Campus.

By Lucy Perry

By Irwin Rapoport CEG CORRESPONDENT

Los Angeles County just opened a $43 million mental health and crisis-care campus in the Antelope Valley, a project delivered under budget by PENTA Building Group and design partner Carrier Johnson + Culture.

The design-build project in the city of Lancaster was completed at approximately 20 percent below its original budget and employed a construction workforce that included approximately 45 percent local workers.

Los Angeles County Public Works served as the lead agency, working with the county’s Departments of Mental Health and Health Services. The campus consolidates multiple behavioral health programs in one location, expanding access to services for residents in north Los Angeles County and reducing the need for patients to travel long distances for care.

see CAMPUS page 44

In February, the FHWA published an updated Q&A document on the Build America, Buy America law. Clarifications on iron and steel construction products can be found in the document, along with a definition of what constitutes being “made in America.”

Application dates for the rule, which eliminates the manufactured products waiver, are also included in the updates.

In the process, the agency keeps the Biden-era manufactured products rule unchanged and removes a waiver that industry groups favored.

With

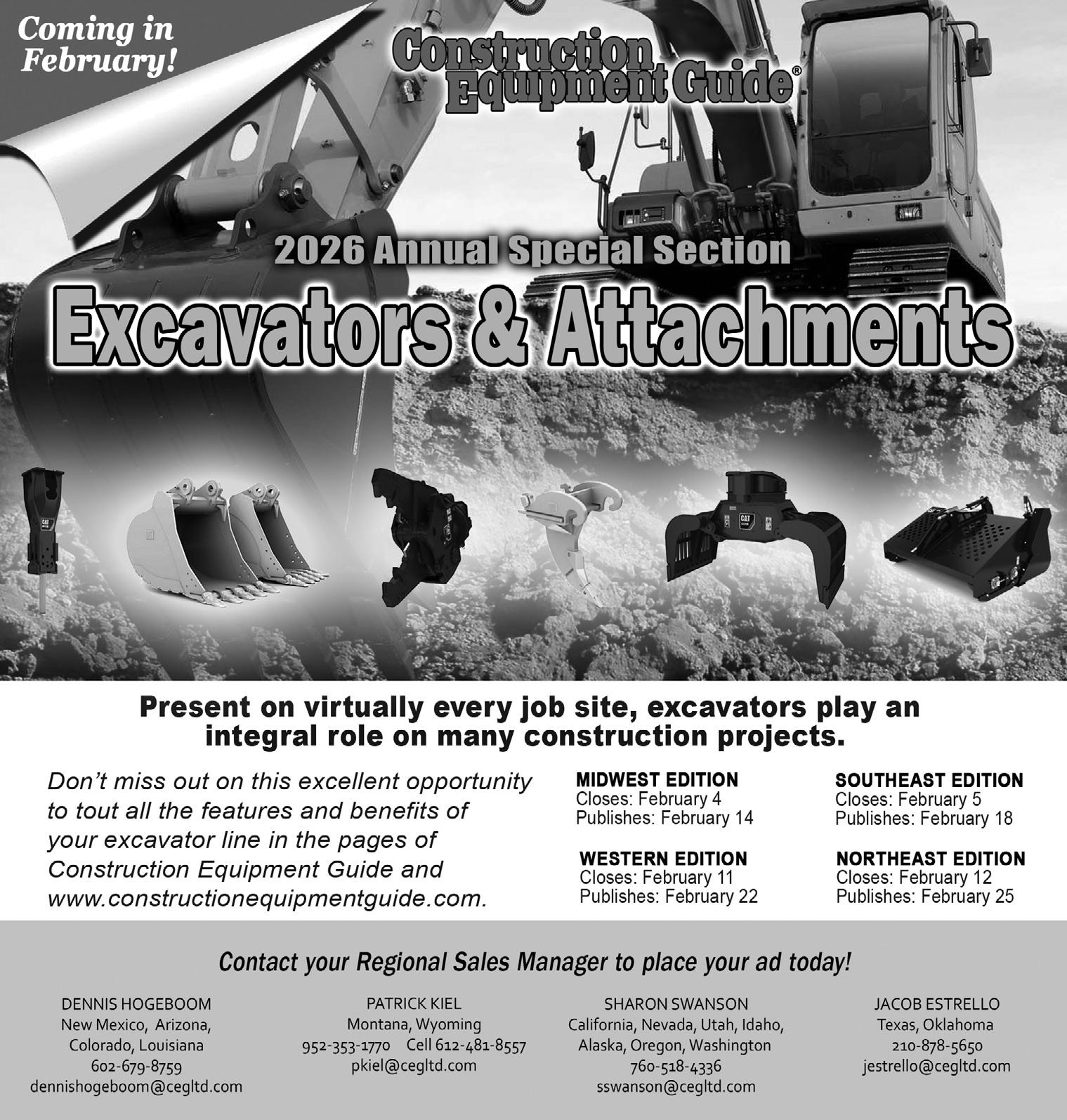

Associated Equipment Distributors (AED) announced a new partnership with OPOC.us, endorsing the organization as the preferred health care and benefits partner for AED members.

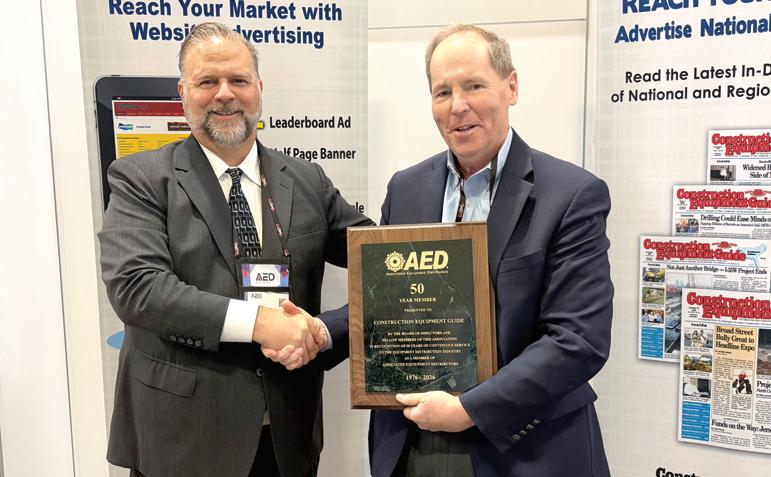

During the AED Summit/CONDEX held Jan. 19-21, 2026, in Dallas Texas, the association’s board of directors and fellow members honored Construction Equipment Guide with an award commemorating 50 years of membership.

AED announced its 2026 leadership appointments during the 2026 AED Summit. The announcements included new chairs for both the AED board of directors and the AED Foundation, along with several new members joining each board.

8 ACQUISITION TALKS

Wacker Neuson and Doosan Bobcat have halted talks about an acquisition of a majority stake in the German construction company, Reuters reported on Jan 22, 2026.

World of Concrete (WOC) unveiled what it billed as the largest-ever showcase of products, enhanced educational programming and strengthened industry networking opportunities at the Las Vegas Convention Center Jan. 19-22, 2026.

The Associated Equipment Distributors gathered Jan. 19-21 in Dallas, Texas, for its annual Summit/CONDEX. The event was an opportunity for members to network, attend seminars, fundraise and see what’s new in the industry.

20

The multi-phase hot-fire rocket engine test facility is designed to address a critical shortage of responsive, altitude-capable propulsion testing infrastructure for the global space industry.

20

At its January regular business meeting, the Wyoming Transportation Commission awarded seven contracts valued at approximately $43.5 million for Wyoming Department of Transportation construction projects.

32

Playing a vital role during this busy time and throughout the year, is Switchback’s 13,000-sq.-ft. hangar and its 60-ft. by 19-ft. Schweiss Doors liftstrap bifold door. The hangar provides storage and maintenance space.

37

Designed to meet the demands of today’s skid steer and compact track loader platforms, these updates reinforce Premier Attachments’ commitment to safety and long-term performance, according to Premier Attachments.

38 WHY POLYCARBONATE PROTECTION IS MUST-HAVE FOR OPERATORS

When it comes to land clearing, mowing and mulching, safety should never take a back seat. Because modern attachments move material at higher speeds than ever before, proper protection is not just recommended, but essential.

38 B&D FABRICATORS ACQUIRES LEADING EDGE ATTACHMENTS

B&D Fabricators announced that it has acquired Leading Edge Attachments Inc., a Hubbardston, Mass., supplier of frost and rock ripping buckets and other heavy attachments.

FireLake

diesel oil incinerator with its

Associated Equipment Distributors (AED) announced a new partnership with OPOC.us, endorsing the organization as the preferred health care and benefits partner for AED members.

This partnership reflects AED’s commitment to providing its members with access to innovative programs that prioritize the well-being of employees and their families.

“Attracting and retaining employees remains one of our members’ biggest challenges,” said Brian McGuire, president and CEO of AED. “With OPOC.us, AED members gain a trusted and innovative partner that brings measurable results to one of their largest business expenses.”

“We are honored to be endorsed by AED and to serve its incredible network of dealers across North America,” said Clark May, CEO of OPOC.us. “Every dealer’s most valuable asset is its people — and our mission is to make sure those people feel supported, cared for and connected through every step of their health care journey.”

Through this endorsement, AED said it reinforces its commitment to delivering proven, high-impact resources that empower members to operate strong, successful businesses. AED remains dedicated to providing the guidance, solutions and support dealerships need to thrive in a competitive and constantly evolving industry.

For more information, visit aednet.org.

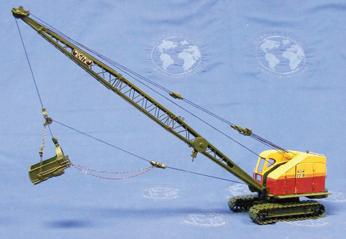

CEG photo

During the AED Summit/CONDEX event held Jan. 19-21, 2026, in Dallas Texas, the association’s board of directors and fellow members honored Construction Equipment Guide (CEG) with an award commemorating 50 years of continuous membership. Ted McKeon (R), president of Construction Equipment Guide, accepts the award from Jon Cruthers (L), senior vice president, market and business development, Associated Equipment Distributors (AED). CEG is celebrating its 68th year in business in 2026.

