Crews Pave Last Unpaved Section of Mount Washington Auto Road

The asphalt cooled within a few hours due to the cooler temperatures and was ready to take on traffic.

By Irwin Rapoport

CEG CORRESPONDENT

By Irwin Rapoport

CEG CORRESPONDENT

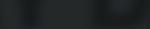

The last unpaved section of the 7.2-mi. Mount Washington Auto Road — two narrow dirt/gravel lanes, one in each direction for 6/10 of a mi. — which takes tourists, various officials and scientists to the summit of Mount Washington (6,288.2 ft.) in New Hampshire, was paved last spring.

This news of the paving was announced when the Mount Washington Auto Road, the private family-owned firm that owns and operates the road, tweeted: “Thank you to Central Paving crews out of Jefferson, N.H., and especially thanks to their drivers who had to drive the dumptrucks *backwards* up the 5-mile stretch to access this section of road. History in the making.”

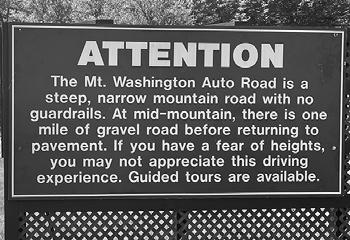

The road, which was established in 1861 at 6,288 ft. above sea level, is narrow and does not have a shoulder or guardrail. Rocks have been placed along the edge of the road to serve as a safety barrier, but there are a few areas where a

misstep would plunge motorists down a sheer drop.

The mountain is the highest peak in the northeastern United States and is notorious for its erratic weather. On the afternoon of April 12, 1934, the Mount Washington Observatory recorded a windspeed of 231 miles per hour at the summit, the world record from 1934 until 1996. Mount Washington still holds the record for highest measured wind speed not associated with a tornado or tropical cyclone.

Engaging in roadwork on this peak is not easy.

The Auto Road is the oldest man-made and continuously operating tourist attraction in North America. It was built by hand using shovels and black powder to clear the route and has been owned for generations by the descendants of the Libby family.

“The paving of the section was a huge day for us and a turning point as our goal was always to get this road paved from top to bottom,” said Tobey Reichert, general manager, Mt. Washington Auto Road, Gorham Land Company.

“A fully paved road will give a much better experience for

THE NEW ENGLAND EDITION A Supplement to: Your New England States Connection • Kent Hogeboom 315-866-1423 ® “The Nation’s Best Read Construction Newspaper… Founded in 1957.” October 26 2022 Vol. LX • No. 22

see PAVING page 8 Other Screeners Available EZ-SCREEN www.ez-screen.com 248-745-5828 6’x5’ Double Deck Screenbox Works with 1/2 to 1 3/4 Yd. Loaders, Kohler Diesel, 24” Conveyor Dumps Screened Product 9’ High, Two (2) Year Warranty! $69,900 plus freight. 2022 EZ-Screen 1200XLS Optional 3 Product Conveyor 508-484-5567 (BROCKTON, MA) 978-454-3320 (Dracut, MA) 603-410-5540 (Bow, NH) Authorized Doosan Dealer Visit Equipment East for a demo. CALL 800-367-4937 *On approved credit Financing Available SHIP WITHIN 48 HOURS SAME DAY PARTS AVAILABILITY 24 HOUR TECHNICAL SUPPORT BACKED BY A 75 YEAR BUSINESS State Supplement sponsored by: Affordable Price. Premium Service. Thousands in Service! CALL YOUR ONE-STOP HAMMER SHOP™ TODAY!!! CALL 888-81-GORILLA(46745) • Largest hammer repair facility in North America • Demolition tools and parts for ALL makes and models • Hammer-equipped excavator rentals • Backed by a 75 year family owned business Specializing in: Demolition, Portable Crushing, Material Sales, C & D Recycling, Land Clearing, Heavy Hauling & Trucking Call for Pricing 2208 Plainfield Pike • Johnston, RI 02919 401-943-7100 • Fax: 401-647-5041 www.jrvinagrocorp.com info@jrvinagrocorp.com LEED Accredited in Waste Management www.foleyengines.com • Exhaust Scrubbers • Perkins Engines • Deutz Engines • Twin Disc/Rockford Clutches ‘05 Caterpillar 928G $36,800 Phil (413) 427-7171 Tibbits Equipment Services, Inc. www.tibbitseq.com 802-479-9696 Specialty Construction Equipment SALES • RENTALS • HAMMERS Since 1989 KWIK KLEET® Traction Cleats

Page 2 • October 26, 2022 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide See Our Complete Inventory at www.wiclark.com stk# 26327, 653 Hrs, ROPS, Deutz diesel, single drum vibratory, good rubber, like new condition..............................................$69,500 2018 HAMM H7I2017 LEEBOY 1000G stk# 27357, 6133 Hrs, Deutz, 30-40% U/C, belts @ 40%, machine does have a travel issue, possible circuit board, if jumped machine travels as it should................$19,500 1997 WIRTGEN W2000DC Cat power, 6'5" 15mm drum, rigid conveyor, 60% bottoms, good belting with grade, stk# 26377................................................$125.000 2010 WIRTGEN 2100 2019 JOHN DEERE 333G stk# 27608, 9702 hrs, C/air, aux hyds, JRB coupler, 3.5 yard bucket one owner machine.. $120,000 2015 JOHN DEERE 624K C/air, 120" 6 way blade, Topcon ready, new bottom with 22" pads, recent service.. Very good condition, 4986 hrs, stk# 27607 $125,000 2016 JOHN DEERE 700K 2018 GENESIS GSD170 stk# 27786, mount plate and stiff arm. Minimal usage on grapple. Fits Deere/ Hitachi 850 class excavators..................................$35,000 stk# 27811, Kubota, 8-13' propane screed, new augurs, 70% main, well maintained....$59,500 Call Mark Doty @ 203-823-2316 stk# 24340, 1493 hours, 78” drums, dealer maintained since new, very good condition...... $84,500 2014 HAMM HD+120IVVH stk# 27123, c/air, hi flow hyds, 2 speed, forestry package, new tracks, 84” bucket........ $69,500

OPRROOVVEN U WITH UPTI

SENNEBOGEN, in kee philosophy to maxim created UPTIME Kits

n-house or on the everything you e, maintenance place. They were ime and money. of related service d nuts to O-Rings omes easy with a o order and stock

IME KITS eping with their mize uptime, has Whether you are a service technician i road, these kits have need for every service and PM task in one p created to save you t Managing hundreds o parts, from belts and and special tools bec single part number to

