By Cindy Riley CEG CORRESPONDENT

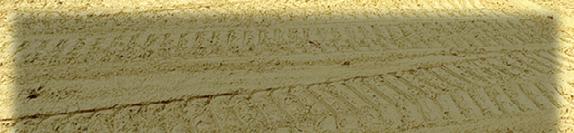

In Craven County, N.C., work has begun on a $242 million project that will upgrade another segment of U.S. 70. Construction focuses on 6.5 mi. between Thurman Road and the Havelock Bypass and includes building three interchanges.

“The intent is to improve regional mobility, assist economic development in primarily rural areas of eastern North Carolina and provide a closer interstate connection to the Port of Morehead City,” said Brad McMannen, North Carolina Department of Transportation (NCDOT) resident engineer.

By Lucy Perry CEG CORRESPONDENT

The U.S. Interstate Highway System turns 70 in 2026. As one of the greatest public works projects in American history enters its septuagenarian era showing its age, the people who build it face their own issues. The new year brings a mix of opportunities and challenges in the areas of labor, logistics, sustainability and the integra-

tion of AI technology.

The infrastructure sector “is entering the latter half of the 2020s with solid growth prospects,” according to portfolio management firm Loan Analytics.

Fueled by government investment to address critical infrastructure needs, the industry will see sustained demand from funding programs such as the IIJA.

The construction to

Knoxville, Tenn.’s McGhee Tyson Airport is preparing to “go vertical” as crews have finished laying the groundwork for its upcoming parking garage and terminal roadway expansion project.

The focus of Linder Industrial Machinery Company’s Bealeton, Va., branch is clear: rebuild trust, strengthen relationships and deliver the dependable service that customers deserve, according to the company.

JCB announced a charity auction featuring a one-of-a-kind, customer hand-painted 3TS-8T teleskid, with proceeds benefitting veterans across the country, through VetsAid.

The celebration began with an official ribbon-cutting ceremony performed by the Kelly family, followed by a catered lunch and guided tours of the facility for guests and staff.

Construction on Lynchburg, Va.’s College Lake Dam removal and stream restoration project has been completed, marking a significant milestone in its commitment to public safety and environmental stewardship.

DEVELON expands its presence in the Southeast with the addition of two new dealerships, announcing The Ironpeddlers as a new dealer in South Carolina at its locations in Duncan and Florence.

After more than 18 years in the ndustry as a heavy and highway foreman and superintendent, Chad Cailteux saw the challenges contractors faced sourcing reliable, specialized equipment for marine and industrial projects.

33

Willbee Transit Mix currently operates a fleet of front discharge redi-mix trucks to service pours. For Willbee, maintaining the efficiency of concrete washouts between deliveries is important to his operation.

36

The fully integrated solution represents Summit’s commitment to advancing technology, designed to upgrade the experience of operators in the field through enhanced equipment performance and streamlined to improve jobsite safety.

43

FOR CRUSHER PERFORMANCE

Much like a football team driving toward the end zone, a job site crew works together to complete specific tasks on time and on budget. In both football and construction, success depends on skilled players and the right equipment.

50 TOMRA LAUNCHES NEW E-BOOK ABOUT AI’S POWER IN RECYCLING

This comprehensive guide explores the rapidly evolving role of artificial Intelligence (AI), particularly deep learning, in revolutionizing the global recycling industry and driving material circularity.

70 TURFMUTT’S MUTT MADNESS FINDS FOREVER HOMES FOR 13 SHELTER DOGS

The TurfMutt Foundation’s 7th Annual Mulligan’s Mutt Madness, held in partnership with the Kentucky Humane Society (KHS) at Equip Exposition 2025, was a huge success with 13 shelter dogs finding their forever homes.

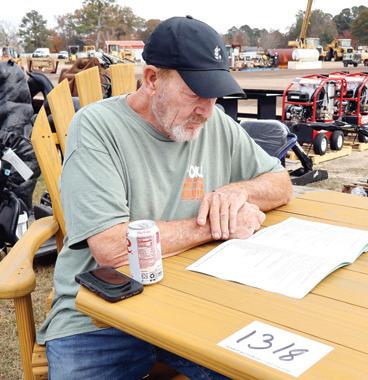

76 DEANCO HOLDS FINAL AUCTION OF 2025 IN PHILADELPHIA, MISS.

Deanco Auction’s final sale of 2025 took place Nov. 19 at the company’s Philadelphia, Miss., headquarters. A strong online bidding presence as well as a large onsite crowd at the two-ring sale made for another successful auction.

The construction to expand Knoxville, Tenn.’s McGhee Tyson Airport is preparing to “go vertical” as crews have finished laying the groundwork for its upcoming parking garage and terminal roadway expansion project, WBIR-TV in Knoxville reported Oct. 16, 2025.

The news station learned that the parking structure’s piers have been laid and half of the foundation is now secured after nearly a year of work at the airport.

WBIR-TV previously reported that the construction was running behind due to weather and ground issues. The $190 million project was set to be completed in early 2027 but is now projected to be finished later that spring.

Once completed, the project will deliver a six-story, 3,500-space parking garage to the airport. Officials of the Metropolitan Knoxville Airport Authority (MKAA) noted that due to the fast rate of growth at the facility, providing more parking is vital.

The structure’s design draws inspiration from east Tennessee and will be a prominent feature at the airport, according to an MKAA news release.

Messer Construction in Knoxville is the general contractor in charge of expanding and renovating the airport.

In late August, the airport authority noted that construction was officially under way inside the Knoxville airport terminal on its Escalator Replacement Project.

This phase of the project was designed to maintain and modernize the facility for the millions of passengers traveling through the airport each year. Both escalators are being replaced, MKAA said on its website, with an expected completion by December.

The reason for replacing the current escalators is simple: they first went into service in 2001 and from then until this past summer they had moved more than 25 million passengers.

“While they’ve served us well, it’s time for an upgrade that ensures a smoother, more reliable experience for our travelers in the years ahead,” MKAA said in a project update.

During the replacement effort, one or both escalators may be closed as the work progresses, but passengers can access nearby elevators and staircases. In addition, for those

travelers with large luggage or who need wheelchair assistance, the best way to enter the terminal is via the secondfloor departures level where airline ticket counters are located.

The MKAA officially broke ground on Knoxville’s McGhee Tyson Airport’s parking garage expansion and Terminal Roadway Improvement Project on Nov. 7, 2024.

At the same event, airport authority leaders announced the launch of Flight Plan, a major expansion and renovation program designed to accommodate the significant passenger growth at the airport.

Flight Plan is a decade-long growth and development blueprint to elevate the airport’s footprint by adding gates and concessions, renovating restrooms and security checkpoints and replacing the escalators — all designed to improve the passenger experience by ensuring a smooth and enjoyable journey from parking to boarding. When complete, the hope is that the upscaled airport also will attract more air service to east Tennessee.

“We couldn’t be more excited for the future of McGhee Tyson Airport and air travel in our region. Flight Plan will help us grow in a smart and thoughtful way,” said Patrick W. Wilson A.A.E. and MKAA president during last year’s project groundbreaking.

“The current terminal was built to accommodate approximately 2.6 million passengers annually. Projections now indicate more than 3.5 million passengers will travel through [the airport] by 2027,” he said. “Because of this record-breaking growth, we developed a forward-looking plan that strengthens our capacity and amenities while ensuring McGhee Tyson remains the convenient community airport passengers know and love.”

The current work to expand McGhee Tyson’s parking facilities and make terminal roadway improvements is the first of many projects ahead under the Flight Plan program.

Beyond the larger parking garage and the air terminal roadway upgrades, plans call for the expansion of the airport’s concourse gates, concourse seating, ticket counters, concessions and TSA security checkpoint area.

“While Flight Plan is charting the course for the future of travel at McGhee Tyson Airport, we are equally focused on ensuring that our passengers and the community are minimally impacted by the construction,” Wilson said. “We will provide clear and consistent communication with the goal of making sure our travelers can enjoy the same easy and efficient airport experience they’ve come to expect at McGhee Tyson.”

