“The Nation’s Best Read Construction Newspaper… Founded in 1957.”

“The Nation’s Best Read Construction Newspaper… Founded in 1957.”

By Lori Tobias CEG CORRESPONDENT

A new $31 million structure under construction in Oregon comes with design elements not often found in the average construction project: security and antiterrorism features.

In August 2025, Oregon National Guard senior leaders and elected officials broke ground for the new Hillsboro Readiness Center. Work crews are now clearing the site and preparing for construction.

“As we break ground for the wonderful new readiness center, we look forward to continuing this legacy of connection and collaboration with Delta Company, 2nd Battalion, 162nd Infantry Regiment and Charlie Battery, 2nd Battalion, 218th Field Artillery Regiment,” Hillsboro Mayor Beach Pace said. “We are excited for the future and remain deeply committed to the Hillsboro community.”

The new Hillsboro Readiness Center, about a mile east of the original armory built in 1954, replaces the original and is expected to meet and extend the National Guard’s capabilities in the community for the next 50 years.

The facility was designed under requirements for security and antiterrorism as outlined by federal Department of Defense Minimum Antiterrorism Standards for Buildings, said Rocky Kumlin, provost marshal.

Contractor Fortis Construction, headquartered in Portland, Ore., teamed with woman-owned CIDA Architects, also based in Portland, on the design-build

project to create two buildings on the site.

“As a military entity, we have additional security and terrorism-force protection,” said Melissa Burns, senior construction manager. “It’s commercial construction, so it’s a little more heavy duty. The Antiterrorism and Force Protection (ATFP) requirements require us to harden the building where we do different structural things. That may include different kinds of glass, such as blast-proof glass, offsets of the building — making sure that the building's in the right place on the site, and things like that to make sure people are safe.”

The project includes two pre-engineered buildings. The main building is the 45,000-sq.-ft. Readiness Center, featuring office space, a drill floor and classroom space doubling as multi-purpose rooms, along with work bays for work on vehicles and a full commercial kitchen for military as well as rental use. It also features a mezzanine for infrastructure mechanics.

“These updates will give the Oregon National Guard proper space to accomplish their mission,” said Stephen Bomar, director of public affairs, Oregon Military Department.

The readiness center will host monthly military drills and other training activities and also will be available for community use.

Fortis Construction is the general

With the painting of final lane markers on the new roadway, construction at the Interstate 86/Interstate15 “Flying-Y” System Interchange in Pocatello, Idaho, is coming to a successful conclusion.

Begun in July 2022, the three-year $112 million project has dramatically changed the drivability of the interchange, according to the Idaho Transportation Department (ITD). The Sundt-Cannon Joint Venture served as contractors

“We spent over eight years from design to actual construction of the project. We’re pretty proud of it,” said Aaron Baird, ITD project engineer. “It’s one of the bigger projects we’ve designed. It’s one of the largest projects ever designed entirely by ITD staff and inspected with ITD personnel. Most of the people on the team live here locally and this has been a really meaningful project for us to make sure we did our very best.”

Critical areas that were improved include the northbound Pocatello Creek on-ramp, the northbound-to-westbound collector distributor, and the eastbound-to-northbound ramp. Each of those improvements made merging from one Interstate to the other smoother and safer for motorists.

“We’re excited for people to use the final product. We hope it’s something that will last

a long time and keep the travelling public safe as they use it,” said Greg Roberts, project manager. The endeavor’s scale has been historic. Approximately 1 million cu. yds. of excavation were completed. In addition, about 490,000 tons of base material was brought in; 116,000 tons of asphalt were placed; and

more than 7,700 cu. yds. of concrete were poured. Nearly 70,000 sq. ft. of retaining walls were built throughout the project area.

Finally, ITD built eight new bridges. Four of those have precast concrete girders and four have steel girders. In all, more than 5 million lbs. of steel were used in the new bridges.