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • October 26, 2022 • Page 3

PTIME

C BEYOND EH HE HIN D T MA virtualI ntime losellyt They are: • Easy to order and ea t d t stockasy to s l dowNO Northourinparts comwithcustomers maximcommitment haboutmoreRead ontractDemolition C stinpartsrepairthehave virtuand Imachineanotherin Ifback.tofrontevery cometahaveThey echnician machine, wntim warehouse.American ready-to-shipofinventoriesplete foruptimeizes aftersaleMachine”he“Beyondourow , Bloomfield Hills, MI or quickly.backunitthegIk theySincedonoloseally bringjust[they]situation,ahaveI overgotomonthaoncethrough wntime… ock. get theSENNEBOGEN y-t tactOGEN f tor ained technicianstr ned tec cians components and too • Ideal for stocking se and trucks Choose from the follo • Central lubrication • Preventive mainte • O-Ring kits • Electrical service k Hydraulic service k :kits shops ols ervice owing kits system kits nance service kits its kits raine • Tervicts • SPar efor(TCO)Ownershipof thinkiWe’reequipment. par ing • Application Special customervery tomachine”the“beyondng NEBOGENNN BOGENSEN ctor suppor xible Financinglists • Fle auptimedependabledeliver throughot ttachments• A CostTotallowerand itsoflifetheout • Hydraulic service k And the best thing is in stock and ready to built to match your m and series. Count on in-house. For more in UPTIME Kits, scan th s that these kits, go, are custommachine model SENNEBOGEN nformation on he QR code. amoreLearn 2-6351) 29(800 ongmeadast LE oaer R1 Shak25 ylet.ww ourtocommitmentour w bout (800 Berli 1980 28A 010, Mow d om omers requipment.c cust 447352) 30 7in, CT 0603 urnpike0 Berlin T sennebogeen-na.com/beyond-the--machine

Construction of Eastern Greenwich Civic Center to Begin

Ceremonial shovels went into the ground Oct. 7, but construction of a new Eastern Greenwich Civic Center in Connecticut will not begin in earnest until next year.

Work is ongoing at the site, though, as the final demolition work is nearing completion, the Greenwich Time reported. At the groundbreaking ceremony, Luigi Romano, the town’s superintendent of construction and maintenance, said he hoped work on the foundation could take place later this year.

“The building is just about demolished,” Romano told the Greenwich news source. “There are a couple of areas where we have some steel on the side, and that’s all being recycled. We’re working on the final portions of the basement that are now coming out. Once that’s out, we’re going to clean the site a little bit more and start preparing for the foundations for the new building.”

Given the unpredictable winter weather likely ahead, Romano said it was “really hard to forecast” when the foundation work would be done.

“We’re going to be working on this all next year coming out of winter,” he added. “When the weather is warm enough for people to be walking past this again, they’re going to see a lot of changes more quickly. The building will start taking shape. It’s very exciting.”

When work on the new one-story facility does get under way, it will be built on the footprint of the demolished older building. The

plan is to complete the new 35,418-sq.-ft. civic center by the fall of 2023.

It will include a full-size multiuse gymnasium with rollout spectator seating, 8,100 sq. ft. of multiuse event space, and three 1,000-sq.-ft. activity rooms, two of which will share a partition that can be opened to create a larger room.

Civic Center to Be Named for Local Couple

In addition to Greenwich First Selectman Fred Camillo and project donors Steve and Alexandra Cohen, nearly 30 people were on hand for the groundbreaking for the new civic center. Among the others were Connecticut State Rep. Stephen Meskers, D-150th District (which includes the civic center), and his Republican opponent in November’s election, Ed Lopez, according to the Time.

The groundbreaking ceremony was hailed as a “very good day for Greenwich” by town resident Gary Dell’Abate, who co-chaired the committee that got the new civic center project going after decades of discussion and planning.

“This was why I wanted to be on the board of Parks and Recreation,” he said. “This project was my passion. There were many before me who tried hard, and their work was important to getting this done. My kids grew up playing here and roller skating here. My wife taught art classes to grammar school students

here. I spent many hours here coaching, shooting hoops, and even attending the occasional charity event.”

Camillo thanked the Cohens, residents of Greenwich, for their contribution that he said “got us off on the right foot” in fundraising. Their foundation donated $5 million as part of a public/private partnership on the building, which is expected to cost a little more than $25 million, the Greenwich news source reported.

In his remarks at the groundbreaking, Camillo called the Cohens “the anchors” of the private fundraising in town.

When completed, the building will be named the Cohen Eastern Greenwich Civic Center after the couple, who own the New York Mets. Their contribution was enough to get Camillo, a lifelong New York Yankees fan, to wear a Mets cap throughout the ceremony.

Cohen Civic Center Will Create New Memories

Greenwich resident Coline Jenkins brought a 1951 edition of the Time newspaper to the groundbreaking that hailed “a new landmark” in Old Greenwich: the creation of a building that eventually became the now-departed civic center.

Then known as the Eckman Center, it was constructed in 1950 as a recreation facility for Electrolux employees and their families.

Elizabeth Menegon, a New York City resident, came to the event because her grandfa-

ther, Frank Zint, who began working for Electrolux in 1932 by cutting grass there before working his way up to be the factory’s director of maintenance, formed the Electrolux Employee Association that pushed for the building’s creation.

Starting in 1954, the Eckman Center was opened for use by the town and for the Boy Scouts, Girl Scouts and other organizations. Eventually, Greenwich took over the building and turned into a community civic center.

Its demolition was bittersweet for Menegon and her family, who hope residents will remember the old building and share stories about it.

“We were heartbroken because we have so many great memories here,” she told the Time, recalling the many activities that she did there, from camping to roller skating.

“Somebody asked me how my grandfather would feel if he saw the building torn down, and I think he would have felt awful because it was a beautiful building. But he also understood progress. Progress is change and change is progress.”

Camillo shared similar sentiments.

“We all have memories here of what went on,” he said. “Whether it was basketball leagues or Babe Ruth drafts, reunions, graduations, political conventions, rollerblading — you name it. But the new civic center will have just as many great memories [and] in a much better venue.”

Classical R.I. High School to Get $34M in Renovations

It was not that long ago that students from Classical High, along with other Providence, R.I., high schools, rallied at the State House to demand sweeping renovations to the district’s crumbling buildings, some of which dated back the turn of the 20th century.

Opened in 1970, Classical High School, like so many found in the state, has suffered from decades of neglect. Buckets in the hallways on rainy days were a common sight. Ceiling tiles occasionally dropped to the floor, and the bathrooms were odiferous.