NEW 2024 CAT 725

5,000 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

NEW 2024 CAT 730

6,000 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

(2) New 2024 Hydrema 922G 4x4

4,250 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

Equipment for Builds/Order

Rigid Water Tanks up to 18,000+ Gallons 4,500-6,000 Gallon Water for Tandem/6x6 Chassis, Heavy Duty Off-Road Construction

Complete NEW CAT Articulated & Rigid Builds (any size) available with HEC tanks/bodies

New Articulated and Rigid Water Tanks for all Sizes and Brands installation at our place or yours Current stock for CAT 725, CAT 730, CAT 740, CAT 773/775, Bell B30, Bell B40

Fuel, Fuel/Lube Builds available. Articulated or Rigid. Open for warm weather or Up to Arctic Level enclosed for extreme cold operation

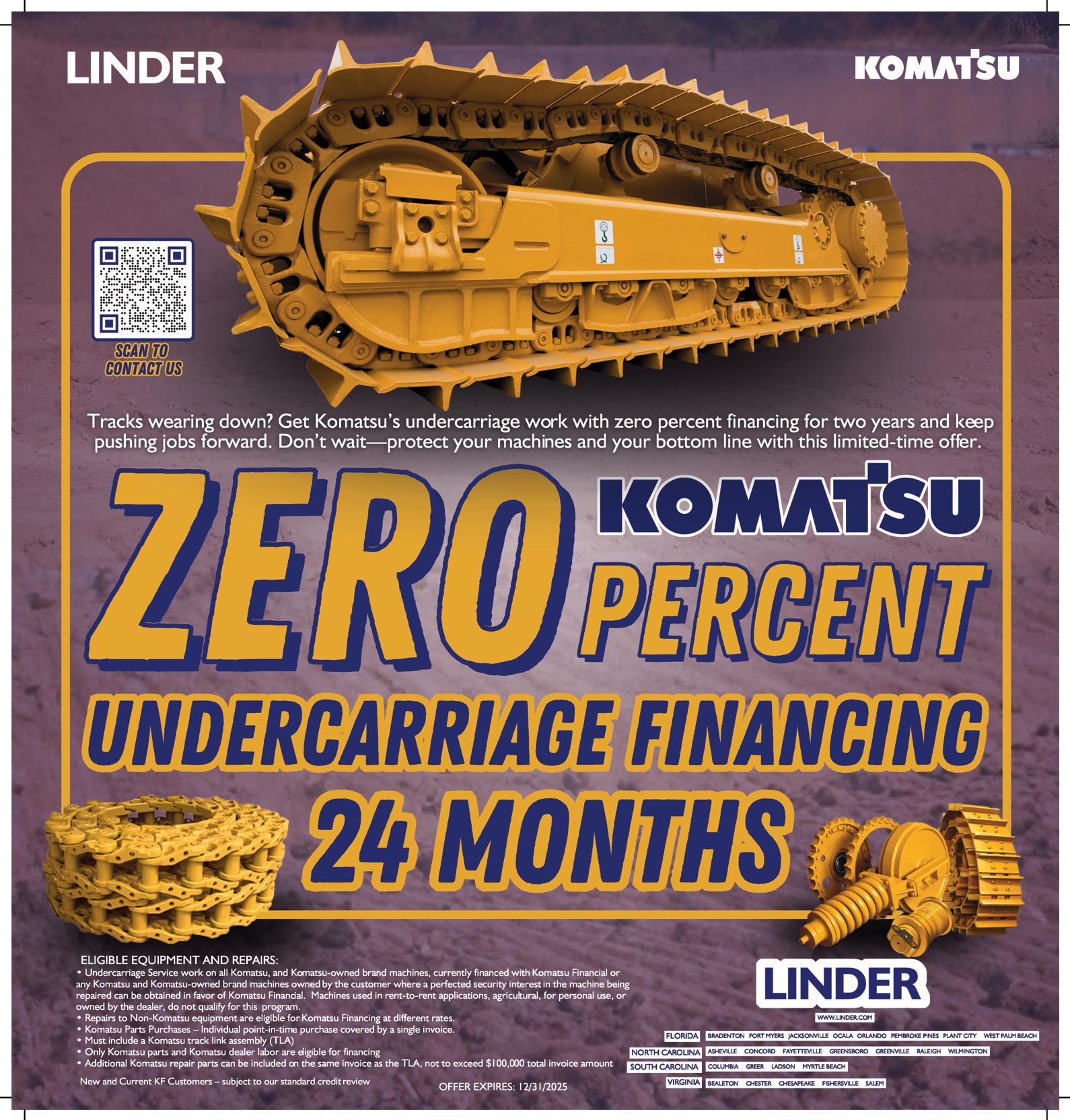

The focus of Linder Industrial Machinery Company’s Bealeton, Va., branch is clear: rebuild trust, strengthen relationships and deliver the dependable service that customers deserve, according to the company.

Linder assumed the operation of the previous distributor in 2024, and the company said it has quickly developed a reputation for responsiveness and technical expertise under the leadership of Mike Myers, service manager, who joined Linder in early 2025 and brings more than 25 years of experience in heavy equipment service and repair. His background includes time as a parts specialist, field service supervisor and truck shop leader — all of which prepared him to oversee a team dedicated to customer satisfaction.

“The challenge of repairing relationships and rebuilding the reputation for this branch were what drew me here,” said Myers. “This was an opportunity with a clean slate to do things the right way. So far, relationships have improved, and we’re turning machines around faster than ever — usually within 24 hours. We also now have daily communication with customers through e-mails, text messages and phone calls to keep them informed throughout the repair process.”

The Bealeton team currently includes three shop technicians and four field technicians, and the branch recently expanded its capabilities by adding an onsite welder and line borer, enabling faster turnaround on complex repairs.

“Our technicians are trained across manufacturers, so we can handle a mixed fleet

with no problem,” said Myers. “From PM services to full rebuilds, we can do it all. We have the manpower now to take care of anything that comes through the door. It’s all about getting customers back up and running

as quickly as possible.”

For longtime technician David Grove, who has worked at the location for several years, the improvements under Linder’s management are tangible.

“They’ve done a great job of stocking the shop with better tools and equipment,” Grove said. “We’ve rebuilt transmissions, engines and even worked on larger miningsize dozers and excavators. Whatever comes in, we make sure it’s right before it leaves.”

Doing the job right reflects Linder’s larger commitment to reliability and customer support across Virginia. Vice President of Virginia Sales Gino Morin said that Bealeton represents a key part of the company’s statewide reinvestment in people, training and service infrastructure.

“Our goal is to communicate clearly and act with urgency,” said Morin. “Customers want to know what’s happening with their machines and when they’ll get them back. We’re building our service departments and parts inventories around those expectations.”

Morin added that Linder’s 75-year history in the industry reinforces its long-term commitment to Virginia contractors.

“We’re here to stay,” Morin said. “We’re selling the best equipment and backing it with exceptional service and parts support.”

As the Bealeton branch continues to grow, Myers added that customer service is at the heart of how the branch will function.

“We know the past hasn’t always been positive, but if customers give us a chance, we’ll earn their trust,” said Myers. “We’re ready to prove what this team and Linder can do.”

(All photos courtesy of Linder Industrial Machinery Company.)

*Ditch Witch Ace ditchwitchace.com

Seaford, DE 302-629-3602

Chesapeake, VA 757-424-5960

Glen Allen, VA 804-798-2590

Manassas, VA 571-359-6081

*Ditch Witch Worx ditchwitchworx.com

Fort Lauderdale, FL 877-935-3656

Jacksonville, FL 866-254-1102

Plant City, FL 855-704-6828

Albany, GA 866-581-4914

Atlanta, GA 866-709-3712

Savannah, GA 888-298-0429

*Don Allison Equipment, Inc. donallisonequipment.com

Arley, AL 800-669-6450

First Choice Farm and Lawn firstchoicekubota.com

Brookland, AR 870-790-2301

Dyersburg, TN 731-882-1855

Eads, TN 901-616-5129

Mayfield, KY 270-856-4355

Savannah, TN 731-925-2141

Union City, TN 731-885-1315

*Forsythe Tractor forsythetractor.com

Shreveport, LA 318-687-1341

National Equipment Dealers

Carolinas nedealers.com

Ashville-Fletcher, NC 828-628-3004

Charlotte, NC 704-228-0455

Clayton, NC 886-629-3784

Grimesland, NC 252-752-1500

Lexington, NC 866-629-3784

Columbia, SC 888-865-1002

Conway, SC 800-968-0754

Piedmont, SC 864-434-1154

Summerville, SC 843-501-0566

Wellford-Spartanburg, SC 843-501-0566

National Equipment Dealers

Florida nedealers.com

Apopka, FL 407-401-8956

Fort Myers, FL 407-754-4646

Fort Pierce, FL 772-212-4043

Jacksonville, FL 904-664-0899

Tampa, FL 813-940-4405

National Equipment Dealers

Georgia nedealers.com

Dallas, GA 770-445-9019

Douglas, GA 912-384-4664

Macon, GA 478-257-8300

Richmond Hill, GA 912-756-7854

State Machinery

statemachineryeq.com

Kenner, LA 504-464-0431

Taylor Construction Equipment taylorconstructionequipment.com

Bessemer, AL 205-428-7050

Huntsville, AL 205-428-7050

Montgomery, AL 205-428-7050

Louisville, MS 833-773-3421

New Albany, MS 304-550-9825

Richland, MS 601-922-4444

LaVergne, TN 304-550-9825

Maryville, TN 662-773-3421

Van Keppel

vankeppel.com

North Little Rock, AR 501-945-4594

Van Buren, AR 479-474-5281

MAKE YOUR MOVE

Push

... more material with the new Hyundai HD100 crawler dozer's best-inclass power-to-weight ratio.

See ...more than ever with the unobstructed view to the blade.

Engage

...more accurately and more productively with standard 2D or optional 3D machine guidance.

Doze

...with confidence, knowing your new 115 hp Hyundai crawler dozer delivers the quality and value you expect from Hyundai, with the peace of mind that comes with our industry-leading warranty.

No wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, na.hd-hyundaice.com.

