Murray Specialty Services has a fleet of six barges of varying thickness and buoyancy that John Murray has modified extensively.

On the eastern edge of Lake Winnipesaukee, in the town of Wolfeboro, N.H., the work of building and maintaining shoreline property is an everyday challenge.

With more than 300 islands, rising property values and complex state regulations governing docks, boathouses and breakwaters, there are only a handful of contractors who can handle the specialized work required on the state’s largest and most iconic lake.

Among them is John Murray, owner of Murray Specialty

Services, a marine contracting firm that has quickly built a reputation for taking on some of the lake’s most demanding projects. From stabilizing homes sliding down embankments to constructing multi-slip dock systems and transporting concrete trucks across the ice in winter, Murray has developed a business that combines engineering know-how with hands-on fabrication skills.

The newest skyscraper changing Boston’s skyline is finally complete after decades of planning and construction.

South Station Tower, a 51-story office and residential building constructed on top of the Massachusetts Bay Transportation Authority’s (MBTA) South Station, unveiled the project Sept. 24.

Rising 690 ft. above the city, the tower includes 166 condominiums on the top 16

floors, 680,000 sq. ft. of office space, an 11th-floor rooftop “skypark” and an expansion of the South Station bus terminal.

“Every great city tells a unique story through its skyline. Today, Boston adds a

see TOWER page 22

The newest skyscraper changing Boston’s

is finally complete after decades of

and

Mauldin's known workhorse model 1860 paver. 12" augers over the main screed new on the "B" model. Sonic Controlled Variable Speed Four Auger Material Feed System for the Most Consistent Head of Material. Dual Operator’s Stations with Full Machine Controls, Including Dual Digital Gauge Displays. Heaviest in Class Screed for Industry’s Best Compaction. 110 HP Tier IV Final Turbocharged Cummins Diesel engine. 9.5 Ton. Hopper Capacity. Pre-Wired for Screed Automation. Two-Speed Polyurethane Crawler Track Drive System. Seamless Paving up to 16.

Mauldin 1560 Tracked Asphalt Paver in excellent condition. This machine features an electric heated screed, auto feed sensors, and solid tracks. Perfect for residential, commercial, or municipal paving work. A late-model paver ready to work immediately.

Mauldin Pavers

Volvo DD30B asphalt roller is known for efficiency, designed to increase performance and reduce fuel consumption on small scale compaction projects. Engine meets Tier 4 Final emissions regulations. Experience high performance machine and enhanced productivity with Volvo.

Operating weight (with ROPS, fully ballasted) 6,839

in Configuration Vibratory.

DD25B is an efficient machine designed to increase performance and reduce fuel consumption on small scale compaction projects. Featuring Volvo D1.7A engine, machine qualifies for Tier 4 Final emissions regulations without adding an exhaust after-treatment system. Experience increased machine performance and enhanced productivity with Volvo.

DD25B Operating weight (with ROPS, fully ballasted) 5,545 lbs Drum or rolling width 39.4 in Rated engine power 24.8 hp Vibration frequency 3,300/4,000 v/min Amplitude 0.021 in Overall length 8′ 4″ ft in Overall width 3′ 6.9″ ft in Overall height 116.3 in Configuration Vibratory.

Perfect machine for the smaller project. DD15 is created for the day laborer that is looking to save all around. A luxury roller that comes with undoubtable service Equipped with Kubota D722. Weight 1.53 t Transport length 2.03 m Transport width 1.02 m Transport height 2.24 m Engine manuf. Kubota Engine type D722B Engine power 13 kW Emission level Tier 4.

By Ken Liebeskind CEG CORRESPONDENT

A major bridge construction project led by MassDOT began in December 2023 to replace or rehabilitate eight bridges at the I90/I-95 interchange in Newton and Weston. The work includes the replacement of the Ramps A/B bridges over the Charles River, Ramp G over the Hultman Aqueduct, Ramp G over I-90 and the mainline I-90 bridges over both I-95 and the Charles River.

SPS-Walsh Joint Venture, based in Salisbury, Mass., is the lead contractor for the $386.6 million project, which is fully funded through Non-Federal Aid/Metropolitan Highway System funding.

This design-build project involves the replacement of the 1,020-ft.-long, four-span I-90 bridge over I-95 and the Charles River, as well as three additional ramp bridges. It also includes two superstructure replacements — one of which is the I-90 bridge over the MBTA/CSX rail — and rehabilitation of three other bridges.

The SPS-Walsh Joint Venture crews continue I-90 mainline Stage 1 bridge construction, according to SPS New England. Pier cofferdam construction in the Charles River has been completed, and crews are progressing with driven pile installation, tremie seal placement and the construction of concrete pile caps and lower columns at Pier 2. This

phase included the placement of 400 cubic yds. of concrete for the Pier 2 bridge foundation elements.

