FileName

Page 1/22

5MWh20ftliquidcooledcontainerenergystoragesystemspecification

Name:5MWh20ftliquidcooledcontainerenergystoragesystem

Model

Prepared Checked Approved

ZhangqingYu QisiDeng

GuanghuiZhang

FileName

ProductSpecification Page 2/22

RevisionHistory

RevRevisedcontentdescriptionDateofissueRevisedbyCheckedbyApprovedby

A/1 Firstedition 20240926

A/2

Secondedition,technicalterm, inset 20250225

ZhangqingYu、 PeifengWu QisiDengGuanghuiZhang

ZhangqingYu、 PeifengWu QisiDengGuanghuiZhang

FileName ProductSpecification Page 4/22

1.Termsdefinition

Table1:Termsdefinition

RJETech GuangzhouRongjieEnergyTechnologyCo.,Ltd

LFP LithiumIronPhosphate

AC AlternatingCurrent

DC DirectCurrent

BMS BatteryManagementSystem

BMU BatteryManagementUnit

BCMU BatteryClusterManagementUnit

BSMU BatterySystemManagementUnit

BOL BeginOfLife

EOL EndOfLife

HVBox HighVoltageControlBox

MSD ManualServiceDisconnect

PCS PowerConversionSystem

SOC StateOfCharge

SOH StateOfHealth

SOE StateOfEnergy

SOP StateOfPower

UPS UninterruptiblePowerSupply

CCS CellConnectionSystem

CAN ControllerAreaNetwork

ETH EthernetModule

PDB PowerDistributionBox

DCCB DCCombinerBox

HVAC HeatingVentilationAirConditioning

MCCB MoldedCaseCircuitBreaker

FileName ProductSpecification Page 5/22

2.Productintroduction

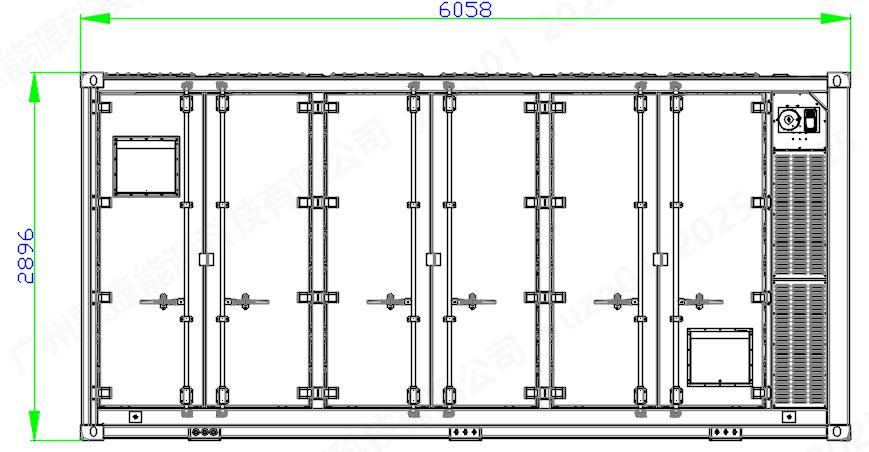

The5MWh20ftliquidcooledcontainerenergystoragesystemconsistsof12clustersof13312V/314Ahbattery cluster,PDB,DCCB,fireprotectionsystem,batterymanagementsystem,andthermalmanagementsystemThesystem outlinediagramisshowninfigure1

Adoptingstandardnon-walk-in20ftcontainer,themodulardesignenhancestheutilizationofspaceinthecontainer.

Theadvancedliquidcoolingcycledesignconceptenablesthebatterysystemtoperformoptimally;thethree-level intelligentbatterymanagementsystemminimizestheriskofthermalrunawayofthesystem,whicheffectivelyimprovesthe all-roundsafetyoftheenergystoragesystemandthelifecycleofthestoragebattery,andprovidesasafertechnical guaranteefortheoperationoftheenergystoragesystem.