Construction crews worked year-round and around the clock for approximately three years to complete the project. To minimize disruption to traffic, key demolition operations were conducted at night. These efforts minimized the impact on traffic while the interchange was being reconstructed.

In addition to the major changes inside the Flying-Y design, the Chubbuck Road overpass was reconstructed as an underpass to improve site distances and vertical clearance on I-15, and to improve access to the Wellness Center from Chubbuck. The new underpass is significantly wider and includes bike lanes and sidewalks.

ITD also worked closely with the Portneuf Greenway to construct a pedestrian and bicycle path on the east side of the work site to connect the Greenway to the Wellness Center.

Work left to wrap up the project will be off the roadway and conducted on the shoulders. In addition, ITD will be seeding open ground with native grasses.

“Thank you for being patient with us and seeing our vision, seeing what we’re trying to do to positively impact this community,” said Zak Johnson, project manager. (All photos courtesy of Idaho Transportation Department.)

The Washington State Department of Transportation (WSDOT) opened the second diverging diamond interchange in the state on July 25, 2025, when it switched to a new traffic pattern designed to improve flow and safety at the Interstate 90/State Route

18 interchange near Snoqualmie.

The new interchange opened after an eight-day, around-theclock closure of SR 18 under the I90 bridges to build the northern end and switch traffic into the new pattern.

Aecon is the project contractor.

A diverging diamond is different than traditional interchanges in several ways. Drivers will notice that northbound and southbound traffic on SR 18 crosses to the left side of the highway to go under the I-90 bridges before crossing back over.

Vehicles no longer have to turn left in front of oncoming traffic, allowing for fewer traffic-signal phases. Along with the SR 18 widening work expected to finish later this fall, the new configuration will help improve traffic flow through the interchange.

The diverging traffic pattern also improves safety by reducing the number of locations in the interchange where vehicles could potentially collide with each other or a pedestrian.

WSDOT opened the state’s first diverging diamond interchange in

2020 at the Interstate 5/State Route 510 (Marvin Way) interchange in Lacey. The first diverging diamond in the nation opened in 2009 in Springfield, Mo., and there are now more than 200 throughout the country.

Although opening the diverging diamond interchange to traffic is a milestone for the I-90/SR 18 Interchange Improvements project, more work remains to complete construction. Crews need to add a top layer of asphalt throughout the interchange and ramps, then come back a few weeks later to paint permanent lane lines.

In addition to building the new interchange, the project is widening more than 2 mi. of SR 18 between I-90 and Deep Creek to two lanes in each direction. The wider roadway, which is expected to be finished later this fall, will work together with the diverging diamond interchange to improve traffic flow through this vital corridor for travelers and freight between southern and eastern King County.

Widening SR 18 included building new four-lane bridges over Lake Creek and Deep Creek and a new two-lane bridge over Raging River next to the existing bridge. Traffic was first shifted onto the new Lake Creek bridge in November 2023, while the Raging River and Deep Creek bridges opened to vehicles in late May 2025.

The new Lake Creek and Deep Creek bridges removed barriers to fish passage and opened wildlife corridors for elk, deer, coyotes and other species to safely pass beneath SR 18. In all, the project will remove six fish barriers and create an open-air stream under the I-90 bridges at the diverging diamond interchange.

The $188 million project was paid for with $183 million from existing gas tax funds and $5 million from the Connecting Washington funding package.

Construction began on the project in the fall of 2022, and road work is expected to finish by late 2025.

MAKE YOUR MOVE

Push

... more material with the new Hyundai HD100 crawler dozer's best-inclass power-to-weight ratio.

See ...more than ever with the unobstructed view to the blade.

Engage

...more accurately and more productively with standard 2D or optional 3D machine guidance.

Doze

...with confidence, knowing your new 115 hp Hyundai crawler dozer delivers the quality and value you expect from Hyundai, with the peace of mind that comes with our industry-leading warranty.

No wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, na.hd-hyundaice.com.

Global construction and development firm Skanska announced on Aug. 14, 2025, that it signed a contract with the Highline Public Schools District for the Pacific Middle School Replacement Project in Des Moines, Wash.

In addition, Skanska announced on Aug. 19, 2025, that it had completed its work on a 90,500-sq.-ft. modernization and expansion of the historic Montlake Elementary School for Seattle Public Schools.

The Highline contract is worth $91 million.

The Pacific Middle School Replacement Project consists of a new three-story facility of approximately 132,800 sq. ft., which will serve up to 950 students in sixth through eighth grades. The new building will include approximately 40 classrooms, administration spaces and instructional support spaces and will be constructed in place of the existing Pacific Middle School buildings.

Work began in July 2025 and is expected to be completed in February 2027.

In addition, the $68.4 million Montlake Elementary project included the modernization of the existing two-story, 16,500-sq.-ft. Seattle schoolhouse and the addition of a new 74,000-sq.-ft. three-story building housing the gym, cafeteria, kitchen, administration spaces, classrooms and library.

New outdoor learning spaces were constructed on the west side of the landmark school building. A central play courtyard also provides direct connection to garden terraces, and a second-floor learning and play terrace directly connects to classrooms in the new building. In addition, to optimize outdoor play space within the less than 2-acre site, a rooftop play area was added atop the new gymnasium.

Since the original schoolhouse, built in 1924, was named a Seattle Landmark in 2015, it was imperative that specific historic elements be maintained during the modernization, including interior woodwork, cabinetry, egress stairs, window frames and the exterior character of the building.

As part of the modernization and addition, several sustainable design solutions were added to the facility — including advanced energy management systems and controls, solar

panels and heat pumps — without compromising the community’s holistic values, health, spirit of place, inclusivity and resilience. A carbon footprint assessment, construction indoor air quality management plan and construction waste recycling program were all part of the development of this project.

“It’s challenging but immensely rewarding to work on a special project like this, when we not only get to execute a brilliant design, but also where we get to work on such an iconic landmark while always being mindful of a tight footprint in a residential neighborhood. It really brings out our best,” said Lew Guerrette, executive vice president and general manager, Skanska USA Building in Seattle.

Skanska served as general contractor/construction management firm for the project, DLR Group served as design firm and Paul Wight served as capital projects manager for the project for Seattle Public Schools.

(All images courtesy of Skanska.)

Sound Transit broke ground on Aug. 12, 2025, on a new electric bus base in Bothell, Wash., that’s considered crucial to the region’s Stride bus rapid transit (BRT) plans, the urbanist.org reported.

Situated within the Canyon Park Business Center, the 10-acre facility will initially support 48 battery electric buses that serve the Stride S1, S2 and S3 lines.

Up to 120 buses can be accommodated at the $274 million base, according to urbanist.org. That will allow Sound Transit to expand its future service and offer charging space for electric buses on other routes.

“This operations and maintenance facility will be the anchor for our upcoming 45-mile Stride bus rapid transit network, connecting 11 cities all along I-405 and SR 522 to Link light rail and to each other,” Sound Transit

CEO Dow Constantine said in a statement.

“It will bring dozens of living-wage jobs to Canyon Park and Snohomish County, operating and maintaining a first-in-the-nation fleet of fast, reliable, all-electric buses.”

Sound Transit hired Denver, Colo.-based PCL Construction in May 2025 to build the base, according to theurbanist.org.

Features of the new Bothell Bus Operations and Maintenance Facility (OMF) will include an operations center, a vehicle maintenance facility, a 255-vehicle parking lot for employees and visitors and charging infrastructure for the all-electric Stride fleet.

The BRT system will tie together the

Eastside with bus service, while improving connections to the west and interfacing with the Link light rail network in Bellevue, Lynnwood, Shoreline Sout and Tukwila, the urbanist.org reported.

