UTAH STATE EDITION

A Supplement to:

®

June 11 2017 Vol. II • No. 12

“The Nation’s Best Read Construction Newspaper… Founded in 1957.” Your Utah Connection – Dennis Hogeboom – 1-877-7CEGLTD – dennishogeboom@cegltd.com

Bingham Canyon Mine Displays Monumental Character By Giles Lambertson CEG CORRESPONDENT

Big. That little word captures the essence of Rio Tinto Kennecott’s Bingham Canyon open pit mine. Situated a few miles southwest of Salt Lake City in Utah, the mine is big…as in one of the largest manmade excavations in the entire world, a hole so vast that astronauts can spot it from space. Big… as in the world’s top copper mine, 20 million tons produced to date and counting. A big mine with big equipment to match — including six-story-tall electric shovels loading 320-ton-capacity haul

His arrival came eight months after a rock avalanche that, in keeping with the monumental character of the mine, was the largest nonvolcanic landslide on record in North America. Some 150 million tons of rock and dirt rushed down the northeast side of the mine at speeds of up to 100 mph. To put the enormity of the slide in perspective, mine publicists say 150 million tons of dirt would cover New York City’s Central Park 64 feet deep. Surprisingly, Rio Tinto restored production within days of the disruptive slide. No loss of life occurred because geotechnical engineers had been monitoring the

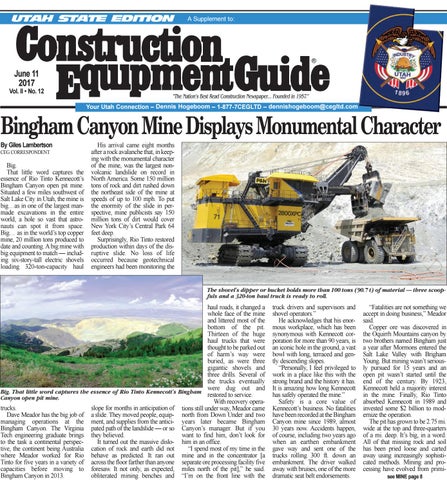

The shovel’s dipper or bucket holds more than 100 tons (90.7 t) of material — three scoopfuls and a 320-ton haul truck is ready to roll.

haul roads, it changed a whole face of the mine and littered most of the bottom of the pit. Thirteen of the huge haul trucks that were thought to be parked out of harm’s way were buried, as were three gigantic shovels and three drills. Several of the trucks eventually were dug out and Big. That little word captures the essence of Rio Tinto Kennecott’s Bingham restored to service. Canyon open pit mine. With recovery operatrucks. slope for months in anticipation of tions still under way, Meador came Dave Meador has the big job of a slide. They moved people, equip- north from Down Under and two managing operations at the ment, and supplies from the antici- years later became Bingham Bingham Canyon. The Virginia pated path of the landslide — or so Canyon’s manager. But if you Tech engineering graduate brings they believed. want to find him, don’t look for to the task a continental perspecIt turned out the massive dislo- him in an office. tive, the continent being Australia cation of rock and earth did not “I spend most of my time in the where Meador worked for Rio behave as predicted. It ran out mine and in the concentrator [a Tinto for five years in a variety of across the floor farther than anyone separate ore processing facility five capacities before moving to foresaw. It not only, as expected, miles north of the pit],” he said. Bingham Canyon in 2013. obliterated mining benches and “I’m on the front line with the

truck drivers and supervisors and shovel operators.” He acknowledges that his enormous workplace, which has been synonymous with Kennecott corporation for more than 90 years, is an iconic hole in the ground, a vast bowl with long, terraced and gently descending slopes. “Personally, I feel privileged to work in a place like this with the strong brand and the history it has. It is amazing how long Kennecott has safely operated the mine.” Safety is a core value of Kennecott’s business. No fatalities have been recorded at the Bingham Canyon mine since 1989, almost 30 years now. Accidents happen, of course, including two years ago when an earthen embankment gave way and sent one of the trucks rolling 300 ft. down an embankment. The driver walked away with bruises, one of the more dramatic seat belt endorsements.

“Fatalities are not something we accept in doing business,” Meador said. Copper ore was discovered in the Oquirrh Mountains canyon by two brothers named Bingham just a year after Mormons entered the Salt Lake Valley with Brigham Young. But mining wasn’t seriously pursued for 15 years and an open pit wasn’t started until the end of the century. By 1923, Kennecott held a majority interest in the mine. Finally, Rio Tinto absorbed Kennecott in 1989 and invested some $2 billion to modernize the operation. The pit has grown to be 2.75 mi. wide at the top and three-quarters of a mi. deep. It’s big, in a word. All of that missing rock and soil has been pried loose and carted away using increasingly sophisticated methods. Mining and processing have evolved from primisee MINE page 8