UTAH STATE EDITION

A Supplement to:

®

September 3 2017 Vol. II • No. 18

“The Nation’s Best Read Construction Newspaper… Founded in 1957.” Your Utah Connection – Debbie Hansen – 1-702-239-0348 – dhansen@cegltd.com

Maintaining Utah’s Rio Tinto Mine By Giles Lambertson CEG CORRESPONDENT

Productive mines are hard on machinery, which are constantly pummeled and stressed by the ore and overburden they process, hour after hour, day after day. The constant flow of rock through the machinery stresses hightensile steel, induces friction in bearings, warps static components in smelting heat and otherwise tests the integrity of engineered equipment. The fundamental challenge every mine manager accepts is to maintain essential machinery while minimally interrupting vital production. In rather spectacular fashion, Patrick Boitumelo proved up to the task. As general manager of engineering and projects at Rio Tinto Kennecott, Boitumelo headed up an unprecedented simultaneous shutdown of major processing units — concentrator, refinery and smelter — at the company’s Bingham Canyon, Utah, mine. The broad shutdown was accomplished in good order. More to the point, it succeeded without a single reportable incident in terms of safety and with far less expense and production loss than anticipated. How did Boitumelo do it? By having leaders engage with maintenance shutdown teams around the clock, by fully partnering with contractors in safety protocols and enforcement and by daily compiling and analyzing “robust” safety data. The result: 260 maintenance projects were completed by the company over a period of more than 400,000 manhours, all without experiencing a recordable injury. The Bingham Canyon mine not only is a gigantic hole stair-stepped into the ground three-quarters of a mile, it is part of a landmark operation. A pit was started in the canyon, which is across a valley from Salt Lake City, at the end of the 19th century after several decades

The fundamental challenge every mine manager accepts is to maintain essential machinery while minimally interrupting vital production.

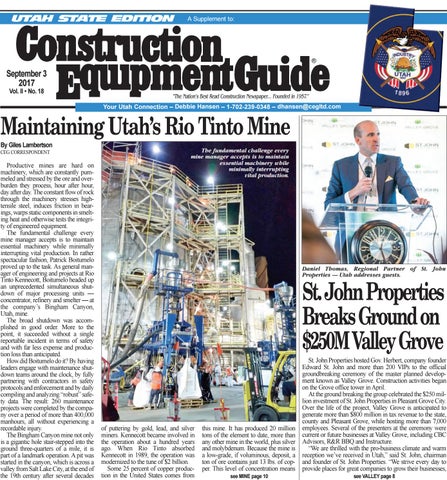

Daniel Thomas, Regional Partner of St. John Properties — Utah addresses guests.

St. John Properties Breaks Ground on $250M Valley Grove

of puttering by gold, lead, and silver miners. Kennecott became involved in the operation about a hundred years ago. When Rio Tinto absorbed Kennecott in 1989, the operation was modernized to the tune of $2 billion. Some 25 percent of copper production in the United States comes from

this mine. It has produced 20 million tons of the element to date, more than any other mine in the world, plus silver and molybdenum. Because the mine is a low-grade, if voluminous, deposit, a ton of ore contains just 13 lbs. of copper. This level of concentration means

St. John Properties hosted Gov. Herbert, company founder Edward St. John and more than 200 VIPs to the official groundbreaking ceremony of the master planned development known as Valley Grove. Construction activities began on the Grove office tower in April. At the ground breaking the group celebrated the $250 million investment of St. John Properties in Pleasant Grove City. Over the life of the project, Valley Grove is anticipated to generate more than $800 million in tax revenue to the state, county and Pleasant Grove, while hosting more than 7,000 employees. Several of the presenters at the ceremony were current or future businesses at Valley Grove, including CBC Advisors, R&R BBQ and Instructure. “We are thrilled with the pro-business climate and warm reception we’ve received in Utah,” said St. John, chairman and founder of St. John Properties. “We strive every day to provide places for great companies to grow their businesses,

see MINE page 10

see VALLEY page 8