But, due to a multi-million state school bond approved by voters in 2018, that is now about to change.

Project to Bring LearningInto Light

The Providence Journal reported recently that Classical, one of the top-performing high schools in the country, is set to embark on a $34 million renovation to transform the cramped, dark and dated facility into a modern learning center.

The first phase, costing $4.5 million, has already gotten under way as the former firstfloor library and locker room now offer “swing space” to allow construction to begin on the upper floor.

Although a completion date for Classical High’s renovation project has not yet been announced, the design of the multi-year project is geared toward enhancing the learning experience for students.

For instance, a new media center with soft furniture is planned so that students can work on their laptops. Small tables in the space will allow for pairs of students to work collaboratively using more technology and fewer books.

Similar to a modern college library, Classical High will include couches and inviting color schemes, lots of natural light, and will train teachers to serve more as facilitators than traditional instructors standing in front of a row of desks.

“Learning can happen anywhere,” Joseph DeSanti, the project manager of Downes Construction Co., New Britain, Conn., told the Journal. “Some students prefer to sit on a couch. Some will sit with other students at a table. It’s all about collaboration.”

Classical, a selective school where students test to be admitted, also will sport a new nurse’s suite, a new girls’ locker room, and a secure entrance — a separate vestibule where visitors must be buzzed into the building.

The high school also will become more welcoming to special-education students. Plans call for a special-education suite with bathrooms fully accessible to people with disabilities, a life-skills room and more spacious classrooms to accommodate wheelchairs.

“Inclusion is very important,” said Philip Conte, an architect and president of StudioJAED, the Providence firm behind the school’s design.

Rhode Island Starts Plans to Update All Schools

The Providence news source reported in late July, Mayor Jorge O. Elorza and the Providence City Council agreed on a $125 million school bond referendum to continue much-needed improvements in school infrastructure. The measure will now go before city voters in November.

Elorza called it a down payment on the community’s future and an investment that will last.

“Providence’s investment in school facilities over the past several years has gone a long way toward bringing our buildings into the 21st century,” explained Providence Public Schools Superintendent Javier

Montañez. “The many improvement projects under way are exciting for our staff, our students and our community. But we’re fixing decades of neglect in our schools, and more needs to be done. This bond proposal is an important next step in building the district our students deserve.”

On the state level, another bond referendum, this one for $300 million, also will go before voters on the November ballot. It is created to provide incentives for early-childhood education, career and technical education facilities, and STEAM (science, technology, engineering, arts and math) facilities.

“This sends a message that we care about our students,” added Rhode Island Education Commissioner Angélica InfanteGreen. “If the next [statewide school construction] bond is passed, that will add up to a $500 million investment in our schools. Every brick we build is about raising our expectations.”

The Journal noted that the legislation, sponsored by Rhode Island Treasurer Seth Magaziner, state Senators Hanna Gallo and Sandra Cano, and Rep. Brandon Potter, also includes new incentives for energy-efficiency and renewable-energy improvements.

Page 4 • October 26, 2022 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • October 26, 2022 • Page 5 www.equipmenteast.com DRACUT 978-454-3320 61 Silva Lane Dracut, MA 01826 BROCKTON 508-484-5567 196 Manley St. Brockton, MA 02301 BOW 603-410-5540 1474 Rte 3A Bow, NH 03304 AUTHORIZED DOOSAN DEALER ©2021 Hyundai Doosan Infracore. All rights reserved. Hyundai Doosan Infracore is an affiliate of Hyundai Heavy Industries Group. The Doosan trademark, , is used under license from Doosan Corporation. Doosan® -7 Series wheel loaders are loaded with technologies and new performance features to help you get more work done today and in the future. EQUIPPED FOR TOMORROW. POWERED BY. INNOVATION. Visit Equipment East for a demo.

Page 6 • October 26, 2022 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide THE MOST MATERIAL HANDLING MACHINES IN NEW ENGLAND SCREENING CRUSHING CONES IMPACTORS CONVEYORS TROMMELS WASHING RECYCLING USED AND NEW MACHINERY RENTALS AND FINANCING AVAILABLE CALL TODAY! 1-800-53-CRUSH Over 100 Machines in Stock Family Owned and Operated for over 20 years Call for Parts Today 140 Nutmeg Road South South Windsor, CT 06074 51 Veterans Drive Loudon, NH 03307 SCREENING CRUSHINGCONVEYORS IMPACTORS TROMMELS 1-800-53 CRUSH WWW.POWERSCREEN-NE.COM LARGEST DEALER IN NEW ENGLAND ROCK SOLID SERVICE WE CRUSH YOUR ROCKS ROCK SOLID SERVICE WE CRUSH YOUR ROCKS

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • October 26, 2022 • Page 7 O Y NTHE OURR O ELINE EPUT EEVER INATO YY IS YDA olus SSale engineered p yeet ktha . Ttt iee gW d teeu no Yo eeps kJob Y unnid rnp au up yoeet khas ttion Pyentalit” monet dt igeh a “wit t nug oollin. Rwardorg fovinu mo hg takinn meee b’vy wehs what’ fife eord mnr aastee font dt ieo g eeps kimeline. Tougherg ttinget . ng. terf Afrovidin achinesw me ovesg mie b ciently terhorg stinget g A tach HitachiConstru e yBecaus hi cm.us ctonMachneryAmercasnc te ivesers dustomerr cud yon. Atd ineare eou’v i Milford, NH 603.673.2640 Brentwood, NH 603.642.5666 Concord, NH 603.225.3361 chappelltractor.com Now Your Hitachi Dealer for Vermont, New Hampshire and Massachusetts

Mountain Paving Project Requires Serious Planning

all of our guests and it’s definitely less maintenance for us. Maintaining a gravel road at an average of 12 to 13 percent grade and at that climate can be very challenging.”

Before the paving operation, which took place between May 25 to 27 and on May 31, could be initiated, Lee T. Corrigan LLC (LTC) was brought in to install some infrastructure and to prep the site for the paving by building up the gravel and stabilizing it. Their work, which was supported by crews from the Mount Washington Auto Road, occurred in early May. The section was located 5 mi. up the mountain, above the treeline.

“The section has some sheer drops and pretty extreme roads to say the least,” said Reichert. “The paving was very challenging as the average width of that section was 20 feet wide.”

Describing the sheer drops, Riechert said, “in some places, we don’t have the luxury of rocks and it goes from pavement to a pretty steep drop. We can’t install guardrails because of our winter traffic.”