2.1Electricaldiagramofcontainertopology

Thecontainersystemadoptsanintegratedsolution

PCSadoptsacentralizedsolution,with12clustersofbatteriespassingthroughahighvoltagecontrolboxandaDCCB, connectedtoonePCSmoduleinputterminal,asshowninfigure2.

:Electricaldiagramofcontainertopology

FileName

2.2BMS

ProductSpecification Page 6/22

Thewholebatterymanagementsystemincludesthreelevelsofarchitecture,whicharefirstlevelslavecontroller, secondlevelmastercontrollerandthirdlevelsystemcontroller,andthefunctionsatalllevelsareshowninfigure3The mainprotectionparametersaredetailedinthe“BMStechnicalprotocol”.

2.3Parametersofcontainer

Thetechnicalparametersofthisproductarebasedonthemeasurementresultsofnewmodulesorbatteriesatroom temperatureof25±2℃.

Table2:Parametersofcontainer No.

1Configuration 1P416S×12 12-clusterspara

2Ratedvoltage 13312V Standardchargeanddischarge

3Ratedenergy 5015MWh Standardchargeanddischarge

4Voltagerange 11648-14976VDC

5Ratedcharge/dischargepower0.5P

6Operatingtemperaturerange-30~55℃(discharge) -3055℃(charge)

Charge:15~35℃ Discharge:0~45℃

Heatingfirstbeforecharging whenbelow0℃

7SOC(%) 30% (25±2)℃

FileName

8AdaptivePCS

Storage condition

10General parameters

ProductSpecification Page 7/22

CentralizedtypePCS

Storage temperature 0~45℃

Storagehumidity5%≤RH≤90%

Altitude ≤2500m >2500mDeratedoperation

Dimension6058×2438×2896mm W×L×H

Weight 42.5t

IPlevel IP55

Thermal managementLiquidcooled

Communication interface CAN\RS485\Ethernet

Communication protocol Modbus\IEC61850

11CertificationContainer

2.4Containerkeycomponentslist

IEC62619/EN61000-6-2/4EN62477-1/UN383/NFPA68/ IEEE693/UL9540A/UL1973/IEC62933/ANSIC634&47CFR PART15B

Table3:Containerkeycomponentslist

Component Quantit y

Batteryrack 6setTwoclustersinonerack,totally12clusters

Batterymodule 48pcs1P104Sinonemodule

HVBox 6pcs

Thermalmanagementsystem 1set

Fireprotectionsystem 1set

Includingisolationswitch,Fuse,Relay, Switchingpowersupply,Pre-chargeresistance

Includingchillerhost,liquidcoolingplate,cooling pipeandHVAC

Aerosolfireprotectionsystem,includingdetector, fireprotectioncontrolhostandpipe

Waterfireprotectionsystem,includingpipeand sprinkler

PDB 1setAuxiliarypowersupply

DCCB 1setContainerlevelDCbusbar

BMS 1setBSMU(includingdisplay),BCMU,BMU

FileName ProductSpecification

3.Keycomponentparameters

3.1Cell

3.1.1Parametersofcell

Table4:Parametersofcell

No. Item Parameter

1Celltype LFP

2Cellmodel RBA4F1

Page 8/22

Remark

3Cellweight 57±03kg Wrappedinbluefilm

4InternalresistanceofBOL 0.18±0.05mΩ 30%SOC,1kHz

5Nominalcapacity 314Ah (25±2)℃,Standardchargeand discharge

6Nominalvoltage 32V (25±2)℃,

7Ratedenergy 1004.8Wh (25±2)℃,

8Operatingvoltage 2.50~3.65V 200~365V T>0℃ T≤0℃

9Energydensity ≥177.8Wh/kg (25±2)℃,Standardchargeand discharge

10SOCrecommended 5%~95%

11Monthlyself-discharge ≤30%

12

13

NewcellsofEOL,25±2℃, 30%SOC,storagefor3months

Maximumcontinuouscharging power 0.5P Charge:15~35℃

Maximumcontinuousdischarge power 05P Discharge:0~45℃

14Dischargetemperaturerange-20~55℃

15Chargetemperaturerange 0~55℃

Note:Thethicknessismeasuredatasurfacepressureof5000±200N

Celldetailedparameterscanbereferencedin“314AhCellProductSpecification”

