterns progressively, harmonising the original design with our creative vision

image 18: design process of the patterns. Own elaboration.

A pivotal aspect in this phase was the intentional redefinition of the purpose inherent in the selected patterns derived from the reference book While the original intent of these patterns was to facilitate folds, we strategically repurposed these lines as reinforcement for our end product Each line in our case means that our fibre will be sewed there as reinforcement of the end material Central to our approach is the exploitation of the inherent spaces created by the fibres, leveraging them as optimal zones for controlled folding and bending (bending zones) This deliberate shift in purpose underscores our commitment to adapt existing methodologies to suit the specific requirements of our envisioned designs, fostering innovation and precision in our exploration of tailored fibre applications.

4.2 Fabrication

Following the formulation of these adapted patterns, our next objective was to assess their bending capabilities to assess their proximity to our desired outcome The next

ps of prototyping were as follows: first 3D ting prototype to test the patterns, then er and cork prototyping to find a form and er cutting to find the desirable bend for the dular units Then, the next phase was to pt the chosen patterns to the unit Initially, used a sewing machine to see how the tern behaves on the unit, and sequently progressed to the TFP machine further refinement. This sequential roach allowed us to methodically iterate, ne, and adapt the patterns to achieve the ired characteristics for the modular units.

4.2.1 3D Printing Prototyping

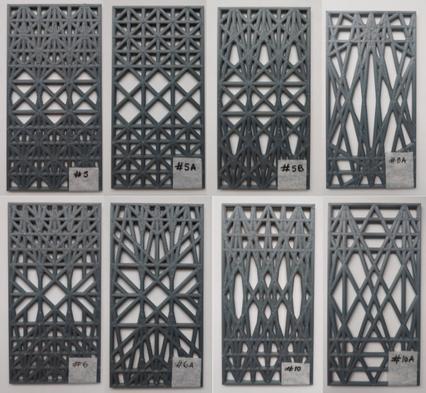

Recognizing the need for precision in replicating the stiffness of our final material after the redesign process, we opted to employ a 3D printer for pattern fabrication. This strategic choice allowed us to closely emulate the characteristics of the intended material, ensuring a more accurate evaluation of the bending behaviour of each pattern The integration of 3D printing technology into our testing methodology exemplifies our commitment to leveraging advanced tools to refine and validate the performance of our innovative designs

The intention behind the 3D print choice was to create a test medium that emulated the rigidity anticipated in the final TFP material. This approach allowed us to systematically assess and quantify the bendability of the fabricated patterns under conditions that simulate the stiffness of the intended TFP product The use of 3D printing in this context aimed to provide valuable insights into the patterns' performance as stiff materials, informing the refinement of our designs for optimal outcomes in subsequent phases of the project.

Upon careful consideration of the aforementioned patterns, we selected to 3D

print four designs that appeared to offer promising results in terms of enhanced bending capabilities Employing Polylactic Acid (PLA) material, each rectangular pattern adhered to standardised dimensions of 10 by 15 centimetres

Following the initial round of 3D printing, further refinements were implemented on the patterns Primarily, these adjustments involved the strategic removal of specific lines, to make the 3D printed results less rigid and enhance the desired bending characteristics. This iterative process allowed us to observe and assess how alterations influenced the patterns' suitability for achieving the optimal bending characteristics.

4.2.2 Physical Prototyping

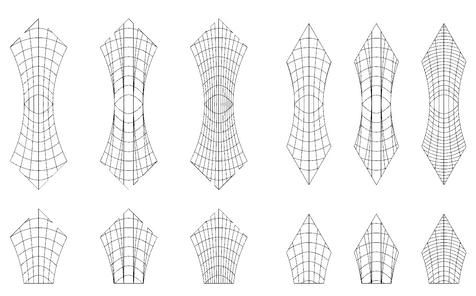

Following a thorough analysis of the created patterns and results from the 3d printing process, the subsequent phase involved identifying a form that could effectively leverage these designs to achieve the desired folds. We aimed to transform the rectangular shapes we were working with into a more conducive form, one that would facilitate modularity and enable easy replication. The goal was to create a modular component that, when replicated, could seamlessly combine to form a larger unit. Furthermore, the repeated multiplication of these units would contribute to the assembly of a more extensive and intricate infrastructure.