Wacker Neuson and Doosan Bobcat have halted talks about an acquisition of a majority stake in the German construction company, Reuters reported on Jan 22, 2026.

Associated Equipment Distributors (AED) announced its 2026 leadership appointments during the 2026 AED Summit. The announcements included new chairs for both the AED board of directors and the AED Foundation, along with several new members joining each board.

Marshall Anderson, executive vice president of RDO Equipment Co., was sworn in as AED’s 2026 chairman of the board, serving a one-year term. Anderson brings extensive industry experience and a deep commitment to advancing AED’s mission of supporting equipment distributors through advocacy, education and workforce development.

“It’s an honor to serve as AED chairman and to represent an industry that plays such a vital role in powering the economy,” said Anderson. “I look forward to working alongside AED’s leadership and membership to strengthen our collective voice, support distributor success and help position our industry for long-term growth.”

In addition, AED announced Ron Barlet, president and CEO of Bejac Corp., as chairman of the AED Foundation. Barlet will serve a twoyear term, during which he will help guide the foundation’s efforts to strengthen the industry through workforce development initiatives, research and professional education programs.

“Workforce development remains one of the most critical challenges facing our industry,” said Barlet. “As chairman of the AED Foundation, I’m excited to help expand programs that attract, train and retain the next generation of skilled professionals and ensure our members have the talent they need to thrive.”

AED also welcomed the following individuals to its board of directors during the summit:

these outstanding leaders to the AED board. Their experience and insights will be invaluable as we continue our advocacy efforts and work to deliver real value to our members.”

The AED Foundation announced the following new members joining its board of directors:

• Patrick Kearns, vice president of distribution, Caterpillar Inc.

• Vikram Savkar, CEO of VitalEdge Technologies

• Eric Mason, vice president of Mason Machinery

According to Wacker Neuson, discussions were under way for Doosan Bobcat to acquire approximately 63 percent of the company from major shareholders as well as a public buyout.

In a statement released by Wacker Neuson on Jan. 22, 2026, the company “remains focused on its strategy to pursue sustainable growth.”

In a company filing, Doosan Bobcat said that after reviewing the acquisition, it has decided not to proceed, according to Reuters.

No additional comments were made by the company.

• Michael Paradis, chairman and CEO of Bramco Inc., who will serve as second vice chairman

• Stephen Farrens, president of Vermeer Heartland, who will serve as an at-large director

• Ken Monroe, CEO of HOLT of California, who will serve as Western regional director

President of AED and the AED Foundation, Brian P. McGuire, welcomed the new AED board leaders, saying, “We are excited to welcome

• Terry Dolan, vice president of Case North America

• Michele Stanley, president and CEO, National Stone, Sand & Gravel Association

McGuire also commented on the foundation’s new leaders, saying, “We are honored to have these individuals on the foundation board. Their guidance and leadership will be critical as we continue to expand workforce development programs and ensure the industry has the talent it needs for the future.”

behind our equipme

For over 120 years, w ent and supporting customers long e’ve earned a reputation for standing inventory to keep yo experienced, respon after the sale. And a ur machines up and running. sive technicians and deep parts s an authorized DEVELON dealer,

Kent Godbersen, GOMACO vice president of worldwide sales and marketing, showcases GOMACO’s new Polymer paver at World of Concrete 2026.

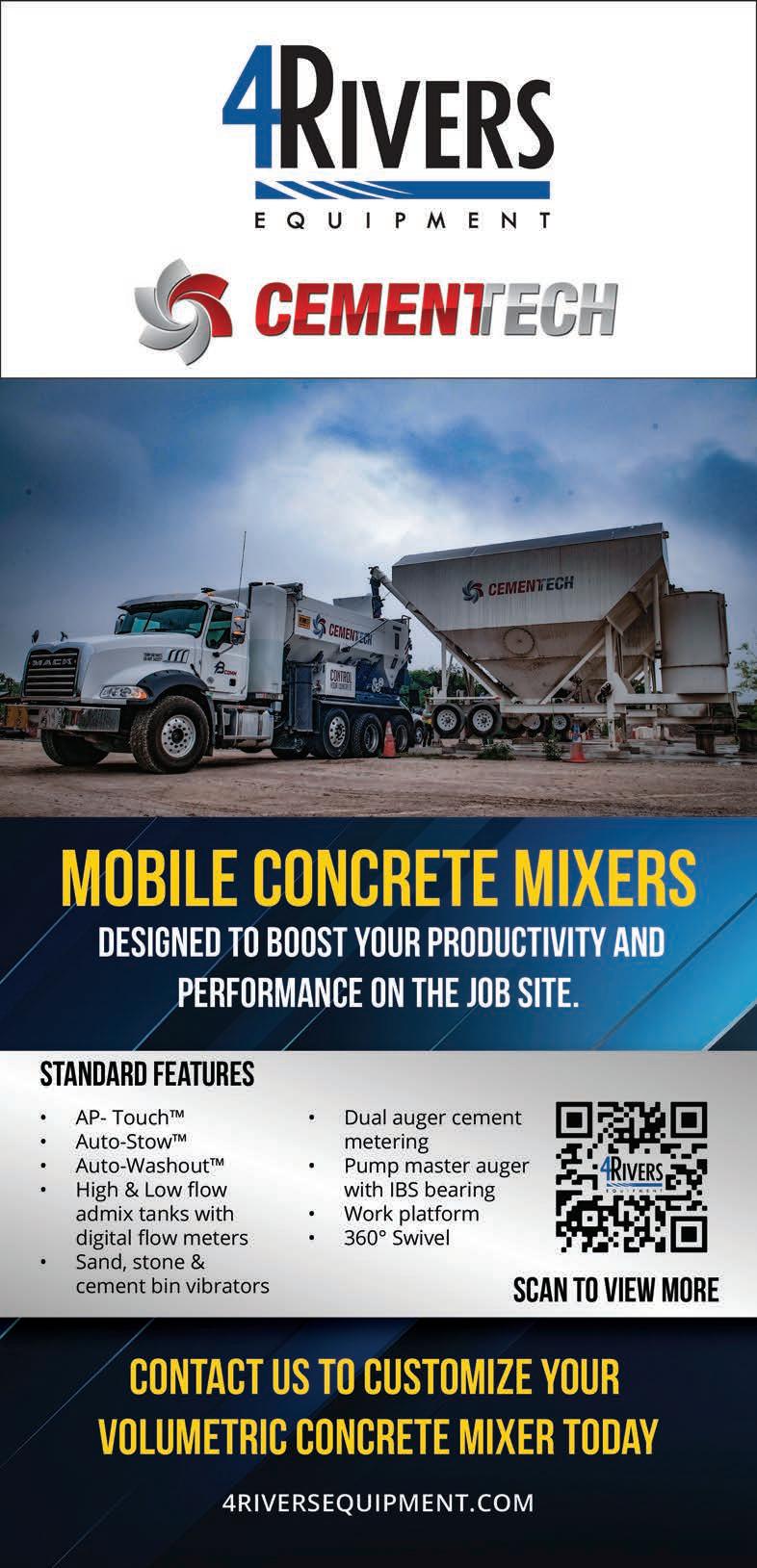

World of Concrete (WOC), the world’s largest concrete construction and masonry tradeshow for more than 50 years, unveiled what it billed as the largest-ever showcase of products, enhanced educational programming and strengthened industry networking opportunities at the Las Vegas Convention Center from Jan. 19-22, 2026.

The show floor featured more than 200 first-time exhibiting companies, bringing new perspectives, building and repair solutions brought to life by emerging technologies. Additionally, product expansion included nearly 100 total categories such as composite materials, resurfacing agents, mixers, pavers, pumps, ready mix and many others.

World of Concrete featured more than 150 educational sessions, with topics covering technical applications, best practices for business, project management and critical safety protocols for every skill level and industry role.

There were more than 60 new topics added to this year’s program and a bilingual learning environment was offered, with Wordly available for certain education sessions, with captioning and translation capabilities allowing attendees to read live captions or listen to audio in dozens of languages using their own devices.

see WOC page 26

and

Alfonso Soriano (L) of Bedrock Concrete Construction Inc. of Petaluma, Calif., talks with Giridhar Addagudi, owner and president of Mano Engineering of Mendota Heights, Minn., about manufacturing a component for the customized equipment he uses in his concrete business.

and

The Vermeer team of Pella, Iowa, (L-R) includes Cole Smith, product specialist; Zach Crabtree, product specialist; and Kegan Strobel, product specialist tree care, rental and landscape. This Vermeer ML100 is a 24.7-hp (18.4 kW) turbocharged diesel-powered, radial-lift mini loader designed for landscaping, tree care and rental markets.

The Purple Wave Auction team (L-R) included Jeff McGough, enterprise account manager construction companies-North America; Marcy Colletti, event marketing manager; and John Beasley, executive sales director.

Darda, an independent division of Brokk, develops, manufactures and supplies high-quality demolition equipment and attachments for a wide range of applications and industries worldwide. (L-R) are Volker Glatz, after sales manager; Bernd Strobele, sales director; and Sebastian Berche, Darda business development manager.