Heatingfirstbeforecharging whenbelow0℃

FileName

3.1.2Dimensionsofcell

1Height(excludingpole)

2Height(includingpole)

3Thickness

4 Width

5Weldingareaofpole

Table5:Dimensionsofcell

Page 9/22

204.4mm(includinginsulationfilm, includingoutergasket) ±0.6mm

2068mm(includinginsulationfilm)±05mm

71.55mm(includinginsulationfilm)±0.5mm

17426mm(Thebottomhemofthe cell,includinginsulationfilm) ±005mm

174.04mm(Themiddlepartofthe batterycellcontainsaninsulating film) ±005mm

Ø16mm(Excludingplasticoutsidethe pole) ±02mm

6Centerdistancebetweenpositivepoleand negativepole 123mm ±0.3mm

FileName ProductSpecification Page 10/22

3.2Batterymodule

3.2.1Parametersofbatterymodule

Table6:Parametersofbatterymodule

No. Item Parameter

Remark

1Configuration 1P104S 104cellsinserries

2Nominalvoltage 3328V

3Nominalcapacity104.5kWh

Standardchargeanddischarge

Standardchargeanddischarge

4Dischargecut-offvoltage 260Voranycellvoltagereaches2.5VT>0℃ 208Voranycellvoltagereaches2.0VT≤0℃

5Chargecut-offvoltage3796Voranycellvoltagereaches365V

6 Maximum charge/dischargecurrent314A(1min)

7Ratedcharge/discharge current 157A

8Operatingtemperature range -30~55℃(Discharge) -3055℃(Charge)

9Storagetemperaturerange045℃

10PowerconnectionFastplug

11CommunicationinterfaceCAN

Maximumcharge/dischargecurrent

Ratedcharge/dischargecurrent

Heatingfirstbeforechargingwhen below0℃

Oversixmonths,completechargeand dischargemaintenanceisrequired

12ShipmentSOC(%)30% (25±2)℃

13Weight 685±5kg

3.2.2Dimensionsofbatterymodule

Figure5:Appearancediagramofbatterymodule

Table7:Dimensionsofbatterymodule

FileName ProductSpecification Page 11/22

3.3Batterycluster

Thebatteryclusterconsistsof43328V/314Ahlithiumironphosphatebatterymodulesconnectedinseries,andthe highvoltagecontrolboxisplacedatthebottomoftherack

3.3.1Batteryclusterparameters

Table8:Batteryclusterparameters

No. Item

Parameter

Remark

1Configuration 1P104S×4 4-Modulesinseries

2Ratedvoltage 1331.2V Standardchargeanddischarge

3Batteryclustercapacity 418kWh Standardchargeanddischarge

4Voltagerange 11648-14976Vdc

5Ratedcharge/dischargepower 05P/05P

3.3.2HVBox

Charge:15~35℃ Discharge:0~45℃

Thetwo-in-onehighvoltageboxisusedTwobatteryclusterscorrespondtooneHVBoxThehighvoltagecontrolbox containsthebatterymanagementunitmastercontrolmodule(BCMU)tomanageandcontrolthebatteryclusterThe isolationswitchisinstalledinthehighvoltagecontrolbox,whichisconvenienttointerruptthehighvoltagecircuitofthe moduleduringsystemassembly,maintenanceandrepair,soastoprotecttheoperatorfromthedangerofhighvoltage electricshock.Theboxisalsointegratedwithrelays,fuses,Prechargeresistorandotherelectricalcomponentstocontrol andprotectthehighvoltagecircuitHVBoxpanel-definitiondiagramisshowninfigure6