This iterative exploration served as a deliberate strategy to enhance our understanding and refine the patterns to align more precisely with our objectives, fostering an iterative and informed design evolution.

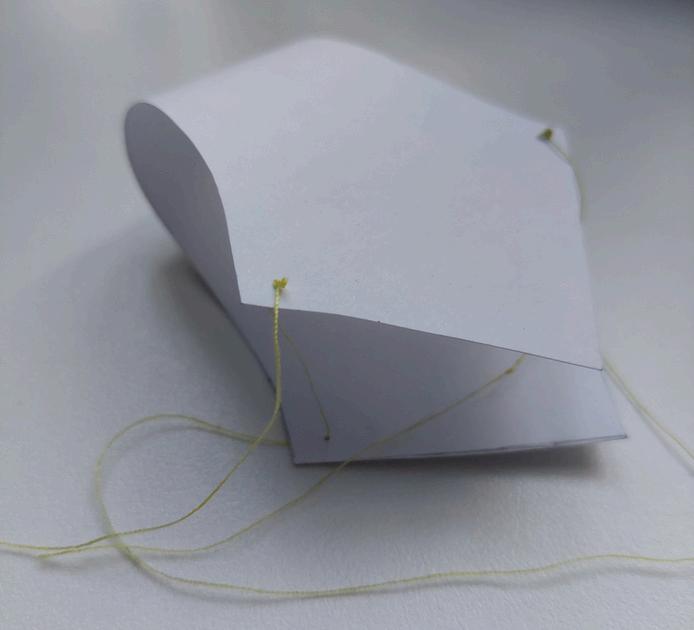

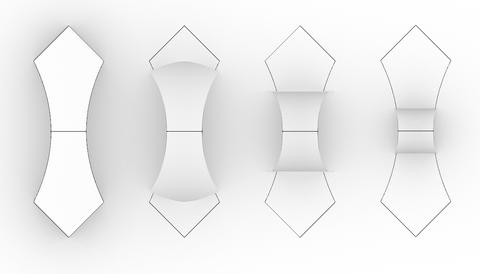

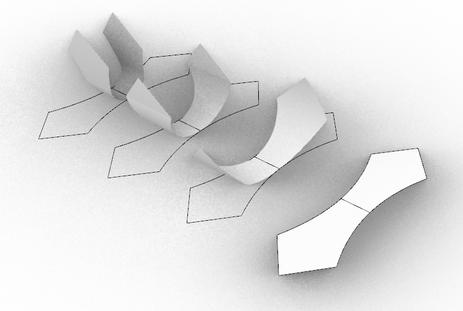

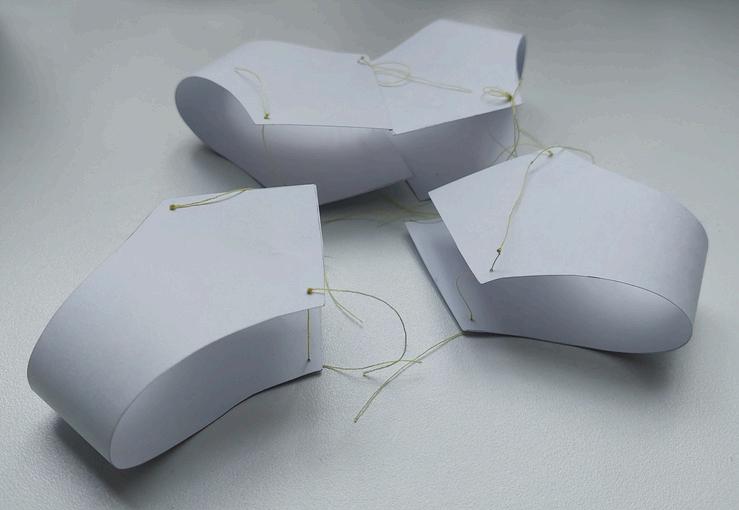

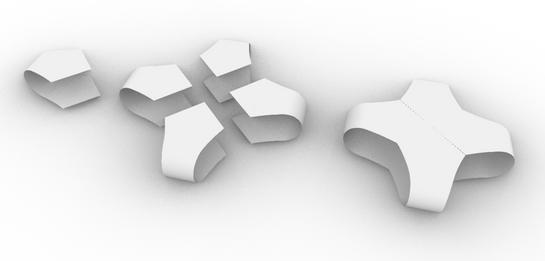

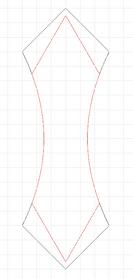

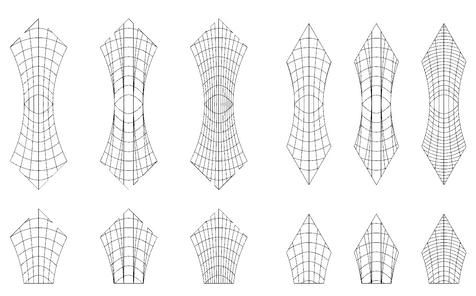

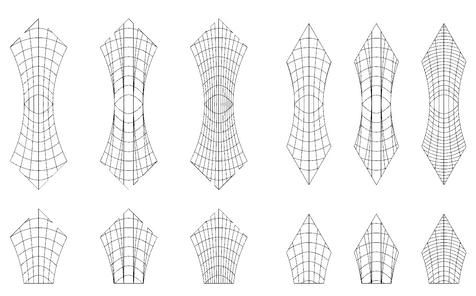

Through experimentation with foundational materials like paper, cork, and textiles, and drawing inspiration from collaborative work with Frank Cheng-Huang Lin, Ph D Fellow at BioMat@ Copenhagen Research Centre, Aalborg University, research titled: "Natural Fiber Reinforced Polymer (NFRP) Composites: Design for Disassembly (DfD) of Structural Modular Units through Tailored Fibre Placement (TFP) Technique for Sustainable Architecture Applications” this form emerged. This form was found to be particularly conducive to highlighting the intended design characteristics we were aiming for The form in the first stage exhibited pronounced curves on both the right and left sides, enhancing the folding capabilities

Since we were aiming for the multiplication of the modular component we incorporated in the design distinct 90-degree angles at the top and bottom, ultimately giving the form the appearance of an arrow. This intentional design choice was made to optimise the efficiency of the desired folds, emphasising the adaptability and versatility of the patterns in shaping a distinct and impactful form. Simultaneously, the design allowed for the modular component to connect with more than one unit, facilitating the creation of diverse units through interconnection This deliberate approach enhances the scalability and adaptability of the design, providing flexibility in constructing various configurations by combining multiple modular components.

The modular component is transformed into a U-shaped form through the folding process with arrowheads at the end of each edge This folding configuration resulted in a distinctive and visually impactful shape, with the arrowheads contributing to the overall design's aesthetic appeal and functionality

Given limited access to the required machinery and a lack of proper training to operate the infusion process, and considering that bending fabric is relatively easy but lacks the accuracy and rigidity desired for the final component, we opted to explore the folded component using a lasercutting approach. This decision was made to assess how the bend would appear in a more controlled and precise manner

The objective was to investigate its potential as a foundational element for generating a comprehensive pattern of interconnected modular units This approach allowed us to explore the scalability and versatility of the curved modular component, considering how it could be repeated and combined to create a cohesive and adaptable modular pattern