Bingham Equipment

binghamequipment.com

Tucson, AZ 520-889-6396

Cisco Equip

cisco-equipment.com

Artesia, NM 575-748-1314

Lubbock, TX 806-745-9595

Odessa, TX 432-550-9181

Ditch Witch of the Rockies

*Compact Equipment Only ditchwitchrockies.com

Nampa, ID 208-376-8394

Pocatello, ID 208-646-4360

Farm Equip USA

farmequipmentusa.com

Fruitland, ID 208-941-6000

G4 Const Equipment, LLC

g4hyundai.com

Commerce City, CO 888-987-3352

Jet City Equip

jetcityequipment.com

Oak Harbor, WA 360-675-4441

Marysville, WA 360-651-9079

Mecom Equipment

mecomequipment.com

Stockton, CA 209-466-5135

National Equipment Dealers

nedealers.com

Houston, TX 800-234-5007

Dallas TX 866-270-1700

Nueces Power Equip

nuecespower.com

Corpus Christi, TX 361-289-0066

Laredo, TX 956-725-0066

San Antonio, TX 210-310-0066

San Benito, TX 956-361-0066

Victoria, TX 361-576-0066

El Paso, TX 915-541-0066

Oklahoma Territory

Const Equip callotce.com

Oklahoma City, OK 866-339-6827

Oregon Tractor oregontractor.com

Roseburg, OR 541-679-6211

Porter Rents

porterrents.com

Corona, CA 951-674-9999

Lakeside, CA 619-390-1197

Pacoima, CA 818-834-0102 Wildomar, CA 951-678-9902

Powerscreen of Washington, Inc.

powerscreen-wa.com Helena, MT 253-236-4153

Powerscreen of Northern California, Inc.

powerscreenofcalifornia.com Dayton, NV 888-797-7276

Dixon, CA 707-253-1874

Rifle Equipment, LLC

*Compact Equipment Only rifleequipment.com

Rifle, CO 970-625-2580

R&S Industries Inc. rsindinc.com

Amarillo, TX 806-737-9410

Clovis, NM 575-769-8659

Tri-State Equipment

*Compact Equipment Only tristateequipmentrentals.com

Lake Havasu, AZ 928-680-6748

Fort Mohave, AZ 928-704-0101

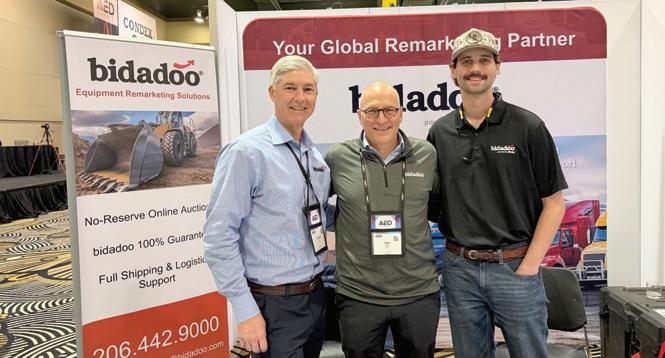

The Associated Equipment Distributors (AED) gathered Jan. 19-21 at the Hilton Anatole in Dallas, Texas, for its annual Summit/CONDEX.

The event was an opportunity for members to network, attend seminars, fundraise and see what’s new in the industry. CONDEX allowed equipment manufacturers the chance to show attendees the latest in equipment, technology and services.

Among the speakers at this year's event was Nikki R. Haley, former two-term governor of South Carolina. In 2010, at age 38, Haley was elected the 116th governor of South Carolina and reelected in 2014. She was the youngest governor in the country and first minority female governor in America. She is the only female governor in South Carolina history.

Other session speakers included Rod Bull, CEO of Komatsu; Katie Hays, director of government affairs of Caterpillar; John Kacsits, acting chief operating officer of Groff Tractor & Equipment; Andrew Ryan, president of LiuGong North America; Scott Young, president/head of region of Volvo CE; Alex Woods, president of Kubota Tractor Corp.; and many more. In total, there were approximately 45 educational seminars during the three-day event.

see CONDEX page 42

was among many forestry-related products attracting the attention of AED dealers. Matt Vantine, director of tree care products, and Nicole Gorsuch, director of marketing and dealer development, both of Morbark spoke with attendees.

1090 W 2181 N Salt Lake City, UT 84116 801-322-1300

atlasmachinery.us

6565 Smith Avenue Newark, CA 94560 510-400-5024

1535 SE 25th Street Oklahoma City, OK 73129 405-310-8700

2035 W Mountain View Road Phoenix, AZ 85021 480-463-4999

5401 S. Arcadia Avenue Tucson, AZ 85706 520-307-1435

Equipmentshare.com

Agile Space Industries announced on Jan. 26, 2026, the groundbreaking of the initial $20 million phase, establishing the Space Test Center (STC).

The multi-phase hot-fire rocket engine test facility is designed to address a critical shortage of responsive, altitude-capable propulsion testing infrastructure for the global space industry.

“The Space Test Center is the first $20 million step in a $200 million propulsion testing ecosystem,” said Nick Aadland, the technical manager at Space Test Center. “This facility is intentionally scalable, built to seed a new space industry hub in Oklahoma and close a critical national gap in modern in-space propulsion test capacity.”

Lyle Building Group of Tulsa is the project contractor.

Built on more than 12 years of propulsion testing heritage at Agile Space Industries, the Space Test Center will provide high-throughput testing services for small- to medium-class rocket engines supporting commercial, civil and national security space missions.

“The Space Test Center is purpose-built to enable speed to space,” said Jim Vasher, general manager OF Space Test Center. “Demand for in-space propulsion is growing rapidly, but access to modern test infrastructure has not kept pace. STC directly addresses that gap with flexible, scalable and secure testing services.”

“Today’s groundbreaking marks an important milestone for Tulsa’s growing space economy,” said Alexis Higgins, CEO of Tulsa International Airport. “This development will

utilize approximately 20 acres of non-aeronautical land at the airport and represents an initial investment of tens of millions of dollars by Agile Space Industries. As the first tenant in this area, Agile Space Industries is helping lay the foundation for a new broader space innovation ecosystem at Tulsa International Airport.”

The global space economy exceeds $600 billion and is projected to grow to more than $1 trillion by 2040. Most SmallSat and ESPAclass spacecraft rely on thrusters under 100 pounds-force (lbf), with development demand concentrated between 25 and 300 lbf. However, few facilities are designed to support high-throughput testing in this thrust class, particularly for hypergolic propellant systems.

Legacy test facilities face long lead times, limited propellant flexibility and outdated testing approaches and have long proven to not be able to keep up with the needed and growing demand of the market, according to the company. The Space Test Center is designed to meet these needs with secure, U.S.-based infrastructure, optimized fast throughput, advanced data collection systems and a renowned team to work on your engines.

The Space Test Center is expected to anchor a broader regional space industry cluster known as the Tulsa Space Park, attracting additional manufacturing, integration and testing capabilities to the region, the company said.

(All photos courtesy of Agile Space Industries.)

At its January regular business meeting, the Wyoming Transportation Commission awarded seven contracts valued at approximately $43.5 million for Wyoming Department of Transportation construction projects.

The commission awarded a bid valued at approximately $13.5 million to Cheyenne, Wyo.-based Reiman Corp. for combined bridge replacements (four structures) and safety grading involving removing concrete bridges, installing cofferdams, excavation, installing steel piling and reinforcing steel, placing structural steel, structural concrete, road base, approach slabs, asphalt pavement and riprap and installing bridge railing at various locations on Interstate 25, Wyoming Highway 320 and Wyoming Highway 94 in Converse and Platte counties. The contract completion date is Nov. 30, 2027.

The commission awarded a bid valued at approximately $7.1 million to Worland, Wyo.-based McGarvin-Moberly Construction Co. for a widening and overlay project involving excavation, reinforcing subgrade, placing road base and asphalt pavement and installing stormwater control components on U.S. 287 beginning at mile marker 402.3 for approximately 2.5 miles between Laramie and Colorado in

Albany County. The contract completion date is Nov. 30, 2026.

The commission awarded a bid valued at approximately $7 million to Afton, Wyo.-based Avail Valley Construction LLC for a project involving milling asphalt pavement, placing asphalt pavement and chip seal, installing stormwater control components and fence work on Wyoming Highway 59 beginning at mm 19.30 between Douglas and Bill in Converse County. The contract completion date is June 30, 2027.

The commission awarded a bid valued at approximately $5.6 million to Gillette, Wyo.-based S & S Builders LLC for a bridge replacement project (two structures) involving removing concrete bridges, excavation, installing steel piling, stormwater control components, precast wall components and concrete slab bridge beams, placing structural concrete, approach slabs, road base and asphalt pavement and installing box beam guardrail on Interstate 90 beginning at mm 98.3 over a machinery pass in Campbell County. The contract completion date is Nov. 30, 2026.

The commission awarded a bid valued at approximately $4.2 million to McGarvin-Moberly for a combined spot

patching and chip seal project involving placing asphalt pavement and chip seal on U.S. Highway 20/26 on approximately 46.8 mi. at various locations between Waltman and Shoshoni in Fremont and Natrona counties. The contract completion date is Aug. 31, 2026.

The commission awarded a bid valued at approximately $3 million to Avail Valley for a pavement patching project involving milling and placing asphalt pavement on Wyoming Highway 22/Teton Pass at various locations in Teton County. The contract completion date is Oct. 31, 2026.

The commission awarded a bid valued at approximately $3 million to Reiman Corp. for combined bridge rehabilitation (four structures) and bridge deck and rail repair (one structure). This project involves installing sheet piles; repairing bridge deck; placing structural concrete; approach slabs; asphalt pavement; and bridge deck overlay; and installing expansion joint material and guardrail at various locations in Converse, Goshen, Johnson and Natrona counties. The contract completion date is Nov. 30, 2026.

Almost all WYDOT projects are awarded to the lowest bid. All of this month’s projects are funded primarily by federal dollars.

For more information on crushing, screening and recycling equipment, visit CEG's Web site at www.constructionequipmentguide.com

Bergkamp announced the launch of the Journeyman mobile mix plant, its first entry into the cold central plant recycling (CCPR) market.

This move marks a significant expansion of Bergkamp’s innovation into cold recycling technologies, building on decades of expertise in slurry and micro surfacing solutions.

Bergkamp. “It’s built to make CCPR more intuitive, more consistent and more reliable from day one.”

The inspiration for Journeyman came from the field. Several of Bergkamp’s customers — many already working in cold recycling — expressed a need for more operatorfriendly equipment that could bridge the gap between performance and usability.

According to Bergkamp, Journeyman is capable of producing mixes with 100 percent RAP, 100 percent virgin aggregates and any blend in between.

Journeyman represents a new standard of innovation, craftsmanship and operator-first design in CCPR, according to Bergkamp.

“The Journeyman brings the Bergkamp commitment to quality and customer support into a category that’s ready for a better experience,” said Scott Bergkamp, president of

Bergkamp began its development process in 2017, building and testing an early prototype to validate performance and operator experience. Rather than retrofitting existing equipment or rushing to market, the team spent years refining the concept — drawing on the success of its EMCADS control technology and direct input from contractors and operators, according to Bergkamp.