Stage 1 progress continues with mainline bridge pier construction, abutment foundation pile driving, drilled micropile installation and MSE wall construction — all in preparation for upcoming structural steel

erection. A second access trestle also is being built across the Charles River. At the MBTA bridge, crews are extending the piers in preparation for superstructure replacement. Ramp A/B bridge raised median demolition also has begun in advance of an upcoming traffic phase shift.

Contract equipment in use by SPS New England includes sectional barges, work skiffs and self-propelled work platforms, as well as a range of general construction equipment such as tractors with three-point attachments, excavators, wheel loaders, skid steers with attachments and compact track loaders.

The project is expected to reach substantial completion by 2028.

Once the project has been completed, the location will feature improved bridge and roadway safety, increased vertical clearance for freight movements, improved seismic resiliency and reduced noise impacts through the installation of noise walls along I-90 in Auburndale to the project’s eastern limit of work, according to Mass.gov. CEG (MassDOT photo)

A local developer hopes to bring commercial opportunities to the corner of Bridgeport Avenue and Constitution Boulevard West in Shelton, Conn., a site that is presently under construction.

The developer, 22-24 Constitutional Blvd. LLC, seeks a zone change on 4 acres fronting Bridgeport Avenue, the under-construction Constitution Boulevard West and Blacks Hill Road, to a fully Commercial CB-2 site.

Currently, the vacant property is split zoned into CB-2, Residence R-1 District and Restricted Business District, the Shelton Herald reported Oct. 3.

The development’s plans have been filed with the Shelton Planning and Zoning Commission, which will open a public hearing at a future meeting.

“The site is currently the ‘missing tooth’ of the commercial corridor as a gap between the abutting commercial zones,” the application read. “The site’s current zoning stands out as one of the few breaks in the entire Bridgeport Avenue commercial corridor. This application rectifies this mistake while the physical features of the site, including the abutting roadways and wetlands, will ensure appropriate buffering to the surrounding area.”

The registered agent for 22-24 Constitutional Blvd. LLC, is Fairfield, Conn., developer Alfonso Cammarota Jr.

The CB-2 requires a minimum lot area of 15,000 sq. ft. and 80 ft. or more due to its location on a public street. The property in question satisfies both requirements, with nearly 174,000 sq. ft. of lot size and 338 ft. fronting Bridgeport Avenue.

The application further states that wetlands exist between the area for commercial development and nearby residential homes.

Work on Constitution Boulevard West began again in earnest this past summer when the city finally received the required state permits.

John J. Brennan Construction Co., located in Shelton, is the contractor charged with completing the work.

Phase one of the development project, which includes construction from Bridgeport Avenue to the nearly 76 acres known as the Mas property, is expected to be completed by next spring 2026. Work on phase two — the internal roads within that property — is continuing.

cials have already agreed to sell portions of the land to various companies, including Bigelow Tea.

The first two phases of road development also are a step toward connecting Shelton Avenue to Connecticut Highway 8, which is expected to relieve traffic downtown and in Huntington Center.

The city initially received $5 million from the state to complete the project’s first phase, which calls for the connection from Bridgeport Avenue, including the lowering of Cots Street by eight to 10 ft. to meet the avenue, to the Mas property.

Construction first got under way in 2023, and Bridgeport Avenue was roughed out when work came to a halt that same year as the city waited for state officials in Hartford to sign off on the necessary permits.

The Constitution Boulevard West extension, until recently only a concept, will allow development of the landlocked Mas property, the Herald noted. Shelton municipal offi-

“It has been a nightmare,” Mayor Mark Lauretti told the Shelton news source in July. Necessary state permits entered an administrative logjam, he explained, and it was during this forced hiatus that the city learned it had to buy the state right of way along Bridgeport Avenue where the city was to break through to connect the roadway.

As a result, Shelton purchased the strip of land, which was leveled, for $876,000.

The city also received a $1.6 million state grant to pay for the completion of the road work inside the Mas property, part of the project’s second phase.

Lauretti believes the $6.6 million in total state grants should cover most — if not all — of the proposed road construction. He told the Herald that he plans to seek more state funding for this major development project as well.

He began the push to develop the property four years ago and expects it to bring longterm financial benefits to the city.

“The initial benefit is the sale of the land,” Lauretti said. “We paid $600,000 [in 1996] for the land, and it is probably going to bring in $6 million.”

But the land’s eventual sale price is a minor part of the picture, he continued, adding that the more important thing is the tax revenue that the development will bring in over the next 40 years.

While the city bought the Mas property from the Federal Deposit Insurance Corp. (FDIC) almost three decades ago, it was not until about three years ago that Lauretti presented a vision to the Shelton Planning and Zoning Commission for developing the site into a manufacturing hub for the region.