State park officials and meteorologists at the observatory reach the summit in winter via big snowcats.

“After a big snowstorm and the wind drifts creating snowbanks, if they have to plough the snow, the guardrails get in the way,” said Reichert. “In the springtime, they would be an obstacle to pushing snow off the edge of the road.”

The recommended speed limit for the road is 20 mph, which is crucial for the 3.5mi. portion of the road that is above the treeline where many of the sheer drops are located.

Prior to the recent paving contract, Central Asphalt Paving Company LLC (CAPC) had

After depositing the asphalt, crews had to go down 5 mi. and wait 45 minutes for the trucks to be reloaded with asphalt.

Additional equipment used included a Takeuchi TB260 excavator.

The road, which was established in 1861 at 6,288 ft. above sea level, is narrow and does not have a shoulder or guardrail.

done work on the mountain road in 2020 and 2021.

“This last section was one of the steeper, more vertical drop-off areas,” said Ed Stanley, CAPC’s owner, whose company lays down approximately 30,000 tons of asphalt annually. “This wasn’t your everyday town road. There were areas that were 15 feet-wide and you could not get two vehicles by.”

The complex project required serious planning and safety precautions as dump trucks carrying asphalt had to drive up 5 mi. of the narrow road to a lookout area where they then turned around and had to complete the remainder of the drive backward in order to pour the asphalt into the paver.

The first thing CAPC did was to bring up a LeeBoy 685C motorgrader to give the prepped area a final grading before paving could begin. The next step was to bring the Caterpillar rollers and LeeBoy 8520B paving machine to the top of the unpaved section. This was done by placing them on a

The mountain is the highest peak in the northeastern United States and is notorious for its erratic weather.

Page 8 • October 26, 2022 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

PAVING from page 1 see PAVING page 12

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • October 26, 2022 • Page 9 G008 .caEquipNEltA•82)5262400(8A ALTTA2Go LT com

Prices are Falling

URI Pushes for $100M Bond Passage to Build New Facilities

Officials including Gov. Dan McKee visited the University of Rhode Island (URI) recently to push for voters to pass a $100 million bond question Nov. 8 they said would make URI’s Bay Campus in Narragansett a leader in efforts to grow the state’s blue economy.

McKee joined URI President Marc B. Parlange at a kick-off event on the university’s Bay Campus to tout Question 1, authorizing spending that would build and modernize facilities at the satellite campus in Rhode Island’s South County.

In 2018, voters approved a $45 million bond referendum that launched Phase 1 construction. The upcoming bond, if approved, would launch Phase 2, designed to create more transformational changes to the Bay Campus, including new buildings and green spaces. Several aging marine science and engineering buildings and laboratories that dot the hillside campus with sweeping views of Narragansett Bay would be replaced with a modern ocean engineering complex if the bond were to pass.

“Rhode Islanders have a generational opportunity to position [the state] and New England as the global leader in a new blue economy with URI as the engine that fuels that activity,” Parlange said. “With the sup-

port of this bond, URI can create a thriving, modern Bay Campus that will spur critical job creation and economic development, drive innovation, and create sustainable and equitable career opportunities for all Rhode Islanders.”

The bond question is one of three appearing on the statewide ballot in November. The spending requests total $641 million and include $250 million for Rhode Island school buildings and $50 million in “Green Economy” bonds.

Interest on the URI Bay Campus project would bring its total cost to more than $160 million, the university noted on its online news service.

Construction is expected to be complete, and the project ready for use, by September 2026. URI estimates that the useful life of the Bay Campus improvements will be about 50 years.

URI Marine Sciences Investments

ÂNo-BrainerÊ

McKee said the work would represent a stake in URI as the state’s flagship research institution.

“This investment in the Narragansett Bay

Campus will help us continue to be a leader in the blue economy, leveraging partnerships with industry leaders, advancing scientific knowledge of our oceans, and creating good paying jobs in the process,” the governor said. “So, let’s support this bond. I will be voting yes. I will be asking everyone to follow my lead. We can afford it and it’s a good investment for the state of Rhode Island.”

Michael F. Sabitoni, president of the Rhode Island Building and Construction Trades Council, called investment in marine sciences in the Ocean State a “no-brainer.”

“I have been around a long time on a lot

of different bond questions,” he said. “I echo what the governor said. This is not just a one-off. This is a plan to continue investments that make sense. Yes, we can afford it, but we can’t afford not to do this.”

Rhode Island’s blue economy, which includes the defense industry, tourism, marine trades, fisheries and soon, offshore wind, generates more than $5 billion every year, according to URI figures. By 2030, that total is projected to double to $10 billion.

“The scientific discoveries and commercial applications being developed at URI are helping to address global issues including climate change and food security, support the blue economy, and generate revenue for the state,” commented Greater Providence Chamber of Commerce President Laurie White.

She added that the state must “double down” and ensure that the Bay Campus has world-class labs and academic facilities that meet the standards of competing research institutions.

“Rhode Island cannot afford to fall behind at a time when others are charging full steam ahead,” White said.

Page 10 • October 26, 2022 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide The Nice Company, Inc Equipment Sales and Rentals 9 Rosenfeld Drive, Hopedale, MA Toll Free# 508-381-3939 • www.theniceco.com We sell NICE machines! 2017 CAT 450F Front Aux. Hydraulics, Heat/AC/Stereo, Auto-Shift, Ride Control, Pilot Controls, X-tend-A-Hoe, 36" Rear Bucket, 96" CAT 4-in-One Front Bucket, In Perfect Condition! $109,000

This is a plan to continue investments that make sense. Yes, we can afford it, but we can’t afford not to do this.”

Michael F. Sabitoni

Rhode Island Building and Construction Trades Council

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • October 26, 2022 • Page 11

Weather Impacts Mt. Washington Job Because … Of Course

trailer and heading up the mountain to a point where the vehicle pulling the trailer could turn around and bring it to the starting point.

“The grader can grade in any direction,” said Stanley, “but the tri-axle dump trucks had to back up to dump the asphalt into the paving machine. The dump trucks drove very slowly.”

To ensure that each backward journey was successfully completed, spotters were placed at the back of the truck, in the front and alongside it.

“It was a case of eyeballs at all times,” said Stanley. “It took about 25 minutes to go five miles from the base of the mountain to the lookout and then another 10 to 15 minutes to back up the dirt road to the paver. The drive down took about 20 minutes and you could only go 25 mph. The drive down was easier, but it was still scary. We had people at every mile with radios to let us know where each truck was coming up and down the road.”