That vision never changed: deliver technology that lowers the learning curve; reduces customer entry costs; and raises expectations for what a CCPR plant can be, according to Bergkamp.

The result: a machine engineered for precision, simplicity and uptime. Journeyman integrates proprietary automation and metering controls that reduce calibration time, while maintaining the rugged durability and features that define Bergkamp equipment, according to Bergkamp. It brings flexibility and precision to the job site, capable of producing mixes with 100 percent RAP, 100 percent virgin aggregates and any blend in between.

“At Bergkamp, we take pride in building equipment that just feels right to use — day after day,” said Bergkamp. “Journeyman reflects that philosophy. It’s the product of listening to customers, designing with the operator in mind, and refusing to compromise on quality.”

For more information, visit bergkampinc.com.

to validate performance and

OVE MSS502 OVE MSS802 forKLEEMANN'smobilecoarsescreeningplantsThe and new applications can be a challenge for many scr C Even more selection to match your requirements! ey'rebuilttotakeon reening plants. Not so hanging locations nnameelk-neercsibom/moc.puorg-negtriw.www coarse screening plants. compact – it's up to you: The MOBISCREEN MSS 502 EVO | MSS 802 EVO were designed for outstanding flexibility and operability. Full-size or 802 EVO can easily adapt to new operating conditions. These machines screening parameter adjustment, the MOBISCREEN MSS 502 EVO and MSS pretty much anything. With their wide range of screening media and simple

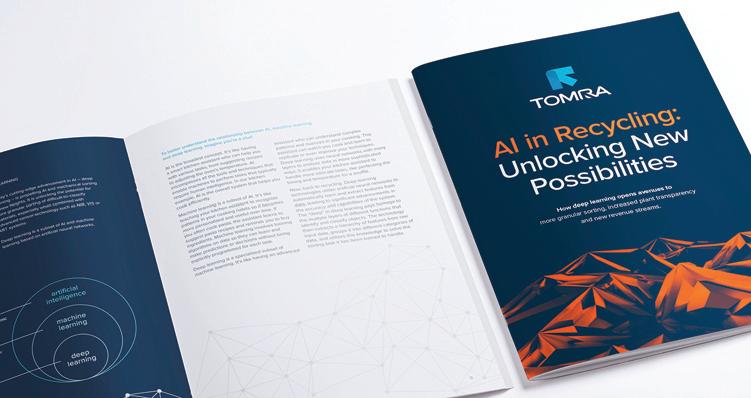

TOMRA Recycling has published its latest e-book, “AI in Recycling: Unlocking New Possibilities.”

This comprehensive guide explores the rapidly evolving role of artificial Intelligence (AI), particularly deep learning, in revolutionizing the global recycling industry and driving material circularity.

Amarillo, TX 806-373-2826

Hewitt, TX 254-261-1370

for KLEEMANNs mobile coarse screening plants. Theyre built to take on Oklahoma City, OK 405-495-7820 Tulsa, OK 918-438-1700 McAlester, OK 918-310-1550

Abilene, TX 325-692-6334

The free-to-download e-book aims to demystify deep learning, explaining its mechanisms and showcasing its practical applications in overcoming complex sorting challenges, such as enabling the separation of previously hard-to-classify materials through the training of vast datasets. From manual processes to the prospect of fully autonomous AI-driven systems, the evolution of sorting technologies is also examined in detail, alongside the core concepts of AI and deep learning.

The e-book details how the powerful synergy achieved by combining deep learning with traditional sensors in optical sorters is unlocking new opportunities for the recovery of valuable resources, enhancing material purity and creating new revenue streams.

including enhanced flexibility, the creation of new high-value material streams, superior sorting accuracy, advanced plant automation and optimized processes. The guide also showcases the growing range of deep learning applications pioneered by TOMRA including real-world examples. Furthermore, it examines the crucial role of AI in meeting the demands of evolving regulations like the Packaging and Packaging Waste Regulation (PPWR), which necessitate advanced sorting capabilities to achieve circular economy targets. Looking ahead, the e-book presents a vision for the future where AI could drive fully transparent and self-optimized recycling plants.

Odessa, TX 432-333-7000 www.kirby-smith.com

Chico, TX 940-678-5046 Dallas, TX 214-371-7777

Ft. Worth, TX 817-378-0600

www.nuecespower.com

Corpus Christi, TX 361-289-0066

Lubbock, TX 806-745-2112

Laredo, TX 956-725-0066

San Benito, TX 956-361-0066

Victoria, TX 361-576-0066

Vinton, TX 915-541-0066

Houston, TX 713-247-0066

San Antonio, TX 210-310-0066

This is exemplified by TOMRA’s awardwinning GAINnext solution for food-grade plastics recovery (for PET, PP and HDPE), PET and paper cleaning and high-purity recovery of aluminum Used Beverage Cans (UBC), as well as the capabilities of the PolyPerception AI-based waste analyzer in providing real-time, end-to-end object tracking and classification of waste streams.

Readers will gain insights into the tangible benefits of deep-learning-based solutions,

“We believe our new e-book will serve as a valuable resource for the global recycling community, providing a clear understanding of how deep learning is not a futuristic concept, but rather a tangible solution that is already delivering significant benefits and paving the way for a truly circular economy,” said Fabrizio Radice, senior vice president and head of sales and marketing of TOMRA Recycling. “By demystifying the technology and showcasing real-world applications, our aim is to encourage recyclers and processors to embrace the transformative potential of AI and explore how it can help them achieve their operational goals, meet rising demand for recycled content and take advantage of new, expanded market opportunities.”

For more information, visit tomra.com/aiebook.

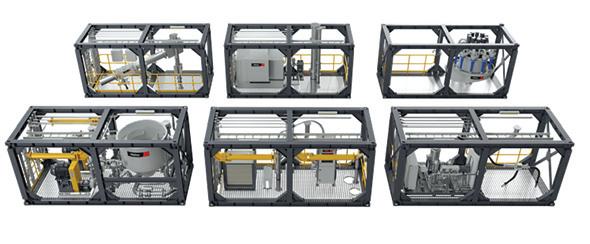

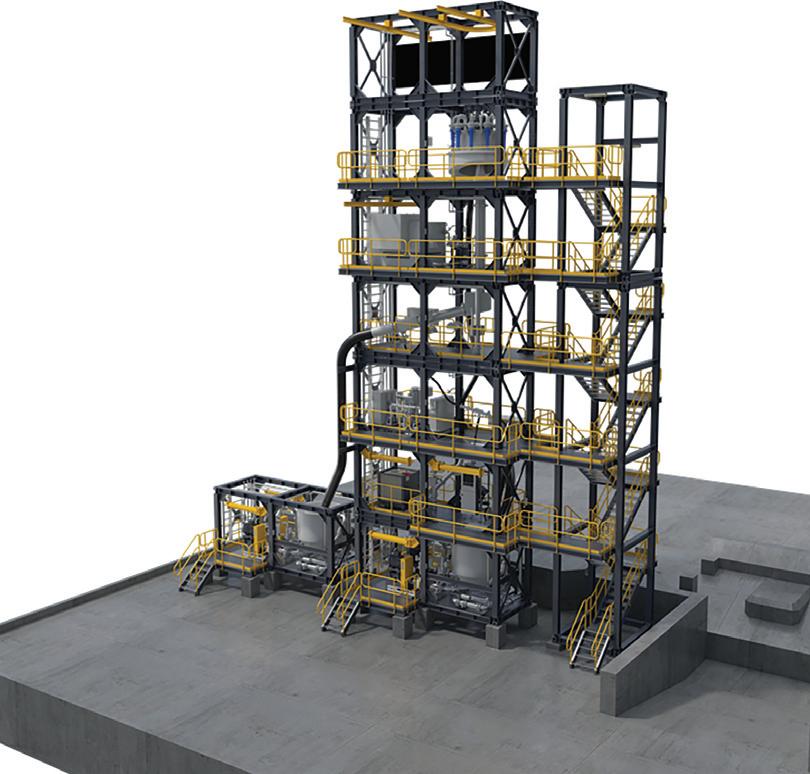

Metso is launching a configurable grinding classification system, setting a new benchmark for the highest efficiency in design, supply and installation of a grinding system while reinforcing safety, quality and reliability in minerals processing, according to Metso.

The design consists of compact preengineered modules for pumps, hydrocyclones, product samplers, liquid resistance starters, particle size analyzers and mill lubrication units, which are easy to install and combine. The modules can be stacked, allowing for compact use of space, while the pre-engineered design eliminates the need for on-site modifica-

tion and improves installation safety. The system is applicable for all types of grinding mills.

“Our customers get multiple benefits from this advanced system that integrates seamlessly into their operation and boosts the efficiency of their grinding systems,” said Jesse Ting, manager of grinding systems of Metso. “Our pre-engineered modules are scalable for different mill types and classification stages, delivering exceptional performance with four times faster installation and more than 20 percent savings in overall cost compared to conventional solutions. Each module is sized to match perfectly with standard 20-ft. or 40-

astecindustries.com

806-364-5687

613 S. 4th Ave Mansfield, TX 76063 817-473-2110

3871 IH - 10 W. Freeway Exit 693 Columbus, TX 78934 979-732-6902

www.texasbearing.com

Representing Stellar industries of Garner, Iowa, (L-R) are Sam Jefson, marketing director; Chris Rycroft, national sales manager for the mechanic truck and crane product lines; Jon Mickleson, regional sales manager; and Richard Holley, regional sales manager.

WOC from page 12

New educational sessions included an economic forecast with Ed Sullivan and Pierre Villere; Engineering: Designing for Constructability; Engineering: Bridging the Gap Between General Contractor and Engineer; The Future is Bright and Blended: Ensuring the Performance of Concrete Mixtures; Women at Work: Tools, Allies and Strategies for Career Growth Strategies in Construction; and Robotic and High Tolerance Floors, a seminar addressing the growing robotic material handling industry and high-precision.