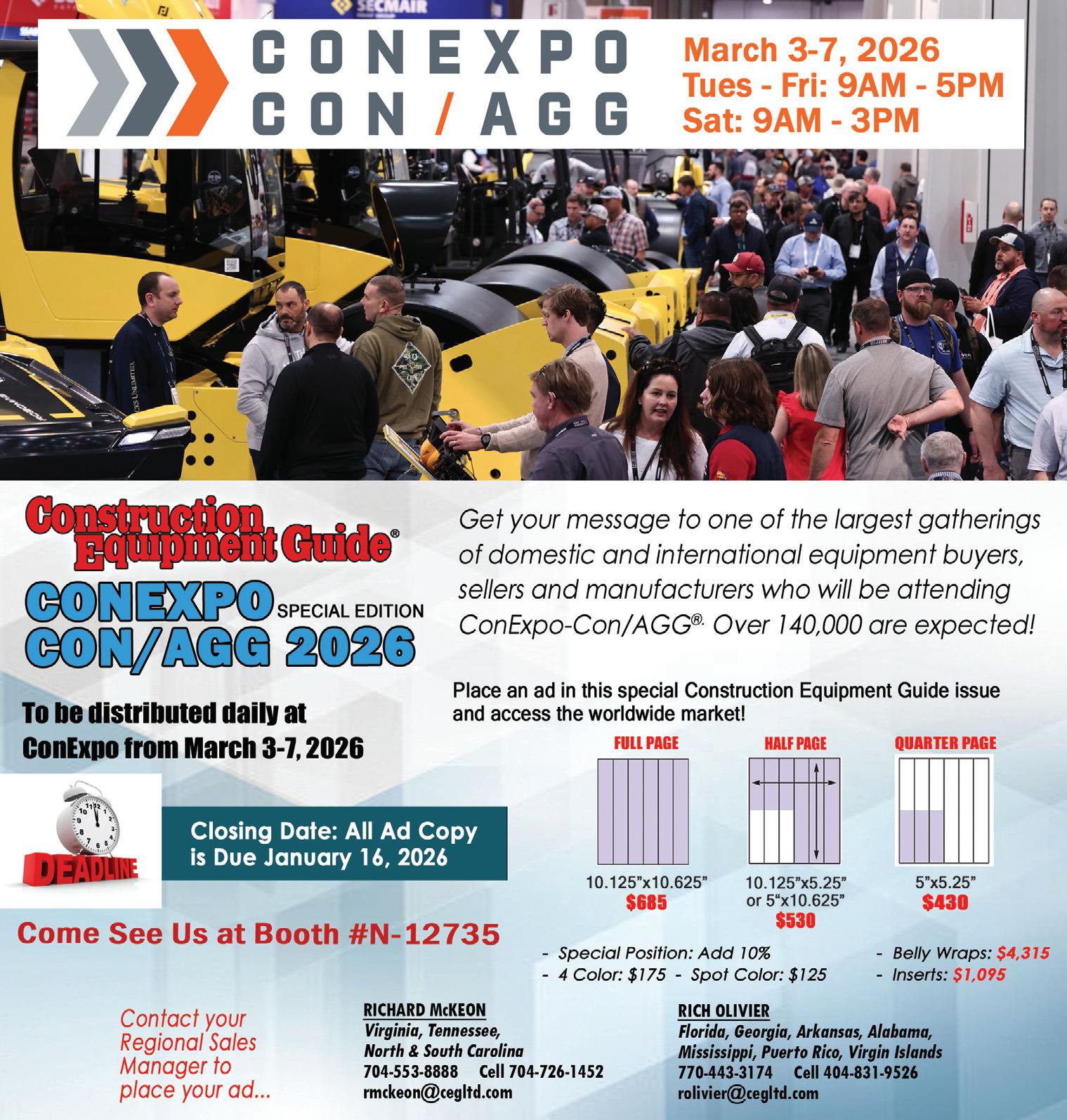

Ted McKeon

Joe McKeon

Richard McKeon

Barry McKeon

Teddy McKeon

Kent Hogeboom

Rich Olivier

Patrick Kiel

Dennis Hogeboom

Sharon Swanson

Natalie Spain

Jacob Estrello

Amanda Guilfoyle

Rich Thompson

Judy Nixon

Theresa Vickers

Jill DePoy

Deby Hogeboom

Denise Giaccio

Mary DeRosa

John Pinkerton

Matt Seslow

Jennifer Hood

Craig Mongeau

Andy Gotlieb

Katherine Petrik

Adam Zeenkov

Cathy Printz

Caitlin Murphy

Maria McKeon

Donna Prendergast

Kathy McDonnell

Kathy Miller

Terry Mazza

Andrea Pinkerton

Stephen Collins

Rob Tredinnick

JCB is revving up its commitment to America’s veterans with a powerful presence and a meaningful mission during this year’s VetsAid charity concert.

At the concert, JCB announced a charity auction featuring a one-of-a-kind, customer hand-painted 3TS-8T teleskid, with proceeds benefitting veterans across the country, through VetsAid.

The exclusive teleskid was located near the main entrance of Intrust Bank Arena during the event, giving concert goers first look at this unique melding of art, purpose and horsepower. It was custom painted by the Monster Jam creative team known for designing iconic trucks like Grave Digger.

The only machine of its kind, it features patriotic styling, inspired by Joe Walsh’s father’s World War II fighter jet, and the same advanced performance capabilities found in JCB’s standard VetsAid edition. The auction, which will open the summer of 2026, will be hosted online through bidadoo, a heavy equipment auction house, giving fans and contractors alike a chance to own a piece of equipment with purpose.

The concert marked the latest milestone in JCB’s partnership with VetsAid. As a signature sponsor, JCB has pledged to raise $1 million to support United States military veterans and their families through VetsAid. The campaign centers on the special edition VetsAid teleskid, pledging $1,000 from each unit sold to the charity. VetsAid directly supports veterans services groups across the United States that provide myriad of types of care for veterans and their families.

“VetsAid isn’t just about raising money and awareness for America’s veterans and their families,” Walsh said. “It’s also about finding common ground amongst musiclovers of all backgrounds and coming together to build and rebuild communities around a shared love of country. It’s a privilege for us at VetsAid to expand upon this vision with Alice, Ann and the entire Bamford family, as well as our friends at JCB.”

“This partnership is deeply personal for us,” said Alice Bamford, senior vice president of JCB North America. “We believe in honoring veterans not just with words, but with real action. Through this collaboration with Joe Walsh and the VetsAid team, we’re helping create opportunities, rebuild lives and show America’s heroes that they’re never alone.”

Bamford recently announced JCB and the VetsAid machine sales have resulted in

over $400,000 for the charity to date.

The VetsAid 3TS-8T teleskid is built to perform with the same dedication shown by the veterans it honors. Each machine features a military green exterior, a custom-stitched seat embroidered with the VetsAid logo and a set of commemorative dog tags.

The teleskid stands out for its telescopic boom, allowing operators to lift up to 13 ft., reach more than eight ft. forward and dig three ft. below grade. A 74-hp engine and JCB’s single-arm boom with side-door entry complete the package.

Adding to the spectacle at the Nov. 15 concert, JCB showcased JCB DIGatron and driver Tristan England — a 2025 Monster Jam World Finals champion — as a symbol of performance, pride and partnership. As the Official Heavy Equipment Partner of Monster Jam, JCB has used the high-energy world of competitive motorsports to spotlight both its machines and its mission at events across the country.

“Monster Jam has been a powerful platform for JCB — not only to demonstrate our equipment in action, but to connect with communities that value service, family and resilience,” Bamford said. “Bringing JCB DIGatron to VetsAid alongside this special edition teleskid is our way of combining that energy with purpose. It’s a celebration of veterans and a commitment to their future.”

Founded in 2017 by Joe Walsh, VetsAid has raised more than $4 million by uniting rock legends and local communities to champion veteran causes. The 2025 concert in Wichita continues that tradition, with a star-studded lineup and an expanded role for JCB that reflects the company’s belief in partnership-driven impact.

By bringing together VetsAid, Monster Jam and bidadoo, JCB transformed this year’s concert into more than a night of music. It’s a rallying point for community, craftsmanship and cause. The debut of the custom-painted teleskid, the presence of JCB DIGatron and the energy of the crowd all served a shared purpose: supporting America’s veterans.

The charity auction for the custom VetsAid Teleskid will run during the summer of 2026. Interested parties can find out more at bidadoo.com/VetsAid-JCB. Proceeds go directly to VetsAid to support veteran-focused services nationwide. For more information, visit jcb.com.

Kelly Tractor hosted a grand opening event Nov. 12, 2025, at its new Ft. Pierce, Fla., facility.

The celebration began with an official ribbon-cutting ceremony performed by the Kelly family, followed by a catered lunch and guided tours of the facility for guests and staff.

Equipment displays filled the grounds, and local staff were on hand to welcome customers and visitors enjoying a picture-perfect South Florida day. Attendees also received an abundance of Cat gear giveaways and had the chance to win various raffle prizes.

The grand opening featured live demonstrations of equipment, along with expert insights from product specialists. Demonstrations included autonomous Cat compaction using Bluelight technology; a Cat dozer equipped with Earthworks and Steer Assist technology; next-generation Cat mini- and mediumsized excavators; the Cat 275 compact track loader with a dozer blade and Earthworks technology for precise grading; and much more. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

see

Whether you’re la or grading Florida CASE delivers.

A a e n e ri I H R

p g g o g s g u d,

andscaping, building a’s toughest ground,

Mini Excavators, Midi Ex &theMinotaur, 0% for 4 CTLs & Skid S teers, 0% months or 1.25% for 72

xc a L th M d ee 0 f o s 1 % r

T R c a e f fo 48 0 o hs a n ed c n a n m nt n u r

Per fect fit for cons landscaping and s Backed by local de and suppor t. xcavators months. for 60 months.