30,31,32: experimenting with the U modular component and its multiplication (paper model). Own elaboration modularcomponents modularunit

33: experimenting with the U modular component and its multiplication (3D). Own elaboration

4 3 Computational design: from components to unit

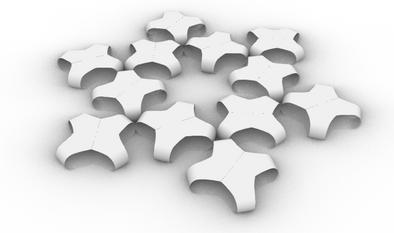

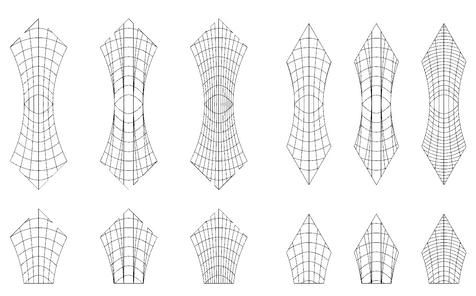

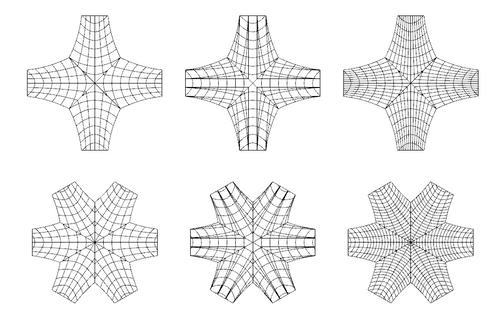

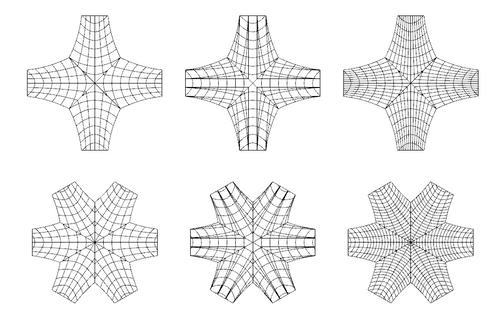

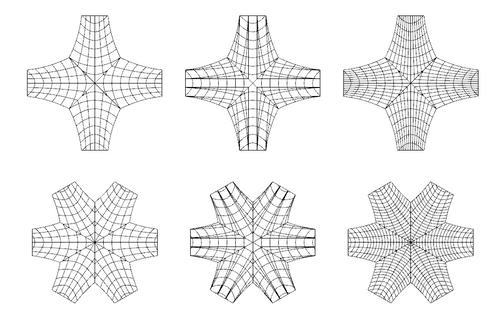

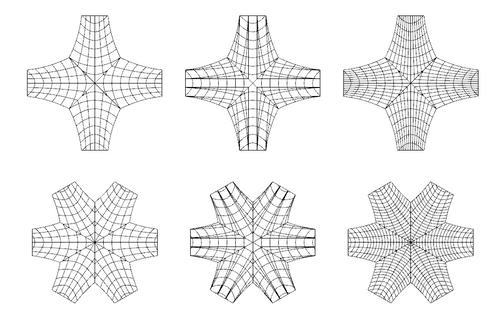

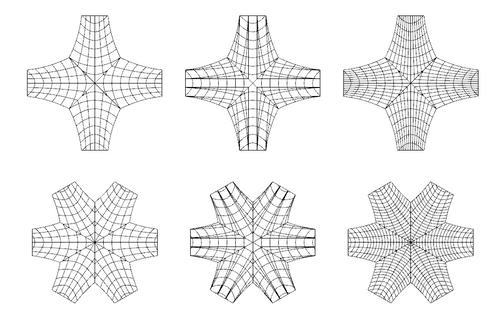

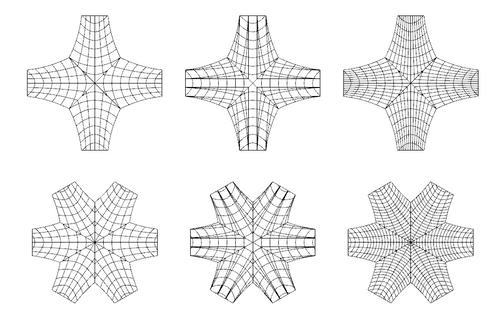

By combining these modular components, we created a cross-looking modular unit aimed to establish a general pattern that not only showcased the individual design characteristics but also demonstrated the potential for creating larger, interconnected structures with enhanced aesthetic and functional appeal.

images 34,35: experimentation with the unit: orthonormal pattern. Own elaboration

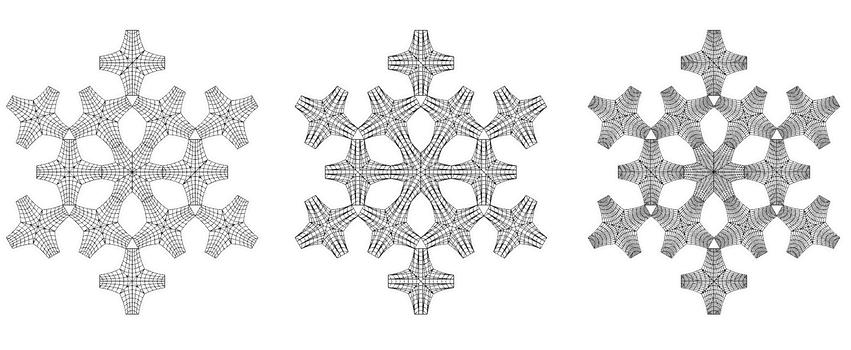

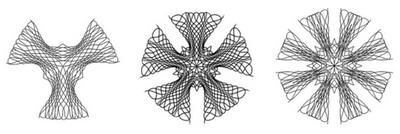

After the establishment of the grid-like pattern using the initial modular component, our exploration evolved by introducing a 60degree angular orientation to the original component This experimentation resulted in the creation of a pattern resembling a snowflake, marked by intricate angles and a visually compelling design

images 36,37: experimentation with the unit: 60-degree angular orientation. Own elaboration