For more information, visit worldofconcrete.com. CEG

(All photographs in this article are Copyright 2026 Construction Equipment Guide. All Rights Reserved.)

Kyle Emanuel, product information specialist of Doosan Bobcat, demonstrates the new Bobcat E20 compact excavator, which is a versatile 1- to 2-ton zero-tail swing machine, ideal for tight job sites, featuring a retractable 39-in. to 53.5-in. undercarriage.

Ignite

NC MACHINERY

www.ncmachinery.com

800-478-7000

Anchorage, AK • 907-786-7500

Dutch Harbor, AK • 07-581-1367

Fairbanks, AK • 907-452-7251

Juneau, AK • 907-789-0181

Prudhoe Bay, AK • 907-659-6900

Wasilla, AK • 907-352-3400

CALIFORNIA

HOLT OF CALIFORNIA

www.holtca.com

Pleasant Grove • 916-921-8969

TRACTOR AND EQUIPMENT

www.tractorandequipment.com

Williston • 701-572-8377

TRACTOR AND EQUIPMENT

www.tractorandequipment.com

Worland • 307-347-4747

TRACTOR AND EQUIPMENT

www.tractorandequipment.com

Billings, MT • 406-656-0202

Billings-Sgt. • 406-245-4426

Bozeman • 406-585-5800

Great Falls • 406-761-7900

Helena • 406-442-2990

MUSTANG CAT

mustangcat.com

Beaumont • 409-892-8412

Bryan • 979-775-0639

El Campo • 979-543-3389

Houston • 713-460-2000

Lufkin • 936-639-5551

NC MACHINERY

www.ncmachinery.com

800-562-4735

Seattle • 425-251-5800

Chehalis • 360-748-8845

Fife • 253-896-0878

Monroe • 360-805-6000

Mt. Vernon • 360-424-4292

Wenatchee • 509-886-5561

Yakima • 509-248-2371

During the Canadian wildfire season, historically between the months of May through September, the team at Switchback Helicopters in Calgary, Alberta, is on call.

The pilots ferry people and equipment to fires and take part in fire suppression efforts by hauling water buckets to and from hot spots. On the ground, the maintenance crew keeps Switchback helicopters in top working order so they can respond to calls.

“Our main business is firefighting,” said Kurt Vickery, hangar manager of Switchback Helicopters.

Playing a vital role during this busy time and throughout the year, is Switchback’s 13,000-sq.-ft. hangar and its 60-ft. by 19-ft. Schweiss Doors liftstrap bifold door. The hangar provides storage and maintenance space for the aircraft while the bifold door makes it easy to move the helicopters in and out quickly.

“Because of the reliability and quality of Schweiss doors, we have had zero issues with our door,” said Mike Freidin, Switchback Helicopter’s co-founder and maintenance manager.

Switchback’s story started with three men, all aviation enthusiasts who worked for the same large Canadian helicopter operator. When that operator entered into creditor protection, the trio of Freidin, Brian MacPherson and Jeff Groom set off on their own.

“We decided we were at a point that is was now or never,” Freidin said.

They set up in a 2,000-sq.-ft. hangar at the Springback Airport and established Switchback Helicopters. In addition to firefighting, the company also provides charter flights and infrared scanning services, used to find animals, fires and individuals among southwestern Alberta’s mountains and forests.

Switchback’s fleet is anchored by two AStar B3 helicopters. This type of helicopter is widely used by law enforcement and firefighting as they are wellequipped to fly in the challenging airspace around mountains. One such helicopter even landed on top of Mount Everest.

When Switchback had the opportunity to build a new hangar with a partner at the airport, they took it. They hired Ironwood Building Corp. of Calgary to erect a 13,000-sq.-ft. hangar which also includes office space.

One thing the Switchback founders liked about their original hangar was the Schweiss door. They’d seen problems with other doors, such as cables failing, and had no intention of taking such a gamble on installing a different brand door on their new hangar.

“We knew that was the way we wanted to go,” Freidin said. “When we built the hangar, we knew we were putting on a Schweiss door.”

They ordered a 60-ft. by 19-ft. liftstrap bifold door, with four windows. The windows were both a design decision and a safety feature as they allow workers to see what is going on outside the hangar when the door is closed.

“We like the strap system of the Schweiss Doors bifold door as opposed to the cable system,” Vickery said. “And we wanted to be able to see out to our helipads and we also wanted the natural light.”

The Switchback door also has Schweiss Doors’ automatic strap latch locking system, which pulls the door against the building and tightly latches it closed without any assistance from the operator. This is a big positive in an area that can get high winds.

Through the process of ordering and installing the new Schweiss doors, Switchback learned two lessons. The first was to find a knowledgeable installer if you don’t plan to install the door yourself. Freidin said they ended up having to find a second installer when the first was unable to correctly finish the job. Schweiss Doors provides customers with a list of qualified installers around their local region.

“It had nothing to do with Schweiss Doors,” Freidin said, adding the second installer found the instructions from Schweiss to be easy to follow. “They were pretty happy with the installation.”

The second lesson was to think of the future when ordering, not only the door, but when designing the building as well. While the building and door perfectly meet current needs, Freidin says they wish they had made both bigger, so the business could grow without having to worry about running out of space.

“The advice is plan for the future growth,” Vickery said. “Don’t focus on the now, focus on where you are going and then planning accordingly for your width and height.”

Looking forward, Switchback Helicopters would be more than happy to purchase a Schweiss door for any future hangar projects and they would be quick to recommend Schweiss Doors to others.

“Oh, yeah, absolutely,” Vickey said.

“In a heartbeat,” Freidin said.

For more information, visit bifold.com.

926-4386

(360) 756-6572

(509) 248-5636 Pasco (509) 545-1959 Wenatchee (509) 884-2934

Spokane (509) 536-7300

Lane Kimble, director of the Wisconsin Transportation Builders Association, said FHWA had used its waiver authority since 1983. The waiver exempted a wide range of materials used on federal aid highway projects, including electronics, ITS hardware and electrical equipment. It also exempted other items, including signal boxes and pumps, from provisions mandating they be produced domestically.

“Manufactured construction products will need to be built in the United States and be made of at least 55 percent U.S.-made components,” said Kimble. “President Trump and the USDOT initially put the rule change on hold last year for review.”

ARTBA noted that removing the waiver, though well-intentioned, could cost the transportation construction industry $8.5 billion over the next decade.

Sean McMaster, FHWA administrator, told ARTBA members he wants to ensure Buy America requirements do not delay projects. But, McMaster told the association’s executive committee, waivers must be “limited, strategic and temporary.”

ARTBA announced the waiver phases out with federal aid projects obligated on or after Oct. 1, 2025, for which final product assembly must take place in the United States.

“The Q&A document does not detail new policies,” the association said in its announcement to members. It said the document “simply clarifies how FHWA intends to interpret and implement the revised Buy America standards in this area.”

Those revisions now include product classification and transition timelines, said the group, adding it is in regular contact with FHWA on the issue.

In early 2024, FHWA released a proposal to roll back the waiver exempting manufactured products from Buy-America rules on federal aid highway projects.

ARTBA reported then that FHWA called it a step toward boosting domestic manufacturing, bolstering critical supply chains and supporting creation of union jobs.

The agency solicited comments on the implications of its proposal for 60 days after publication in the Federal Register.

“FHWA proposes requiring that domestic content of manufactured products exceeds 55 percent, as measured by the cost of their components,” said ARBTA. “In justifying the proposed change, the agency repeatedly cites domestic manufacturing as a policy priority for the White House and Congress.”

The agency’s plan was to pursue targeted waivers for specific manufactured products to minimize costs and delays.

Manufactured construction products on federal aid projects, including iron, steel and cement, now must be built in the United States and must be made of at least 55 percent U.S.-made components.

ARTBA said the industry supported the waiver because it would be costly, and perhaps impossible, to ensure many materials were Buy America-compliant.

In a 2023 survey co-sponsored by ARTBA, two-thirds of contractors believed a change in the waiver would cause a major effect on their operations. These effects would require “significant additional time and costs to document and certify countless components within these items,” said the group.

ARTBA noted then that the IIJA maintained Buy America coverage for iron, steel and manufactured products while expanding it to construction materials.

“The law also requires periodic reviews of waivers like this one,” the association said in explaining the rollback to members.

In its Q&A section explaining the changes to the Manufactured Products Final Rule, FHWA outlines updates to several materialspecific requirements.

It said the final rule clarifies what kinds of products are subject to FHWA’s Buy America requirements for steel and iron versus manufactured products.

For projects obligated on or after March 20, 2025, recipients of funds must classify products based on the definitions in the code. These definitions stand “regardless of any previous methods used to differentiate these two categories,” said the agency.

FHWA said the new manufactured products rules are “generally” the same as those under the Build America, Buy America (BABA) Act.

“However, the application of FHWA’s Buy America requirements may differ from the application of BABA’s requirements,” it added.

For example, BABA applies only to infrastructure projects, said the transportation agency. That’s any work related to the construction, alteration, maintenance or repair of infrastructure regardless of whether it also is the primary purpose of the project.

“FHWA’s Buy America requirements apply to all projects funded with Title 23 funds, even those not generally considered to be infrastructure projects,” it said. “FHWA’s Buy America requirements also provide distinctions for certain manufactured products not included in the BABA requirements.”

The agency said Buy America rules do not apply to the non-iron or non-steel components of an iron or steel product.

Under the rule, a product can be classified as an iron or steel product even if it contains non-iron or non-steel components.

“In such a case, the Buy America requirements for steel and iron … apply to such products, not the requirements for manufactured products or construction materials.”

The agency also said the cost of the foreign iron or steel product is only the cost of the foreign iron or steel in the product.

If an iron or steel product contains noniron/steel components, recipients should use just the cost of the individual foreign iron or steel components.

For projects obligated between March 20, 2025, and Sept. 30, 2025, the waiver applies to manufactured products permanently incorporated in such projects.

“For projects obligated on or after Oct. 1, 2025, all manufactured products permanently incorporated into the project must be manufactured in the United States.”

For projects obligated on or after Oct. 1, 2026, all manufactured products in the project must meet the final assembly requirement.