The price for the land ranges from $85,000 to $125,000 per acre to various groups for use in industrial and retail capacities, he said.

Equipment East has = job the compact machine to ell do w one.

ork modes pl and w us one of the highest

The Newport City Council in Rhode Island approved a contract amendment recently that guarantees a $5.5 million maximum construction price for state-funded renovations to the Florence Gray Center.

The construction contract with Ahlborg Construction Corp. of Warwick, R.I., was initially awarded by the council in April when it approved a roughly $38,000 expense for pre-design construction manager services. Those services included Ahlborg working with the city, its partners on the project and construction consultants to draft building plans that would meet the $5.5 million figure.

A mid-September council vote amended the contract to give Newport and its partners some legal standing if the total is exceeded, even though the maximum price amount is subject to project change orders and other factors.

About $7.5 million has been awarded to the city through the Rhode Island Pandemic Recovery Office to upgrade the building and have it designated as a municipal learning center to support educational, health and workforce programming.

Renovations are slated primarily for the interior of the building, particularly in its

Gallagher wing, Newport This Week reported Oct. 2.

The city is the fiscal agent for the project, giving it the power to approve related contracts. The building effort is grant-funded, and construction requires city funds.

Newport Councilor David Carlin, who cast the sole vote opposing the measure, took issue with the April vote to approve funding for pre-design services. That earlier motion made clear that the $38,000 expenditure was awarded to craft a maximum price agreement for the project, though Carlin asked why the city was not presented with other bids at the time.

“You’re asking this council to approve a $5.5 million request, and I have nothing regarding who those other bidders were or what their bids were,” Carlin said.

In February, the city formed a selection committee consisting of Teresa Crean, Newport’s director of the Department of Resilience and Sustainability; Rhonda Mitchell, of the Newport Housing Authority; construction consultants and representatives from the Boys and Girls Clubs of Newport County; and the town of Middletown.

At that time, Newport and its housing authority advertised a request for proposals

The Newport City Council approved a contract amendment recently that guarantees a $5.5 million maximum construction price for state-funded renovations to the Florence Gray Center.

for a construction manager. Four bids were received, according to project officials. They were scored by members of the committee on a system that factored in technical and cost components. In the end, they selected Ahlborg, according to Manny Ferreira, the city’s contracted project manager for the renovations.

In 2023, the Newport Housing Authority and the local Boys and Girls Clubs signed on as partners to the project. The same year, Middletown and Newport inked an agreement to combine grant allocations for the

project and ensure that the learning center be used by residents in both communities.

Earlier this year, the Newport City Council passed a resolution barring City Manager Colin Kennedy from signing any contracts related to the project above $250,000 without the council’s approval.

At the city level, the project falls under the purview of the Department of Resilience and Sustainability. Crean added that the city also is in communication with the state’s Pandemic Recovery Office and Lori Turner, Middletown’s Healthy Communities coordinator, who is spearheading the project for that town.

Approximately 20 similar projects are happening in Rhode Island as the state implements a larger role for municipalities in public education in the post-pandemic landscape. Two years ago, Gov. Dan McKee kicked off his Learn365 initiative at the Boys and Girls Clubs of Newport County with the goal of improving academic outcomes and boost attendance to higher levels than those in Massachusetts.

Newport This Week noted that the Florence Gray Center project must have a certificate of occupancy by October 2026 to meet its grant requirements.

New Hampshire officials are gathering public input on the state’s next 10-year transportation improvement plan, which outlines more than $4.5 billion in roadwork projects.

Residents of the Monadnock region of southwestern New Hampshire have been given three opportunities in October to weigh in on local projects included in the plan.

New Hampshire Executive Councilor David Wheeler, who represents District 5 (which covers most of the Monadnock region), hosted a hearing on Oct. 8 at the Hillsborough Fire Station and plans to hold another at the Jaffrey Fire Station on Oct. 15. His colleague, Executive Councilor Karen Liot Hill, also has scheduled a meeting at the Peterborough Town Library on Oct. 22.

Among the key projects open for comment is the long-delayed bridge replacement at U.S. Highway 202 and N.H. Highway 123 over the Contoocook River in Peterborough. The upgrade is budgeted at nearly $24.5 million, with construction set to begin in 2028. The town also is due to receive a stone box rehabilitation or replacement under U.S. 202 at a cost of $2.5 million.

Overall, the Monadnock region is set to receive roughly $65 million over the next decade, the Ledger-Transcript in Peterborough reported Oct. 6.

Many roadwork projects across New Hampshire have been either partially or entirely removed from the plan, Liot Hill said, and no new projects were accepted this year due to a $400 million shortfall in state and federal funds. The Monadnock area made it out relatively unscathed as no current projects were stripped.