Figure6:HVBoxfrontpaneldefinition

FileName

3.4PDB

3.4.1Appearanceofpowerdistributionbox

Page 12/22

Figure7:Powerdistributionbox

3.4.2Listofkeycomponents

Thelistofkeycomponentsofpowerdistributionboxisshownintable9

Table9:Listofkeycomponents

FileName

3.5DCCB

3.5.1AppearanceofDCcombinerbox

Figure8:AppearanceofDCcombinerbox

3.5.2Listofkeycomponents

ThekeycomponentslistoftheDCcombinerboxisshownintable10

Table10:Listofkeycomponents

3.6Thermalmanagementsystem

3.6.1Thermalmanagementsystemlayout

Thethermalmanagementsystem,asshowninfigure9,ismainlycomposedofachillerhostandseveralliquidcooled pipelines

FileName

14/22

:Assemblydrawingofthermalmanagementsystem

Theliquidcooledandliquidheatingsystemadoptsahigh-efficiencyfrequencyconversiontechnologyschemefora 60kWliquidcoolingunit,withreal-timeintelligentspeedregulationofthefan,whichisefficientandenergy-saving,meter ratio,theflowofeachbatterypackisevenlydistributed,thusbettercontrollingthetemperaturedifferenceoftheentire systemTheclusterlevelbidirectionalglobevalveisusedtofacilitateclusterlevelmaintenanceandsavelaborcost Thankstotheuseofadvancedcompositetemperaturecontrolstrategy,combinedwiththeself-circulationsystem,the batteryhasalwaysmaintainedthebeststateofoperationandtheenergyefficiencyofthesystemhasbeengreatlyimproved SpecificparametersareshowninTable11.

Table11:Specificparameters

Items Unit Parameters

Dimension(W×D×H) mm1200×440×2400

Refrigeratingcapacity kW60

Heatingcapacity kW24

RatedCirculationFlowrate L/min500@150kPa

Coolant /50%GlycolSolution

Powersupplyrange V,Hz400/480,3Phase,50/60

IPlevel /IPX5

NoiseLevel dB(A)≤80

FileName

ProductSpecification Page 15/22

Authentication /CE/UL

3.6.2HVAC

TheHVACinsidethecontainerisshowninfigure11,mainlycomposedofairconditioningandairducts.

Figure11:HVACsystemdiagram

TheHVACinsidethecontaineradoptsa3kWhigh-efficiencyvariablefrequencyairconditioningtechnologyscheme, withreal-timeintelligentspeedregulationofthefan,whichisefficientandenergy-saving

Byadjustingappropriateairducts,uniformairsupplycanbeachievedineacharea,therebybettercontrollingthe temperatureandhumidityinsidethecontainerbox

Specificparametersareshownintable12.

Table12:HVACparameters

Dimension(W×D×H)

mm500×250×1300

Refrigeratingcapacity kW3

Heatingcapacity kW10/25

Internalcirculationairvolume m³/h700

Powersupplyrange V、Hz220/230±10%,50/60;

NoiseLevel dB(A) ≤70

IPlevel /IP55

Authentication /CE/UL

3.7Fireprotectionsystem

3.7.1Fireprotectionsystemcomposition

Thefireprotectionsystem,asshowninfigure11andfigure12,includesbothagasfiresuppressionsystemandawater firesuppressionsystem

Thegasfiresuppressionsystemprimarilyconsistsofafirecontrolmainunit,astoredpressuretypeperfluorohexanone fireextinguishingdevice,explosion-prooffans,smokedetectors,temperaturedetectors,hydrogendetectors,soundandlight

FileName

ProductSpecification Page 16/22

alarms,manual/automaticswitch,firenozzles,andpipelines,etc.Thefireextinguishingagentusedisperfluorohexanone, withatotalvolumeofabout50kg,integratedwithinadedicatedfiretank.