Plus, the cost of components that are mined, produced or manufactured in the United States must be greater than 55 percent of the total cost of all components.

Under the rule, specific requirements apply to precast concrete products, intelligent transportation systems (ITS) and other electronic hardware systems products installed in the highway right-of-way

“For such precast concrete products, components that consist ‘predominantly of iron or steel or a combination of both’ must meet FHWA’s requirements for iron and steel.”

see BUILD age 56

Premier Attachments announced advancements to its earth auger drive product lineup with the launch of the enhanced H0 series, effective Jan. 12, 2026.

Designed to meet the demands of today’s more powerful skid steer and compact track loader platforms, these updates reinforce Premier Attachments’ commitment to innovation, safety and long-term performance, according to Premier Attachments.

At the core of the H0 upgrade is a new planetary drive design, engineered to deliver high torque capabilities while maintaining optimal RPM performance across a wide range of machine sizes and applications. This design allows Premier Attachments to remain flexible and responsive as equipment horsepower and hydraulic capabilities continue to evolve and improve, according to Premier Attachments.

According to Premier Attachments, key H0 drive unit improvements include:

• New Proprietary Planetary Design — built to handle today’s higher-output machines while maximizing digging performance.

• American-Made Manufacturing built in the United States for quality, consistency and reliability.

• Service Window Access — enhanced serviceability to reduce downtime and simplify maintenance.

• High-Torque Output — delivering power, efficiency and productivity on the job site.

In addition to performance improvements, Premier Attachments has introduced several standard safety and durability enhancements across its auger drive lineup:

• Hose spring kit is now standard on all full-sized skid steer and Duo-Tach auger drive kits, helping protect hydraulic hoses during operation.

• New no-slip welded tread provides improved footing on entering and exiting of standard skid steers adding operator safety on the job site.

• H020 with up to 2,229 ft./lbs. of torque

• H025 with up to 3,288 ft./lbs. of torque

• H030 with up to 4,155 ft./lbs. of torque

Premier Attachments photo Premier Attachments announced advancements to its earth auger drive product lineup with the launch of the enhanced H0 series.

• H035 with up to 5,214 ft./lbs. of torque

Each new model delivers increased torque capacity and refined RPM ranges to support auger sizes up to 42 in., depending on configuration, ensuring performance across a wide variety of ground conditions and applications, according to Premier Attachments.

“As machines continue to get more powerful, Premier Attachment’s performance must lead the way and remain ahead of the curve,” said Jim Hunt, sales and marketing manager of Premier Attachments. “These H0 drive unit improvements reflect our commitment to American-made innovation and quality, smarter serviceability and the flexibility our dealers and customers need as the industry evolves.”

The enhanced H0 earth auger drive units and standard safety upgrades will be available through Premier Attachments’ authorized dealer network beginning Jan. 12, 2026.

For additional specifications, dealer information or product availability, visit premierattach.com.

When it comes to land clearing, mowing and mulching, safety should never take a back seat.

From flying debris and dust to unpredictable weather and rough terrain, operators face constant exposure to hazards that can quickly turn a routine job into a risky one. Because modern attachments move material at higher speeds than ever before, proper protection is not just recommended, but essential.

“Polycarbonate cab reinforcement offers a proven line of defense between operators and the harsh realities of the job site,” said Nate Cleveringa, vice president of engineering and product management of Diamond Mowers. “Built to withstand heavy impact and designed for easy installation, these durable panels keep your team safe and your equipment in top shape, all while reducing interruptions that can cost time and productivity. The result is greater uptime, longer equipment life and peace of mind knowing crews are backed by industry-grade safety materials.”

Every job and machine is different, so the right fit and design matter. While a variety of solutions exist across the industry, the experts at Diamond Mowers outline several key factors operators should consider when evaluating or upgrading their cab protection. These solutions make it simple to outfit skid steers, excavators or tractors with a perfectly matched kit that enhances visibility and job site confidence without slowing down operations.

Operator safety is a top priority, so it is widely recommended to use a minimum ½-in. polycarbonate shield when running heavyduty attachments. This highimpact protective barrier offers strength and shatter resistance, making it one of the most effective ways to help prevent injuries caused by flying material, wood chips and other projectiles.

Polycarbonate solutions are engineered to outperform standard cab glass and are designed to help operators stay protected without sacrific-

ing visibility. The heavy-duty layer not only absorbs impact but also reduces glare, blocks dust and deflects branches.

“Whether managing overgrown brush, tackling roadside maintenance or operating in unpredictable environments, it helps crews stay safe and focused no matter the challenge,” Cleveringa said.

Diamond Mowers’ polycarbonate solutions are engineered to handle the toughest outdoor environments, according to Diamond Mowers. Each kit is engineered to match the dimensions and contours of a machine’s cab, ensuring a secure fit that stands up to long hours, heavy workloads and the demanding nature of vegetation management, according to Diamond Mowers.

Treated with UV and abrasionresistant coatings, these panels maintain clarity and strength season after season, meaning less wear, fewer replacements and lasting visibility operators can rely on.

“This level of resilience gives

operators confidence that their cab protection will hold up season after season, no matter how demanding the job or environment,” said Cleveringa. “It’s the kind of longterm dependability that keeps equipment performing at its best, and crews focused on the work ahead instead of the wear and tear on their machines.”

Minimizing downtime is crucial, so a well-designed polycarbonate panel should install quickly and securely. Through close collaboration with equipment manufacturers, Diamond offers exact-fit solutions for brands such as John Deere, Bobcat and Kubota that help eliminate guesswork during installation and maintain the integrity of the machine’s original enclosure.

Each self-installed kit arrives ready to go, drop-shipped directly to a shop or job site, so operators can get back to work without delay. Fleet managers also appreciate the consistency across equipment lines, making it simple to outfit an entire team with coverage. Whether run-

ning a single skid steer or a mixed fleet of excavators and tractors, Diamond’s custom-fit approach ensures every operator benefits from the same dependable coverage.

Even the toughest materials eventually show signs of wear.

“Operators should inspect polycarbonate panels regularly and replace them if they show visible scratches, hazing or impact marks that could impair visibility or reduce structural strength,” Cleveringa said. “Staying proactive not only keeps crews safe but also extends the life of equipment and upholds the highest standards of job site safety.”

Polycarbonate cab protection is a smart, cost-effective way to enhance safety while ensuring every machine meets recommended protection standards.

For more information, visit diamondmowers.com.

B&D Fabricators announced that it has acquired Leading Edge Attachments Inc., a Hubbardston, Mass., supplier of frost and rock ripping buckets and other heavy attachments. This positions Leading Edge Attachments as part of B&D’s growing proposition of standard and customized heavy attachment.

and delivering construction equipment that enhances the versatility of excavators and backhoes. Its couplers and attachments are developed through close collaboration with contractors, ensuring that the products meet real-world demands. This hands-on development process, combined with decades of engineering and industry experience, enables LEA to produce durable and reliable equipment, according to the company.

“The acquisition of Leading Edge Attachments by B&D Fabricators represents a strategic milestone in expanding Entegra’s heavy attachments industry growth platform,” said Michael Flannery, CEO of Entegra Attachments LLC. “This direction will enable further investment and support in the expansion of LEA’s product lines,” said Lee Horton, prior owner of Leading Edge Attachments. “Partnering with B&D provides the resources and strategic alignment needed to accelerate innovation, without compromising our commitment to quality and customer service.”

“I’m excited about the opportunities this partnership brings,” said Todd Brinkman, president and founder of B&D Fabricators.

LEA has built its reputation on designing

The company prioritizes minimizing downtime for operators and continuously seeks customer feedback to improve existing products and develop new solutions that make jobs faster, easier and more efficient. Leading Edge Attachments will operate under B&D Attachments LLC, while maintaining its current product lines and names.

Founded in 2007, B&D Fabricators is a manufacturer of heavy equipment attachments. Headquartered in Edgar, Wis., the company operates with a reputation for engineering excellence and customer-focused solutions.

For more information, visit bdfabricators.com.

Braedon Russell of True Attachments showcased the company’s aftermarket buckets, quick couplers and thumbs.

MB Crushers displayed its wide range of crushing and screening buckets, as well as other attachments for excavators, backhoe loaders and skid steers. Pictured with the company’s popular BF70.2 crusher are Bryan Sims (L) and Stefano Leghissa.

CONDEX from page 17

AED was founded in 1919 by Morton R. Hunter and serves the construction, mining, forestry, power generation, agricultural and rental industries.

For more information, visit aednet.org. CEG

(All photographs in this article are Copyright 2026 Construction Equipment Guide. All Rights Reserved.)

Joel Frost of Topcon touts the LN160, which is a compact, self-leveling 3D layout tool designed to improve productivity on construction sites.

Paul Barlow, president of HUDDIG Inc., displayed the 1370 all-in-one machine, which handles all construction and utility works in almost any terrain.