State leaders are exploring a road toll and gas tax hike to ease the deficit.

Tolls in New Hampshire are the lowest cost per mile in the country, a state transportation official said at a previous hearing, and have not been raised since 2007. Increasing them would require approval by the executive council.

The state’s gas tax — currently set at 23.83 cents per gallon of fuel — has not risen since 2014.

“The cost of projects has only increased in that time and, in recent years, very significantly,” Liot Hill told the Ledger-Transcript. “The funds that were allocated are not … completing as much of the work as they were originally intended to do, and so that’s why we’re in the deficit and that’s why we’re interested to hear what people think

about how to close that deficit.”

Liot Hill also said New Hampshire is on the hook for millions of dollars each year to pay loans it took out for transportation upgrades years ago. That, combined with decades without fee increases and skyrocketing construction costs, has put the state government in its current predicament.

After soliciting feedback, the state Department of Transportation (NHDOT) will submit the 10-year plan to the Legislature for approval next year. Following that, it will go into effect in 2027.

Here are the Monadnock-area projects included in the state’s 10-year plan:

• Hillsborough is to see bridge work on N.H. 149 over the Contoocook River, a project worth $5.7 million, in addition to a $2.1 million effort to replace the community’s Bog Road bridge over Sand Brook.

• Four projects totaling $4.8 million are on the drawing board for the town of Antrim and its surrounding villages, including road work on N.H. 9 in several areas throughout Antrim, Hillsborough and Stoddard. In addition, crews will work on a $1.5 million project set for Antrim’s Red List bridge on N.H. Route 31 over Steel Pond Brook; build a $2.1 million bridge replacement on Liberty

Farm Road over North Branch River; and make $1.9 million in safety improvements to crosswalks and sidewalks on U.S. 202 and N.H. 31.

• In Greenfield, a $1.5 million bridge replacement on School House Road over a stream is slated to be built.

• Another Red List bridge carrying railroad tracks over Glass Factory Road will be erected in Lyndeborough at a cost of $365,500.

• Safety improvements worth $9.1 million to N.H. 101 in Wilton, Milford, Amherst and Bedford are scheduled to be made.

• Four additional projects also are proposed for the town of Wilton: The replacement of a small bridge to carry Old County Farm Road over Blood Brook ($174,204); a pair of new pedestrian bridges over Stony Brook at the Wilton Riverwalk ($1 million) and across the Souhegan River ($1.1 million), the latter of which will connect Riverside Way and Howard Street; and a $2 million bridge replacement on Temple Road over Blood Brook.

• In New Ipswich, the state wants to spend $2 million to replace the Taylor Road bridge over the West Brook stretch of the Souhegan River.

• Bridge work totaling $2.6 million also is planned on U.S. 202 over Mountain Brook and Contoocook River in Jaffrey.

Connecticut Gov. Ned Lamont said Sept. 26, 2025, that his administration is making a $50.5 million investment in public infrastructure and facilities in downtown New Haven that are targeted toward propelling growth in the life sciences industry and the emerging sector of quantum technologies, setting the stage for a new generation of research, innovation and business and job growth in these sectors.

The investments are included as part of the first grant award made under the state’s newly launched Connecticut Innovation Clusters Program, which is administered by the state’s Department of Economic and Community Development (DECD).

“Every day in downtown New Haven, workers are developing the cutting-edge research, technologies and products that are changing the world and propelling Connecticut forward as a leader in the fields of life sciences and quantum technologies,” Lamont said in a news release. “We want to build on this foundation, encourage new growth and further cement New Haven’s reputation as a groundbreaker in these sectors. These targeted investments in the downtown neighborhood’s public infrastructure and facilities will enable us to further partner with these businesses and accelerate job growth and more opportunities here in Connecticut.”

The funding available for this wide-ranging project will seed the next era of growth in New Haven’s downtown innovation district, an existing cluster of world-class expertise in the life sciences that will expand and add new strength in quantum technologies and cross-industry collaborations.

Its components will include:

• The New Haven Innovation Center, a $1.3 million investment to create a 4,500sq.-ft. “early start” activation space within the downtown area at the 101 College Street development site.

• QuantumCT, a newly established organization that serves as the statewide coordinating body for quantum infrastructure, research, testbed deployment and commercialization. Connecticut will provide $10 million in critical financial support to this nonprofit, convening industry, academia and startups.

• Financing $17.5 million for public infrastructure such as pedestrian-first streetscapes, stormwater management and climate-resilient mobility necessary to support Parcel B, a development that was created following the removal of the Conn. 34 expressway located east of 101 College Street.