Stanley shared the risks that his drivers faced as he personally drove some of the dump trucks.

“After depositing the asphalt, we had to go down five miles and wait 45 minutes for the trucks to be reloaded with asphalt,” he said. “Then, we had to go all the way back up the steep grades. There were a couple of drivers that didn’t want to do it, which I certainly understood. If you were comfortable doing it, you did it. Last year, when we got

off the mountain, I said, I would never do it again and we went back this year. We must be getting used to it and it all worked out. Our truckers were stressed at times, but other than that, everyone held their own and came together.”

Approximately 60 loads of asphalt were brought up the mountain. The dump trucks were not fully loaded to make the journey safer. The paving crew consisted of the paving machine operator and personnel who did the raking and shoveling and set up the

drainage and swales. The asphalt cooled within a few hours due to the cooler temperatures and was ready to take on traffic.

LTC provided some of the dump trucks. In total six were used, consisting of Mack and Peterbilt models.

The road was shut down to tourist traffic for the duration of the paving work. Although it was open for the Memorial Day weekend and Monday holiday, The road was closed on Tuesday to allow crews to do some overlay operations in another section.

Weather impacted the work.

“The first day was a little cooler and windy, and that was spooky because as the bodies of the dump trucks would lift up, you could feel the wind blowing and shaking the trucks,” said Stanley. “The second day was absolutely beautiful — it was 70 F, which was rare. Friday was the final day and there were clouds above us, but we were able to finish up.”

All the projects that CAPC completed on the mountain road were performed without any injuries or incidents.

Stanley praised Reichert for his participation in the paving operation.

“He keeps a close eye on everything that goes on and he knows the characteristics of the road,” said Stanley.

The paving of the dirt road section drew reaction from participants in the bi-annual Mount Washington Road Race held in June, via its Facebook page.

“Some commented about how they preferred it to be dirt in that area because they got to drift a little bit more,” said Stanley. “And others said we want it to be asphalt so it would be faster. It was a big thing in the racing world.”

CAPC had approximately 18 people on site daily, assisted by six or eight people from the Auto Road.

Assisting Stanley was his son, Ed; nephew, Ed Dorr; paver operator Chris “Critter” Shannon; and Jeffrey Heath, roller operator.

Page 12 • October 26, 2022 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

The boulder walls were constructed using a Cat 321D excavator.

The section has some sheer drops and pretty extreme roads.

The first thing CAPC did was to bring up a LeeBoy 685C motor grader to give the prepped area a final grading before paving could begin.

PAVING from page 8

see PAVING page 14

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • October 26, 2022 • Page 13 NEW ENGLAND’S EXCLUSIVE MCCLOSKY DEALER!!! 2021 MCCLOSKEY SDX130: Serial Number: 90666, New Telescoping Stacker 36"x130' Electric Hydraulic Power WEG 20HP. Standard Hopper, Pivot Point, Hydraulic Landing Gear, Hydraulic Wheel Drive, Remote Greaselines, Walking Beam w/Lift Axle>>>Call 2022 MCCLOSKEY ST100T: Hours: 53, Serial Number: 92129, Stacker with Impact Idlers Under Hopper, Upgraded Belt Cleaner/Scraper, Telematics, Upgraded Hydraulics, CAT C2.8 Tier 4F/ Stage V 74HP Engine>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>Call 2022 MCCLOSKEY TS4065: Hours: 11, Serial Number: 78684, Standard Hopper, Wear Plate Lining in Hopper, Impact Bed in Hopper, Hydraulic Top Fold, Remote Greaselines, CAT C2.2 Tier 4/Stage V 67HP Engine>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>Call 2020 MCCLOSKEY C3: Hours: 1614, Horsepower: 510 hp, Serial Number: 91189, METSO designed cone, 300 HP Class. Volvo D13 Medium Cone Liner currently installed.>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>Call 2021 MCCLOSKEY J40: Hours: 389, Serial Number: 90232, Belt Protection Deflector Plate, Overband Magnet on Main, Working lights, Safety Beacon Lights, Telematics, Volvo D8 T4F 252HP Engine>>>>Call 2022 MCCLOSKEY ST80TLA: Hours: 10, Serial Number: 92289, Lift Axle, Hopper Wear Plates, Impact Idlers, Belt Cleaner/Scraper, CAT 2.2 Tier 4F 49HP Engine>> >>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>Call 2020 MCCLOSKEY S190 3D: Hours: 543, Horsepower: 130 hp, Serial Number: 91405, Tracked Triple Deck Heavy Duty Screener. CAT Tier 4F Engine. 15ft Feeding Hopper. Chevron Belt on Main Conveyor. Remote Machine Shut Off>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>Call 2021 MCCLOSKEY RF80: Hours: 124, Serial Number: 77883, Hopper Wear Plates, Extended Hopper Wing Plates, Upgraded Belt/Cleaner Scraper, Variable Speed and Start Stop Feeder Kit, CAT C3.6 Tier 4/Stage V 134HP Engine>>>>>>>>>>>>>>>>>>>>>>>>>>>>>Call 2006 EXTEC ROBOTRAC: Hours: 5,008, Serial Number: 9872, Well maintained. Deutz Engine. 10’x8’10” screen deck with side discharge conveyor>>>>>>>>>>>>$59,500 2022 MCCLOSKEY 516R-T: Hours: 68, Serial Number: 92344, Hydraulic Tipping Grid over Hopper, Remote Start/Stop Feeder, Fitted Safety Beacons, Telematics, CAT C3.4 Tier 4F 74HP Engine>>>>>>>>>>>>>>>>>>>>>>>Call 2003 TEREX PEGSON 2644 PREMIERTRAK: Hours: 11,448, Engine: Cat C9, 1 Owner Machine, New Jaw Dies, New Cheek Plates, Jaw Box has been recently rebuilt, New Bearings in Pittman, New Toggle>>>>>>>>>>>>>$225,000 2021 MCCLOSKEY R105: Hours: 809, Serial Number: 77461, Screener with Remote Variable Speed Feeder, Remote Machine Shut off, Safety Beacon Lights, Telematics. CAT Tier 4F 130HP>>>>>>>>>>>>>>>>>>>>>>>Call NEW MWS CSP200 COMPACT SAND PLANT, Serial Number: 20349, cost and energy efficient, exceptional performance, 14 x 6 dewatering screen, can produce 1 grade of sand, self regulating sump tank>>>>>>>Call 2021 MCCLOSKEY ST80: Hours: 6, Serial Number: 92183, CAT 2.2 Tier 4F 49 HP, Hydraulic Axle Jacks, Hydraulic Axle Extensions, Hydraulic Landing Gear, Hopper Wear Plates, Impact Idlers under Hopper Call 2021 MWS S190: Hours: 165, Serial Number: 91989, Screening Plant with Fitted Rinser Kit with Spray Bars on Screenbox, Aux Drive Circuit, Plain Belt on Main Conveyor>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>Call 2021 MCCLOSKEY C2: Hours: 324, Serial Number: 92089, Metal Detector on Feeder, Discharge Chute on Main Conveyor, Upgraded Belt Cleaner/Scraper on Main, Telematics, CAT C9.3B Stage V/Tier 4F 375 HP Engine>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>Call

CAPC Reports No Injuries, Incidents On Dangerous Project

members on this project.