Howard Hawk (R), president of bidadoo, was joined by Seth Lamar (C), vice president of strategic accounts, and Jason Roberson, area sales manager.

www.wpi.com

12320 S. Main Street Houston, TX 77035 713-723-1050 Buffalo, TX 903-322-7150 Bryan, TX 979-314-1191

Corpus Christi, TX 361-884-8275

Edinburg, TX 956-386-0107 Kilgore, TX 903-984-2011

Lufkin TX 936-243-6056

Pflugerville, TX 512-251-0013 Port Arthur, TX 409-721-5305 San Antonio, TX 210-648-4444 Tomball, TX 281-351-9016

Corporate Office 5000 Vasquez Blvd., Denver, CO 80216 303-355-5900

Colorado Springs, CO 719-576-5541

Grand Junction, CO 970-241-1550 Milliken, CO 970-587-1188

www.powermotivecorp.com

Cheyenne, WY 307-634-5149 Durango, CO 970-259-0455 Albuquerque, NM 505-345-8383 Bloomfield, NM 505-324-8601 Carlsbad, NM 505-485-1700

El Paso, TX 915-872-1001 Chandler, AZ 602-986-3003 Phoenix, AZ 602-463-3772 Tucson, AZ 520-649-2858

www.kirby-smith.com

Oklahoma City, OK

405-495-7820

McAlester, OK

918-310-1550

Tulsa, OK 918-438-1700

Abilene, TX

325-692-6334

Amarillo, TX

806-373-2826

Chico, TX

940-678-5046

Dallas, TX

214-371-7777

Ft. Worth, TX

817-378-0600

Hewitt, TX

254-261-1370

Lubbock, TX

806-745-2112

Odessa, TX

432-333-7000

www.modernmachinery.com

Corporate Office

Missoula, MT

409-842-1754

Boise, ID

208-336-8670

Jerome, ID

208-324-4522

Pocatello, ID

800-829-4450

Billings, MT 800-735-2589

Columbia Falls, MT

800-434-4190

Eugene, OR

800-826-9811

Portland, OR 800-950-7779

Kent, WA

800-669-2425

Rochester, WA

800-304-4421

Spokane, WA 800-541-0754

www.clairemontequipment.com

San Diego, CA

858-278-8351

Escondido, CA

760-739-9100

Fontana, CA 909-429-9100

Imperial, CA

760-355-7700

Indio, CA 760-863-5558

San Diego, CA

858-278-8338

The campus consists of two one-story buildings that house three programs: an Adult Crisis Residential Treatment Program, a Children’s and Youth Crisis Stabilization Unit and a Mental Health Hub serving children and youth. The facilities represent the county’s first fully integrated continuum of mental health treatment for children, youth and adults.

Construction began in October 2024. Project costs included approximately $21.4 million for the Crisis Residential Treatment Program, $10.8 million for the Crisis Stabilization Unit and $10.8 million for the Mental Health Hub.

The two 9,900-sq.-ft. buildings were constructed on four acres of previously vacant land on the northeast side of the High Desert Regional Health Center campus. One building houses the adult crisis residential program, while the second contains the crisis stabilization unit and mental health hub.

HMC Architects served as the scoping architect, with Carrier Johnson responsible for building design.

“The project construction had a 12-month deadline,” said Steven Kiss, director of civic, Carrier Johnson + Culture. “This meant that design and construction had to be aligned very early so that long lead items could be procured. The project was also able to obtain building permits within four months from contract execution. The design team focused on permit-related items and comments while working with the Construction team on details and installation issues.”

The buildings feature sloped roof elements at entry canopies, roof overhangs to reduce heat gain and exterior insulated finish systems. Interior layouts were designed to balance patient safety with efficient staff workflows, while compressed building heights helped reduce construction and longterm maintenance costs.

PENTA Project Manager Edgar Gonzalez explained how the project was delivered 20 percent under budget.

“[That happened by] working with our subcontractors on constructability of the project while design was being finalized to find installations that would save cost and time,” he said, “[and by] having all the MEP subs involved in BIM coordination to locate all overhead and underground systems to minimize any rework.”

PENTA said it overcame several hurdles on the project.

“The biggest challenge faced during the project was coordinating installation of a new transformer for the site that would be

used to feed the new buildings, but also an existing building on campus,” Gonzalez said. “Coordination with the utility company began in late 2024, with an install date for August 2025 set. The team worked to make sure all infrastructure was installed weeks prior to install so the utility company could inspect and approve prior to the transformer install.”

“Another challenge faced was installing all the MEP systems in a ceiling space that was only 1-foot high,” he added. “This involved coordinating with the MEP subcontractors and ceiling contractor to ensure all ducts, pipes and cables had their location set prior to installation. This helped mitigate rework in areas where ceiling widths were constricted by rerouting MEP systems that had more flexibility and keeping the rigid items in place. In the end, only one water line had to be moved during installation due to the detailed preplanning that took place.”

The first step was to excavate the 4-acre site and prepare it for the foundation pouring of the two structures.

“During this construction, the entire lot was prepared by the previous team as they found remnants of the existing neighborhood that used to be on that lot,” Gonzalez said. “The team removed swimming pools that were filled with dirt and left the entire lot ready for the future when the project wrapped up in 2020. When we were awarded this current project, we had prior knowledge of where all the existing utilities were located, so we were able to avoid any issues with moving utilities and had no challenges during foundation work.”

Scrapers and graders were used during the

initial grading of the site, along with a wheel loader. After grading, the project had multiple telehandlers on site to assist with framing and moving materials around the job site, a large Hitachi excavator was used during the installation of the underground water detention system for excavation. Smaller excavators and backhoe loaders were used during the installation of utilities with walk-behind compactors and plate compactors.

The next step was to pour the foundations for the new buildings, which proceeded smoothly.

“The roof system itself consists of a single-ply system over mechanically fastened

insulation sloped to roof drains,” Gonzalez said. “The walls were all ground framed and set in place with the use of a telehandler working from east to west on each building. … The HVAC system is a VRF system with compressor units located on the roof and FCU located in staff-occupied rooms to keep noise to a minimum in client areas.”

Although the project did not pursue LEED certification, the campus incorporates multiple sustainable features, including photovoltaic panels, high-performance insulation, stormwater storage systems, electric vehicle parking, shaded parking areas, secure bicycle parking and drought-tolerant landscaping.

The county also integrated arts and healing elements throughout the campus, commissioning 24 artworks by eight Los Angeles-based artists to enhance the therapeutic environment.

County Supervisor Kathryn Barger said the campus will provide alternatives to emergency room visits and inpatient hospitalization by offering crisis care closer to home for Antelope Valley residents.

“These new facilities are a game-changer for the Antelope Valley,” said L.A. County Supervisor Kathryn Barger. “For the first time, children, families and adults experiencing a mental health crisis won’t have to leave their community to find help. This campus provides meaningful alternatives to unnecessary emergency room visits and hospitalizations, and it will help ensure that individuals struggling with mental illness are stabilized, supported and kept off the streets.”

Funding included $39.7 million from the state’s Behavioral Health Continuum Infrastructure Program and $3.3 million from Mental Health Services Act Capital Facilities funds, county officials said.

The Mental Health Hub expands services previously provided at the nearby High Desert Regional Health Center and focuses on children involved in the foster care and child welfare systems. The expansion increases annual service capacity from about 850 youth to more than 2,650.

The Adult Crisis Residential Treatment Program provides short-term, intensive care for individuals discharged from county hospital psychiatric emergency services, inpatient psychiatric units and urgent care centers. The program includes 16 beds. The Crisis Stabilization Unit offers an alternative to emergency rooms and hospitalization for children and youth experiencing mental health crises and is a new resource for the county’s Service Area 1 region. CEG

(All photos courtesy of Los Angeles County.)

FireLake Manufacturing of Hutchinson, Minn., manufactures incinerators and crematoriums, serving the medical, veterinary and law enforcement sectors.

FireLake’s product line offers a wide range of load capacities with 16 different chamber sizes and numerous customization options. Their units are capable of incinerating 200 to 1,600 lbs. of waste at a time, depending on the user’s needs and the model selected.

FireLake’s president, Kent Wischmann, recognized an emerging demand for mobile incinerator units and sought a partner to develop a custom trailer solution for their Model X incinerator. The smaller-scale mobile unit would expand market opportunities for the Minnesota-based incinerator manufacturer.

The mobilized Model X incinerator unit would serve two key markets: law enforcement and veterinary services. Law enforcement agencies needed a secure way to destroy drug evidence on site without transportation risks, while veterinary clinics sought flexible solutions to serve multiple locations.

This market opportunity required FireLake to find a partner who could design a trailer specifically engineered to support their A850XMBL-2D-SC2X4100 diesel oil incinerator with its 27 cu.-ft. capacity.

Familiar with Felling Trailers’ custom manufacturing, FireLake contacted Felling for assistance with its mobilization project.

“Our (FireLake’s) incineration system would require specific structural support for transport,” said Wischmann.

The design also would need to incorporate user

safety, providing adequate space on the platform (deck) for users to move around and operate the incinerator unit.

Wischmann collaborated with TJ Schwartz, Felling Trailers OEM sales manager, throughout the custom build process, ensuring all details were considered, from wiring protection to equipment layout.

“This project was a custom build from the ground up,” said Schwartz.

“Felling’s custom design support and options were essential to our needs,” said Wischmann. “The ability to send and receive drawing files during the design process was efficient and seamless. Communication between their (Felling’s) engineering team and our design department was excellent.”

The engineering team at Felling carefully considered every aspect of the design, with particular attention to the suspension system and weight distribution relative to the equipment layout, which FireLake identified as “very important to the final

design.” The resulting trailer features dual 6K torsion axles, offering adequate support for the heavy load while ensuring a smooth ride during transport.

The finalized mobile unit combines FireLake’s Model X incinerator technology with Felling’s custom trailer engineering. The trailer solution provides FireLake with a mobile platform allowing their customers to:

• transport incineration capabilities directly to needed locations;

• facilitate secure on-site destruction of sensitive materials for law enforcement;

• enable veterinary clinics to serve multiple locations with a single unit; and

• expand FireLake’s market reach with a differentiated product offering.

“Felling is great to work with on special needs,” said Wischmann. “They look for the ‘how-to’ solutions.”

For more information, visit felling.com.

Ian Hucker, vice president of GM Envolve, will present the keynote address at Green Truck Summit, the commercial vehicle technology conference that kicks off Work Truck Week 2026 on March 10, 2026. His keynote will delve into the ongoing evolution of multi-stage commercial vehicles, including advances in vehicle design, powertrains, connectivity and equipment integration.

Work Truck Week 2026 runs March 1013, 2026, at the Indiana Convention Center in Indianapolis. “More Than a Trade Show,” it encompasses Green Truck Summit, The Work Truck Show, NTEA Annual Meeting, Work Truck Week Ride & Drive, educational programs and more. Green Truck Summit is March 10, educational sessions run March 10-12 and Work Truck Show exhibits are open March 11-13. Work Truck Week is produced by NTEA — The Work Truck Association.

demands that are driving us forward,” said Kevin Koester, NTEA managing director. “His unique grasp of the dynamics that underpin customer expectations makes him an ideal keynoter to set the tone for the 2026 Green Truck Summit.”