ASE t ti a s ev i op e struction, ite development. ealer ser vice E

Construction on Lynchburg, Va.’s College Lake Dam removal and stream restoration project has been completed, the city announced Nov. 24, 2025, marking a significant milestone in its commitment to public safety and environmental stewardship.

The removal of the high-hazard College Lake Dam, one of the municipality’s top priorities following the August 2018 overtopping of the dam during a major rainstorm, has eliminated a long-standing safety risk to the community.

After the dam’s demolition during the early stages of the construction project in May 2024, College Lake Dam was delisted as a high-hazard barrier, and downstream areas of Blackwater Creek no longer faced an inundation risk from a potential dam failure.

“This project was first and foremost a public safety project,” said Erin Hawkins, the water quality manager of Lynchburg Water Resources, who oversaw the work for the city. “Removing the risk that this dam presented to people, property and infrastructure downstream of the old College Lake is a tremendous achievement for the [Lynchburg] and our partners in this effort.”

Taking apart the structure resulted in the re-emergence of Blackwater Creek through the former lakebed of College Lake as well as reconnecting the upstream and downstream sections of the creek for the first time in 90 years.

The project’s construction since the final breaching of the dam focused on restoration of the former lakebed of College Lake into a resilient, thriving ecosystem. This phase of work included:

• The removal and management of legacy sediment in the

former lakebed of College Lake.

• construction of a new, stabilized stream channel for Blackwater Creek;

• stabilization of the floodplain area surrounding the stream;

• creation of new wetlands to improve water quality and encourage wildlife habitat; and

• stabilization of the former Lakeside Drive bridge as a future overlook.

Additional plantings of native grasses, shrubs and trees are scheduled for the late winter and early spring of 2026 along Blackwater Creek to continue the restoration. Because of this, and separate work happening on the Creekside Trail, the work area and trail remain closed to the public until further notice.

The best vantage point from which to see the newly stabilized Blackwater Creek and surrounding wetlands is from the sidewalk along the new Lakeside Bridge.

“One of the biggest takeaways from this project is that, while public safety was top of mind with the dam’s removal, the restoration of Blackwater Creek and the wetlands around it really focused on environmental protection and water quality for [not only the creek, but] the James River and the Chesapeake Bay,” Hawkins said. “We’re already seeing this area come to life with native plants, pollinators and wildlife.”

The entire project was performed in collaboration with the University of Lynchburg and in consultation with AECOM, a Texas-based environmental engineering firm; and with MBP, a construction management company located in Fairfax, Va.

Construction on Lynchburg, Va.’s

removal and stream restoration project has

The dam removal and stream restoration was completed by English Construction of Lynchburg and its subcontractor, Resource Environmental Solutions, a Texas company. Lynchburg city officials also coordinated with multiple state and federal agencies, including the Virginia Department of Conservation and Recreation Dam Safety, the state Department of Environmental Quality, the U.S. Army Corps of Engineers and the Federal Emergency Management Agency.

DEVELON expands its presence in the Southeast with the addition of two new dealerships, announcing The Ironpeddlers as a new dealer in South Carolina.

The Ironpeddlers will stock DEVELON heavy and compact construction equipment at its locations in Duncan and Florence, S.C. The Duncan store serves the Greenville and Spartanburg areas, while the brand-new Florence store serves the northeast and central regions of South Carolina.

“We were intrigued by DEVELON because of the product offering, namely the dozers and articulated dump trucks,” said Ben Miller, chief executive officer of The Ironpeddlers. “We were particularly impressed by the ‘intelligent’ excavators and dozers with integrated 2D and 3D capability. With the addition of the DEVELON equipment lineup, we can offer a full line of heavy and compact construction equipment to contractors in the Carolinas.”

Miller said the DEVELON parts distribution center (PDC) in Suwanee, Ga., also was an important factor in the company’s decision to partner with DEVELON. The 100,000-sq.-ft. PDC, which opened in Suwanee in 2018, serves as a major hub for readily available genuine DEVELON parts for dealers.

“Parts and service are the number one concerns among our customers,” said Miller. “We need to be sure that if we don’t have the parts on our shelves, we can still satisfy a customer’s needs quickly. Having the PDC so close to our area only confirms our decision to build our relationship with DEVELON.”

Morgan Stallings, senior director of dealer development and marketing at DEVELON, said the partnership with The Ironpeddlers is mutually beneficial and will expand the DEVELON footprint in the Southeast.

“We’re pleased to announce this new partnership with a company that has been in business for more than 50 years,” said Stallings. “The Ironpeddlers has a strong history of serving contractors in the Southeast, and our DEVELON machines will enable the dealer to meet their customers’ equipment needs, particularly the advanced features on our excavators and dozers.”

Started in 1974 in Monroe, N.C., the company remains owned by three original founding families. Initially focused on used equipment and parts, the company transitioned to a dealer entity in 2017, serving customers with six locations in the Carolinas and a parts-only location in Kentucky.

For more information, visit develon-ce.com/en.

By Katherine Petrik CEG EDITORIAL ASSISTANT

Founded in 2015 by Chad Cailteux, 5R Enterprises, Morris, Ill., was created to provide contractors working on lakes, rivers and ports with the right tools and lasting partnerships.

After more than 18 years in the heavy equipment industry as a heavy and highway foreman and superintendent, Cailteux saw the challenges contractors faced sourcing reliable, specialized equipment for marine and industrial projects. His goal was to offer better solutions supported by stronger relationships.

What began as a regional operation on the Illinois River has grown into a nationwide business serving clients across the Gulf, Atlantic and Pacific coasts, as well as the Great Lakes and inland waterways throughout the United States.

The strength of 5R lies in its products and its people.

Tom Ellis, vice president of PLM Products, brings more than 50 years of experience in construction, heavy equipment and material handling. A former U.S. Navy Seabee and past president of Howell Tractor, Ellis joined 5R to help redefine the dutycycle crane market.

Alan Johnson, area manager, contributes a lifetime of experience in heavy construction equipment rental and sales consulting, offering practical insights and solutions to clients.

John Kissner, area manager, adds expertise from his years with Anvil and Bateman, specializing in heavy material handling attachments.

Nick Klein, territory manager, joined 5R in 2018 after a career in crane and rigging operations and national equipment rentals.

global name in crane innovation.

Today, PLM designs and builds both series and custom cranes, combining oldworld craftsmanship with modern engineering. This shared focus on quality and innovation led to the partnership between PLM and 5R Enterprises, which introduced the PLM duty-cycle crane line to North America.

Together, they deliver performance and customization that meet the needs of dredging, scrap and marine construction professionals.

Mantisinen, a division of SMH Group, offers a diverse range of hydraulic material handlers and attachments. The company strives to design machines that are economical and ecological without compromising safety, according to the company.

Mantsinen’s HybriLift is an energy-saving system that can decrease energy consumption up to 50 percent, according to Mantsinen.

His field experience continues to drive the company’s growth and success.

5R Enterprises supports a wide range of markets, including dredging and marine construction; demolition; heavy industry and construction; scrap metal operations; and lake and river terminals.

The company is an active member of several key industry organizations, including Inland Rivers, Ports & Terminals (IRPT); Recycled Materials Association (ReMA); National Demolition Association (NDA); and Western Dredging Association (WEDA).

5R Enterprises’ offers a variety of equipment from PLM Cranes, Atlas, Mantsinen,

A cornerstone of 5R’s success is its partnership with PLM, a company with more than a century of engineering heritage. Founded in 1920 in the Netherlands, PLM began as a transport and construction company and later shifted its focus to crane manufacturing after the Dutch floods of 1953.

By 1954, PLM was producing specialized cranes to rebuild the nation’s waterways. The business continued to expand internationally and, under the leadership of the third generation, Pieter Pulleman, evolved into a

These machines are available from 150,000 to 900,000 lbs. with rubber tire, crawler and specialty undercarriage mounts. Engines are available in diesel and full electric.

A division of SMH Group, Atlas, founded in 1919, offers material handlers for scrap, wood, bulky goods, special recycling, port and vacuum operations.

These hydraulic material handlers from 35,000 to 126,000 lbs. are equipped with rubber tire, crawler and specialty undercarriage mounts. The machines can be designed to use diesel, full electric and battery-powered engines.

Chad Thompson (C), Kelly Tractor’s CDI (Certified Dealer Instructor), goes over the Cat 275 CTL equipped with a dozer blade with slope assist and 3D capabilities to a group at the demo.

Kelly Tractor staffers and their customer friends came together throughout the day including Jim Murray (L) of Kelly Tractor and Jorge Rivera of Ranger Construction Industries, West Palm Beach, Fla.

A well-stocked parts department with second level mezzanine storage is a feature in the design of this branch.

After lunch and tours of the facility, a crowd made its way to the demo area to see some of the newest products and technology from Cat and SITECH South.

For customer convenience, parts, rentals, conference room, showroom and merchandising are all in one central area of the facility.

(L-R): Tommy Buchmeyer and Ron Buchmeyer of Tommy Hawkins & Sons, Ft. Pierce, Fla.; Bill Colosi, Kelly Tractor; R.J. Buchmeyer, Tommy Hawkins & Sons; Chris Kelly and Tony Parada, both of Kelly Tractor, discuss the new facility.