Theaerosolfireprotectionsystemmainlyconsistsoffirecontrolhost,aerosolfireextinguishingdevice, explosion-prooffan,smokedetector,temperaturedetector,compositedetector,soundandlightalarm,manualandautomatic switch,firenozzleandpipelineetcThecompositionofthefireextinguishingagentisaerosol,integratedintoadedicated aerosolfireextinguishingdevice.

Thewaterfiresuppressionsystemutilizesmultiplenozzlesfor360°spraycoverage,comprehensivelycoveringthe packspaceItworksinconjunctionwiththegasfiresystemtosignificantlyreducetheriskofsystemthermalrunaway, ensuringsafetyandreliability

:Fireprotectionsystemlayout(perfluorohexanone)

3.7.2Firesystemlogic

ThefirecontrolhostcontrolstheoperationoftheentirefiresystemWhenafirealarmoccurs,thefirehost communicateswiththeBMSandsendsthealarminformationtotheBMSTheBMScontrolsthedisconnectionofthe high-voltagecircuitaccordingtorelevantstrategiesanduploadsthewarningandfireinformationtotheEMS;Thefire controlhostactivatesthesoundandlightalarmtoissueawarning,starts/closestheexhaustfanandinletlouvers,andsprays aerosoltoextinguishthefire(orandspraystheperfluorohexanoneextinguishingagent.).

Inemergencies,thewaterfiresuppressionsystemcanbemanuallyactivatedbypowerstationpersonnelasthelastline ofdefenseforfiresafetyThewaterfiresystemprovidesacoolingeffect,ensuringthatinextremesituations,firedoesnot spreadwithinthecontainer

FileName ProductSpecification Page 18/22

Figure13:Fireprotectionsystemlogic

3.8Containerdesign

3.8.1Containerstructure

Thedesignofcontainerstructuremainlyincludestheappearance,selectionofsteelstructure,shellprotection,and designofcontainerinletandoutletlinesThespecificdesignisasfollows:

1Size:Containerouterdimensions:20ftouterdimensions

2.Appearance:ThecontainershellissprayedwithimportedUVresistanttopcoat,withacolorofRAL9003.

3Antisepsis:Thecontainerhasgoodanti-corrosion,fireprevention,waterproof,dust-proof,shockproof,UVresistant, anti-theftandotherfunctions,ensuringthatthecontainerisprotectedfor25yearsThecontainerwillnotmalfunction duetofactorssuchascorrosion,fireprevention,waterproofing,dustprevention,andultravioletradiation.Itshouldbe paintedandmaintainedevery5years

4.Fireproofsealingperformance:Ensuringthatallcontainershellstructures,thermalinsulationmaterials,internaland externaldecorativematerialsaremadeofflame-retardantmaterialsTheoverallprotectionlevelofthecontaineris IP55,andthepartsofthecontainerdoorpanelthatareconnectedtotheoutsideareprotectedbysealingstripsto preventdustorrainwaterfromenteringtheinteriorofthecontainerwhenencounteringwind,sandorrainyweather

FileName ProductSpecification Page 19/22

outdoorsEnsurethatthereisnowateraccumulation,seepage,orleakageatthetopofthebox,norainonthesideof thebox,andnowaterseepageatthebottomofthebox.

5Equippedwithdust-proof(windandsand):ensuringtheinstallationofeasilyreplaceablestandardventilationfiltersat theairinletofthecontainerandequipment,andeffectivelypreventingdustfromenteringtheinteriorofthecontainer intheeventofstrongwindandsand

6.Equippedwithshock-absorbingdesign:Ensuringthatthemechanicalstrengthofcontainersandtheirinternal equipmentmeetstherequirementsundertransportationandearthquakeconditions,withoutdeformationorfunctional abnormalitiesFrequentvibrationandfailuretooperate.