• Gap financing totaling $14.5 million to facilitate the development of more than 200,000 sq. ft. of Parcel B, owned by the

City of New Haven; and 265 South Orange Street, the Square 10 site (formally the home of the New Haven Coliseum) where a more than 277,000-sq.-ft. life sciences building is planned.

• The Arch Street Bridge and Church Street Promenade, a $4.2 million multimodal pedestrian corridor connecting Union Station to both New Haven’s downtown and Hill neighborhoods via a signature pedestrian arc bridge, linear park and pedestrian/bike promenade.

• BioCT, the voice of Connecticut’s bioscience industry, will receive $3 million to activate the cluster with programming designed to bring together civic, academic and business partners within the heart of the district and from across the state.

“The strategic value of this investment is enormous, as we are essentially doubling down on areas where Connecticut already has competitive advantages,” said Daniel O’Keefe, DECD commissioner and the state’s chief innovation officer. “Supercharging our life sciences and innovation capacity will have far-reaching positive impacts on the state’s ability to attract new talent, investment and companies, as well as strengthen our overall competitiveness.”

which could bring up to $160 million in additional federal investment to the state.

Besides operating its shared-use test-bed facility, QuantumCT also will support venture development and advance workforce development initiatives.

“Being selected for the Innovation Clusters Program affirms the central role QuantumCT will play in shaping Connecticut’s future economy,” noted QuantumCT CEO Albert M. Green in Lamont’s news release. “By bringing together universities, companies and investors, we are creating the infrastructure, talent pipeline and partnerships needed to make Connecticut the place where next-generation industries take root and grow.”

Representing 300 member organizations, BioCT’s mission is to foster Connecticut’s burgeoning life sciences ecosystem and attract entrepreneurs, companies and jobs to the state, according to BioCT CEO Jodie Gillon.

“Our industry is a driving force in the state’s economic development, with New Haven at its center,” Gillon said. “The innovation cluster further catalyzes a critical mass, marking a pivotal moment for state investment.”

Yale University and UConn are central to the success of the cluster.

QuantumCT is a newly established nonprofit that serves as the statewide coordinating body for quantum infrastructure, research and commercialization.

The organization is the result of a landmark partnership between Yale, located in New Haven, and the University of Connecticut that was launched in response to the National Science Foundation’s Regional Innovation Engines program,

While Yale brings top research capabilities in quantum science and biomedical innovation, as well as strengths in accelerating entrepreneurship through Yale Ventures, UConn provides expertise in advanced manufacturing, engineering and translational research, and is a key partner in workforce development and commercialization efforts.

Together, these institutions will help drive the cluster’s mission to translate research into scalable businesses and jobs.

The Quantum and Bioscience Cluster is a

“We want to build on this foundation, encourage new growth and further cement New Haven’s reputation as a groundbreaker in these sectors.”

Ned Lamont Connecticut Governor

coalition of stakeholders that includes QuantumCT, Yale University, UConn, L&G, Winstanley Enterprises, BioCT and the City of New Haven. Other higher education institutions in the region are also expected to play an active role in the cluster moving forward.

This industry cluster award will reinforce and complement several other state investments in the area, including:

• Brownfield redevelopment grants to clean up and spur projects at the Square 10 sites;

• investment in 101 College Street;

• housing investments at the Orange and State intersection, State Street and near Union Station;

• the CT Community Challenge pedestrian improvements along the State Street corridor;

• community Investment Fund 2030 and Connecticut Department of Housing support for the State Street location of the Downtown Evening Soup Kitchen and colocated community health services from the Cornell Scott Hill Health Center; and

• the Connecticut Department of Transportation redevelopment of the Union Station parking lot into a vibrant, mixed-use development anchored by two 16-story towers, designed to bring new housing, retail and jobs.

“New Haven is a growing national hub for life sciences and an innovation ecosystem poised to leverage the promise of quantum computing and technology,” Mayor Justin Elicker said. “This $50.5 million investment by the state will help further catalyze New Haven and Connecticut’s economic growth and future in these industries, creating new businesses, new jobs and new opportunities for our residents and our city while also growing our tax base.

“With our new BioCity career pathways program, we’re also already working to create the pipeline of New Haven students who will enter these fields and take advantage of these future job opportunities in their home town.”

The Connecticut Innovation Clusters Program is a $100 million initiative to support the continued growth of critical sectors of the state’s economy, including biotechnology, financial and insurance technology and advanced manufacturing in support of the national defense.

The program leverages private and public investment to support the application of next-generation technologies, such as artificial intelligence and quantum computing, to accelerate innovation in the state’s highgrowth industries.