Jim Heimer (R) of Dickerson Infrastructure, Ft. Pierce, Fla., the company that performed the site prep for this new Kelly Tractor facility, talks with SITECH South’s David Turner.

Using the AI-powered Bluelight system, a Cat CS12 roller worked continuously and autonomously during the demonstrations. The Cat 255/265/275/285s, were on display next to the outdoor demonstration area.

Yanmar Compact Equipment offers branded attachments optimized for use with its compact track loaders.

The Yanmar attachments include a full range of buckets, augers, trenchers, stump grinders, soil conditioners, breakers, sweepers, pallet forks, brush mowers, grapple rakes, grapple buckets and snow and grading blades.

The introduction of the new attachments streamlines the purchasing process for fleet owners, contractors and rental centers by allowing Yanmar dealers to act as a one-stop shop for a comprehensive package of Yanmar equipment and attachments.

In addition, customers can be confident that their attachments are matched and tested to ensure maximum efficiency and performance when used with their Yanmar compact track loader.

“We’re excited to offer yet another reliable and versatile set of tools to help fleet customers and contractors be productive right out of the gate and conquer the evolving demands of any construction job site head-on,” said Peter Ovrebo, director of product management, Yanmar Compact Equipment North America. “Additionally, Yanmar customers can save time by buying their machine and attachments all from one place.”

The attachments, available through Yanmar’s dealer network, allow for seamless compatibility for use with all Yanmar-branded compact track loaders. This allows operators to simply attach the tool and get to work with the confidence to get the job done.

Plus, owners have access to the same signature 24month/2,000-hour warranty offered on Yanmar compact track loaders backed by the manufacturer’s reliability and durability standards. This provides peace of mind with parts

and support available directly from Yanmar.

In addition to offering the convenience of buying a compatible Yanmar attachment with a matching machine, the new attachment line is simple to finance. Eligible buyers can

for use with its compact track loaders.

buy a Yanmar machine through a Yanmar dealer and finance the attachment with the equipment as a bundle in one convenient package.

For more information, visit yanmarce.com.

Amulet Manufacturing Co. has released a full line of ditching buckets for small excavators and most backhoe loaders up to 20,000 lbs., with larger bucket sizes planned for 2026.

Built 100 percent in the United States with U.S.-made steel and a full 2-year warranty, the new Amulet ditching buckets are built to last, according to Amulet.

Featuring AR400 serrated “grip” side plates and AR400 smooth or toothed bucket edges, the new Amulet ditch bucket’s

design allows for longer bucket lifespan than standard excavator buckets, as well as a more positive gripping capability when used opposite of any type of thumb, according to Amulet.

“We have had countless requests by customers asking that Amulet bring back their generalpurpose bucket line”, said Mark Elliott, Amulet’s national sales manager. “For a number of years foreign-made buckets flooded the market putting small companies like Amulet at a competitive disad-

vantage, but the tide is slowly turning, and we are now hearing from folks looking for a quality, American-made bucket built here in the U.S.

“And being a thumb manufacturer, we took it a bit further and designed a true, general-purpose bucket with a unique profile that maximizes the gripping ability and overall capability of the excavator,” he added. “Digging, demolition, land-clearing, rock work. You name it. Equipment operators love it.”

For nearly 45 years Amulet has been known for their thumbs, rippers, rakes, couplers, hydraulic tilt buckets and railroad buckets. With the addition of backhoe and small excavator buckets, Amulet will continue to be the first call for equipment dealers, rental yards and end-users alike who are needing quick availability, unbeatable personal customer service and a great attachment selection for their next project, according to Amulet.

For more information, visit amulet.com.

Amulet photo

Amulet Manufacturing Co. has released a full line of ditching buckets for small excavators and most backhoe loaders up to 20,000 lbs.

You will find the parts you need at MOBRO Marine, Inc. We purchase in bulk directly from the manufacturers to maintain our large inventory. We also have a large inventory of long-lead time parts for cranes that can’t be found anywhere else. Not only does this mean we have the part you need in stock, it also saves you money. Because we buy in volume, we can buy for less and pass the savings on to you.

Our large inventory keeps construction equipment performing at optimum levels. We offer same-day shipping on most partsyou’ll experience minimal downtime.

We are a full-service company. We not only supply parts, but we also service and repair construction equipment and cranes of any type.

Willbee Transit Mix, a concrete supplier for Jackson, Mich.’s construction industry, currently operates a fleet of front discharge redi-mix trucks to service pours. For Willbee, maintaining the efficiency of concrete washouts between deliveries is important to his operation.

“For us … the cycle time [on concrete washouts] is critical … between loads, or between color loads, or on a state job when the trucks have to be empty every time, we re-batch” said Stephen Willbee, president of Willbee Transit Mix.

Efficient use of space also is essential for the fifth-generation family business that provides a range of ready-mixed concrete, bagged products, building supplies and tools. As a result of this and other factors, the company opted against employing a conventional settling pond, which occupies considerable real estate.

“It is important for us to keep [our concrete washout process] compact so we can utilize our property for additional products and more inventory,” said Willbee.

Settling ponds also require continual maintenance like sludge cleanup and repairing or replacing torn liners, which can strain scarce company resources.

To expedite the concrete washout process

and reclaim valuable materials, Willbee Transit Mix has used a concrete washout system for the past 22 years called a Redi-

Wash washout system, by Jadair International Inc., a manufacturer of concrete reclaiming and washout solutions.

Despite its decades of reliable service to the business, Willbee decided after 22 years it was time to replace the concrete washout system with a newer model. Recognizing the substantial technological advancements since its installation, he anticipated significant productivity gains from the upgrade.

“Our previous system was analog, with dials and switches,” said Willbee, noting the considerable improvements since his previous system was manufactured. “We had good luck with [our previous] system, so we went right back to Jadair for an updated model.

Like the original, the updated Redi-Wash washout system provides both concrete reclamation and water clarification in one self-contained, closed-loop unit. The machine separates and discharges the sand and stone, which enables the complete recovery of those items. The sand is not washed out of the aggregate. The water is clarified and reused for future washouts. Cement fines are discharged separately, and a loader can then handle them easily as a dry, clay-like product.

To perform a washout, a driver simply drives the concrete truck up to the machine and presses a button. The machine adds

W. R. Meadows Inc. introduced Tilt-Crete W/B, a waterbased cure and bond breaker engineered to elevate performance, consistency and sustainability in tilt-up construction, according to W. R. Meadows.

Designed with a proprietary blend of organic materials, this dual-action formula delivers both film-forming and reactive properties that ensure clean panel release while curing the casting slab, simplifying the process and improving job site efficiency, according to W. R. Meadows.

With a VOC content under 10 g/L, Tilt-Crete W/B complies with the strictest regional regulations, including CARB SCM 20019, SCAQMD, National AIM and OTC Phases I and II, offering contractors a greener solution that doesn’t compromise performance. This product meets the moisture retention requirements of ASTM C309 on steel-troweled surfaces, providing results even under variable site conditions.

“Tilt-Crete W/B represents the evolution of our commitment to job site reliability and environmental responsibility,” said Jim Becker, product group manager, construction liquids for W. R. Meadows. “Contractors told us they wanted a cleaner, easier-to-use bond breaker that performs flawlessly and aligns with today’s sustainability expectations. This product delivers exactly that; streamlining application, improving consistency and helping crews stay on schedule.”

Formulated for tilt-up, lift-slab and precast applications,

Tilt-Crete W/B offers excellent stability, resists oxidation and wash-off from rain or dew and leaves no staining on concrete surfaces when properly applied, according to W. R. Meadows. By combining curing and bond-breaking functions, it reduces inventory demands and handling costs, a practical edge for large-scale contractors and precast producers alike.

Tilt-Crete W/B is available in 5-gal. pails and 55-gal. drums through authorized W. R. Meadows distributors. For more information, visit wrmeadows.com/tilt-cretewb-concrete-bond-breaker/.

WILLBEE from page 33

recycled water to the truck’s rotating cylinder, which then mixes the water with any remaining concrete. The truck then dumps the water and concrete mixture back into the machine and the machine processes and reclaims the materials and recycles the water.

“The drivers pull up, push a button, wait for about 30 seconds and they’ve got their water. Depending on what they have in their truck, sometimes they’ll have to cycle another count, but it’s fast, it’s easy… I watched a driver [washout] three yards in about 3-1/2 minutes,” said Willbee.

Willbee points out that the streamlined concrete washout system aligns with his motto of “Keep it simple.”

According to Willbee, with the new, two station concrete washout system at their plant, their drivers washout, and are back at the plant quickly, ready for re-loading. The system allows them to cycle their trucks in and out of the yard

www.blanchardmachinery.com/paving Columbia, SC 803-791-7100 Florence, SC 843.678.8520 Rock Hill, SC 803.324.9600 Simpsonville, SC 864.963.3645

Myrtle Beach, SC 843-399-2074

Summerville, SC 843.871.2001 Hilton Head, SC 843-784-6766

CAROLINA CAT www.carolinacat.com

Charlotte, NC 704-596-6700

Asheville, NC 828-251-2500

Greensboro, NC 336-294-5240

Hickory, NC 828-464-7045

Monroe, NC 704-292-1555

Boone, NC 828-268-9992

much faster and more efficiently than they otherwise could.