“The guys have been working together for years and they have a good rapport,” said Stanley. “Heath was pretty handy in the process. The crews did 100 percent — they did great. I thanked them all very much and we were done early on Friday.”

Additional equipment used included a Takeuchi TB260 excavator.

CAPC’s yard was 20 mi. from the project and mechanics were sent to the site as needed.

“They were just a phone call away,” said Stanley. “All the trucks were checked out prior to the work and the mechanics said everything was good to go. Everybody knows their equipment and inspects their pieces every morning. On nights and weekends, the mechanics keep an eye on things.”

Lee T. Corrigan was on site in early May to prep the area for the paving.

“Our company, along with the Auto Road crew, started the project by replacing culverts on the gravel section of road that was slated to be paved,” said Corrigan, owner of Lee T. Corrigan LLC. “The work started in the fall 2021 and was halted after a few weeks due to winter weather setting in. All work was performed at night when the Auto Road was closed to traffic. Work resumed last May before the Auto Road opened to the public with the building of boulder walls and travel lane widening.

“The narrow sections of the road were widened using boulders found on site, but we also had to haul in roughly 400 tons of boulders for use in the retaining walls,” he added. “The boulder walls were constructed with a Cat 321 excavator. A level sub grade was established where possible, sometimes up to 15 feet below the road edge, then boulders and backfill material was carefully placed and compacted to create a wider travel lane.”

His company had a small crew of four team

“Without supportive and dedicated crew members, our job as owner operators is futile,” said Corrigan. “We rely on team member efforts to carry out seemingly impossible tasks, all while staying safe and efficient. A special recognition to Frank Edmondson and Randy Davis who safely carried out their tasks. Frank and Randy hauled boulders and backfill material up the Auto Road as I operated the Cat 321 excavator. A special thanks to Tobey Reichert, whose vision and drive led the push to complete this section of road. A great team effort between LTC, Central Asphalt Paving and the Mt. Washington Auto Road crew to see this project through.”

LTC used Cat 321D and 314E excavators and Mack and Volvo tri-axle dump trucks.

CAPC has purchased its LeeBoy equipment from Ambrose Equipment in Hooksett, N.H., for more than 25 years and have always maintained a great rapport personally and professionally.

“We’ve also purchased several Cat rollers from Milton CAT located in Londonderry, N.H.,” said Stanley. “It’s been an asset to our business to maintain great relations with our dealerships whether it pertains to service or purchases.”

LTC purchases Cat equipment exclusively from Milton CAT in Londonderry and Richmond, Vt.

“Milton CAT has been a valuable partner to LTC over the last 15 years and their support of our equipment and our team has helped us grow and stay on the leading edge with the use of GPS and UTS machine control, as well as infield layout,” said Corrigan. “LTC maintains a fleet of 13 Caterpillar machines and is looking forward to adding three more Next Gen models to our fleet this year.”

(All photos Courtesy of Mt. Washington Auto Road and Lee T. Corrigan LLC.)

Page 14 • October 26, 2022 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

CEG

Approximately 60 loads of asphalt were brought up the mountain.

A LeeBoy 8520B paver lays down asphalt in an unpaved section.

The Auto Road is the oldest man-made and continuously operating tourist attraction in North America. It was built by hand using shovels and black powder to clear the route and has been owned for generations by the descendants of the Libby family.

PAVING from page 12

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • October 26, 2022 • Page 15 Y RES CALLUS OUR ERVE TODAYTO REN WI TALS NTER CONNECTICUT 410 Burnham St., South Windsor, CT 06074 860-289-2020 MASSACHUSETTS 120 Interstate Dr, W. Springfield, MA 01089 413-363-0780 Proud to be your Full Service Dealer NEW Inventory In Stock! WHY CHOOSE ABLE TOOL and EQUIPMENT... • Local Ownership with flexible approach • Trained staff for repairs and maintenance • Dedicated Parts personnel on site • Focused on the Heavy Construction Industry • Providing the BEST support equipment available • Experienced outside sales staff Sales • Service • Parts • Rentals abletool.net CR 3 Reversible Plate Rammer SRV 590 CF 2A Forward Plate Reversible Plate Compactors & Rammers CR 8 MFM Reversible Plate

Redevelopment of Historic 19th Century Mill Begins

A more than 150-year-old mill building in the heart of West Warwick, R.I.’s historic Arctic Village, its windowpanes broken or boarded over, is getting a new lease on life.

Elected officials, developers and community members convened at the Arctic Mill site June 6 to celebrate the start of the redevelopment of two buildings into a mixed-use complex that will be made up of both commercial space and residential rental apartments.

“Reflecting on West Warwick’s lively past as a mecca of manufacturing along the Pawtuxet River, as a premier retail center in downtown Arctic and as a melting pot of the many ethnicities who came here seeking opportunities and settled in our many small villages to work and raise families, I’m energized by the vision to redevelop this property into something that we can all be proud of,” said Mark Knott, West Warwick’s town manager, during the ceremony with the 19th-century building as a backdrop behind him.

Rhode Island Gov. Dan McKee, U.S. Sen. Jack Reed, Congressman Jim Langevin and state General Treasurer Seth Magaziner also were among those who had gathered outside the historic mill buildings, the former site of textile manufacturing in Arctic.

Situated beside a stone dam on the Pawtuxet River, the main mill building was built in 1865 using the stone walls of an earlier mill structure. In 1885, a textile manufacturer bought the property, where 35,824 spindles and 1,039 looms operated into the 20th century.

The Factory Street building most recently housed NATCO Products Corporation.

The Kent County Daily Times in West Warwick reported that Knight Street Capital approached the Arctic Village Redevelopment Agency with a proposal to

rehabilitate the building into something resembling its development at Warwick’s Pontiac Mills.