7HasUVprotection:EnsuresthatthematerialsinsideandoutsidethecontainerwillnotdeteriorateduetoUVradiation, andwillnotabsorbUVheat

8Containerentryandexitlines:Includingpowerlines,communicationlines,opticalcables,controlcables,etc,are arrangedinabottominandbottomoutmannerThecontainerisequippedwithprotectivemeasuressuchas identification,automaticfireextinguishinggasreleasesoundandlightalarm

3.8.2Containerthermalmanagement

Theinnerwallofthecontaineradoptsfireproofboardastheinsulationlayer,andthegroundfillingthicknessisnot lessthan100mmthick.ThefireproofboardhasafireratingofAandafireresistancelimitofnotlessthan2hours,making thesystemhavethefunctionsofheatstorage,insulation,andflameretardancy.Consideringtheon-siteoperating environmentoftheenergystoragesystem,inordertoensurethelong-termreliableoperationofthebattery

Thecontainerisdividedintoanelectricalcompartment,abatterycompartment,andaliquidrefrigerationunit compartmentTheelectricalcompartmentmainlyhousesbusbars,distributioncabinets,andsupportingfire-fighting facilities,whilethebatterycompartmentmainlyhousesbatteryclusters.Toensurethatthetemperatureinsidethecontainer remainswithinacertainrangeandmeetthetemperatureadaptabilityrequirementsofthebattery,itisnecessaryto supplementtheheatlossofthecontainerinlow-temperatureenvironmentsatnightandbalancetheheataccumulation insidethecontainerinextremehigh-temperatureenvironmentsBasedonthecomprehensiveconsiderationofexternal environmentaltemperature,containerheatloss,andbatterycharginganddischargingheatgeneration,oneindustrialgrade liquidcoolingunit(batterycompartment)withacoolingpowerof60kWandone3kWair-cooledairconditioner(electrical compartment)areselectedforthecontainertoensurethatthetemperatureinsidethecontainerismaintainedwithin20± 5℃,andtheairconditionerispoweredbyAC380V

Theindustrialgradeliquidcoolingunitforthebatterycompartmentisinstalledattheendofthecontainer,withanair conditioningcoolingpowerof60kW,andswitchesbetweencooling/heatingmodesbasedontheambienttemperatureinside thecontainer.Theliquidcoolingunitadjuststhetemperatureofeachbatteryclusteruniformlythroughtheliquidcooling pipelinetoensuretheconsistencyofbatterytemperature

3.8.3Containergrounding

Thecontainerprovidesuserswithatleast2groundingpointsintheformofgroundingbarboltstoachievereliable groundingoftheentirecontainer'snotfunctionalconductiveconductorTheeffectivecross-sectionalareainthegrounding systemshallnotbelessthan250mm²Inordertoachievegoodgroundingeffectandachievesafeandreliableoperationof thesystem,thegroundingimpedanceofthegroundingpointprovidedbytheusershouldbe≤4Ω,andtheconnection impedanceshouldbe≤0.1Ω.Thereisagroundingbarinsidethecontainer,andthegroundingwiresofdistribution cabinets,controlcabinets,etc.areconnectedtotheinternalgroundingbar.

3.8.4Containerwiring

1Theinstallationofbatterycabinetsinsidethecontainerandthewiringbetweencabinetsareneat,reliable,andarranged reasonablyTheinsulationdesignmeetsrelevantstandards

2Thepowercableroutingoftheelectricalcabinetinthecontaineristhesameasthatofthesecondarycontrolwire,andthe communicationwireisarrangedseparately,whichisaestheticallypleasingandorderlytoavoidinterference

4.Specificationforcontainertransportationandinstallation

4.1Preparationandinspectionbeforeunloading

Whenthecontainergoodsarriveatthesite,unloadthecontainerandplaceitonthefoundationBeforeunloading, checkifthefollowingitemsarecomplete

1Hastheconstructionofthecontainerfoundationbeencompleted;

2Thefoundationofthecontainershouldbemadeofcement,andtheload-bearingstrengthofthegroundshouldnotbeless than3t/㎡.