The biggest factor for Willbee is the time and labor savings … “If I can save 10 minutes on every trip, by the end of the day that is 70 or 80 minutes. That gives us the opportunity to haul another load, so our overall efficiency improves,” said Willbee.

In addition to time savings, the washout system also recovers a substantial amount of material that can be reused or sold as an additional source of revenue.

While reclaimed material is not always suitable for high-spec concrete jobs, it can typically be used in lowerspec mixes such as foundations or as base material. Today, these closedloop, concrete reclamation and water handling units can reclaim all the sand and aggregate from returned loads.

“We have contractors that buy the mixture [of sand and stone] and use it as a base under their new slabs,” said Willbee.

The system also is much easier to use and maintain than settling ponds, which create a messy “sludge” or “soup,” according to Willbee.

“With this updated system [we] can control the consistency and thickness of the [cement fines] that come out, which is huge,” said Willbee, adding that “within a couple of days we can get rid of it.”

This feature of the system helps keep his plant neat and clean, while reducing maintenance on loaders and other equipment.

In addition to the increased efficiency of Willbee Transit Mix’s washout process, the equipment’s design has held up to the family business’s heavy workload with minimal maintenance.

“We have been Jadair customers for over two decades and we’ve always had good luck with parts. Customer service has been extraordinary, and we appreciate it,” said Willbee.

For more information, visit jadair.com.

GOMACO offers the full range of concrete slipform pavers, curb and gutter machines, trimmers, placer/spreaders, texture/cure machines and bridge/canal finishing equipment. GOMACO equipment features our exclusive and proprietary G+® control system, created in-house by our software engineers from the wants and needs of contractors paving in the field. At the heart of GOMACO equipment is our passion for concrete and our commitment to our customers. We look forward to visiting with you about your upcoming paving projects and your concrete paving equipment needs. Our worldwide distributor network and our corporate team always stand ready to serve and assist you.

Crossville, TN 931-484-4040 Knoxville, TN (East) 865-546-1414

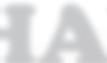

Summit Truck Bodies introduced its high-performance 829 Hydraulic Crane and Advanced Safety Electronics (ASE) Phase 5 Control System at a press conference at Utility Expo 2025.

The fully integrated solution represents Summit’s commitment to advancing technology, designed to upgrade the experience of operators in the field through enhanced equipment performance and streamlined to improve jobsite safety.

With its 29-ft. maximum horizontal reach, the 829 Crane delivers a 48,000-ft.-lb. rating and an 8,000-lb. maximum lifting capacity, making it Summit’s highest-capacity crane in its 7 Series truck profile.

Despite increased strength, the crane weighs 30 percent less than previous models while providing 37.5 percent greater strength through advanced engineering and high-strength steel construction.

“These innovations continue to improve the overall experience for operators in the field,” said Chris Walter, plant manager of Summit Truck Bodies. “Our mission is to engineer the best service trucks and truck-mounted equipment that any operator can have, and we believe the new 829 and ASE Phase 5 meet our objectives and then some.”

weight of the truck while also incorporating the continuous rotation feature,” said Glascock.

Walter emphasized Summit’s collaborative development approach. The process starts with the feedback that Summit’s sales and service department receives from customers, which is then conveyed directly to the company’s R&D team and ultimately to every department in its plant.

“The 829 Crane and ASE Phase 5 incorporate significant technological advancements that elevate the operator’s experience and overall jobsite efficiency,” said Christian Glascock, product development engineer of Summit. “Our engineering team focused on creating the lightest and strongest crane possible, using an optimal, manufacturable configuration with high-strength steel and a new profile.”

Key innovations include a fully proportional control valve that enables seamless movement of all functions simultaneously.

“It gives users the ability to command multiple functions at once, and to increase their positioning speeds by as much as three times,” Glascock said.

The crane features a redesigned rotational assembly that weighs more than 100 lbs. less than its predecessors and allows for continuous rotation.

“The new design enables us to reduce the overall height and

Summit Truck Bodies photo Summit Truck Bodies introduced its high-performance 829 Hydraulic Crane at Utility Expo 2025.

main control interface.

The system also features an integrated vehicle alarm that provides theft deterrence when equipment is unattended. An enhanced wireless remote enables users to operate key crane functions such as auto-deploying, auto-retracting of outriggers and auto-stowing of the crane without returning to the truck, thereby improving efficiency and jobsite safety.

“Summit’s new crane and next-gen controls address key features requested by our customers and the industry at large,” said Dan DeAces, national sales manager of Summit Truck Equipment. “Power truly does meet precision with our newest crane offering.”

“The system provides significant and measurable ROI for fleet managers, helping to protect assets from damage and technicians from injury,” DeAces said. “We have a simple but profound motto at Summit: ‘Start safe. Work safe. Stay safe.’”

“This provides incredible flexibility, allowing users to deploy the crane quickly and stow it just as fast after completing a job. Additionally, it seals the compartment from water, dust and road chemicals, protecting the valuable assets inside.”

With its 29-ft. maximum hor izontal reach, the 829 Crane delivers a 48,000-ft.-lb. rating and an 8,000-lb. maximum lifting capacity, making it Summit's highest-capacity crane in its 7 Series truck profile.

A relocated winch and the lowered crane height, provide customers access to more locations. Added user safety is provided by the new anti-two-block system, which requires zero adjustment and features modular components for easier maintenance.

With its updated screen, the ASE Phase 5 offers enhanced customization, ease of use and access to diagnostic capabilities encompassing all devices within the truck’s electrical environment. “The new system supports greater user customization capabilities, allowing increased maintenance and event logging and tracking for fleets or operators, and saves them up to 150 percent in replacement part costs,” Glascock said.

The updated ASE Phase 5 control system features a dedicated maintenance menu that enables operators to track service intervals and access diagnostic data directly through the

“Summit’s unique factorydirect sales model starts with our sales team working directly with customers and our engineers to design and deliver the right truck for their needs,” DeAces added.

“Once that truck is in service, customers have a direct line to our factory parts and service professionals, who can troubleshoot in real time and ship parts directly from our warehouse. Summit also supports every customer with training, detailed documentation and true 24-hour availability.”

The 829 Crane and ASE Phase 5 are byproducts of Summit’s direct and intimate understanding of its customers, the environments they work in and their specific needs, according to Summit.

“We are in a position to hear firsthand the pros and cons of how equipment performs in the field,” said DeAces. “Our customers’ work is challenging and changing daily, and they deserve a partner willing and able to change with them.”

The 829 Hydraulic Crane and ASE Phase 5 Control System will be available for purchase beginning in early 2026. The technologies represent the foundation for broader product line enhancements, with plans to integrate many of the related innovations across Summit’s entire hydraulic crane lineup. For more information, visit summitbodies.com.

Stellar Industries announced it has entered into a definitive agreement to acquire Elliott Equipment Co.

The transaction is expected to close in the first quarter of 2026, subject to customary closing conditions.

This acquisition strengthens Stellar’s long-term growth strategy by expanding its lifting equipment and work-at-height solutions, widening its presence across core vocational markets and creating additional opportunities for distributors, customers and employee-owners.

Founded in 1948, Elliott Equipment pioneered the first truck-mounted telescoping aerial platform and continues to design equipment for utility transmission, commercial construction, municipal services and fleet maintenance applications.

“Stellar has always pursued growth opportunities that align with our culture, vision and commitment to excellence,” said Dave Zrostlik, president of Stellar. “The addition of Elliott Equipment Co. represents an exciting step forward as we continue to build upon our shared values of quality, innovation and customer service. We’re

proud to welcome Elliott to the Stellar team.”

Following the close of the transaction, Elliott Equipment will operate as a distinct

business unit of Stellar, maintaining its current employees, facilities, brand identity and dealer relationships in Omaha, Neb. Jim Glazer, president of Elliott Equipment, will

continue to lead the organization.

“We are thrilled to continue the Elliott Equipment Co. story with Stellar,” said Glazer. “This acquisition represents a strong cultural fit between two organizations that share a commitment to people, product integrity and long-term growth.”

Stellar’s 100 percent employee-owned structure aligns employee success directly with company performance. Through the ESOP, employee-owners share in the organization’s long-term growth, reinforcing a culture of collaboration, innovation and accountability.

With the addition of Elliott, Stellar will broaden its capabilities in aerial work platforms, utility lifting solutions and materialhandling technologies, enabling both companies to better serve existing customers and pursue new opportunities in adjacent markets. Both organizations remain committed to United States manufacturing, exceptional service and engineering.

For more information, visit stellarindustries.com.

11301 Reames Road Charlotte, NC 28269

980-859-4680

125 Wilsons Mills Rd. Extension Wilson’s Mills, NC 27577 919-938-8145 141 Brickyard Rd. Lexington (Columbia), SC 29072 803-520-0032

6325 Central Avenue Pike Knoxville, TN 37912 865-766-2571

MGX Equipment Services, through its “Upfits by Aspen Equipment” brand, is redefining work truck versatility with Palfinger articulated crane boom attachment solutions. As the authorized Palfinger distributor in Minnesota, Iowa and Nebraska for more than a decade, the upfits team brings deep expertise in delivering truck solutions to meet the specialized needs of customers.