“Stride will dramatically cut travel times and improve transit reliability between Burien and Bellevue, Bellevue and Lynnwood and from Shoreline to Bothell,” the agency said.

Battery electric buses will run every 10-15 minutes and will primarily use dedicated lanes or high-occupancy vehicle (HOV) lanes, according to theurbanist.org.

The agency originally promised the three Stride bus lines in its Sound Transit 3 (ST3) package that regional voters approved in 2016.

Although Sound Transit’s first pledged to open the lines in 2024, delays have pushed the likely start of service to 2028, according to the urbanist.org.

(Image courtesy of Sound Transit.)

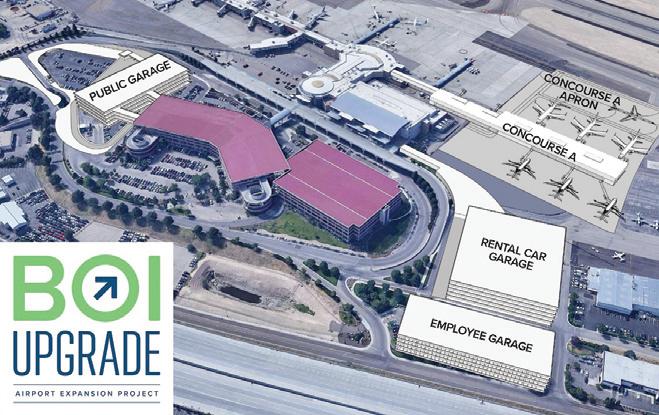

Boise Airport (BOI) announced on Sept. 3, 2025, the selection of Hensel Phelps as construction manager/general contractor for the Concourse A and Terminal Improvements project, which are key components of the BOI Upgrade expansion effort that began in 2019.

The Boise City Council approved the contract for Hensel Phelps at its Aug. 19 meeting. The contract has a not-toexceed amount of $700 million for projects scheduled through 2029.

Within this term, multiple guaranteed maximum price agreements will be developed and brought to the city council for approval. The agreements will align with constructing the following:

• a new, expanded back-of-house baggage handling system to support increasing passenger volumes;

• a central utility plant to meet the heating, cooling and electrical needs of Concourse A and the rest of the terminal;

• Concourse A, featuring up to 10 new gates to accommodate future passenger growth and air service offerings; and

• two phases of enhancements to improve passenger flow and increase capacity in the existing terminal.

The construction manager/general contractor (CM/GC) model being used for these projects helps ensure collaboration, flexibility and cost certainty— especially important for complex, phased construction in an operating airport.

Unlike the traditional design–bid–build approach, CM/GC allows the contractor to be involved early in the design process, offering valuable input on constructability, phasing, scheduling and budgeting.

The not-to-exceed framework of this agreement enhances flexibility, allowing the airport to issue task orders as funding becomes available and project priorities evolve. Importantly, no local taxpayer dollars are used to fund capital projects or operational expenses at Boise Airport.

Hensel Phelps was selected following an extensive evaluation process that began in January 2025, when the airport issued a request for qualifications. Of the seven firms that submitted proposals, four were invited to interview with an evaluation committee comprised of city of Boise leaders and industry experts. The evaluation committee ultimately recommended Hensel Phelps to Boise City Council for approval.

Headquartered in Greeley, Colo., Hensel Phelps is a nationally recognized leader in aviation construction, with a portfolio of more than 375 major aviation projects totaling $29 billion. Their experience includes passenger terminals and concourse expansions, baggage handling systems, security upgrades and more.

The Concourse A and Terminal Improvements projects are part of Boise Airport’s broader BOI Upgrade capital development program, designed to meet the needs of the fast-growing Boise and Treasure Valley region.