Hucker will discuss how multi-stage commercial vehicles are expected to evolve over the next five to 10 years. He will examine the influence of technological and customer-driven forces, and will highlight anticipated industry advances in vehicle design, powertrains, connectivity and equipment integration. The session will deliver valuable insights into how leading chassis OEMs are preparing for the next generation of commercial vehicle platforms and multi-stage applications.

bachelor’s degree in manufacturing engineering from Brunel University and an executive MBA from Bayes Business School in London.

Hucker’s keynote runs from 9-9:30 a.m. It is followed by three one-hour general sessions: Adapting Upfitting Practices to Emerging Vehicle Technologies, ADAS Integration in Multi-Stage and Commercial Vehicle Platforms and Navigating Technology Shifts: Cross-Industry Perspectives on Adoption and Impact to Commercial Vehicles. Green Truck Summit attendees then choose from nine 45-minute GTS breakout sessions covering a range of technology, fuel options and data in the afternoon.

As vice president of GM Envolve, Hucker oversees General Motors’ fleet and commercial operations. He focuses on building strong customer relationships and driving sales growth through integrated fleet solutions, including a comprehensive portfolio of vehicle options and intelligent OnStar telematics, diagnostics and safety software designed to reduce costs and streamline fleet management.

Before joining GM, Hucker was chief commercial officer for Hyundai Capital Europe where he worked with partners to develop financial products to support electric vehicle sales. He also held leadership roles at Lynk & Co. (Geely Group) as chief commercial officer and vice president of sales and remarketing.

“With his extensive background in senior sales leadership across the global commercial vehicle industry, Ian Hucker understands the technological forces and customer

Hucker started his career with GM, gaining global experience in senior sales leadership positions in the United States, Germany, Russia and the United Kingdom. He has a

The Green Truck Summit (GTS) conference package includes all Summit sessions and lunch on March 10, as well as access to any Work Truck Week (WTW) breakout sessions March 10-12, admission to Work Truck Show exhibits, Work Truck Week Ride & Drive and Opening Reception. After Work Truck Week is over, registered GTS conference package attendees can access some breakout session materials ondemand.

For more information, visit worktruckweek.com/greentrucksummit.

Kenworth is expanding availability of its PACCAR TX-12 PRO automated transmission, bringing it to several models within the company’s medium-duty line.

Ranging from Class 7 to light Class 8, the vocational transmission is available on the Kenworth T380 and T480, when matched with the PACCAR PX-9 engine.

The PACCAR PX-9 can be spec’d with peak horsepower ranging between 260- and 380 for on-highway and vocational use; up to 450 hp with 1,250 lb.-ft. of torque for fire service vehicles.

“Versatility and durability are what the Kenworth T380 and T480 are all about,” said Kevin Haygood, Kenworth’s assistant general manager of sales and marketing. “For customers who prefer an AMT [automated manual transmission] over an automatic option, the TX-12 PRO is the solution. It gives customers great performance and toughness when they use the T380 or T480 in demanding vocational applications.”

The PACCAR TX-12 PRO was designed for rugged service and low-end drive performance applications like dump truck, snowplow or in chassis-

mounted tanker configuration, according to Kenworth.

In addition, the TX-12 PRO features an extreme-duty clutch for low-speed maneuvering and Rock Free mode to help trucks get unstuck in mud or sand. Plus, it has an off-highway calibration tuned for changing soil conditions. The 12-speed gear set provides wide ratio coverage, allowing for excellent maneuverability without sacrificing fuel economy at highway speeds.

For those applications requiring a PTO, The TX-12 PRO is available with dual openings — a bottom mount 8-bolt and 4-bolt rear mount for a combined 95 hp capacity.

To monitor performance and to ensure long-life, the transmission and clutch are both equipped with internal oil temperature sensors. Their temperatures can be displayed on the in-cab 7-in. digital display and can provide driver notifications in situations causing excessive temperatures.

Oil maintenance intervals for the TX12 PRO are 250,000 miles and the clutch is maintenance-free.

For more information, visit paccarpowertrain.com/.

Tucson, AZ 520-579-0261 Phoenix, AZ 602-437-0351 Spokane, WA 509-536-7300 El Cajon, CA 619-448-0770 Corona, CA 800-491-9004

The Standard in Strength and Payload.

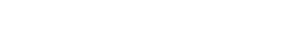

From the lightweight MVP™ smooth side to the rugged steel dump, MAC Trailer dump trailers are engineered for performance and built for durability. Whether you’re hauling aggregate, scrap, or agricultural loads, our aluminum and steel options are designed to maximize payload without compromising integrity. Backed by a trusted nationwide dealer network for parts, service, and support, MAC Trailer delivers the dump solutions that keep your business moving.

NEW AND SURPLUS STRUCT. STEEL JUMBO BEAMS, PIPE, ROAD PLATE

Joseph Fazzio Inc.com • 856-881-3185 N.J

• Supply us with a photo of a machine (one machine per Bargain Ad) and a maximum 17 word description, plus contact and phone number.

• Either email your copy & photo to: production@cegltd.com, or mail to: Construction Equipment Guide, 470 Maryland Drive, Ft Washington, PA 19034.

• Cost is $140 per ad, $65 additional for color.

• Your ad will run for two consecutive issues in 1 region.

Your Ad Will Be Seen By Over 21,163 Construction Equipment Buyers in the Western States. For more information, call Construction Equipment Guide today at 800/523-2200

Purple Wave Auction is exhibiting at ConExpo-Con/AGG, underscoring its commitment to customer service and offering inperson guidance for equipment buyers and sellers nationwide.

Visit Booth N-12002 where Purple Wave Auction's industry experts will be available to provide full-service support for buying and selling equipment.

Purple Wave is a leader in online, noreserve equipment auctions serving the construction, agriculture, government and fleet industries, providing customers with opportunities to buy and sell equipment with confidence, according to Purple Wave.

In 2025, Purple Wave conducted 141 biweekly auctions. The opportunity to buy or sell is always at your fingertips with the ability to bid 24/7, and expert sales team members available to make the selling journey easy.

Selling your equipment with Purple Wave is easy and only takes seven simple steps:

• Consult with a territory sales manager.

• Agreement to sell with Purple Wave.

• Purple Wave comes to you and handles all pre-auction photos and listings.

• Your equipment is marketed nationwide.

• Bidding starts as soon as your equipment is posted online.

• Equipment sells to the highest bidder at auction close.

• Payments sent to sellers (checks sent within 15 business days of auction close).

Attendees can meet directly with Purple Wave's team to receive expert guidance tailored to their needs and learn how the company supports sellers through a straightforward, online auction experience.

In addition to hands-on support, Purple Wave Auction will provide insight into current equipment market trends, including historical pricing data and demand indicators to help sellers make more informed decisions. The company also will highlight its Purple Wave shipping and appraisal services, offering customers a comprehensive, full-service solution that supports equipment from evaluation through sale and delivery.

ConExpo-Con/AGG attendees are encouraged to schedule meetings in advance, to ensure dedicated time with our team members.

Meetings can be scheduled in advance at purplewave.com/event/conexpo.

List Your Wanted Items. If you would like to place your Wanted To Buy listings on our website for inclusion in our newsletters, simply visit: www.constructionequipmentguide.com/wanted-to-buy and enter your listings. Inappropriate or Sale Ads will be Deleted

WANTED: LARGE PORTABLE OR STATIONARY GENERATORS IN ANY CONDITION. ALL MODELS: CAT, CUMMINS, DETROIT, MTU, PERKINS, VOLVO (DIESEL OR NATURAL GAS). CAN REMOVE IF NEEDED. EMAIL: MICHSURPLUS@GMAIL.COM; PHONE: 201-587-6300

WANTED: VOLVO L70G WHEEL LOADERS. GOOD VOLVO L70G WHEEL LOADER, L70F, L70E. EMAIL: FRANK.HORAN@ HOFFMANEQUIP.COM; PHONE: 732-674-2095

WANTED: CATERPILLAR 988K STRAIGHT EDGE GP FINISH PRODUCT BUCKET. EMAIL:

DUBOISLIVESTOCK@GMAIL.COM; PHONE: (207)-282-4445

WANTED: JOHN DEERE 850J LGP CRAWLER DOZERS. WANT TO BUY BULLDOZER 850JLGP SIX WAY ENC CAB WITH WINCH 2005 AT 2012 REAL HOURS UNDER 900. THANKS, YOU HAVE MY EMAIL FOR PICTURE. EMAIL: JEANMAURICEBOUTIN@ VIDEOTRON.CA

WANTED: PART FOR CATERPILLAR CRAWLER DOZER - 943 CAT SPRING FOR TRACK ADJUSTER PART# 7P1675, SERIAL # 19Z00380. PETE 631-774-1905 EMAIL: LIEARTH3@AOL.COM; PHONE: PETE @ 631-774-1905.

WANTED (WORLDWIDE): LIEBHERR WHEEL LOADER. EMAIL: MABAT_560@YAHOO.CO.UK

WANTED (WA): CATERPILLAR BACKHOE LOADERS+. LOOKING TO BUY USED EQUIPMENT IN THE FOLLOWING CATEGORIES: KOMATSU LOADERS WA200, WA270 WITH QUICK COUPLERS, LOW HOURS, GOOD PRICE; KOMATSU EXCAVATORS 138-8+ AND CAT 320 CL/DL/EL (ANY HOURS, ANY CONDITION; CAT GRADERS 140G/140H (1990 OR NEWER); CAT BACKHOES C/D/E/F SERIES; CASE BACKHOES - JD 310G – SG; OTHER CAT LOADERS, GRADERS, AND EXCAVATORS. PLEASE PROVIDE YEAR, HOURS, CONDITION, LOCATION, AND PRICE. EMAIL: JAN@GOLDENHORSEMACHINERY.COM; PHONE: 425-217-6188.

WANTED (US): KOMATSU D475A-5E0 CRAWLER DOZER. WANT TO BUY KOMATSU BULLDOZER 475A-5 OR 475A-8 WITH BIG BLADE TO PUSH WOOD. UNDER 6000 HOURS, REAL HOURS METER AND FRAME. EMAIL: JEANMAURICEBOUTIN@VIDEOTRON.CA PHONE: 450-346-8975