Recognizing the need to enhance the snowflake pattern, we introduced a new hexagonal-shaped unit for the centre. Aligned with the conceptual framework of the original modular component, this hexagonal unit consists of six individual components. Notably, the new unit differs by being 1 cm shorter in total length compared to the original, and it incorporates 60-degree angles at the top and bottom, deviating from the initial 90-degree angles

38,39: new modular component: The red line represents the new component compared to the black line which is the shape of the original one (left) Hexagonal unit that consists of 6 of the new modular components (right). Own elaboration

This deliberate modification introduces an additional layer of complexity to the shape, contributing to the overall aesthetic and structural intricacy of the snowflake design Through this iterative process, we aimed to optimise the modular units for cohesion and

balance within the larger pattern, highlighting the adaptability of our design concept.

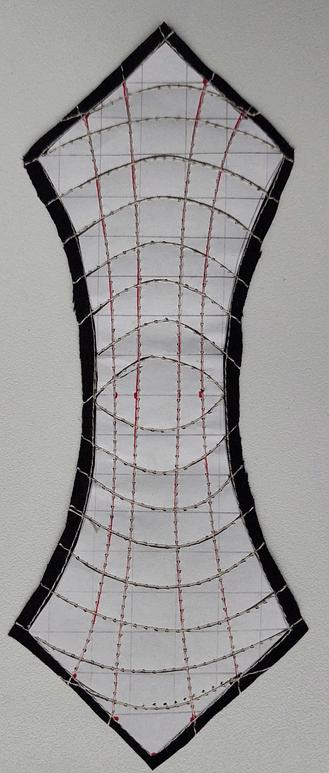

4.4 Pattern Generation: Sewing Machine & TFP

In the subsequent phase of our research, our focus redirected towards determining the optimal pattern that would facilitate the desired bending characteristics in our modular units Building upon our prior experimentation with patterns and their bendability through the 3D printing process, we were prepared to design a pattern