Knott said the town looks forward to working with the developer to make that vision a reality.

The restoration of West Warwick’s neighborhoods and business community has been a priority of the town council, Knott explained to the assembled crowd that also included Sen. John Burke, U.S. Rep. Tom Noret, West Warwick Town Council Vice President Maribeth Williamson and Town Council member Jason Messier, according to the local newspaper.

“We’re excited to see an expansion of affordable living options with rental units and are particularly intrigued by the possibility of a craft brew pub overlooking the scenic waterfall,” Knott explained over the sound of the Pawtuxet’s rushing water.

Upgraded Mill to Bring More Affordable Housing to State

The development will feature 136 apartments — 31 of which will be for households earning at or below the area median income — as well as around 10,000 sq. ft. of retail space, offices and the brew pub. Plans also include media rooms and a boxing gym.

The total development will cost $32.7 million, funded by sources including RIHousing’s Workforce Housing Loan, the Rebuild RI Tax Credit program and developer equity, the Times Daily noted.

The project also is set to receive $4.3 million in federal historic tax credits — something that Reed said fills him with pride.

“[Rep. Langevin] and I fight every year to make sure those tax credits are available, and

[that] they come to Rhode Island,” Reed said. “If you have the resources — as demonstrated by this project — you can put them to very good use.”

Langevin added that for him, the impact the Arctic Mill development will have on affordable housing in the state is especially exciting.

“It’s no secret that Rhode Island has been lacking in affordable housing,” he said. “We need to remedy this problem by creating more affordable housing units.”

Chiefly, a need exists to offer housing across various price points, added Larry Phillips of Knight Street Capital, and the Arctic Mill development’s residential options will include both market-rate and middle-income housing.

Carol Ventura, executive director of RIHousing, said in a statement from her office that the mill project will provide “much-needed rental homes in a very, very tight rental market.”

She added, “Today’s high demand, paired with low supply, has driven housing prices in Rhode Island out of reach for most middleincome families.”

The West Warwick news source reported that that was the impetus behind the creation in 2019 of RIHousing’s Workforce Housing Innovation Challenge — a program meant to help those caught between high housing costs and being ineligible for traditional affordable housing assistance.

“This program is one important tool that helps respond to the need for middle-income housing by filling a growing and significant gap in a tight housing market of rising rents that has just been exacerbated by the COVID-19 pandemic,” Ventura explained.

“Investing in housing at a range of price points makes sound economic sense.”

Could Arctic Become Busy Place

Once Again?

Between its various amenities and the rental homes it will provide, the Arctic Mill property is destined to become a gathering place that will “breathe life into this whole area,” Langevin added.

“Families, friends, neighbors will come together to make the most of this storied space,” he said. “It’s an important part of this town, and it’s going to become even more important going forward.”

This project is bound to spur further development in the area and perhaps help Arctic become a bustling village once more, Reed added.

“It’s time again for Arctic Mill to be the center of life and community in West Warwick,” he said.

Gilbane Building Co. Completes MGM Music Hall at Fenway

Boston Mayor Michelle Wu, alongside officials from Fenway Sports Group Real Estate (FSGRE), a subsidiary of Fenway Sports Group (FSG), Live Nation and the City of Boston, joined representatives from Gilbane Building Company and D’Agostino, Izzo & Quirk Architects Inc., as well as members of the greater Boston community to celebrate the official grand opening of the new 91,500-sq. ft. MGM Music Hall at Fenway.

The Gilbane-built, four-story venue has a concert capacity of 5,000 and hosted grand opening national headliners including James Taylor, Chris Stapleton and Bruno Mars.

Tightly nestled into the former triangular lot behind the Fenway Park bleachers, the new music venue is the centerpiece of a larger scope of work, as Gilbane delivered the Truly Terrace, an open concept concession area, and the 521 Overlook, a standalone event space that overlooks Fenway Park, which can accommodate up to 600 guests, earlier this year.

Gilbane started construction in September 2021 with a scope that entailed enabling work including the demolition of a portion of the existing Fenway Garage and renovation of the remaining space to include back-of-house facilities for Fenway Park operations. The project also included a two-

story vertical addition above the garage to support the integration of the new 521 Overlook and Truly Terrace.

In addition to hosting live shows and concerts, the venue also provides an epicenter for the vibrant Boston arts community. The grand opening ceremony featured student performances from the neighboring Boston Arts Academy (BAA), including the BAA acapella group, as well as BAA alumnus SBM. During ceremonial remarks, officials from FSG and their partners from Live Nation, reinforced their formal commitment to supporting the Boston Arts Academy and its students; noting that they hope the BAA community will view the new MGM Music

Hall as an extension of their new remarkable school, just across the street.

“We continue to be inspired by Fenway Sports Group’s vision and commitment to the City of Boston,” said Mike O’Brien, senior vice president and Massachusetts business unit leader of Gilbane. “We value our longstanding partnership and are beyond excited to have played a part in delivering this iconic new venue as a welcomed addition to the already vibrant arts community in our great city.”

The new MGM Music Hall at Fenway is operated in partnership with Live Nation. For more information, visit www.gilbaneco.com.

Page 16 • October 26, 2022 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

“It’s no secret that Rhode Island has been lacking in affordable housing. We need to remedy this problem by creating more affordable housing units.”

Jim Langevin U.S. Representative

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • October 26, 2022 • Page 17 More standard features. More value. www.hceamericas.com To learn more about the what the new Hyundai A-Series machines can offer your business, contact your Hyundai dealer today. ©2022 Hyundai Construction Equipment Americas. All Rights Reserved. Discover the NEW A-Series Hyundai Construction Equipment is excited to announce the launching of our new A-series machines. Along with a new look, these machines are packed full of standard new features and benefits to get the job done efficiently. • Cummins Performance Series Engines Stage V emissions compliant engines • EPFC (Electric Positive Flow Control) Reduces daily fuel consumption by 8-11% • EPIC (Electric Pump Independent Control) Improved controllability with reduced RPM drop • Serviceability/Safety Enhanced cab visibility Easy access engine panels Kahn Tractor & Equipment, Inc. 520 Pond Road North Franklin, CT 06254 860/642-7596 www.kahntractor.com Chappell Tractor 391 Loudon Rd. Concord, NH 03301 603/225-3361 www.chappelltractor.com 251 NH-125 Brentwood, NH 03833 603/642-5666 454 RTE 13 Milford, NH 03055 603/673-2640 2160 Hotel Road Auburn, ME 04210 207/346-0279 17 Houlton Road Presque Isle, ME 04769 207/346-0279 Whited Equipment Co. 837 Portland Road Saco, ME 04072 844/430-6810 www.whitedhyundai.com Quality Fleet Service, Inc. 548 New Ludlow Road South Hadley, MA 01075 413/213-0632 www.qualityfleetservice.com Lorusso Heavy Equipment, LLC 160 Elm Street Walpole, MA 02801 508/660-7600 www.lhequip.com Butler Equipment 631 New Park Ave West Hartford, CT 06110 860-233-5439 www.butlerequip.com

Amherst Asks State for ARPA Funds to Upgrade Jones Library

Calling on the state of Massachusetts to once again be a “library champion,” the Amherst Town Council is appealing for more money to help fund its “once-in-a-generation” Jones Library expansion and renovation project.