• Local Ownership with flexible approach • Trained staff for repairs and maintenance

• Dedicated Parts personnel on site • Focused on the Heavy Construction Industry • Providing the BEST support equipment available • Experienced outside sales staff

Murray was raised in Wolfeboro, where his family still keeps a home his great-grandfather built in the 1920s on Lake Wentworth, a smaller lake near Winnipesaukee. He attended Brewster Academy, which sits right on the shoreline, and grew up around water — though not around heavy equipment.

In fact, his early plans were far from construction.

“I was going to go to school for biochemistry,” he said. “I took AP calculus, AP physics, biology. But it would have ended up being too boring.”

Instead, Murray discovered a talent for mechanical work. He trained in automotive repair in Pennsylvania and returned home to run his own shop in Ossipee for nearly a decade. There, he specialized in repair, restoration and fabrication.

“I liked working with my hands and solving problems,” he said.

That background eventually brought him to Beckwith Builders, where he was introduced to marine contracting. The company performed shoreline and barge work similar to what he does now.

“I ran the marine operations, ran the barges,” Murray said. When the company began to scale back, he saw his opening.

“They were semi-retiring, and that’s when I started doing it on my own.”

Murray Specialty Services’ scope of work is broad.

“Basically, anything to do with marine construction,” Murray said.

That includes docks, breakwaters, shoreline stabilization, boathouses, material shuttling and even house stabilization

on steep slopes.

Some projects are straightforward dock jobs. Others are massive undertakings. One client purchased an entire island, and Murray was hired to handle the shoreline grading, dock construction and site preparation for a new home, kitchen building and pickleball court. On another job, he stabilized a hillside home with ground screws while simultaneously repairing woodwork.

In winter, when the lake freezes, the work doesn’t stop. Murray uses barges to break ice and move equipment.

“Sometimes when we’re framing a dock, we’ll walk across the ice,” he said.

It’s demanding work that requires equipment built to handle both summer waves and winter ice.

Regulations on Winnipesaukee are strict. Breakwaters, for example, are only permitted where there is at least two miles of prevailing wind fetch to justify the need. Sometimes, contractors must conduct wave studies, measuring and photographing wave heights to prove the case.

Boathouse rules have shifted over time, as well. For years, state requirements forced builders to dig boathouses into the

see MURRAY page 18

MURRAY from page 14

shoreline, a practice Murray opposed because of the disruption it caused. Starting next year, regulations will once again allow over-the-water boathouses, built on cribs or pilings.

“It makes much more sense,” Murray said. “We’ll be doing more of them in the future.”

Breakwaters also require a gap to shore to prevent sediment build-up.

“If you don’t leave that gap, it creates a low-pressure area and everything drops out — sand, particulates — and you end up having to dredge more often,” Murray said.

Despite the size of his projects, Murray Specialty Services is a lean operation.

“There’s only two of us that are actually employees,” Murray said.

He supplements with subcontractors, including a carpenter crew and a landscape crew, as needed.

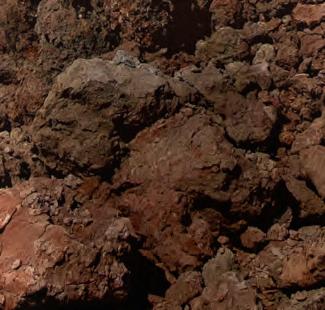

A DEVELON DX140 excavator purchased from Equipment East harvests rocks from the bottom of Lake Winnipesaukee from one of Murray Specialty Service’s custom-built barges.