Since 2014, Boise Airport has experi-

enced an 81 percent increase in passenger traffic, reaching nearly 5 million passengers in 2024. Passenger volumes in the first half of 2025 have already surpassed last year’s record-setting numbers. To meet this demand, the airport has already completed several major projects under the BOI Upgrade initiative, including:

• expanded security checkpoint;

• new public and employee parking garages; and

• ongoing construction of a new rental car center.

Representatives from Aalo Atomics and Idaho National Laboratory (INL) broke ground on Aug. 28 on Aalo-X — the first experimental extra modular nuclear reactor (XMR), according to postregister.com.

The facility will be next to INL’s Materials and Fuels Complex. Construction is expected to be completed, with the reactor capable of producing power, by July 4, 2026.

The groundbreaking occurred just two weeks after Aalo was picked by the U.S. Department of Energy (DOE) to participate in President Trump’s Nuclear Reactor Pilot Program, postregister.com reported.

Aalo co-founder and CEO Matt Loszak discussed his ambitions for the U.S. nuclear energy industry in an Aalo press release.

“Our selection for the Nuclear Reactor Pilot Program is a significant catalyst for achieving our goal of going from ‘founding to fission’ in less than three years — a feat many deemed impossible just a year ago,” said Loszak. “This milestone, groundbreaking event is a testament to the potential that can be unlocked when public entities and private companies partner together in the critical interest of the nation. This is a pivotal time for the U.S. nuclear energy industry, and we are incredibly proud to be at the

forefront.”

According to the release, the DOE announced the Reactor Pilot Program in June 2025, following the President’s Executive Order 14301, which reforms reactor testing. The program’s goal is to expedite the testing of advanced reactor

designs that the department will authorize at sites outside the national laboratories.

Aalo was chosen for the program after a competitive Request for Applications (RFA) process. It aims to be the first recipient to begin construction on a test facility, postregister.com reported.

INL Director John Wagner, who spoke at the groundbreaking, noted the similar interests between the two entities.

“Today’s groundbreaking symbolizes the progress that can be achieved when innovation, vision and national purpose come together,” said Wagner. “At Idaho National Laboratory, we are proud to support the Department of Energy’s efforts to accelerate advanced nuclear technologies that strengthen America’s energy security, provide reliable power, and inspire the next generation of innovators. Projects like AaloX reflect the promise of nuclear energy to meet our nation’s historic demand growth and help enable a more prosperous future for our nation.

Aalo, which was founded in 2023, will build the Aalo-X XMR at its pilot factory in Austin, Texas, according to postregister.com. It will then be transported and installed at INL.

The device is the Aalo Pod precursor — which is expected to provide commercial power in 2029, according to the release.

Aalo has raised more than $136 million from investors, according to Interesting Engineering. Those include Valor Equity Partners, NRG Energy, Hitachi Ventures, among others.

GUARD from page 1

“It's right next to the fairgrounds, and the hope is that when they have events at the Fairground Event Center, we would kind of be overflow for additional classroom space and different things like that, so they could walk across the street and use our facility. Also, we rent out the facilities and people can use them for weddings and different activities. Because it has a big drill floor in the middle of it, sometimes there are local businesses that need a bigger space to train their staff.”

The second building is a 20,000-sq.-ft. storage facility for the M777 howitzers with pass-through bay doors, “allowing the field artillery soldiers to safely store and protect their equipment,” Bomar said.

Along with the DOD security requirements, the facility also was designed to LEED Silver standards and includes polished concrete floors and rooftop solar panels.

While the ATFP requirements added design considerations, Burns said they haven’t had any real challenges so far.

“We’re just starting ... there's always unforeseen conditions, she said. “We haven’t had anything come up yet. The design team and the contractor and all of us have all worked really well together and come up with good solutions for things, and everything has gone well. Some of the ATFP and additional things we have to do for that are just different.

“Those are things that not every contractor and designer are used to having. But we as a team have come together and worked really well together and made sure that we've met all those requirements.” CEG

(All photos courtesy of the Oregon National Guard.)