Councilors agreed Oct. 10 to send a letter to state officials asking that they distribute American Rescue Plan Act (ARPA) funds for the library, which has seen its construction costs jump significantly in recent weeks.

Cost increases also have been a problem for 11 other town libraries being expanded, renovated or replaced across the state, including those in the nearby communities of Deerfield and Orange, the Amherst Bulletin reported.

“We know you have been a library champion in the past,” read the letter, signed by Council President Lynn Griesemer, and endorsed by her colleagues at the Oct. 10 meeting. “This grant is a once-in-a-generation opportunity for our community to have the improved library facility and services it needs, wants and deserves, for at least the next 50 years.

“We ask that you be a library champion again and do all you can to provide additional ARPA funds to Amherst and the other 11 municipalities. Please help us make our library the true community hub it has the potential to be.”

The council voted 10-1 in favor of the contents of the letter, with two councilors abstaining from the vote.

One concern came from District 3 Councilor Dorothy Pam, who asked whether ARPA money might be sought for projects being funded through the Massachusetts School Building Authority, including Amherst’s planned elementary school project that would replace both the Fort River and Wildwood elementary schools.

Griesemer said that effort is being considered, though school buildings receive their funding through a different pot of money based on the state sales tax.

Library Could Cost $10M More Than Expected

The request comes as concerns arise over whether the $13.87 million grant awarded to Amherst by the Massachusetts Board of Library Commissioners will be sufficient for what had been projected as a $36.3 million expansion and renovation of the Jones

Library. Recent estimates have shown that cost could be $10 million or more higher, the Bulletin reported.

Massachusetts Senate President Karen Spilka and House Speaker Ronald Mariano, as well as Amherst’s legislative delegation, Rep. Mindy Domb, and Sen. Jo Comerford, also are expected to receive the letter.

It spells out challenges specific to Amherst, including the town’s four major capital projects. Besides the Jones Library, the others include the new elementary school, new headquarters for both Department of Public Works and the fire station, as well as the costs of inflation and supply chain issues that affect all communities.

The appeal for ARPA funding also noted the Massachusetts Public Library Construction Program (MPLCP) grants handed out $96.3 million for projects initially estimated to be $235.5 million but have since gone up by 37 percent, to $323.2 million.

“To say we’re experiencing sticker shock is an understatement,” the Amherst letter reads. “The MPLCP funding has gone from providing our towns with 41 percent of the total project costs down to 30 percent.”

Already, a request was sent by the affected communities to the Baker-Polito administration asking to include an added $87.7 million of ARPA money earmarked for library construction projects in the supplemental budget now being created. That would bridge the cost gap created by the pandemic.

Amherst Could Get Answer Soon

Jones Library Director Sharon Sharry told trustees at a meeting in late September that libraries should know by Thanksgiving whether more state support will come their way. She said people who support the project should advocate on behalf of libraries in any way they can.

Should the renovation and expansion project not move forward in Amherst, the Bulletin added, the town would still have to do work on the building, including making it more accessible, repairing the heating, ventilation and air-conditioning systems and atrium roof, and do upgrades to other mechanical, electrical and plumbing systems.

Those efforts would cost Amherst between $14.4 and $16.8 million, according to estimates provided two years ago by a town consultant.

Page 18 • October 26, 2022 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide NEW ENGLAND SUPPLEMENT ADVERTISER INDEX The Advertisers Index is printed as a free editorial service to our advertisers and readership. Construction Equipment Guide is not responsible for errors or omissions. ABLE TOOL & EQUIPMENT..........................................15 ALTA EQUIPMENT COMPANY/NITCO LLC....................9 ARGUS INDUSTRIAL COMPANY....................................1 BARRY EQUIPMENT CO. INC.......................................20 BOSTON FREIGHTLINER/NEW ENGLAND..................11 CHAPPELL TRACTOR....................................................7 EQUIPMENT EAST........................................................1,5 FOLEY INC - WORCESTER............................................1 GORILLA HAMMERS........................................................1 HYUNDAI CONSTRUCTION EQUIPMENT....................17 J R VINAGRO CORPORATION........................................1 M G EQUIPMENT............................................................1 POWERSCREEN NEW ENGLAND..................................6 ROCK & RECYCLING EQUIPMENT LLC......................13 ROGERS BROTHERS CORPORATION........................19 SHAWMUT EQUIPMENT CO INC..................................15 T-QUIP SALES & RENTAL INC......................................15 THE N.I.C.E. COMPANY................................................10 THE W. I. CLARK COMPANY..........................................2 TIBBITS EQUIPMENT SERVICES INC............................1 TYLER EQUIPMENT CORPORATION............................3

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • October 26, 2022 • Page 19 The Ultimate in Trailers® ROGERS BROTHERS CORPORATION ALBION, PA Over a CENTURY of building the very best heavy-duty trailers for your hauling needs! Contact your local dealer for a quote today. TRAILERS TO MEET EVERY HAULING CHALLENGE! Committed to building superior quality, reliability and durability into every trailer. Tyler Equipment www.cn-wood.com 200 Merrimac St. Woburn, MA 01801 (781) 935-1919 140 Wales Ave. Avon, MA 02322 (508) 584-8484 3 Rocky Hill Road Smithfield, RI 02917 (401) 942-9191 C.N. Wood Co., Inc. www.tylerequipment.com 251 Shaker Road East Longmeadow, MA 01028 (413) 525-6351 • (800) 292-6351 Parts: (877) 255-6351 1980 Berlin Turnpike Berlin, CT 06037 (860) 356-0840 • (800) 352-4473 Parts: (860) 356-0848

Page 20 • October 26, 2022 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

By Irwin Rapoport

CEG CORRESPONDENT

By Irwin Rapoport

CEG CORRESPONDENT