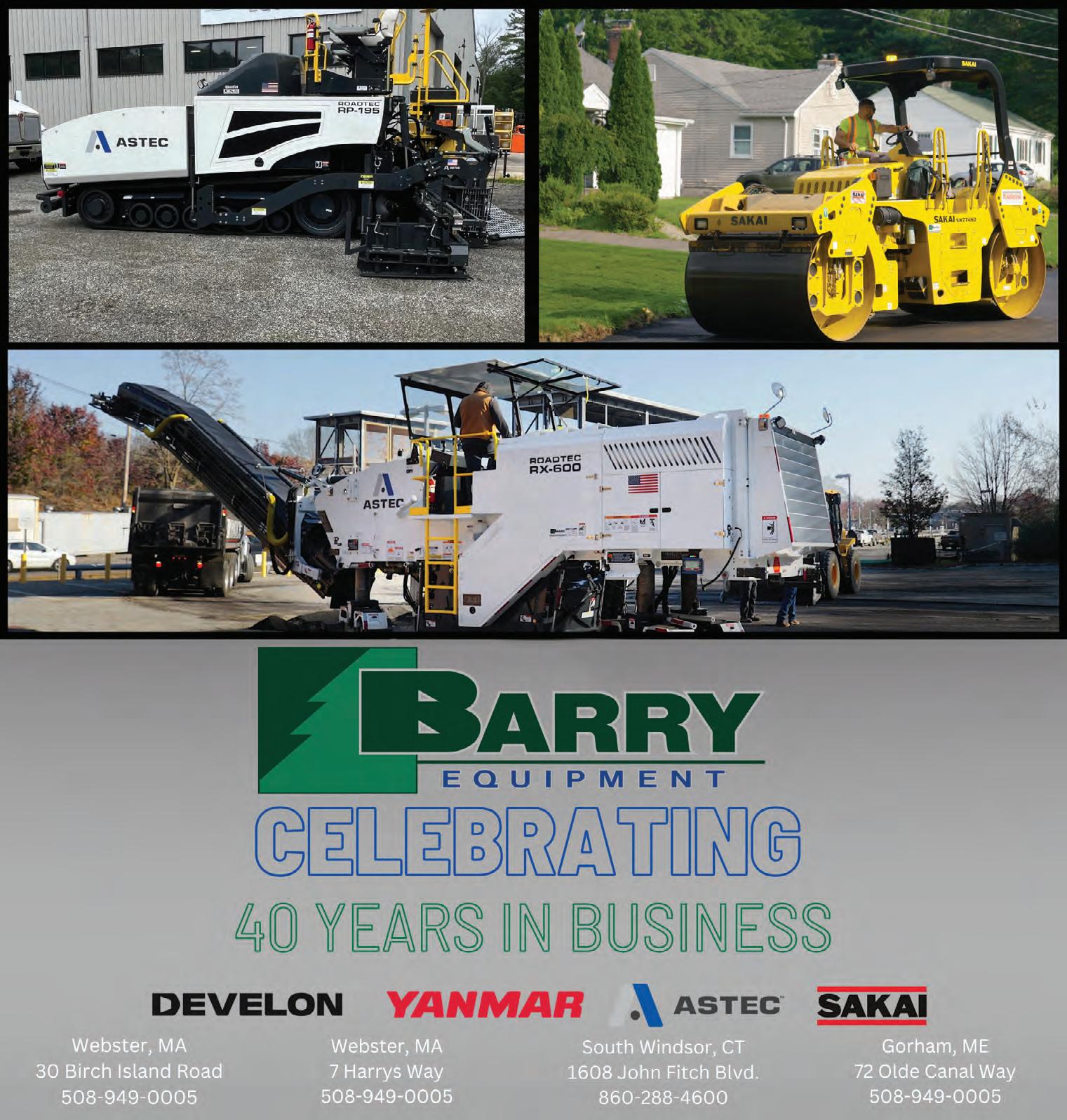

The company’s fleet includes six barges of varying thickness and buoyancy, all steel sectional platforms that Murray has modified extensively. His fabrication background comes through in custom ramps, adjustable engine mounts and other adaptations that allow his barges to carry everything from mini-excavators to tri-axle dump trucks and even concrete trucks.

That fleet gives Murray flexibility.

“Every barge is different,” he said. “We don’t run them all at once, but it means I always have the right setup for the job.”

At the center of all this work is a trio of DEVELON excavators — a DX55, DX89 and DX140 — all purchased from Equipment East LLC with the guidance of Territory Manager Scott Beaulac.

For Murray, selecting the right excavators wasn’t just about brand preference; it was about finding machines that could do heavy work while still fitting within the unique limitations of marine construction.

“You can’t just drop a 30-ton machine on a barge and hope for the best,” he said. “You need the right size classes.”

• The DX55 runs on his 3-ft.-thick barge and is used for tight dock framing and smaller projects.

• The DX89 is the mid-size workhorse, versatile enough for shoreline grading or shuttle-barge projects.

• The DX140 is the heavy hitter, run on his 5-ft. barge, capable of carrying multiple dump trucks and handling major riprap placement.

“The different sizes mean I’ve always got the right tool,” Murray said. “That’s why I went with the DEVELON lineup.”

Murray credits Beaulac as a major factor in his equipment decisions.

“Scott’s been with me from the start,” he said. “He didn’t just sell me machines — he helped me figure out what would work on the barges, how to balance weight and buoyancy and how to make it all practical.”

Beaulac coordinated delivery and transport logistics, making sure the machines reached lake access points and could be loaded onto barges without incident. Since then, he’s been the first call whenever questions or service needs come up.

“Every time I call, Scott picks up,” Murray said. “It doesn’t matter if it’s a part, a service call or just something I need to ask about settings on a machine. He’s there.”

Marine construction doesn’t leave much room for downtime. If a machine breaks down on an island job in the middle of winter, work can grind to a halt. That’s where Equipment East’s service has proven invaluable.

“We run these machines hard,” Murray said. “If something breaks in February, I can’t afford to wait weeks. Equipment East gets me what I need fast. Scott makes sure it happens.”