Palfinger’s articulated cranes, also known as knuckle boom cranes, are available with a wide range of boom attachments to turn a single-function crane truck into a multi-purpose machine. One standout option is the hydraulically driven auger attachment which enables crews to dig holes for fence posts, road signs and utility poles without the need for additional equipment such as skid loaders or digger derricks, according to the company.

The upfits team at the Des Moines branch partnered with a municipality in Iowa to combine the Palfinger PK 12.501 SLD5 knuckle boom crane with 32-ft.

are available including compact options compatible with Class 5 truck chassis.

“Unlike a typical flatbed crane, [we] upfitted this truck with a heavy-duty steel utility body with customized sign storage, welder, workbench bumper and lighting to give the road crew the storage and functionality of a service truck,” said David Phillips, territory manager — Upfits by Aspen Equipment brand of Nebraska and Iowa. “For several decades, we’ve been a premier supplier of customized sign truck solutions for cities, counties and states that need a multi-functional tool to dig holes, set poles, install signs and more.”

system features

couplers and a hydraulic hose track for easy integration. Multiple auger drive sizes

Beyond augers, a full suite of Palfinger crane attachments including personnel baskets, pallet forks, rope winches and more are available. Service and mechanics bodies are available for upfitting on a variety of truck chassis. Turnkey upfitting services are available for direct purchase or through state and regional government procurement contracts.

NCDOT from page 1

“It will also benefit military interconnectivity and make the corridor safer by reducing intersections. It will provide a corridor that will increase the efficiency between the military bases, MHC port, Global Transpark and the Triangle.”

According to NCDOT, the project will eliminate conventional U.S. 70 intersections, such as those with stop signs and traffic signals. Along the route, Stately Pine Road, Fisher Avenue and Camp Kiro Road will be converted into interchanges.

Balfour Beatty Infrastructure Inc., the prime contractor, is also upgrading 5.1 mi. of U.S. 70 to interstate standards in the James City area, directly west of this new project closer to New Bern. Balfour Beatty was selected to complete the Havelock Bypass to the east of this new segment, which will become I-42 around Havelock. The Havelock Bypass will be a four-lane, median-divided highway that will provide a high-speed alternative to using U.S. 70 through Havelock, which is hampered by numerous traffic signals at intersecting side streets.

Design work on the Thurman Road segment began in early 2023. Field work started in November 2024, with construction expected to be completed by summer 2028.

Subcontractors on the project include Bullington Construction; Curtin Co.; Evergreen Clearing; Gosalia Concrete; Hendrix Barnhill Co.; Hunting Creek Construction; Sadler Landscaping; T&H Electrical; Delta Contracting; Barnhill Contracting; North State Trucking; and Stay Alert Safety Services.

As with most projects, motorists will have to adjust during construction.

“There will be lane closures periodically to perform work on or beside the roadway,” said McMannen. “We will have a few temporary traffic shifts to move traffic while we construct the structures and walls.”

Clearing and grubbing, utility relocations and grading work is under way.

“The main challenge is working with utility companies to

relocate their existing facilities, so project work can be performed,” said McMannen.

Regarding site work, grading operations have been under way. The contractor is laying drainage pipe, cutting ditches and hauling in borrow material to build new roadway.

There will be building demolition required at some locations, as well as the need to remove existing asphalt roadway for road realignments. During excavation, crews anticipate roughly 1.4 million cu. yds. of borrow being hauled in and used on the project.

“We will also install four new concrete box culverts under U.S. 70. The work will require traffic shifts to build it in sections and not impact motorists.”

As for unexpected issues, said McMannen, “There have been some delays with right-of-way acquisitions and utility relocations we had to deal with and resolve.”

McMannen said nearby Marine Corps Air Station Cherry Point military base has been good to work with.

“We are in contact with them often, so they can notify their personnel about upcoming work and traffic updates. They also let us know about upcoming events.”

During grading operations, crews are using Caterpillar excavators, Caterpillar backhoes, Caterpillar motor graders, Caterpillar sheeps foot rollers and John Deere tractors. Aside from borrow material from a local pit, chief materials include aggregate stone from Martin Marietta and asphalt from Barnhill.

McMannen noted that weather can definitely have an impact on construction.

“We get rain that can affect the grading operations. During the winter weather months, cold temperatures can sometimes affect concrete pours and placement of asphalt.”

After unavoidable interruptions, McMannen said it’s gratifying to see construction under way on this important effort.

“It’s nice to see work finally start. It’s rewarding to watch a project from start to finish, which the public will enjoy, and that looks great and makes travel safer and more efficient.

www.equipmentshare.com

10179 US-78 Ladson, SC 29456 843-709-2458

145 Thunderbird Dr. Richmond Hill, GA 31324 912-400-0752

2919 E. Napolean St. Sulphur, LA 70663 337-284-9804

120 Mann Drive Piperton, TN 38017 (Memphis) 800-238-5591

2115 N. Thompson Lane Murfreesboro, TN 37129 877-200-5654

5200 Hollywood Ave. Shreveport, LA 71109 800-548-3458

364 Bob Jobe Rd. Gray, TN 37615 855-201-7453 10110 Roberts Way Covington, GA 30014 770-788-0888

7651 Theodore Dawes Rd. Theodore, AL 36582 251-653-5955

825 31st Street North Birmingham, AL 35203 205-323-6108 LINK-BELT MID ATLANTIC www.link-beltmidatlantic.com Ashland, VA 866-955-6071 Chesapeake, VA 800-342-3248 Frederick, MD 833-546-5235

www.parmantractor.com

3570 Dickerson Pike Nashville, TN 37207 615-865-7800

1485 Bear Creek Pike Columbia, TN 38401 931-388-7273

MID SOUTH MACHINERY, INC. www.gomidsouth.com 3233 Highway 80 West Jackson, MS 39204 601-948-6740

3145 Cliff Gookin Blvd. Tupelo, MS 38801 662-690-6553

7422 Hwy 49 N Hattiesburg, MS 39402 601-268-2222

Dennis Howard

SPECIAL TO CEG

We are in the full swing of fall sports seasons. After a long week on job sites, we’re sitting on the couch and turning on the TV to watch our favorite team.

Much like a football team driving toward the end zone before the clock runs out, a job site crew works together to complete specific tasks on time and on budget. In both football and construction, success depends on skilled players and the right equipment.

On a crushing site, the crusher plays the role of the running back — powerful, reliable and essential for driving production forward. But the machine that delivers material to the crusher is where the play begins, much like a quarterback handing off the ball. Choosing the right support machine, whether an excavator or a wheel loader, can affect the accuracy and efficiency of the crusher machine.

Before diving into the excavator vs. wheel loader debate, let’s break down the different types of crusher machines. Crushers are developed for different materials and loading capacities. Kleeman crushers, for example, come in three major types.

• Jaw Crushers: Designed for primary crushing of hard stone and recycling materials with high throughput and mobility.

• Impact Crushers: Ideal for soft to medium-hard stone and recycling, producing high-quality, well-shaped aggregates.

• Cone Crushers: Used for secondary and tertiary crushing of hard and abrasive stone with precision and efficiency.

While some contractors like TKB Excavation, based in southern Utah, opt to use all three models to produce the materials they need to deliver to their customers, others choose the crusher based on the orders they’re filling. Once the main crusher machine has been selected, the contractor can choose an excavator or wheel loader that

will deliver consistent material and keep the crusher producing the desired output(s), whether that’s gravel, sand or specific rock

sizes for landscapers. While both excavators and wheel loaders have their place on the job site, one clearly earns the MVP title when it comes to optimizing crusher performance.

Excavators allow operators to pick out and move uncrushable or oversized material before it hits the crusher rotor. In tight spaces and uneven terrain, an excavator’s reach and maneuverability make it the ideal choice for in-place crushing applications.

Excavators’ ability to maintain a consistent material bed depth and feed rate into the rotor improves throughput and reduces wear on some components to potentially lower material production costs.

Wheel loaders can handle high-volume and fast-paced operations. In such instances,

Built to deliver a long reach required for barge loading/unloading and large scrapyard applications, the new Cat MH3295 material handler features a dedicated swing pump for smooth, coordinated movement and a wide track undercarriage for optimum stability and performance. Electrohydraulic controls plus Caterpillar technology help boost productivity on jobs that demand high performance, according to Caterpillar

“The new MH3295 material handler is based on the rugged and reliable Cat 395 excavator platform, sharing common service parts, but features a purpose-built design for the demands of large scrapyard and port applications to offer consistent operation,” said Vincent Migeotte, senior global product consultant of Caterpillar. “Plus, standard technologies like swing assist, Cat payload and 2D E-fence help operators to work more efficiently and safely. The new design of the MH3295 is about elevating jobsite performance and delivering long-lasting durability and value.”

The new material handler features a 59.1ft. reach plus two counterweight configurations to meet job site conditions. Its wide, 15.7-ft. track gauge retracts to a 13.5-ft. width to simplify transport. The wide operating track gauge combines with the undercarriage’s 23.6-ft. track length to deliver smooth, stable operation at extended reach. Its 543 hp Cat C18 engine meets U.S.

EPA Tier IV Final and EU Stage V emission standards and offers reliable operation up to 9,840 ft. above sea level without derating. Operators can match machine performance to the job at hand using three power modes — Power, Smart and Eco — to help save fuel. Giving operators control when needed, an advanced electrohydraulic system helps provide the optimum balance of power and efficiency.