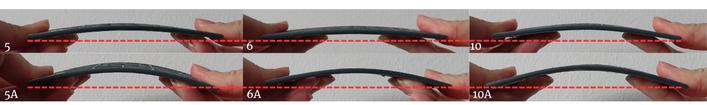

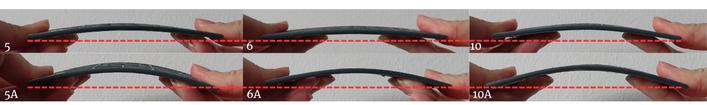

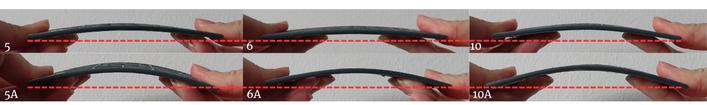

Having curated a comprehensive selection of patterns, our attention narrowed to three specific designs. These were subjected to experimental testing to assess their performance in terms of bending and their visual impact on the modular components.

weft warp

This rigorous approach allowed us to evaluate and refine the patterns based on their effectiveness in achieving the desired aesthetic and functional outcomes. These patterns' deliberate selectio represent a strategic effort des of m

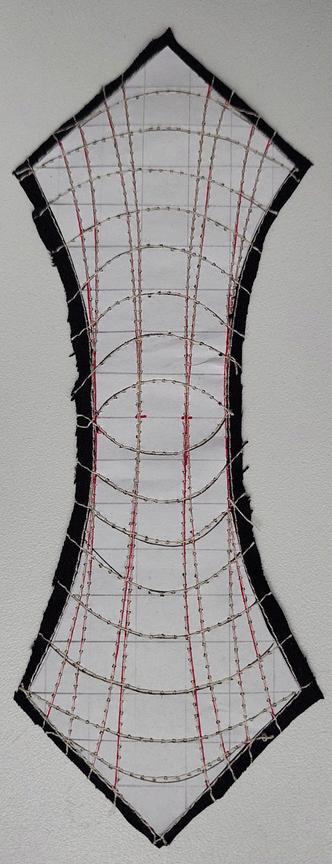

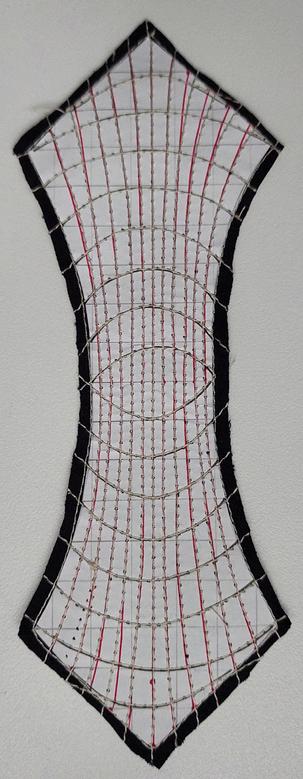

Before conducting tests with the TFP machine, we sought to explore the behaviour of the designs using a sewing machine. Utilising a standard yarn, we carefully sewed these designs onto a denim fabric This experimental phase allowed us to observe and evaluate how the designs interacted with the fabric and how well they maintained their structural integrity during the sewing process.

Given the favourable bendability and aesthetic appeal observed in the denim fabric, we decided to maintain the current designs without alterations. Our next step involved progressing to the testing phase with the TFP machine to observe how the patterns would perform in the intended environment This decision was driven by the positive outcomes observed during the sewing machine experimentation, affirming the suitability of the designs for further exploration using the TFP machine