Technicians have been dispatched lakeside for onsite repairs, and preventive maintenance schedules have been adjusted to account for the unusual stresses of barge work. For Murray, the support after the sale is as important as the machines themselves.

“The difference is really in the backing,” he said.

For all the engineering, fabrication and regulatory hurdles, Murray is clear about what makes his company run.

“The machines are the centerpiece of what we do,” he said. “We can have the barges, we can have the crew, but without the excavators, we can’t move material, we can’t place stone, we can’t build docks. Everything depends on having the right machines.”

And for him, the right machines are DEVELON.

“They’ve got the hydraulic power I need, but they’re efficient. The fuel burn is lower than other brands I’ve used. And with Equipment East behind them, I know I’ve got the support to keep going.”

As Winnipesaukee continues to grow and regulations evolve, Murray Specialty Services is poised to stay busy. Rising property values mean more redevelopment, more shoreline work and more demand for contractors who can navigate both the water and the permitting process.

For Murray, that means more long days on barges, more winters breaking ice and more reliance on the machines that have become the backbone of his business.

“We build on water, with waves, with ice, with barges moving under us,” he said. “It’s not easy work. But with the right machines and the right support, it’s possible.” CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

“We run these machines hard,” John Murray said. “If something breaks in February, I can’t afford to wait weeks. Equipment East gets me what I need fast. Scott makes sure it happens.”

A

Push

... more material with the new Hyundai HD100 crawler dozer's best-inclass power-to-weight ratio.

See ...more than ever with the unobstructed view to the blade.

Engage

...more accurately and more productively with standard 2D or optional 3D machine guidance.

Doze

...with confidence, knowing your new 115 hp Hyundai crawler dozer delivers the quality and value you expect from Hyundai, with the peace of mind that comes with our industry-leading warranty.

No wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, na.hd-hyundaice.com.

“This tower is so much more than just steel, glass and concrete. It’s a symbol of vision, innovation and determination.”

powerful new chapter,” announced John Fish, CEO of Boston-based Suffolk Construction, at an unveiling ceremony on the night of Sept. 25. “This tower is so much more than just steel, glass and concrete. It’s a symbol of vision, innovation and determination.”

MassLive.com reported that planning for the $1.5 billion building project first began 27 years ago, when Hines, a Houston-based developer; and its architectural partner in the venture, Pelli Clarke & Partners in New Haven, Conn., signed on.

From there, though, the effort faced repeated delays, due both to financial circumstances such as the 2008 Great Recession and governmental roadblocks. For instance, the development team of Hines needed sign-offs from multiple government agencies — from working with the MBTA to reshape the train and bus station to negotiating with the Federal Aviation Administration (FAA) over the height of the building.

Site work finally began in 2018, followed by a groundbreaking in 2020. However, just a few weeks later the arrival of the COVID19 pandemic caused further delays, although construction work never completely halted during that time, according to MassLive.com.

“When a project spans three decades, it has the opportunity and the obligation to be better, frankly, to absorb, adjust and reflect the best of evolving societal issues,” Fred Clarke, partner at Pelli Clarke & Partners, told the Massachusetts news source.

“Sometimes when buildings mature, it takes a while to get done. They tend to get denatured [and] they tend to lose their soul and their vibrancy. This project got better and better and better over time.”

On its website, Pelli Clarke & Partners

noted that the new tower features “a faceted glass form [that], while contemporary, is sculpted to be sympathetic in massing to the historic South Station headhouse at its base.”

The condos, which start at a sale price of $1.3 million, are managed by the luxury hotel brand Ritz-Carlton. The first residents are expected to begin moving in later this fall.

To date, three office tenants have been announced: Citadel, a hedge fund management firm; FM, a Rhode Island property insurer; and the law firm of Jones Day.

Since the pandemic, commercial real estate and office buildings in particular have struggled with vacancies as office workers continue to work from home. As a result, Boston’s downtown felt the effects and office vacancies led to pressure on serviceoriented businesses in the areas that usually relied on foot traffic from people coming into various sections of the city during the day.

However, over the past year, this trend has begun to reverse, MassLive.com noted, leading some to become more optimistic.

Boston Mayor Michelle Wu said at the Sept. 25 event that nearly 20 companies have moved into the city’s downtown since the pandemic subsided, representing approximately 9,000 new jobs over the last two and a half years, and dozens of new small businesses have helped cut the retail vacancy rate nearly in half.

Wu called South Station Tower “a crucial piece in the puzzle of a revitalized, prosperous post-pandemic downtown.”

“South Station Tower is going to bring even more families, more businesses and more visitors downtown,” she said. “This building is a testament to our city’s mission, making Boston home for everyone.”