SmartBoom technology allows the boom to freely travel up and down without using pump flow, enabling operators to focus on stick and attachment movements.

A variety of Cat work tool attachments are available to meet a range of material and density types. Valve priority helps operators direct hydraulic pressure and flow where it is needed.

Boosting operating efficiency, Cat Payload for the new MH3295 assists operators with achieving precise load targets, helping to eliminate overloading of over-theroad trucks and enabling more accurate production tracking, according to Caterpillar. Real-time weight estimates are displayed incab when picking up a material load without swinging.

Standard swing assist technology automatically stops upper machine rotation at preset points to help operators hit more repetitive swing targets, reduce fuel consumption and improve cycle times, accord-

ing to Caterpillar. Quickly established, the operator simply swings to a desired stopping point and sets the target using the in-cab monitor or a preset joystick button. When approaching the predefined limit, the machine automatically decelerates and does not allow the stick to travel beyond the set point.

Leveraging data wirelessly, VisionLink provides actionable insights for the new MH3295 material handler. It allows fleet managers to review equipment data from a desktop or mobile device to help maximize uptime and optimize assets. Dashboards provide machine operating details like hours, location, idle time and fuel use, so informed fleet decisions can be made to help lower costs.

Standard remote services technologies help the new material handler operate with maximum uptime and efficiency. Remote troubleshoot allows the Cat dealer to diagnose issues remotely without impacting machine performance, so they are resolved quickly with less machine downtime. Updating onboard software without requiring a technician to be present, remote flash enables the company to initiate software updates at a time convenient to the production schedule, increasing overall efficiency, according to Caterpillar.

The material handler’s fixed cab riser provides 360-degree visibility and includes floor windows to help improve visibility

when loading material. The new premium plus cab design includes small pillars and large windows, plus rearview, left-side and right-side-view cameras to enhance safety while operating. The rear cab door entry design features enclosed stairways and integrated lights to safely access the cab. Wide walkways provide quick, easy and safe access to upper service platform maintenance areas.

Inside the cab, a wide seat adjusts to accommodate operators of all sizes, while the controls are positioned in front of the operator for comfortable machine control. Accommodating operators of all skill levels, the high-resolution, 10-in. touchscreen monitor presents the job site dashboard in an intuitive format. Productivity applications are displayed on the monitor in grid view to easily read on the go, and touchscreen functionality is programmed to ensure continued job performance without any interruptions, according to Caterpillar.

Standard cab avoidance assists with evading contact between the work tool attachment and cab, enhancing safety while operating and improving machine longevity, according to Caterpillar. Automatic climate control provides comfortable operating temperatures throughout the shift, and storage compartments are located beneath and behind the seat, plus overhead and in the consoles to stow plenty of gear. Operators can connect personal devices using the standard radio’s USB ports and Bluetooth technology.

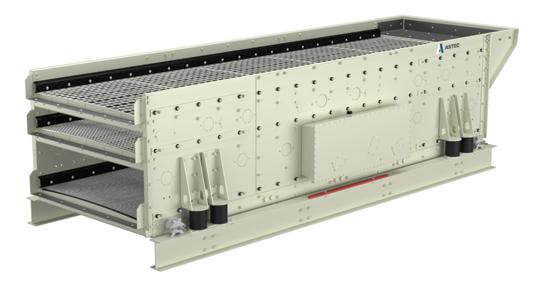

Astec Industries announced the launch of its groundbreaking Vari-Frequency technology implemented on our 6203 LP Horizontal Screen, a solution built to boost screening performance. The new design minimizes blinding and maximizes uptime, giving producers a smarter, more reliable way to keep processing material.

Installed on the bottom deck of a horizontal screen, the vari-frequency deck significantly increases throughput and efficiency while minimizing plugging and blinding — two of the most common challenges in screening operations. The live portion of the deck’s flexible surface is supported by a system of tensioned cables that create rapid, localized g-force spikes across the screen, stimulating the screen media and material to maintain throughput.

erates screen media vibration spikes to minimize buildup.

• Low maintenance: Cleaner screen media reduces the need to climb between decks for manual cleaning and downtime.

• Energy independent: Operates without external power for cost-effective performance.

• Seamless integration: Screens with vari-frequency technology will be interchangeable with standard units requiring replacement or a performance upgrade.

Built for standard side-tensioned screen cloth and requiring no external power source, the vari-frequency technology provides an adaptable, energy-independent solution that integrates into existing systems, according to Astec. Its development was driven by testing and customer collaboration to ensure performance in demanding conditions.

Key features include:

• Increased efficiency and throughput: New deck design delivers significantly higher throughput.

• Reduced blinding: Flexible, cable-supported deck gen-

vari-frequency

As part of Astec’s broader commitment to continuous innovation, the company plans to incorporate vari-frequency technology into additional screen models across its robust product portfolio. Attendees of ConExpoCon/AGG 2026 will have the opportunity to preview the 8-ft. model, the next piece of equipment in the technology rollout.

The vari-frequency horizontal screen continues Astec’s legacy of designing durable, practical and forward-thinking equipment that meets the evolving needs of producers worldwide.

For more information on Astec’s screening solutions, visit astecindustries.com/products/details/vari-frequencyscreen?b=/screens-feeders/screens/horizontal-screens.

operators need to pay attention to Kleeman’s Constant Feed System (CFS) so they keep the faster pace and act as finished material movers when the crusher produces the final product.

One thing to note, though, is that on asphalt and concrete rubble applications, wheel loaders can pose a higher risk of bridging, leading to uncrushable material entering the crusher, which can cause increased wear and downtime.

Watch this episode of “The Track” to hear Crushing Product Specialist Ronnie Trushenski explain how he works with contractors to choose the right machine for the desired material outcome.

Bottom Line: Application Drives Decision

There’s no one-size-fits-all answer. Excavators are the best bet for crews working in tight spaces or needing precision feeding. They’re like the nimble ball carrier, avoiding obstacles and

RDO Equipment photo

While some contractors like TKB Excavation opt to use all three models to produce the materials they need to deliver to their customers, others choose the crusher based on the orders they’re filling.

operating efficiently. On the flip side, like a power back whose role is just to hit the line hard time and time again, wheel loaders can come in clutch for bulk material handling, though they may carry some risk.

For more information, visit RDOEquipmentCo.com. (Article reprinted with permission of RDO Equipment.)

5038 Buford Hwy. Norcross, GA 30071 770-582-0377

Blue Ridge, GA 706-632-3777

Cumming, GA 770-887-6119

Hiawassee, GA 706-970-3077

McDonough, GA 770-957-3370

Villa Rica, GA 678-952-2037 Perry, GA 478-987-1173 Savannah, GA 912-208-5349

Waverly Hall, GA 706-582-3193 Stowers Machinery Corporation stowerscat.com/bandit

Tree Care

6301 Old Rutledge Pike Knoxville, TN 37924 865-546-1414

10644 Lexington Drive Knoxville, TN 37932 865-218-8800

1825 Veterans Boulevard Sevierville, TN 37862 865-595-3750

9960 Airport Parkway Kingsport, TN 37663 423-323-0400

4066 South Access Road Chattanooga, TN 37406 423-698-6943

215 Interchange Drive Crossville, TN 38571

931-456-6543

TREES, BRANCHES, LIMBS, AND STUMPS

ARE NO MA ,, ATTCH FOR A B From roadways to right-of to road clearing, get your w more efficiently than ever machinery! Choose from d sizes to suit your needs. C yours or to request a dem BANDIT® -ways, lot clearing ork done faster and before with Bandit ifferent styles and all today to reserve onstration.

TOMRA Recycling has published its latest e-book, “AI in Recycling: Unlocking New Possibilities.”

This comprehensive guide explores the rapidly evolving role of artificial Intelligence (AI), particularly deep learning, in revolutionizing the global recycling industry and driving material circularity.

The free-to-download e-book aims to demystify deep learning, explaining its mechanisms and showcasing its practical applications in overcoming complex sorting challenges, such as enabling the separation of previously hard-to-classify materials through the training of vast datasets. From manual processes to the prospect of fully autonomous AI-driven systems, the evolution of sorting technologies is also examined in detail, alongside the core concepts of AI and deep learning.

The e-book details how the powerful synergy achieved by combining deep learning with traditional sensors in optical sorters is unlocking new opportunities for the recovery of valuable resources, enhancing material purity and creating new revenue streams.

This is exemplified by TOMRA’s awardwinning GAINnext solution for food-grade plastics recovery (for PET, PP and HDPE), PET and paper cleaning and high-purity recovery of aluminum Used Beverage Cans (UBC), as well as the capabilities of the PolyPerception AI-based waste analyzer in providing real-time, end-to-end object tracking and classification of waste streams.

Readers will gain insights into the tangible benefits of deep-learning-based solutions,

including enhanced flexibility, the creation of new high-value material streams, superior sorting accuracy, advanced plant automation and optimized processes. The guide also showcases the growing range of deep learning applications pioneered by TOMRA including real-world examples. Furthermore, it examines the crucial role of AI in meeting the demands of evolving regulations like the Packaging and Packaging Waste Regulation (PPWR), which necessitate advanced sorting capabilities to achieve circular economy targets. Looking ahead, the e-book presents a vision for the future where AI could drive fully transparent and self-optimized recycling plants.