3.Hasthecontainerliftingvehiclebeeninplace?Pleaserefertothe"ContainerLiftingandTransportationPlan"forspecific liftingspecifications

4Atleastonequalifiedsupervisorresponsibleforindustrialsafetyispresent

5.Theunloadingshouldbesupervisedbyrepresentativesofthebiddingandtenderingpartiespresent.

4.2Dischargingprecautions

1Allitemsshouldbehandledwithcareandoperatedaccordingtothesafetysignsonthecontainer

2Unloadingshouldbeavoidedinrainyweather

4.3Liftingofenergystoragecontainer

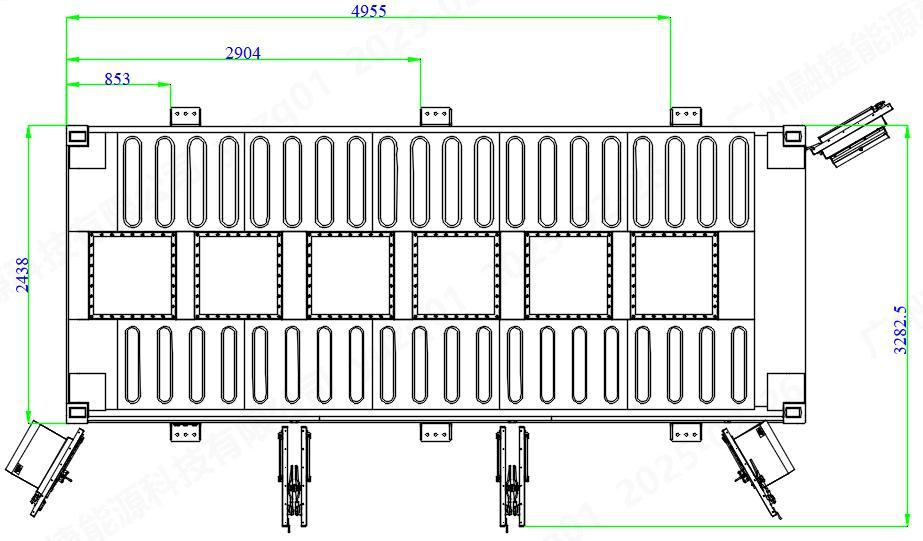

Thetotalweightofasingleenergystoragecontainersystemisabout425t,withdimensionsof6058mminlength, 2438mminwidth,and2896mminheight.Thenominalvoltageis1331.2V.Theshapeofthecontainerisshowninthe followingfigure14.

FileName ProductSpecification Page 21/22

Liftingpoint

Figure14:Schematicdiagramofcontainerlifting

Liftingpoint

4.4Fixationofcontainer

Duetothelargeweightandsizeofthecontaineritself,itgenerallydoesnotneedtobefixedHowever,containershave relativelyhighrequirementsforinstallationfoundations,andthebottomofthecontainermusthaveaconcretefoundation withsufficientstrengthandflatnessThefoundationshouldmeettherequirementsofGB50204-2015"CodeforAcceptance ofConstructionQualityofConcreteStructures"Duringcontainerinstallation,sufficientsupportareaandbearingcapacity arerequiredatthefourcornersandbottomsidebeamsofthecontainer

1Containerlifting

CompletethecontainerliftingworkaccordingtotherelevantinstructionsintheContainerLiftingandTransportation Plan,andarrangethecontainerattheplaceofusePleasepayattentiontothecontainernumberandorientationPleaserefer tothelayoutdiagramoftheenergystoragesystem

2Containersecuringrequirement

Itisrecommendedtousepebblesforcompactiontreatmentatthebottomofthecontainerfoundationtoavoid settlementofthefoundation;Thesurfaceofthefoundationshouldbeflatwithoutanyprotrusions,andthereshouldbeno wavelikefluctuationsafterplacingthecontainer

3Footmargin

FileName ProductSpecification Page 22/22